Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Solve indentation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

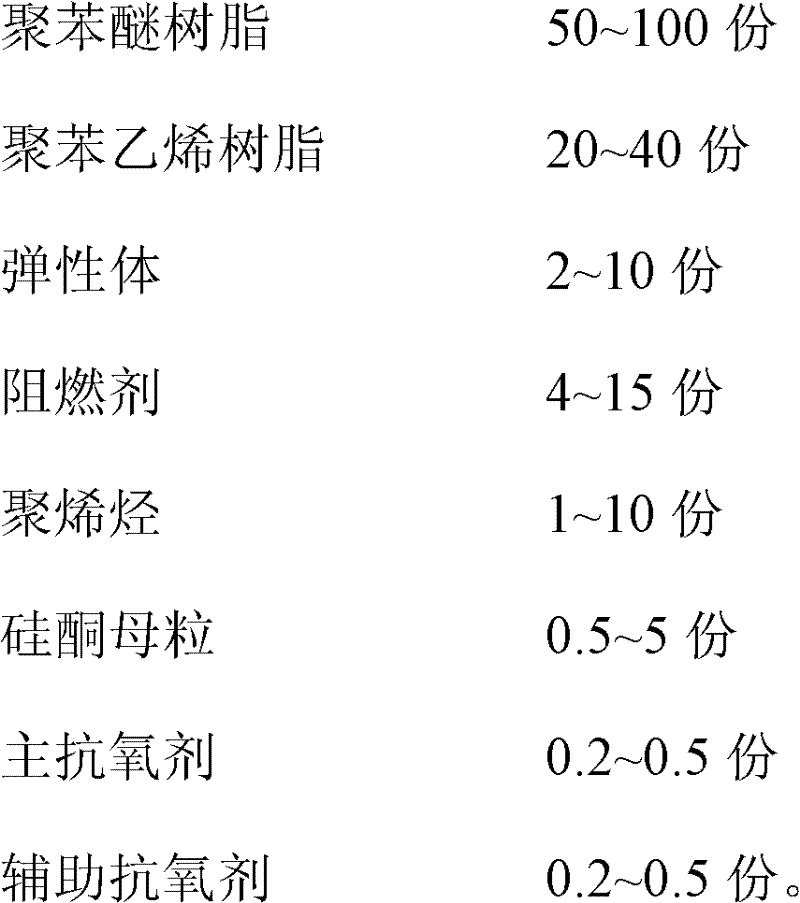

Polyphenyl ether resin material used for processing charger case

The invention discloses a polyphenyl ether resin material used for processing a charger case, which consists of polyphenyl ether resin, polystyrene resin, an elastic body, fire retardants, polyolefin, silicone masterbatch, main antioxidants and auxiliary antioxidants. Through adding proper auxiliary agents into a polyphenyl ether resin composition, the invention improves the surface lubricating effect of manufactured elements, reduces the pressure required during welding, and solves the problems of impression, scratches and the like occurring during the ultrasonic welding of products. The products are mainly applied to the fields requiring the ultrasonic welding, such as charger cases, wiring cases and the like.

Owner:NANTONG XINGCHEN SYNTHETIC MATERIAL +1

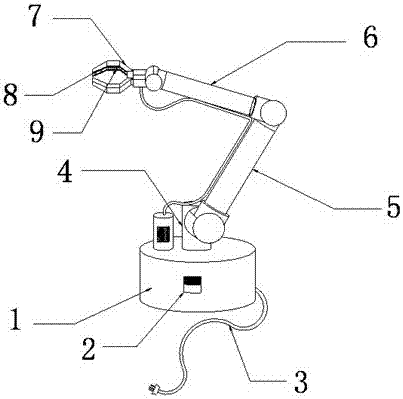

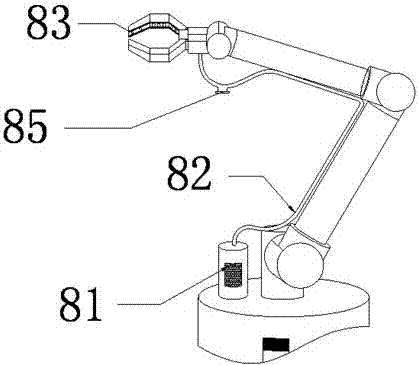

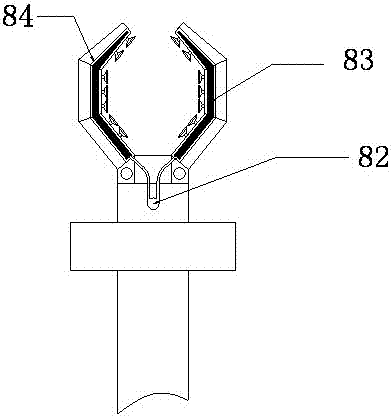

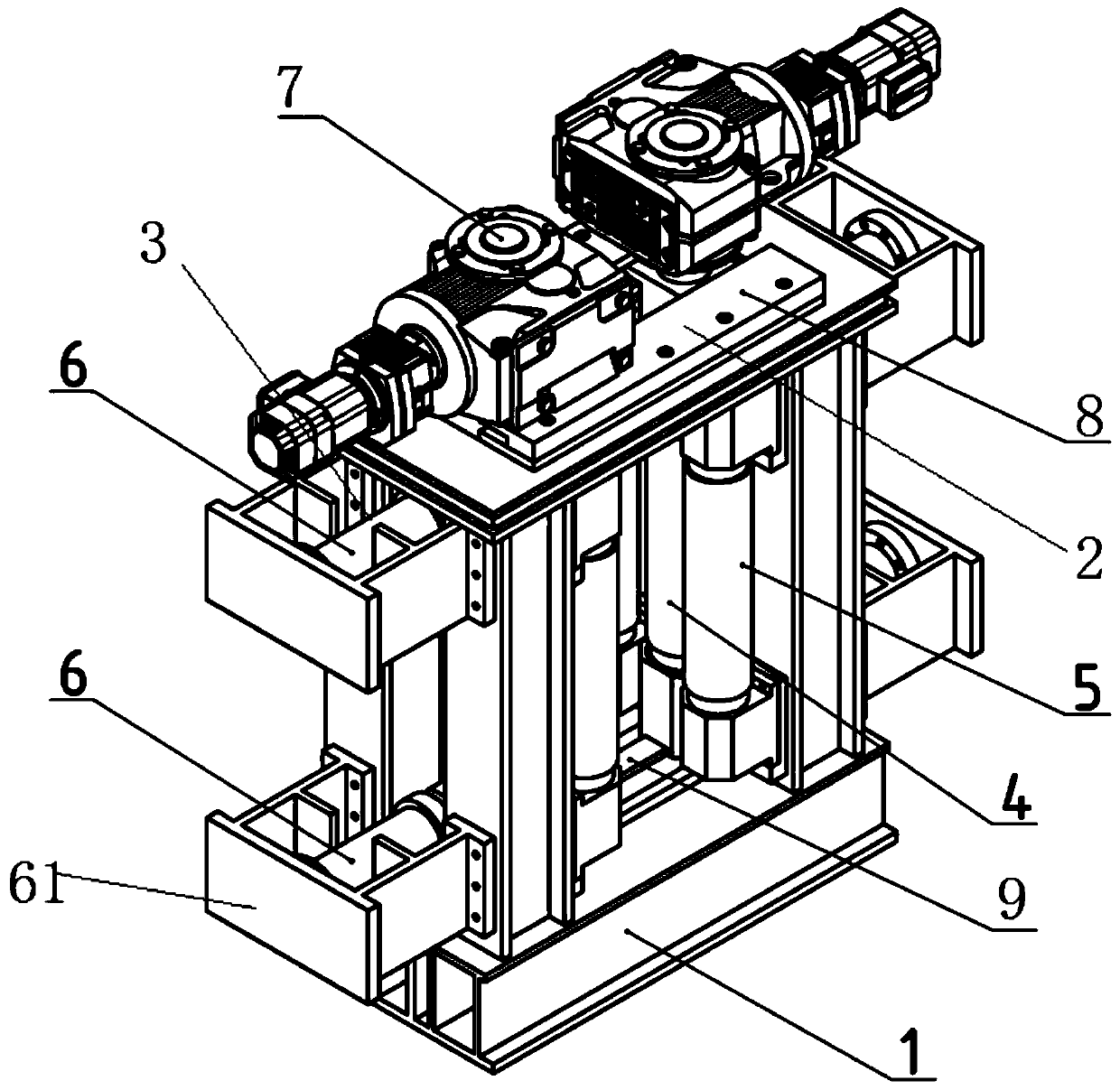

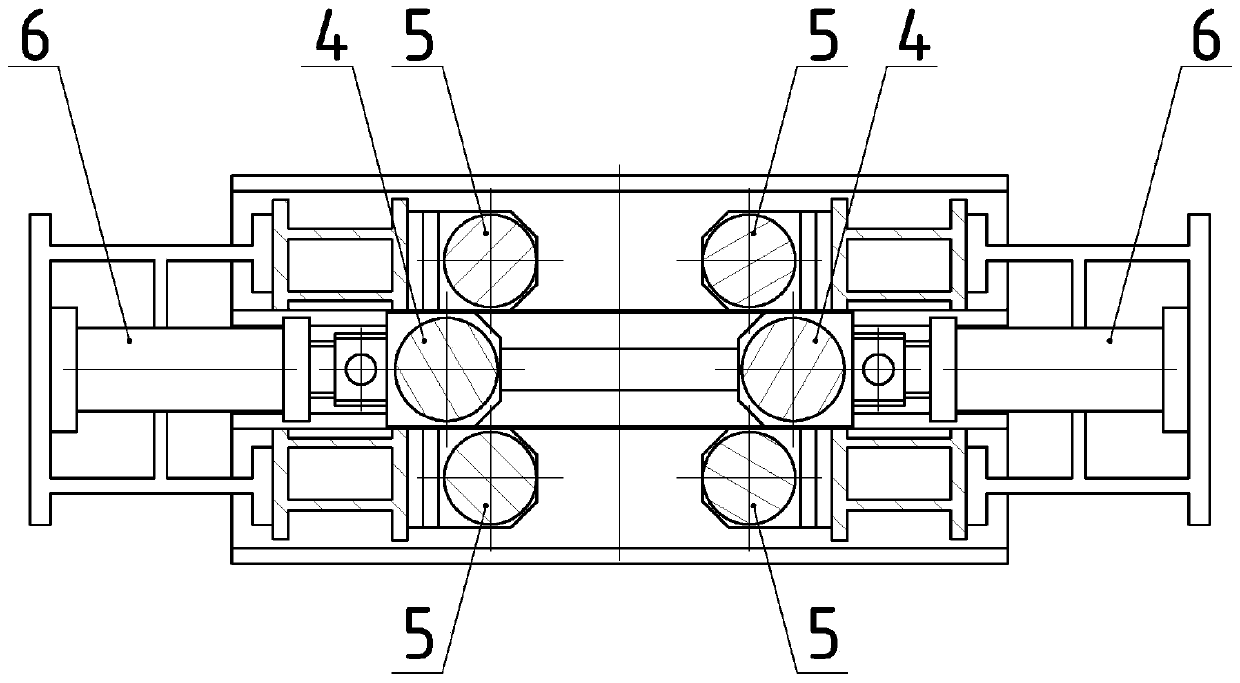

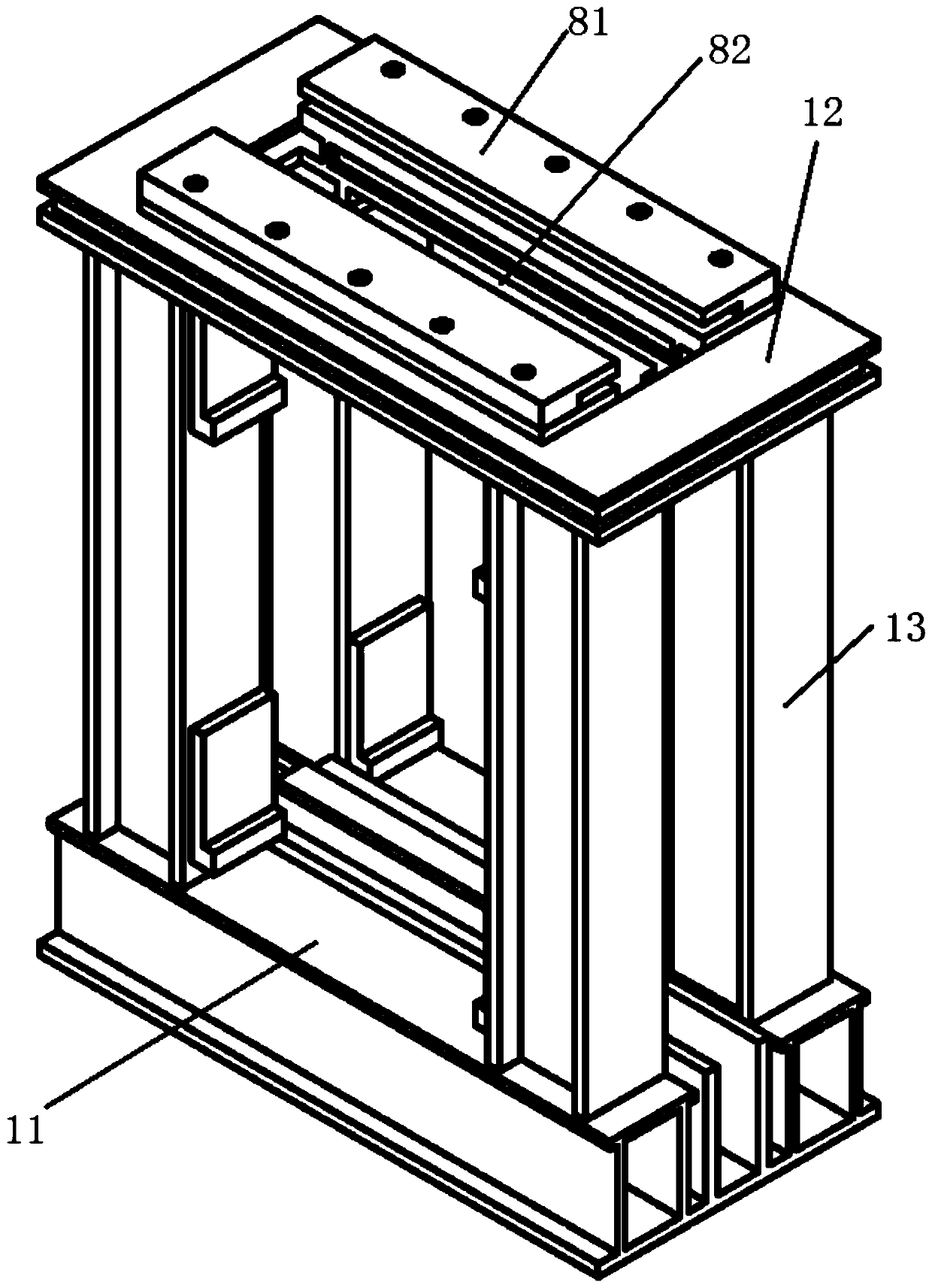

Automatic equipment part clamping mechanism

InactiveCN107139201AAvoid indentationProtect IntegrityProgramme-controlled manipulatorGripping headsSmooth surfaceEngineering

The invention provides a clamping mechanism for automatic equipment parts, which includes an inflator, a rubber hose, a strip air bag, a rubber suction cup and a spring. The upper end of the pipe is connected with the bar-shaped air bag, the bar-shaped air bag is installed in the air bag groove, the lower end of the rubber suction cup is connected with the rubber pad one, the spring upper end is connected with the rubber pad one, and the spring bottom is connected with the rubber pad two. The clamping mechanism produces indentations when clamping the parts, which is beneficial to protect the integrity of the clamped parts, facilitates the clamping of parts with smooth surfaces, and makes the clamping mechanism more powerful in clamping functions.

