Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

123results about How to "Full rinse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

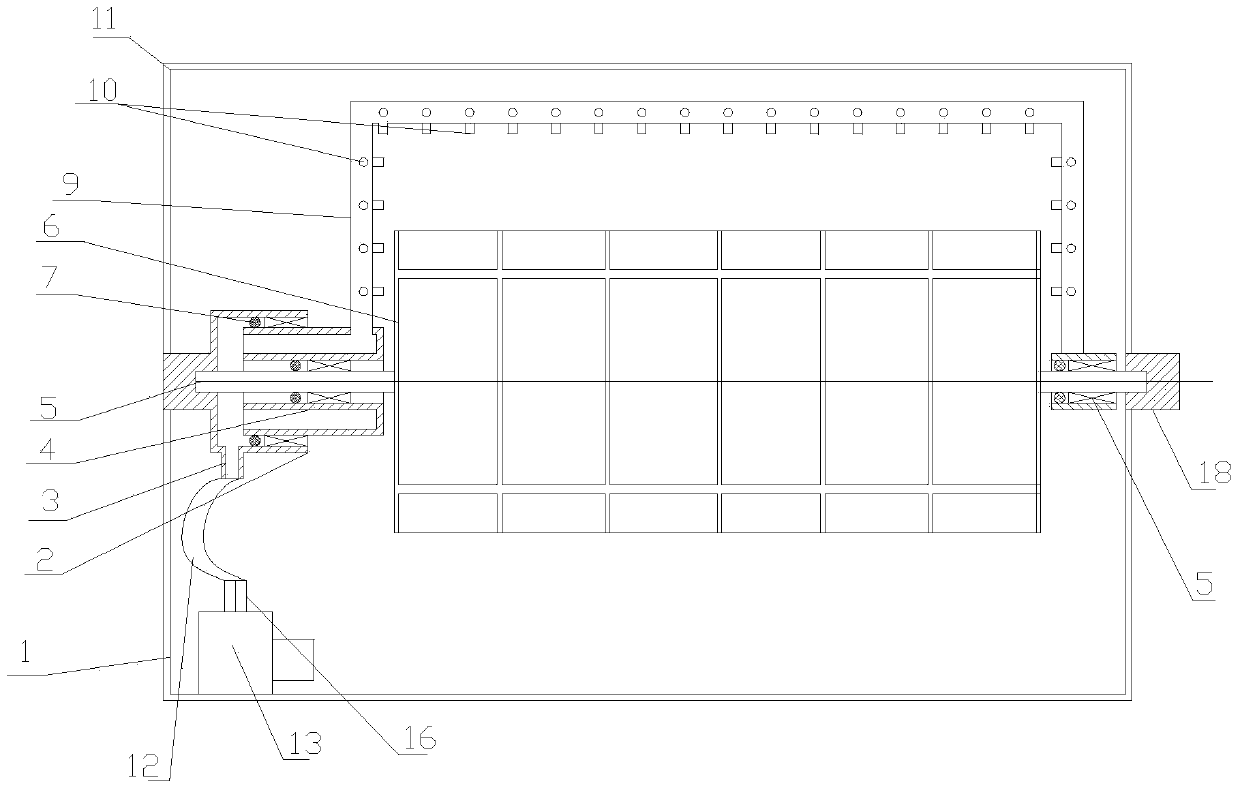

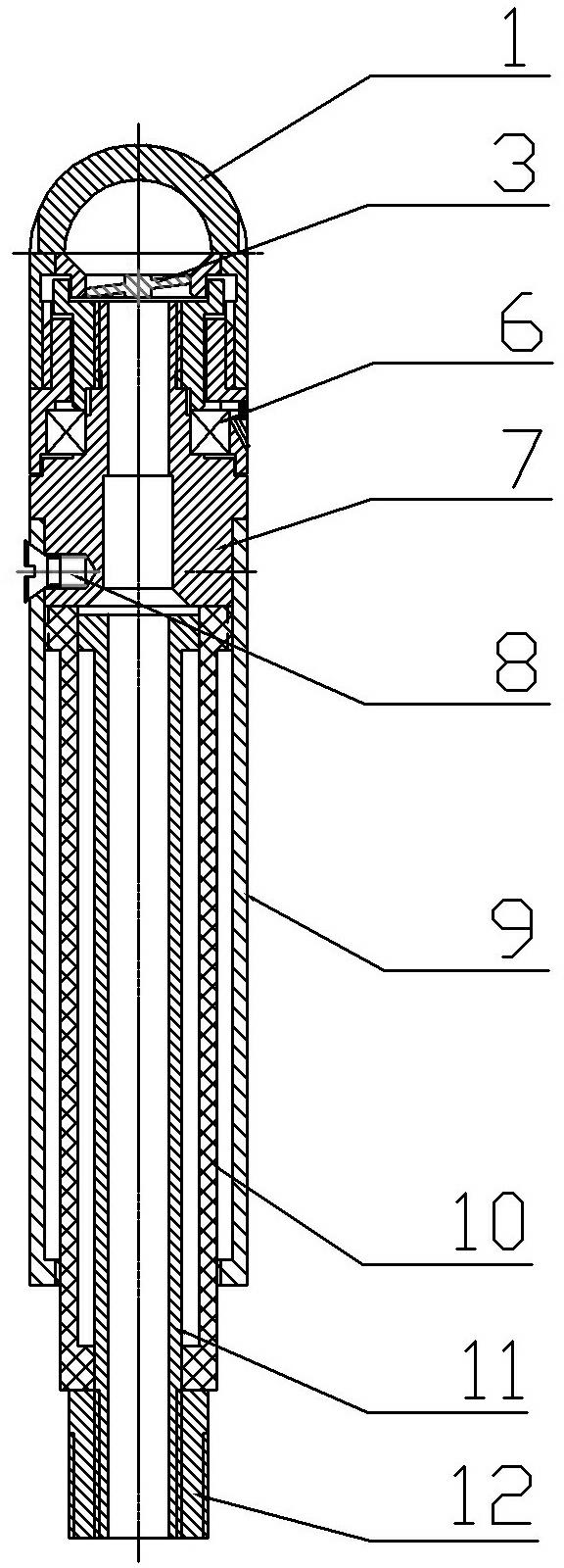

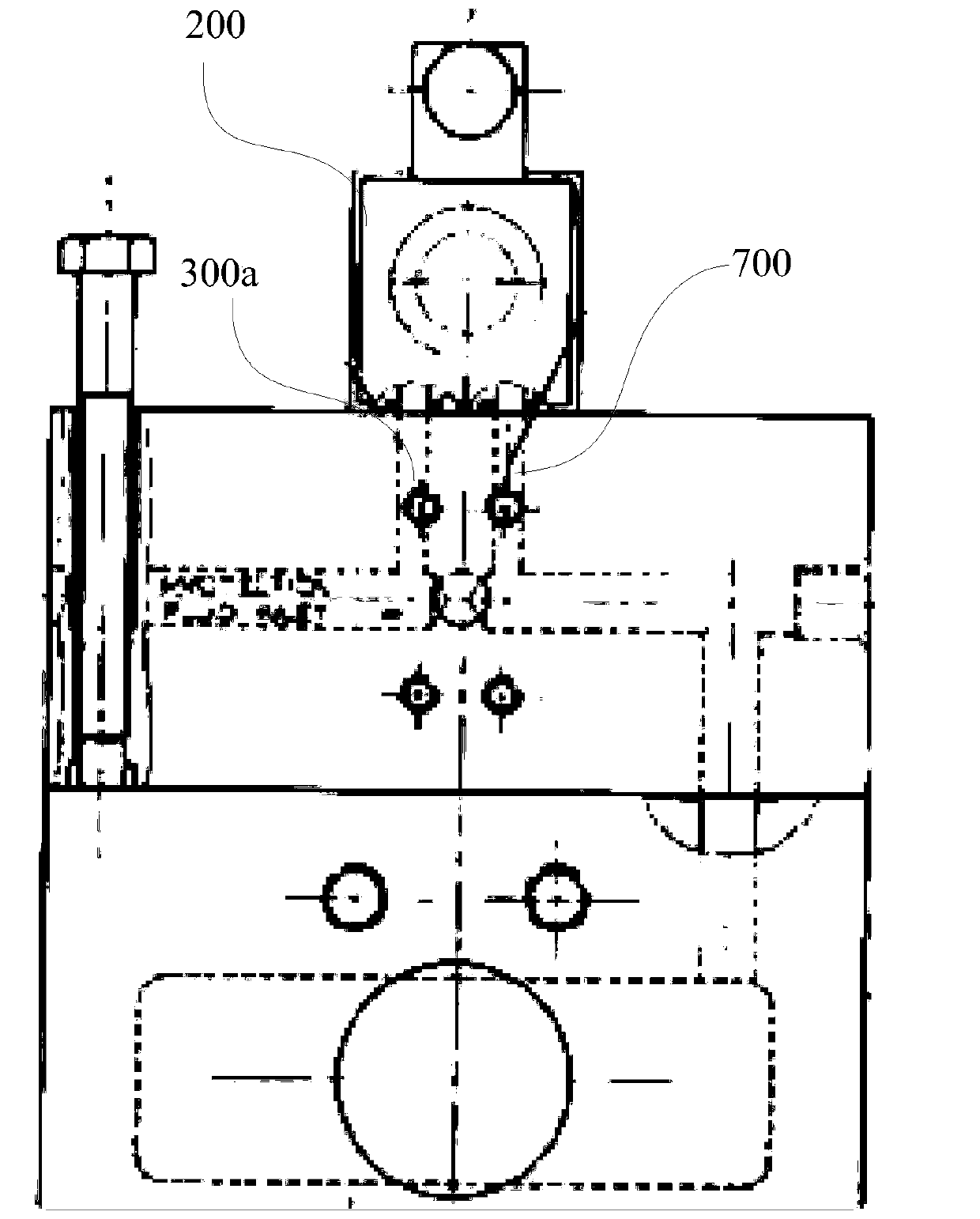

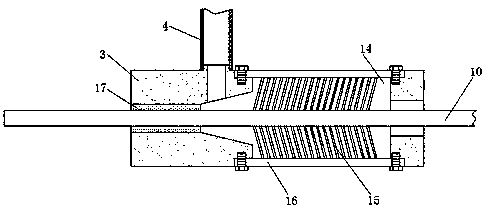

Flushing device for mechanical seal of centrifugal pump

ActiveCN106122108AFlow is stable and cleanPrevents deposition of particulate impuritiesPump componentsPumpsCentrifugal pumpOrifice plate

The invention discloses a flushing device for a mechanical seal of a centrifugal pump, and belongs to the technical field of centrifugal pumps. The flushing device comprises a flushing pipe connected to the centrifugal pump; the liquid feeding end of the flushing pipe is connected with the outlet end of the centrifugal pump; the liquid discharging end of the flushing pipe is connected with the mechanical seal of the centrifugal pump; the flushing device is characterized in that the flushing pipe is connected with a tubular filter, a pressure gauge and a throttling orifice plate; the tubular filter is close to the outlet end of the centrifugal pump; the throttling orifice plate is close to the mechanical seal of the centrifugal pump; a first stop valve and a second stop valve are arranged on the flushing pipe; the first stop valve is positioned between the outlet end of the centrifugal pump and the tubular filter; and the second stop valve is positioned between the pressure gauge and the throttling orifice plate. The flushing device can both achieve a good cooling effect on the mechanical seal and prevent particle impurities from being deposited on the sealing surfaces of