Heat exchanger

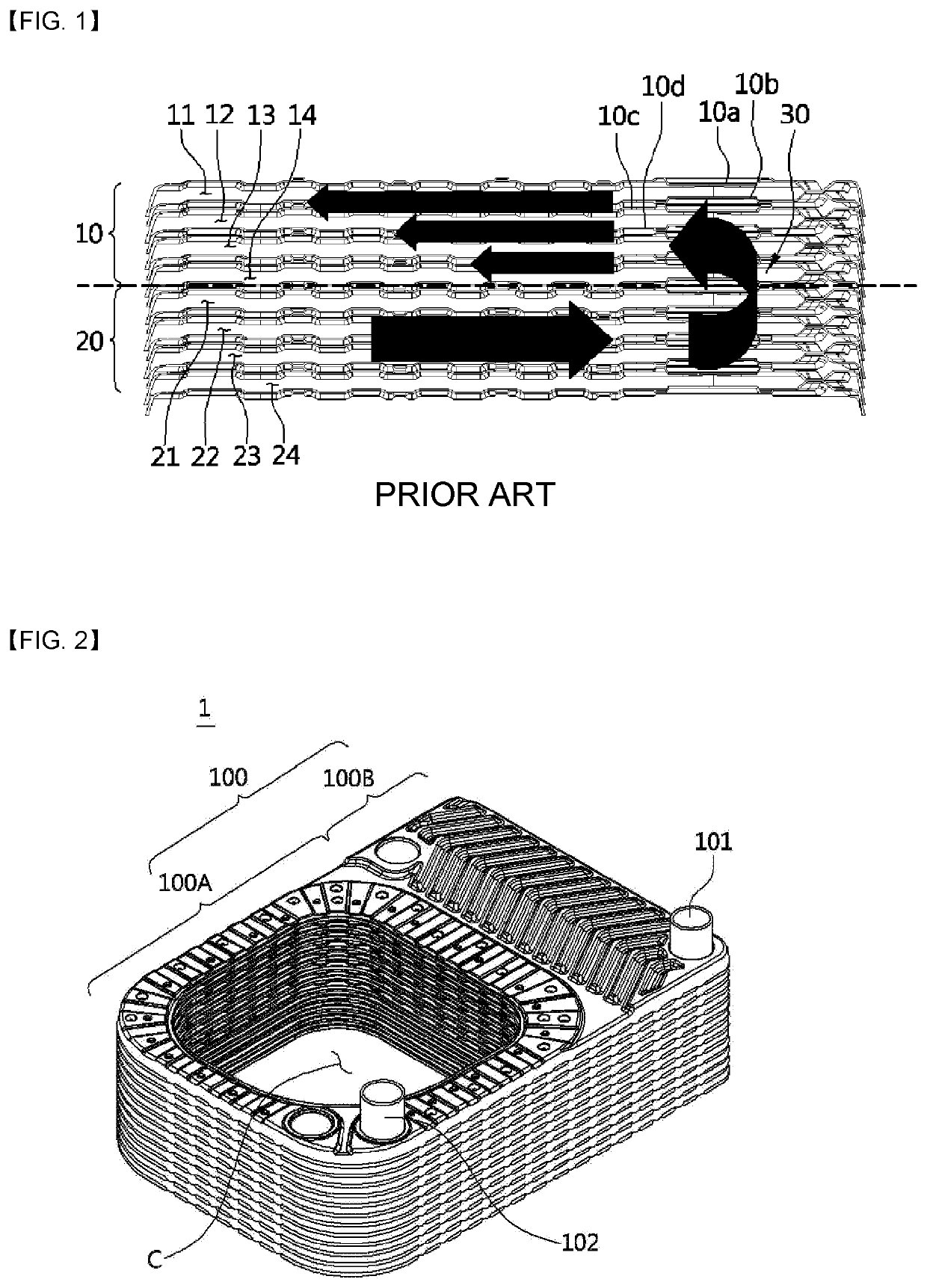

a technology of heat exchanger and heat exchanger layer, which is applied in the direction of indirect heat exchanger, light and heating apparatus, laminated elements, etc., can solve the problems of non-uniform flow rate of heating medium distributed to the heating medium layer, thick tubes, and inability to secure a wide heat transmission area, so as to achieve effective distribution, simplify heating medium differential distribution unit, and improve heat transmittance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082]Hereinafter, configurations and operations related to exemplary embodiments of the present invention will be described below in detail with reference to the accompanying drawings.

