Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Suppress boiling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

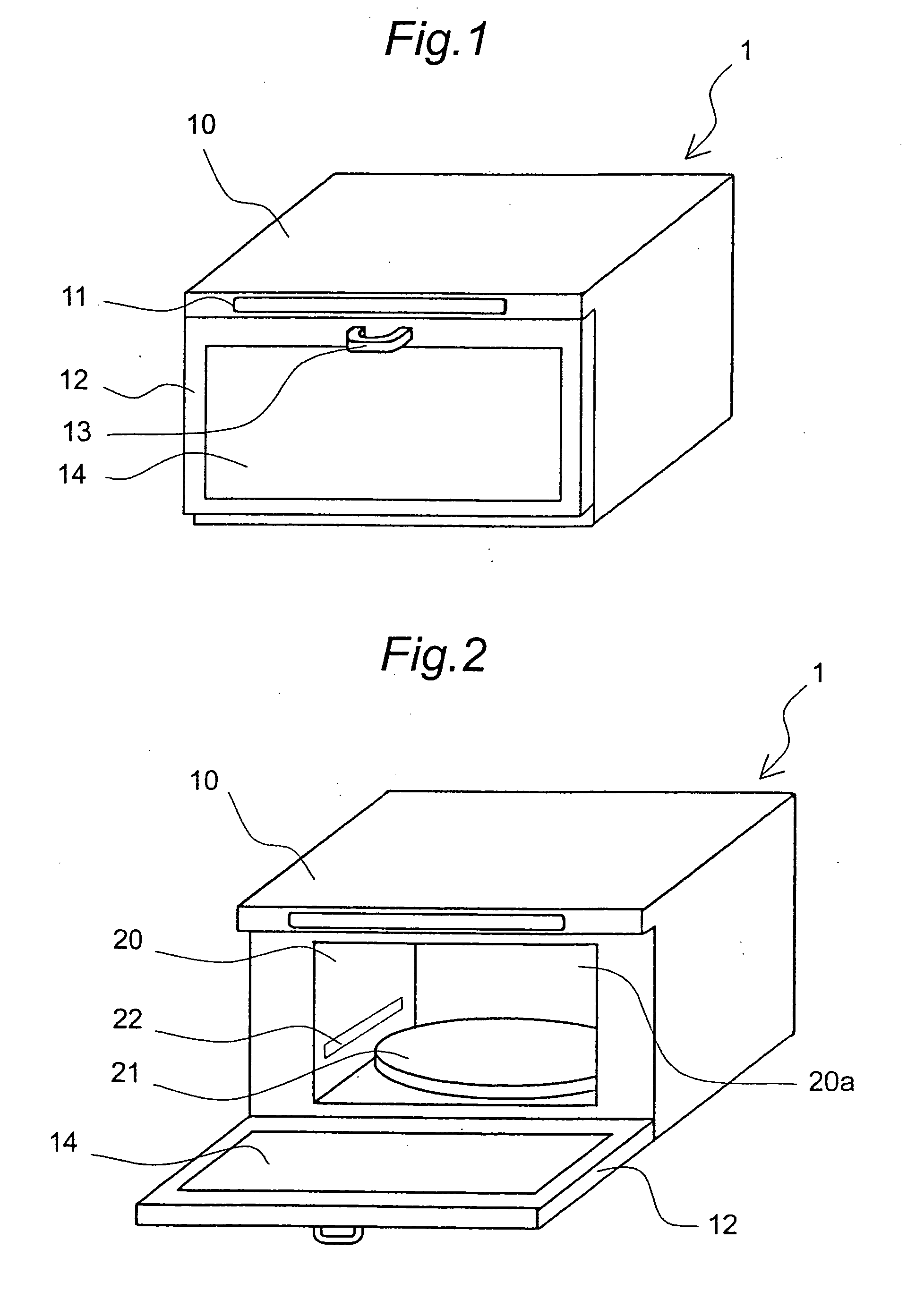

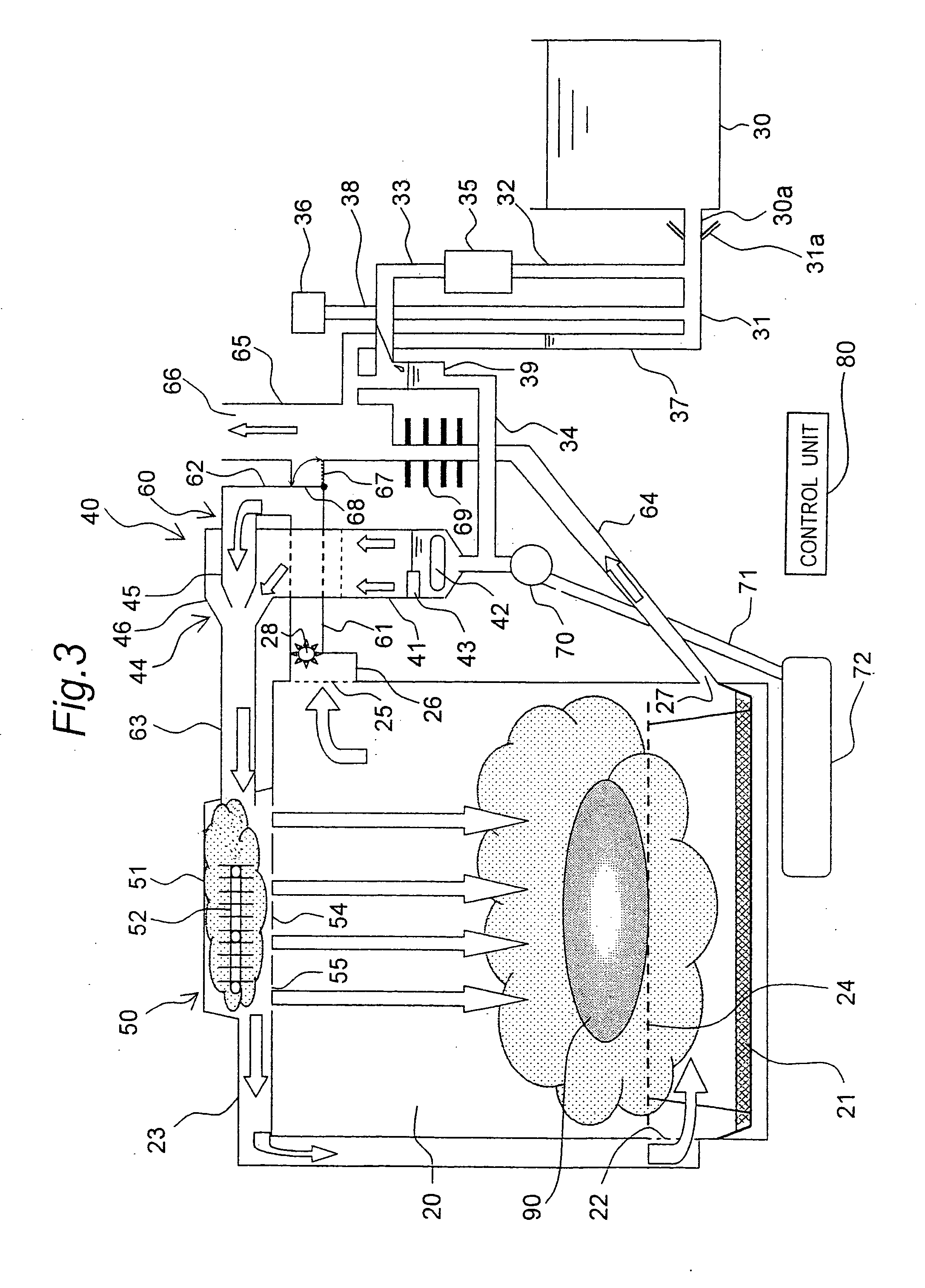

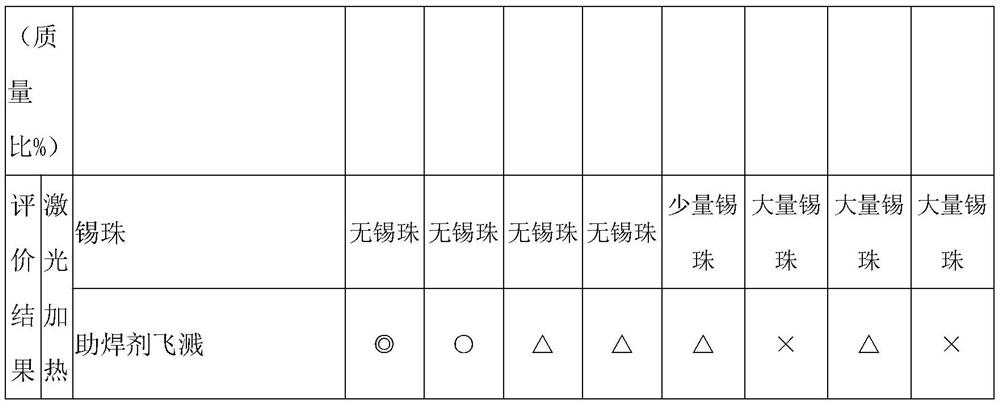

Heating cooker

InactiveUS9173408B2Accurate detectionReduce steam pressureDomestic stoves or rangesSteam generation heating methodsSteam pressureWater level

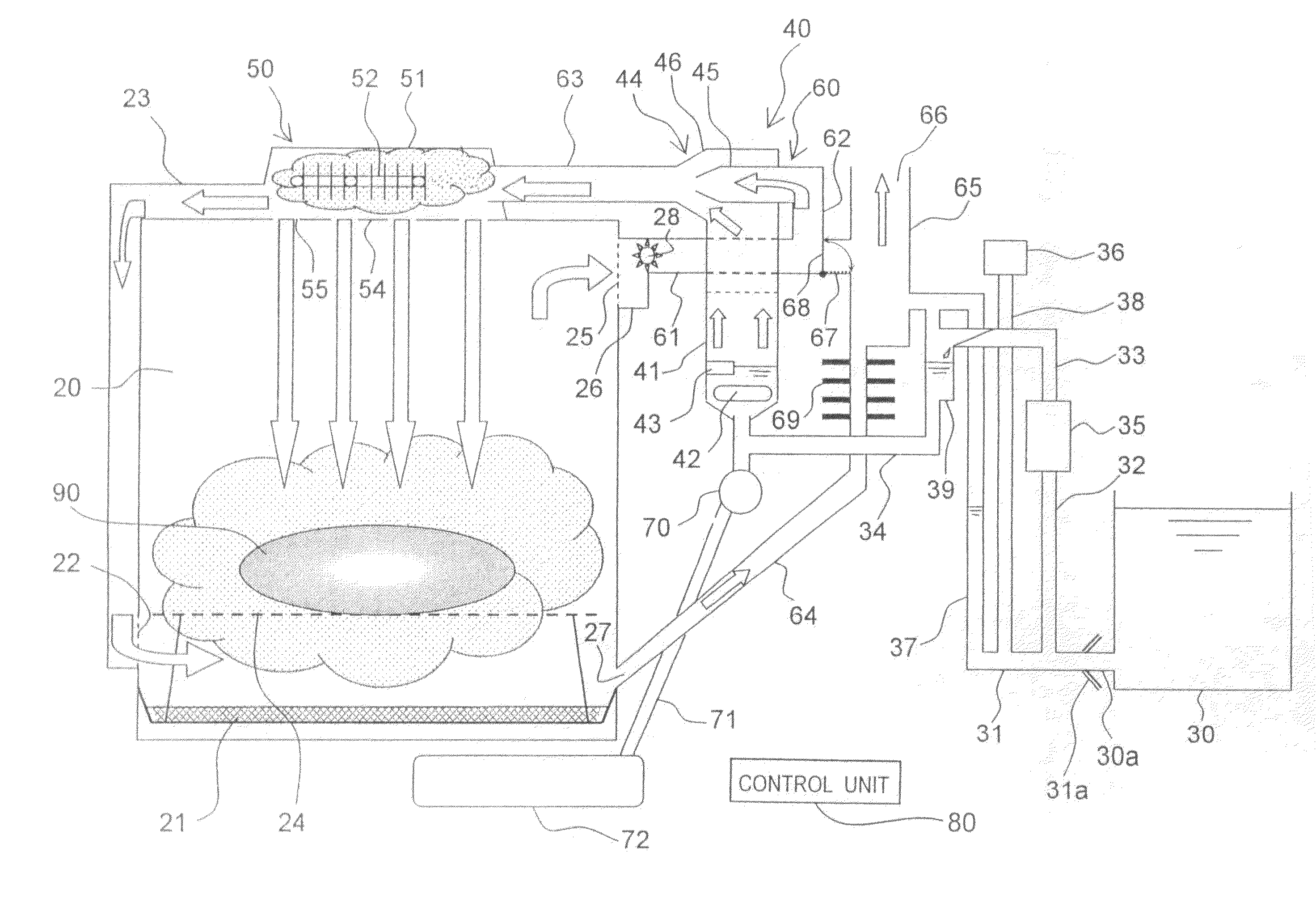

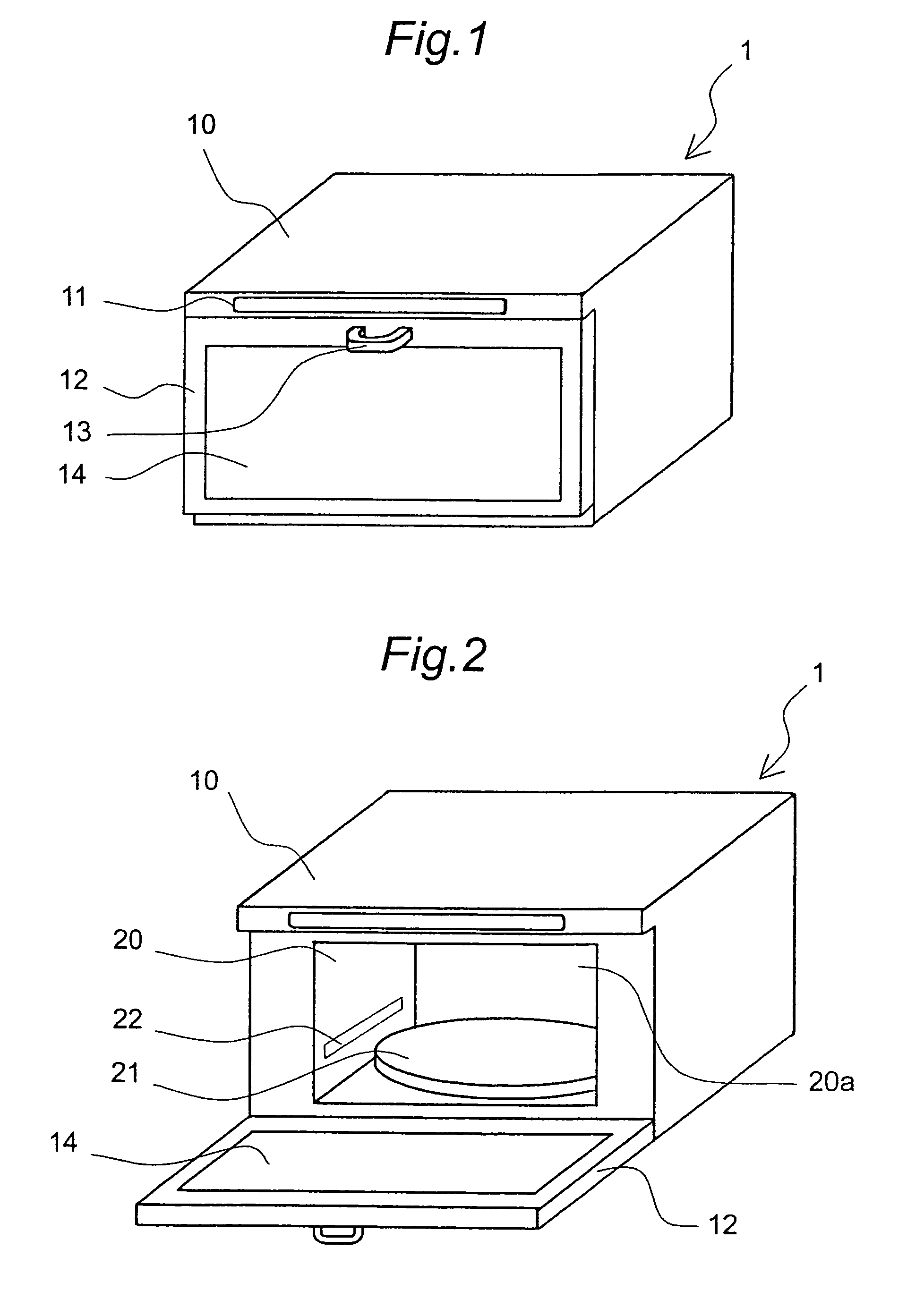

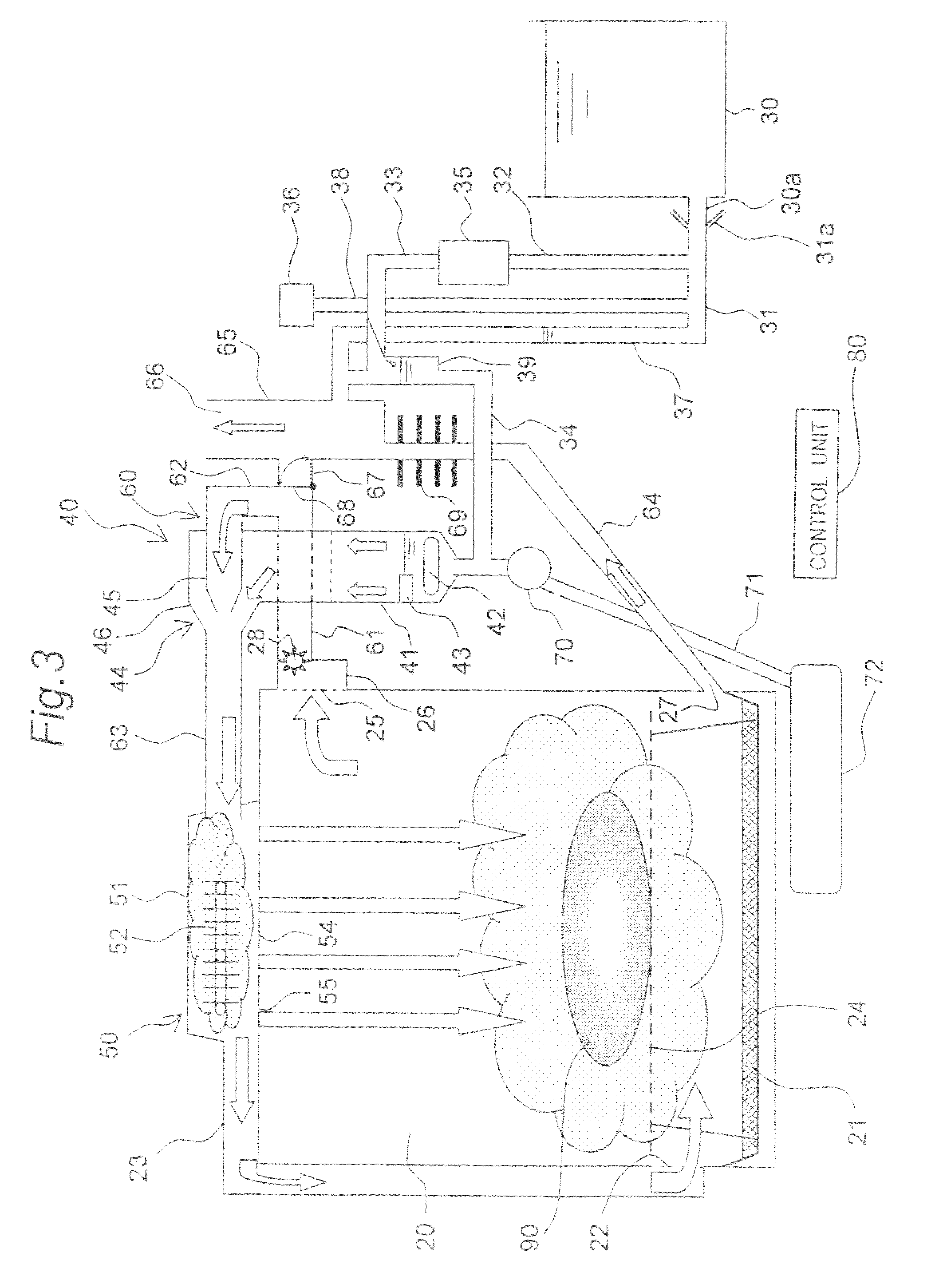

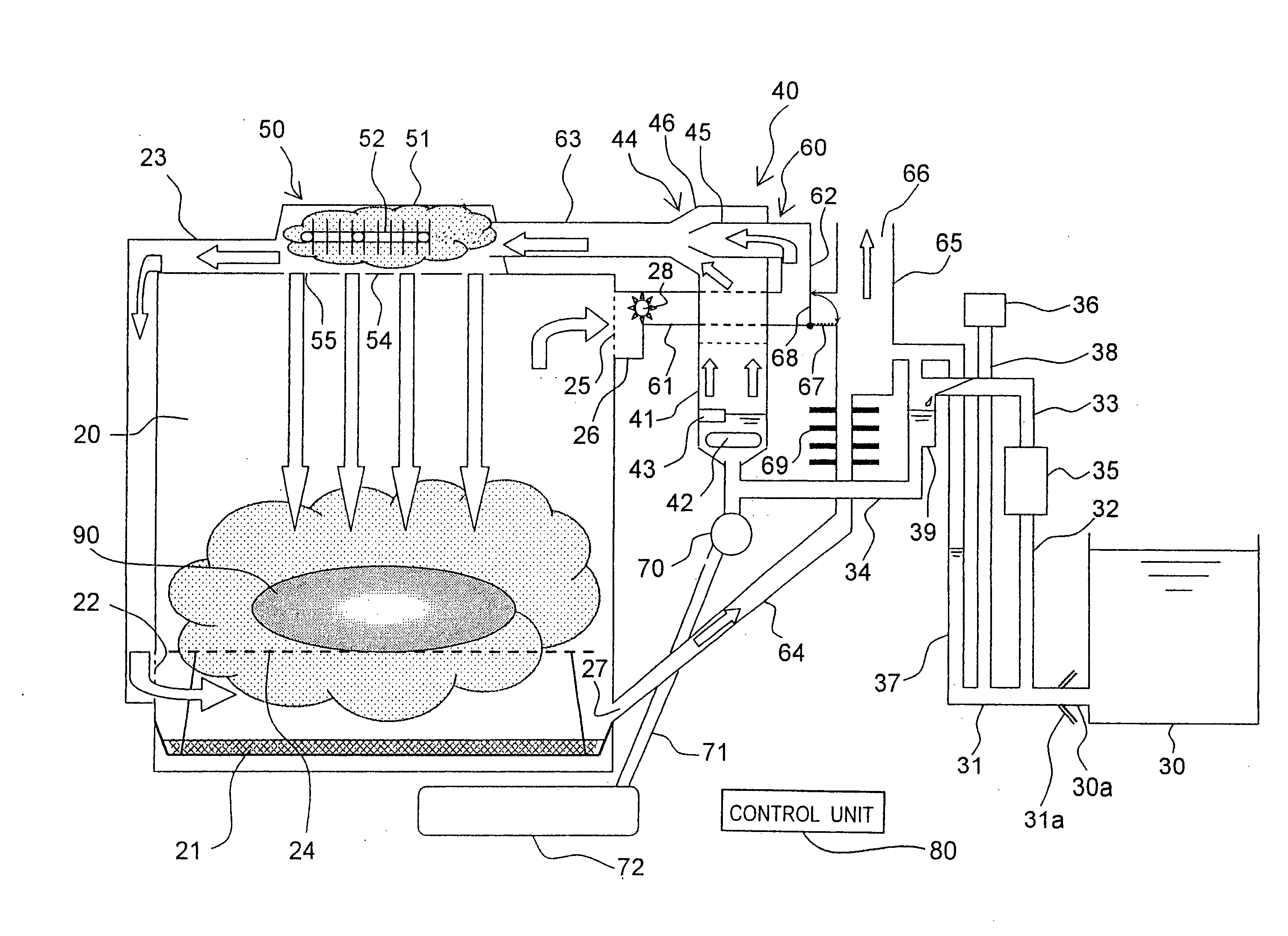

A water level sensor (91) is provided in an auxiliary tank (39) whose bottom portion communicates to a bottom portion of a pot (41) for generating steam and which is opened to the atmosphere. When water in the pot (41) keeps boiling and the stop time of a pump (35) reaches a predetermined time (e.g., 60 sec.), the pump (35) is driven for a predetermined time (e.g., 6 sec.) to supply water to the pot (41). This temporarily suppresses the boiling of water in the pot (41), lowering a steam pressure in a space formed by an external circulation passage (60), a heating chamber, and the pot (41). The water level in the auxiliary tank (39) then returns to a normal one, making it possible to correctly detect the water level in the pot (41).

Owner:SHARP KK

Heating cooker

ActiveUS20100126356A1Accurate detectionReduce steam pressureDomestic stoves or rangesSteam generation heating methodsSteam pressureWater level

A water level sensor (91) is provided in an auxiliary tank (39) whose bottom portion communicates to a bottom portion of a pot (41) for generating steam and which is opened to the atmosphere. When water in the pot (41) keeps boiling and the stop time of a pump (35) reaches a predetermined time (e.g., 60 sec.), the pump (35) is driven for a predetermined time (e.g., 6 sec.) to supply water to the pot (41). This temporarily suppresses the boiling of water in the pot (41), lowering a steam pressure in a space formed by an external circulation passage (60), a heating chamber, and the pot (41). The water level in the auxiliary tank (39) then returns to a normal one, making it possible to correctly detect the water level in the pot (41).