movable and fixed rings, thus effectively protecting the sealing surfaces of the movable and fixed rings, relieving wear and enhancing the sealing effect; and therefore, normal and stable operation of the centrifugal pump is guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP +1

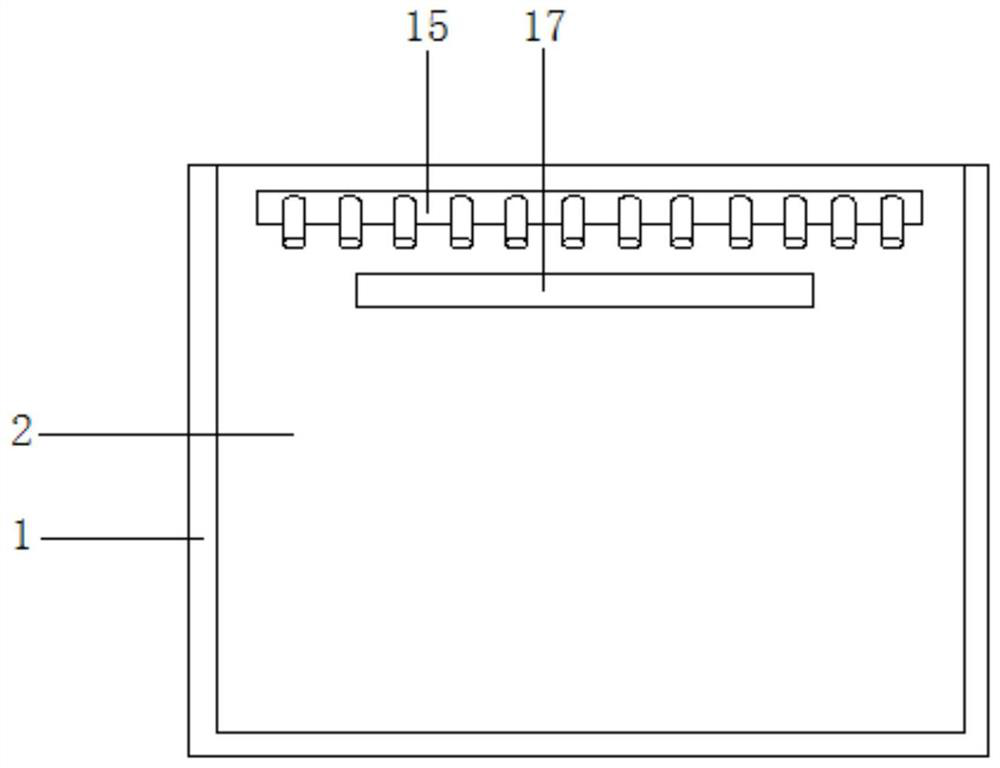

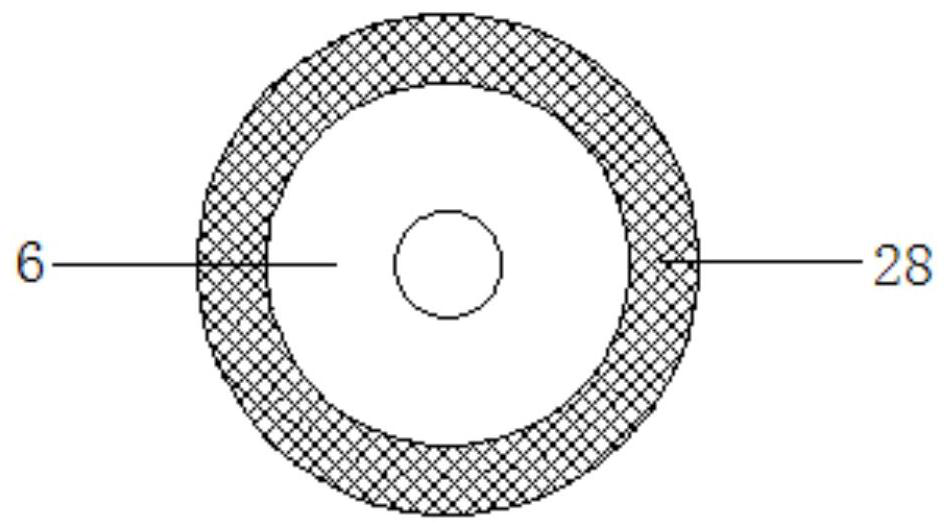

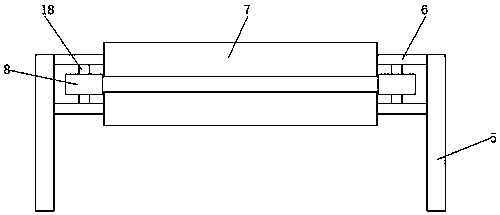

A kind of all-round washing dish washing device

ActiveCN105286746BEasy to operateEasy to implementTableware washing/rinsing machinesFixed bearingEngineering

An all-round washing dishwashing device, which relates to the technical field of cleaning equipment, is characterized in that it includes a lower water tank, a cover is provided above the lower water tank, and a water-passing bearing seat is provided in the cover, and the water-passing One end of the bearing seat is connected with a side nozzle, and a water jacket is installed on the water bearing seat, bearings are arranged between the water jackets, and a water seal is arranged next to the water jacket, and one end of the side nozzle is connected with a water pipe , the water pipe is connected to the circulating water pump through a one-way valve, a placer is provided on one side of the water-passing bearing seat, and a semi-annular nozzle is arranged outside the placer, and the semi-annular nozzle is connected to the bearing. A nozzle is provided, a fixed bearing base is provided on the other side of the placement frame, and a bearing is provided on the fixed bearing base. The invention has the advantages of reasonable structure, convenient implementation and comprehensive cleaning and flushing capabilities.