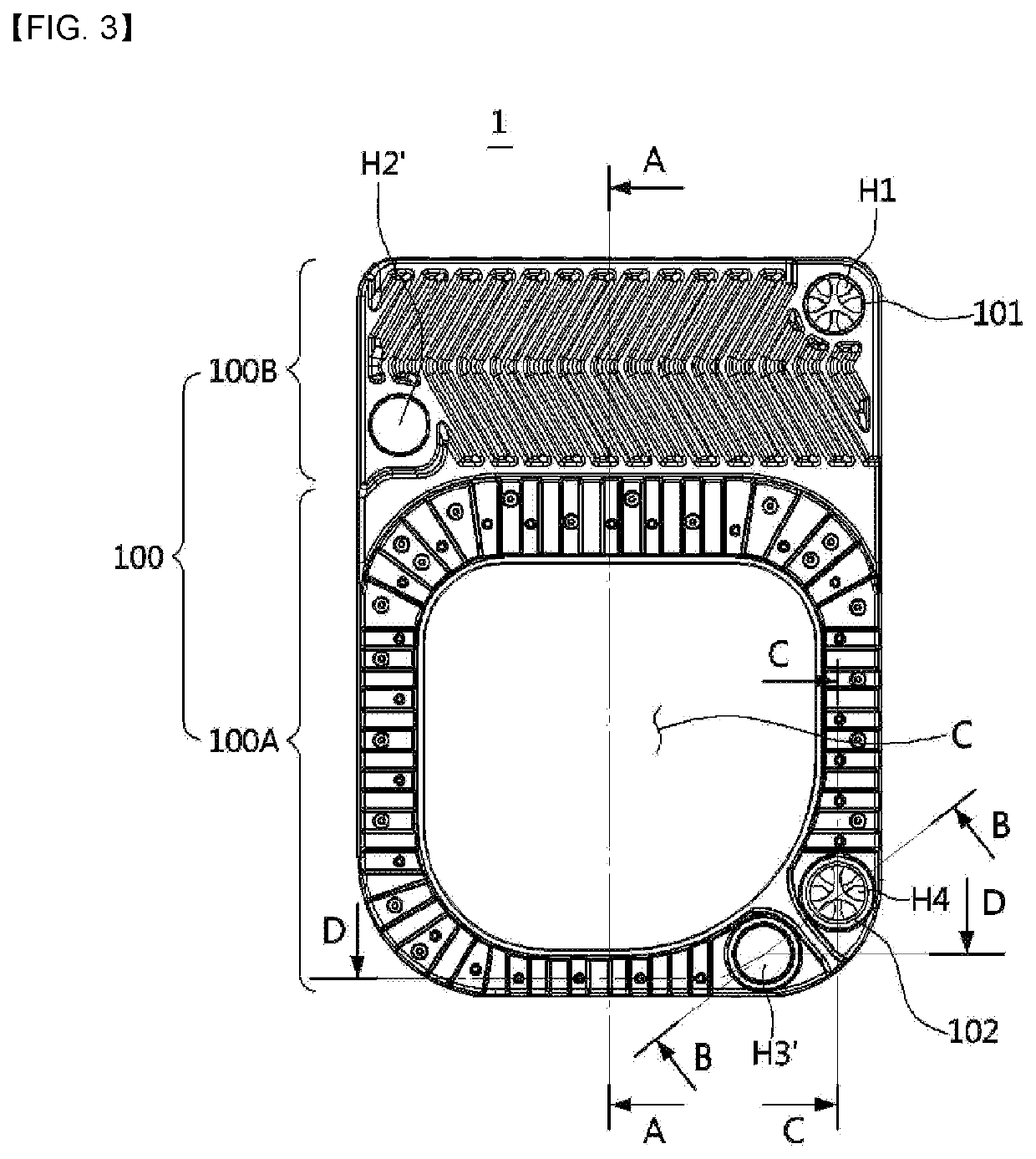

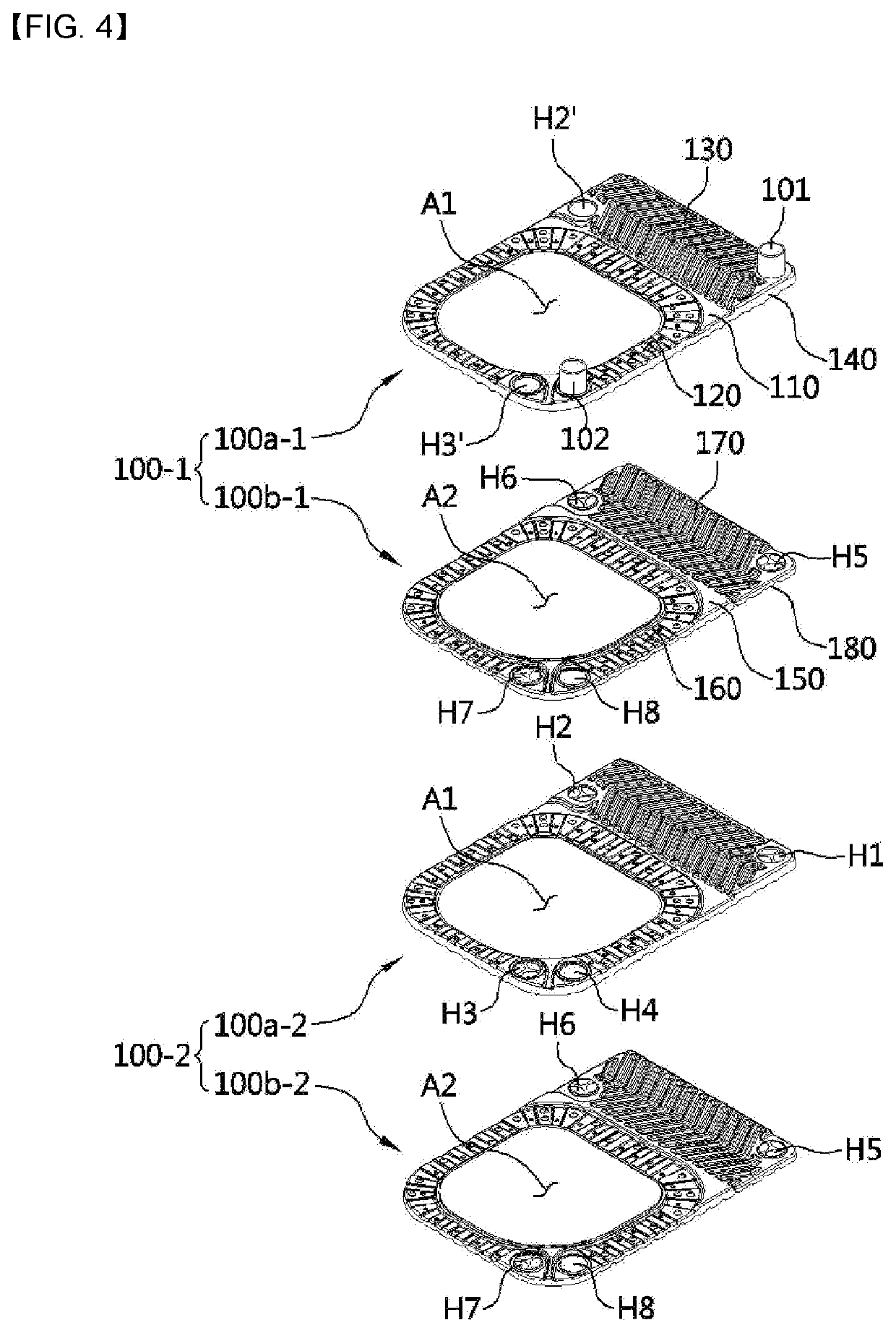

[0083]Referring to FIGS. 2 to 7, a heat exchanger 1 according to one embodiment of the present invention includes a heat exchange unit 100 formed of a plurality of plates stacked around a combustion chamber C in which combustion heat and combustion gas are generated due to combustion of the burner (not shown).

[0084]The heat exchange unit 100 includes a sensible heat exchange unit 100A surrounding an outer side of the combustion chamber C and including one side regions of the plates to heat a heating medium using sensible heat of the combustion gas generated by combustion of the burner and a latent heat exchange unit 100B including the other side regions of the plates to heat the heating medium using latent heat generated while water vapor included in the combustion gas, of which heat is exchanged in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com