Owner:SUZHOU FUTENG INTELLIGENT TECH CO LTD

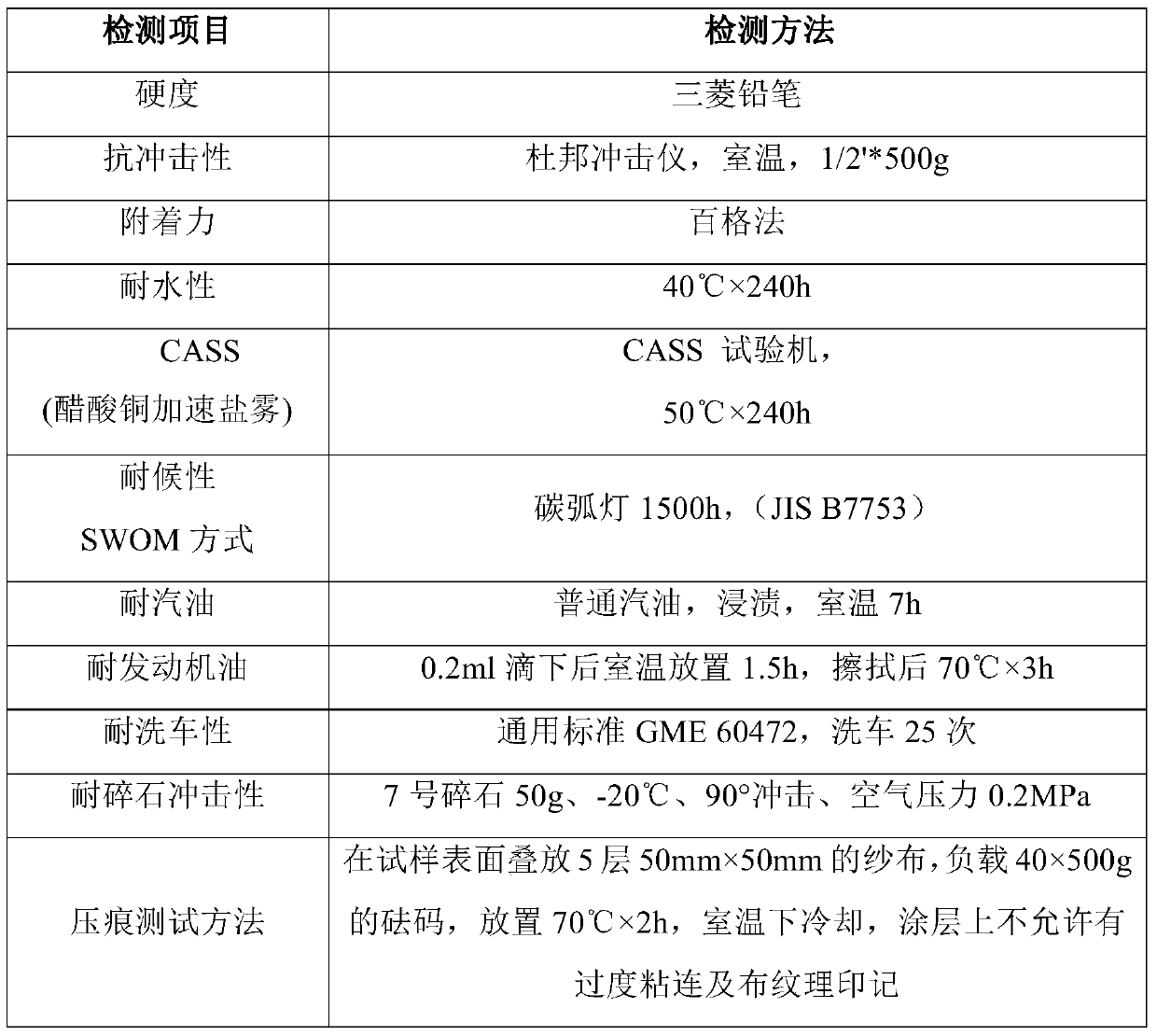

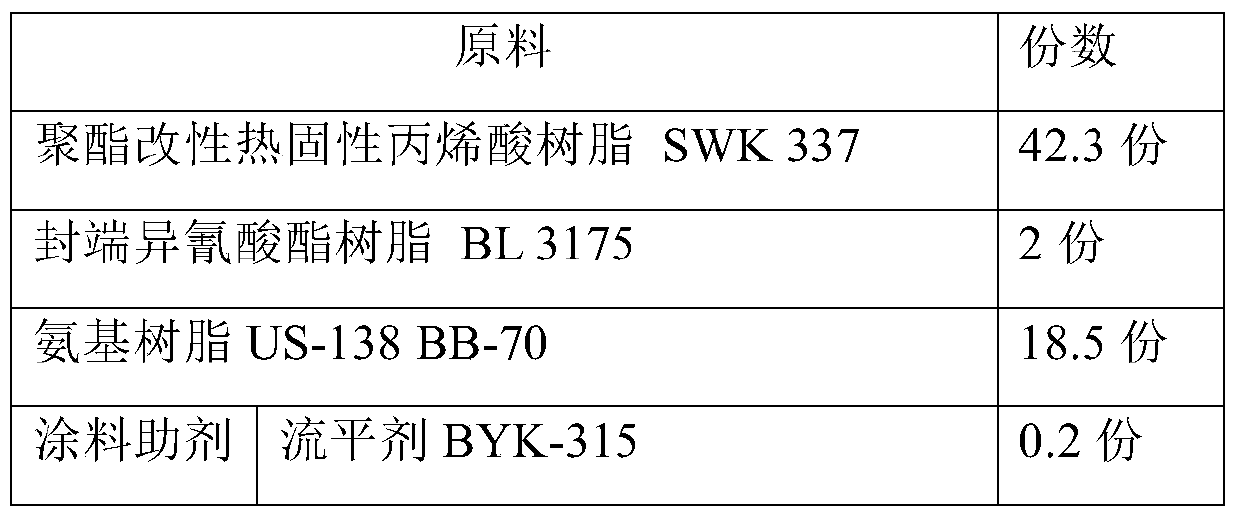

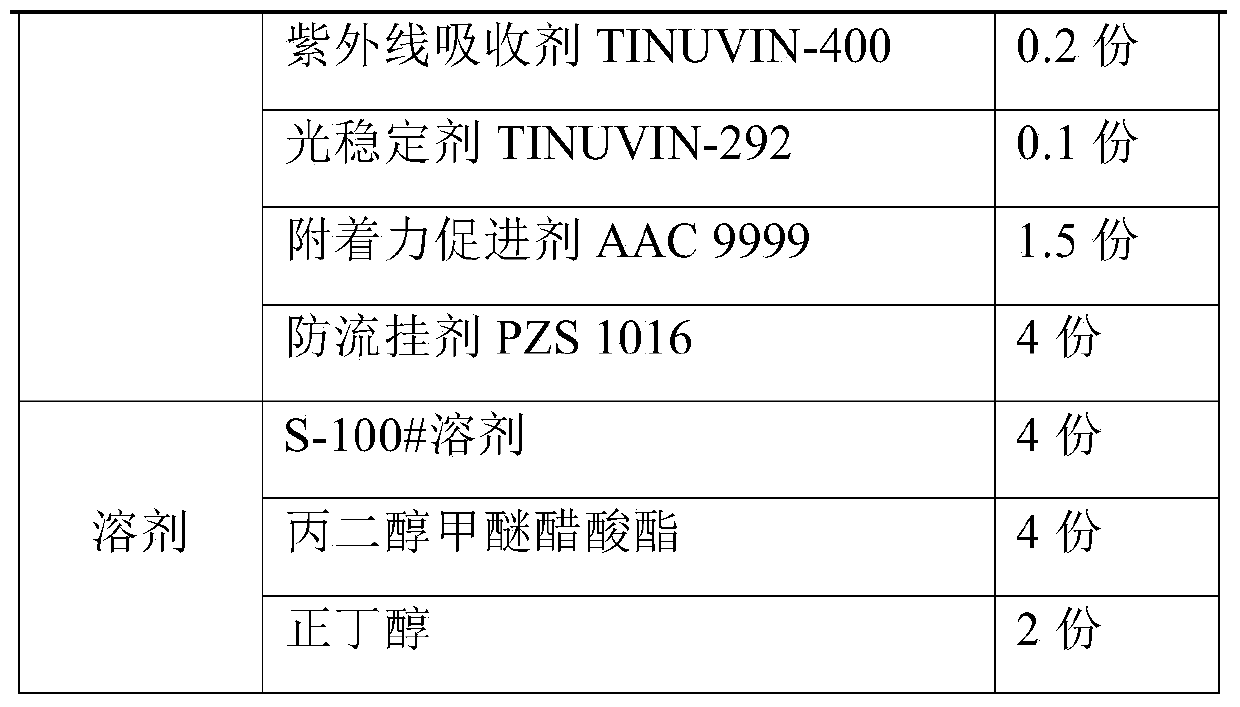

Anti-indentation amino baking paint and preparation method thereof

ActiveCN105505067AImprove product qualification rateSolve indentationPolyester coatingsSolventPolyester

The invention discloses anti-indentation amino baking paint which can be applied to automobile hub glazing coating and a preparation method of the anti-indentation amino baking paint. The anti-indentation amino baking paint is mainly prepared from, by weight, 42-55 parts of polyester-modified thermosetting acrylic resin, 2-3 parts of end-sealed isocyanate resin, 18-22 parts of amino resin, 6-8 parts of an auxiliary and 10.0-20.0 parts of solvent. The anti-indentation amino baking paint is mainly applied to automobile hub glazing coating, the polyester-modified thermosetting acrylic resin and the amino resin are taken as reaction main bodies to react with each other to generate the amino baking paint of which the pencil hardness can reach 2H, therefore, the hub surface indentation problem caused by stacking and extruding after automobile hub coating is offline can be effectively solved, and the product qualification ratio of an automobile hub manufacturing enterprise is increased. The anti-indentation amino baking paint is simple in preparation technology and suitable for industrialized production.

Owner:LANGFANG NIPPON PAINT +1

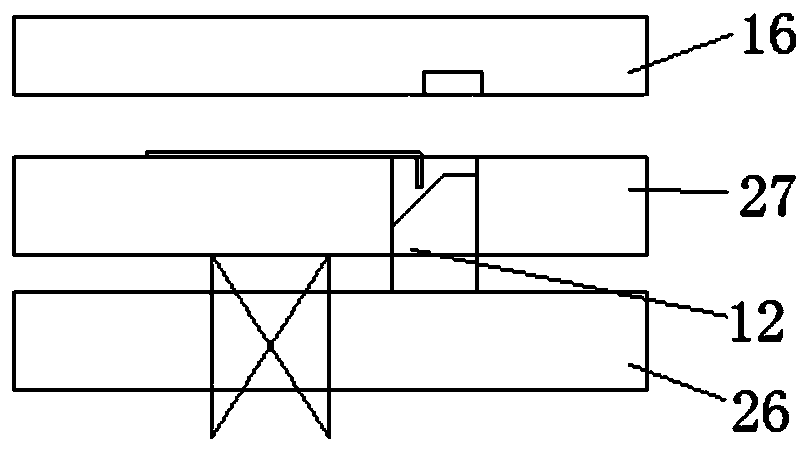

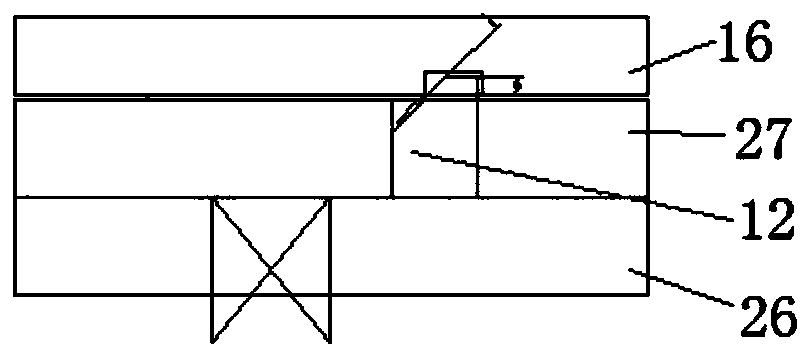

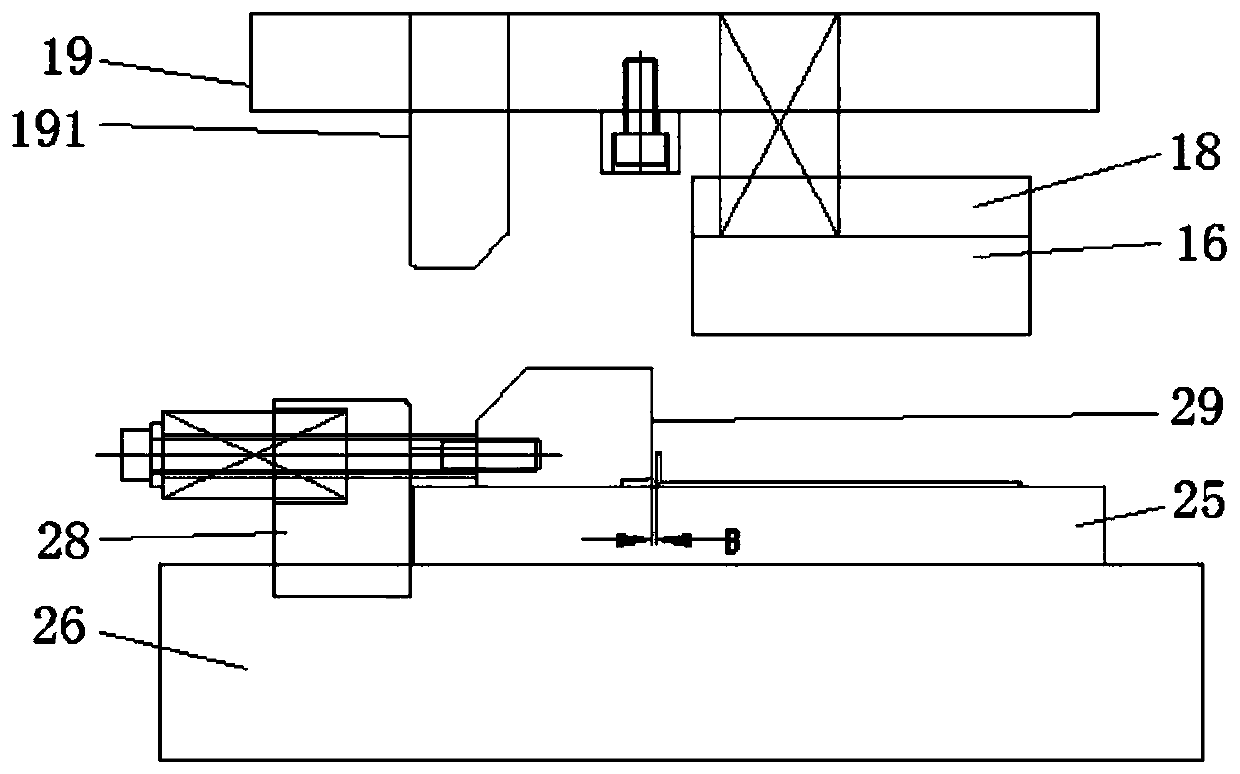

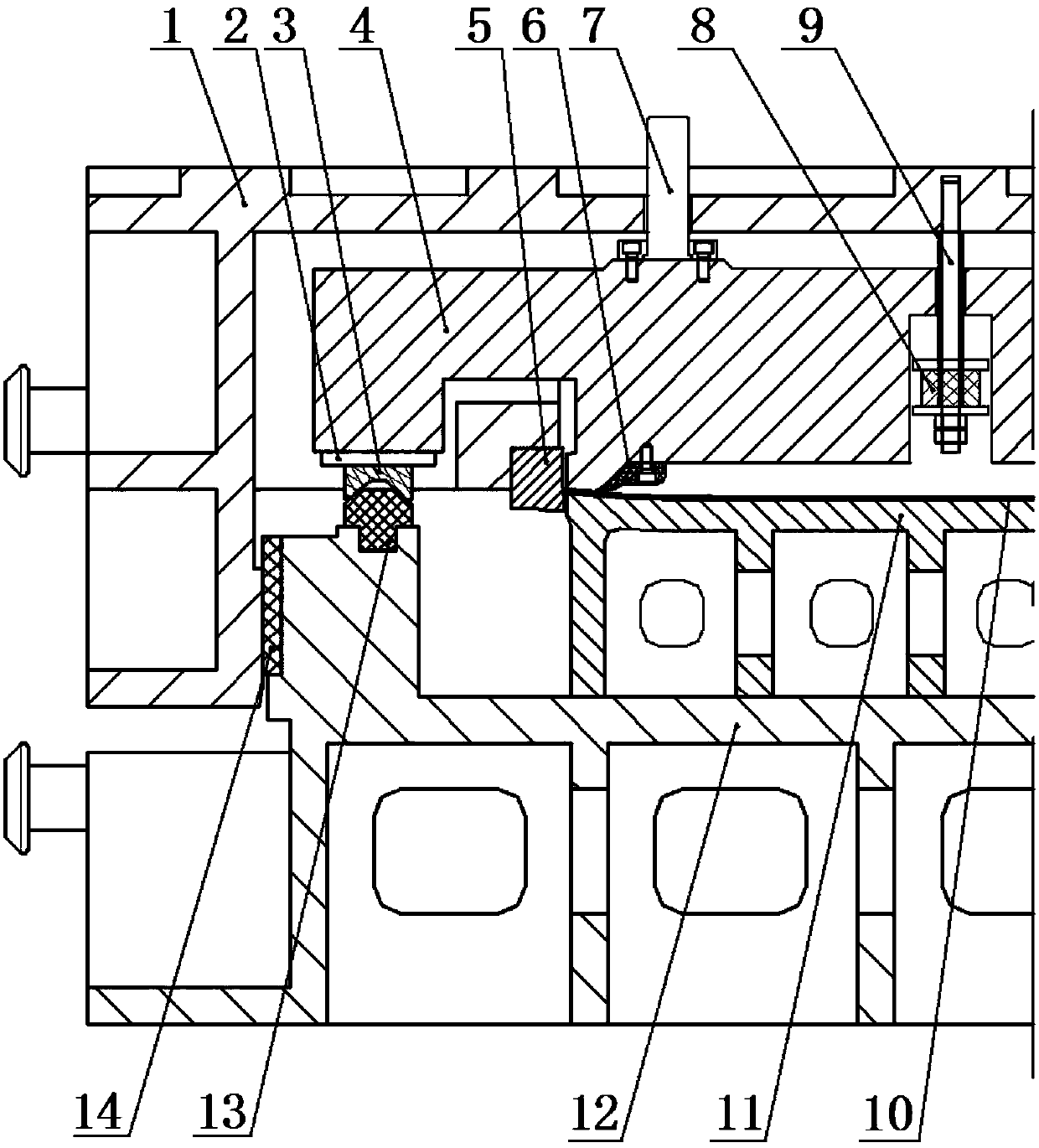

Polishing equipment for optical glass mirror surface

InactiveCN112454072APlay a limiting roleAvoid breakingOptical surface grinding machinesGrinding drivesPolishingEngineering

The invention discloses polishing equipment for an optical glass mirror surface. The polishing equipment comprises a base, an automatic polishing device is arranged between the top of a supporting frame and an inner cavity, second conveying devices are symmetrically arranged on the opposite sides of first fixing blocks, first conveying devices are arranged on the opposite sides of second fixing blocks, and automatic adsorption devices are arranged in the middles of the first fixing blocks and on a top support of the base. The invention relates to the technical field of glass polishing. According to the polishing equipment for the optical glass mirror surface, the problems that a polishing device of a polishing machine is relatively single, the surface of glass cannot be polished in all directions, the clamping force is required to be considered during clamping, the clamped surface of the glass can be impressed or broken, when feeding and discharging are conducted, moving is conducted manually, the glass can fall off in the carrying process, the body of a person can be injured, and in addition, the polishing efficiency can be greatly reduced through manual feeding and discharging are solved.