Owner:张文杰

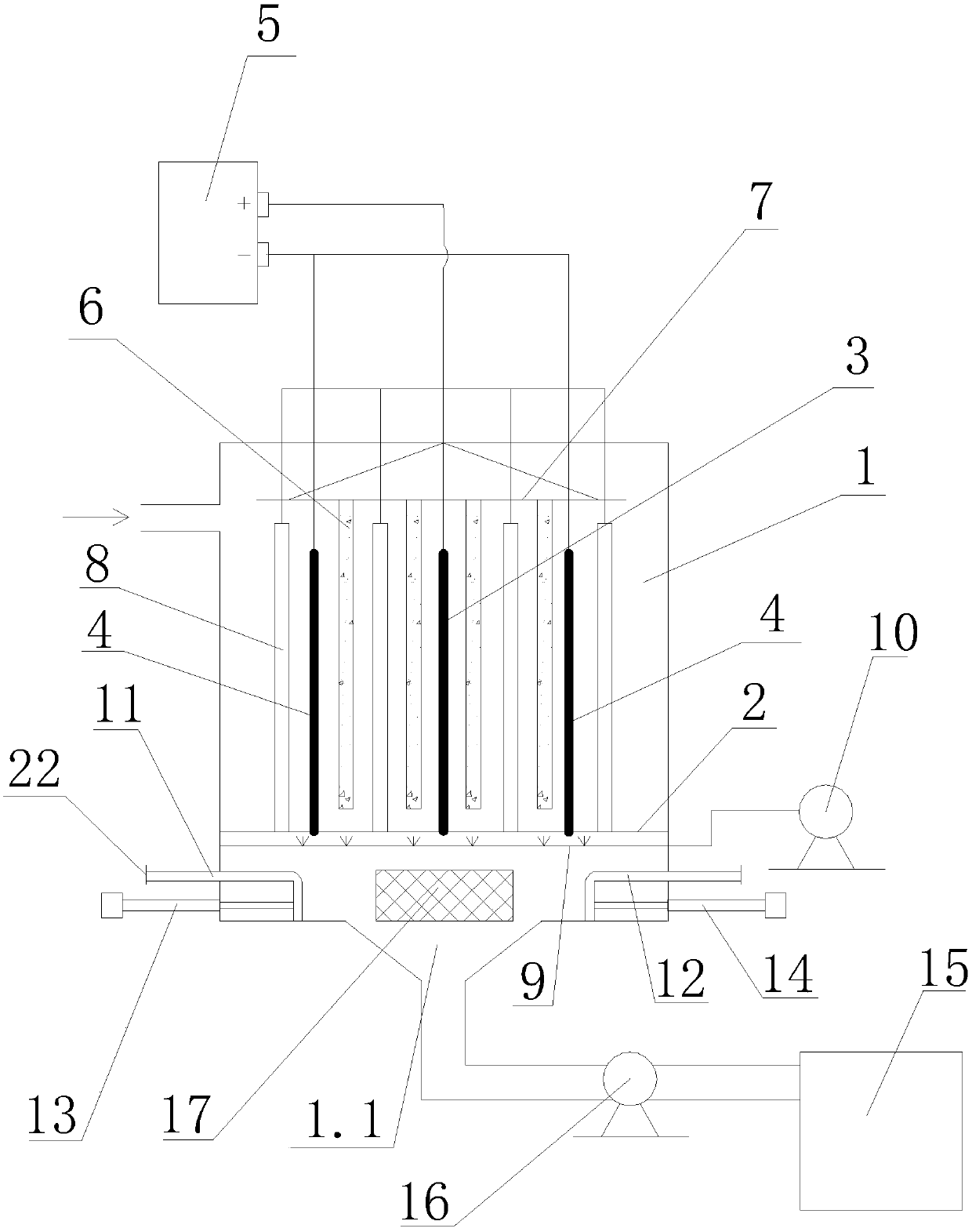

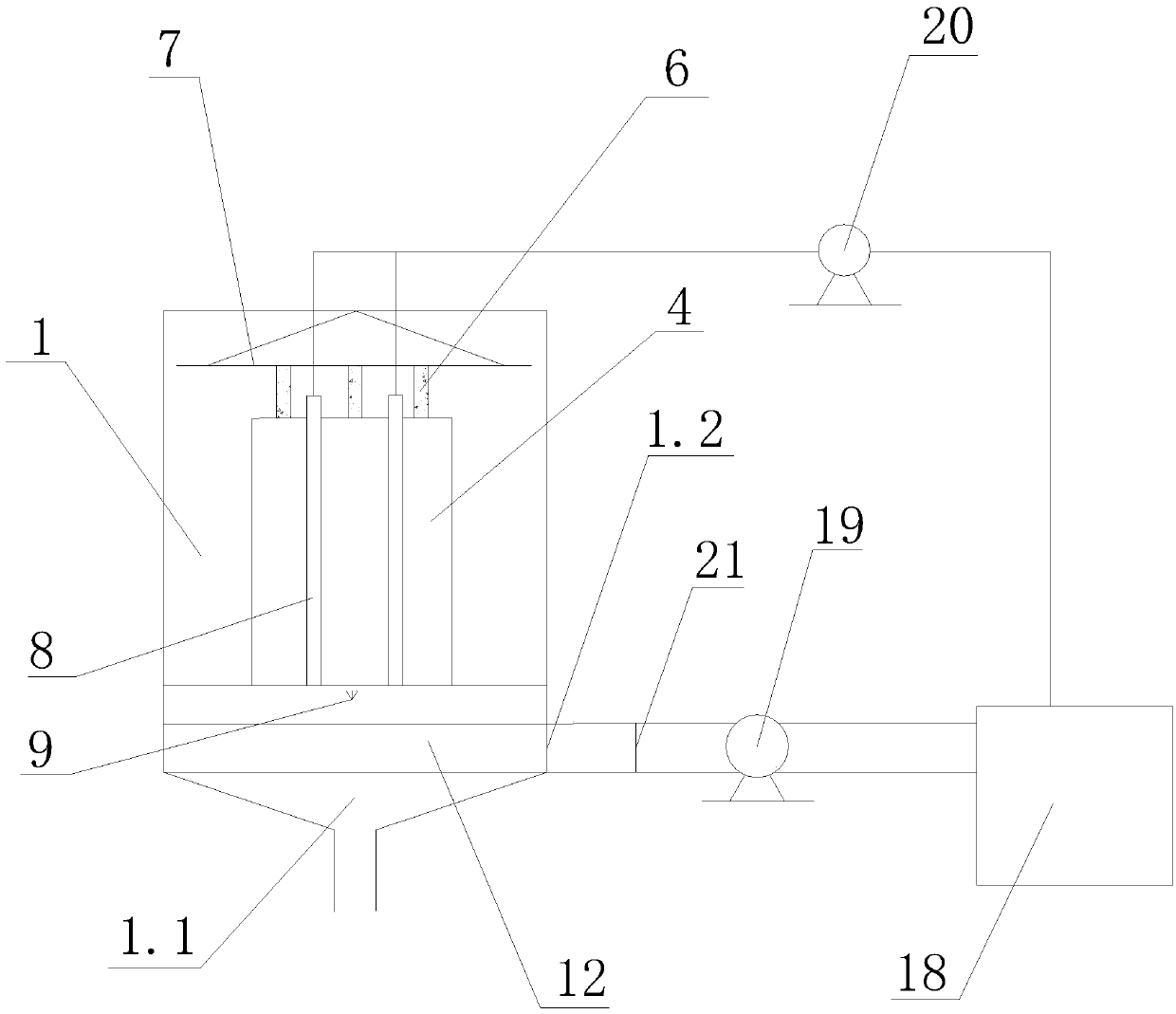

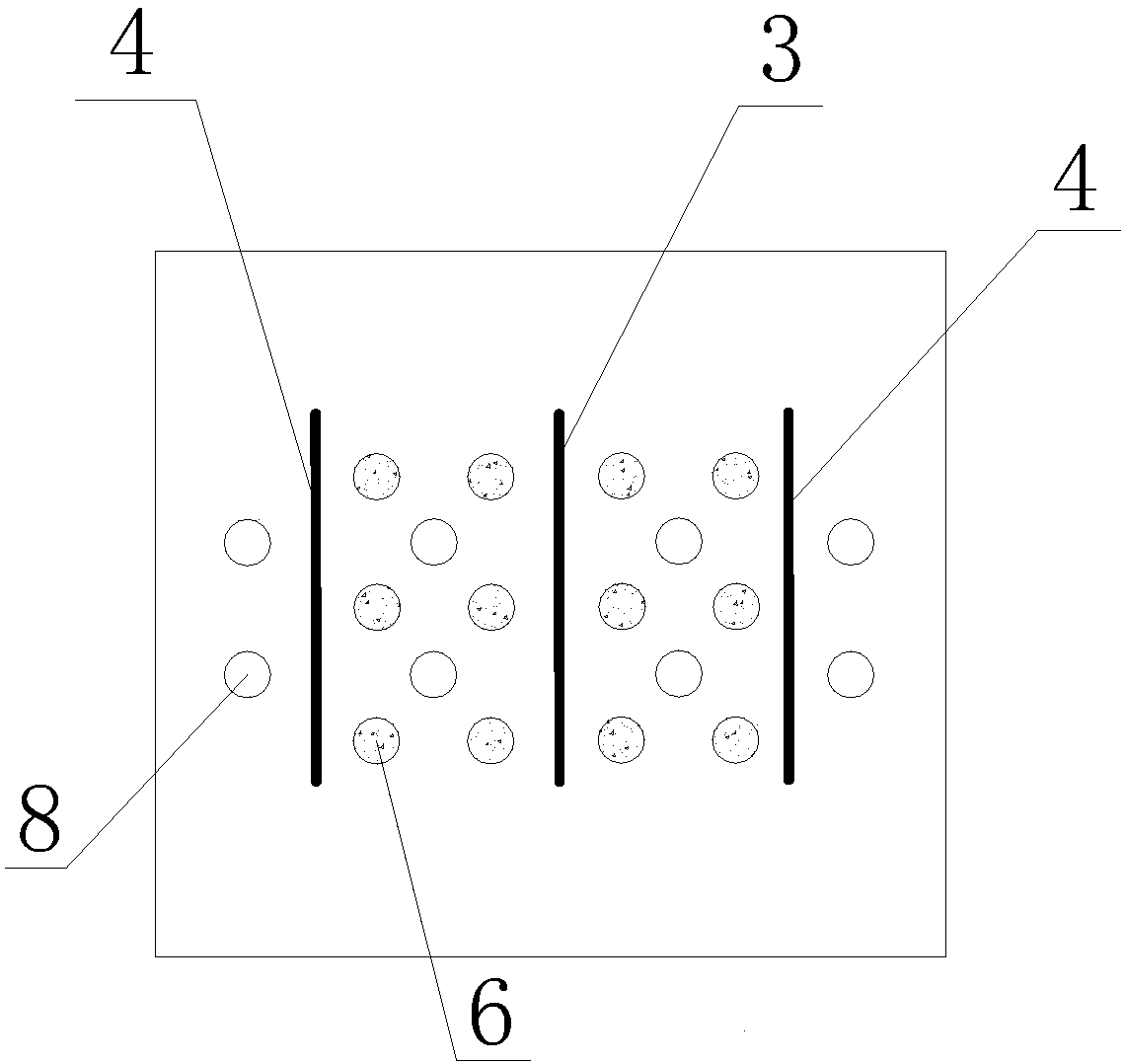

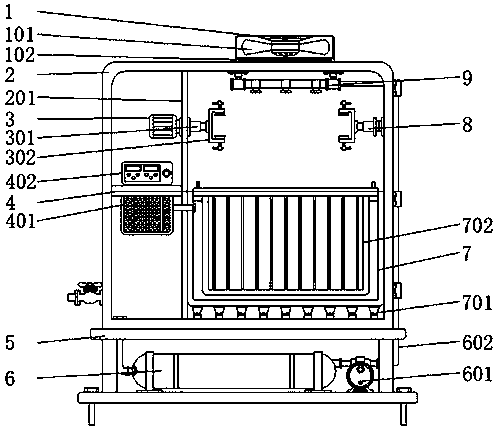

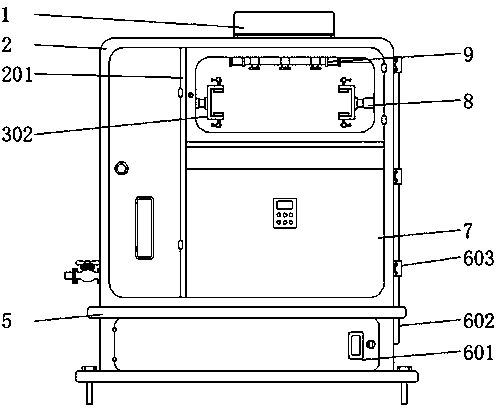

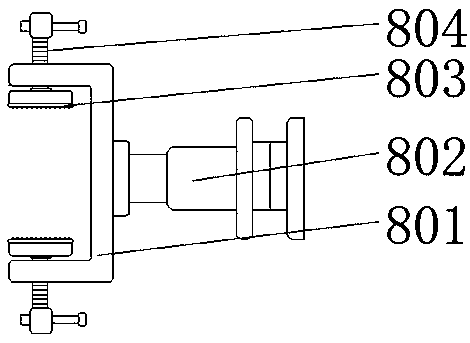

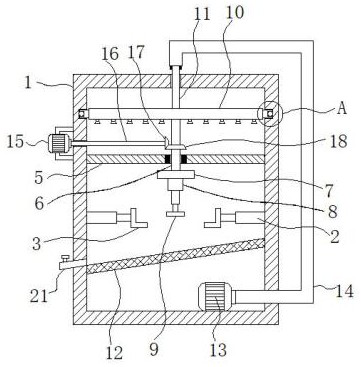

Coking wastewater electrolysis unit with backwash function

The invention relates to a coking wastewater electrolysis unit with a backwash function. The coking wastewater electrolysis unit comprises a tank body, wherein a support frame which is fixedly connected with the tank body is arranged in the tank body; an anode plate and two cathode plates are vertically arranged on the support frame; the anode plate is arranged between the two cathode plates; theanode plate and the cathode plates are connected with an external power supply; a plurality of carrier rods filled with composite catalysts are distributed between the anode plate and the cathode plates; the plurality of carrier rods are suspended on the top of the tank body through a lifting plate; and a plurality of spray pipes are arranged on the support frame. According to the coking wastewater electrolysis unit disclosed by the invention, the plurality of spray pipes are arranged in the electrolysis unit and distributed on two sides of the cathode plates and the anode plate, and electrodeplates in the electrolysis unit are subjected to backwashing by utilizing the wastewater subjected to electrolytic filtering, dirt attached onto the surface of the electrode plate is fully cleaned, and the service life of the electrode plate is prolonged. Moreover, the back-washing water is the treated wastewater, recycling is realized, the waste and pollution of water resources are reduced, andthe cost is saved.

Owner:PINGXIANG HUAXING ENVIRONMENTAL PROTECTION ENG TECH CO LTD

Method for treating heavy metal pollution in soil by using a low-position leaching high-position extraction technology

ActiveCN110125158AEffectiveImplementableContaminated soil reclamationVacuum extractionVacuum pressure