Owner:SHARP KK

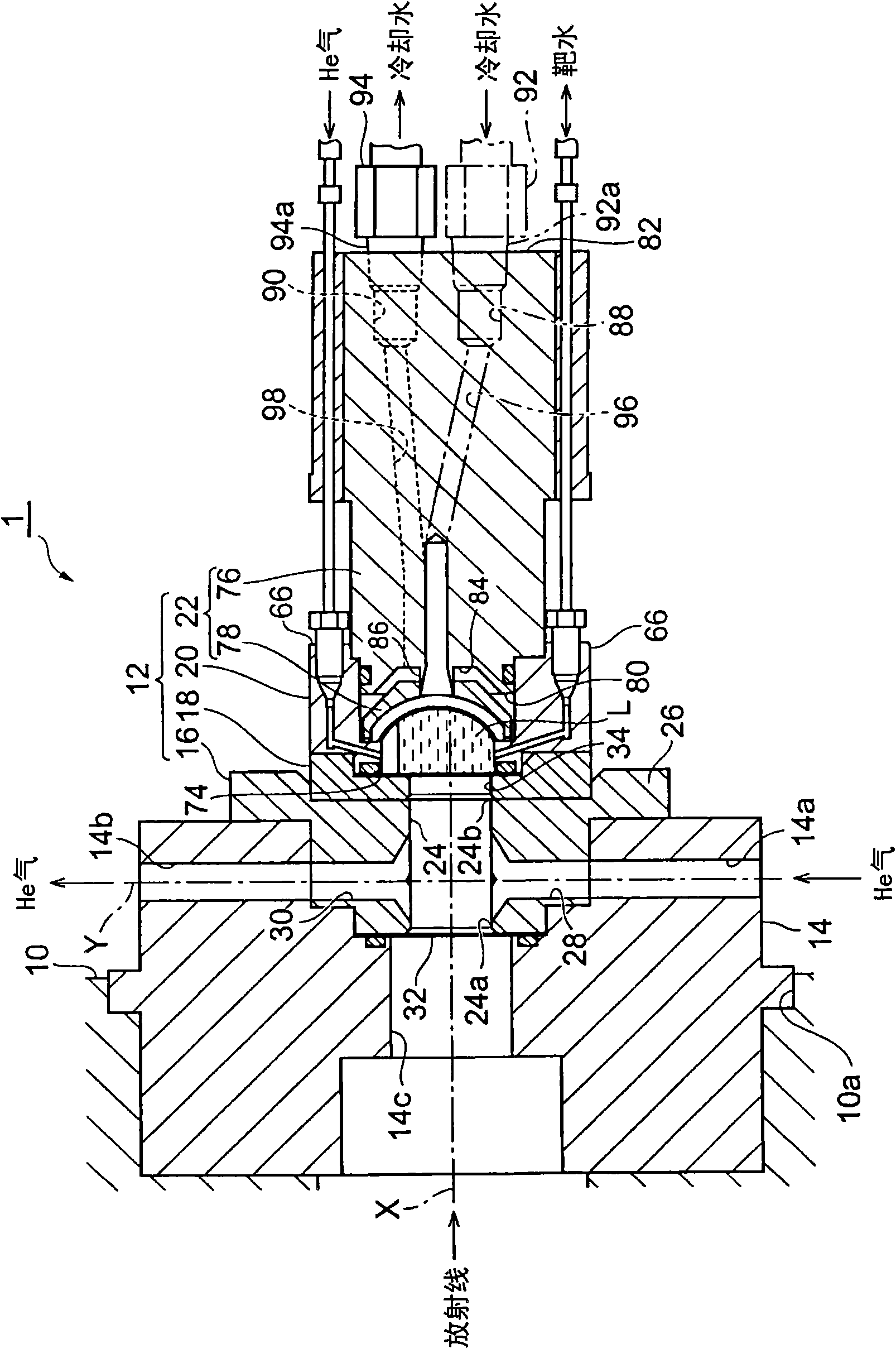

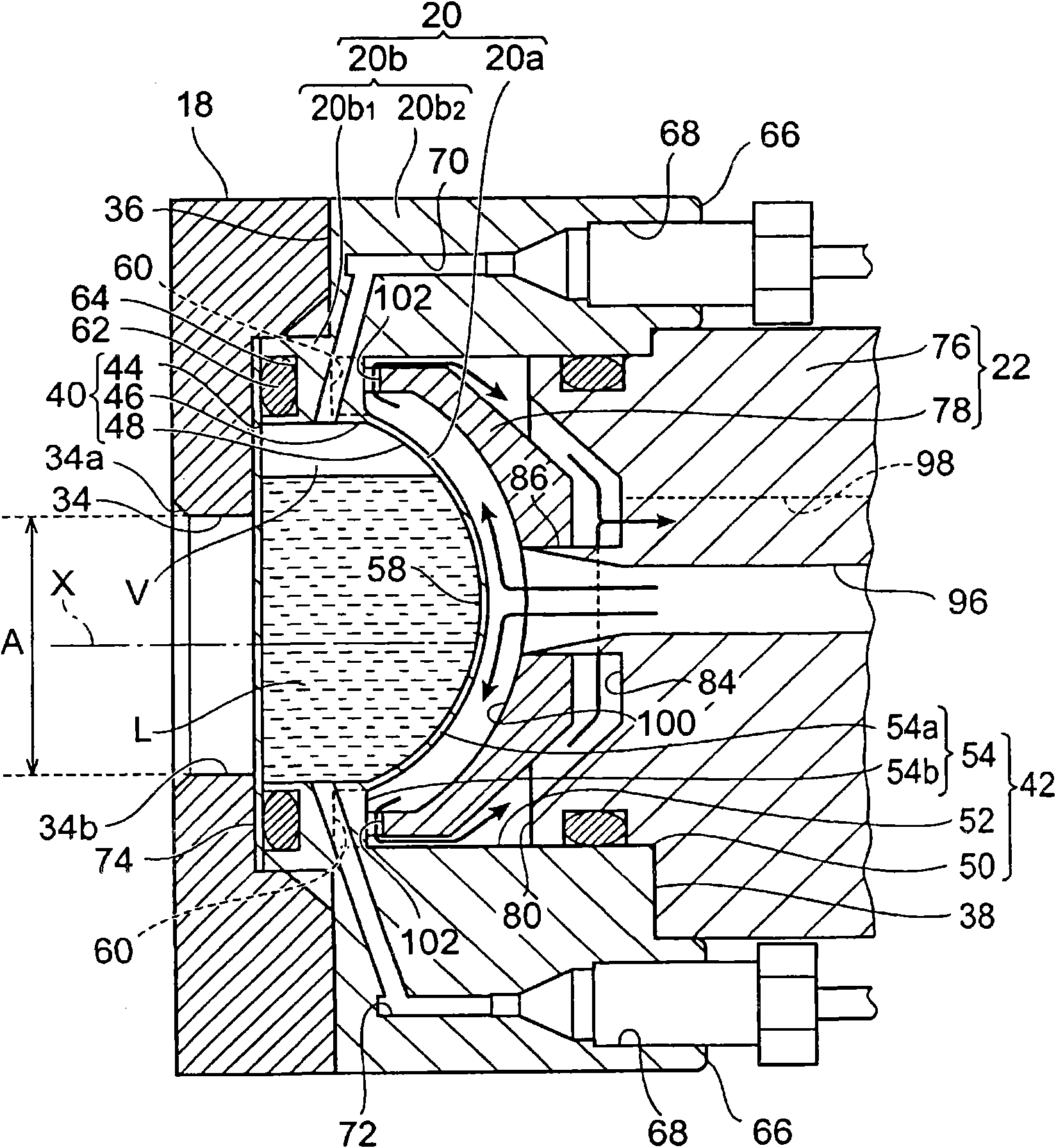

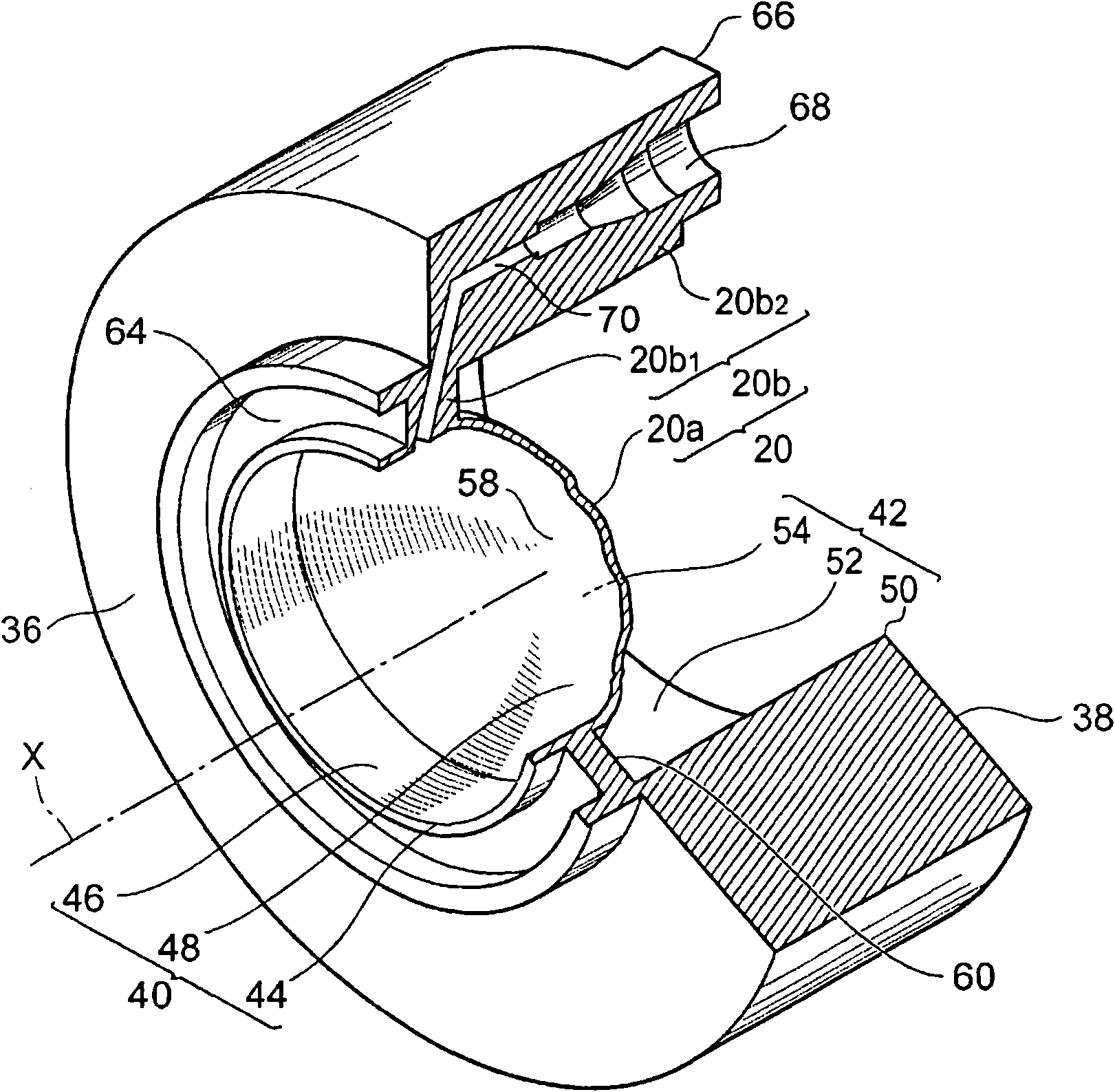

Radioisotope production system and radioisotope production method

ActiveCN101681689AImprove pressure resistanceImprove cooling effectConversion outside reactor/acceleratorsMagnetic resonance acceleratorsCooling effectEngineering

Boiling of a target liquid is suppressed sufficiently by enhancing both pressure tightness of a target and cooling effect of the target liquid. The radioisotope production system includes a cyclotronfor irradiating radiation, and a target (20) having a recess (40) for containing a target liquid L. The containing recess (40) includes an opening (44) for introducing radiation irradiated from the cyclotron, and a spherical bottom surface (48) recessed toward the direction receding from the opening (44) to have a top (58). The target (20) is arranged such that the intersection of the irradiationaxis X of radiation from the cyclotron and the bottom surface (48) is located directly under the top (58).

Owner:SUMITOMO HEAVY IND LTD

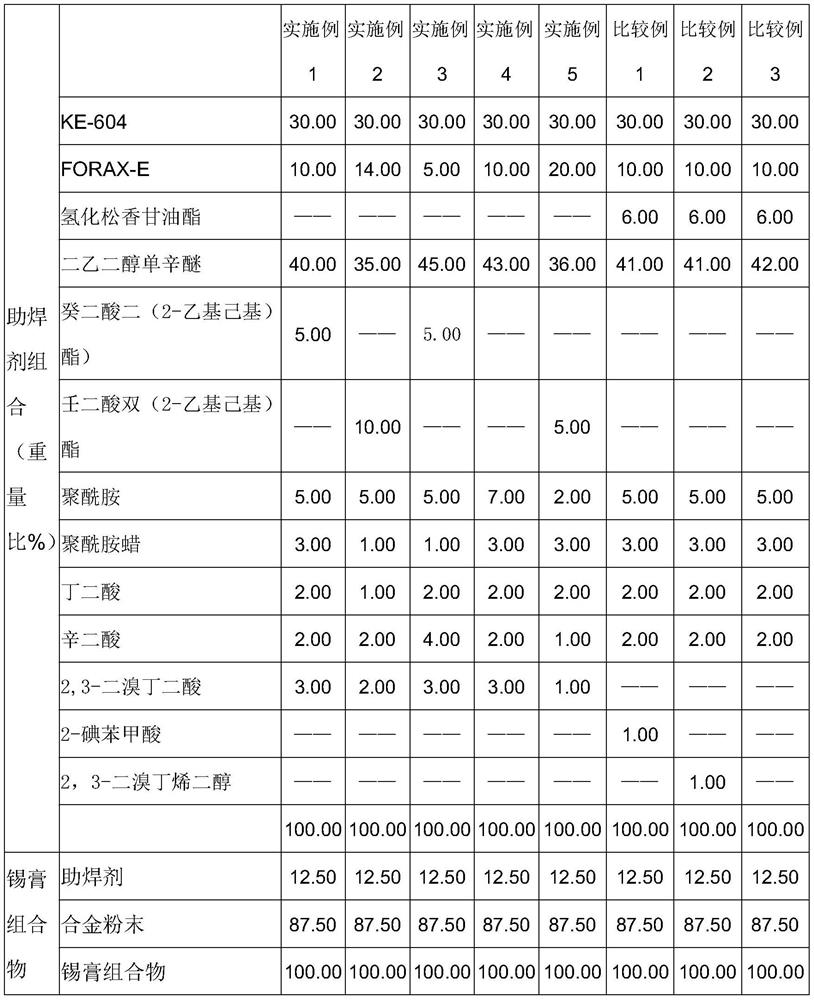

Laser welding solder paste and preparation method thereof

PendingCN112276412APrevent solder paste from flowingInhibits flux boilingWelding/cutting media/materialsSoldering mediaActive agentOrganic acid

The invention relates to laser welding solder paste and a preparation method thereof. According to the technical scheme, the laser welding solder paste is composed of the following raw materials in percentage by weight: 86-88% of alloy powder and 12-14% of a paste soldering flux, wherein the alloy powder is formed by mixing one or more than two kinds of tin-based alloy powder and has eutectic components; and the paste soldering flux is composed of the following raw materials in percentage by weight: 35-50% of rosin, 5-10% of a thixotropic agent, 3-6% of an organic acid active agent, 1-3% of anorganic halogen active agent, 35-45% of an organic solvent and 5-10% of a special solvent. The laser welding solder paste has the advantages that soldering flux boiling caused by rapid heating can berestrained, and the effect of restraining splashing of solder balls generated by rapid heating of solder paste and the soldering flux is achieved.

Owner:苏州恩斯泰金属科技有限公司

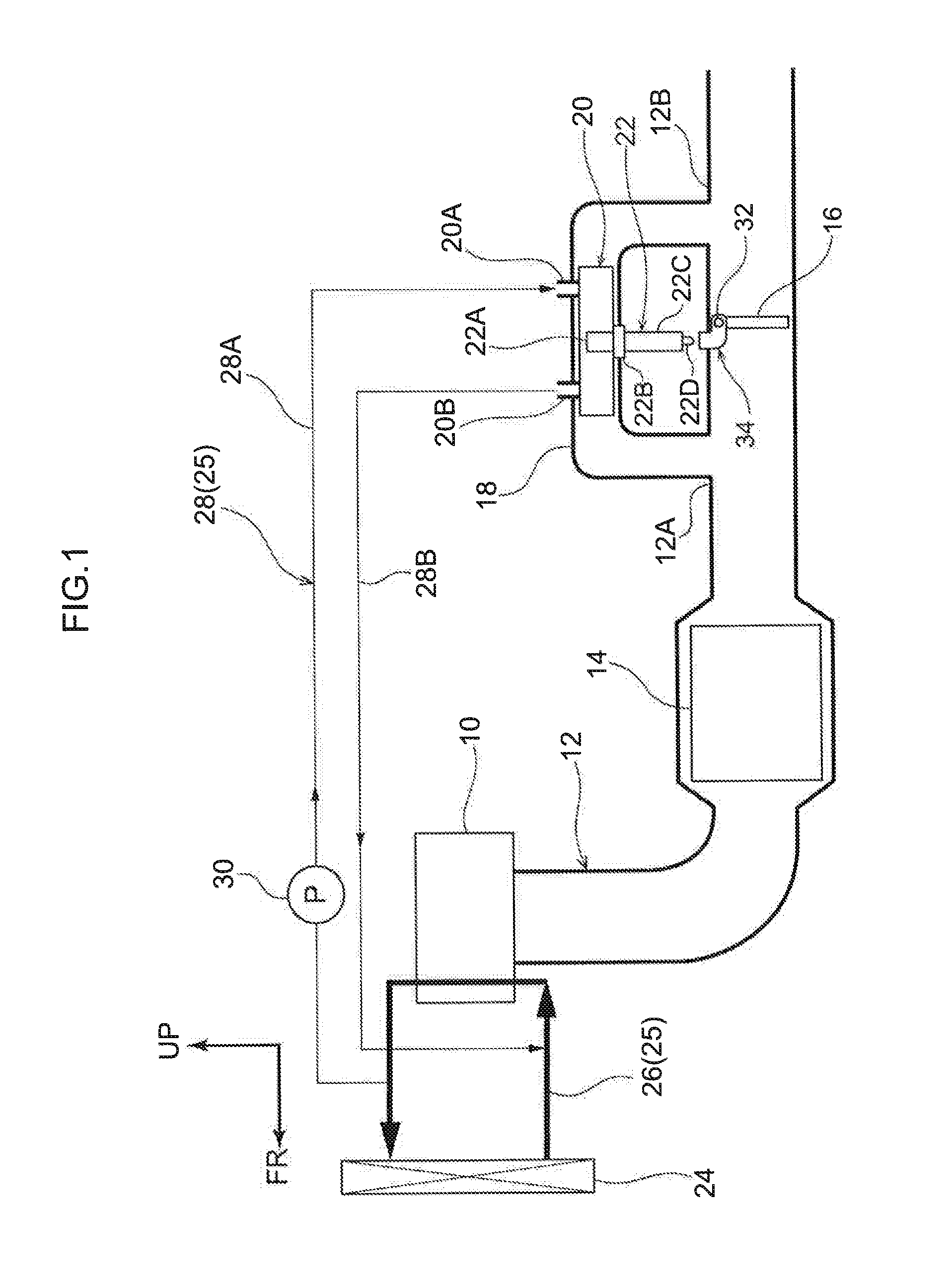

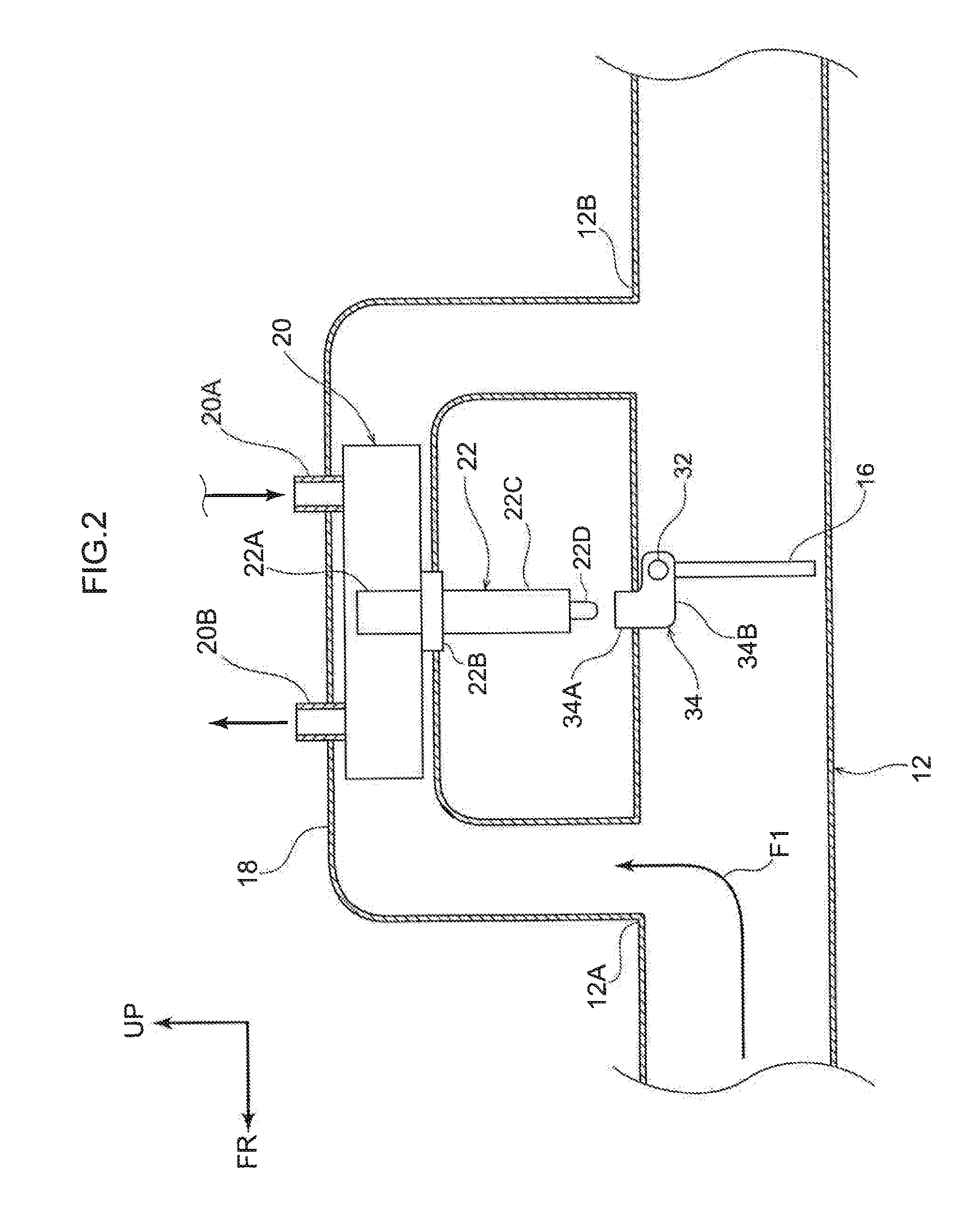

Exhaust heat recovery structure

ActiveUS20160376970A1Improve engine performanceIncrease temperatureInternal combustion piston enginesRecuperative heat exchangersEngineeringThermostat

There is provided an exhaust heat recovery structure that may suppress boiling of coolant in a heat exchanger. The exhaust heat recovery structure includes a first pipe, a second pipe, a valve and a thermostat. Exhaust gas from an engine flows in the first pipe. The second pipe branches from the first pipe and a heat exchanger that exchanges heat between the coolant and exhaust gas is provided at the second pipe. The valve is provided at the first pipe or the second pipe. The valve adjusts a flow amount of exhaust gas flowing into the second pipe by opening and closing. The thermostat is equipped with a heat-sensing portion that is disposed inside the heat exchanger. When the temperature of the heat-sensing portion is high, the thermostat opens or closes the valve to reduce the flow amount of exhaust gas flowing into the second pipe.

Owner:TOYOTA JIDOSHA KK

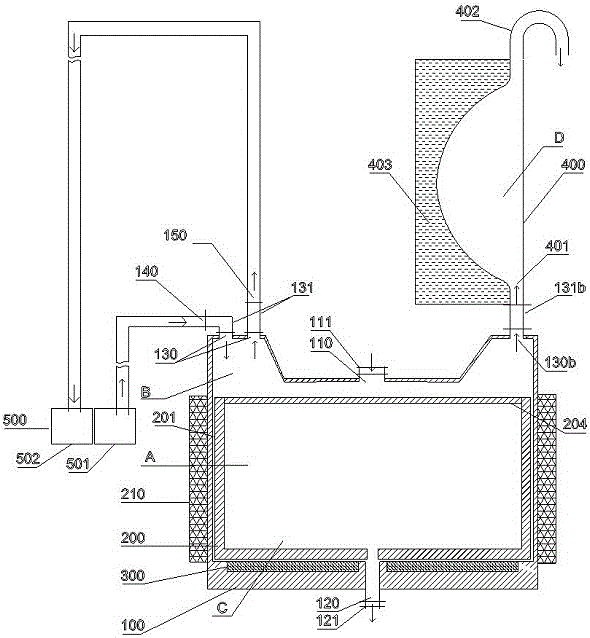

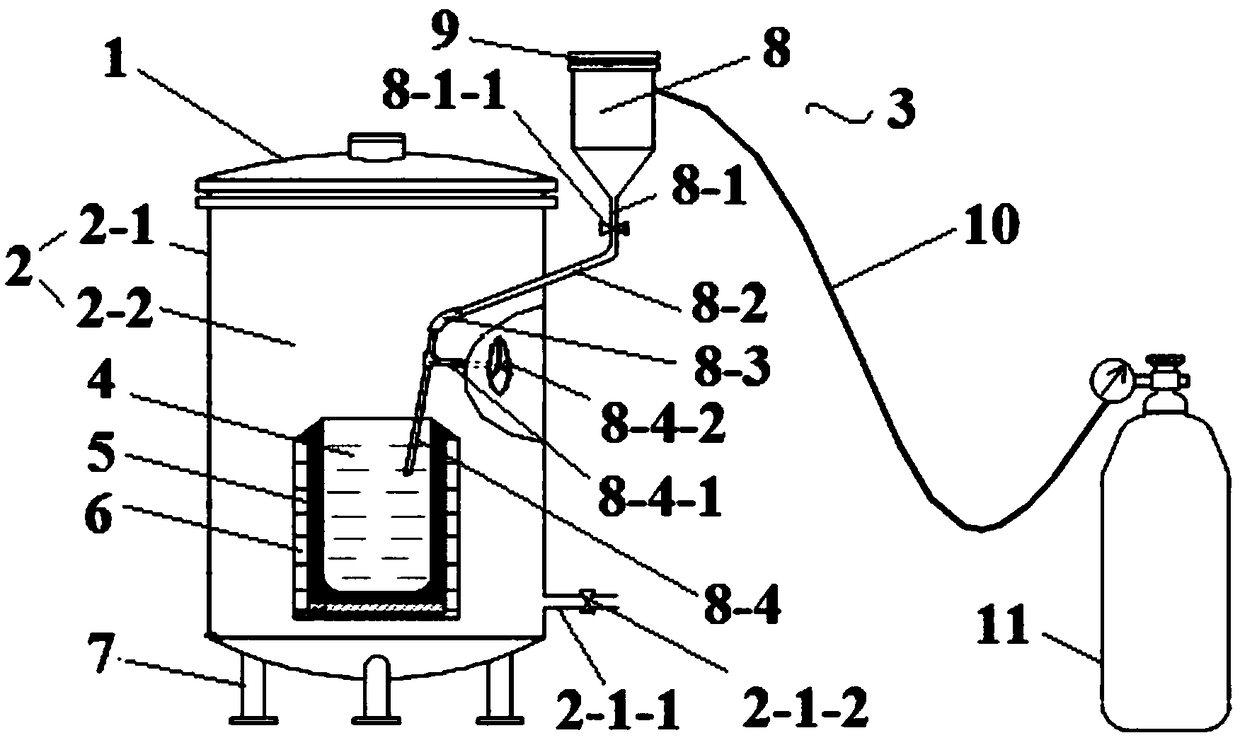

Stirring pulp cooking and air-controlled pulp inlet and outlet device and stirring pulp cooking and air-controlled pulp inlet and outlet method

ActiveCN106260006AEvenly heatedAvoid cakingPaper recyclingFood shapingPulp and paper industryControl valves

The invention relates to a stirring pulp cooking and air-controlled pulp inlet and outlet device for pulp food, and the stirring pulp cooking and air-controlled pulp inlet and outlet device comprises a pulp cooking barrel, a stirring device, a heating device, an overflowed pulp return device, and an air pressure control device, wherein the pulp cooking barrel is provided with a pulp inlet, a pulp outlet, and an air port, the stirring device comprises a stirrer and a stirring driver, the air pressure control device comprises a steam generator and a sucking device, a closed cavity is formed inside the pulp cooking barrel, the pulp inlet of the pulp cooking barrel is provided with a control valve which can be automatically opened or closed according to the pressure of the pulp cooking barrel, the air port of the pulp cooking barrel is provided with a control valve connected with the air pressure control device, and is also connected with overflowed pulp return device, the inner wall of the overflowed pulp return device is smooth and is provided with a return cavity with unidirectional slope, the low point of the return cavity is provided with a first connection port connected with the pulp cooking barrel, the overflowed pulp return device is also provided with a second connection port, one connection port of the overflowed pulp return device is provided with a control valve which can be automatically opened or closed according to the pressure of the pulp cooking barrel, the stirrer is arranged in the pulp cooking barrel, the stirring driver is arranged outside the closed cavity, and a coupling action force is formed between the stirrer and the stirring driver. According to the stirring pulp cooking and air-controlled pulp inlet and outlet device, pollution-free, rapid and safe heat processing treatment on the pulp food can be realized by closed pulp cooking, isolated stirring, overflowed pulp return and air-controlled pulp inlet and outlet.

