Mould

A mold and lower mold technology, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of unfavorable surface quality of outer panels, surface quality problems of outer panels, and high processing accuracy requirements, so as to shorten the debugging cycle and reduce the The effect of repair rate and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

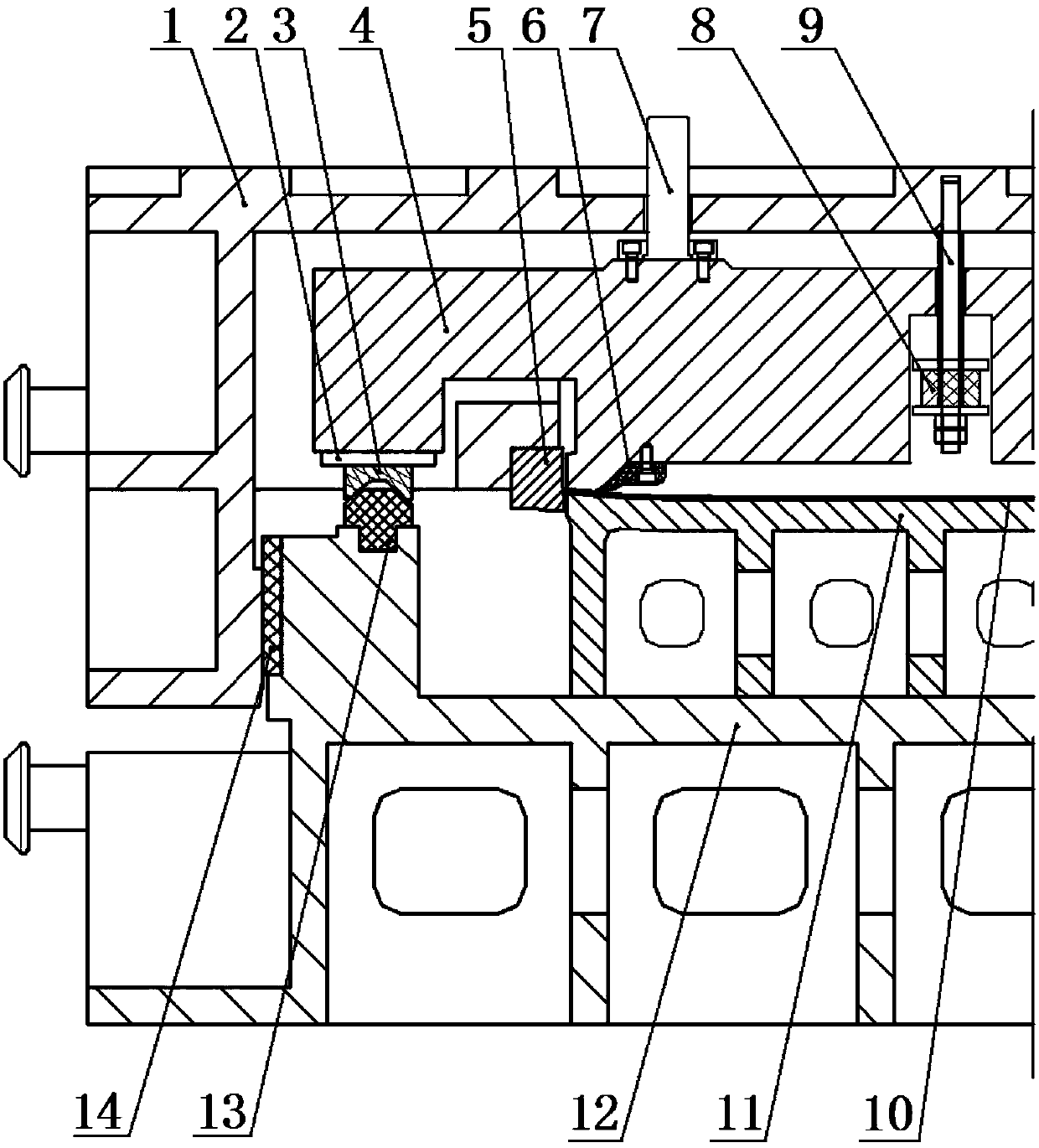

[0026] The invention will be described below with reference to the accompanying drawings, which show one embodiment of the invention. However, it should be understood that the present invention can be presented in many different ways, and is not limited to the embodiments described below; in fact, the embodiments described below are intended to make the disclosure of the present invention more complete and to the Those skilled in the art fully explain the protection scope of the present invention. It should also be understood that the embodiments of the invention herein can be combined in various ways to provide yet more additional embodiments.

[0027] It should be understood that in the drawings, the dimensions of some of the features may have been distorted for clarity.

[0028] It should be understood that the terminology used in the specification is for the purpose of describing particular embodiments only, and is not intended to limit the invention. Unless otherwise de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com