The invention discloses a method for treating heavy metal pollution in soil by using a low-position leaching high-position extraction technology. The method comprises: constructing a packed drain well, laying a clay working bed course on the earth surface, arranging a leaching agent pipe in the packed drain well, arranging a vacuum filtering pipe in the vertical direction of the working bed course, digging a ditch groove, laying a plastic film on the upper portion of the working bed course, drilling at the positions, corresponding to the leaching agent pipe and the vacuum filtering pipe, on the plastic film, preparing a carbon dioxide leaching agent, introducing the carbon dioxide leaching agent into the leaching agent pipe, controlling the flow rate of carbon dioxide while opening a vacuum system, controlling the vacuum degree and the leaching agent introducing time, and controlling the vacuum extraction time. According to the present invention, the leaching process and the extractionprocess are performed simultaneously, wherein carbon dioxide diffuses upward to accelerate and expand the range of the bicarbonate forming soil so as to achieve the complete leaching treatment, and the heavy metal salt in the mellow soil layer cannot migrate downward due to the migration effect of the vacuum pressure so as to effectively prevent groundwater and soil from being polluted by the heavy metal salts.

Owner:山东天大泰泽环保科技有限公司

Process for preparing halophyte organic fertilizer using marine culture sludge

InactiveCN1546435AReduce pollutionReduce the amount of applicationClimate change adaptationSewage/sludge fertilisersHalophyteSucrose

A process for preparing plant fertilizer through mariculture comprises the steps of, air-drying mariculture sludge and the pond sludge in cane sugar factories, subjecting the cultivation sludge to eluting desalinization, mixing the eluted sludge with the air-dried pond sludge by the mass ratio of 2:5, controlling humidity between 50%-60% (mass ratio), agitating and ventilating 5-15 minutes each day, fermenting 20 days at 35 deg. C-45 deg. C, air-drying to obtain the halophytic vegetation fertilizer.