Owner:广州鸿科金属材料有限公司

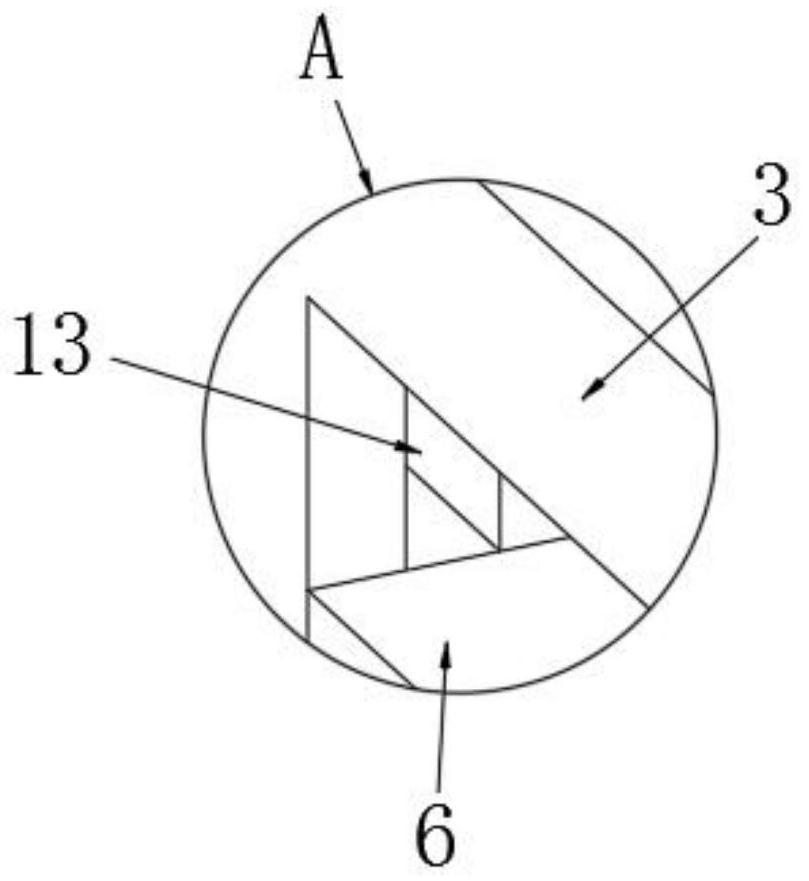

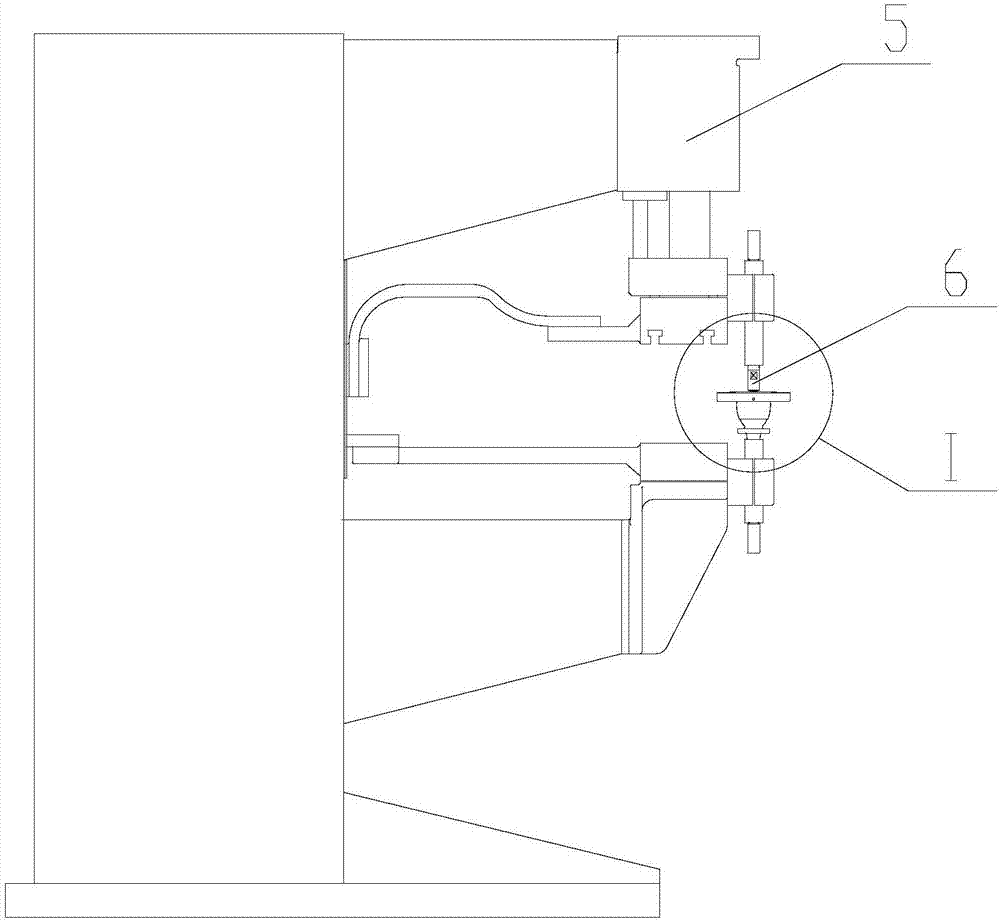

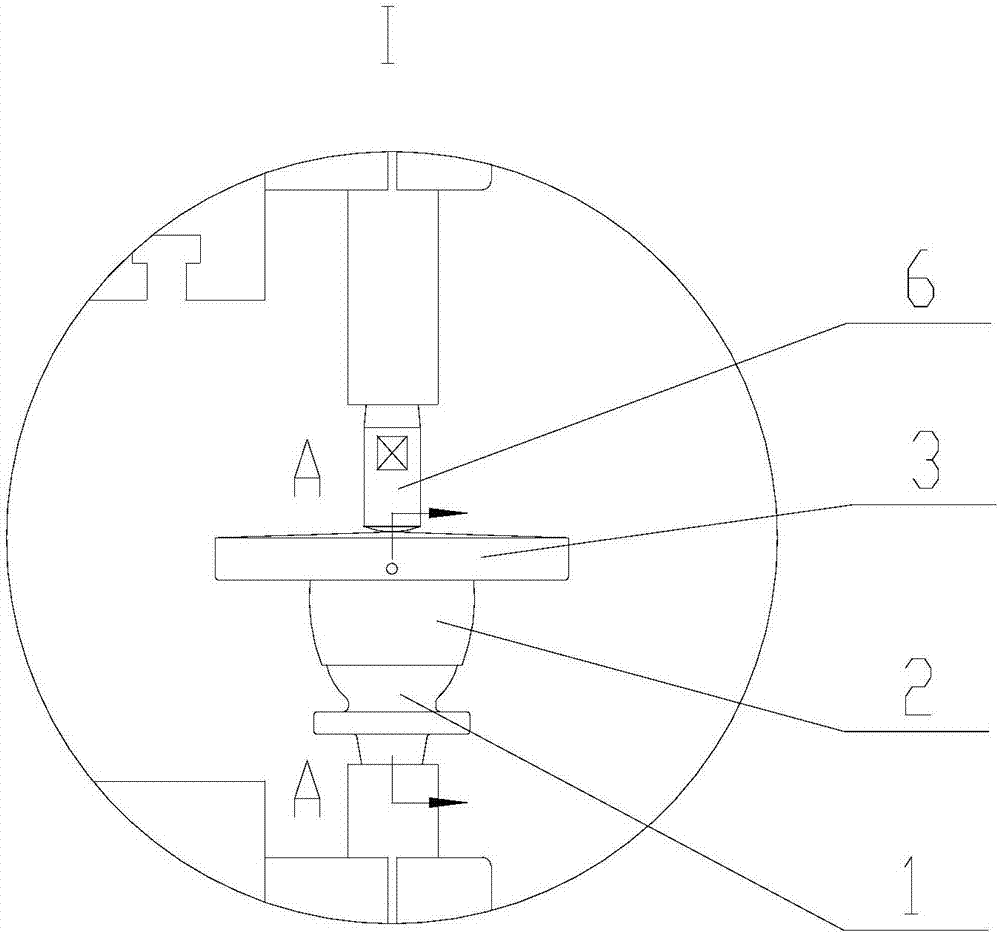

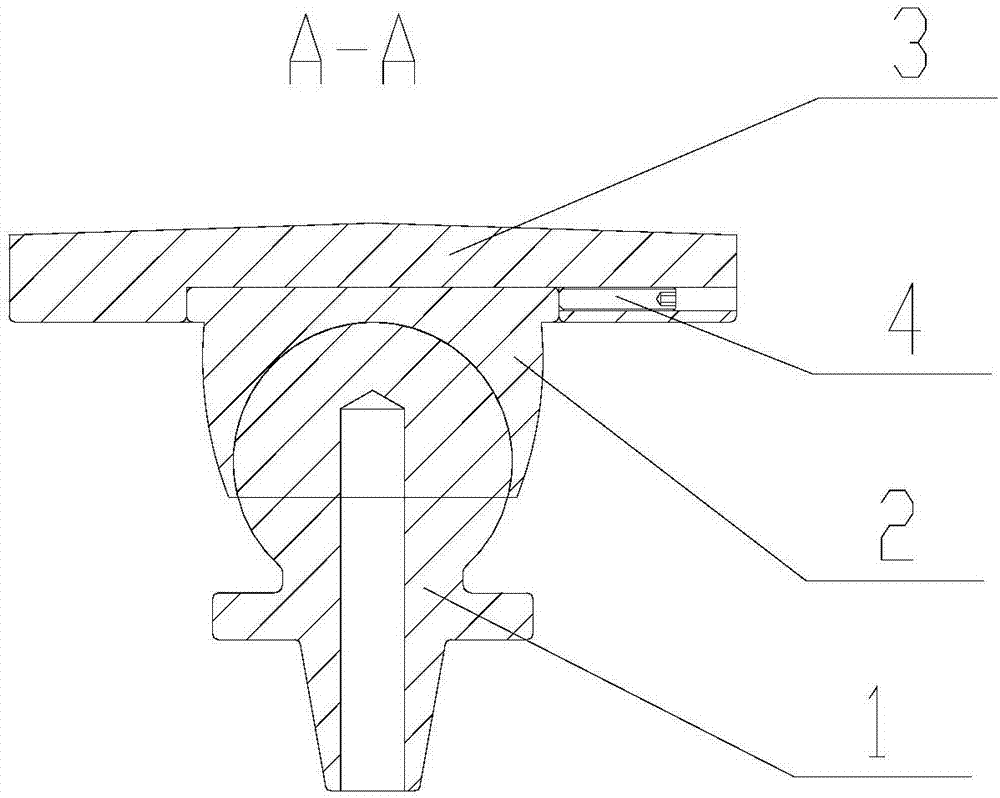

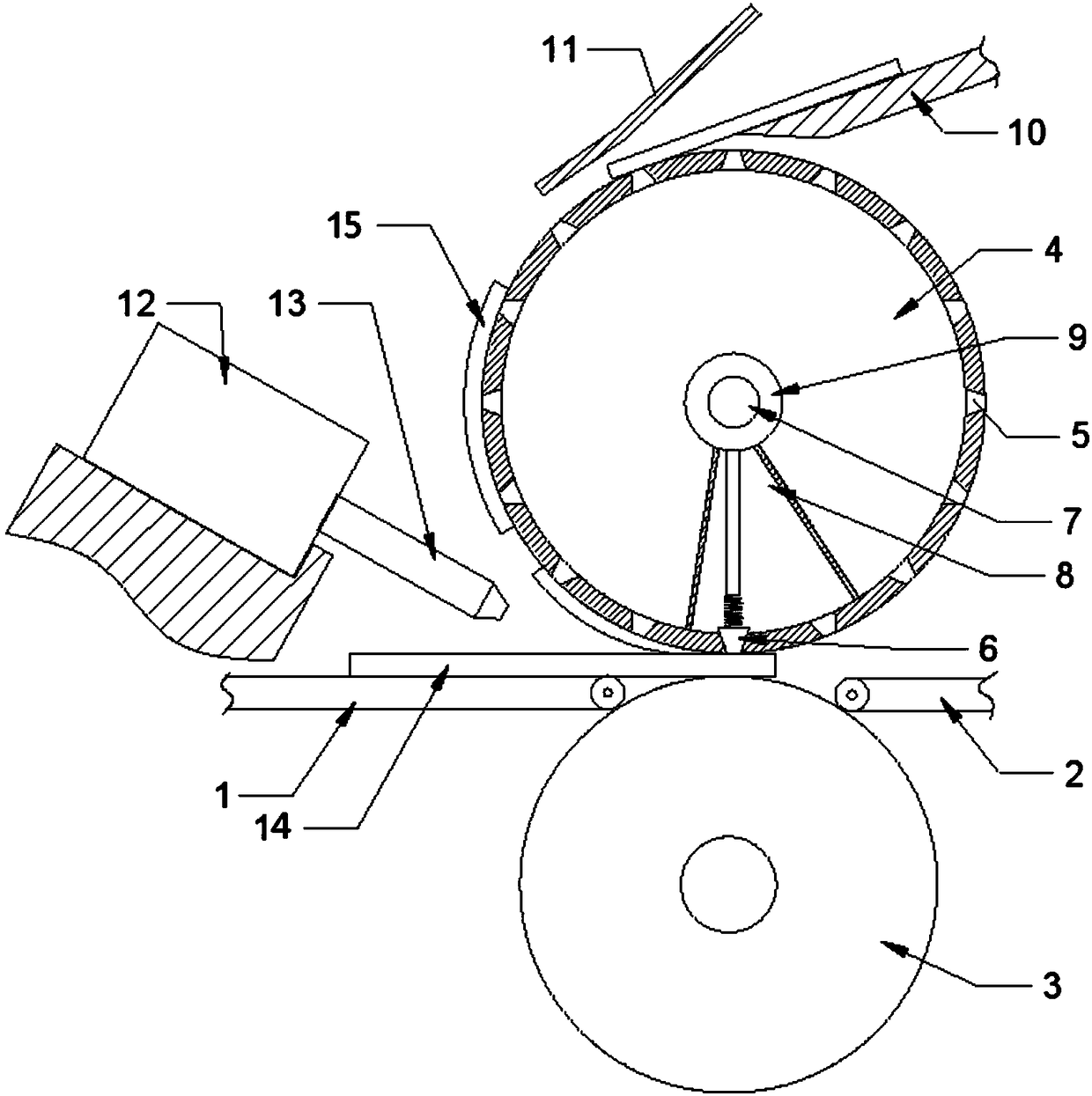

Welding structure of non-indentation universal arc surface electric resistance welding

PendingCN107876955ASolve indentationEasy to processResistance electrode holdersPlanar electrodeElectrical resistance and conductance

The invention relates to a welding structure of non-indentation universal arc surface electric resistance welding. The welding structure is used for electric resistance spot welding of an arc surfacestructure of a roof in a high-speed bullet train and comprises electric resistance spot welding equipment, and an upper electrode holding rod and a lower electrode holding rod are mounted on the upperpart and the lower part of an operating table of the electric resistance spot welding equipment correspondingly; the upper end of the lower electrode holding rod is connected with a universal arc surface lower electrode which comprises a lower electrode universal ball head, an electrode head is arranged on the lower electrode universal ball head, and the lower part of the electrode head is provided with a spherical containing cavity in clearance fit with the electrode universal ball head; and the upper part of the electrode head is provided with an arc surface plate, and the radius of the arcsurface plate is consistent with the radius of the arc surface of the roof in the high-speed bullet train. A traditional spherical surface electrode and a planar electrode are replaced by the universal arc surface lower electrode, the radian of a lining plate on the top of the lower electrode can be replaced according to the product radian, the welding structure is suitable for electric resistance spot welding of products with different radians, the surface has no indentation after welding, the production processing procedure is simplified, the production efficiency is improved, the requirement for skill of an operator is lowered, and the problems of arc surface attaching and indentation are solved.

Owner:KTK GRP

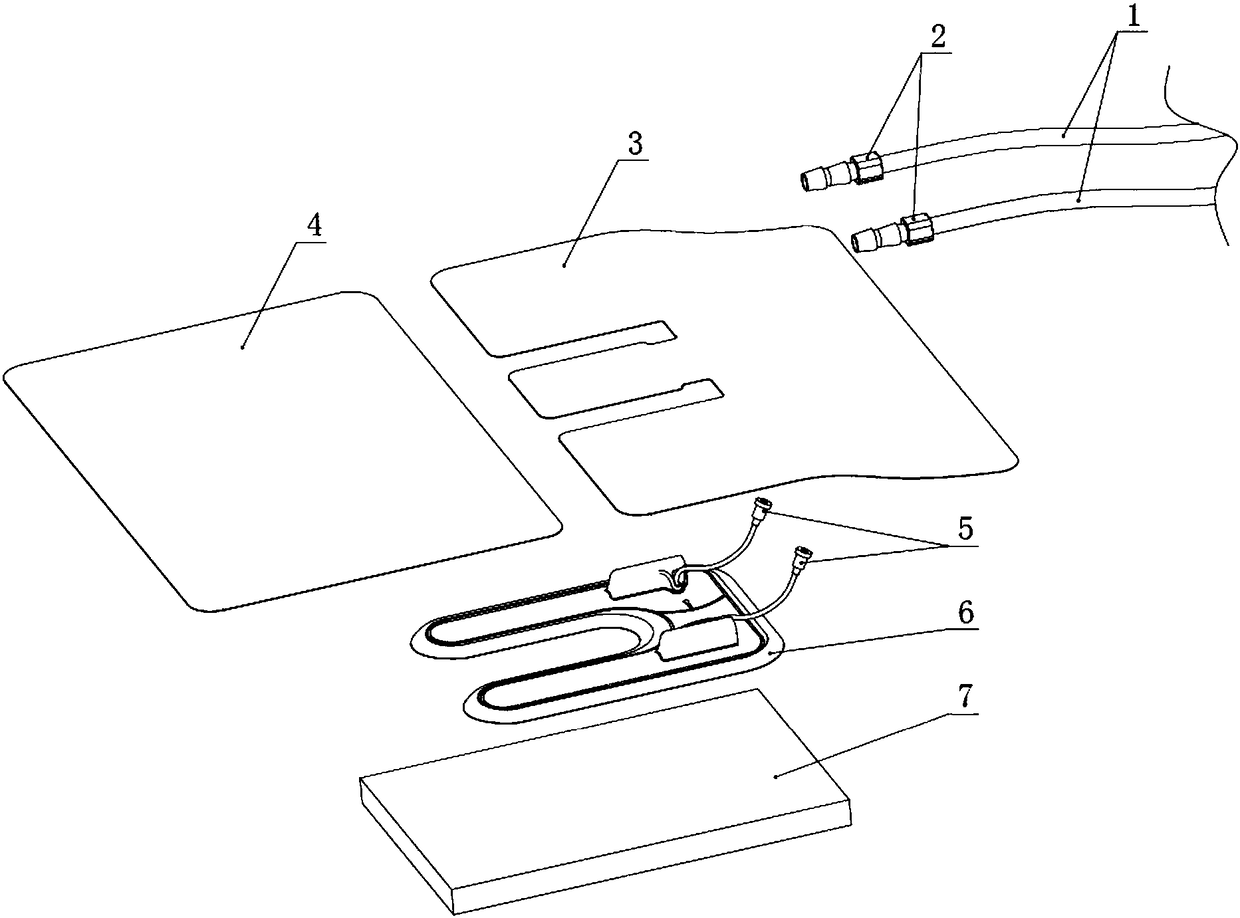

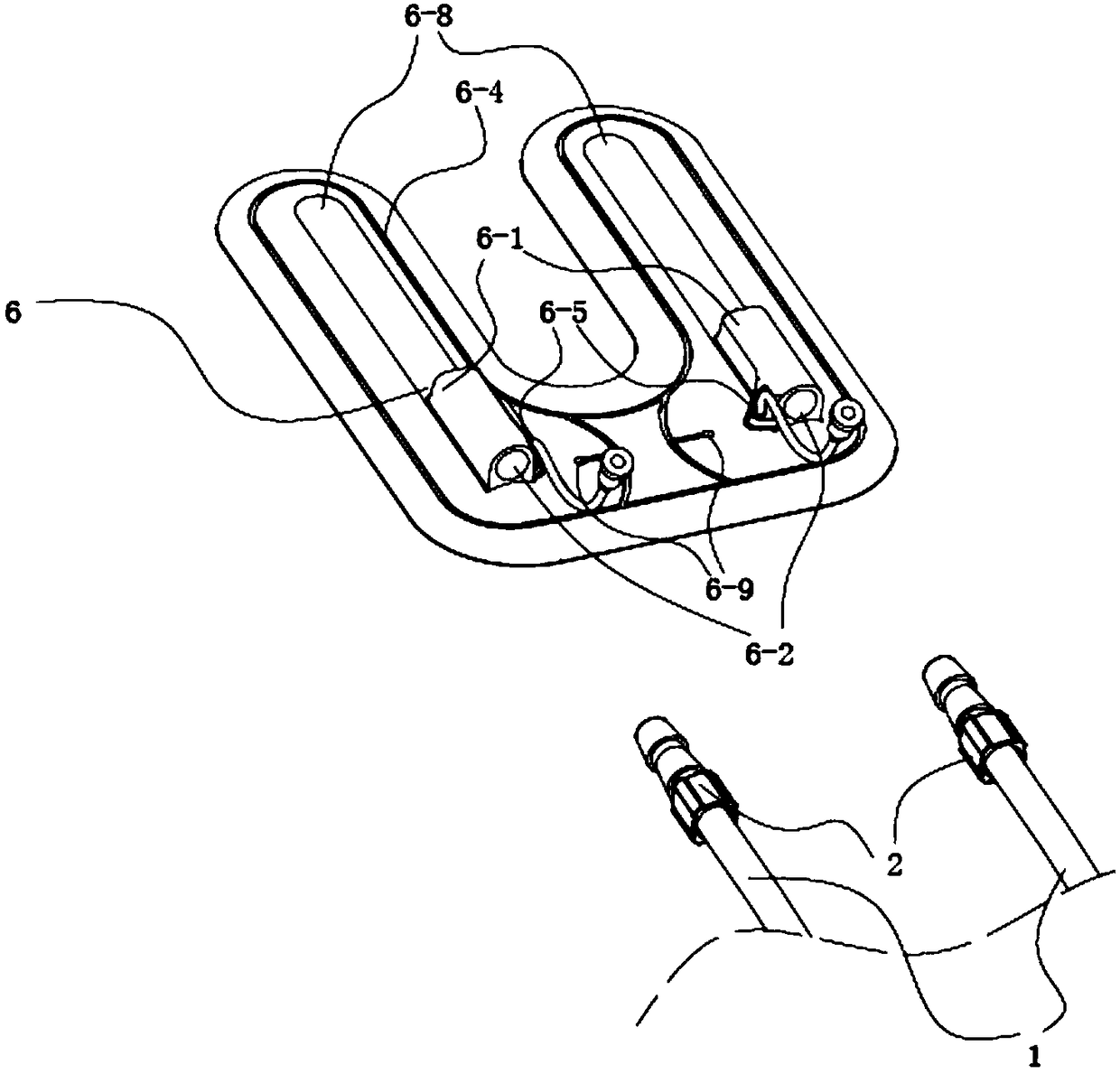

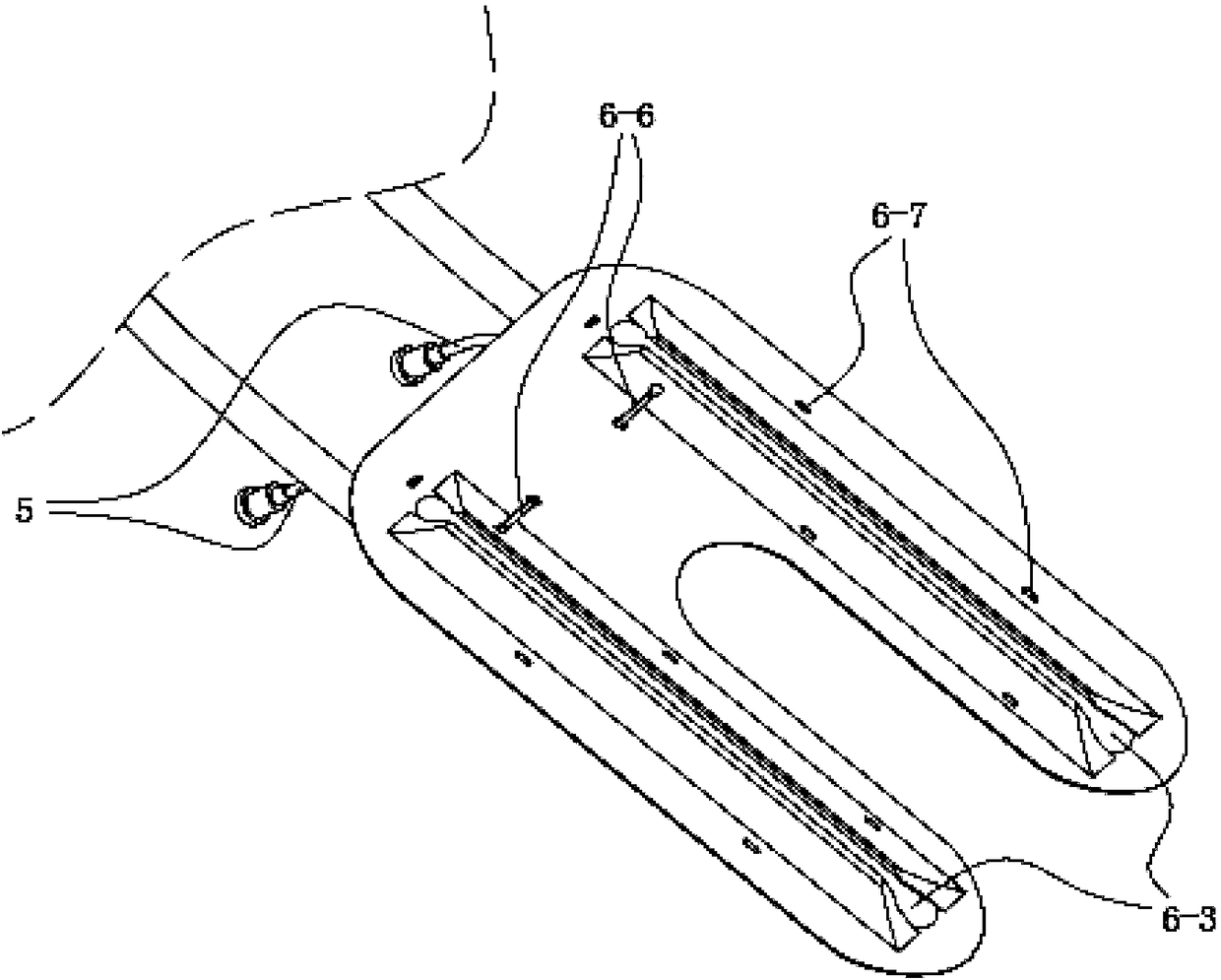

Embedded-type vacuum sealing drainage device for comprehensive washing

PendingCN108378988ASolve indentationEffective flushingMedical devicesAdhesive dressingsWound skinBody contact

The invention discloses an embedded-type vacuum sealing drainage device for comprehensive washing. The embedded-type vacuum sealing drainage device comprises a lower surface and a porous foam body contacting with the wound skin surface of a patient. A flow guide connector is arranged on the upper side of the porous foam body, and is provided with a flow guide channel, a washing channel and a catheter support base. The front end, connected with a liquid collection bottle, of an external drainage pipe is fixed to the catheter support base through a pagoda-shaped joint, and is communicated with the drainage channel. An external washing pipe connected with an external washing liquid storage container is fixed to the catheter support base, and is communicated with the washing channel. A medicalfilm arranged on the upper side of the flow guide connector seals the flow guide connector, the porous foam body and the skin of the patient. The embedded-type vacuum sealing drainage device has theadvantages that exudates of a to-be-drained region is drained actively, continuously and efficiently through external negative pressure, the wound surface is enabled to be in a zero-gathering environment, and secondary absorption of organism toxin is reduced; sponge and the wound surface are washed comprehensively and continuously by washing liquid, and indentations are avoided without reduction of drainage effect when the wound surface is treated for a long time.