Owner:上海洛瓷动力科技有限公司

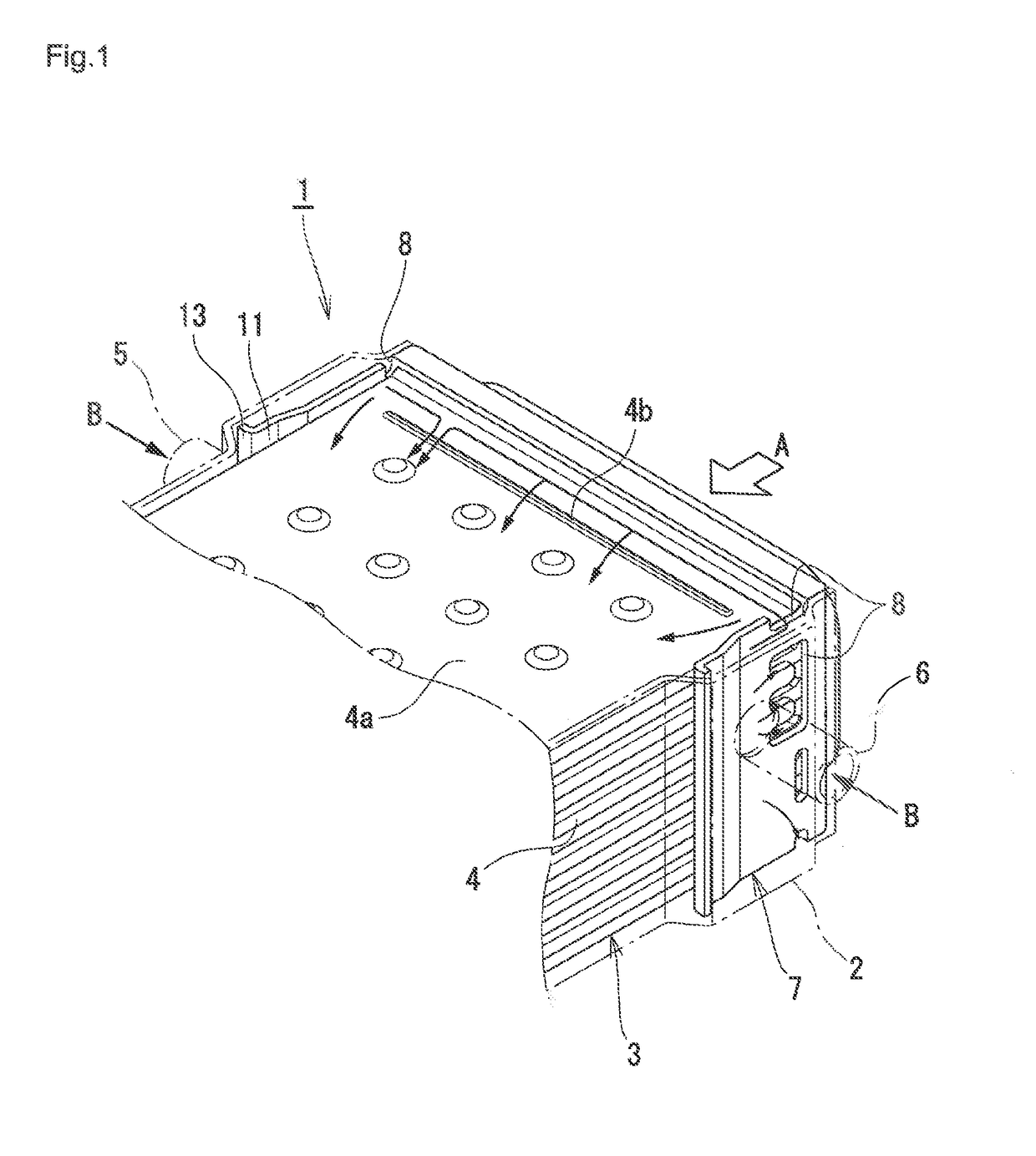

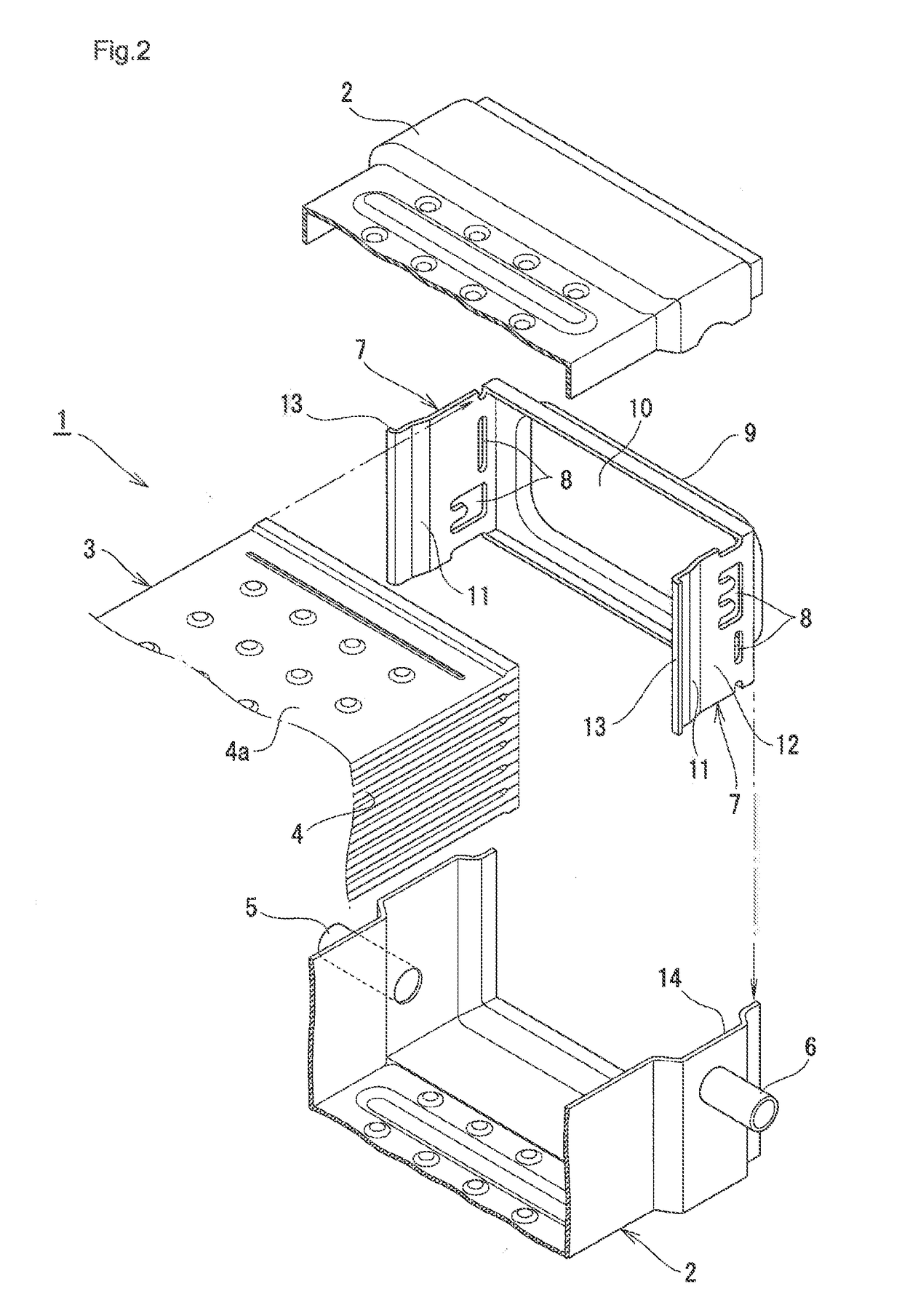

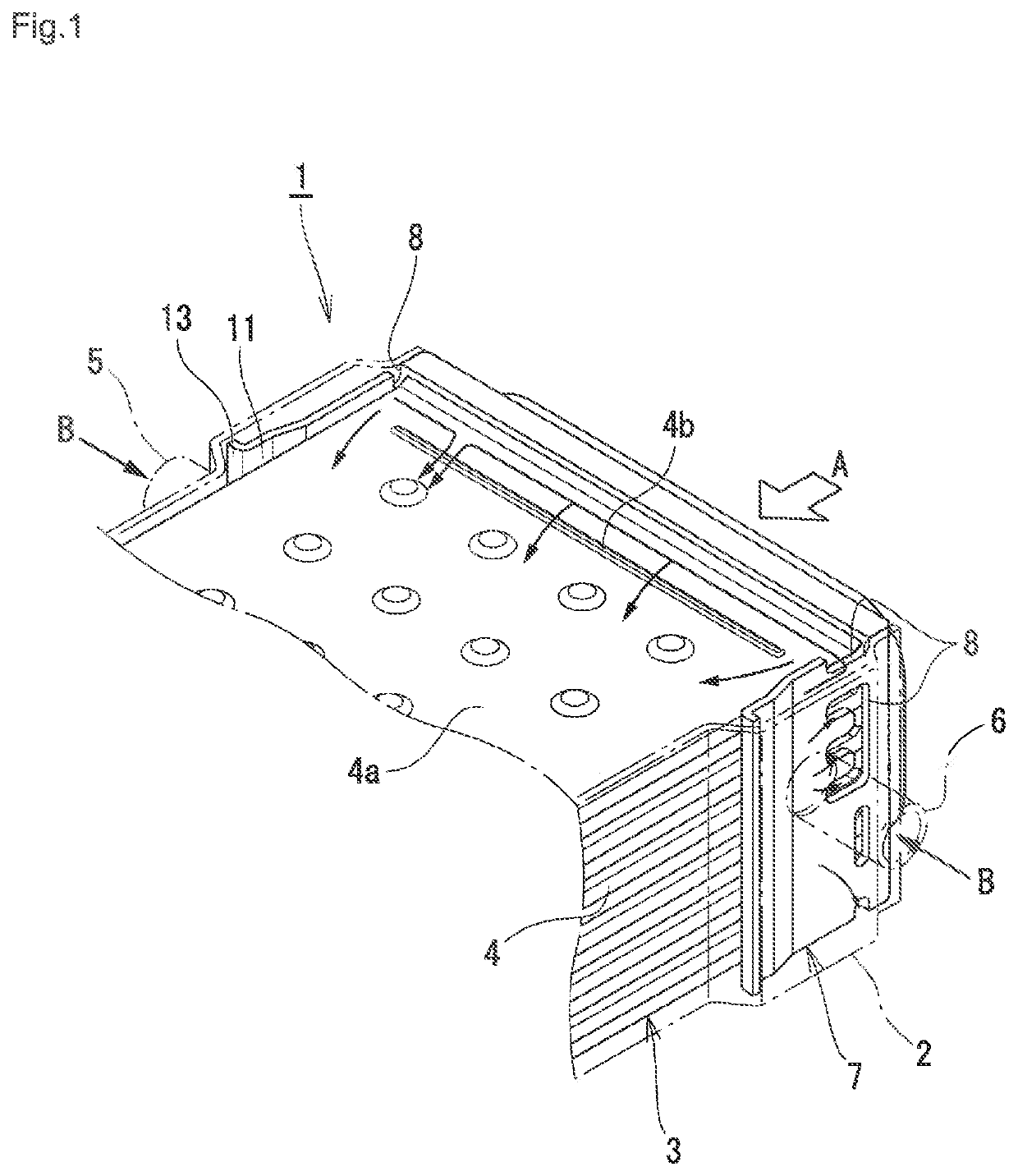

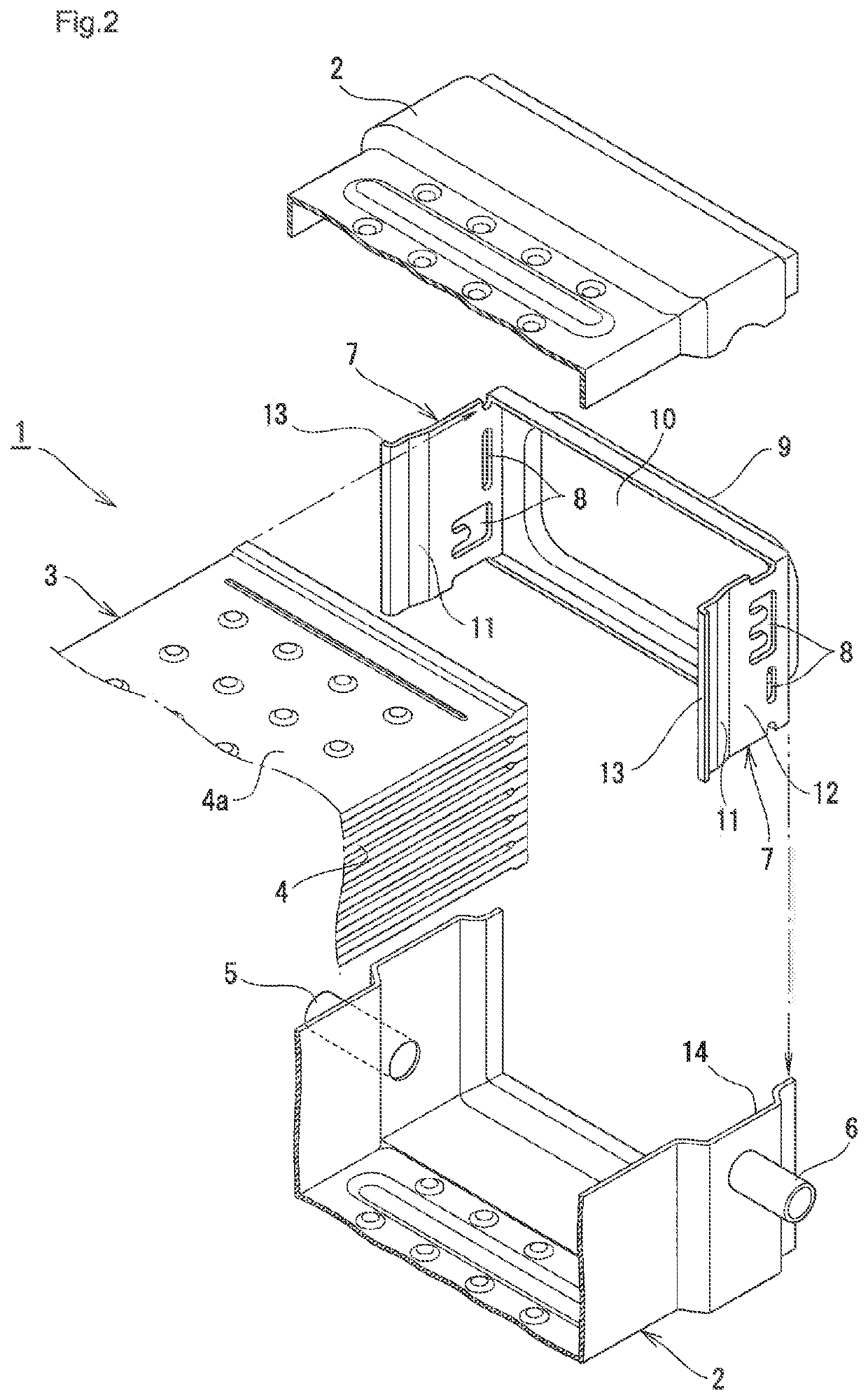

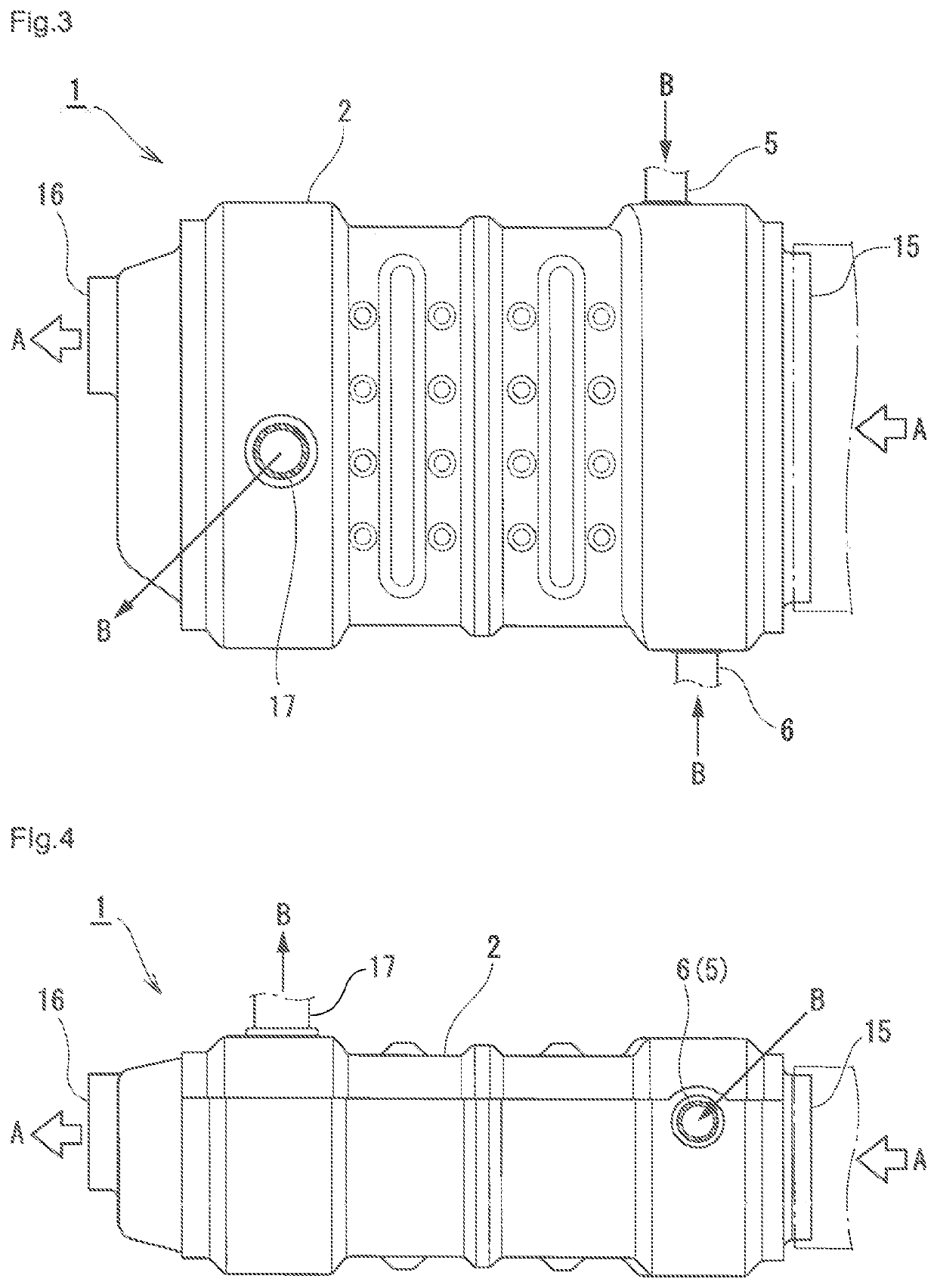

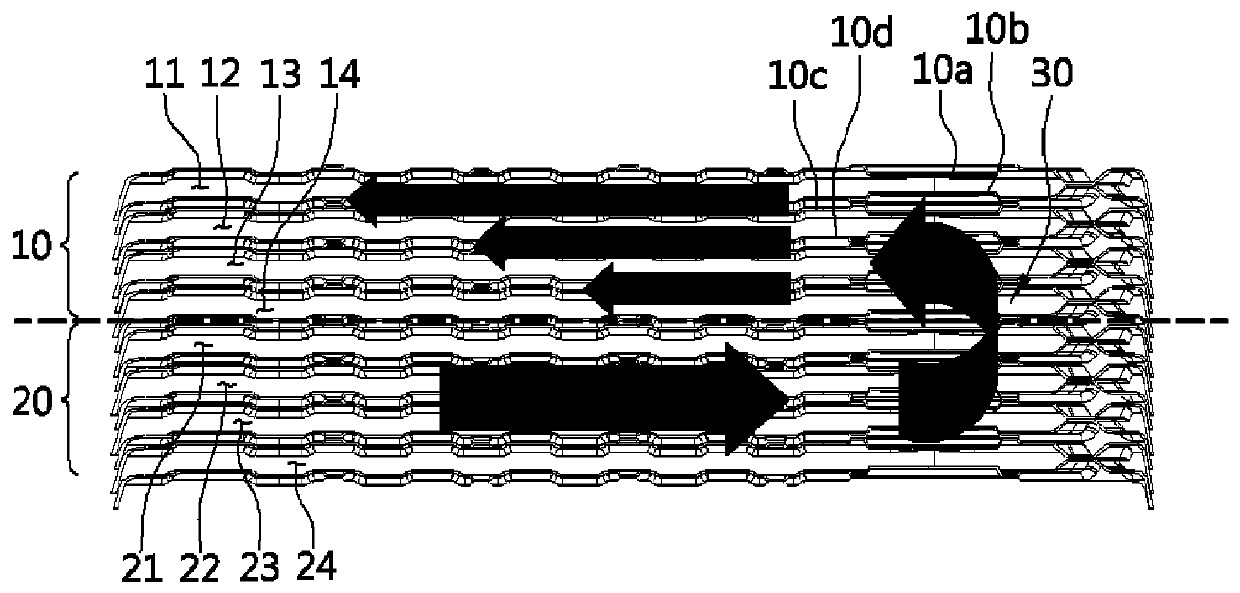

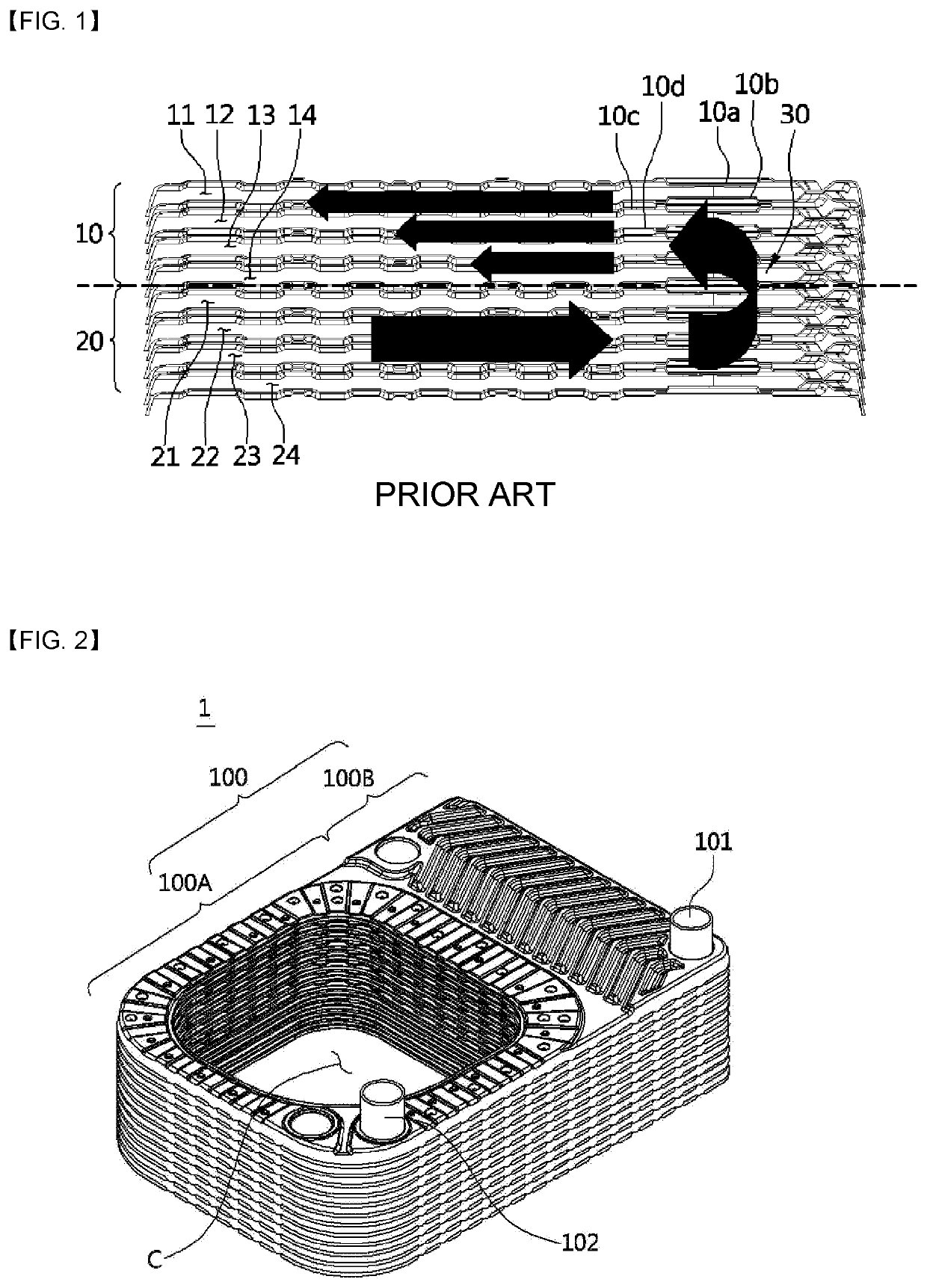

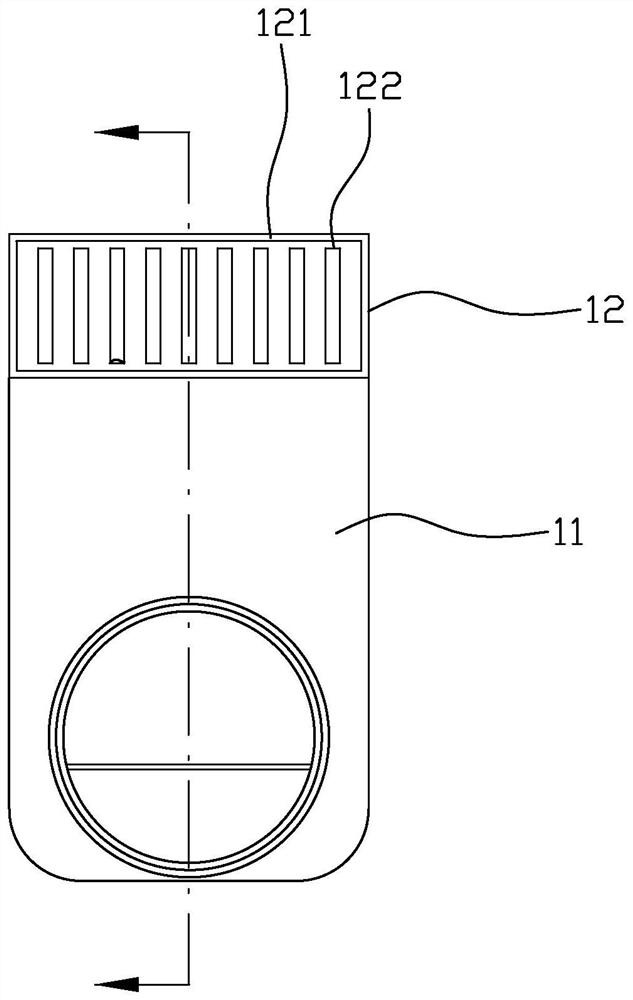

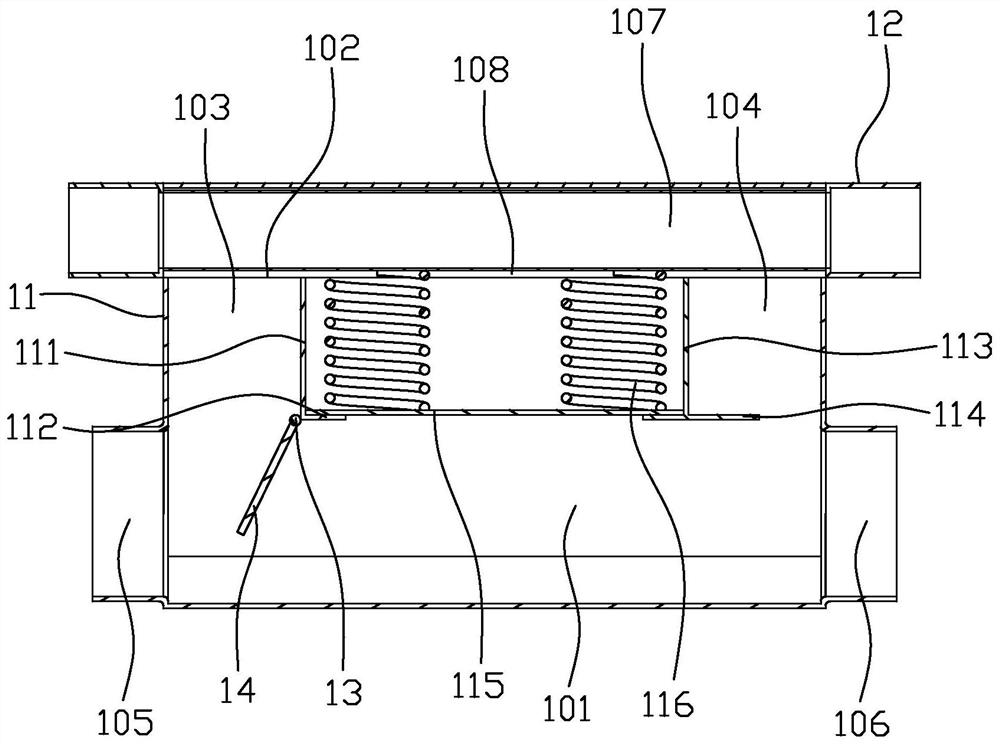

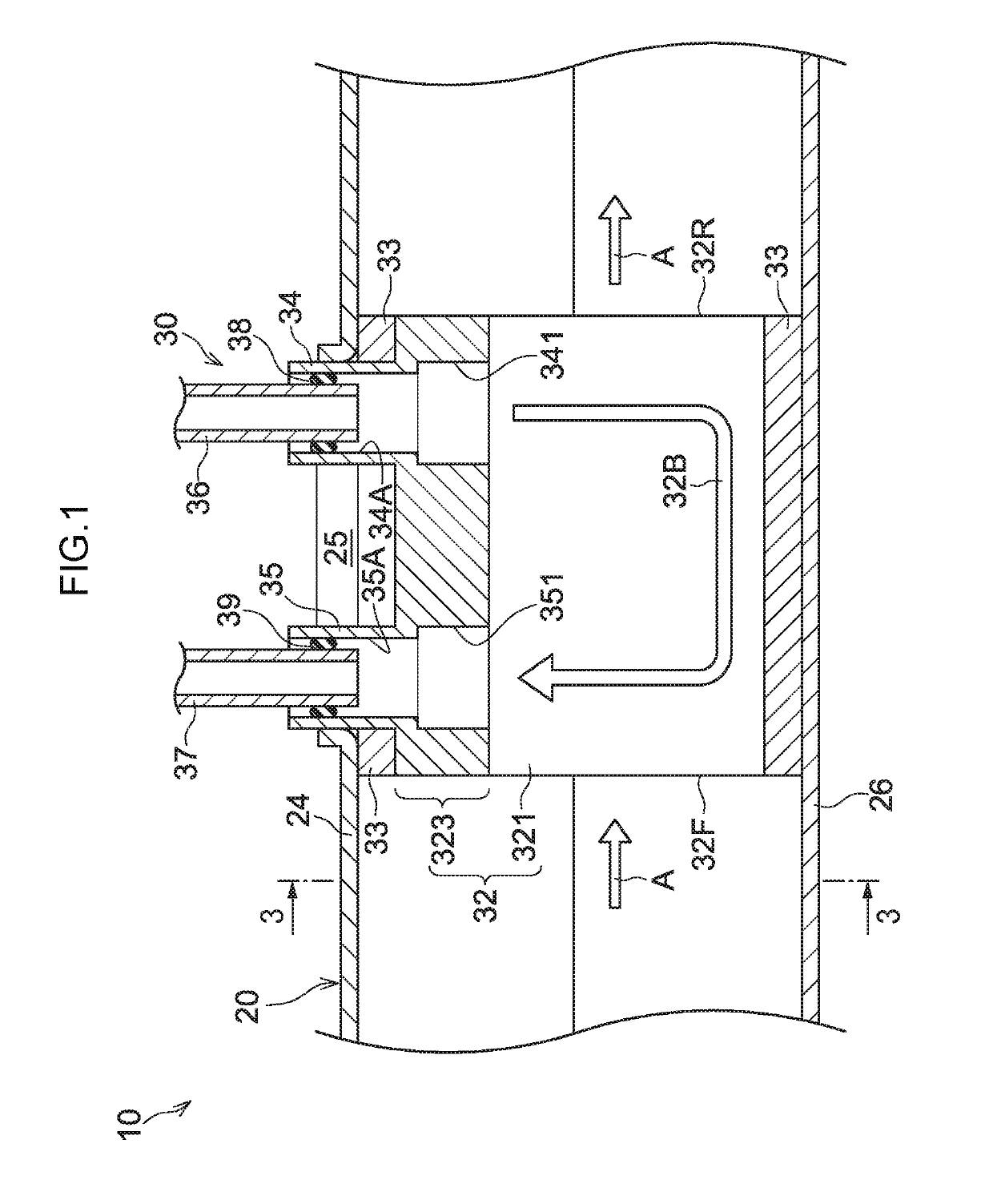

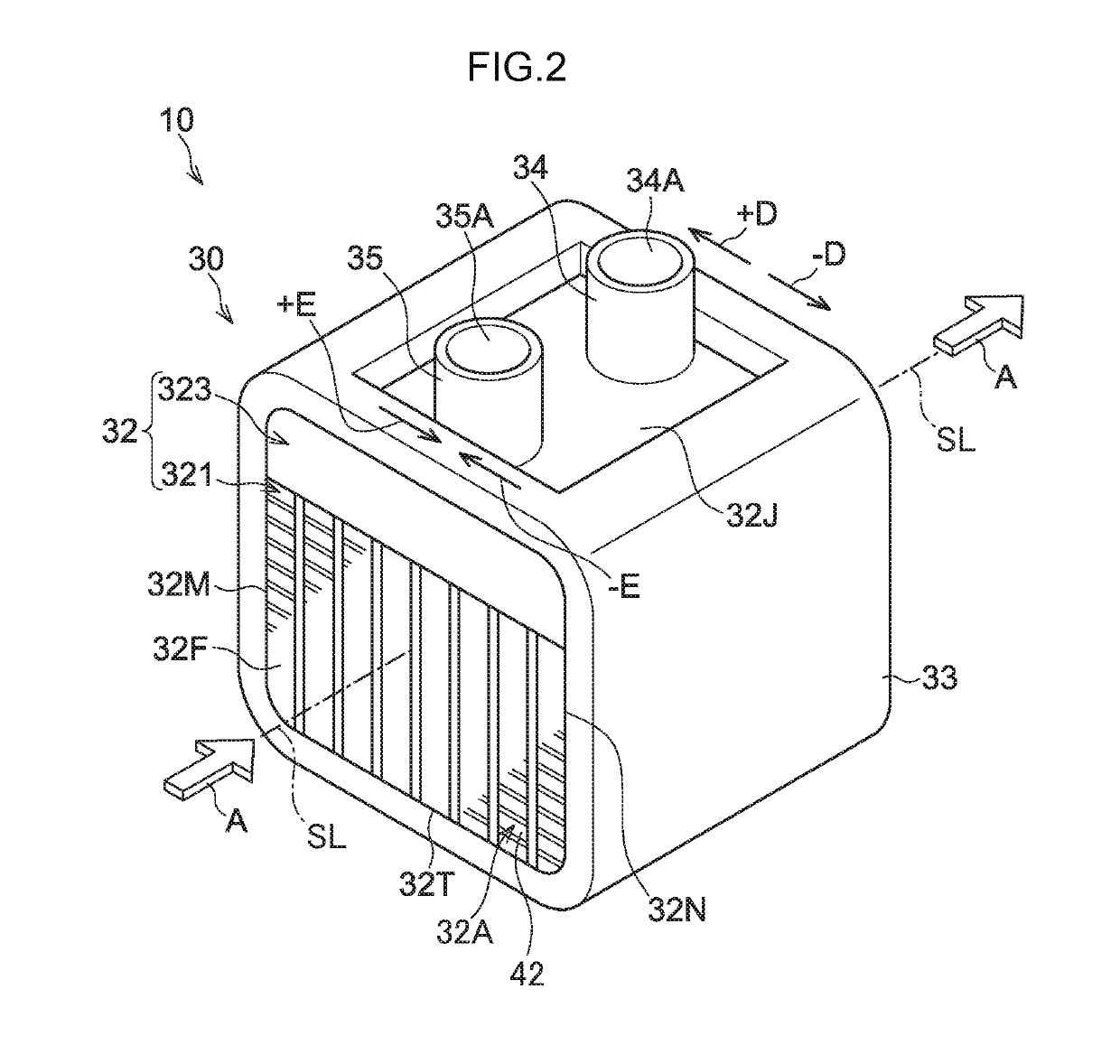

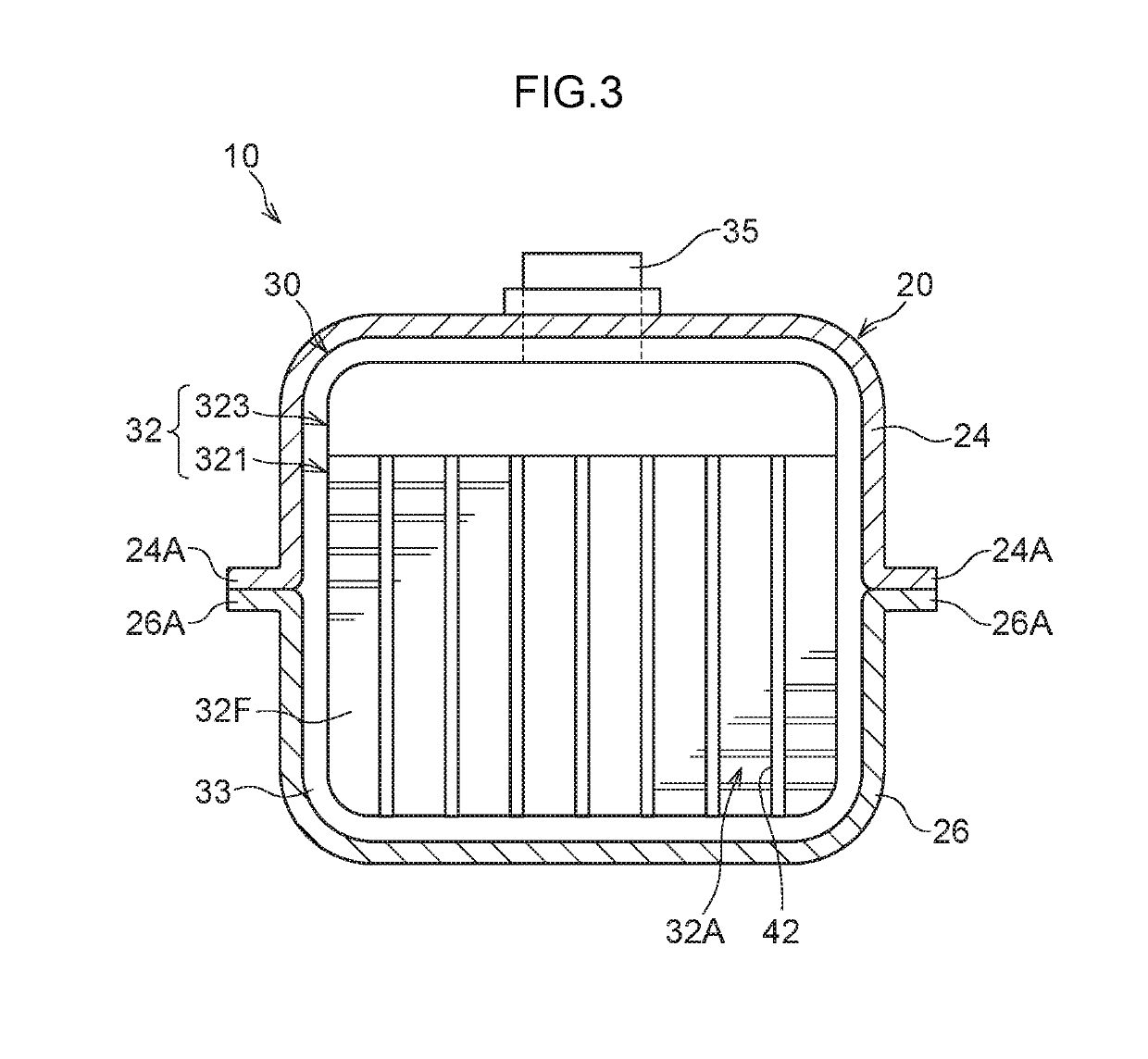

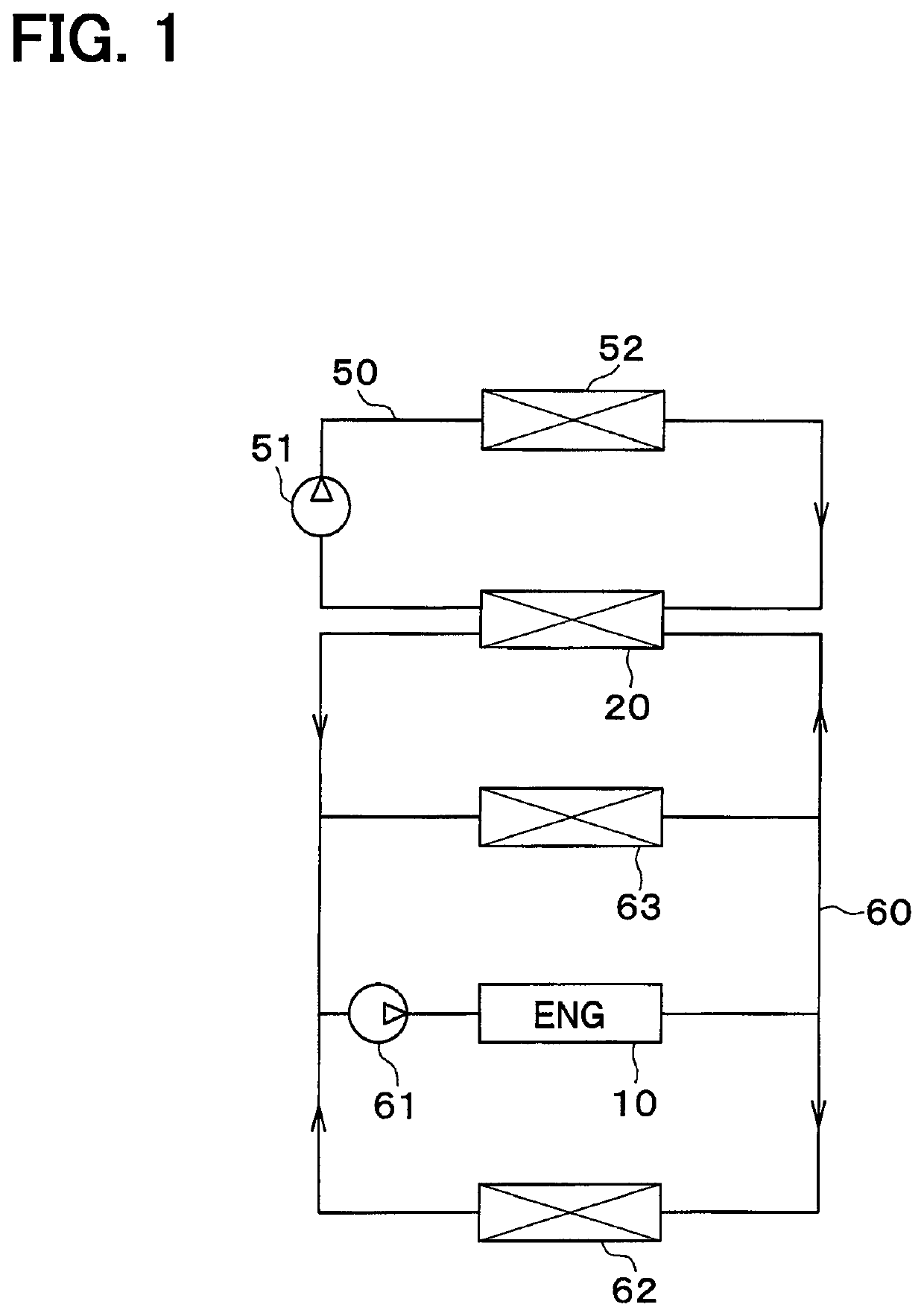

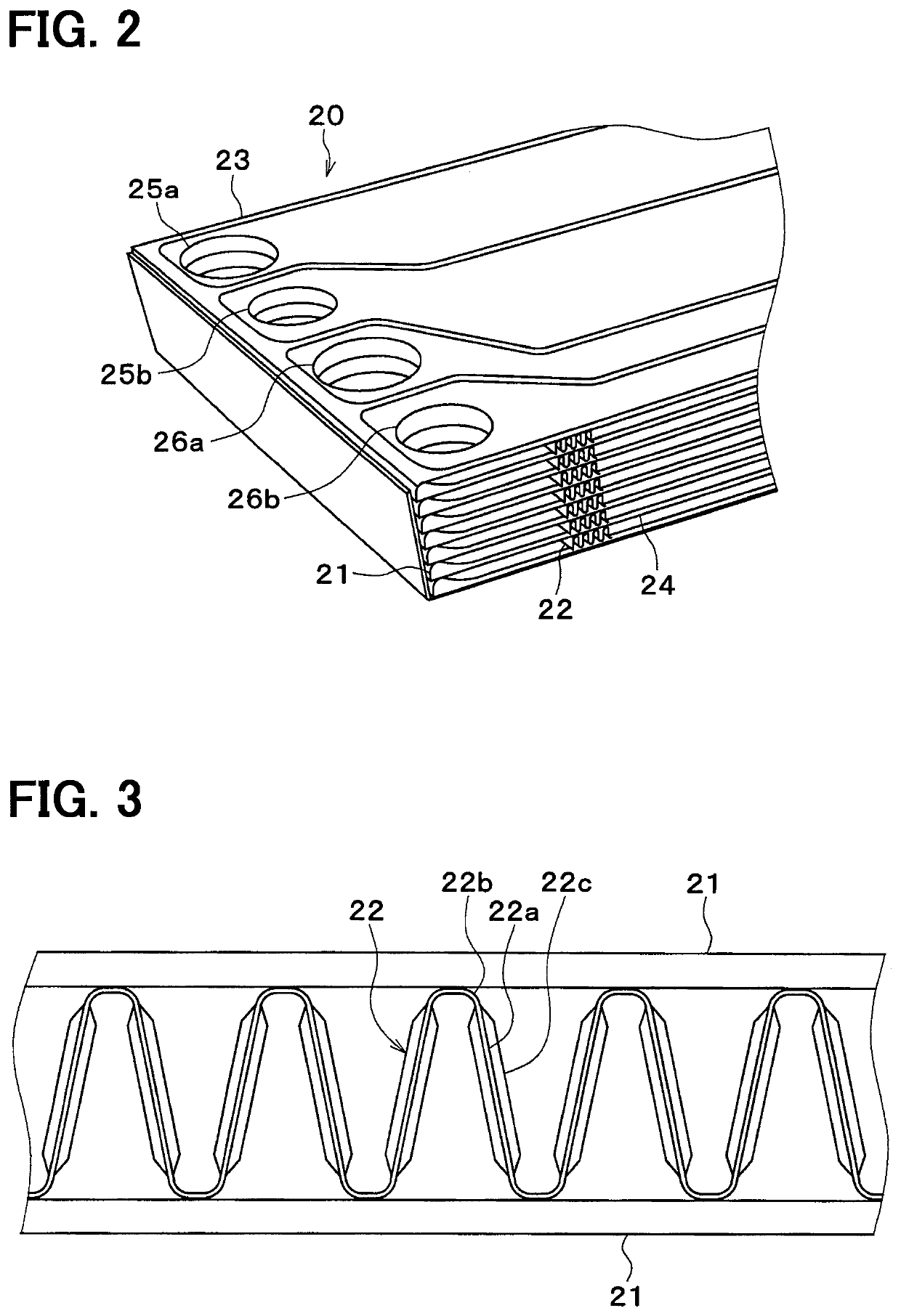

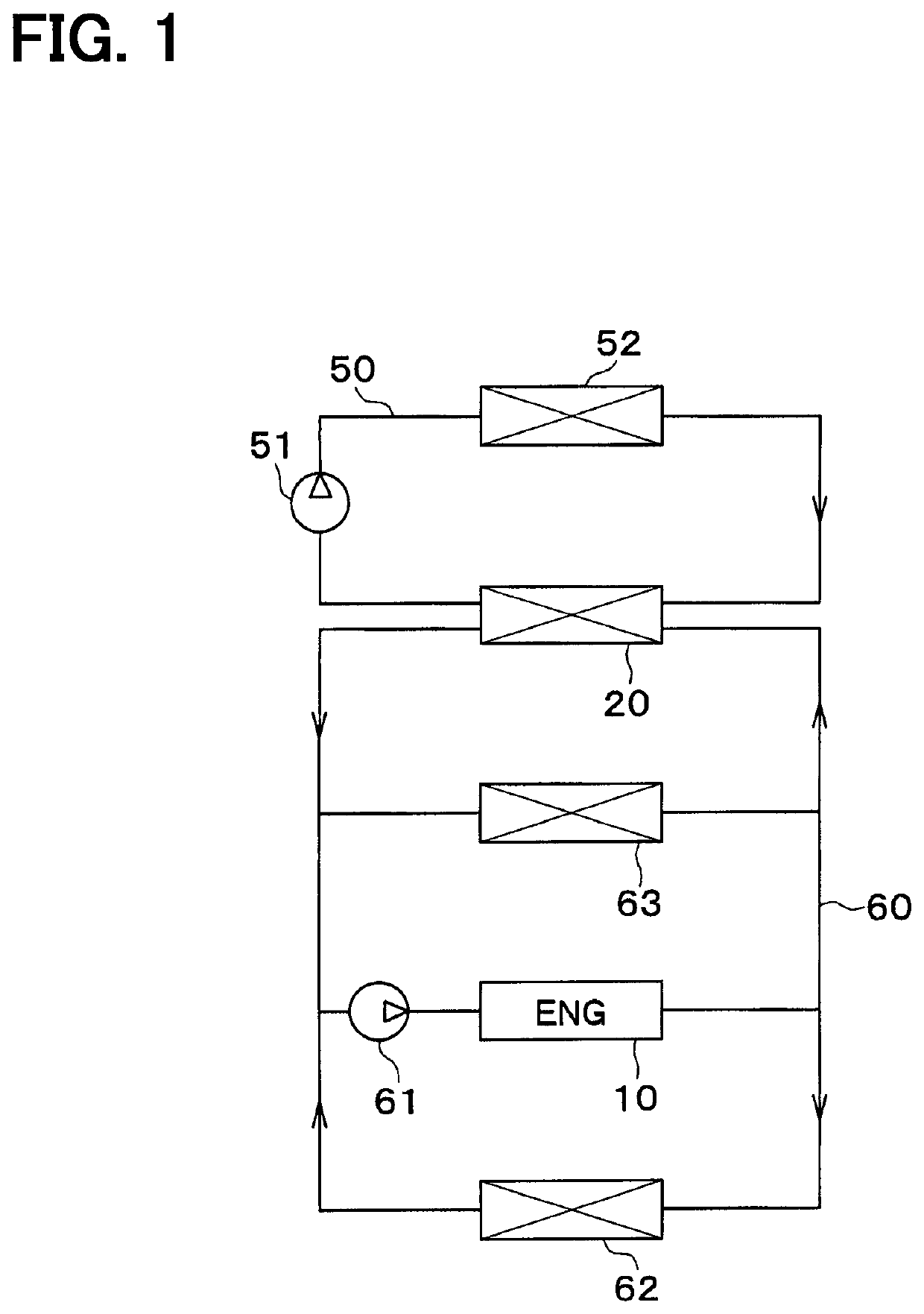

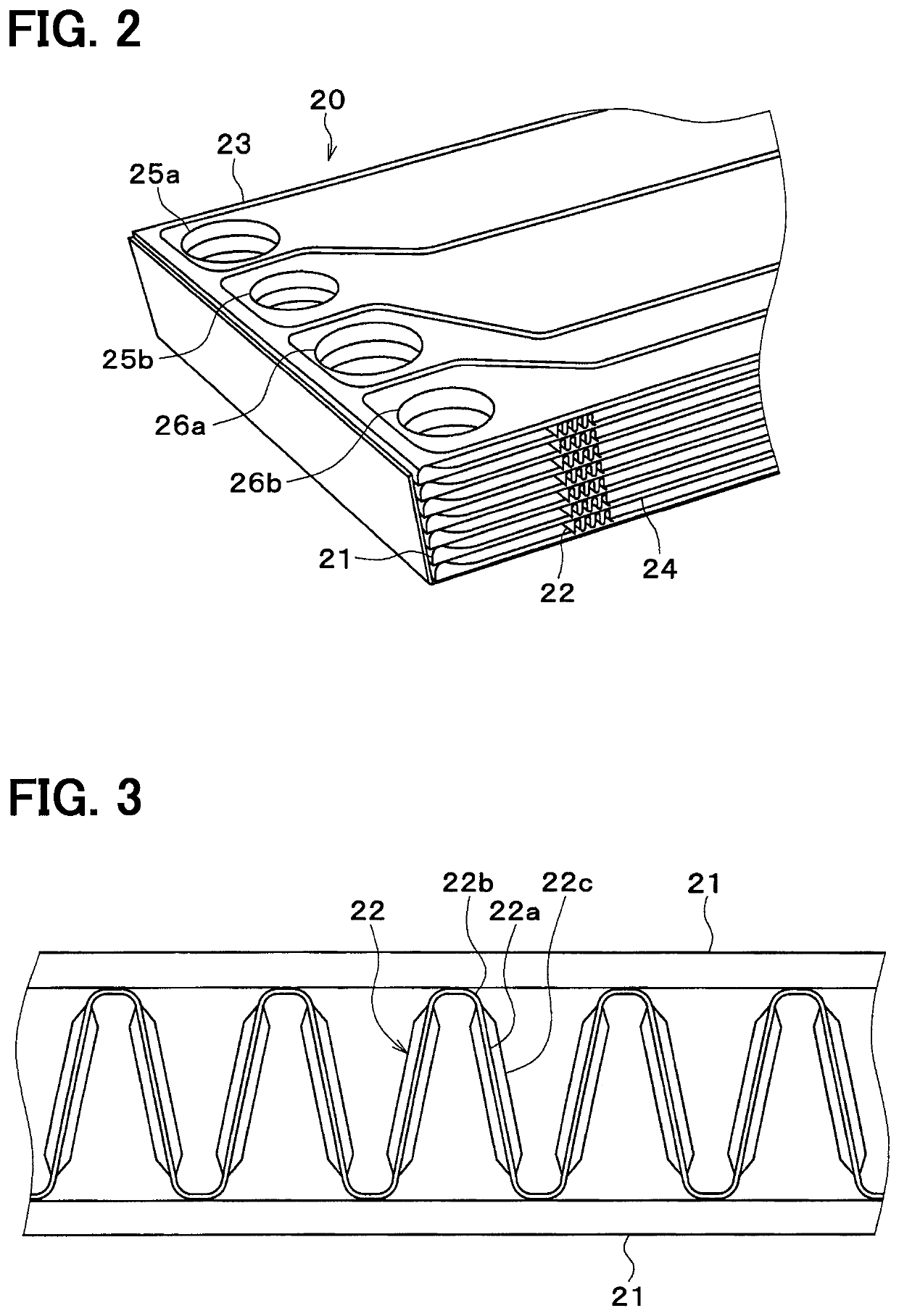

Exhaust gas heat exchanger having stacked flat tubes

ActiveUS20190017471A1Avoid flyingSuppress boilingRecuperative heat exchangersExhaust apparatusExhaust gasEngineering

An exhaust gas heat exchanger having stacked flat tubes includes a stacked tube body configured by stacking a plurality of flat tubes in multiple tiers with spaces therebetween and arranged inside a case; exhaust gas flows in from a first end part of the stacked tube body in a tube axis direction, circulates through each flat tube, and flows out from the a second end part; and cooling water from the case is supplied to the first end part to circulate along an exterior surface side of each flat tube. The cooling water is introduced into the tubes from two locations of the case and in mutually opposite directions which are parallel to flat surfaces of the tubes and vertical in the axis direction of the flat tubes.