Owner:NANJING AGRICULTURAL UNIVERSITY

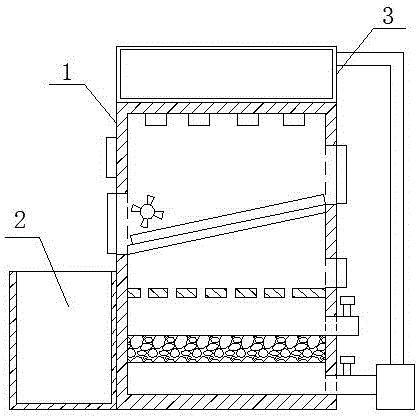

Lotus root washing device

InactiveCN106617185AImprove cleaning efficiencyEasy to operateClimate change adaptationFood treatmentWater resourcesPulp and paper industry

The invention discloses a lotus root washing device and relates to the technical field of agricultural equipment. The lotus root washing device comprises a washing tank, wherein a feeding hole and a discharging hole are formed in a side wall of the washing tank; the feeding hole and the discharging hole are arranged relatively; the horizontal height of the feeding hole is greater than that of the discharging hole; a plurality of high-pressure nozzles are arranged at the top of the washing tank; the washing tank is internally provided with a washing plate; the washing plate is located below the plurality of high-pressure nozzles; one end of the washing plate is connected with the feeding hole and the other end of the washing plate is connected with the discharging hole; at least three baffles are arranged on the washing plate; the longitudinal section of each baffle is of a triangular structure; the washing plate is further provided with a through hole; a blow-off pipe is further arranged below a side wall of the washing tank; and turning covers are arranged on the feeding hole and the discharging hole. The lotus root washing device is convenient to operate and flexible to use and can be used for washing completely; and water resources are saved.

Owner:安徽菲扬新材料有限公司

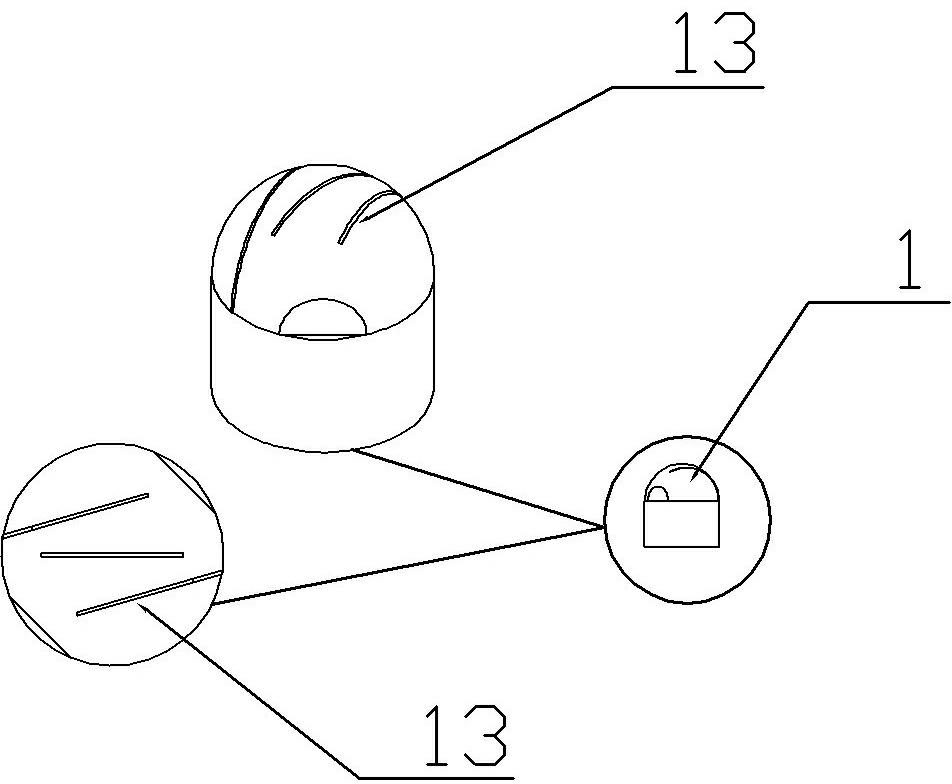

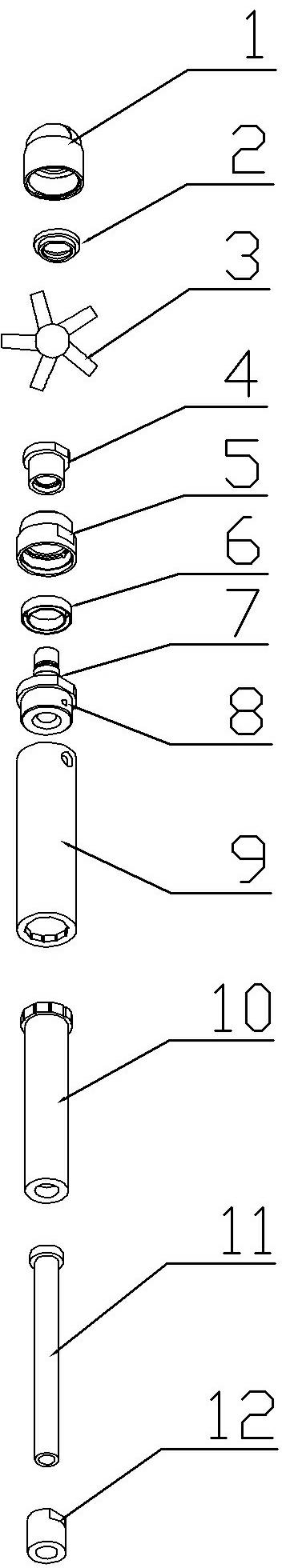

Rotary spraying-flushing device lifted by water power

InactiveCN102580963AWith rotation functionIncrease heightMovable spraying apparatusHollow article cleaningImpellerRotation function

The invention discloses a rotary spraying-flushing device lifted by water power. An outer sliding sleeve is sleeved on an inner sliding sleeve and can slide up and down along the inner sliding sleeve; a bearing is arranged on the outer surface of the water outlet end of the outer sliding sleeve; a rotary spraying ball is fixed at the outer side of the bearing; and a plurality of irregular holes are arranged on the side wall of the rotary spraying ball. The rotary spraying-flushing device lifted by the water power has the advantages that: 1, when water is sprayed, a sleeve pipe can be driven by the water power to extend upwards, so that the sleeve pipe has the function of increasing the height; and an impeller of the rotary spraying-flushing device and gaps on a spraying nozzle can cause the water flowing through a spraying pipe to obtain a rotation function; 2, the flowing route in the spraying pipe can be lengthened by the sleeve pipe, so that the rotary spraying-flushing device has the advantage of low energy consumption; 3, the rotary spraying-flushing device can achieve thorough flushing and can flush parts with any angle, and the cleaning efficiency is excellent; and 4, the rotary spraying-flushing device is compact in structure, can be driven by cleaning solution and has the advantages of self-lubrication and self-rotation.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