Owner:WUHAN VSD MEDICAL SCI & TECH CO LTD

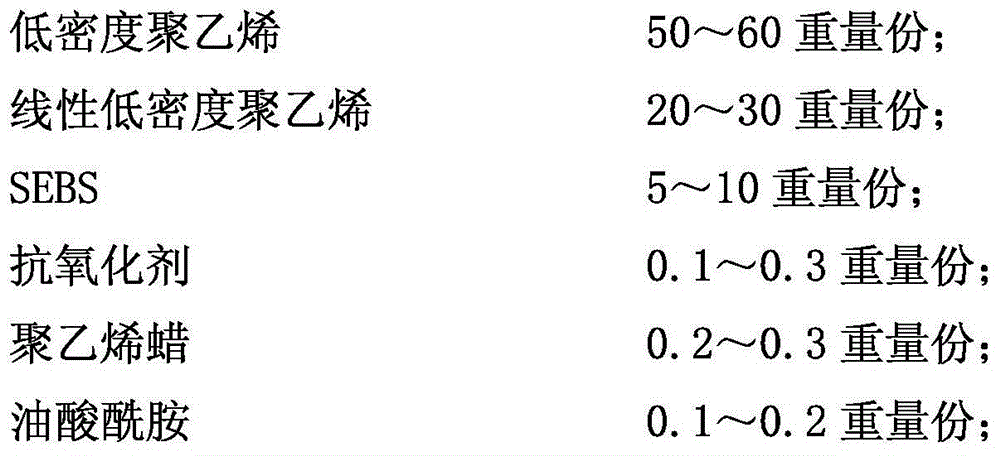

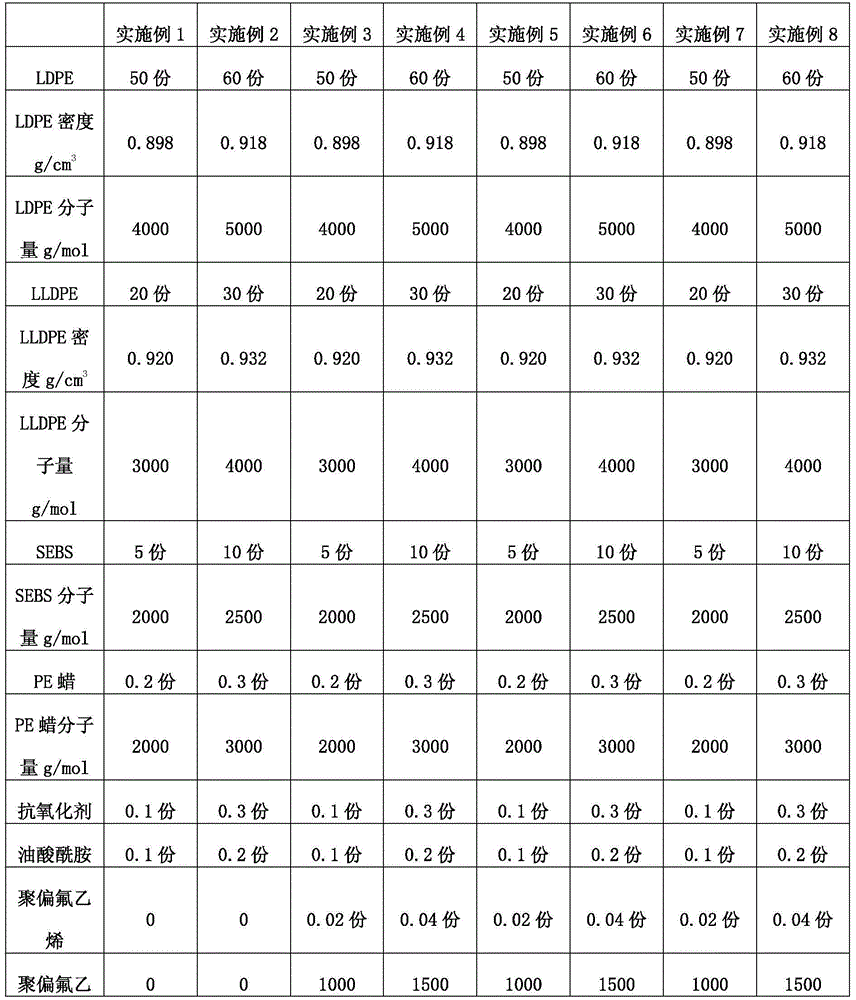

Formula for special protective film of brushed aluminum plate

ActiveCN104788774AReduce risk of precipitationSolve indentationLow-density polyethyleneTectorial membrane

The invention discloses a formula for a special protective film of a brushed aluminum plate. The formula comprises the following materials in parts by weight: 50-60 parts of low-density polyethylene, 20-30 parts of linear low-density polyethylene, 5-10 parts of SEBS, 0.1-0.3 part of an antioxidant, 0.2-0.3 part of polyethylene wax, and 0.1-0.2 part of oleamide. Through the adoption of the elasticity and self adhesive force of SEBS, the problem of glue residues on a glue coating film is effectively solved, and the problems of indentation, scratch, pollution and the like appearing in a stamping process of the brushed aluminum plate are solved; through the addition of the polyethylene wax, the protective film can be quicker and more convenient to form and easy to peel off, so that the sticky phenomenon after stamping of the brushed aluminum sheet is prevented, that is, not only can the stickiness be kept, but also the protective film can be conveniently tore down; through the introduction of a composite antioxidant in the formula, the ageing-resistant performance of the protective film is greatly improved, and the weathering-resistant performance of the brushed aluminum plate is improved. Therefore, the protective film is more durable.

Owner:昆山金华安电子科技有限公司

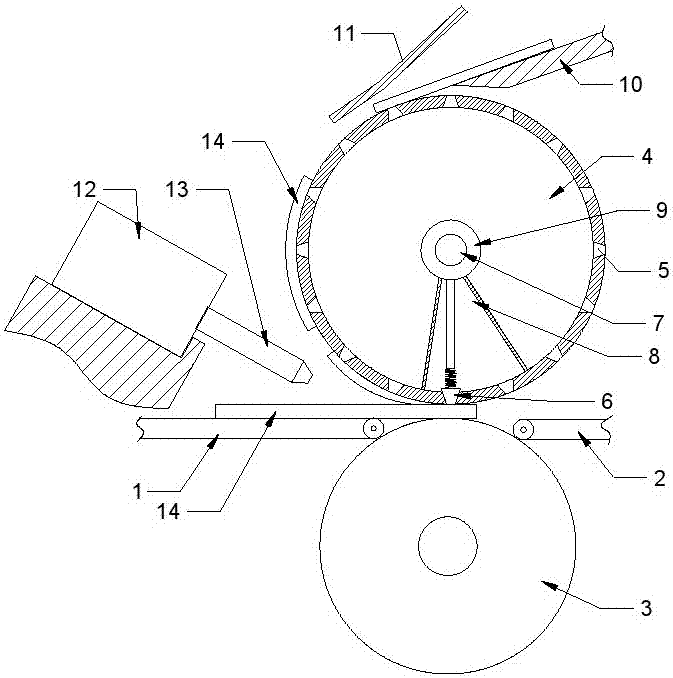

Device for attaching nameplate to keyboard shell

The invention relates to a device for attaching a nameplate to a keyboard shell. An attaching mechanism is embedded between conveying belts and comprises a fixed pressing roller and a conveying roller abutting against the fixed pressing roller. The contact surface between the fixed pressing roller and the conveying roller is located on the same plane with the upper surfaces of the conveying belts. The interior of the conveying roller communicates with negative pressure, and through holes are formed in the circumferential wall of the conveying roller. The conveying roller is fixedly mounted on a rotary shaft. The rotary shaft is sleeved with a bearing. A shielding case and a plug block are mounted on the bearing. An opening of the shielding case faces downwards and abuts against the inner wall of the conveying roller, and the abutting portion of the shielding case is of a flexible structure. The plug block is located in the shielding case, and a compression spring is connected between the plug block and the rotary shaft. A conveying mechanism further comprises a conveying trough and a guide plate, and the conveying trough and the guide plate are located above the conveying roller. A heating mechanism comprises a hot air cylinder, wherein a nozzle is arranged on the hot air cylinder, and the nozzle faces the space between the fixed pressing roller and the conveying roller. By implementing the scheme, the effect of attaching the nameplate without bonding is achieved.

Owner:邳州市景鹏创业投资有限公司

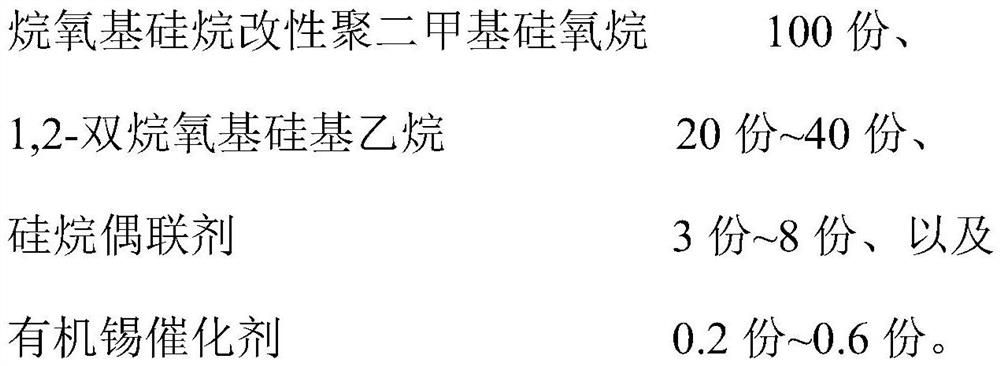

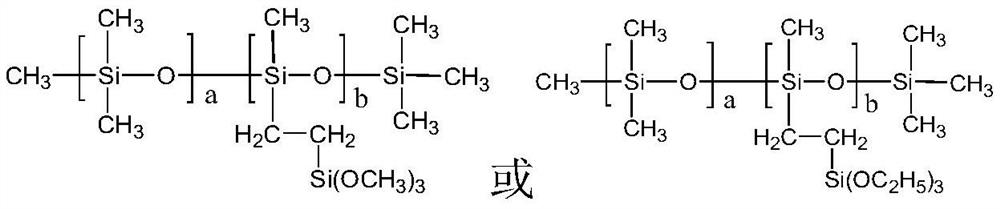

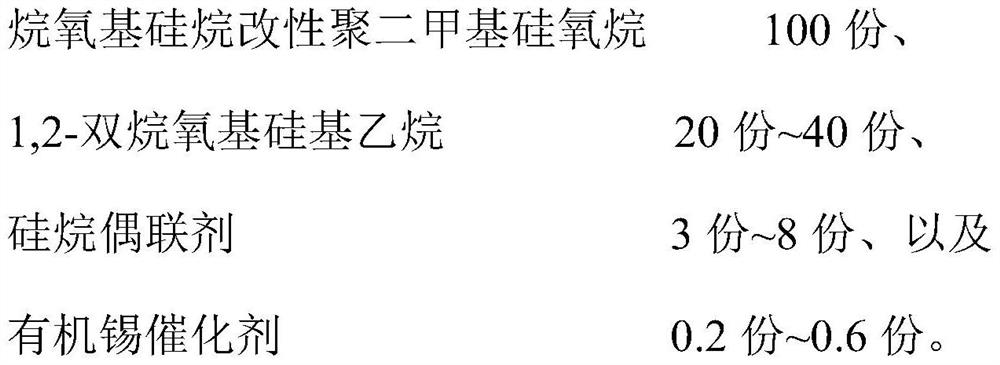

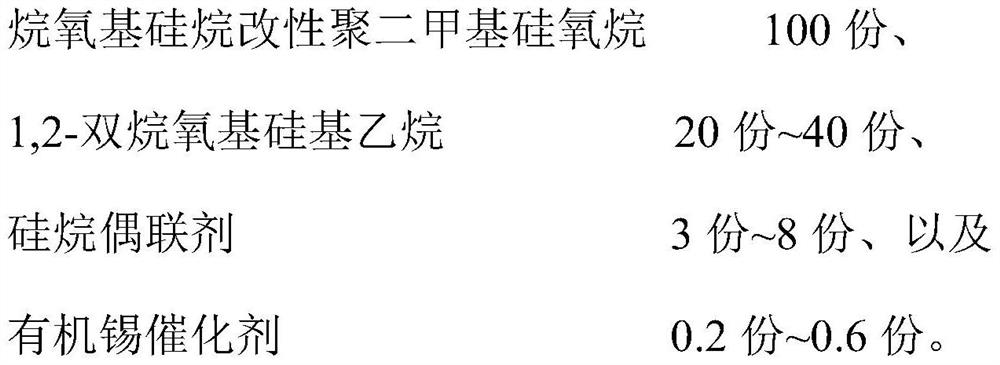

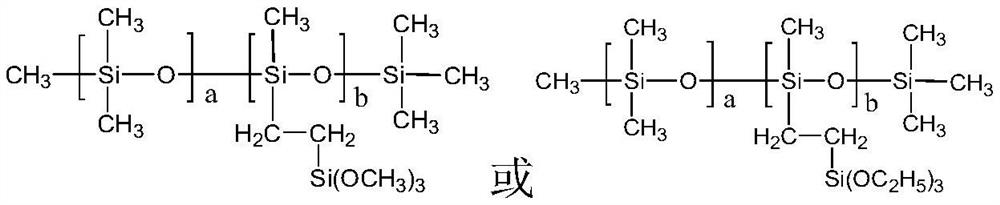

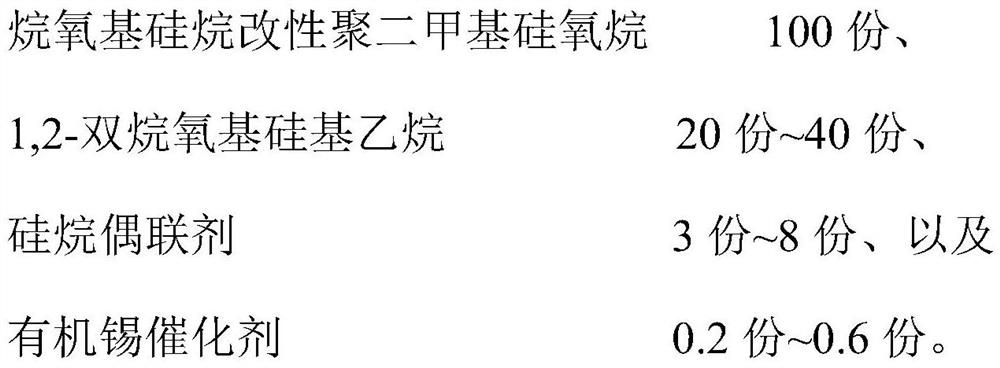

Double-component organic silicon packaging adhesive as well as preparation method and application thereof

ActiveCN112724925AHigh viscositySolve indentationNon-macromolecular adhesive additivesSemiconductor devicesPolymer sciencePtru catalyst

The invention relates to a two-component organic silicon packaging adhesive as well as a preparation method and application thereof. The double-component organic silicon packaging adhesive comprises a component A and a component B, wherein the component A is prepared from the following components in parts by mass: 100 parts of hydroxyl-terminated polydimethylsiloxane and 10 to 30 parts of methyl MQ silicon resin; and the component B is prepared from the following components in parts by mass: 100 parts of alkoxy silane modified polydimethylsiloxane, 20 to 40 parts of 1, 2-dialkoxy silyl ethane, 3 to 8 parts of a silane coupling agent and 0.2 to 0.6 part of an organic tin catalyst. The double-component organic silicon packaging adhesive can keep high transparency under the condition that the viscosity difference between the component A and the component B is small, and deep curing is fast.

Owner:GUANGZHOU BAIYUN CHEM IND

The device for attaching the keyboard shell to the nameplate

ActiveCN106976615BDifficult to clean upAvoid being re-adsorbedLabelling machinesEngineeringNameplate

The invention relates to a device for attaching a nameplate to a keyboard shell. An attaching mechanism is embedded between conveying belts and comprises a fixed pressing roller and a conveying roller abutting against the fixed pressing roller. The contact surface between the fixed pressing roller and the conveying roller is located on the same plane with the upper surfaces of the conveying belts. The interior of the conveying roller communicates with negative pressure, and through holes are formed in the circumferential wall of the conveying roller. The conveying roller is fixedly mounted on a rotary shaft. The rotary shaft is sleeved with a bearing. A shielding case and a plug block are mounted on the bearing. An opening of the shielding case faces downwards and abuts against the inner wall of the conveying roller, and the abutting portion of the shielding case is of a flexible structure. The plug block is located in the shielding case, and a compression spring is connected between the plug block and the rotary shaft. A conveying mechanism further comprises a conveying trough and a guide plate, and the conveying trough and the guide plate are located above the conveying roller. A heating mechanism comprises a hot air cylinder, wherein a nozzle is arranged on the hot air cylinder, and the nozzle faces the space between the fixed pressing roller and the conveying roller. By implementing the scheme, the effect of attaching the nameplate without bonding is achieved.