Owner:T RAD CO LTD

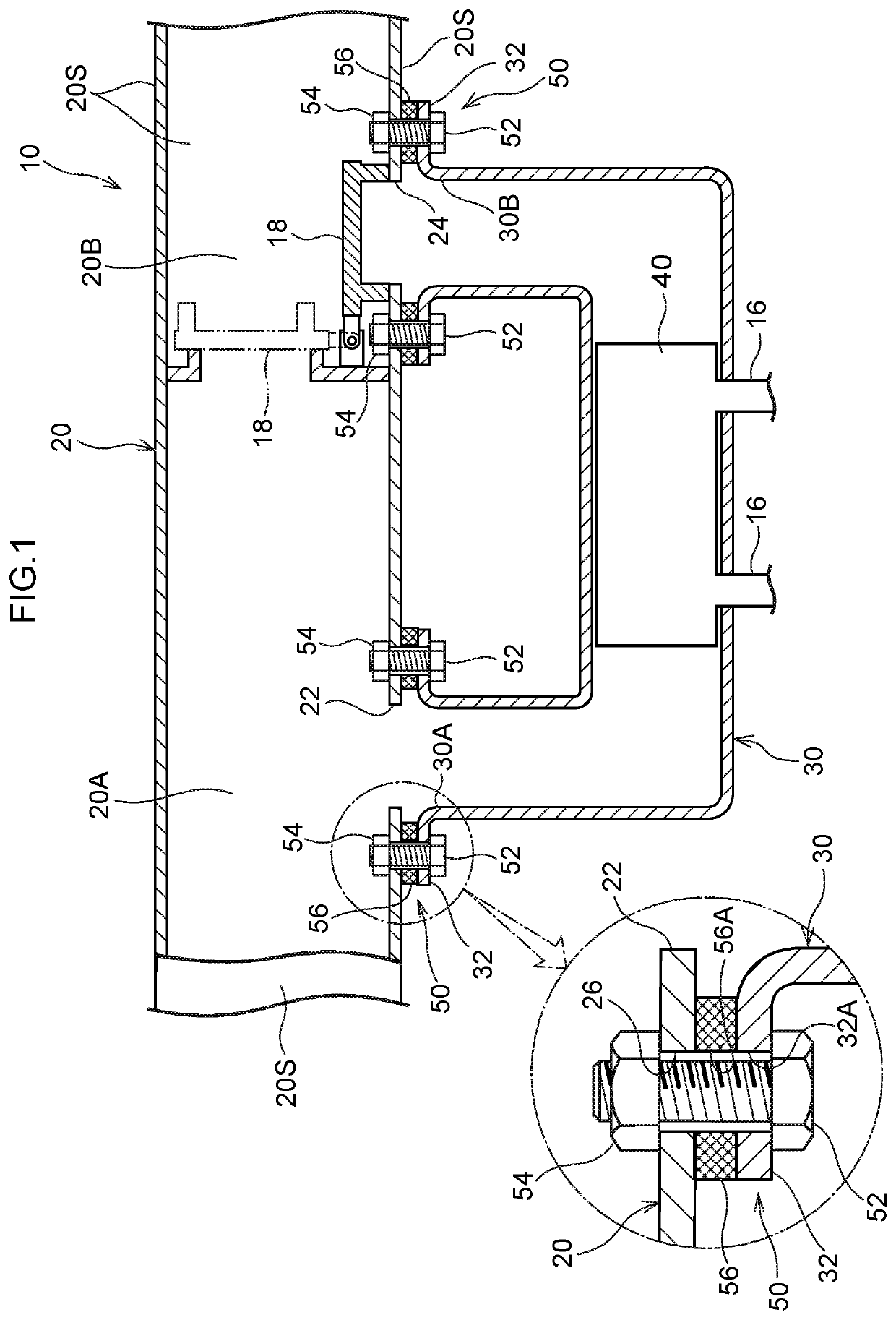

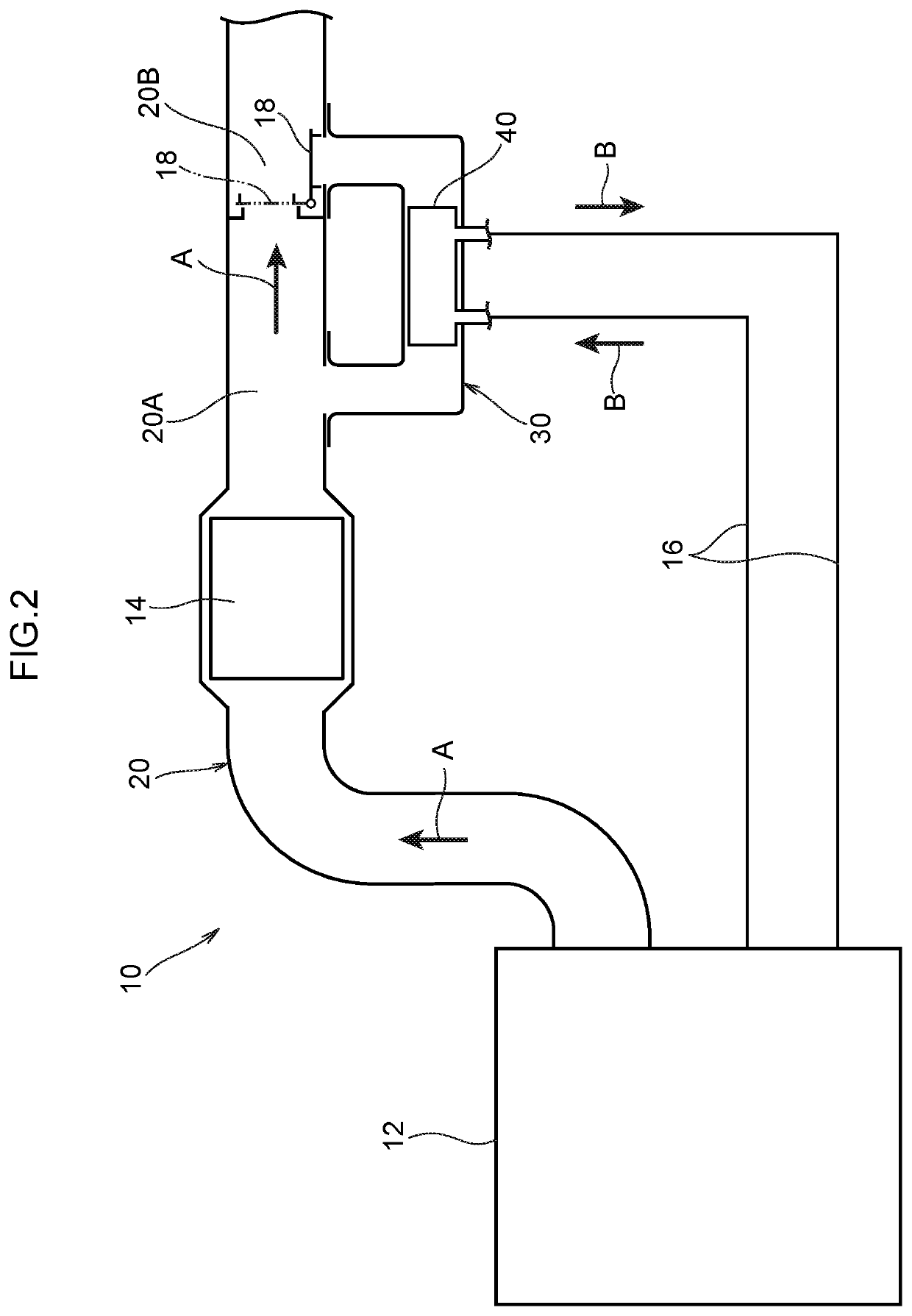

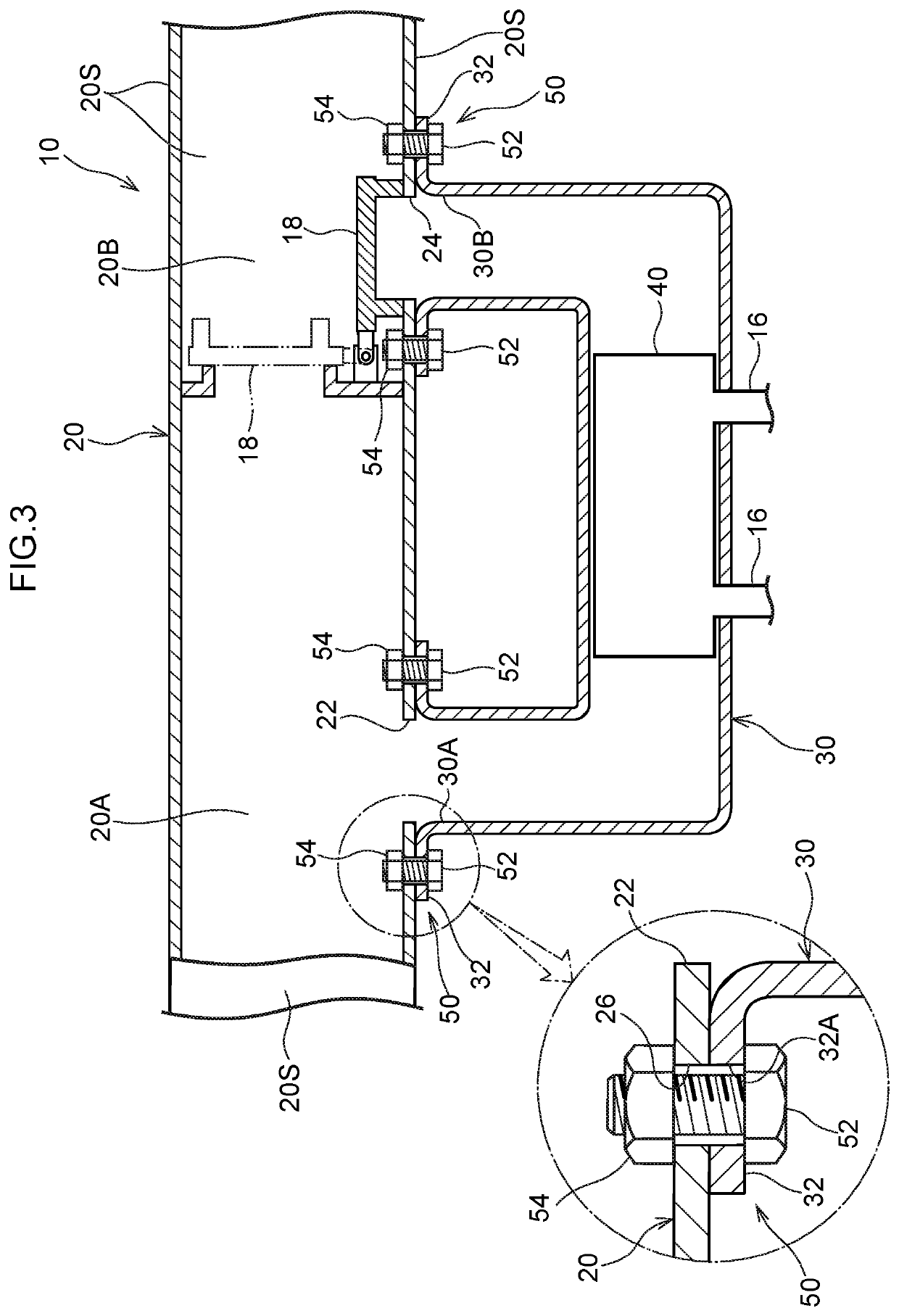

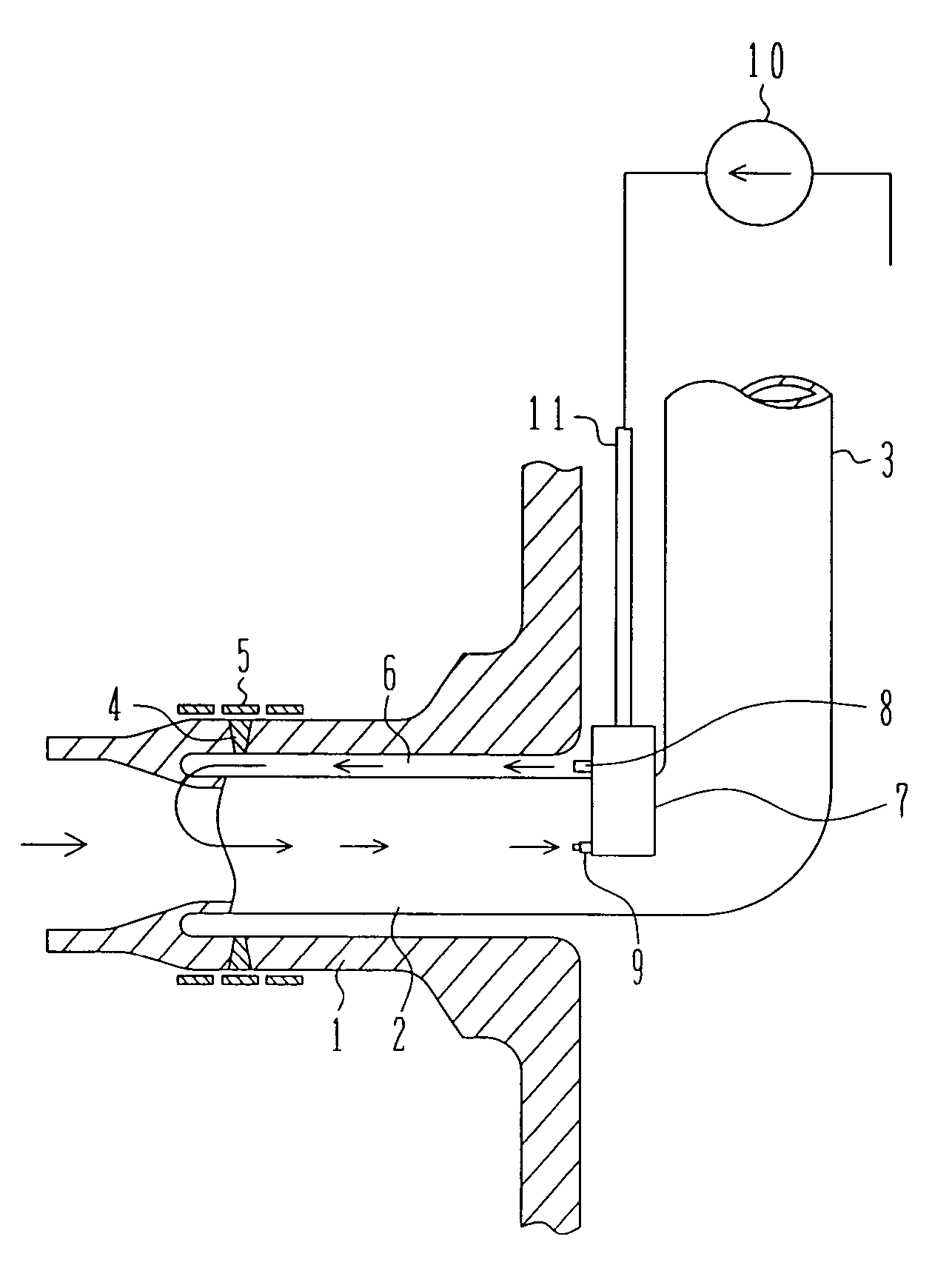

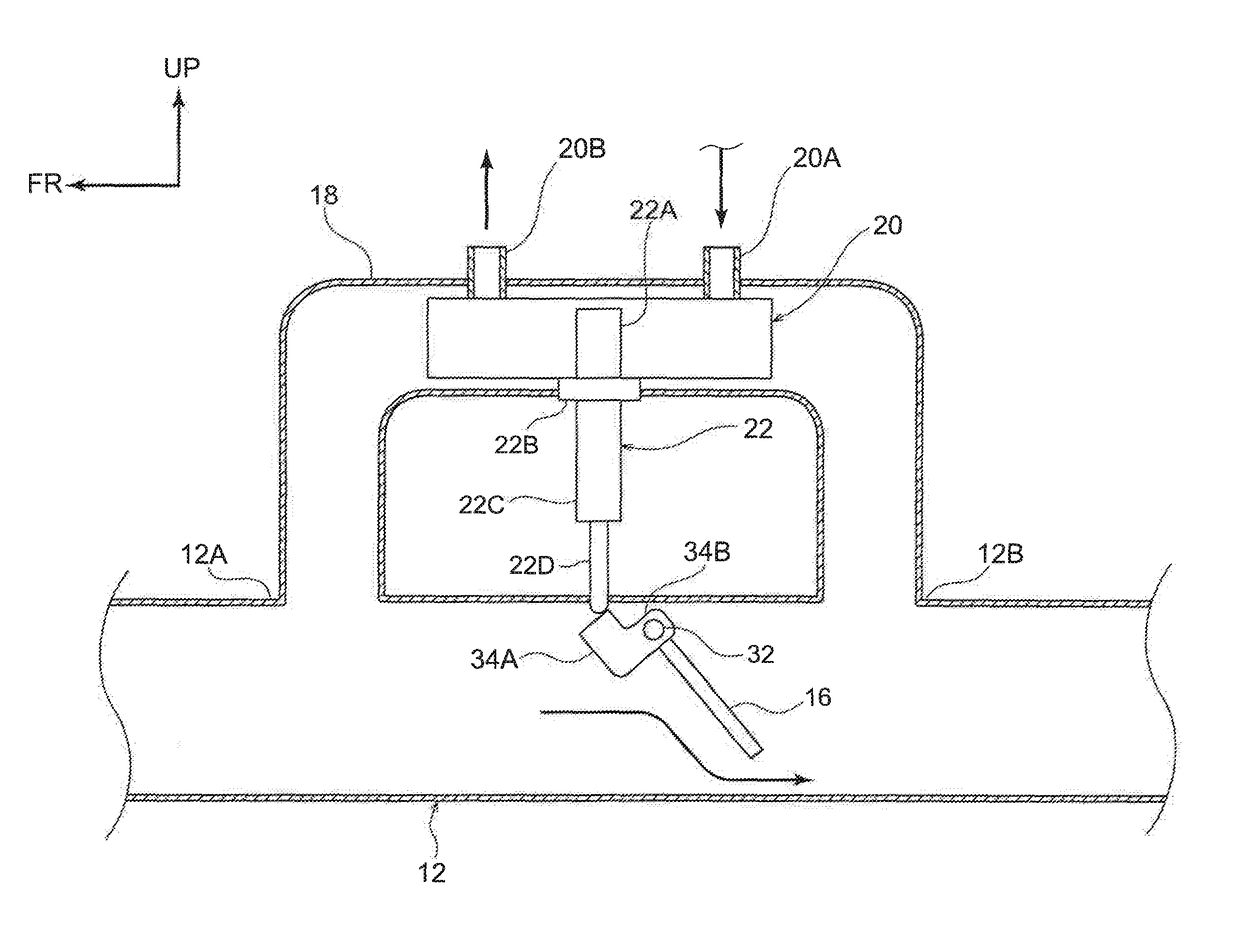

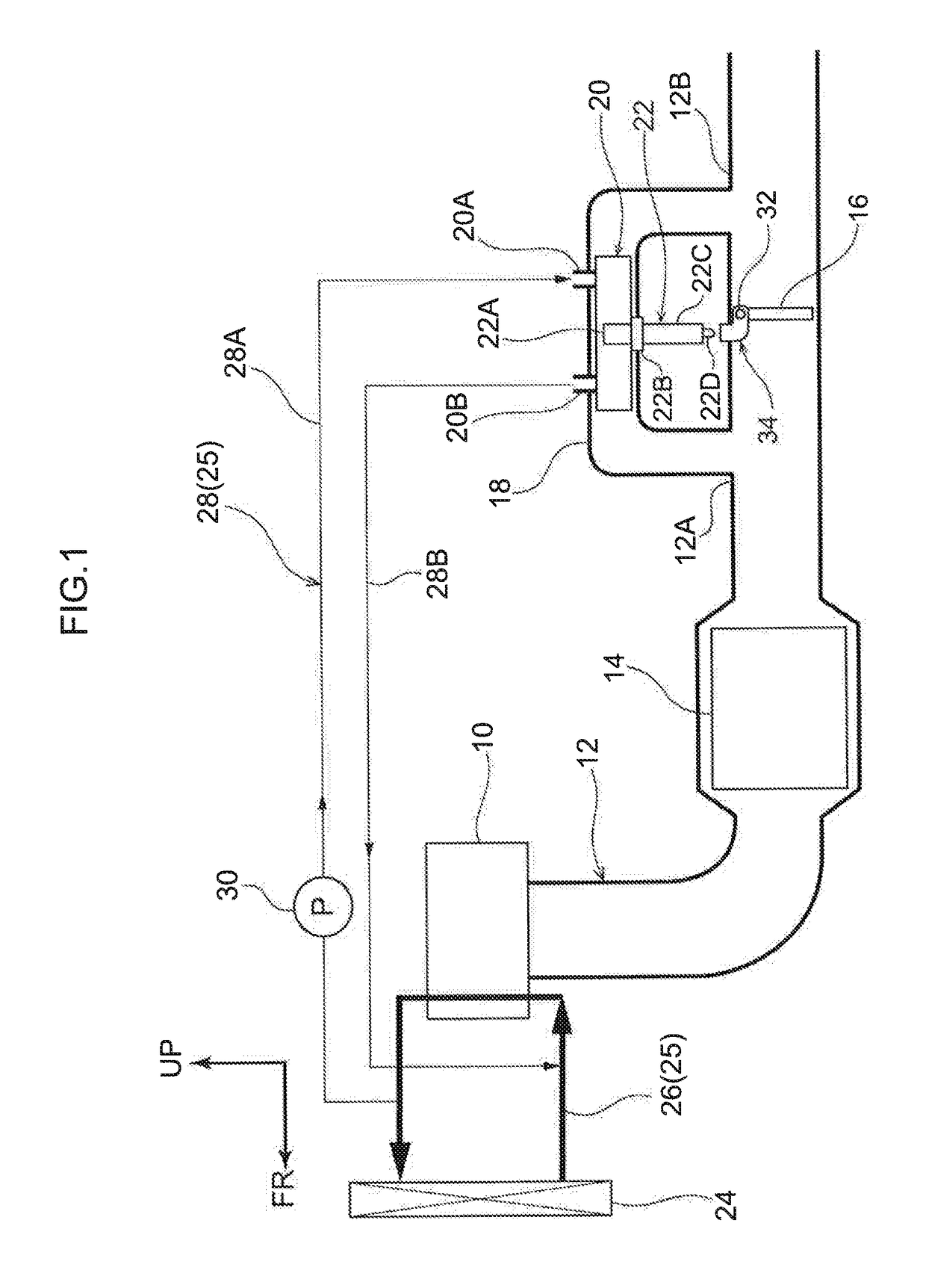

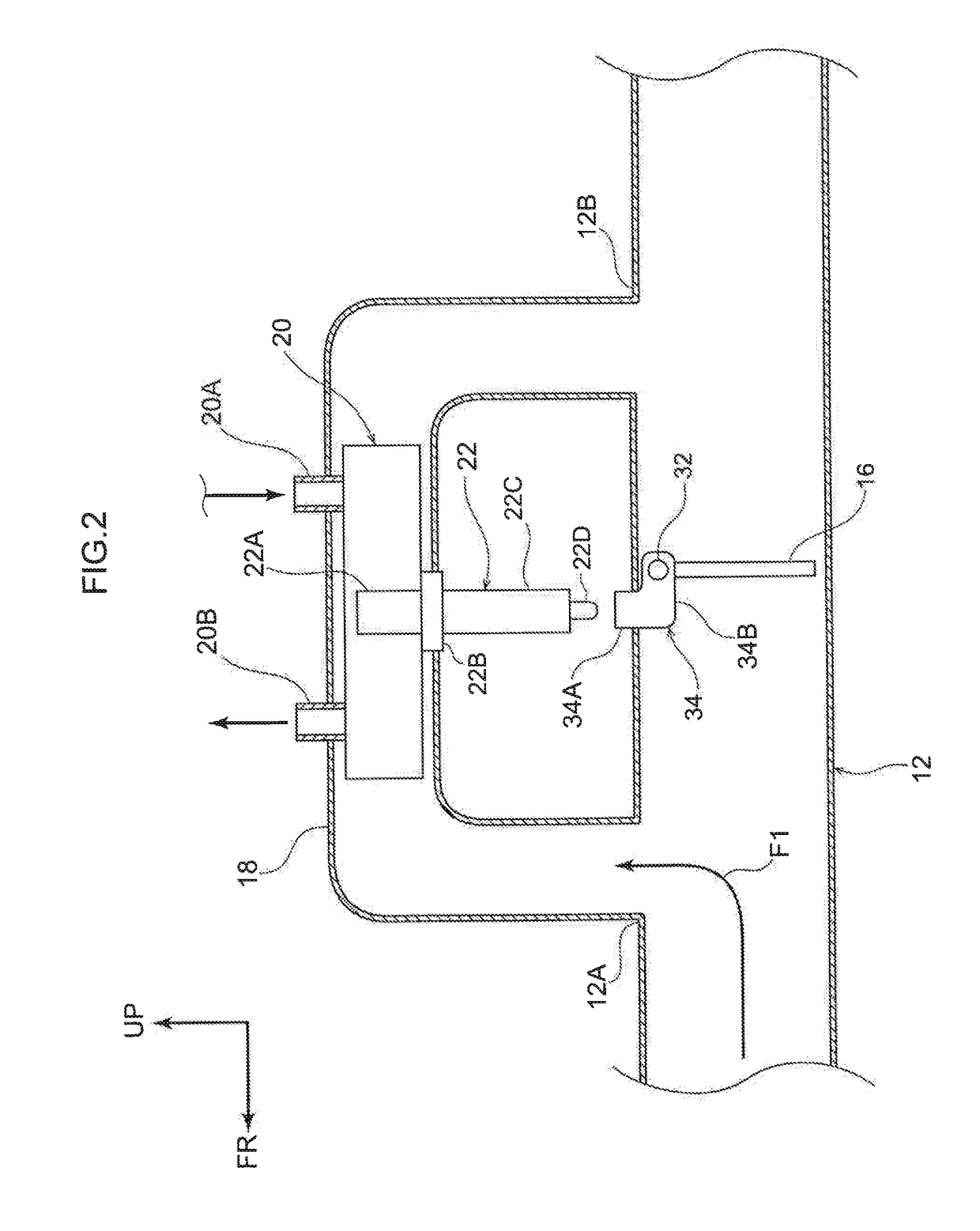

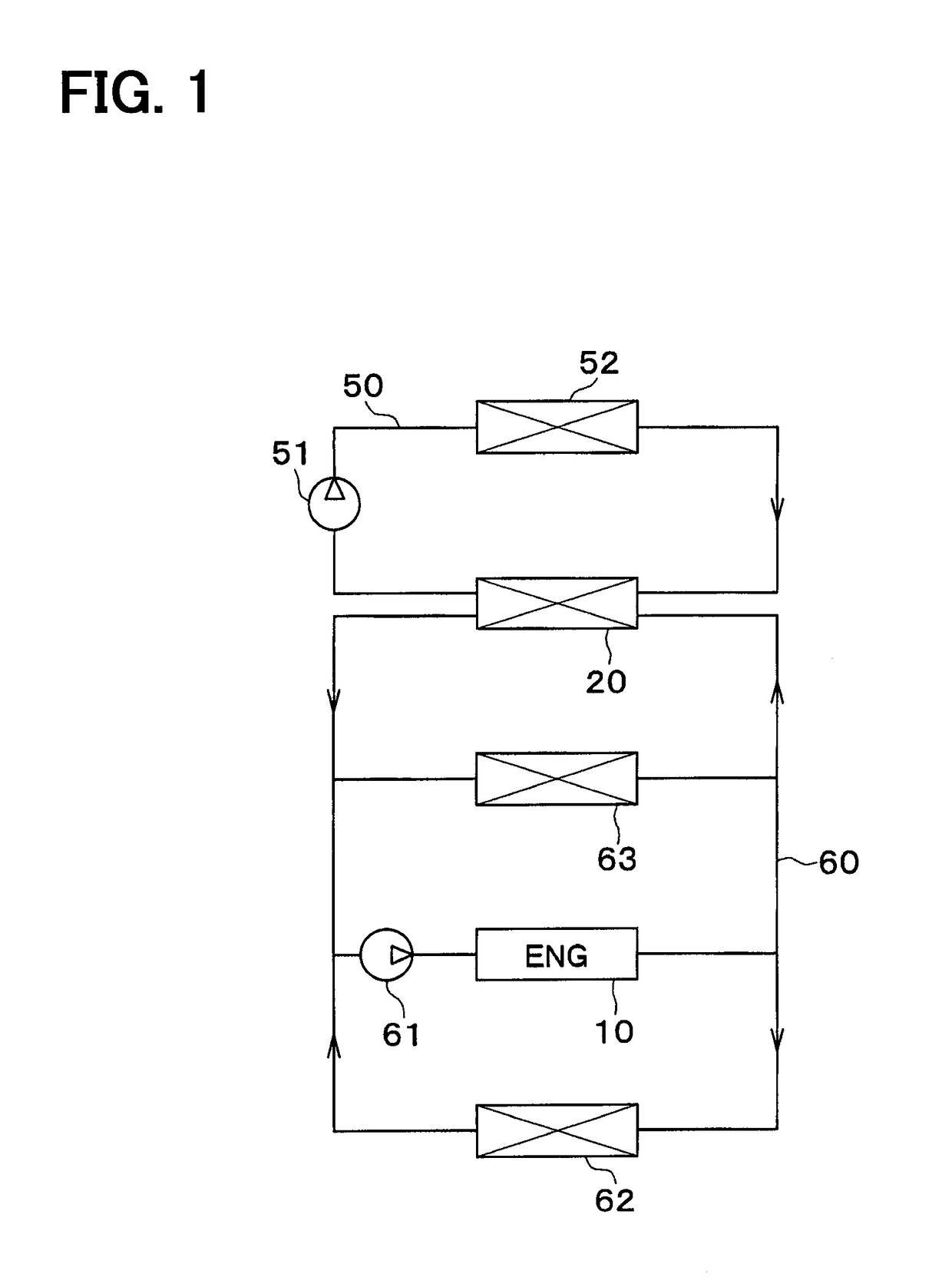

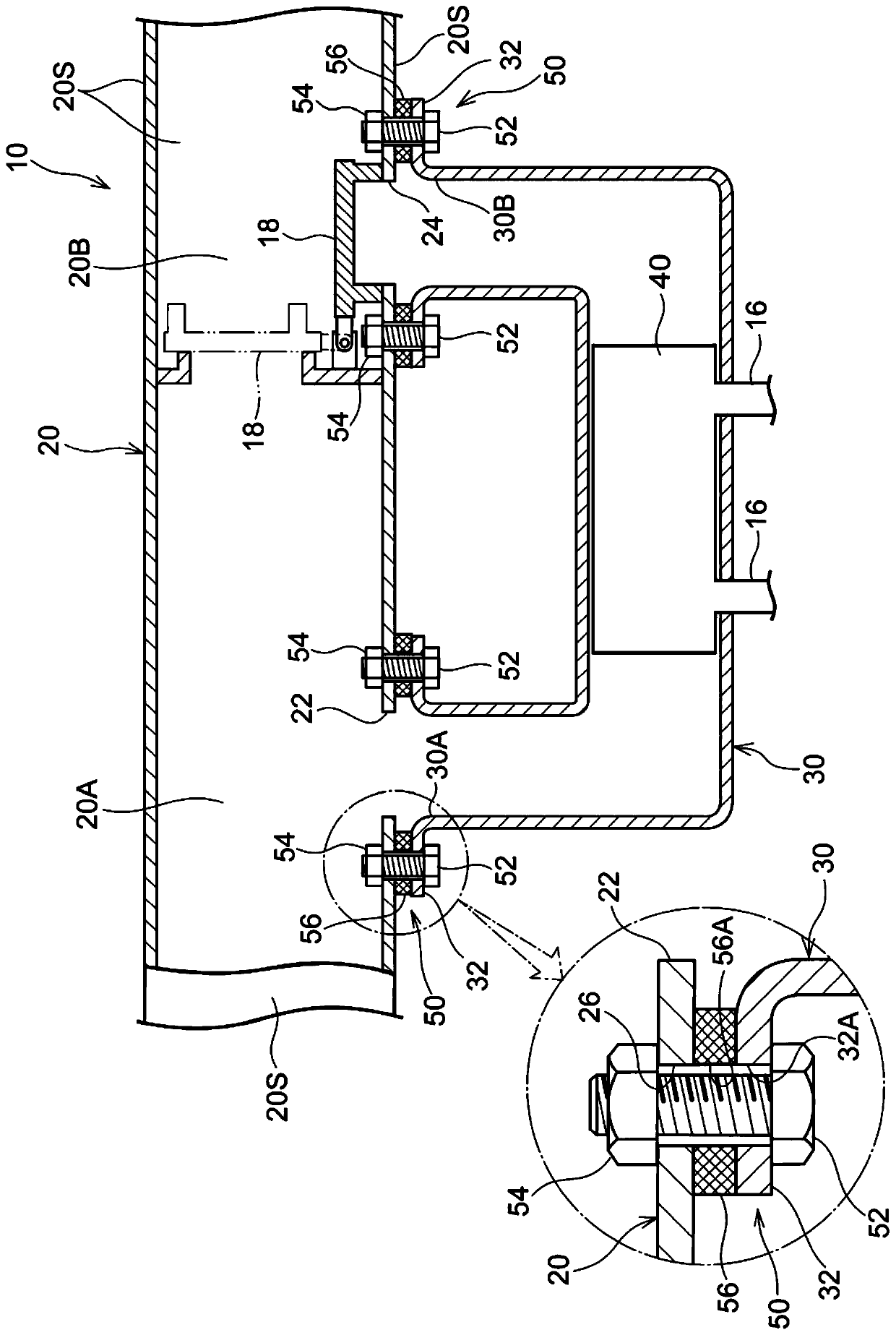

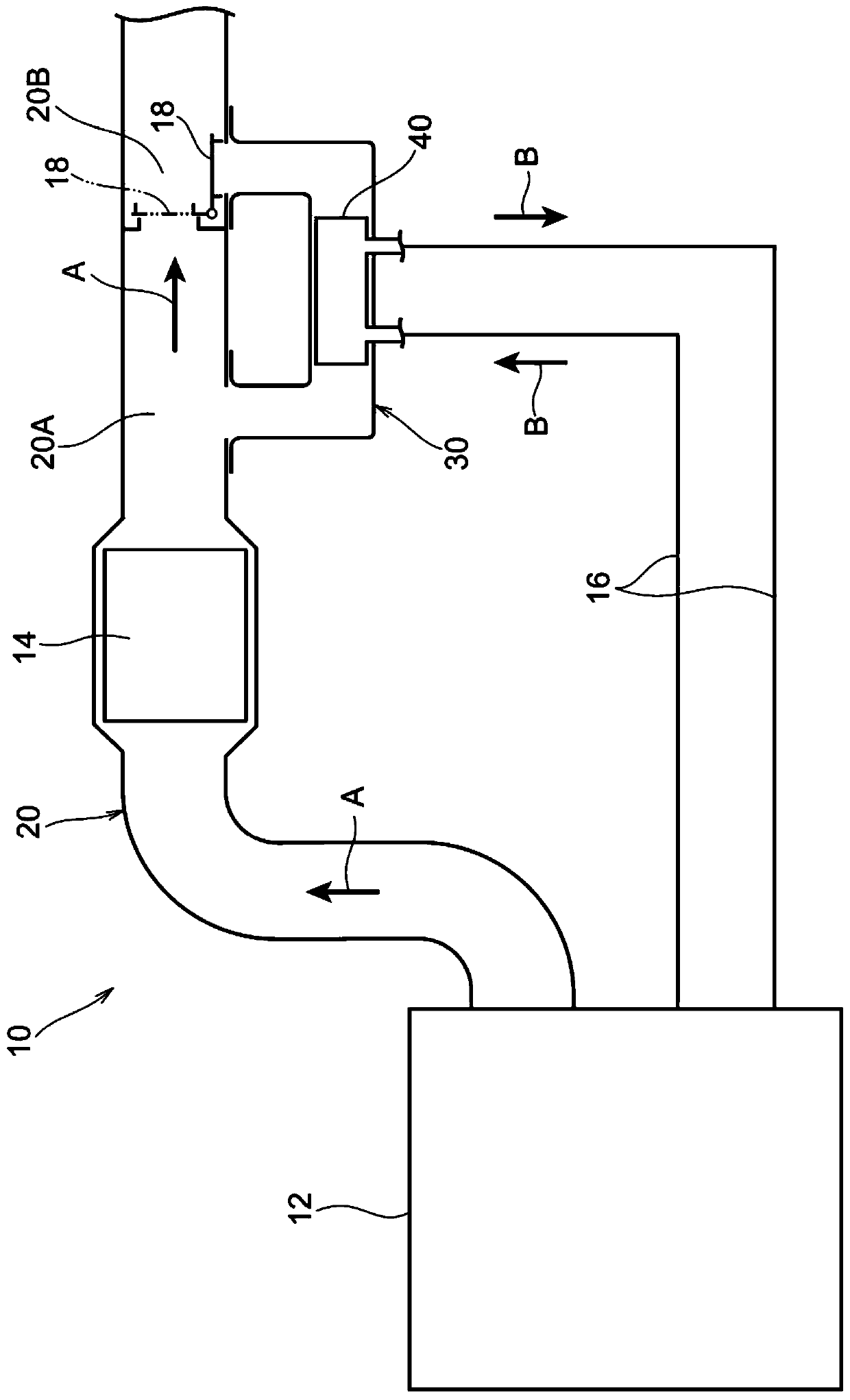

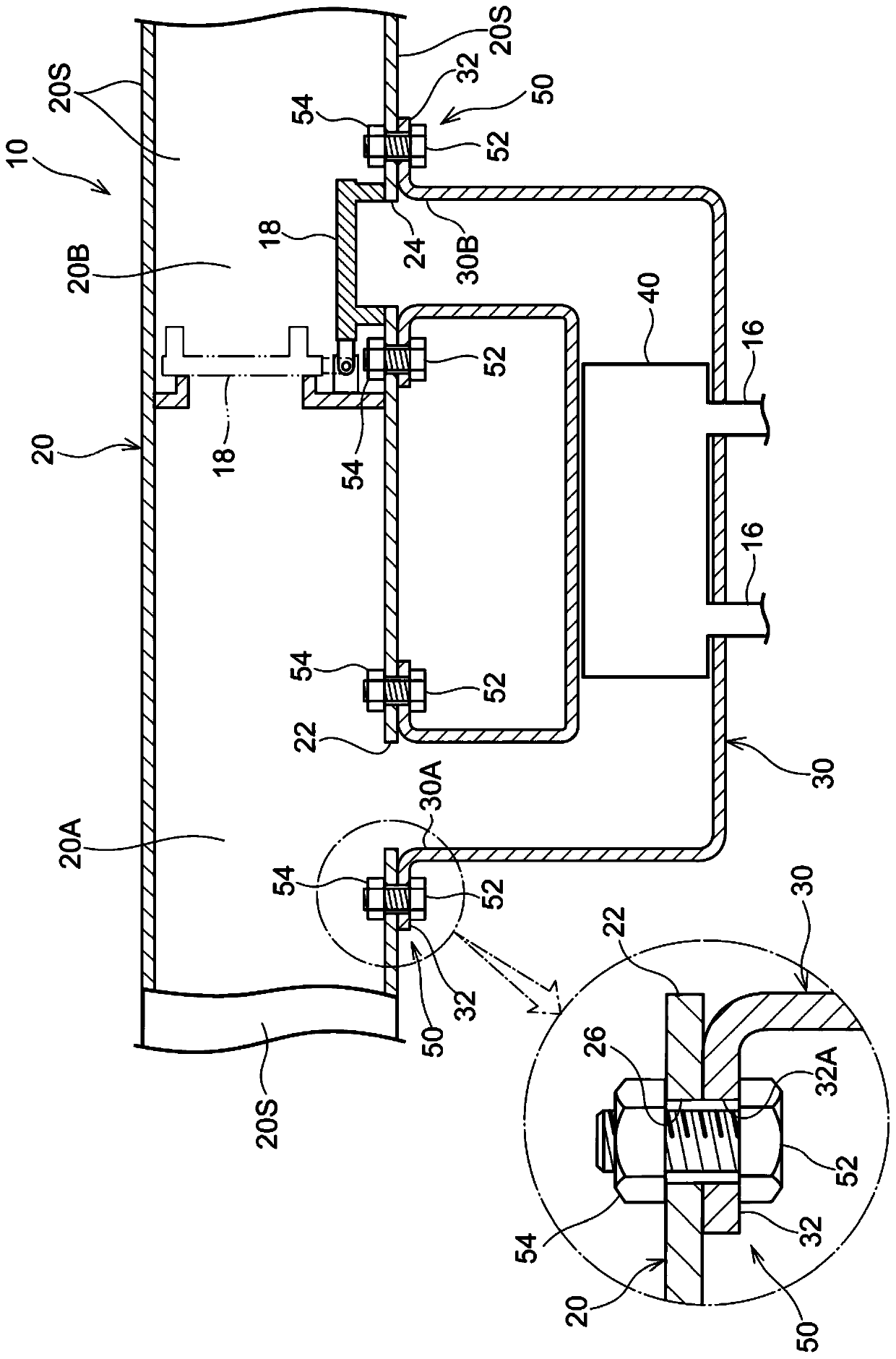

Exhaust heat recovery device

ActiveUS10502118B2Suppress boilingInternal combustion piston enginesExhaust apparatusWaste heat recovery unitExhaust fumes

An exhaust heat recovery device includes: a first pipe through which exhaust gas from an engine flows; a second pipe that communicates with the first pipe and bypasses the first pipe; a heat recovery unit that is disposed at an interior of the second pipe, and that exchanges heat between the exhaust gas and cooling water that circulates at an interior of the heat recovery unit, and that recovers heat of the exhaust gas; and a heat transfer suppressing mechanism that is provided at a portion connecting the first pipe with the second pipe, and that suppresses transfer of heat from the first pipe to the second pipe.

Owner:TOYOTA JIDOSHA KK

Exhaust gas heat exchanger having stacked flat tubes

ActiveUS10563624B2Suppress boilingRecuperative heat exchangersExhaust apparatusExhaust fumesMechanical engineering

An exhaust gas heat exchanger having stacked flat tubes includes a stacked tube body configured by stacking a plurality of flat tubes in multiple tiers with spaces therebetween and arranged inside a case; exhaust gas flows in from a first end part of the stacked tube body in a tube axis direction, circulates through each flat tube, and flows out from the a second end part; and cooling water from the case is supplied to the first end part to circulate along an exterior surface side of each flat tube. The cooling water is introduced into the tubes from two locations of the case and in mutually opposite directions which are parallel to flat surfaces of the tubes and vertical in the axis direction of the flat tubes.

Owner:T RAD CO LTD

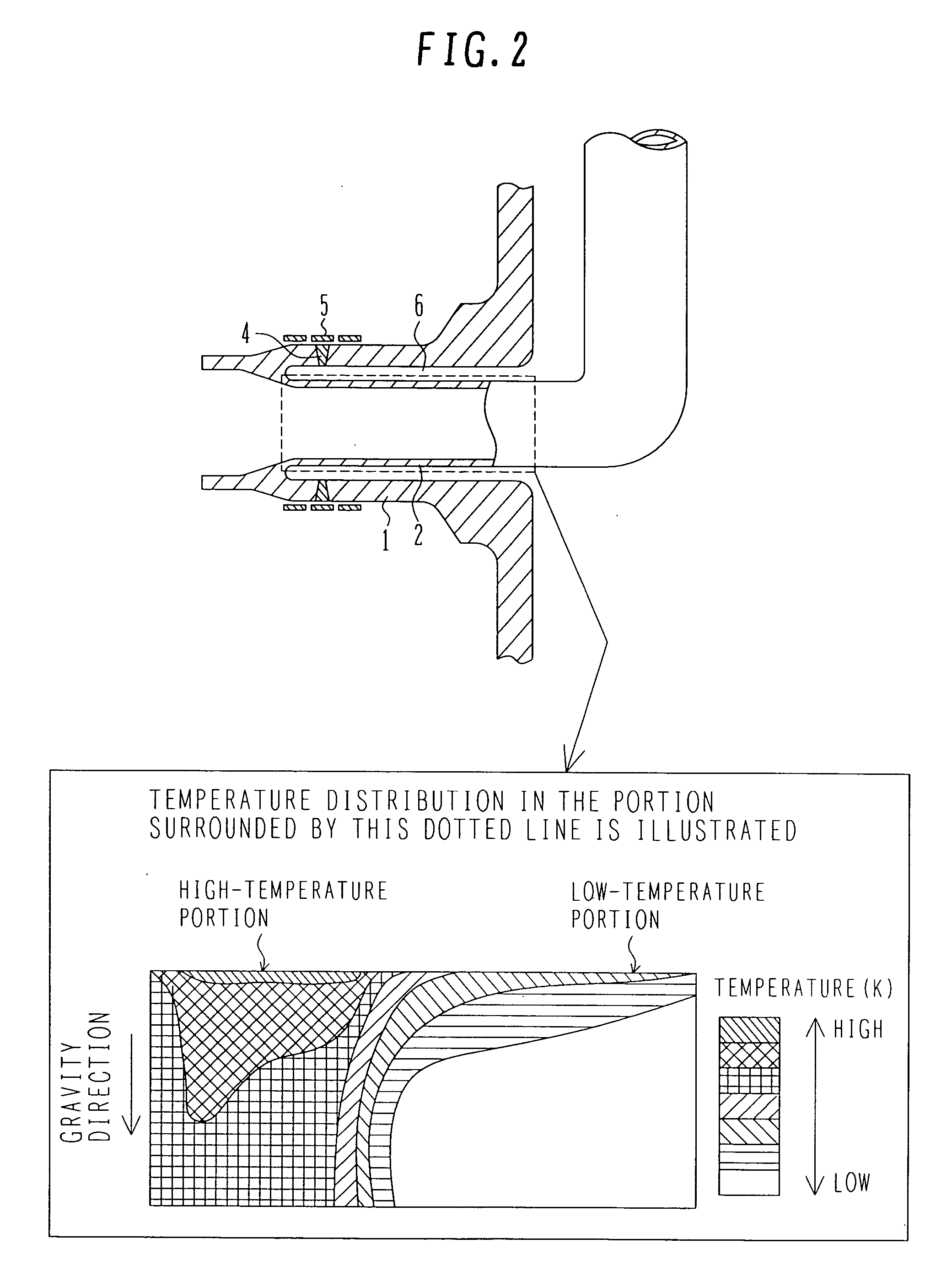

Induction heating stress improvement

ActiveUS20060197638A1Improve cooling effectAvoid flowMagnetsNuclear monitoringNuclear plantCooling effect

In implementing an induction heating stress improvement (IHSI) method in a nuclear plant, cooling characteristic with respect to the inner surface of piping is improved by appropriate structure / layout of nozzles, and further, the cooling effect when applying IHSI to a real machine is verified by installing a thermometer, as well as air in the portion subjected to IHSI is removed by heating the piping prior to the execution of IHSI.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

Exhaust heat recovery structure

ActiveUS10054026B2Suppress boilingInternal combustion piston enginesRecuperative heat exchangersEngineeringThermostat

There is provided an exhaust heat recovery structure that may suppress boiling of coolant in a heat exchanger. The exhaust heat recovery structure includes a first pipe, a second pipe, a valve and a thermostat. Exhaust gas from an engine flows in the first pipe. The second pipe branches from the first pipe and a heat exchanger that exchanges heat between the coolant and exhaust gas is provided at the second pipe. The valve is provided at the first pipe or the second pipe. The valve adjusts a flow amount of exhaust gas flowing into the second pipe by opening and closing. The thermostat is equipped with a heat-sensing portion that is disposed inside the heat exchanger. When the temperature of the heat-sensing portion is high, the thermostat opens or closes the valve to reduce the flow amount of exhaust gas flowing into the second pipe.