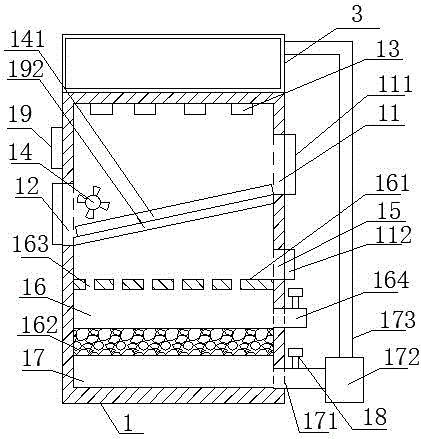

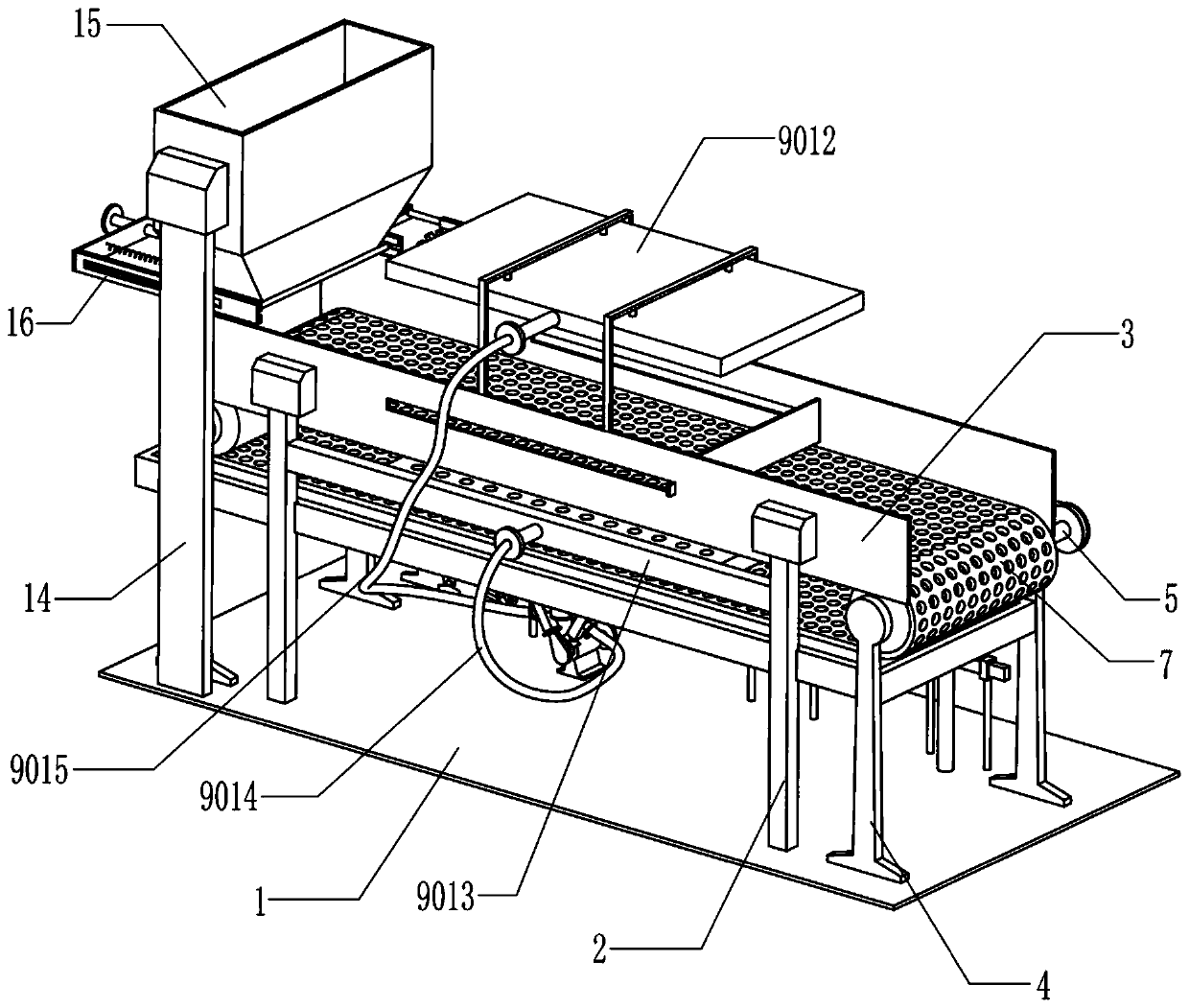

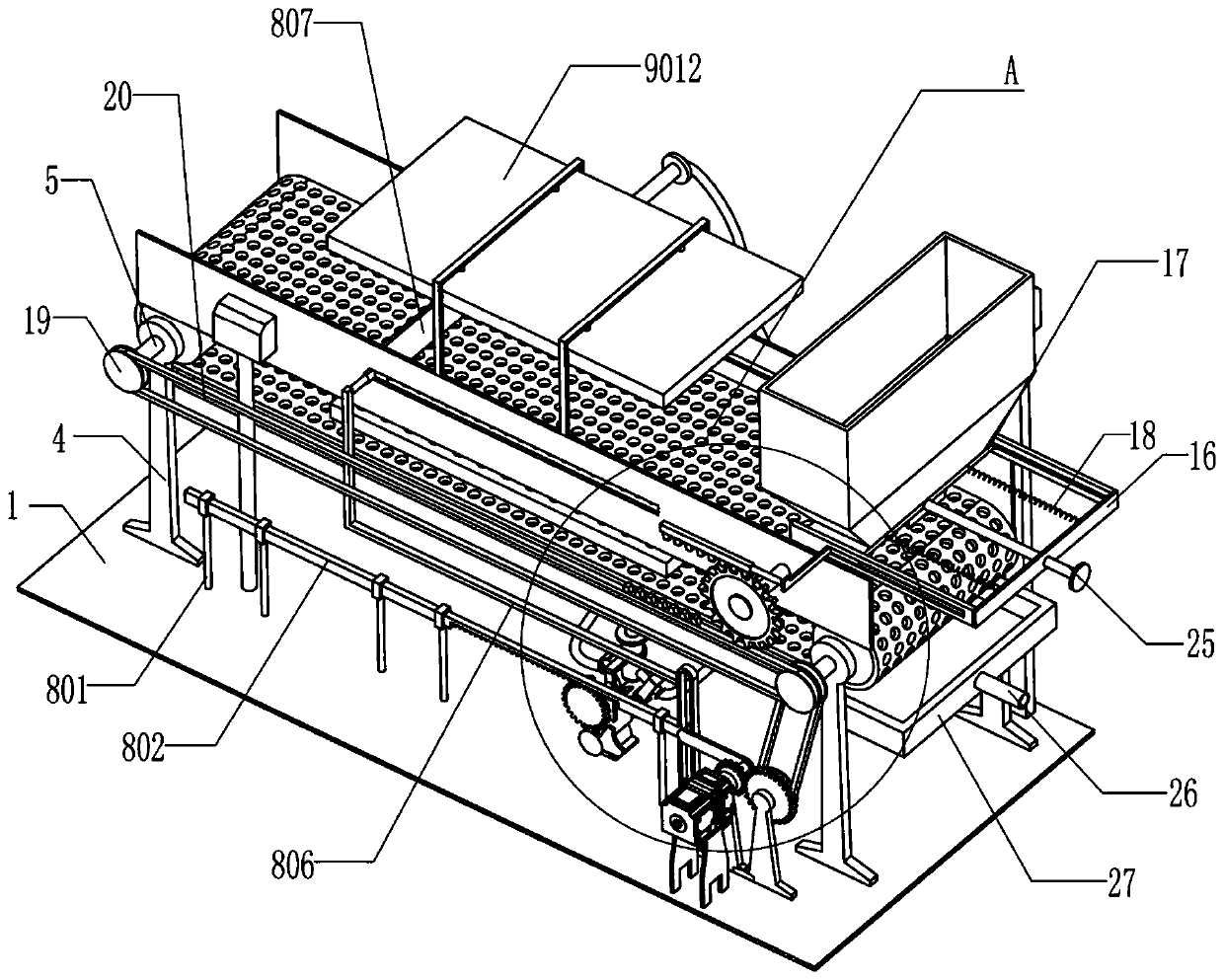

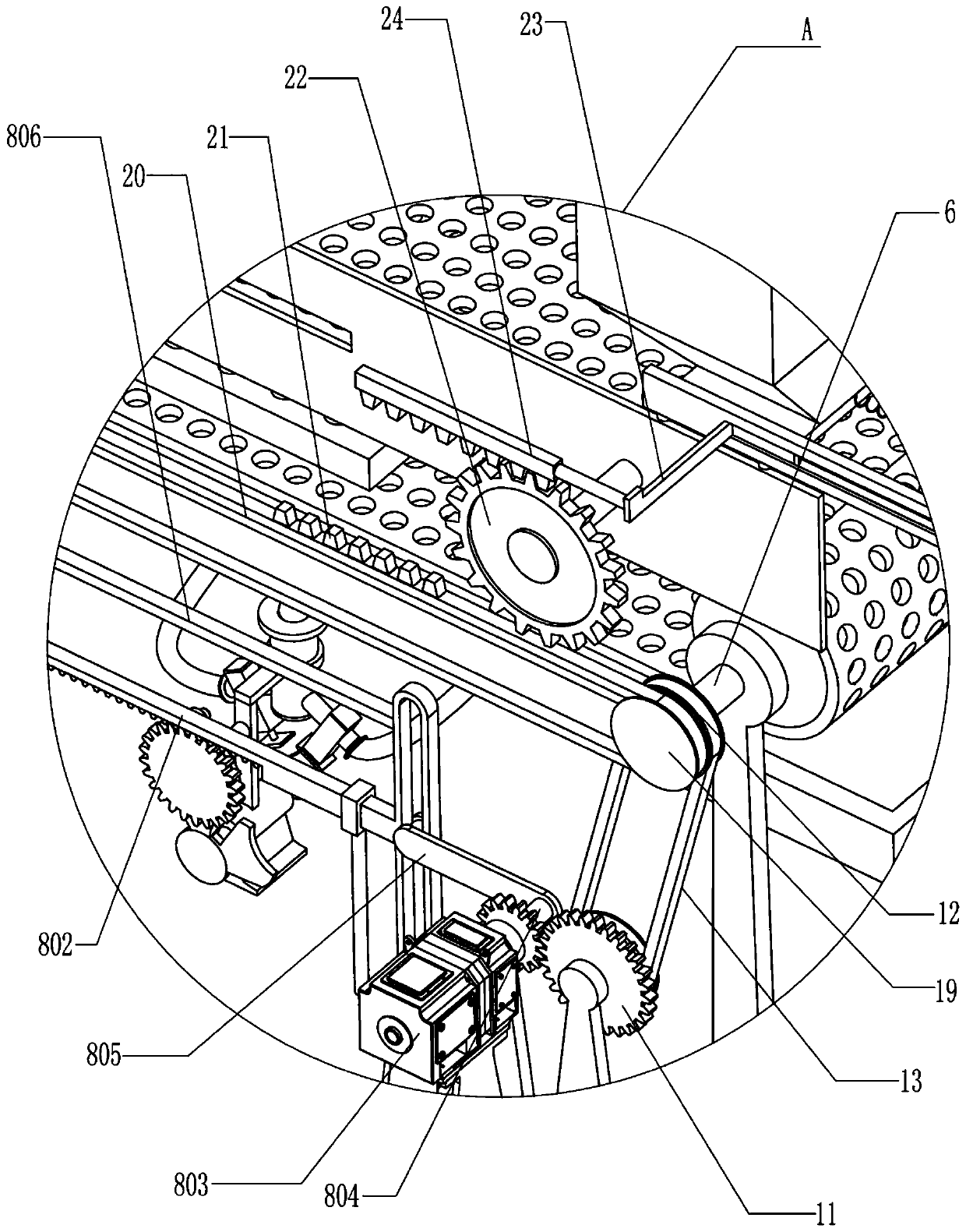

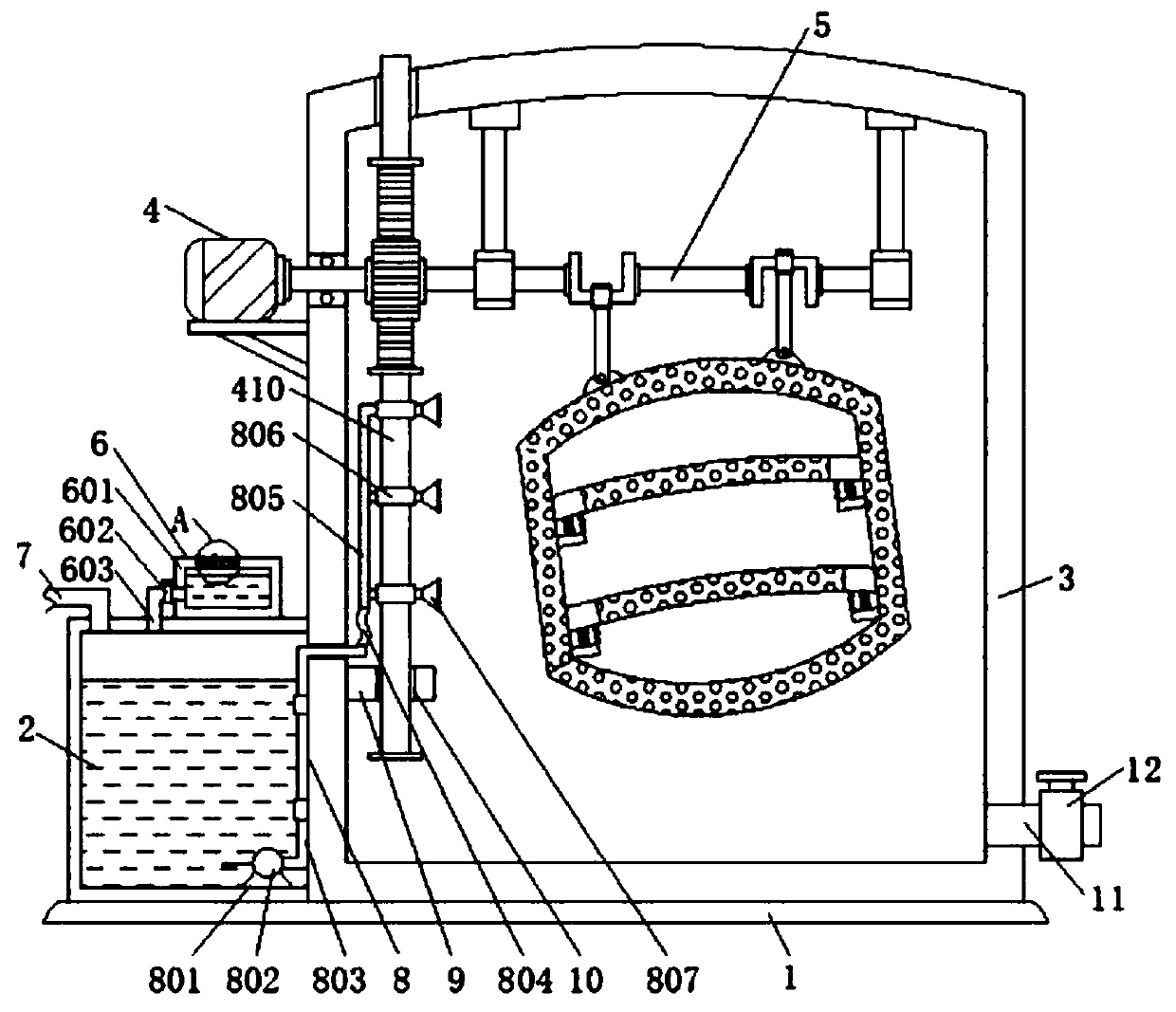

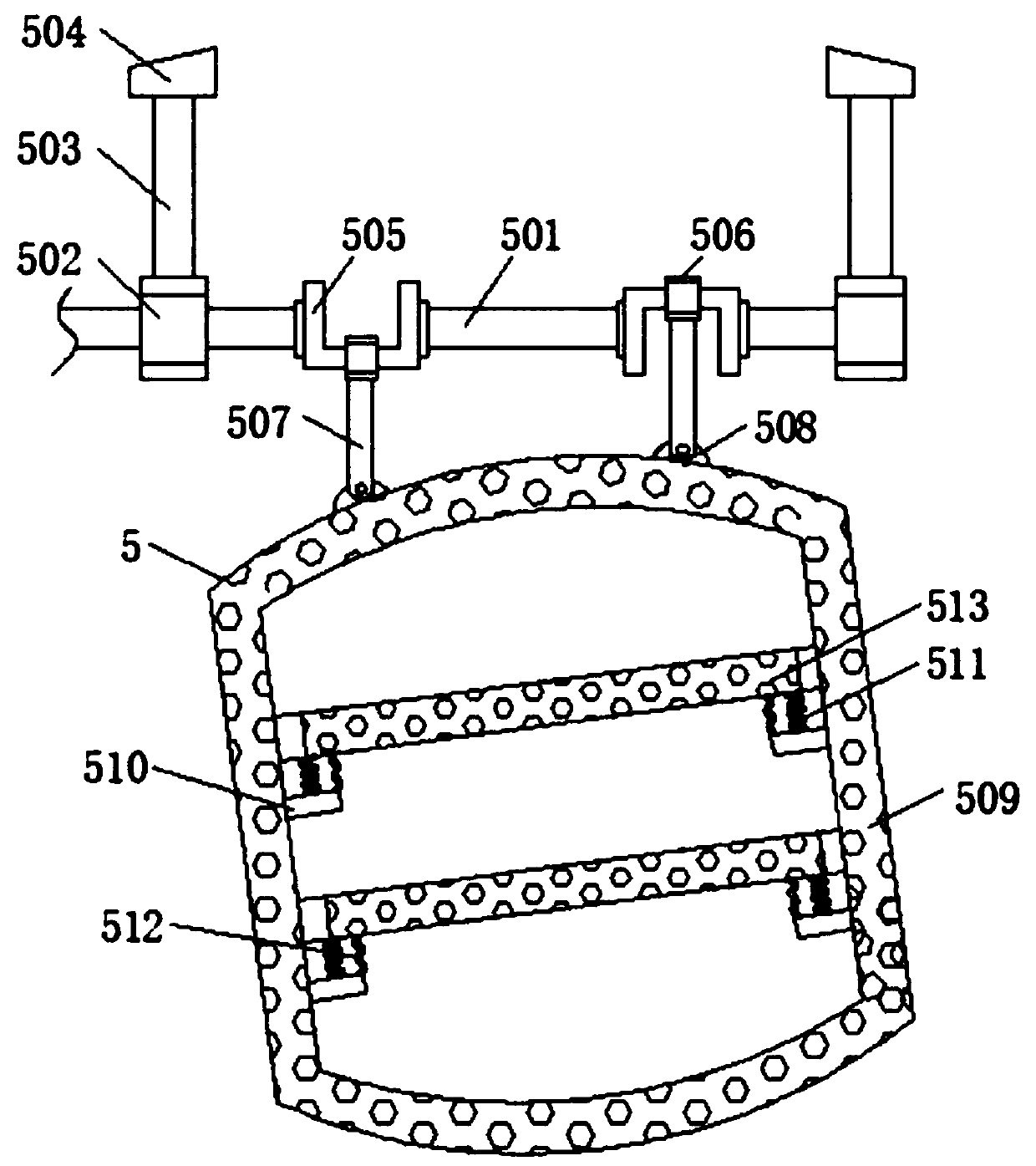

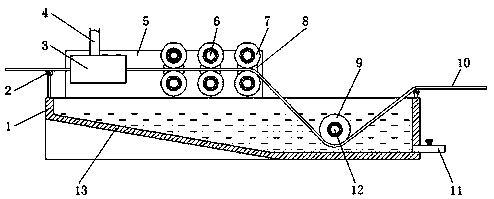

Multi-face washing equipment for broken glass for glass production

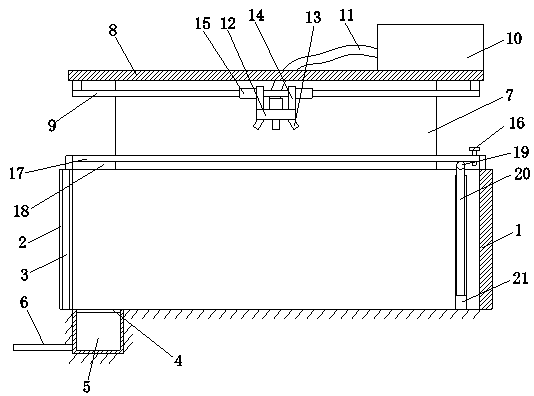

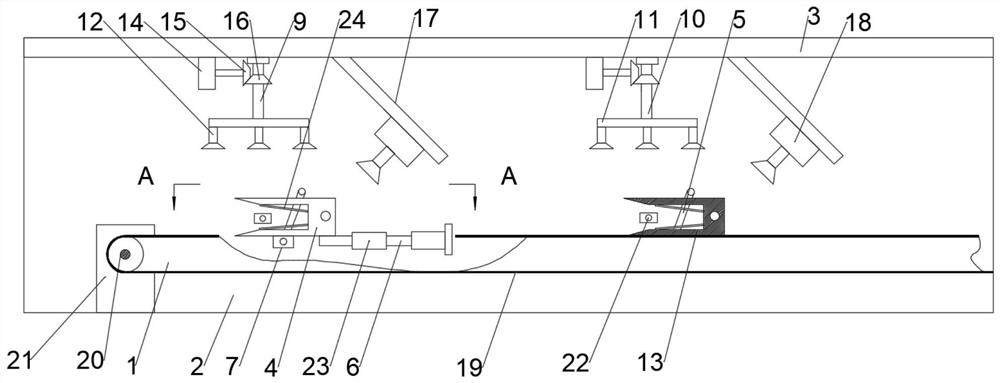

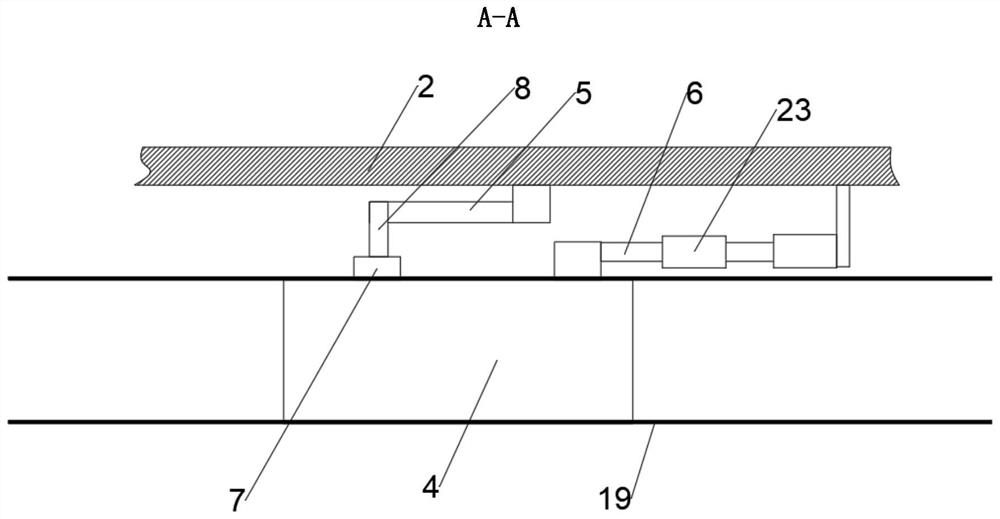

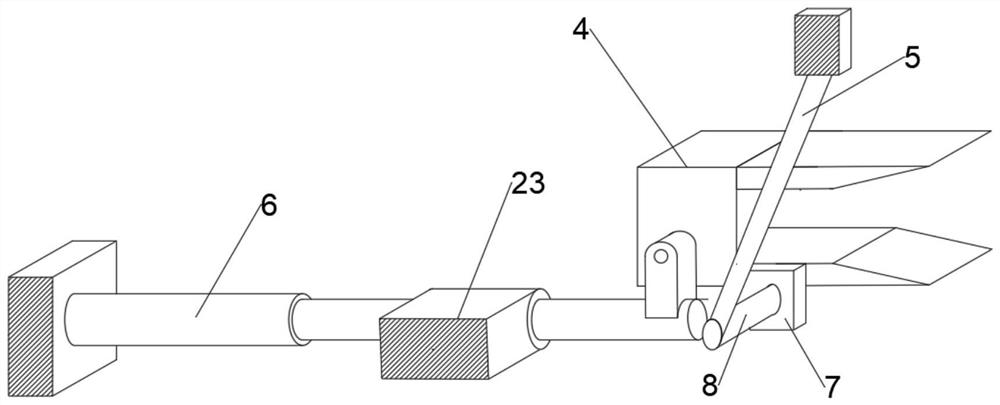

ActiveCN111570373AMeeting Hygiene NeedsFull rinseWater/sewage treatmentFlexible article cleaningConveyor beltGlass production