Owner:邳州市景鹏创业投资有限公司

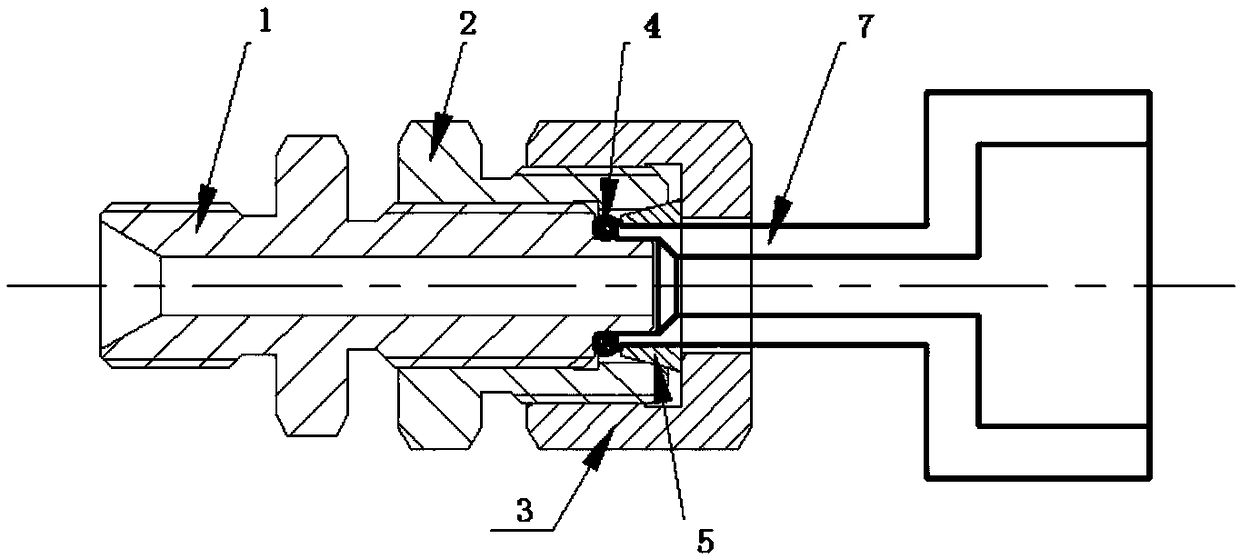

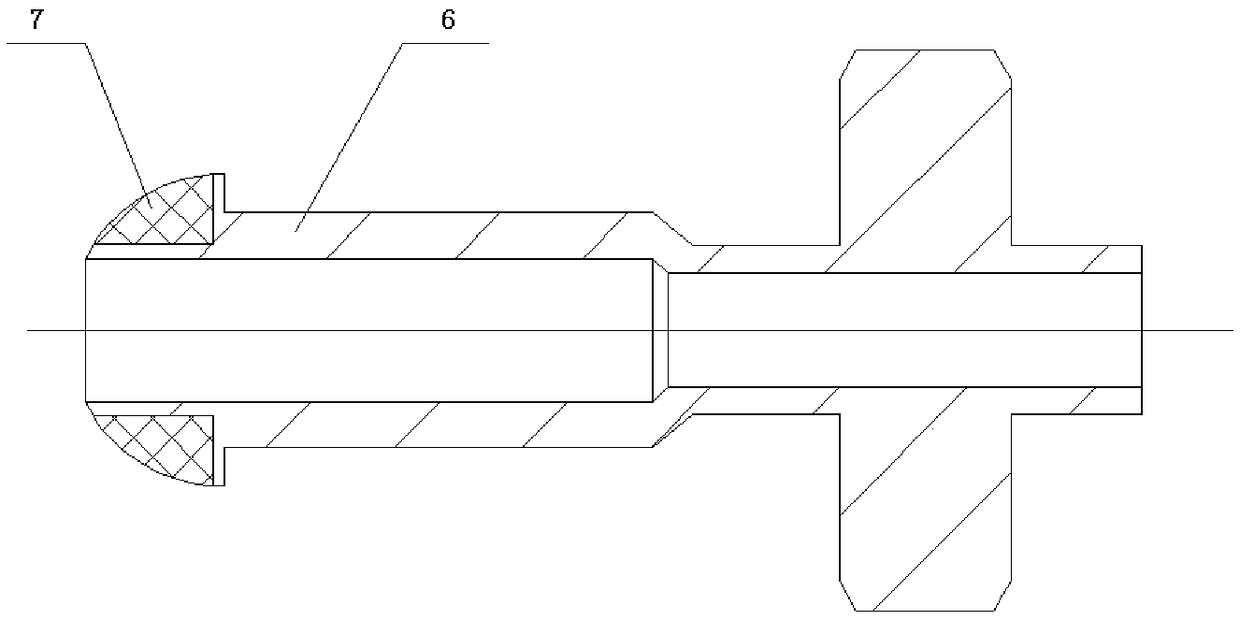

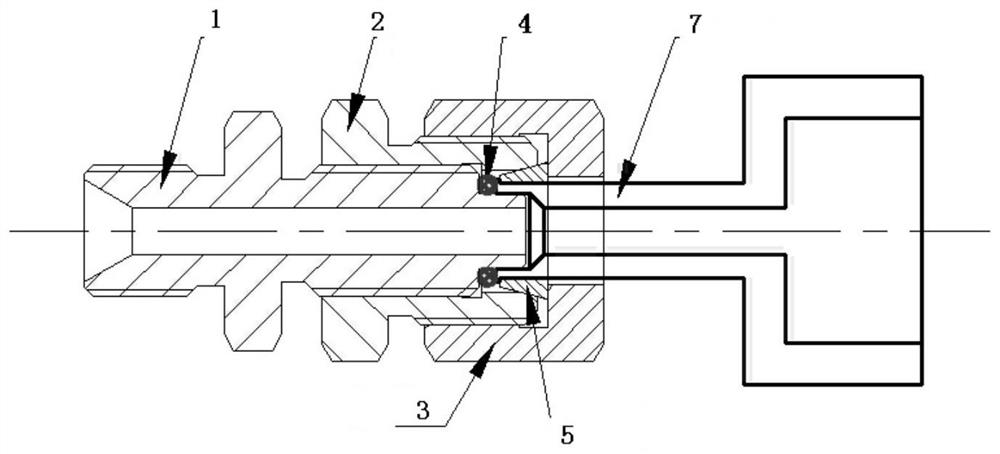

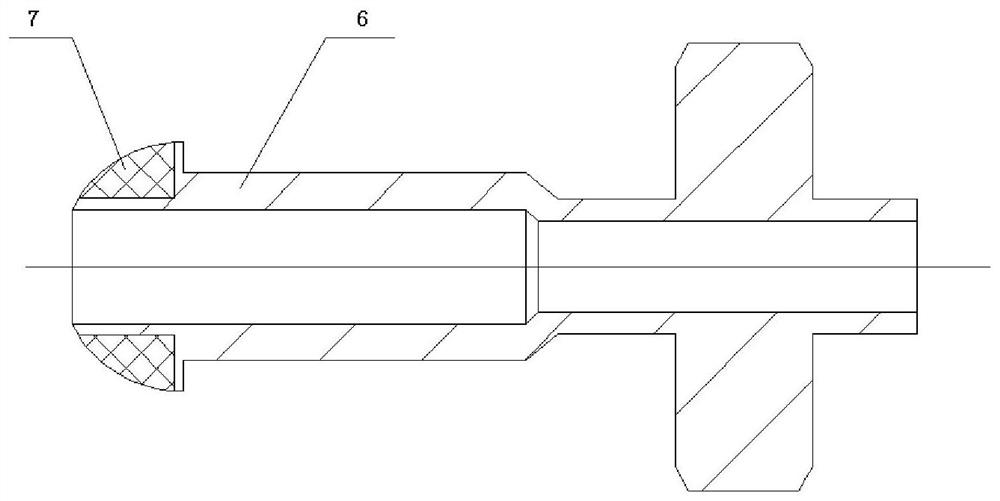

Adapter device for special-shaped connector of special aerospace valve

ActiveCN109340479ATroubleshoot transfer issuesFix Damaged NozzlesJoints with sealing surfacesButt jointEngineering

The invention discloses an adapter device for a special-shaped connector of a special aerospace valve. The adapter device for the special-shaped connector of the special aerospace valve comprises a pipe joint nozzle, a screw sleeve, an outer sleeve, a seal ring, a taper sleeve and a seal rod, wherein the pipe joint nozzle is a hollow rotary body; a limiting step is arranged on the outer wall of the right end; external screw threads are arranged at two ends of the outer wall of the pipe joint nozzle; the screw sleeve is screwed onto the outer wall of the right end of the pipe joint nozzle; theright end of the screw sleeve and the right end of the pipe joint nozzle are on the same plane; an embedded cavity is formed between the pipe joint nozzle and the screw sleeve; the small end head of the special-shaped connector is embedded into the embedded cavity; the inner wall of the special-shaped connector at the embedded part fits to the outer wall of the pipe joint nozzle; the limiting stepis in butt joint with a smooth step, and the butt-joint part is sealed by the seal ring; the taper sleeve is of a tapered rotary body structure and is arranged on the right side of the smooth step ofthe small end head of the special-shaped connector; the outer sleeve is screwed onto the outer wall of the screw sleeve; and the taper sleeve is extruded into the embedded cavity. The fixed connection and the cavity communication between the pipe joint nozzle and the special-shaped connector are realized, so that the connection problem of the test of the special aerospace valve with the special-shaped connector is solved.

Owner:CAPITAL AEROSPACE MACHINERY +1

5G part stamping die and stamping method

PendingCN111531036AReduce processReduce the amount of developmentShaping toolsStructural engineeringOblique angle

The invention relates to the technical field of metal plate stamping, and particularly discloses a 5G part stamping die and stamping method. The 5G part stamping die comprises an upper die unit and alower die unit, wherein the upper die unit comprises a guide column, the lower die unit comprises a guide sleeve corresponding to the guide column, and the guide column is in sliding fit with the guide sleeve; the upper die unit further comprises a bending punch obliquely arranged, the lower die unit further comprises a bending assembly, the bending assembly comprises a bending lower die and a first spring arranged at the lower end of the bending lower die, and the bending lower die rebounds under the action of the first spring; and the bending lower die is in an inverted trapezoid shape and comprises an upper supporting face, a lower connecting face, a left sliding face and a right bending face, and the obliquely-arranged angle of the bending punch is the same as the oblique angle of theright bending surface. According to the 5G part stamping die and stamping method, the appearance quality, the production reliability and the production stability of stamped parts can be effectively guaranteed, meanwhile, the forming procedure can be favorably simplified, and the production efficiency can be improved.

Owner:WANSHENGXING PRECISION TECH HUIZHOU CO LTD

Mould

InactiveCN109940093AMake up for the defects caused by uneven research and mixingShorten the development cycleShaping toolsMaterials sciencePolyurethane

The invention relates to a mould. The mould comprises a movable upper mould and a still-keeping lower mould, wherein a pressing plate(4) used for pressing workpiece is arranged on the upper mould, anda forming mould(11) used for supporting the workpiece is arranged on the lower mould. The mould is characterized in that the pressing plate(4), at least the pressing area for pressing the workpiece located on the forming mould, is provided with a buffer, wherein the buffer is made of polyurethane.