Owner:TOYOTA JIDOSHA KK

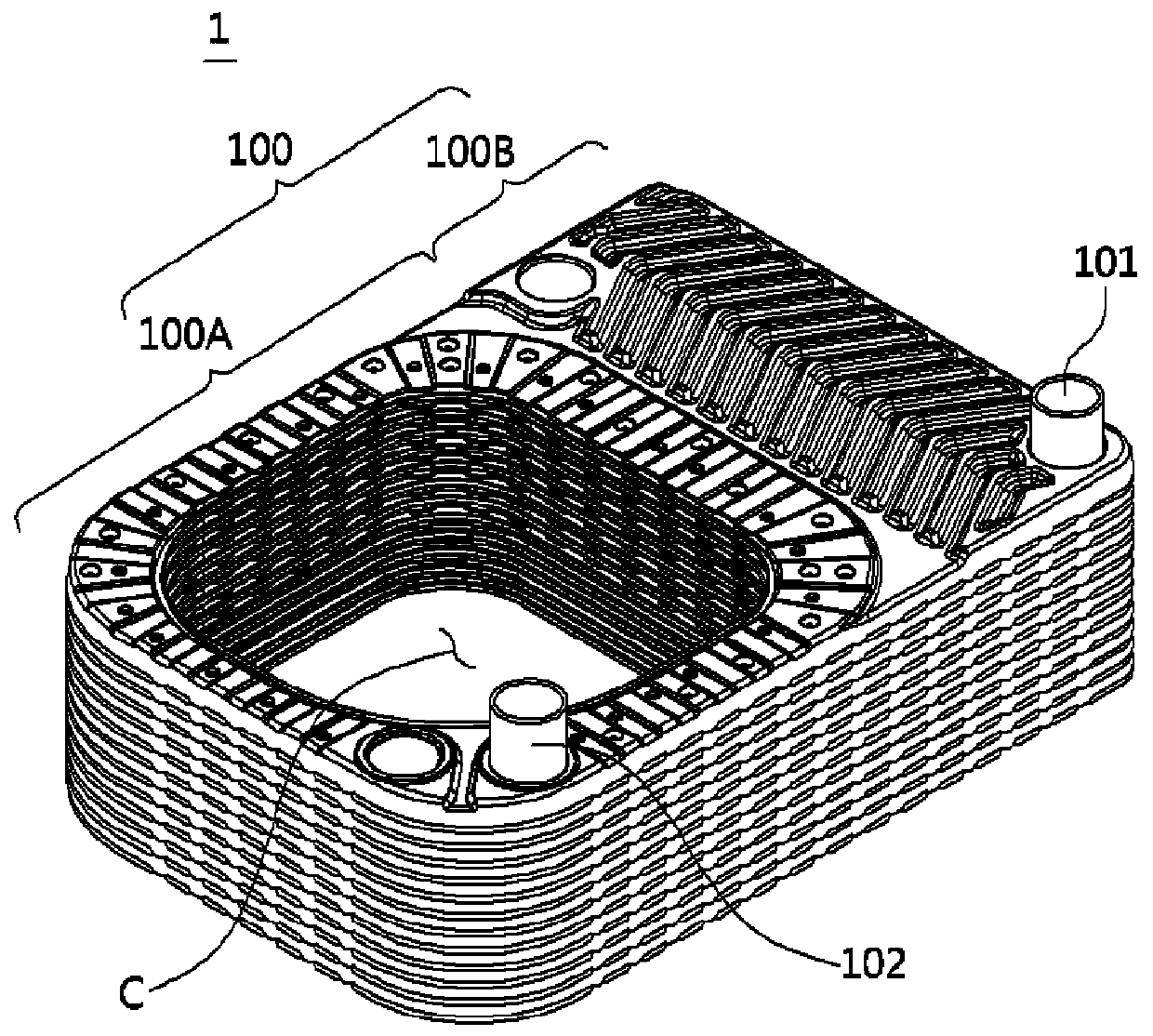

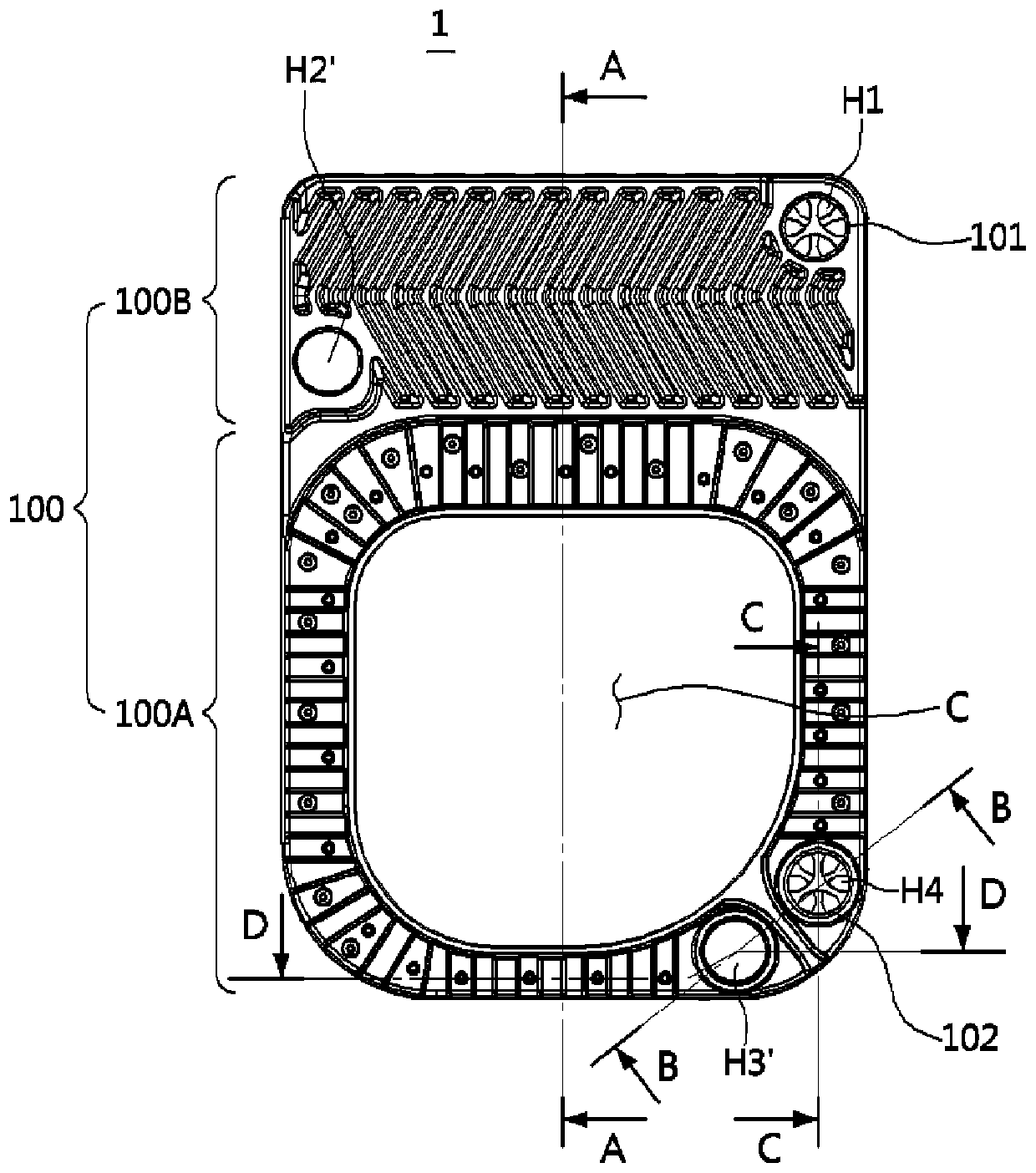

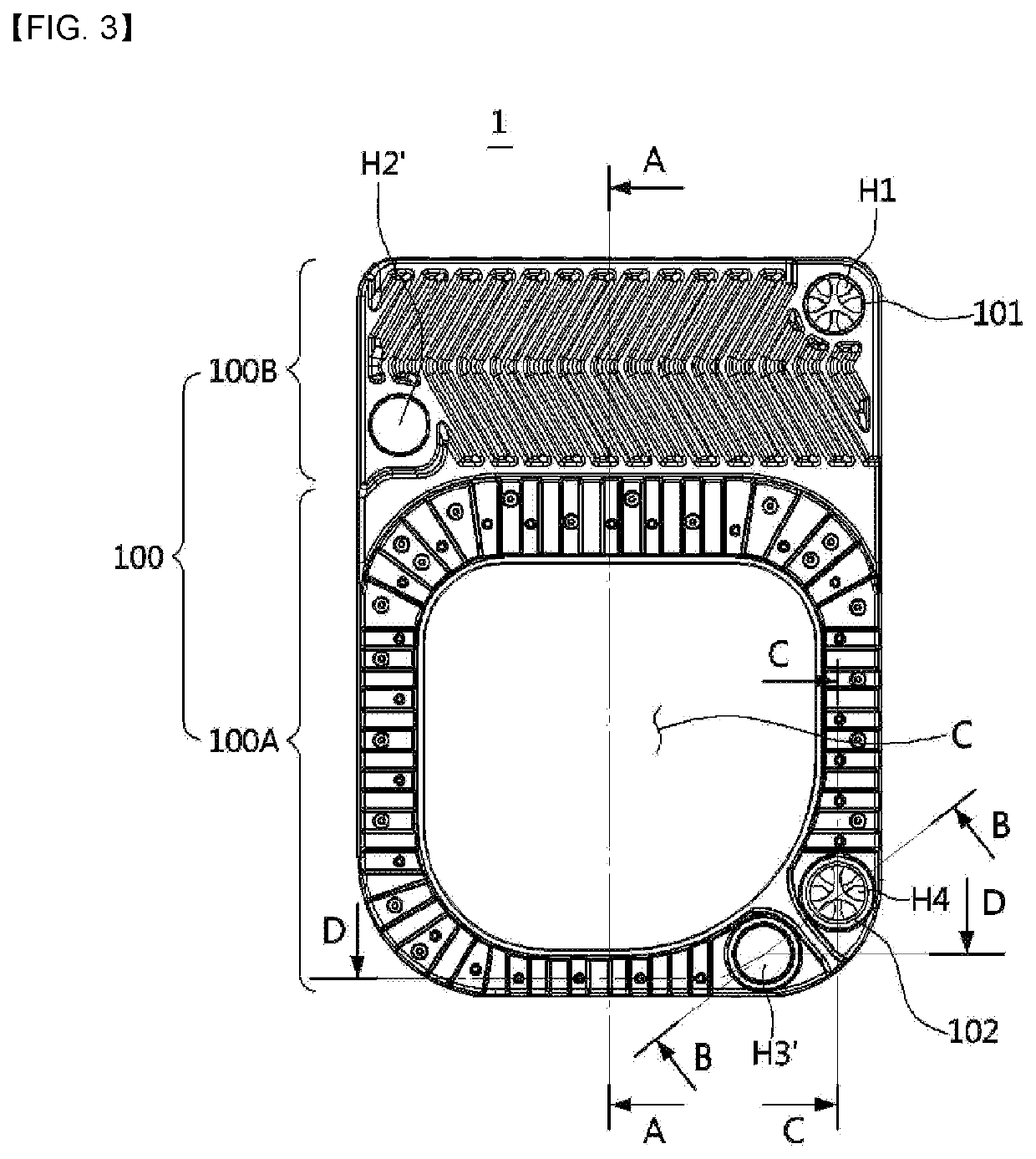

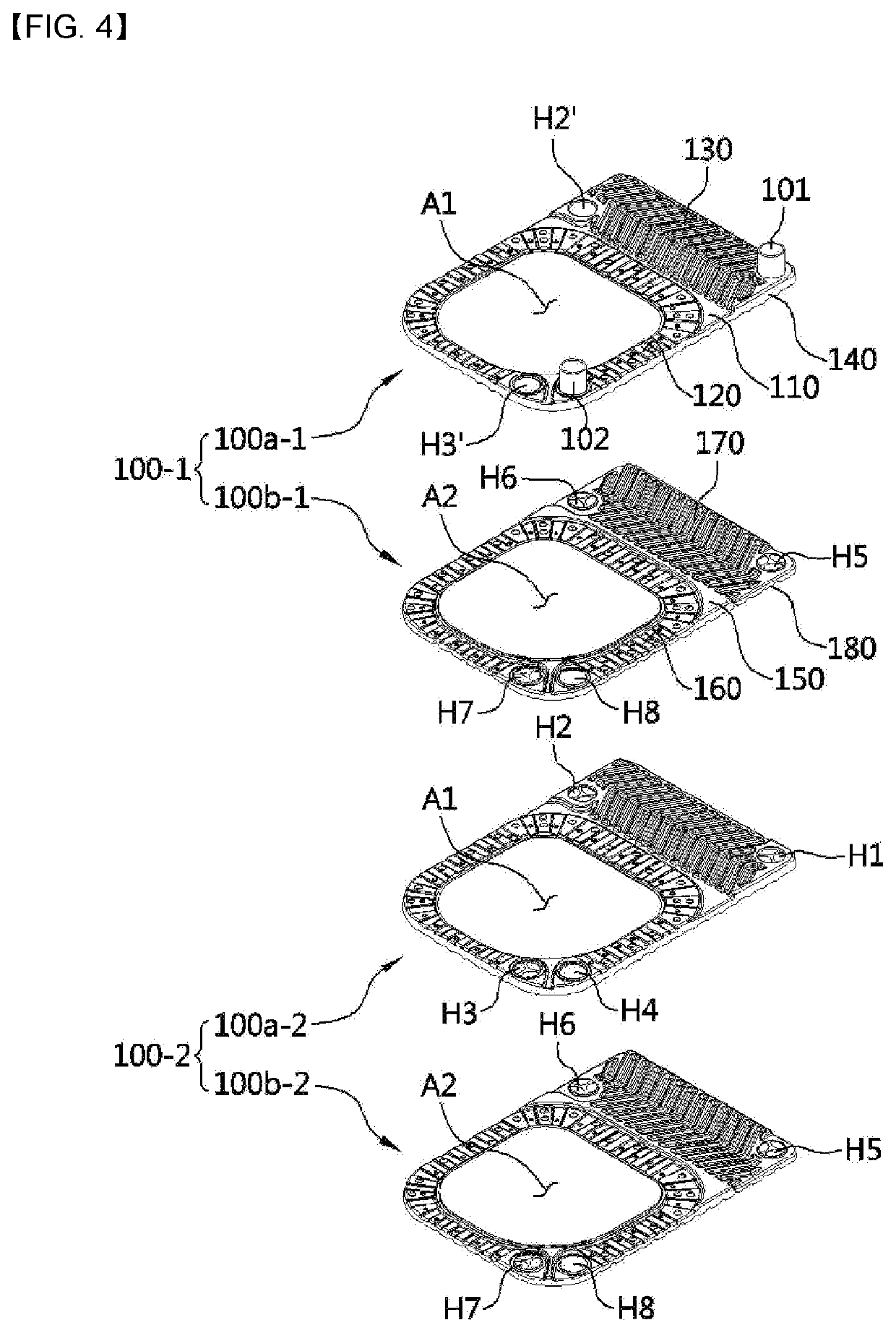

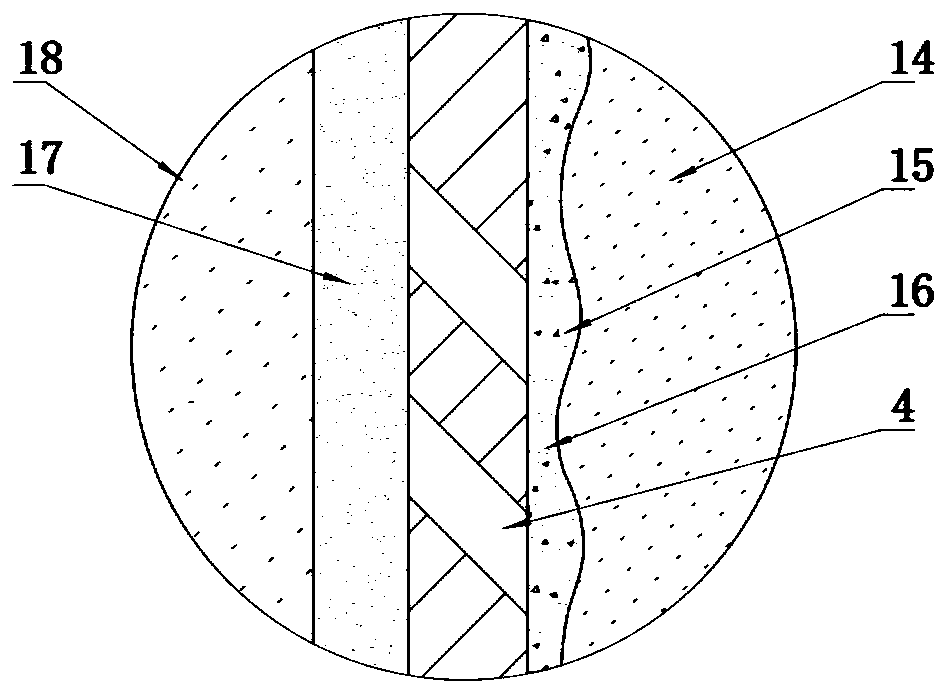

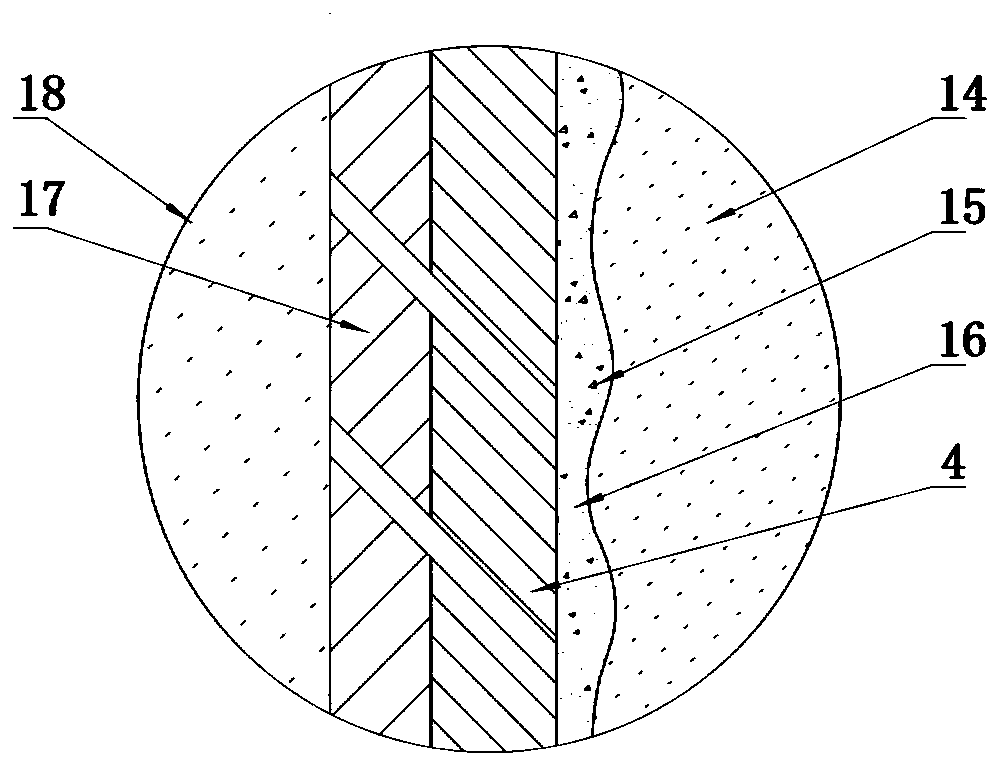

Heat exchanger

InactiveCN111406193ASuppress boilingPrevent precipitationMechanical apparatusHeat storage plantsEngineeringHeat transfer efficiency

The purpose of the present invention is to provide a heat exchanger capable of suppressing boiling and lime precipitation due to local overheating of a heating medium and at the same time improving heat transmittance efficiency. The heat exchanger of the present invention for achieving said purpose comprises: heating medium flow paths, through which a heating medium flows, inside a plurality of laminated plates; and a heat exchange unit in which combustion gas flow paths, through which a combustion gas flows, are alternately formed to be adjacent to each other, wherein the heat exchange unitshave a heating medium differential distribution unit which enables the flow rate of the heating medium to be differentially distributed to parallel heating medium flow paths of the heat exchange unitsuch that the flow rate of the heating medium passing through the parallel heating medium flow paths is balanced with the quantity of absorbed heat transmitted to the plates.

Owner:KYUNGDONG NAVIEN

Heat exchanger

InactiveUS20200386441A1High light transmittanceSuppress boilingMechanical apparatusHeat storage plantsEngineeringHeat exchanger

The purpose of the present invention is to provide a heat exchanger capable of suppressing boiling and lime precipitation due to local overheating of a heating medium and at the same time improving heat transmittance efficiency. The heat exchanger of the present invention for achieving said purpose comprises: heating medium flow paths, through which a heating medium flows, inside a plurality of laminated plates; and a heat exchange unit in which combustion gas flow paths, through which a combustion gas flows, are alternately formed to be adjacent to each other, wherein the heat exchange units have a heating medium differential distribution unit which enables the flow rate of the heating medium to be differentially distributed to parallel heating medium flow paths of the heat exchange unit such that the flow rate of the heating medium passing through the parallel heating medium flow paths is balanced with the quantity of absorbed heat transmitted to the plates.

Owner:KYUNGDONG NAVIEN

Exhaust waste heat recovery device and automobile

ActiveCN113250851APrevent heat radiationAvoid heat transferInternal combustion piston enginesExhaust apparatusInlet channelHeat transmission

An exhaust waste heat recovery device comprises an exhaust shell and a heat exchanger. An exhaust channel is arranged in the exhaust shell, the heat exchanger is arranged at the top of the exhaust shell, a first partition plate, a second partition plate, a movable plate and an elastic piece are arranged in the exhaust shell, and the first partition plate and the second partition plate are oppositely arranged and connected to the inner wall of the exhaust shell; a heat exchange air inlet channel is formed between the first partition plate and the inner wall of the exhaust shell and communicates with the exhaust channel and the heat exchanger, a heat exchange air outlet channel is formed between the second partition plate and the inner wall of the exhaust shell and communicates with the exhaust channel and the heat exchanger, and the movable plate is movably arranged between the first partition plate and the second partition plate; and the elastic piece is connected between the heat exchanger and the movable plate, and airflow in the exhaust channel and the heat exchanger can push the movable plate. According to the exhaust waste heat recovery device, heat radiation and heat transfer of the movable plate to the heat exchanger can be avoided. The invention also relates to an automobile.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Exhaust heat recovery unit

ActiveUS20190093599A1Thermal conductivity be lowerSuppress boilingInternal combustion piston enginesRecuperative heat exchangersEngineeringWaste heat recovery unit

An exhaust heat recovery unit, includes: a heat exchanger that is provided inside an exhaust pipe through which exhaust gas flows, the heat exchange being formed from silicon carbide, and the heat exchanger performing heat exchange between the exhaust gas and a heat medium; and a retention member that is provided at the periphery of the heat exchanger, is formed of a ceramic sheet or an expandable graphite sheet, and is sandwiched between the exhaust pipe and the heat exchanger, thereby retaining the heat exchanger in the exhaust pipe.

Owner:TOYOTA JIDOSHA KK +1

Improved polymerizable compositions

Owner:ROHM & HAAS CO

Technology for extracting V2O5 from vanadium-containing molten iron

InactiveCN111004889AImprove liquidityAchieve recyclabilityVanadium oxidesProcess efficiency improvementPhysical chemistryIron(III) oxide

The invention discloses a technology for extracting V2O5 from vanadium-containing molten iron. The technology comprises the following steps: at first, blowing oxygen into molten iron, then, continuingto add ferric oxide powder under the oxygen blowing condition, and finally, oxidizing vanadium in molten iron into vanadium pentoxide. According to the technology, through improving the adding mannerof ferric oxide powder and the corresponding technological conditions, the molten iron is further prevented from stirring boiling, and the oxidizing vanadium extracting efficiency is improved. With adoption of the technology, vanadium pentoxide is extracted from molten iron, finally, high-vanadium slag containing 20-30% of vanadium pentoxide is obtained, the vanadium recovery rate is as high as 95% or above; the processing time is short, and the production efficiency is high; and moreover, high-purity pig iron can be generated favorably and can be directly used as industrial pig iron or for precision manufacturing.

