Radioisotope production system and radioisotope production method

A radioactive isotope and manufacturing device technology, which is applied in the direction of irradiation devices, measuring devices, radiation measurement, etc., can solve the problem that it is difficult to fully suppress the boiling of the target liquid, and achieve the effect of suppressing boiling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment approach

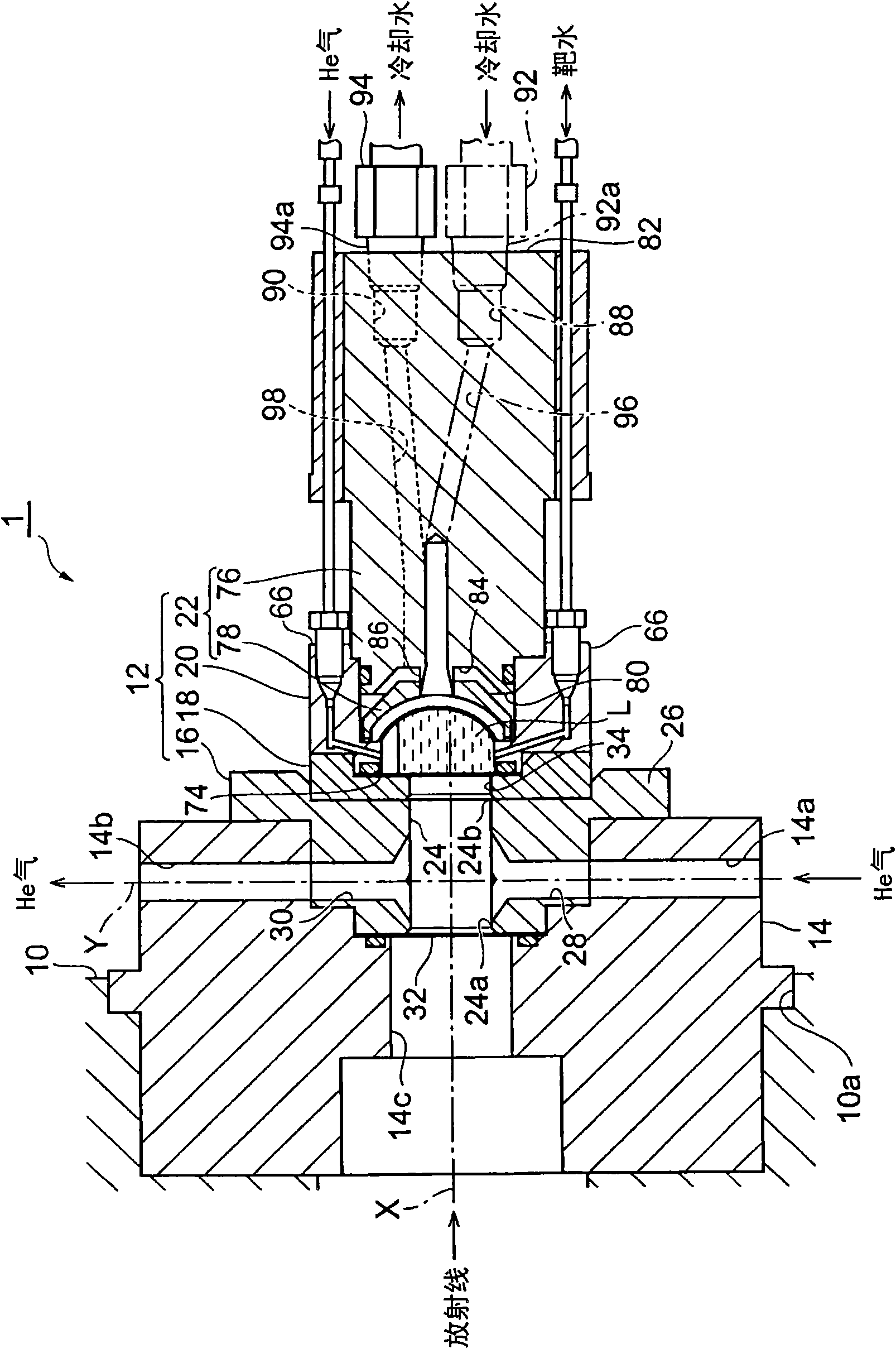

[0086] (2.1) Structure of radioisotope manufacturing facility

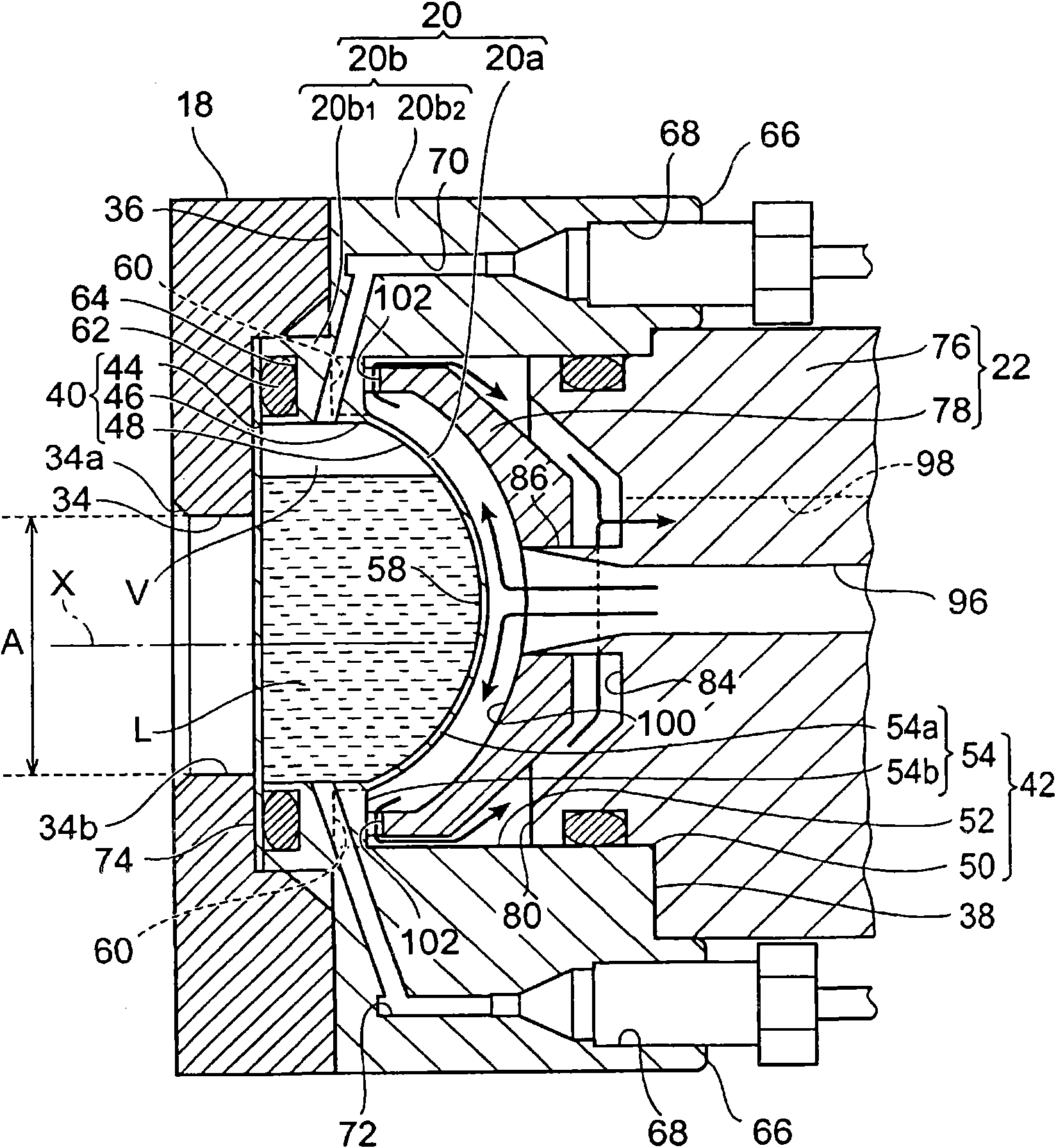

[0087] Next, refer to Figure 7 ~ Figure 13 The configuration of the radioisotope manufacturing apparatus 2 according to the second embodiment will be described focusing on differences from the radioisotope manufacturing apparatus 1 according to the first embodiment.