Owner:BMW BRILLIANCE AUTOMOTIVE

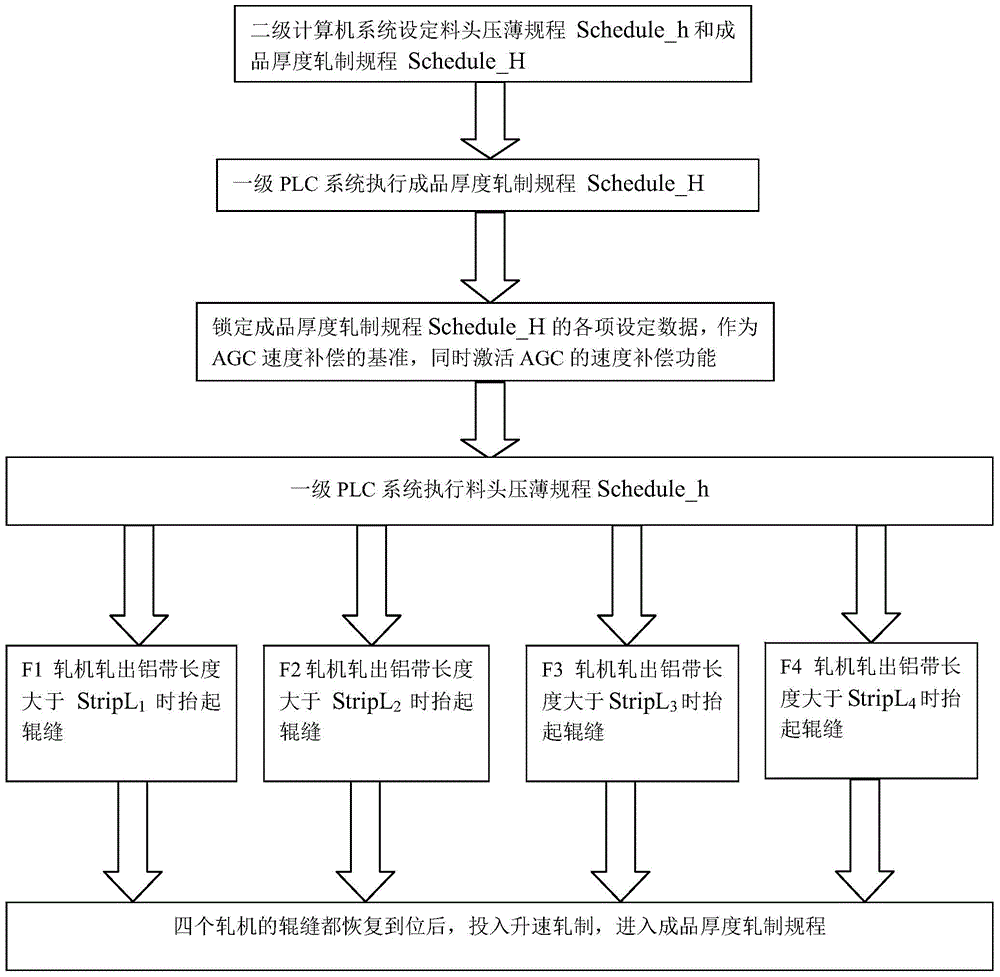

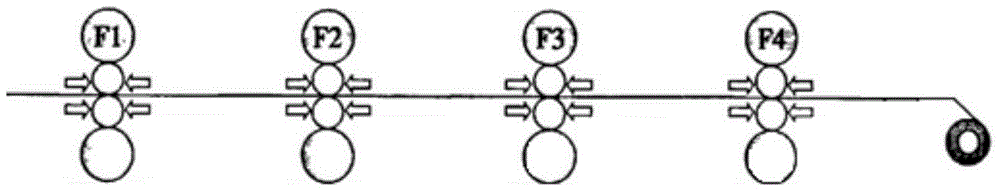

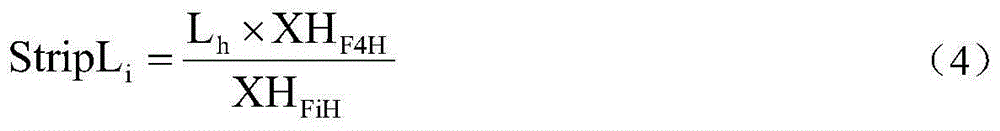

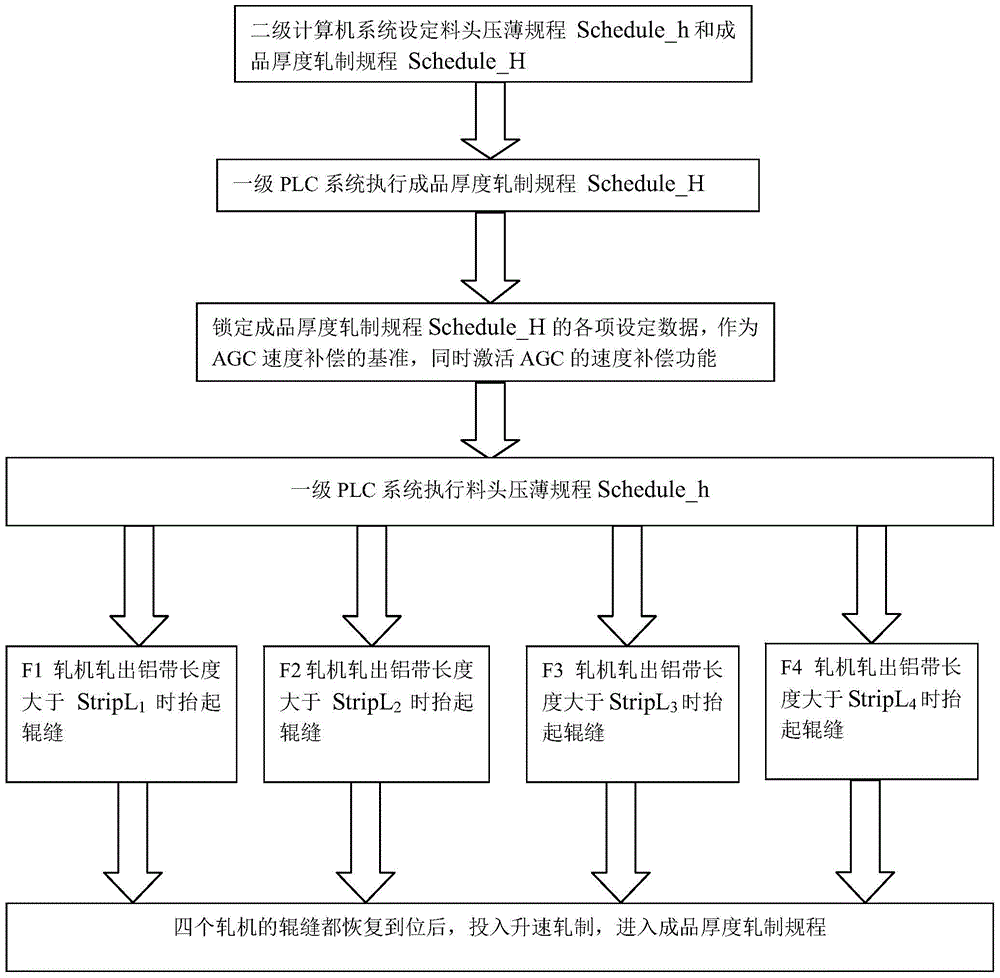

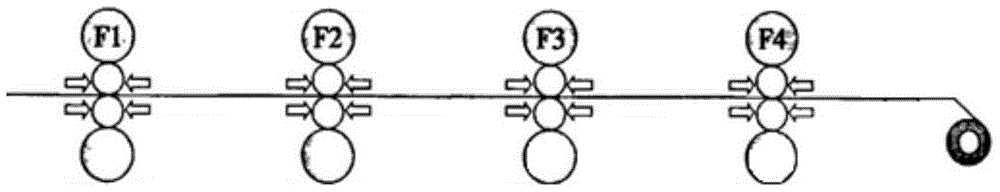

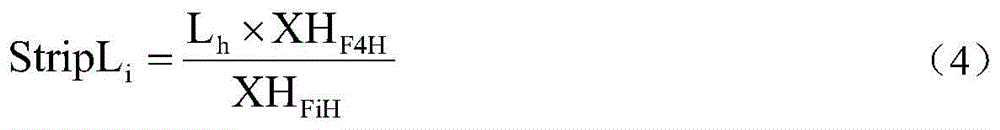

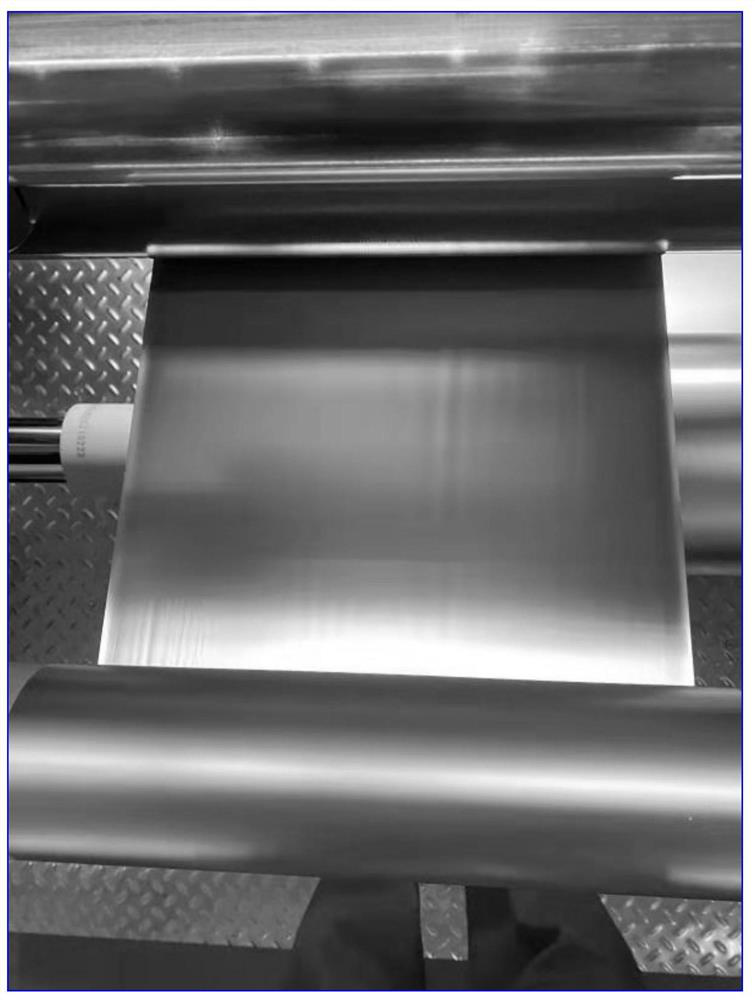

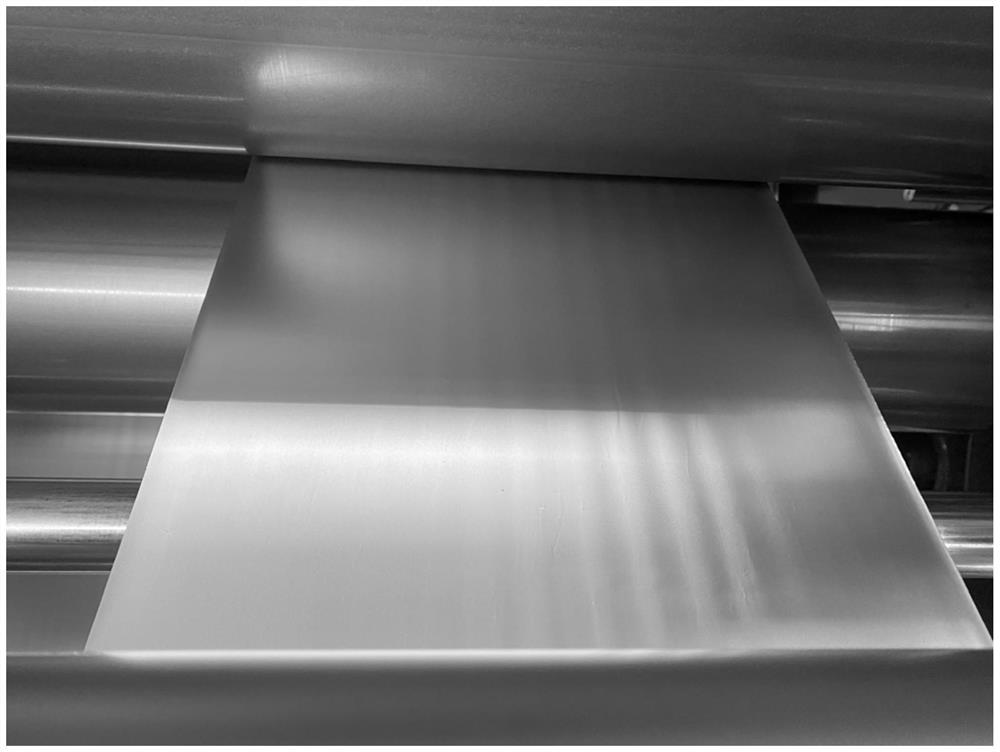

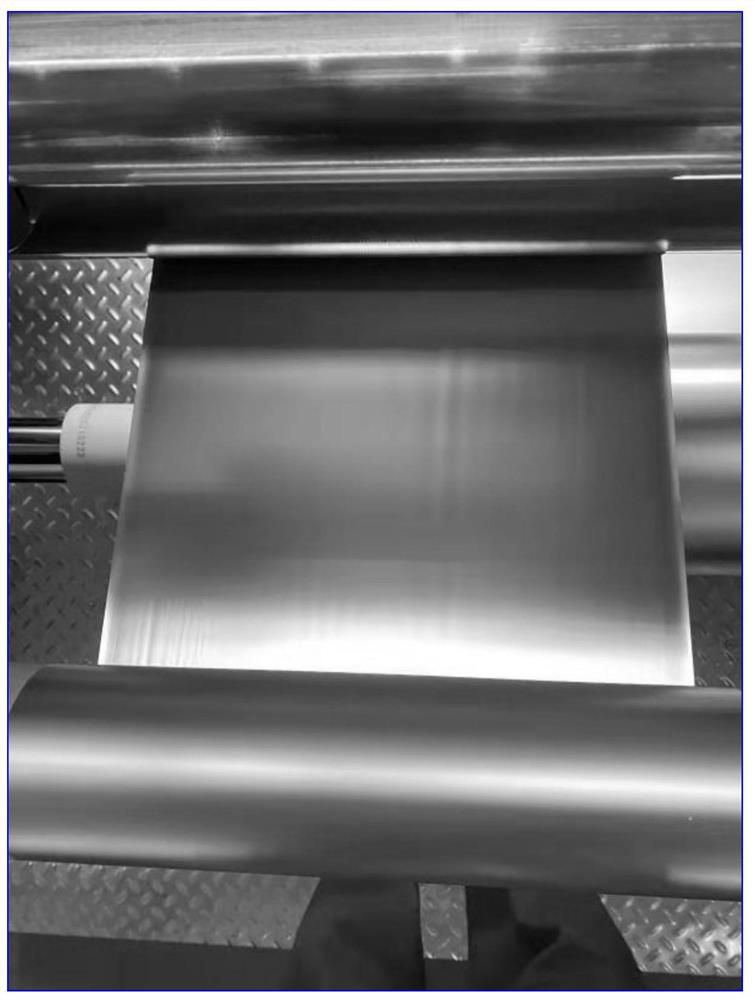

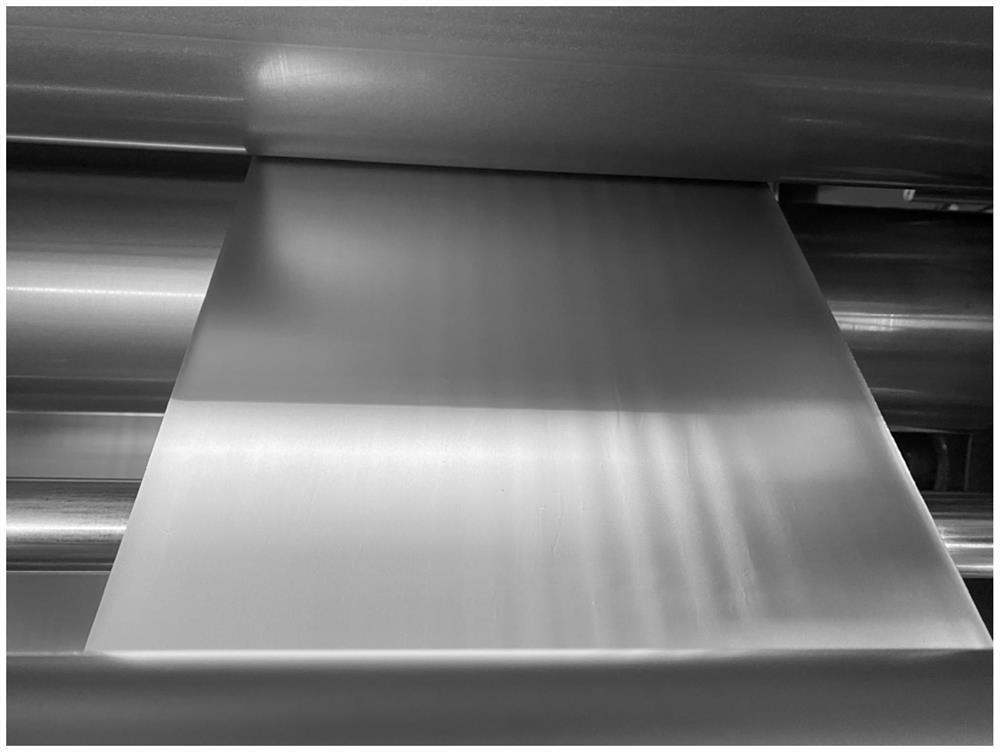

Method for reducing surface folding and bonding damage of aluminum coil caused by head coiling diameter thickness deviation

The invention discloses a method for reducing the surface folding and bonding damage of an aluminum coil caused by head coiling diameter thickness deviation. When a hot-rolled aluminum coil with a finished product thickness of more than or equal to 6.0mm is rolled, the head of an aluminum strip is pressed and thinned to be less than 6mm, and time for enlarging a roll gap to a roll gap with a set thickness is calculated according to the length of the aluminum strip machined by each rolling mill. The method has the beneficial effects that the head position of the aluminum strip is pressed and thinned in an aluminum strip rolling process, and a thickening deformation area of the aluminum strip is machined into an abrupt thickness change-free wedge-shaped area, so that abrupt thickness changes are avoided, the problem of dents or folding caused by the excessive thickness of the head of the aluminum coil can be effectively solved, and the finished product rate is greatly increased; moreover, additional hardware equipment is not required, and only a conventional program is required to be modified, so that the method is low in cost and high in practicability.

Owner:UNIV OF SCI & TECH BEIJING

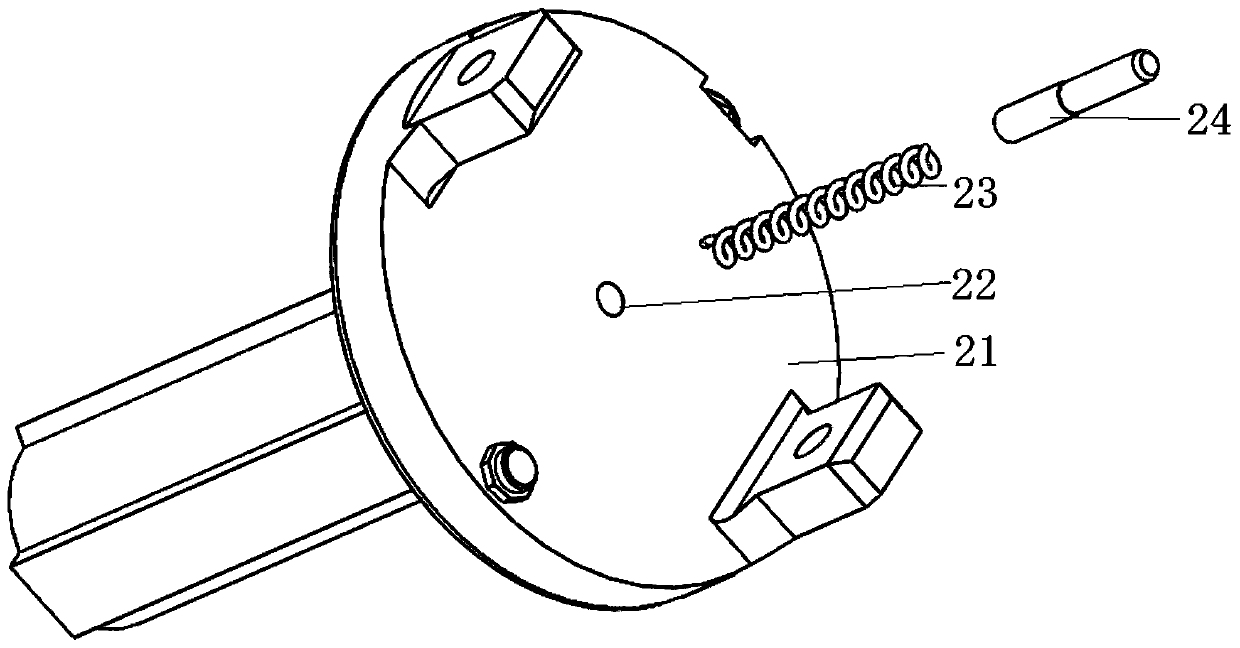

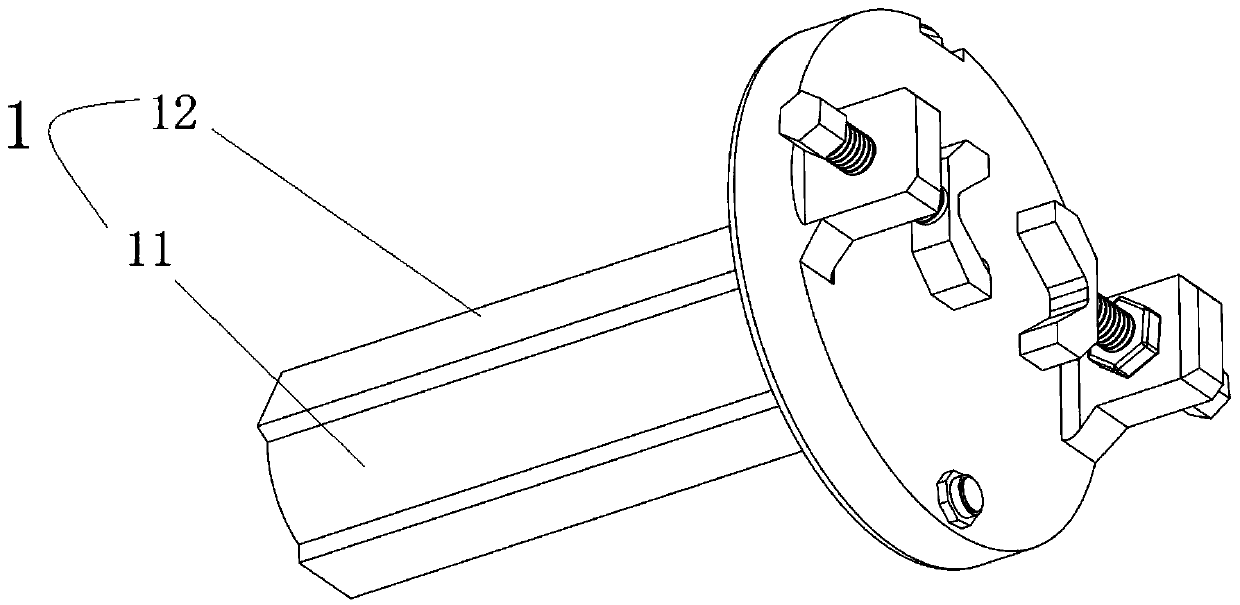

Numerical control lathe clamp

InactiveCN110977512APrevent slidingAvoid hard contactMeasurement/indication equipmentsPositioning apparatusNumerical controlMachine tool

The invention provides a numerical control lathe clamp. The invention belongs to the technical field of machining tools. The clamp comprises a clamp body, a positioning disc, clamping devices and a tool setting device, the clamp body is cylindrical, one end of the clamp body is fixedly inserted into one end of a chuck, the other end of the chuck is fixed to the center area of the end face of the positioning disc, the two sets of clamping devices are fixedly arranged on the other end face of the positioning disc and are symmetrically arranged along the center point of the positioning disc, andthe tool setting device is arranged on the positioning disc. When the clamp is used, the clamp body is fixed in the chuck, the machining position of a workpiece is determined through the positioning disc, the clamping devices are used for clamping the workpiece, and before machining is started, the tool setting device is used for determining the machining zero point. The clamp is simple in mechanism and easy to operate, the workpiece is driven to move mainly by clamping the clamp body, and the problem that in the prior art, indentations and scratches are formed in the surface of a finished workpiece due to the fact that a universal clamp is adopted is solved.

Owner:天津精国机械制造有限公司

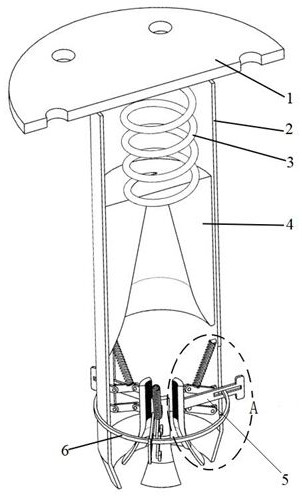

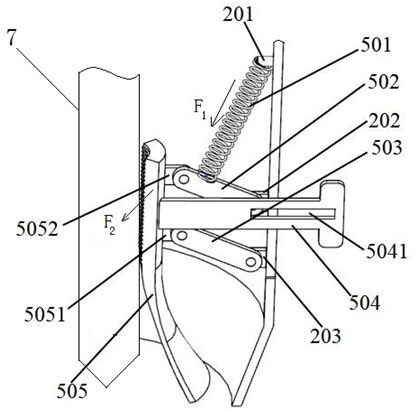

Clamper for robot paintbrush

The invention discloses a gripper for a robot paintbrush, comprising a flange cover; a pen holder, the top surface of the pen holder is welded or fixedly connected with the bottom surface of the flange cover; a spring A, a sleeve, and the sleeve can be slidably mounted on Inside the pen barrel, the two ends of the spring A are in contact with or bonded to the flange cover and the sleeve respectively, and the middle of the sleeve is provided with a conical hole for the installation of the brush; a plurality of buffer clamping mechanisms are fixedly installed at the bottom of the pen barrel to clamp the brush. Buffer clamping mechanism. When the brush is in inclined contact with the drawing board during use, the radial component force of the drawing board on the brush will be offset by the spring B on the buffer clamping mechanism, which solves the problem that the brush tip of the pencil is broken on the drawing board or the brush is used. The problem that the tip of the marker is retracted on the drawing board. The synchronizing ring drives the lever to move upwards synchronously, further drives the clamping blocks to move upwards, and simultaneously opens the plurality of clamping blocks to realize the quick disassembly of the brush.

Owner:NANNING UNIV

A method to reduce the surface fold and stick damage of aluminum coil due to the thickness jump of the head coil diameter

The invention discloses a method for reducing the surface folding and bonding damage of an aluminum coil caused by head coiling diameter thickness deviation. When a hot-rolled aluminum coil with a finished product thickness of more than or equal to 6.0mm is rolled, the head of an aluminum strip is pressed and thinned to be less than 6mm, and time for enlarging a roll gap to a roll gap with a set thickness is calculated according to the length of the aluminum strip machined by each rolling mill. The method has the beneficial effects that the head position of the aluminum strip is pressed and thinned in an aluminum strip rolling process, and a thickening deformation area of the aluminum strip is machined into an abrupt thickness change-free wedge-shaped area, so that abrupt thickness changes are avoided, the problem of dents or folding caused by the excessive thickness of the head of the aluminum coil can be effectively solved, and the finished product rate is greatly increased; moreover, additional hardware equipment is not required, and only a conventional program is required to be modified, so that the method is low in cost and high in practicability.

Owner:UNIV OF SCI & TECH BEIJING

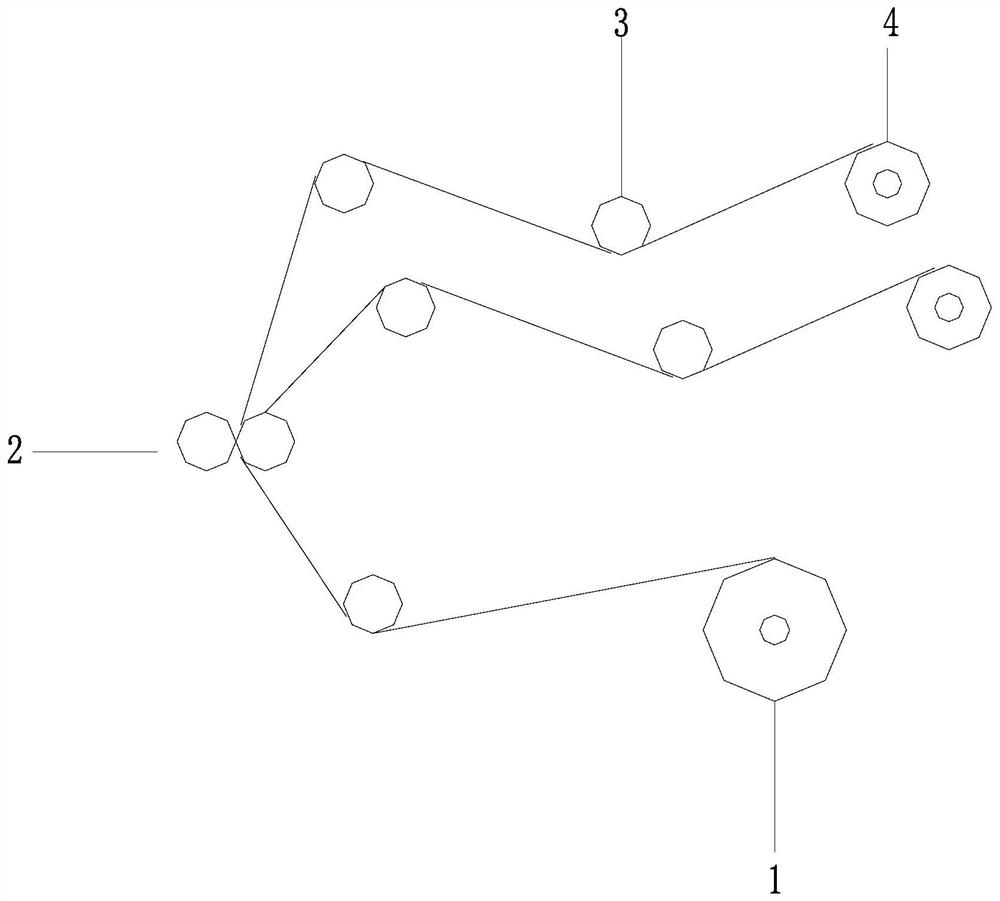

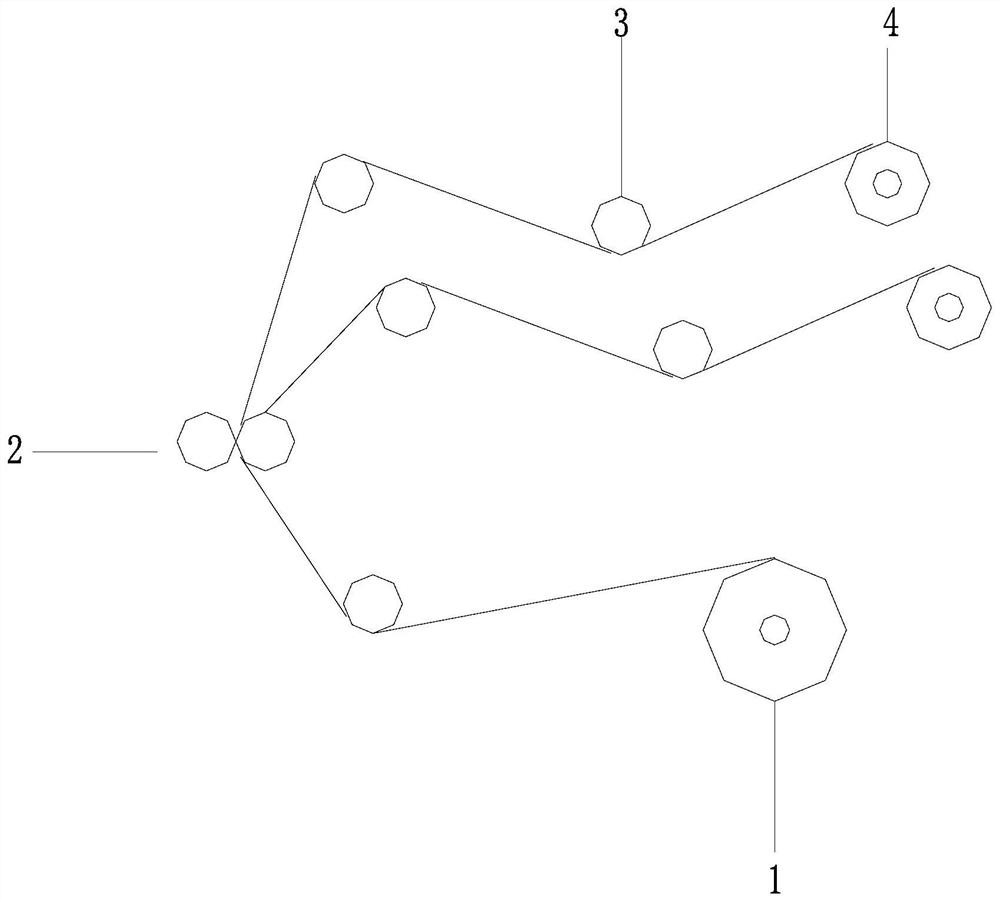

A wide-width copper foil anti-tightening guide roller, electrolytic copper foil slitting machine

ActiveCN113246208BStretchingSolve indentationMetal working apparatusArticle deliveryPower batteryElectrolysis

The invention discloses a guide roller for preventing tightness of wide copper foil and an electrolytic copper foil slitting machine; it belongs to the technical field of electrolytic copper foil for new energy vehicle power batteries; its technical key points include: a first step is provided on the surface of the guide roller. A side thread section and a second side thread section, the first side thread section and the second side thread section are arranged symmetrically; the first side thread section and the second side thread section have opposite directions of rotation. The application of a guide roller for anti-straining of wide copper foil and an electrolytic copper foil slitting machine can solve the problem of wrinkling of large wide copper foils during the copper foil slitting process.

Owner:GUANGDONG FINE YUAN SCI TECH CO LTD

Polyphenylene ether resin materials for processing charger housings

The invention discloses a polyphenylene ether resin material for processing a charger shell, which consists of polyphenylene ether resin, polystyrene resin, elastomer, flame retardant, polyolefin, silicone masterbatch, main antioxidant, Auxiliary antioxidant composition. The invention improves the surface lubrication of the parts by adding suitable additives to the polyphenylene ether resin composition, reduces the pressure required for welding, and solves the indentation and scratches that occur when the products are ultrasonically welded. question. This product is mainly used in areas requiring ultrasonic welding, such as charger shells and junction boxes.

