Exhaust waste heat recovery device and automobile

A recovery device and exhaust waste heat technology, which is applied in the direction of exhaust devices, mufflers, internal combustion piston engines, etc., can solve problems such as coolant leakage, heat exchange pipeline damage, pressure increase, etc., to avoid heat radiation and heat Transmitting, avoiding damage, suppressing the effect of boiling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

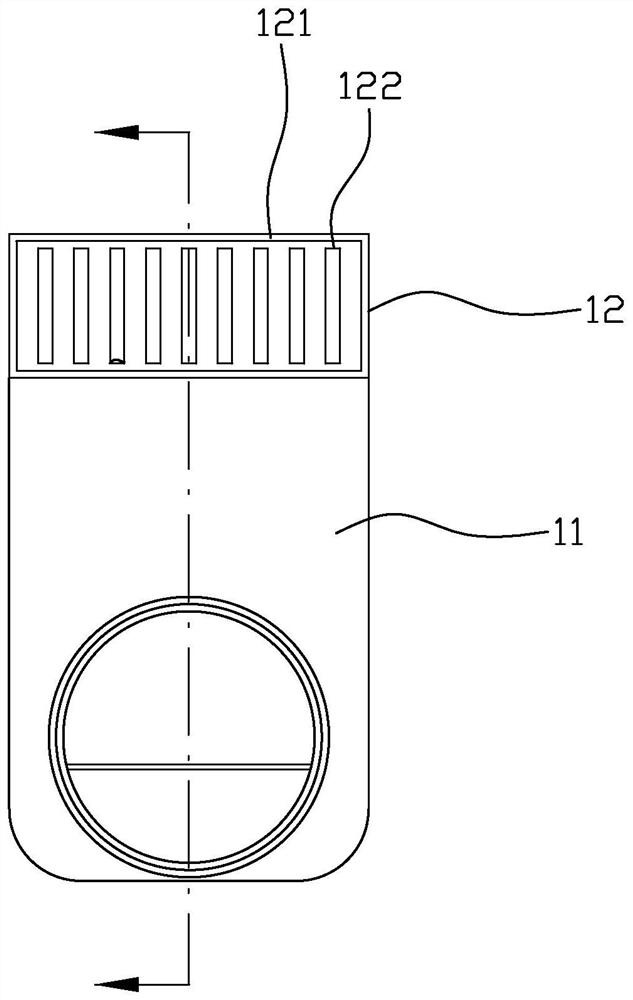

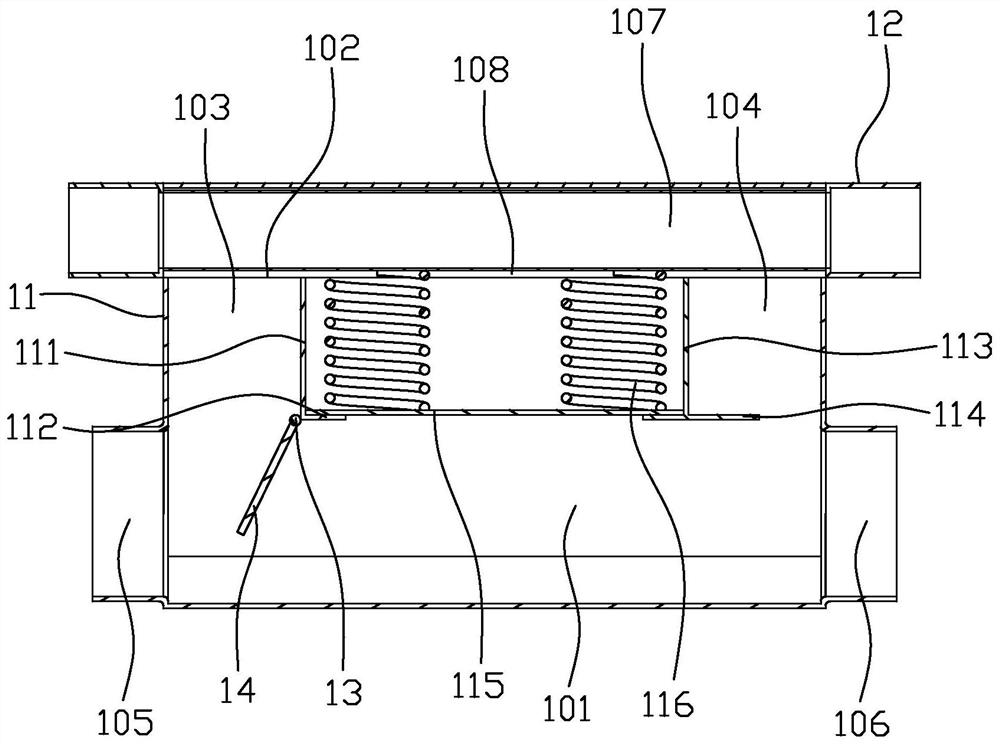

[0020] figure 1 is a schematic partial side view of the exhaust waste heat recovery device of the present invention, figure 2 yes figure 1 The cross-sectional schematic diagram of the exhaust waste heat recovery device shown, as shown in figure 1 and figure 2 As shown, the exhaust waste heat recovery device includes an exhaust casing 11 and a heat exchanger 12, the exhaust casing 11 is provided with an exhaust passage 101, and the heat exchanger 12 is arranged on the top of the exhaust casing 11. The first partition 111, the second partition 113, the movable plate 115 and the elastic member 116, the first partition 111 is arranged opposite to the second partition 113, and the first partition 111 and the second partition 113 are connected to the exhaust casing On the inner wall of 11, a heat exchange inlet passage 103 is formed between the first partition 111 and the inner wall of the exhaust shell 11, and the heat exchange inlet passage 103 communicates with the exhaust p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com