Owner:永平县勇泰工业废渣有限公司

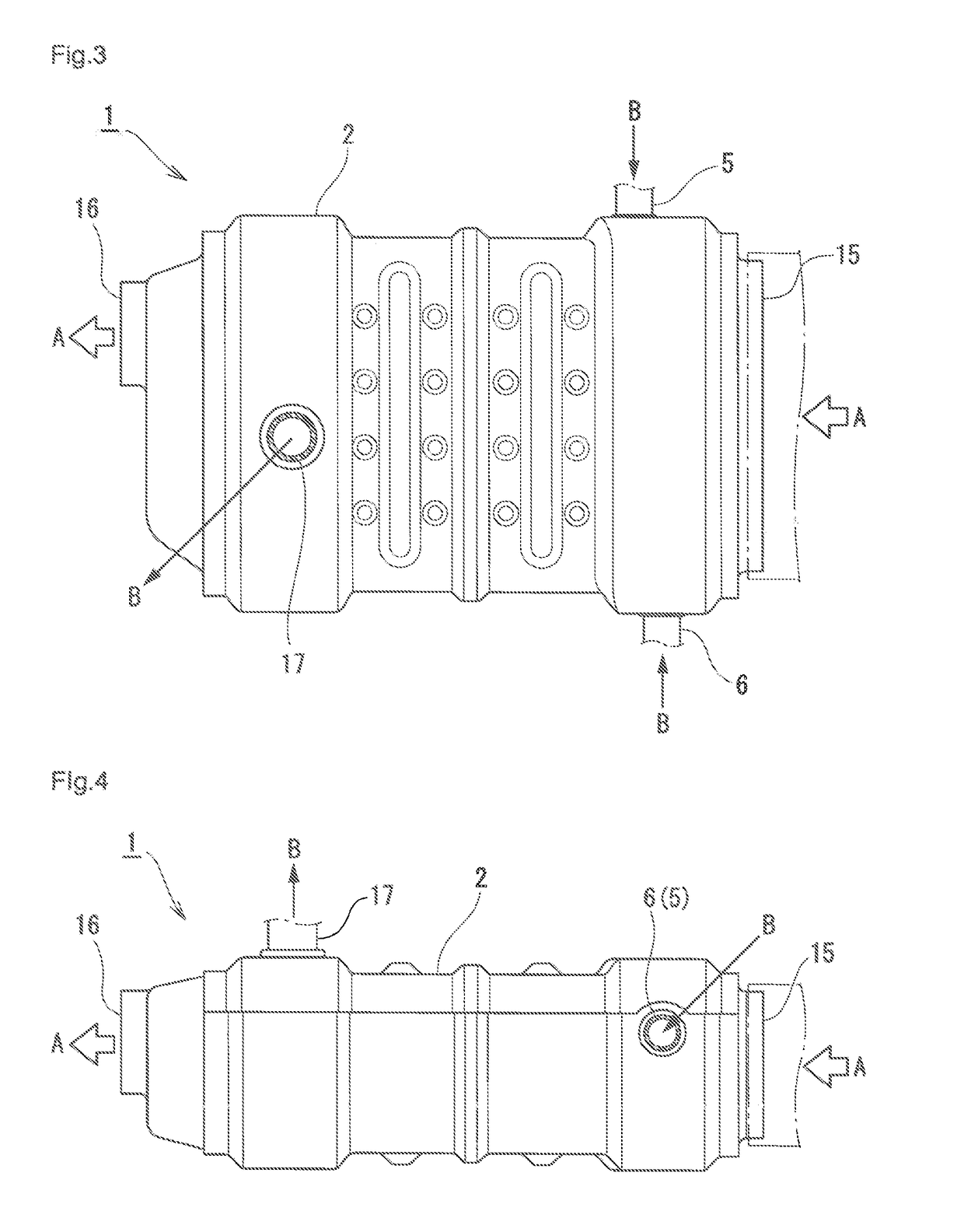

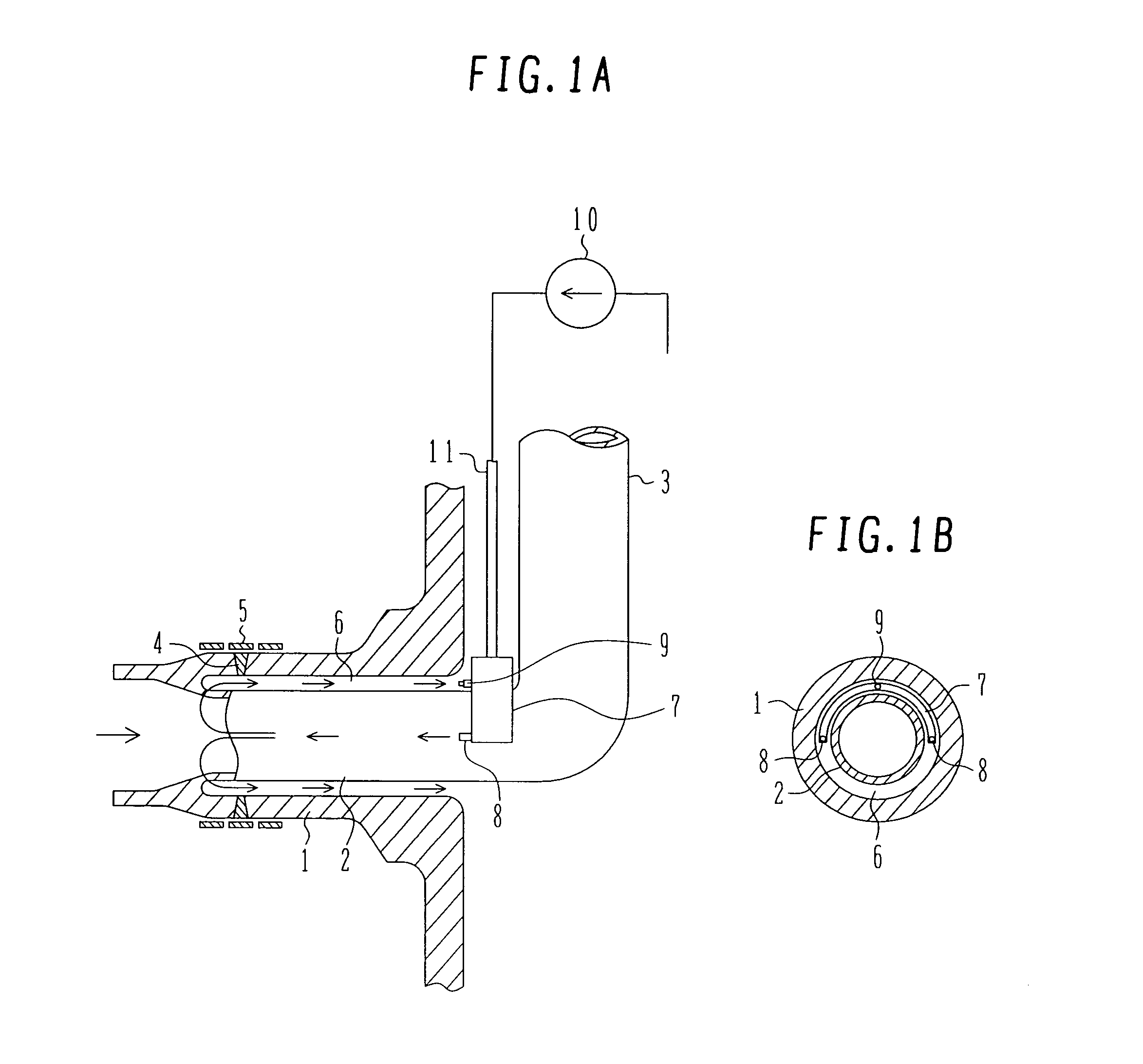

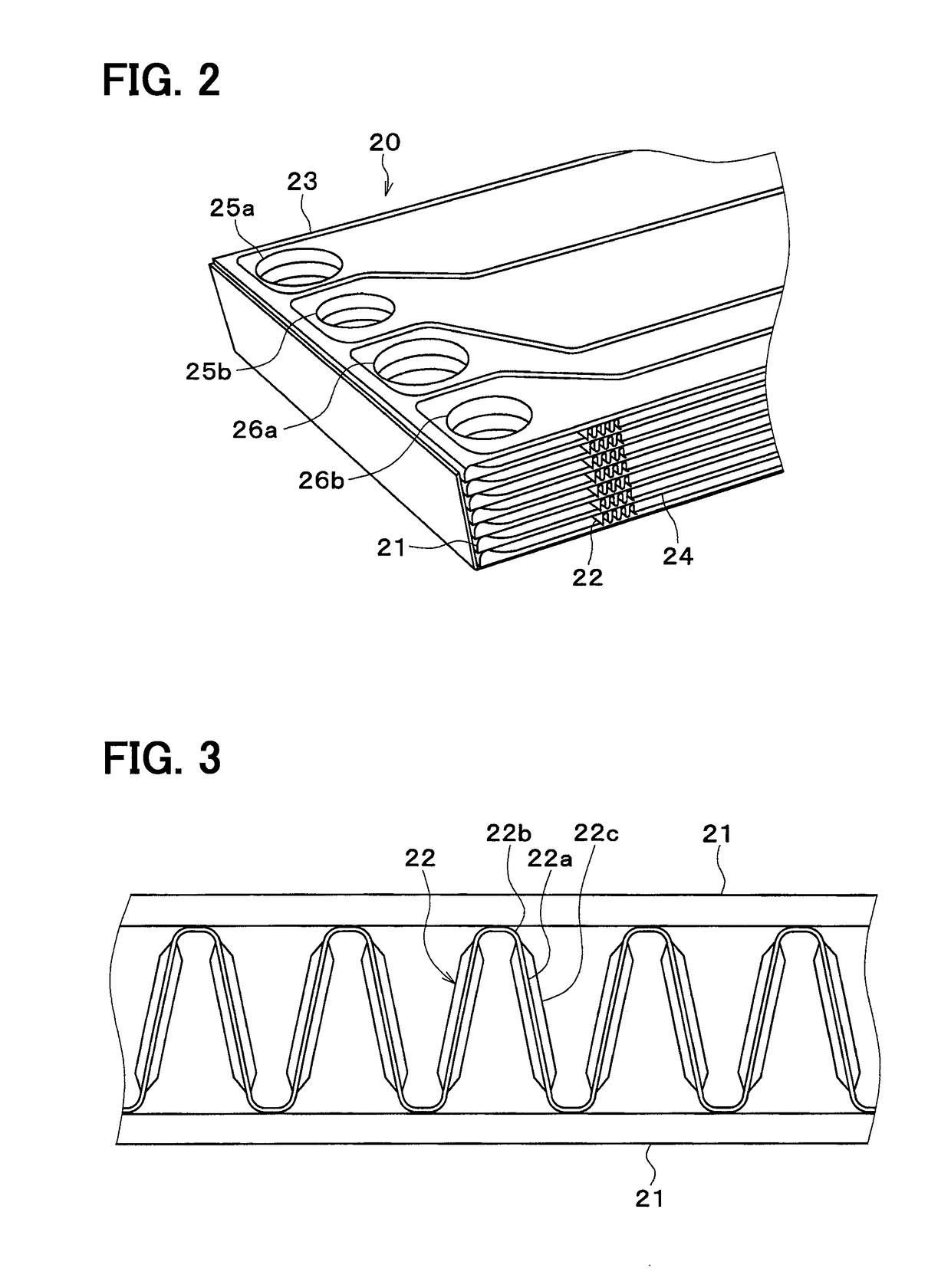

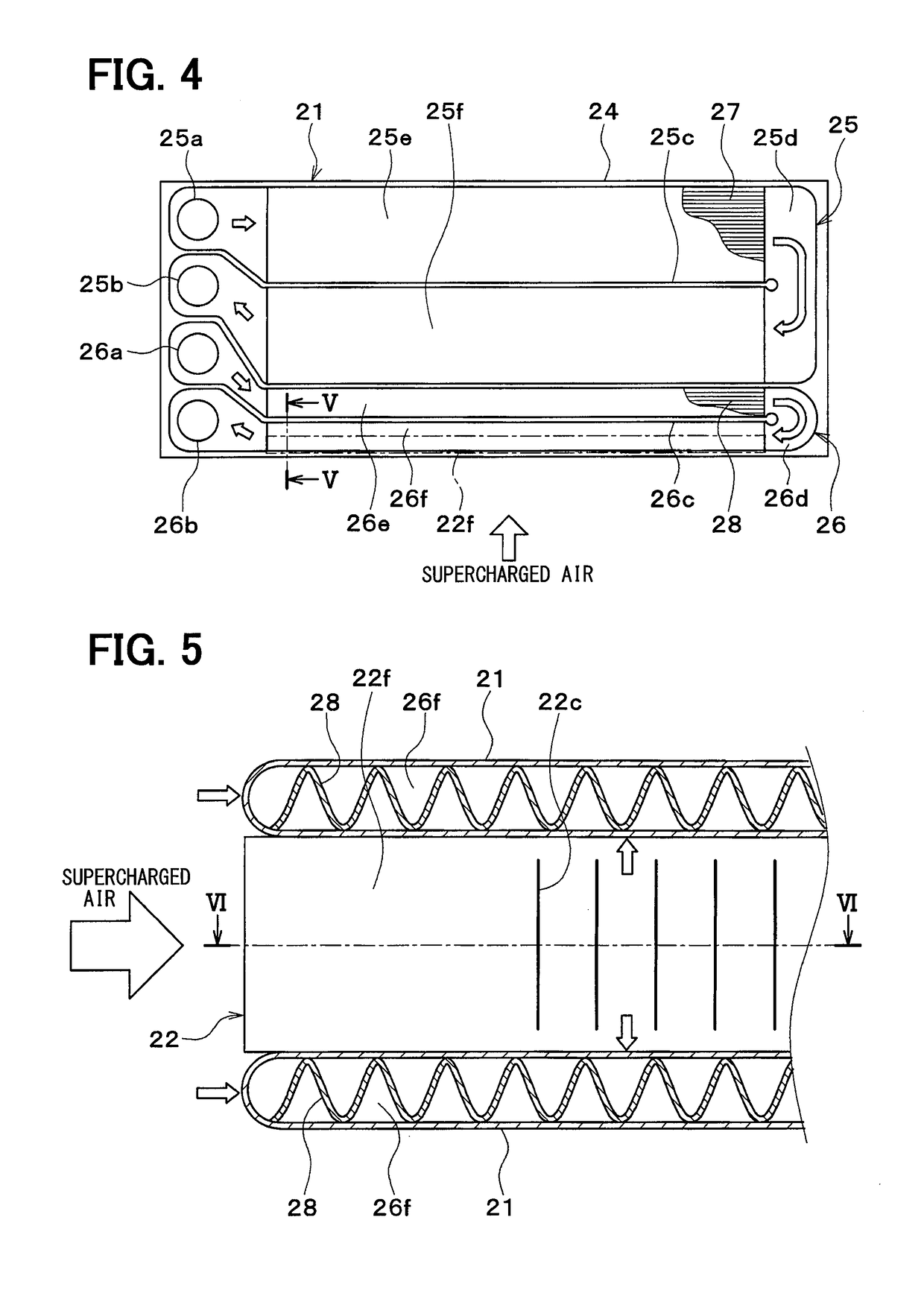

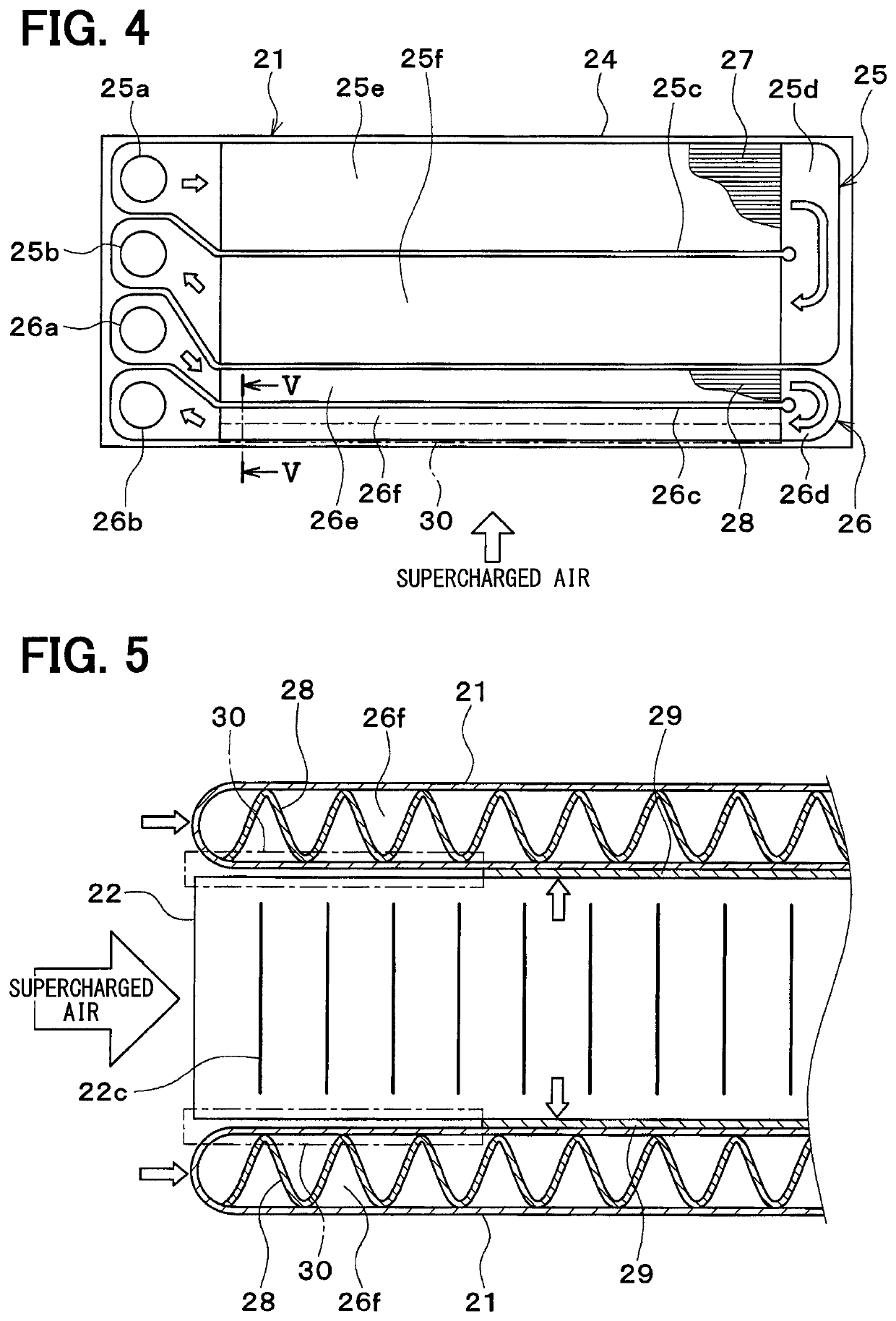

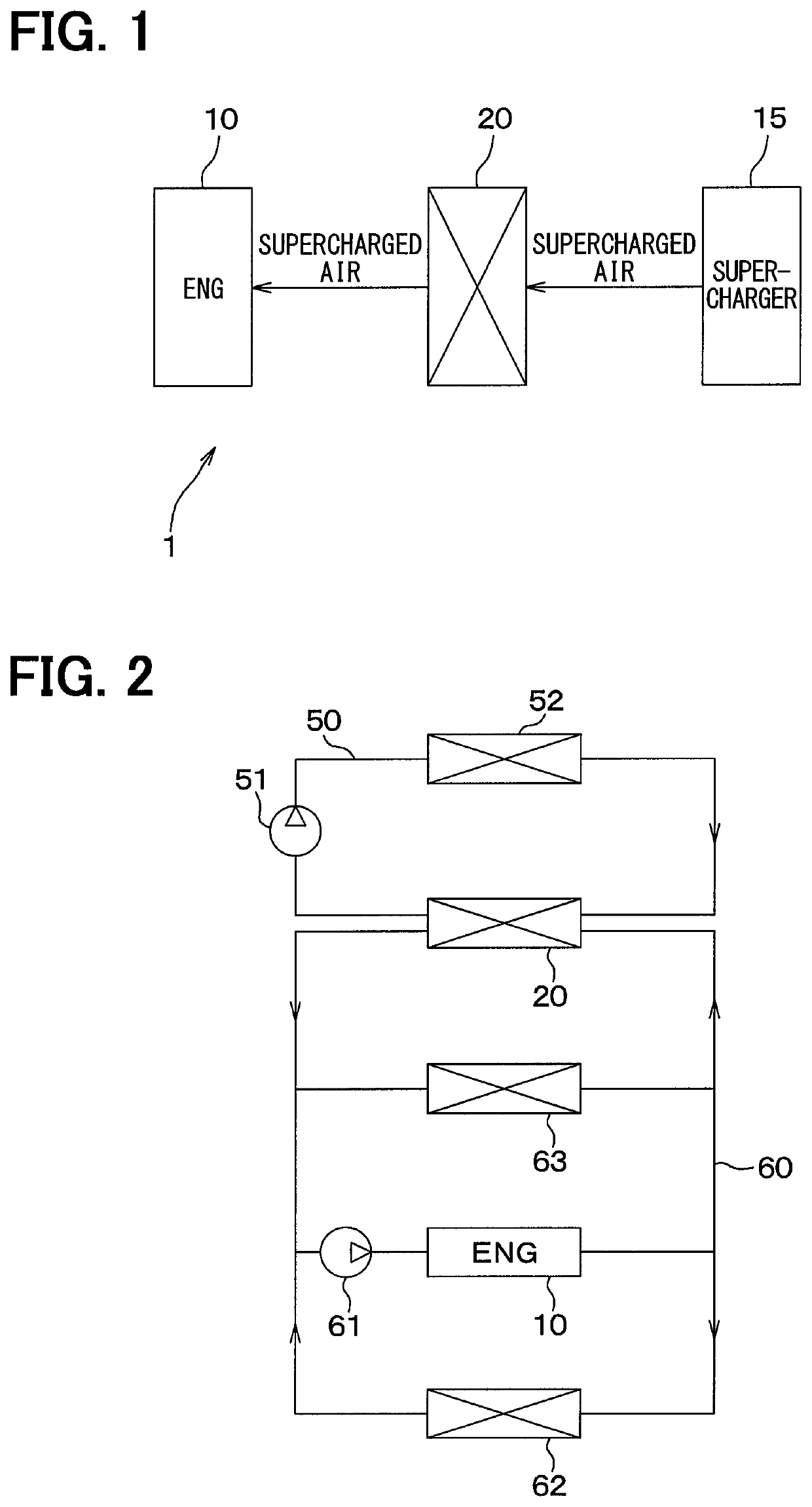

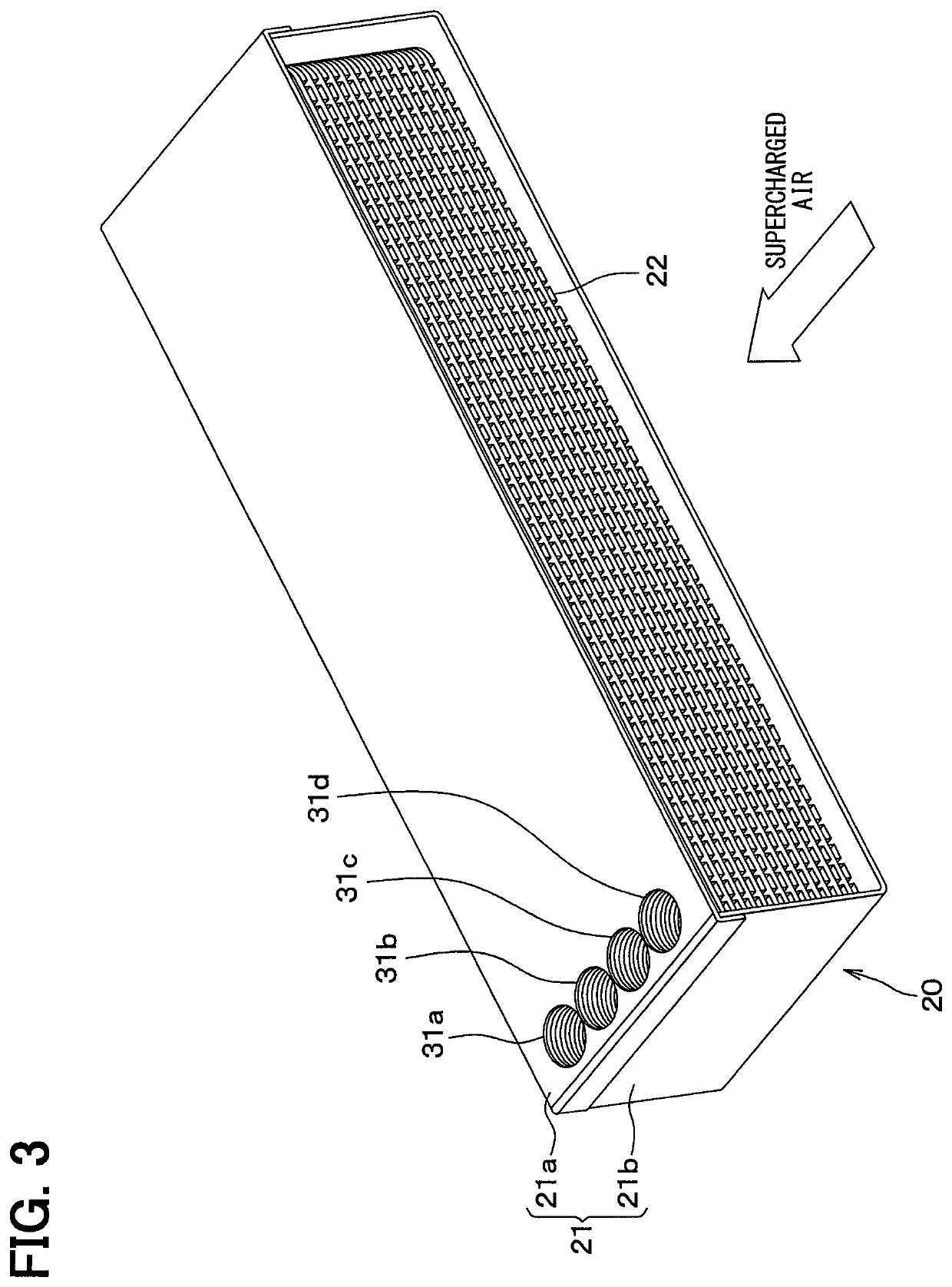

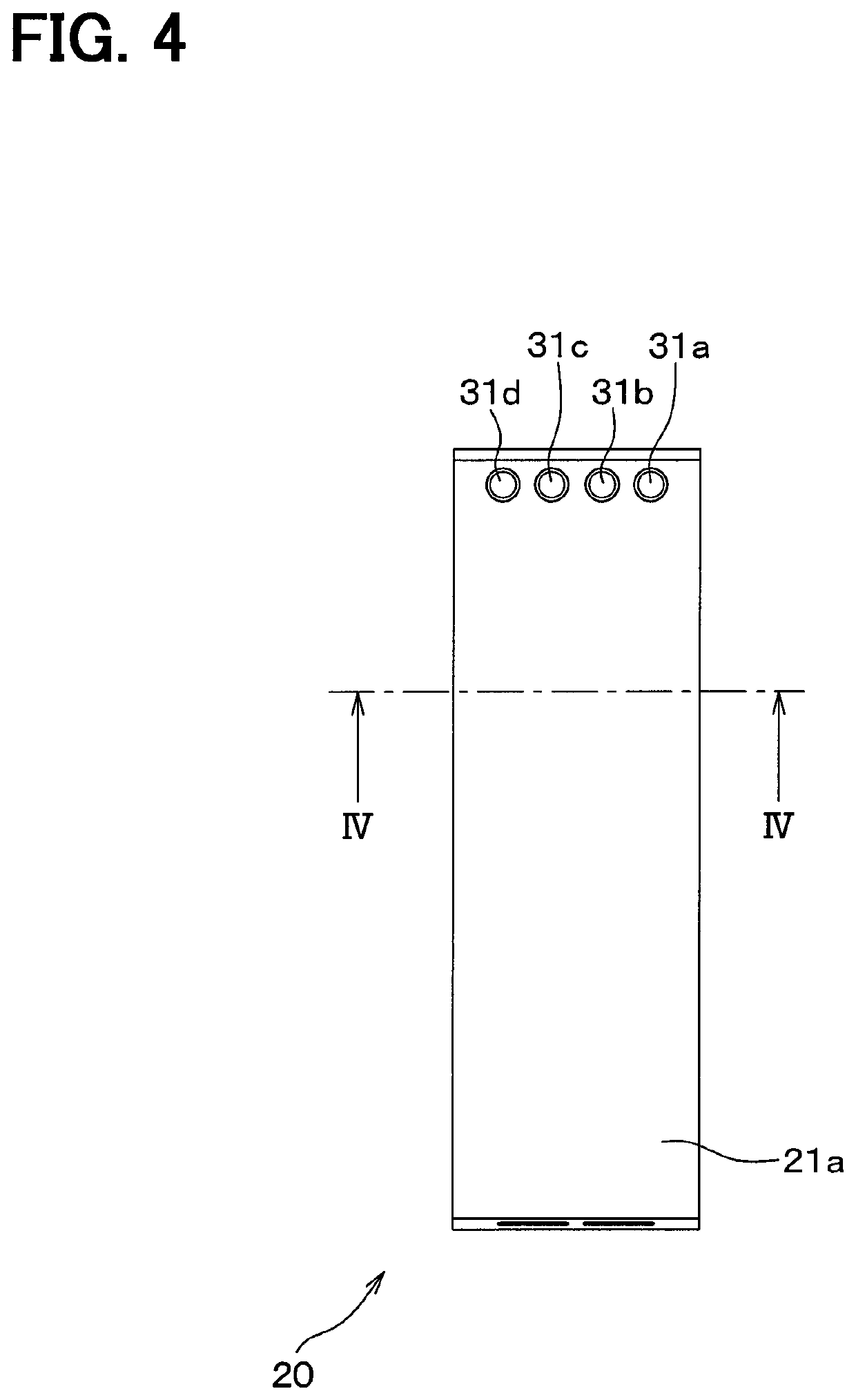

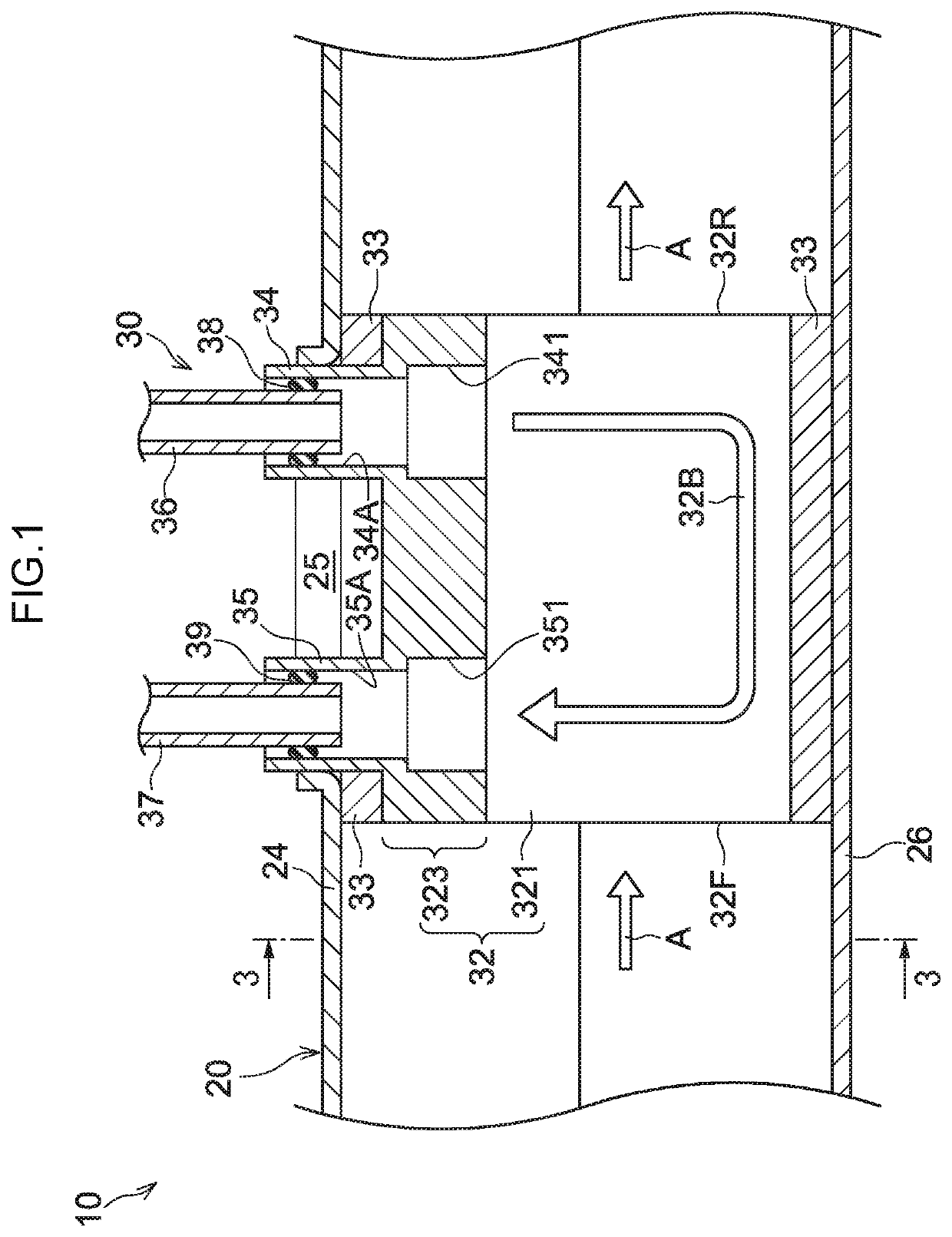

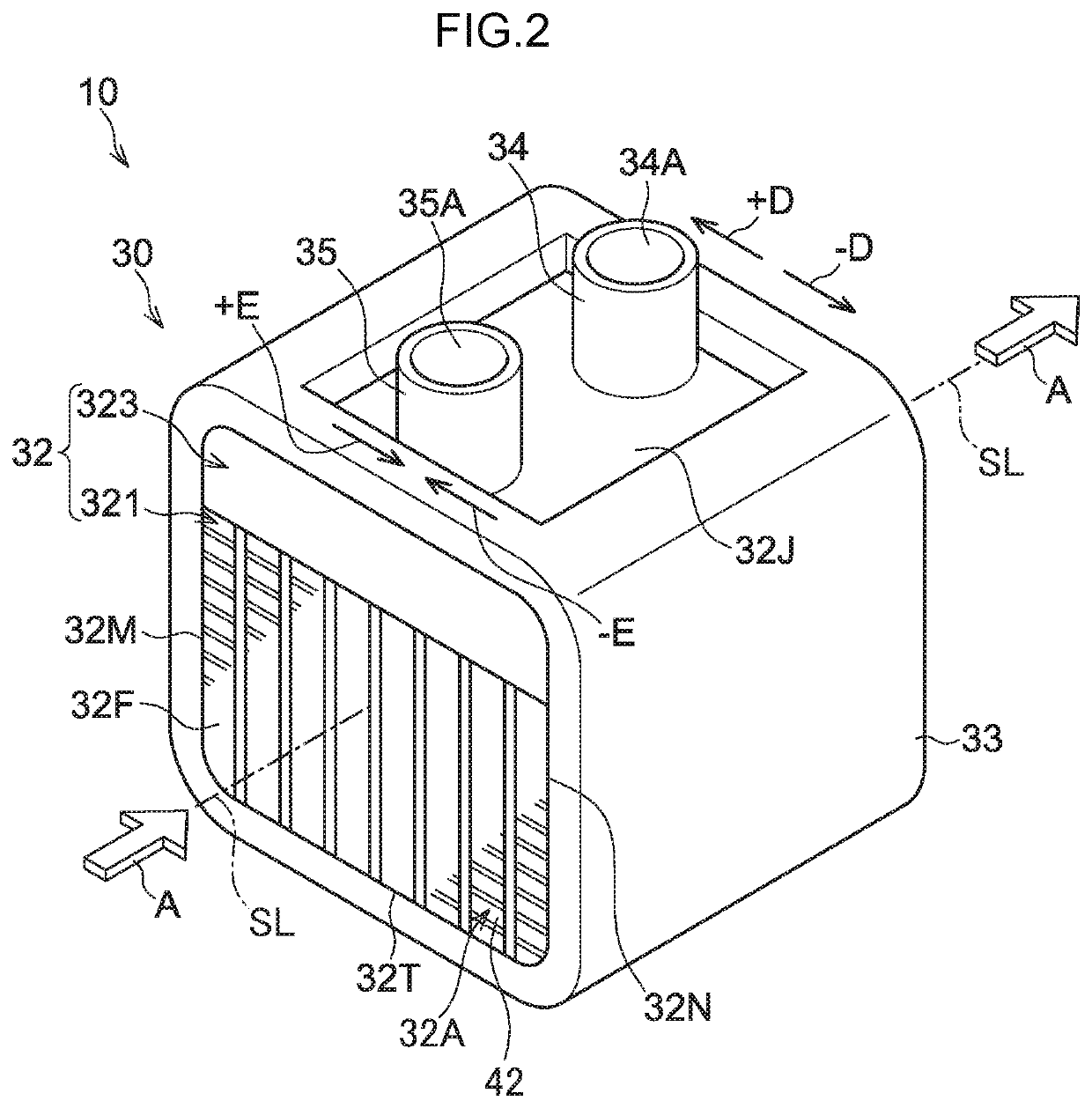

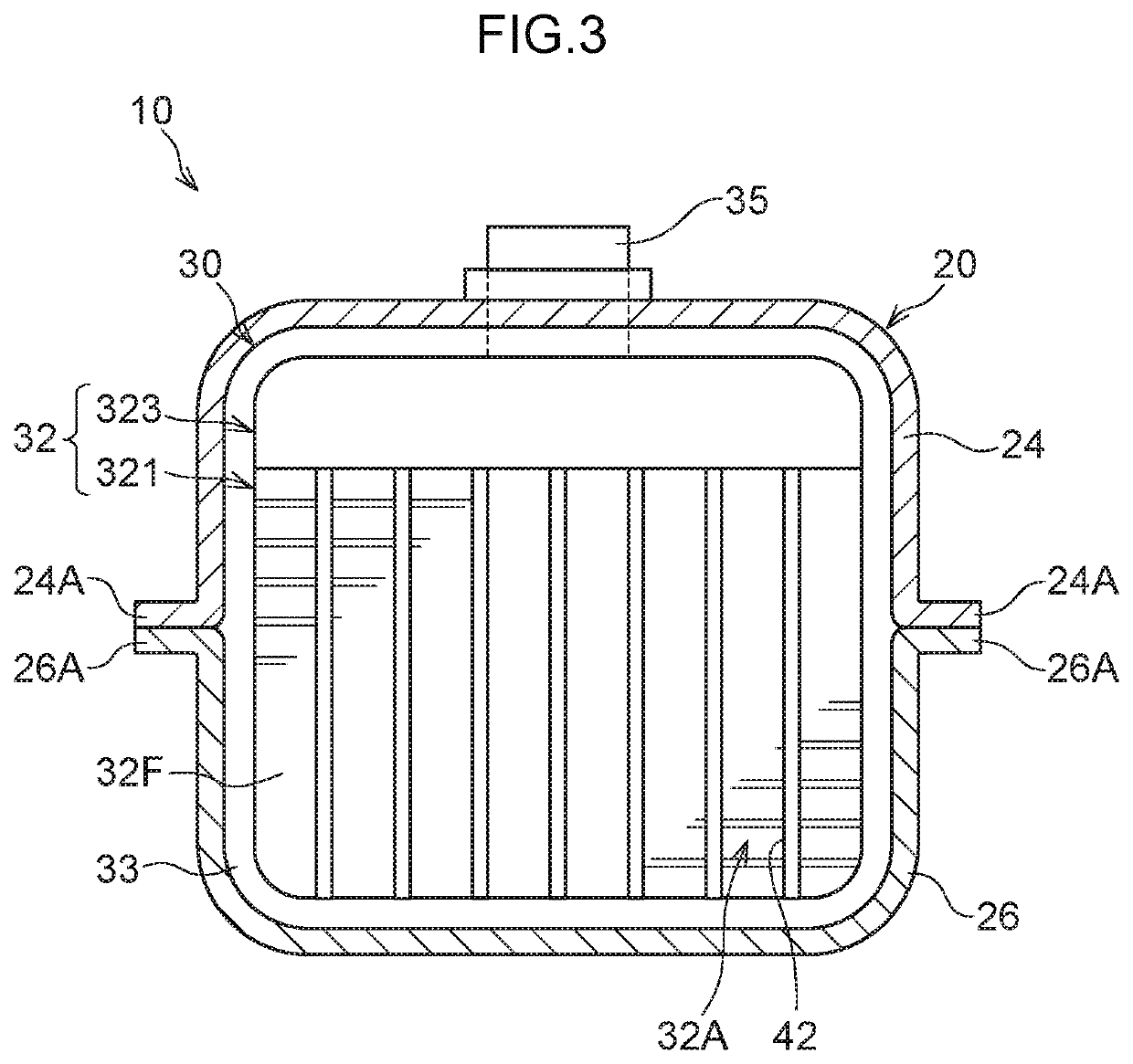

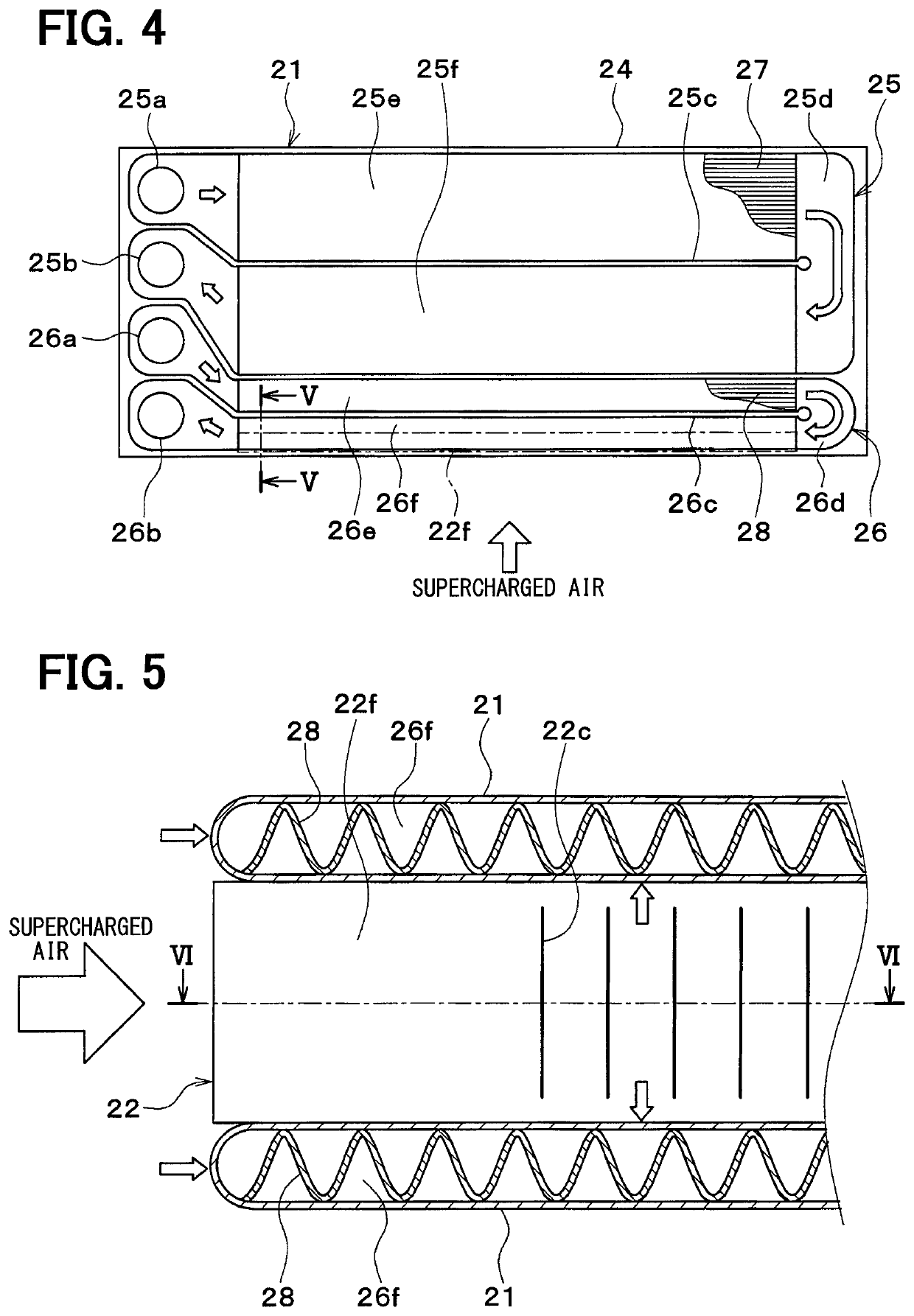

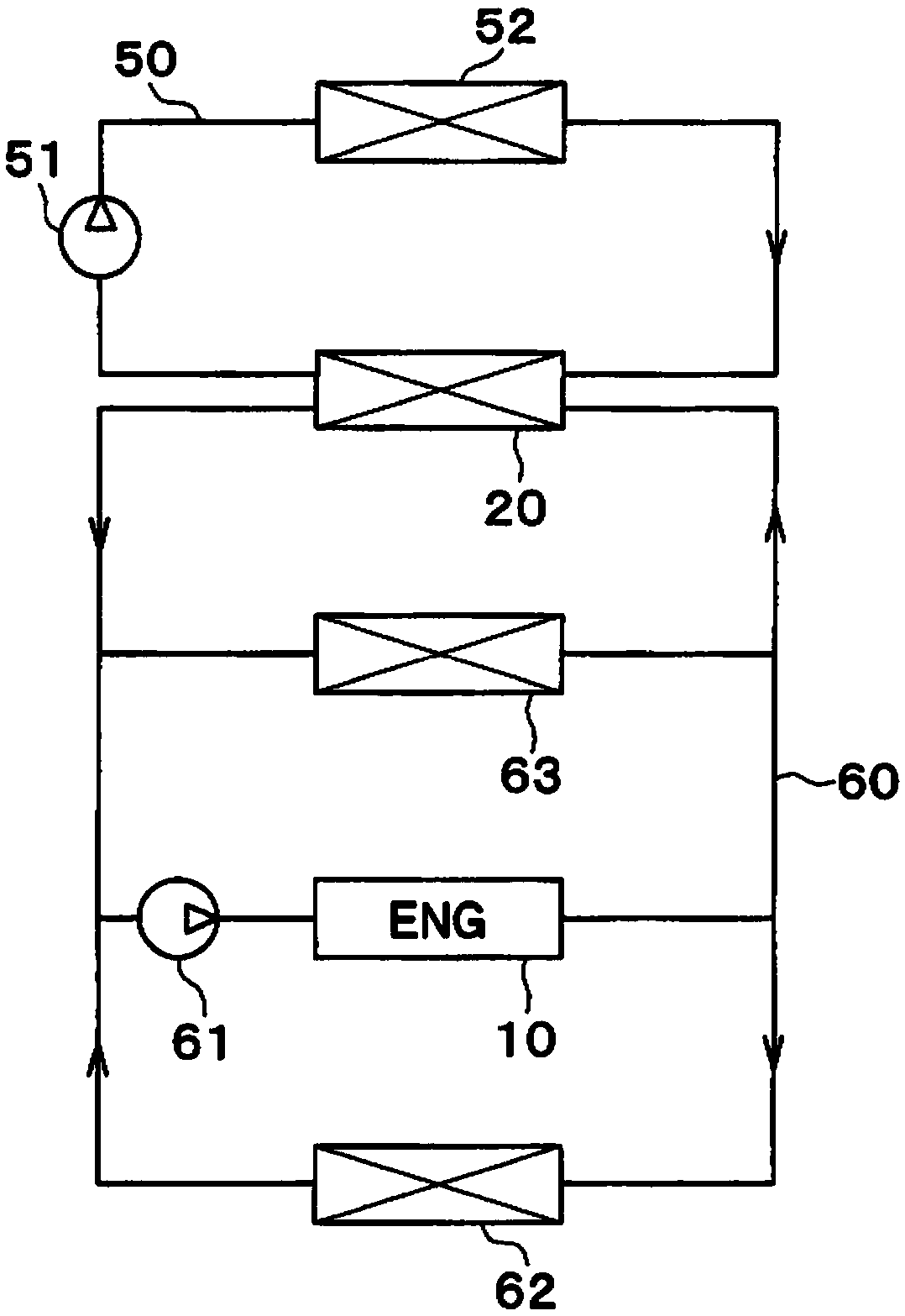

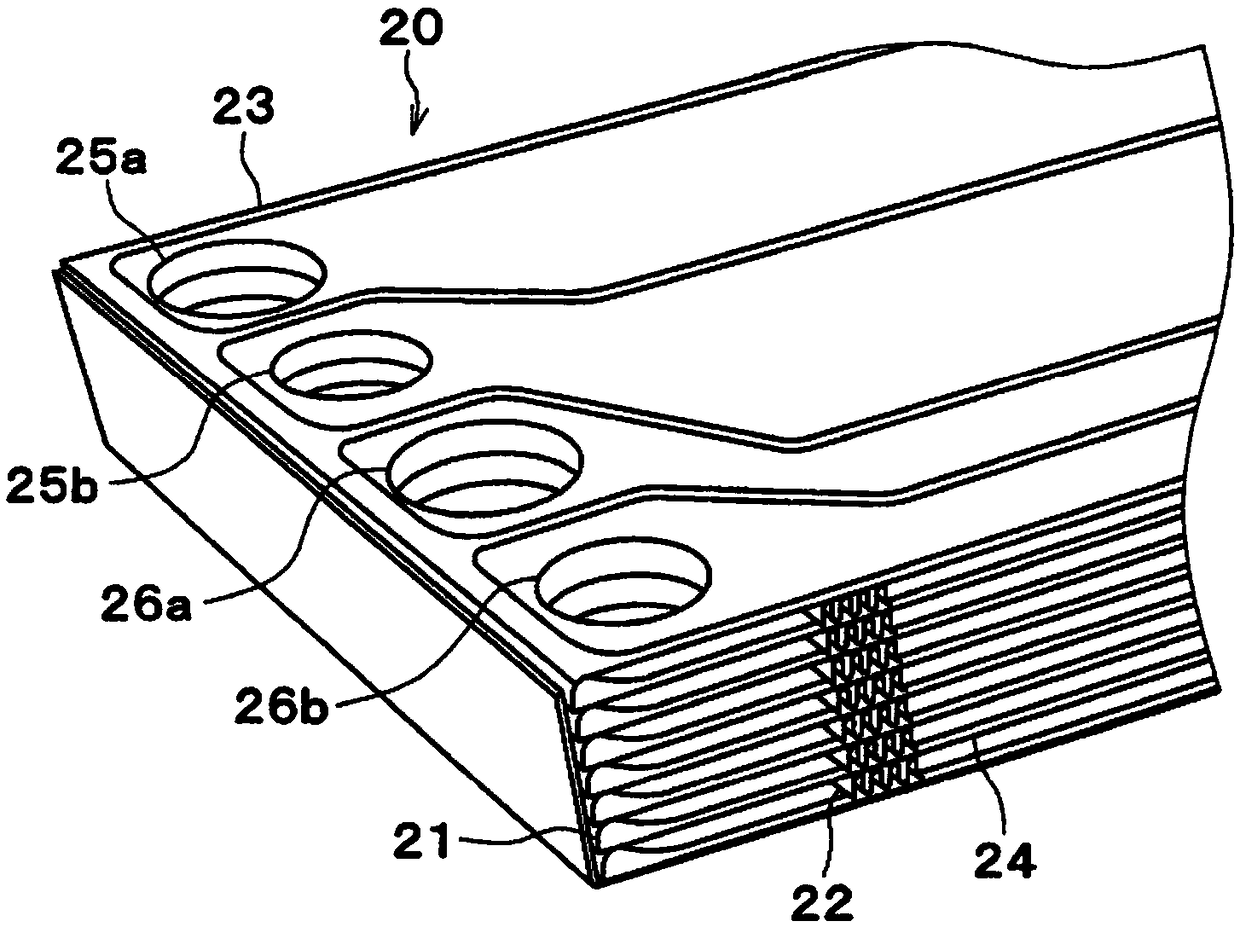

Intercooler

ActiveUS20190048786A1Suppress boilingEasy to boilInternal combustion piston enginesEngine cooling apparatusIntercoolerEngineering

An intercooler includes a heating portion in which flow path tubes and fins are stacked with each other. A second cooling medium flow path of the flow path tubes is located upstream of a first cooling medium flow path of the flow path tubes with respect to a flow direction of supercharged intake air. The second cooling medium flow path includes a second U-turn portion in which the second cooling medium makes a U-turn. In the second cooling medium flow path, a downstream flow path located downstream of the second U-turn portion is located upstream, in the flow direction of the supercharged intake air, of an upstream flow path located upstream of the second U-turn portion. The fins include a heat exchange limiting portion at least in a part adjacent to a most upstream part, in the flow direction of the supercharged intake air, of the downstream flow path.

Owner:DENSO CORP

Intercooler

ActiveUS10612457B2Suppress boilingEasy to boilInternal combustion piston enginesEngine cooling apparatusIntercoolerHeat sink

An intercooler includes flow path tubes and fins stacked with each other. Cooling medium includes first cooling medium and second cooling medium. A second cooling medium flow path of the flow path tubes is located upstream of a first cooling medium flow path with respect to supercharged intake air. The second cooling medium flow path includes a second U-turn portion. In the second cooling medium flow path, a downstream flow path located downstream of the second U-turn portion is located upstream, in a flow direction of the supercharged intake air, of an upstream flow path located upstream of the second U-turn portion. A heat exchange limiting portion is provided at a position between the flow path tubes and the fins, the position being adjacent to a most upstream part, in the flow direction of the supercharged intake air, of the downstream flow path.

Owner:DENSO CORP

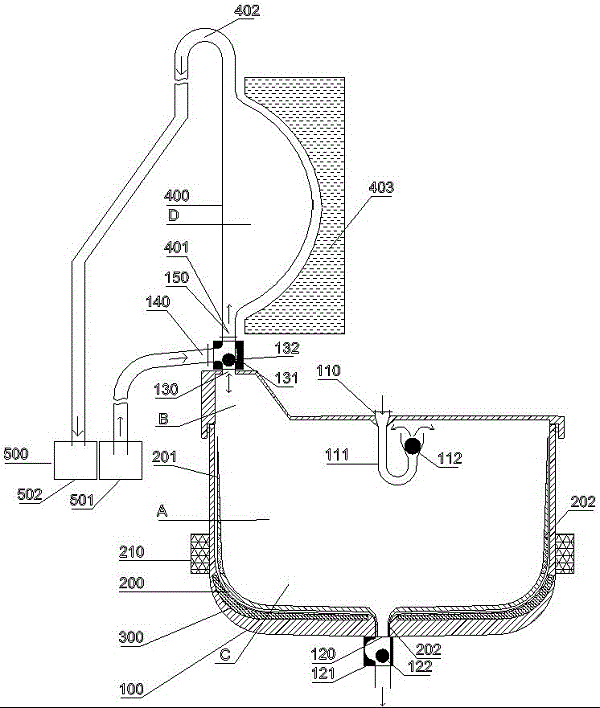

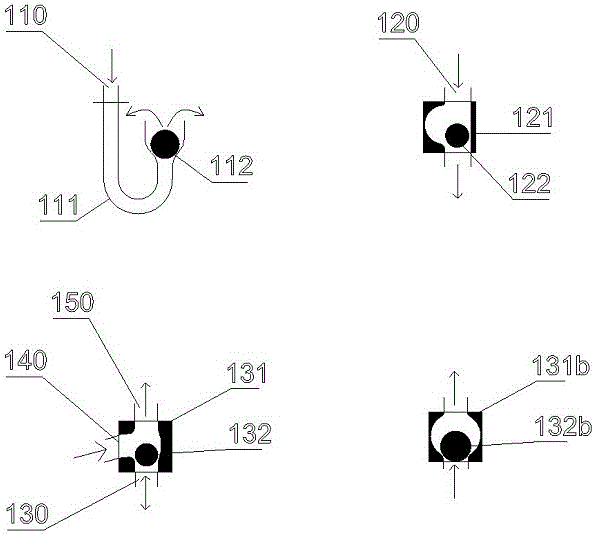

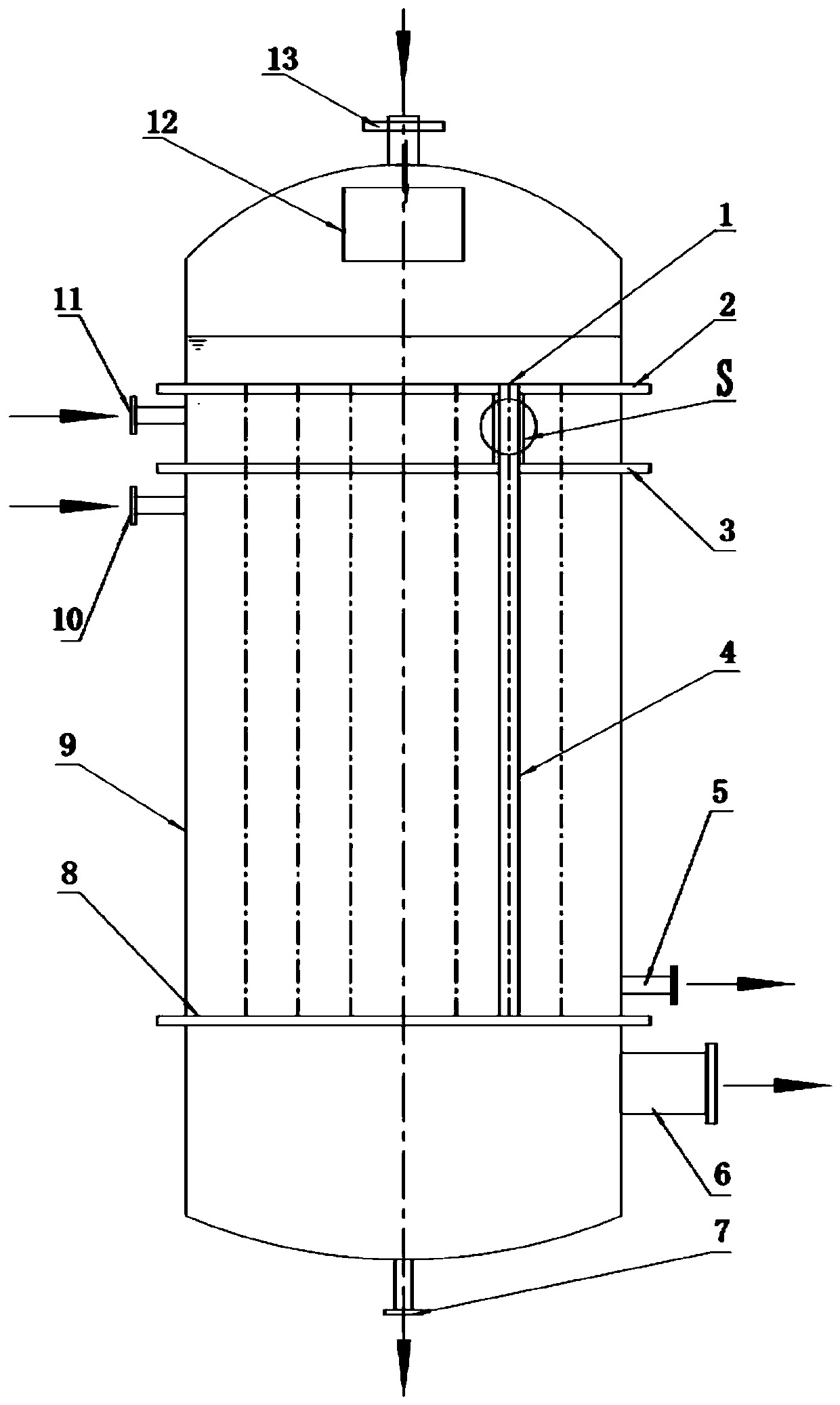

A Vertical Tube Falling Film Evaporator

ActiveCN107774001BSuppress boilingImprove heat transfer coefficientEvaporator accessoriesEvaporators with vertical tubesVertical tubeMaterials science

The invention relates to the technical field of evaporating devices and in particular relates to a vertical tube falling-film evaporator. The vertical tube falling-film evaporator comprises a shell, wherein a feeding cavity, a carrier gas cavity, a heating cavity and a gas-liquid separation cavity are sequentially formed inside the shell from top to bottom; a liquid dispenser is arranged inside the feeding cavity; a liquid distributor is arranged at the bottom of the feeding cavity; a plurality of evaporation tubes are vertically arranged in the shell; one end of each evaporation tube is connected with the liquid distributor, and the other ends of the evaporation tubes penetrate through the carrier gas cavity and the heating cavity and are communicated with the gas-liquid separation cavity; the carrier gas cavity is filled with non-condensable gas; and the non-condensable gas passes through side walls of the evaporation tubes so as to enter the evaporation tubes. According to the vertical tube falling-film evaporator provided by the invention, liquid films in the evaporation tubes are disturbed by utilizing the non-condensable gas, so that the heat exchange efficiency is improved,and scaling phenomena in the evaporation tubes are reduced. Moreover, the problem in the prior art that the falling-film evaporator is relatively low in heat exchange efficiency is solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Exhaust heat recovery device

ActiveCN107284185BSuppress boilingAir-treating devicesCoolant flow controlExhaust fumesProcess engineering