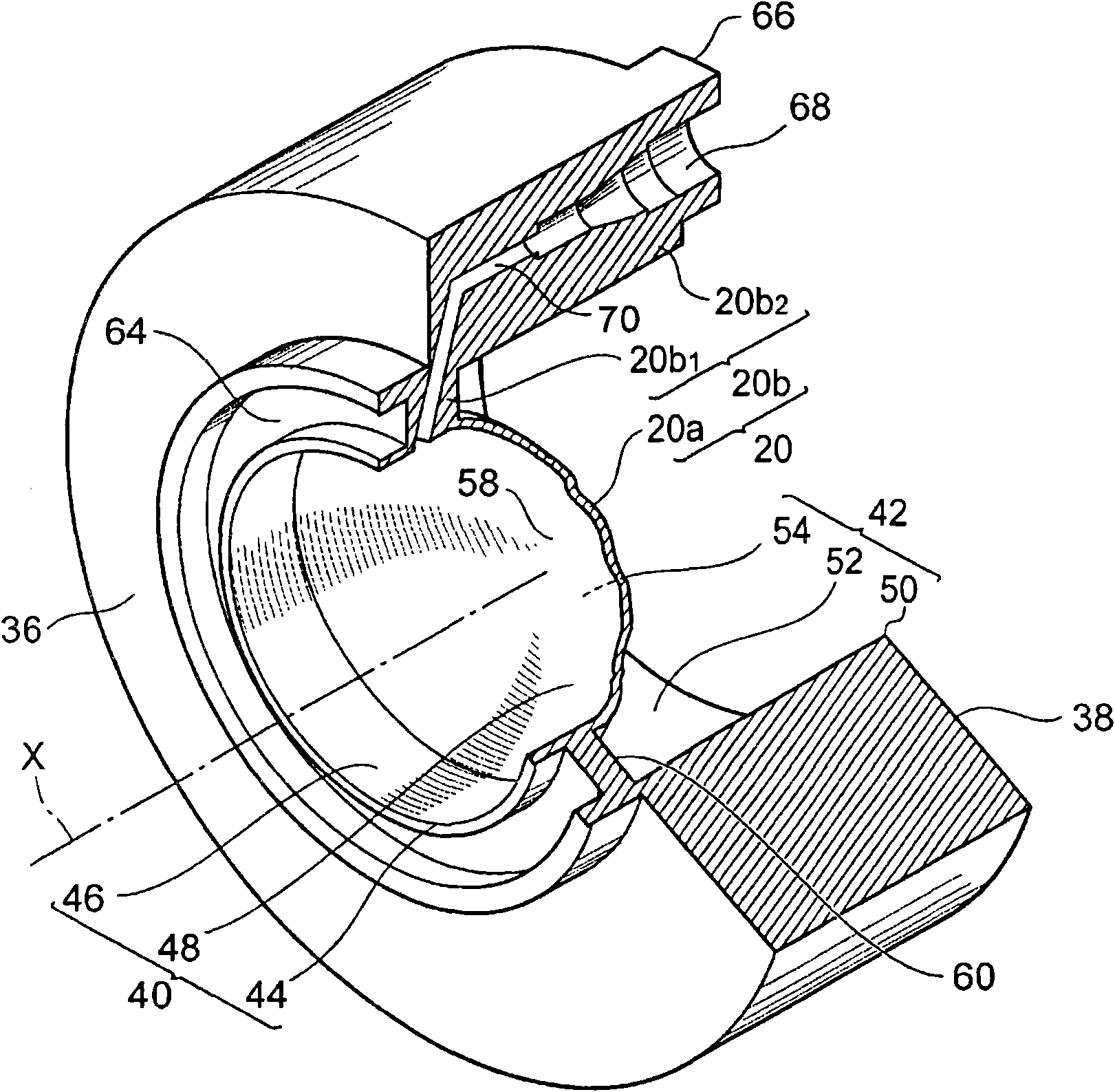

[0088] like Figure 7 ~ Figure 11 As shown, the target 20 has a thin-walled shell-shaped portion 20a and an annular support portion 20b that supports the thin-walled shell-shaped portion 20a so as to surround the periphery of the thin-walled shell-shaped portion 20a. Therefore, in the target 20, the space surrounded by the thin-walled shell-shaped portion 20a and the annular support portion 20b constitutes a storage recess 40 for storing the target liquid L on the front end surface 36 side, and a housing recess 40 for storing the target liquid L is formed on the base end surface 38 side. 3 The fitting recess 42 of the body part 22. In addition, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com