Owner:NANTONG XINGCHEN SYNTHETIC MATERIAL +1

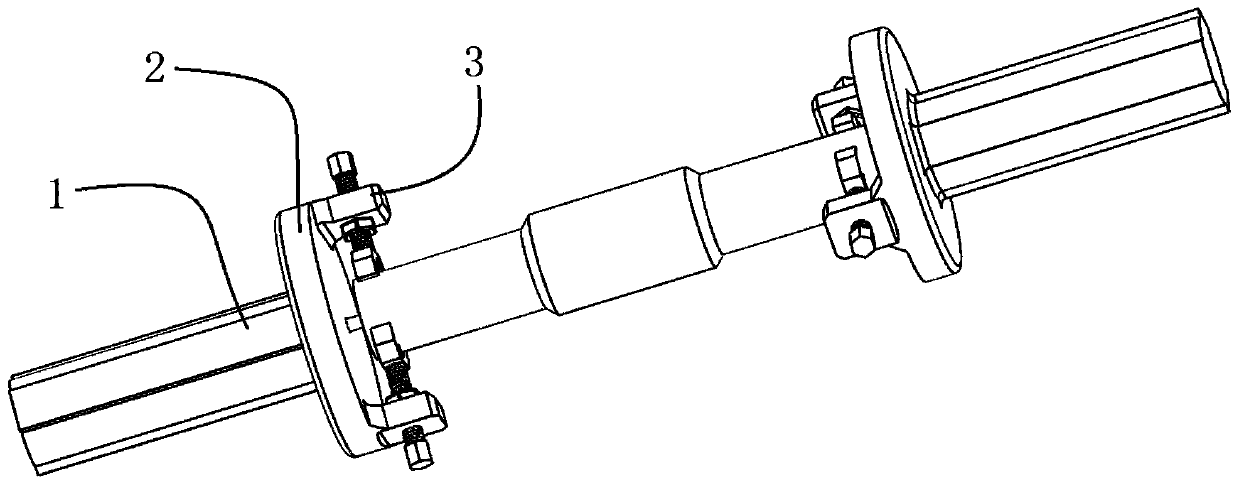

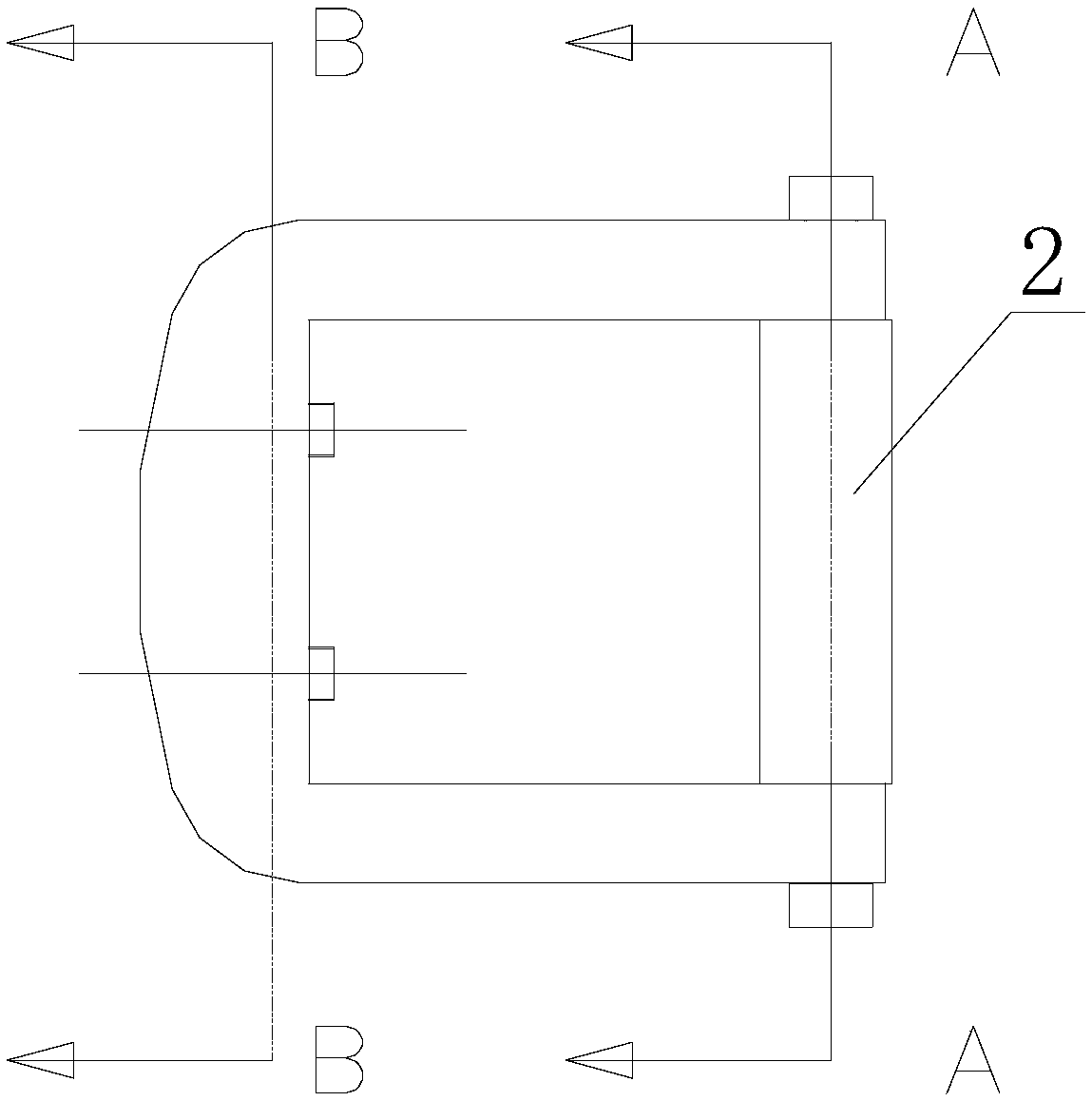

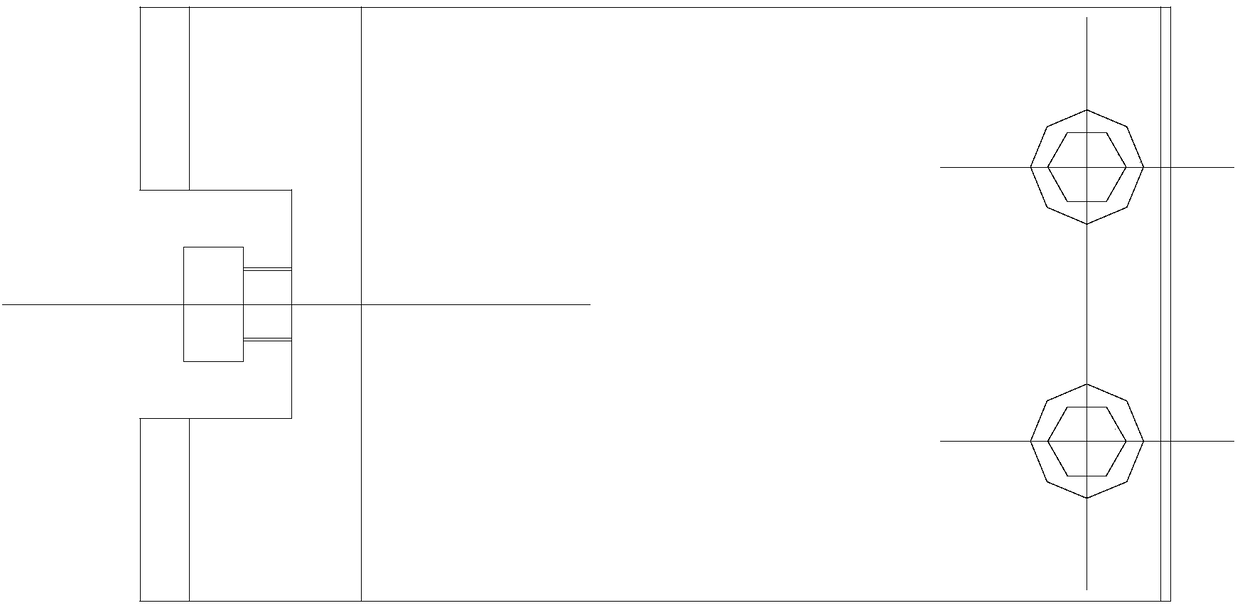

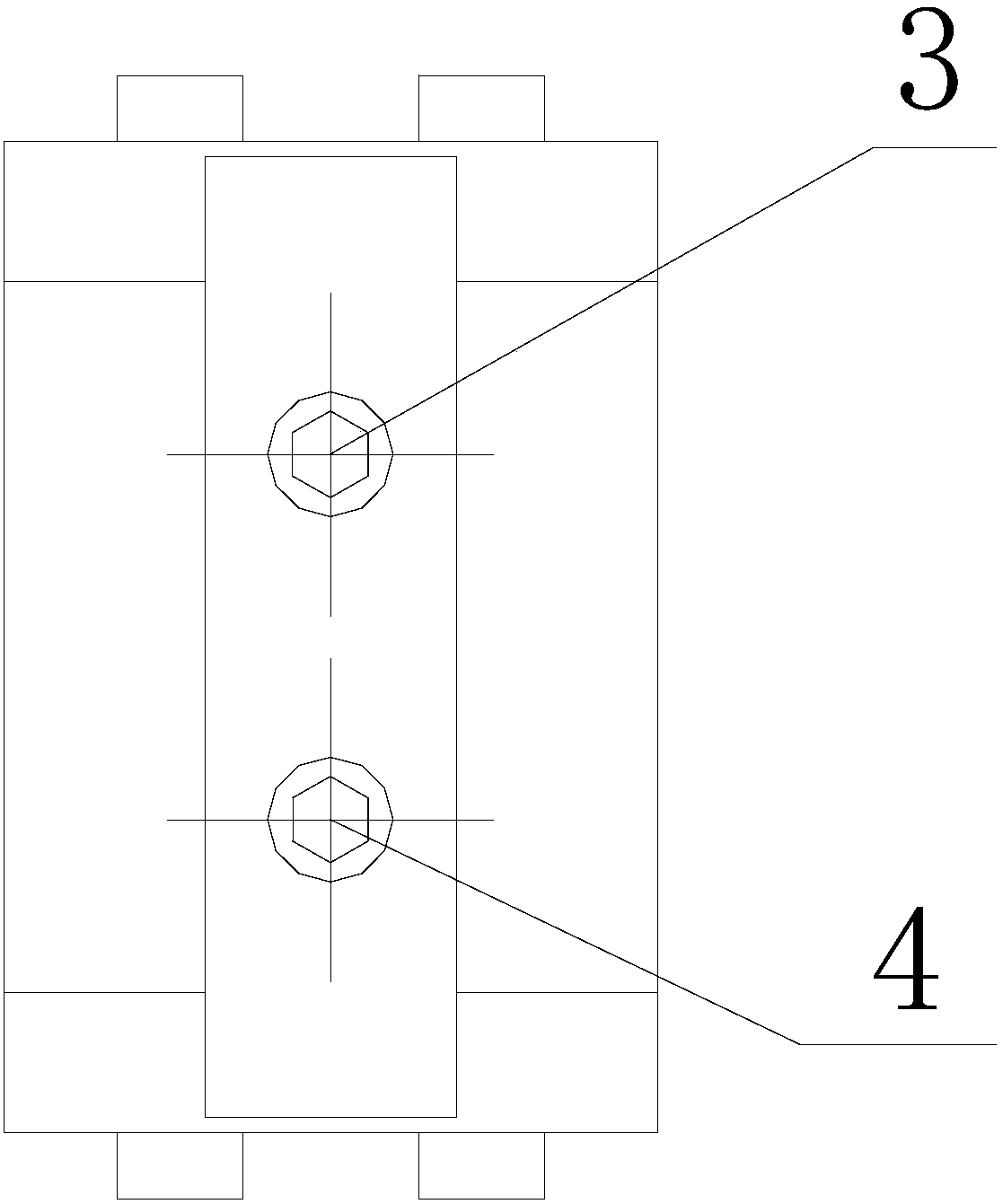

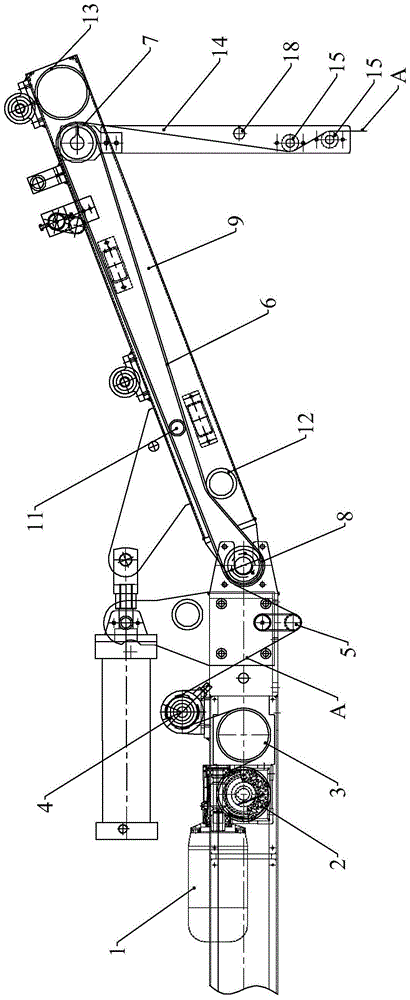

Auxiliary clamping device for turning steam turbine rotor on horizontal lathe

ActiveCN106695366BSolve indentationSolve the scratchWork clamping meansPositioning apparatusEngineeringCopper

The invention provides an auxiliary clamping device used by a horizontal lathe for turning a steam turbine rotor and relates to the clamping device. The clamping device aims to solve the problems that in the machining process of an existing steam turbine rotor, jaw clamping force causes dents and scratches to a rotor fine machining face when a horizontal lathe clamps a rotor, a copper gasket between a jaw of the horizontal lathe and the fine machining face generates the axial channeling phenomenon, and higher personnel and equipment secondary harm is caused due to loosening of the copper gasket. The auxiliary clamping device comprises a U-shaped plate, a cuboid copper gasket and a plurality of bolts, and the cuboid copper gasket is arranged in an opening of the U-shaped plate. By means of the auxiliary clamping device, the problems that in the machining process of the existing steam turbine rotor, dents and scratches are caused to the fine machining face when the horizontal lathe clamps the rotor, the copper gasket between the jaw of the horizontal lathe and the fine machining face generates the axial channeling phenomenon, and higher personnel and equipment secondary harm is caused due to loosening of the copper gasket are solved, and the auxiliary clamping device is applicable to auxiliary clamping of the steam turbine rotor.

Owner:HARBIN TURBINE +1

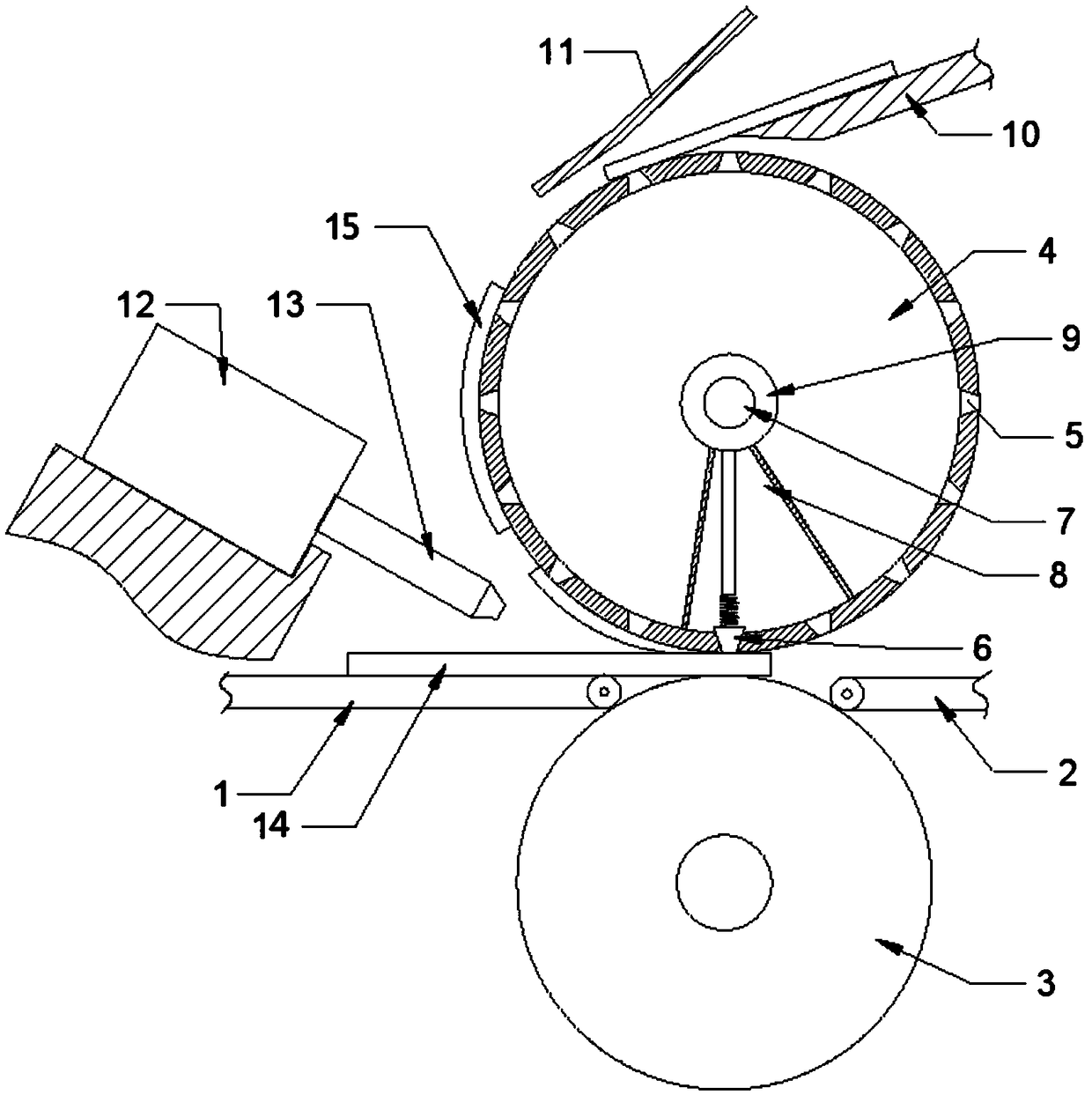

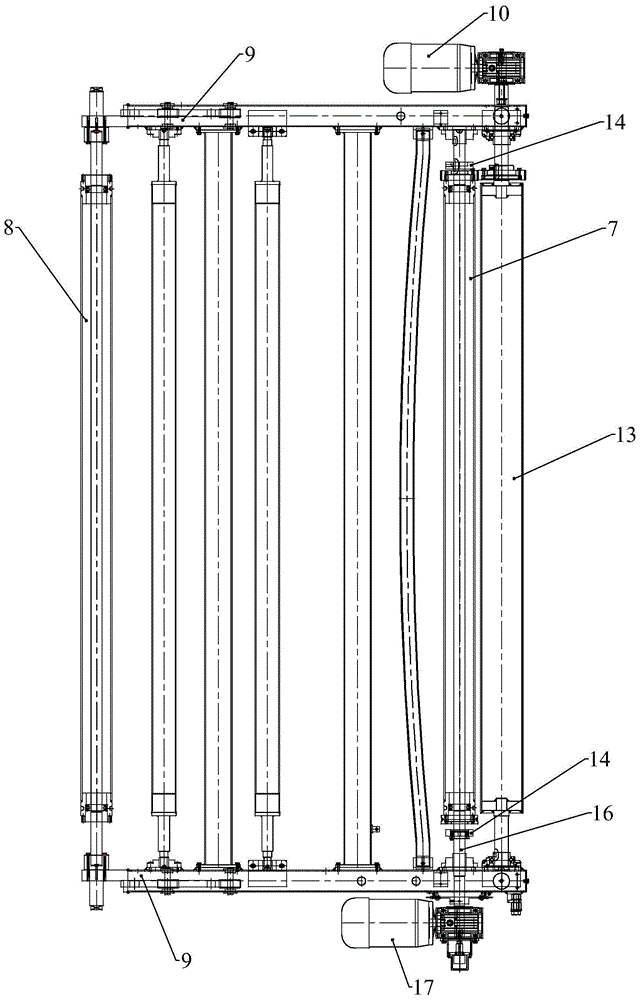

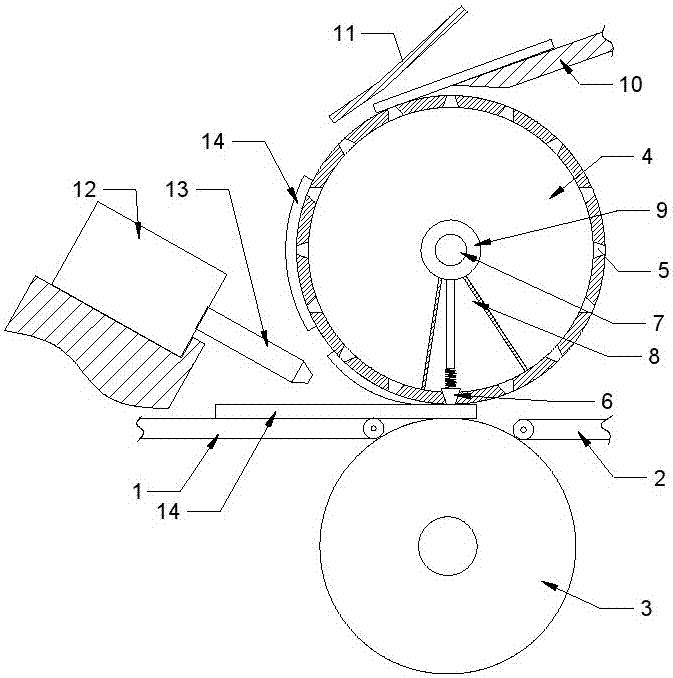

An ultra-low tension doffing device

ActiveCN104986611BSolve the problem of edge indentationSolve indentationFolding thin materialsWrinkle skinDrive motor