The present invention provides an exhaust heat recovery device comprising: a first pipe that circulates exhaust gas from an engine; a second pipe that communicates with the first pipe and connects to the first pipe. a detour; a heat recovery device disposed inside the second pipe, and performing heat exchange between the cooling water circulating inside and the exhaust gas, thereby recovering the heat of the exhaust gas; a heat transfer suppression mechanism , which is provided at a connection portion where the first pipe and the second pipe are connected, and suppresses transfer of heat from the first pipe to the second pipe.

Owner:TOYOTA JIDOSHA KK

A melting process of bismuth-containing free-cutting stainless steel

The invention provides a smelting process of bismuth-containing free-cutting stainless steel. The bismuth-containing free-cutting stainless steel is obtained through batching and feeding, vacuum smelting, refining, air inflation and pressurization, adding bismuth powder and pellets, and pouring. In the present invention, the bismuth powder granules are quickly and evenly sprayed into the melt inside the vacuum furnace through the powder granule feeding mechanism under the action of compressed inert gas, which can effectively suppress the boiling and volatilization of bismuth, and improve the yield of bismuth. Thereby, a bismuth-containing free-cutting stainless steel with evenly distributed bismuth content is obtained. The smelting process of the bismuth-containing free-cutting stainless steel provided by the invention has the advantages of fast feeding speed, high melting material efficiency, high element recovery rate and significantly reduced burning loss rate. The bismuth-containing free-cutting stainless steel obtained by the invention has cutting performance equivalent to that of the lead-containing free-cutting stainless steel, has good environmental protection, and is favorable for popularization and utilization.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Intercooler

ActiveUS10544727B2Increase temperatureReduced strengthInternal combustion piston enginesStationary plate conduit assembliesEngineeringIntercooler

An intercooler includes a heat exchanger that has a first heat exchange portion through which a first heat exchange medium flows and a second heat exchange portion through which a second heat exchange medium flows. The first heat exchange medium flowing through the first heat exchange portion cools the supercharged intake air by exchanging heat with the supercharged intake air. The second heat exchange medium flowing through the second heat exchange portion cools the supercharged intake air by exchanging heat with the supercharged intake air. The heat exchanger includes an inner fin configured to enhance the heat exchange between the supercharged intake air and the first heat exchange medium. The heat exchanger includes a boiling suppression portion configured to suppress a boiling of the first heat exchange medium flowing in an upstream part, in a flow direction of the supercharged intake air, of the first heat exchange portion.

Owner:DENSO CORP

Exhaust heat recovery unit

ActiveUS10626823B2Suppress boilingInternal combustion piston enginesRecuperative heat exchangersCarbide siliconGraphite

Owner:TOYOTA JIDOSHA KK +1

Intercooler

ActiveUS10655530B2Suppress boilingEasy to boilInternal combustion piston enginesEngine cooling apparatusEngineeringIntercooler

Owner:DENSO CORP

Intercooler

InactiveCN108699947ASuppress boilingIncrease temperatureInternal combustion piston enginesEngine cooling apparatusEngineeringIntercooler

Owner:DENSO CORP

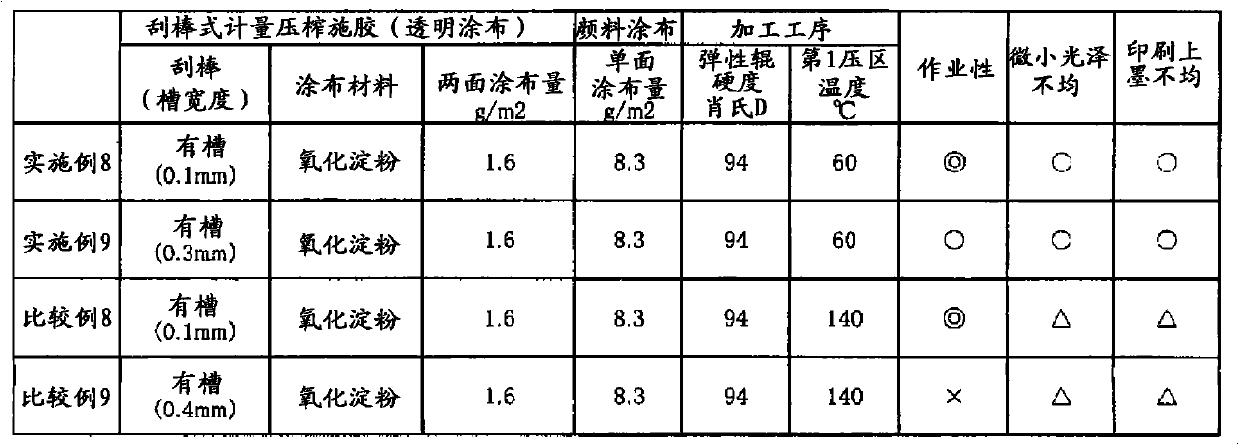

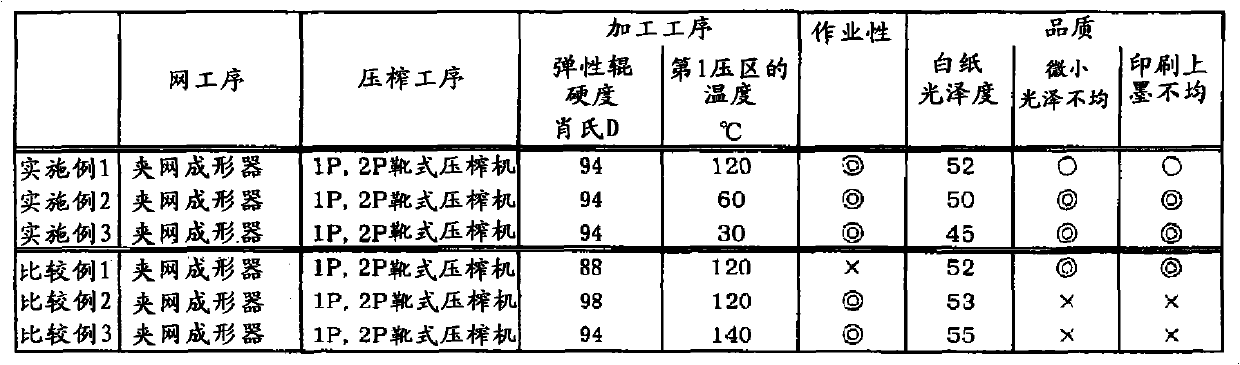

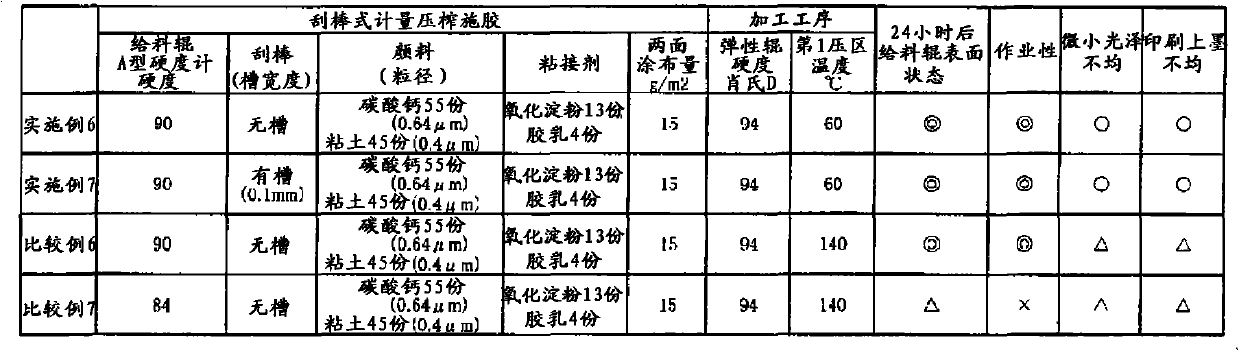

Method for producing coated paper

InactiveCN101910516ASuppress boilingImprove workabilityCoatings with pigmentsCalendersPolymer scienceAdhesive

Provided is a method for producing a high-quality coated paper with high operability, while preventing the surface of an elastic roll of a soft calender from being scratched during a high speed operation. A method for producing a coated paper comprises a step of making a base paper, a step of providing one or more pigment coating layers by applying a coating liquid containing a pigment and an adhesive onto the base paper, and a step of performing a surface treatment of the pigment coating layers by means of a soft calender. In the method, the operating speed of the papermaking step and the coating step is 1300 m / min, the outermost pigment coating layer is treated with two or more nips in the surface treatment step by using a soft calender consisting of a metal roll and an elastic roll, the Shore D hardness of the elastic roll is 90-96, and the surface temperature of the metal roll at the first nip is lower than 130 DEG C.

Owner:NIPPON PAPER IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com