Stirring pulp cooking and air-controlled pulp inlet and outlet device and stirring pulp cooking and air-controlled pulp inlet and outlet method

An air extraction device and air control technology, which is applied in the field of stirring slurry cooking and air control slurry inlet and outlet devices, can solve the problems of pot at the bottom of the container, easy to bring danger, processing pollution, etc., so as to avoid secondary pollution and avoid bumping. , avoid wasteful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

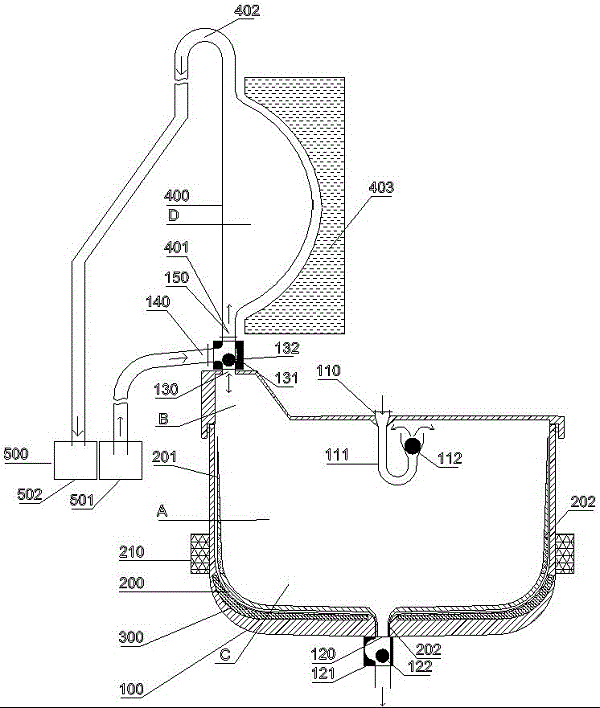

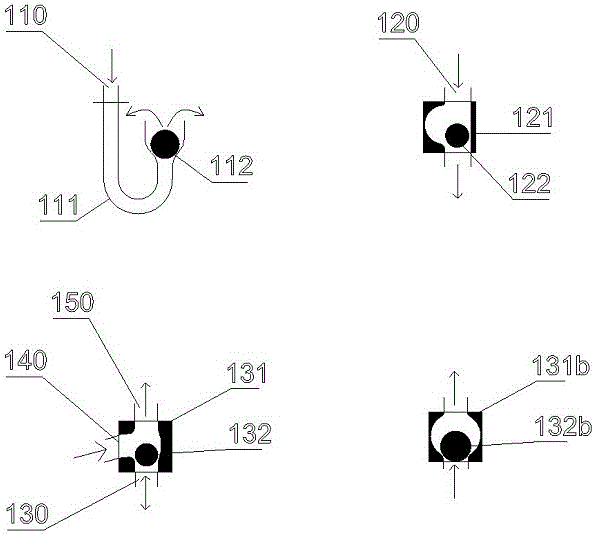

[0026] Such as figure 1 , 2 As shown, a device for stirring and cooking pulp and air-controlled pulp in and out according to the present invention includes a pulp cooking tank (100), a stirring device (220), a heating device (300), an overflow reflux device (400), an air pressure Control device (500). There is an airtight cavity (A) inside the cooking tank (100), on which there are pulp inlet (110), pulp outlet (120) and air vent (130 / 130b), and the stirring device (220) includes a stirrer ( 200) and a stirring driver (210), the air pressure control device (500) includes a steam generating device (501) and an air extraction device (502). In this embodiment, the pulp inlet (110) of the pulp cooking tank (100) is provided with a control valve (111), and the control valve (111) realizes automatic Opening and closing, so as to realize the automatic control of the slurry feeding process of the cooking tank (100), and help to accelerate the grouting. In this embodiment, the agit...

Embodiment 2

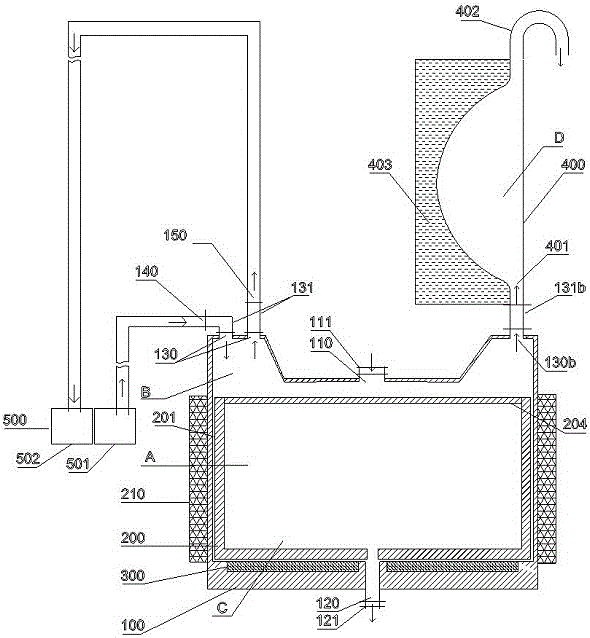

[0028] Such as image 3 As shown in the present invention, a device for stirring and cooking pulp and air-controlled pulp in and out, the difference between this embodiment 2 and embodiment 1 is that the closed cavity (A) of the pulp cooking tank (100) is a ring-shaped bulge , the number of the vents (130 / 130b) is multiple, and each vent (130 / 130b) is connected to the air inlet (140), the exhaust port (150) and the overflow through the two-way control valve (131). Reflux (400).

Embodiment 3

[0030] Such as Figure 4 As shown in the present invention, a device for stirring and cooking pulp and air-controlled pulp in and out, the difference between this embodiment 3 and embodiment 1 is that the stirring drive (210) adopts a permanent rotation coaxial with the agitator (200). magnet set.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com