Owner:GUANGDONG RUITUO ENVIRONMENTAL PROTECTION MACHINERY

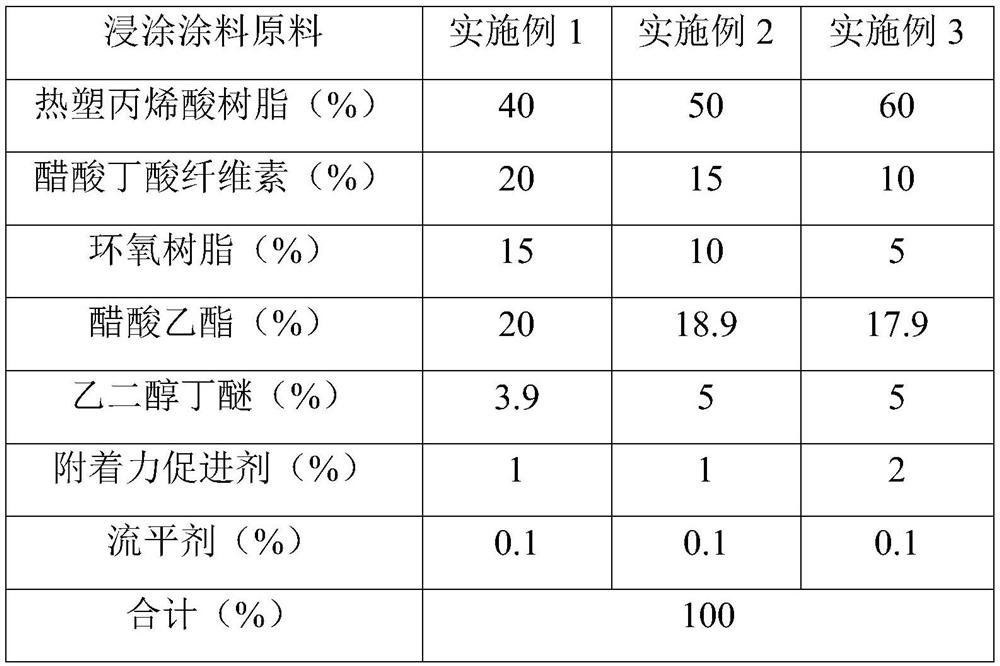

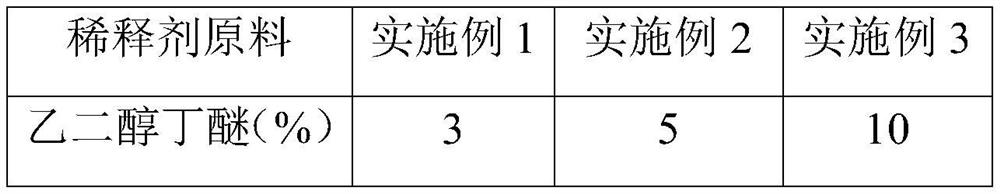

Dip coatings for metal surfaces and methods of making and using the same

ActiveCN110437692BSolve indentation defectsImprove dip coating effectEpoxy resin coatingsEpoxyCellulose

The invention belongs to the field of metal coatings, and in particular relates to a dipping coating for metal surfaces and a preparation method and application method thereof. Based on the total weight of the dip-coating paint as 100%, the dip-coating paint includes the following components in weight percentage: thermoplastic acrylic resin 40-60%; cellulose acetate butyrate 10-20%; epoxy resin 5% ‑15%; adhesion promoter 1‑2%; leveling agent 0.1‑0.5%; ethyl acetate 8‑20%; butyl glycol ether 0‑5%. The coating has good effect of dipping, smooth surface, high gloss, no indentation in construction, no need to bake, and the dried paint film has excellent resistance to salt spray and citric acid.

Owner:CHINA PAINT MFG CO SHENZHEN

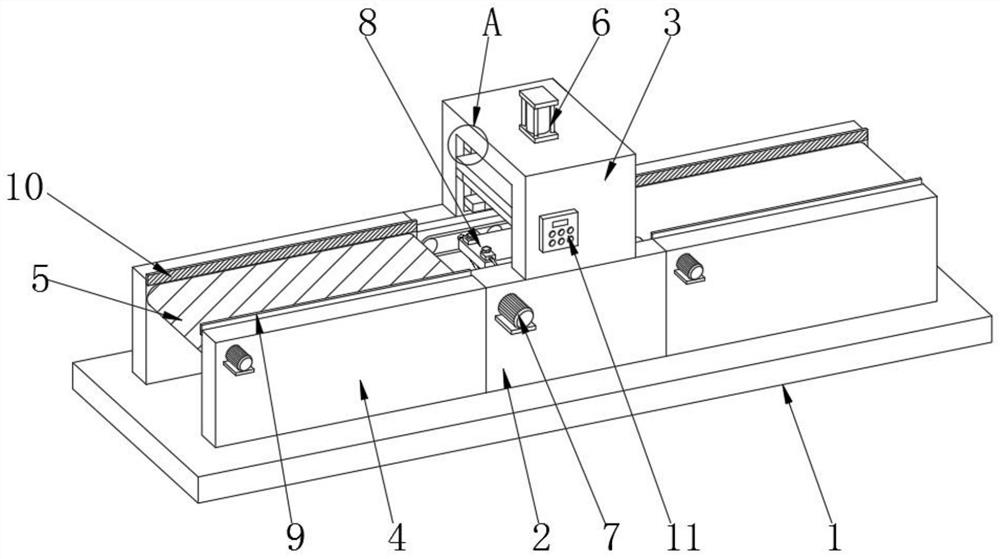

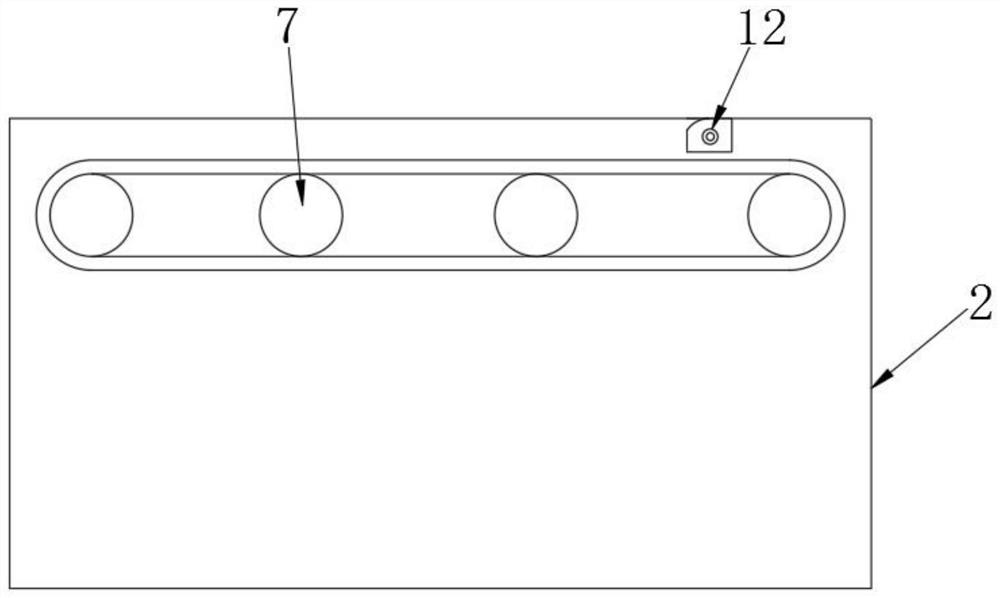

Roll forming machine

The invention provides a roll forming machine comprising a rack. The left end and the right end of the rack are symmetrically provided with vertical fixed working roller sets respectively, each fixedworking roller set comprises two fixed working rollers arranged front and back, and the upper and lower ends of the fixed working rollers are rotatably connected with the rack respectively. A guide mechanism with a left-right guide function is arranged between every two fixed working rollers arranged front and back. The left and right ends of the rack are symmetrically provided with vertical movable working roller mechanisms respectively. Each movable working roller mechanism comprises a vertical movable working roller and a driving oil cylinder group for driving the movable working roller tomove along the corresponding guide mechanism. The top ends of the movable working rollers are connected with driving devices for driving the movable working rollers to rotate. According to the roll forming machine, roll forming replaces a traditional bending technology, the requirement for product precision can be met, the product quality and the production efficiency can be improved, the production cost is reduced, and the problems of product indentations and insufficient consistency are solved.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

Two-component silicone encapsulant and its preparation method and application

ActiveCN112724925BHigh viscositySolve indentationNon-macromolecular adhesive additivesSemiconductor devicesAlkanePolymer science

The invention relates to a two-component organosilicon encapsulant and its preparation method and application. The two-component silicone encapsulant includes a component A and a component B; in parts by mass, the component A includes the following components: 100 parts of hydroxyl-terminated polydimethylsiloxane, and methyl MQ 10 to 30 parts of silicone resin; in parts by mass, the component B includes the following components: 100 parts of alkoxysilane-modified polydimethylsiloxane, 1,2-bisalkoxysilyl ethyl 20 to 40 parts of alkane, 3 to 8 parts of a silane coupling agent, and 0.2 to 0.6 parts of an organic tin catalyst. The two-component silicone encapsulant can maintain high transparency under the condition that the viscosity difference between the A component and the B component is small, and the deep curing is fast.

Owner:GUANGZHOU BAIYUN CHEM IND

A special-shaped joint adapter device for aerospace special valves

ActiveCN109340479BTroubleshoot transfer issuesSolve the repeatabilityJoints with sealing surfacesEngineeringScrew thread

The invention discloses an adapter device for a special-shaped connector of a special aerospace valve. The adapter device for the special-shaped connector of the special aerospace valve comprises a pipe joint nozzle, a screw sleeve, an outer sleeve, a seal ring, a taper sleeve and a seal rod, wherein the pipe joint nozzle is a hollow rotary body; a limiting step is arranged on the outer wall of the right end; external screw threads are arranged at two ends of the outer wall of the pipe joint nozzle; the screw sleeve is screwed onto the outer wall of the right end of the pipe joint nozzle; theright end of the screw sleeve and the right end of the pipe joint nozzle are on the same plane; an embedded cavity is formed between the pipe joint nozzle and the screw sleeve; the small end head of the special-shaped connector is embedded into the embedded cavity; the inner wall of the special-shaped connector at the embedded part fits to the outer wall of the pipe joint nozzle; the limiting stepis in butt joint with a smooth step, and the butt-joint part is sealed by the seal ring; the taper sleeve is of a tapered rotary body structure and is arranged on the right side of the smooth step ofthe small end head of the special-shaped connector; the outer sleeve is screwed onto the outer wall of the screw sleeve; and the taper sleeve is extruded into the embedded cavity. The fixed connection and the cavity communication between the pipe joint nozzle and the special-shaped connector are realized, so that the connection problem of the test of the special aerospace valve with the special-shaped connector is solved.

Owner:CAPITAL AEROSPACE MACHINERY +1

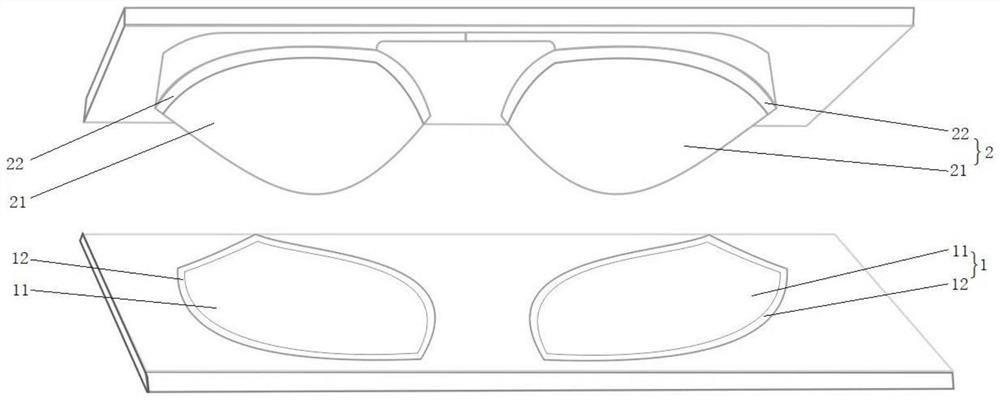

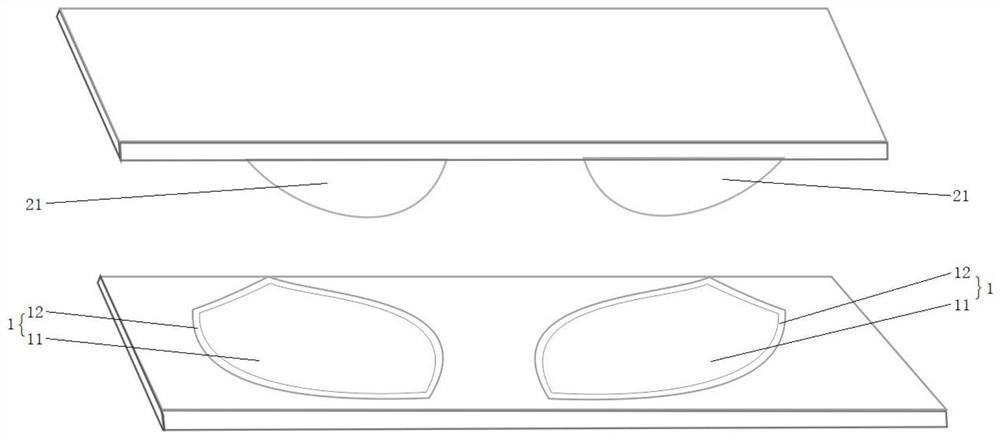

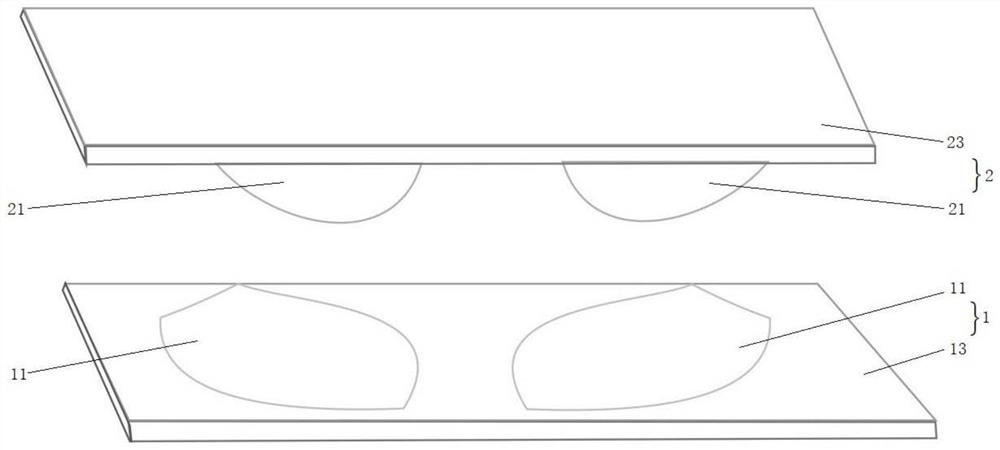

Mold pressing mold for improving cloth cup indentation and cloth cup manufacturing method

The invention discloses a mold pressing mold for improving cloth cup indentation and a cloth cup manufacturing method, the mold pressing mold comprises an upper mold and a lower mold which are oppositely arranged, the lower mold is provided with a female mold, and the female mold is provided with a spherical groove which is recessed downwards and correspondingly forms a cloth cup; the upper die is provided with a male die matched with the female die, the male die is provided with a spherical body facing the spherical groove, and the spherical body is provided with a pressing face. A downwards concave groove is formed in the spherical groove, and the groove is arranged around the edge of the upper surface of the spherical groove by a circle; the groove is internally provided with a buffer part which is used for abutting against the pressing face when the female die and the male die are assembled, the buffer part is formed by filling a flexible organic silicon material, and the upper surface of the buffer part is flush with the upper surface of the groove. According to the mold pressing mold for improving the cloth cup indentation, the problems of cloth cup edge indentation and aurora in bulk production can be solved, the attractiveness of finished bras is improved, and the defective rate of bulk production is reduced.

Owner:SUZHOU MEISHANZI GARMENTS CO LTD

A bonding method for keyboard case and nameplate

The invention relates to an attachment method for a keyboard shell and a nameplate. An attachment mechanism is embedded in the middle of a conveying belt and comprises a fixed press roller and a conveying roller abutting against the fixed press roller. The contact face of the fixed press roller and the conveying roller and the upper surface of the conveying belt are located on the same plane. Negative pressure communicates in the conveying roller. Through holes are formed in the circumferential wall of the conveying roller. The conveying roller is fixedly mounted on a rotating shaft. The rotating shaft is sleeved with a bearing. A shielding cover and a plug block are mounted on the bearing. An opening of the shielding cover is downward and abuts against the inner wall of the conveying roller. The abutting part of the shielding cover is of a flexible structure. The plug block is located in the shielding cover. A press spring is connected between the plug block and the rotating shaft. A material transport mechanism comprises a conveying groove obliquely formed above the conveying roller and a guide plate. A heating mechanism comprises a hot air barrel. A nozzle is arranged on the hot air barrel and faces the position between the fixed press roller and the conveying roller. Through implementation of the above scheme, the effect of nameplate attachment is achieved without a pasting manner.

Owner:重庆西曼新材料有限公司

Attachment method for keyboard shell and nameplate

The invention relates to an attachment method for a keyboard shell and a nameplate. An attachment mechanism is embedded in the middle of a conveying belt and comprises a fixed press roller and a conveying roller abutting against the fixed press roller. The contact face of the fixed press roller and the conveying roller and the upper surface of the conveying belt are located on the same plane. Negative pressure communicates in the conveying roller. Through holes are formed in the circumferential wall of the conveying roller. The conveying roller is fixedly mounted on a rotating shaft. The rotating shaft is sleeved with a bearing. A shielding cover and a plug block are mounted on the bearing. An opening of the shielding cover is downward and abuts against the inner wall of the conveying roller. The abutting part of the shielding cover is of a flexible structure. The plug block is located in the shielding cover. A press spring is connected between the plug block and the rotating shaft. A material transport mechanism comprises a conveying groove obliquely formed above the conveying roller and a guide plate. A heating mechanism comprises a hot air barrel. A nozzle is arranged on the hot air barrel and faces the position between the fixed press roller and the conveying roller. Through implementation of the above scheme, the effect of nameplate attachment is achieved without a pasting manner.

Owner:重庆嘉涌电子有限公司

Guide roller for preventing wide copper foil from being tightened and electrolytic copper foil splitting machine

ActiveCN113246208AStretchingSolve indentationMetal working apparatusArticle deliveryCopper foilEngineering

The invention discloses a guide roller for preventing a wide copper foil from being tightened and an electrolytic copper foil splitting machine, and belongs to the technical field of new energy automobile power battery electrolytic copper foils. According to the technical key points, a first side threaded section and a second side threaded section are arranged on the surface of a guide roller body, and the first side threaded section and the second side threaded section are symmetrically arranged; and the first side threaded section and the second side threaded section are opposite in rotating direction. According to the guide roller for preventing the wide copper foil from being tightened and the electrolytic copper foil splitting machine, the problem that the wide copper foil is wrinkled in a copper foil splitting process can be solved.

Owner:GUANGDONG FINE YUAN SCI TECH CO LTD

A kind of anti-indentation amino baking varnish and preparation method thereof

The invention discloses an anti-indentation amino baking varnish which can be used for the finish coating of automobile hubs and a preparation method thereof. The anti-indentation amino baking varnish of the invention mainly includes the following components in weight percentage: polyester modified thermosetting acrylic resin 42 ‑55 parts by weight; 2‑3 parts by weight of blocked isocyanate resin; 18‑22 parts by weight of amino resin; 6‑8 parts by weight of auxiliary agent; 10.0‑20.0 parts by weight of solvent. The invention is mainly applied to the finish coating of automobile wheels, and uses polyester modified thermosetting acrylic resin and amino resin as the main body of the reaction to generate amino baking varnish with a pencil hardness of up to 2H, which can effectively solve the problems caused by the off-line coating of automobile wheels. The problem of indentation on the surface of the wheel hub caused by accumulation and extrusion can improve the product qualification rate of automobile wheel hub manufacturers. The preparation process of the invention is simple and suitable for industrialized production.

Owner:LANGFANG NIPPON PAINT +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com