The invention relates to the technical field of glass processing, in particular to multi-face washing equipment for broken glass for glass production. The multi-face washing equipment for the broken glass for the glass production can spread and disperse the broken glass before washing a large amount of the broken glass, so that each piece of the broken glass can be washed, the upper and lower sides of the broken glass can be washed, and the recycled broken glass can better meet the secondary recycling sanitary standard. According to the technical scheme, the multi-face washing equipment for the broken glass for the glass production comprises a bottom plate, support plates, a limit plate, a support seat, a first transmission roller, a second transmission roller, a mesh conveyor belt and thelike. A plurality of supporting plates are fixedly installed on one side of the bottom plate. Broken glass piles on the mesh conveyor belt can firstly be spread and dispersed, so that each piece of the broken glass can be washed, and the upper and lower sides of the broken glass can be washed completely and thoroughly.

Owner:SUZHOU YUQIAN INFORMATION TECH CO LTD

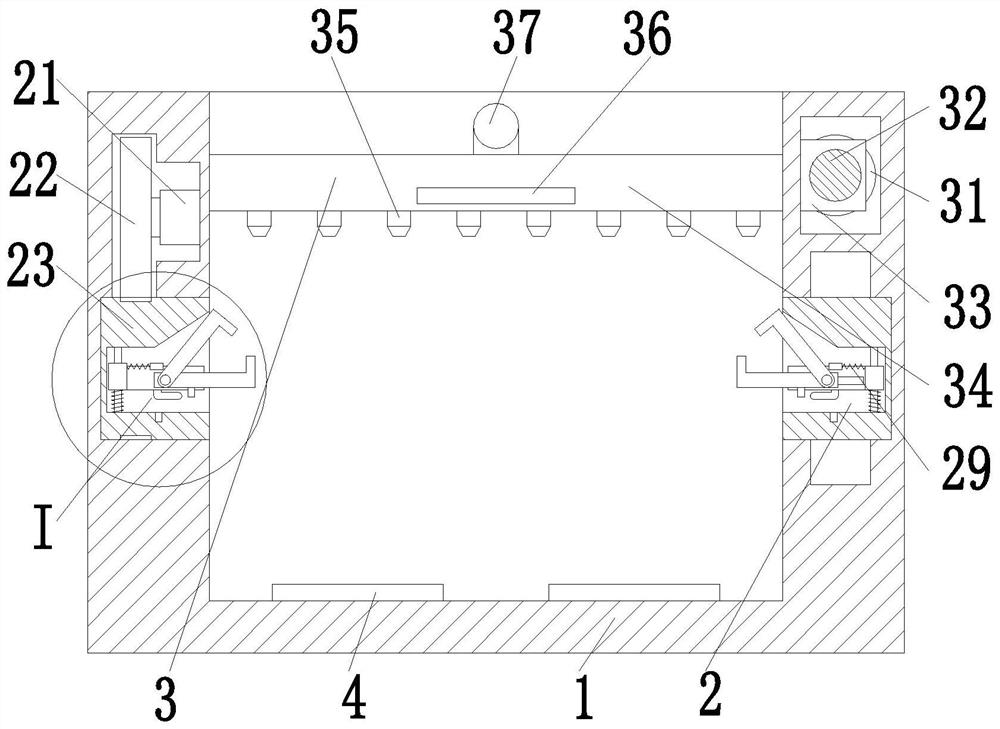

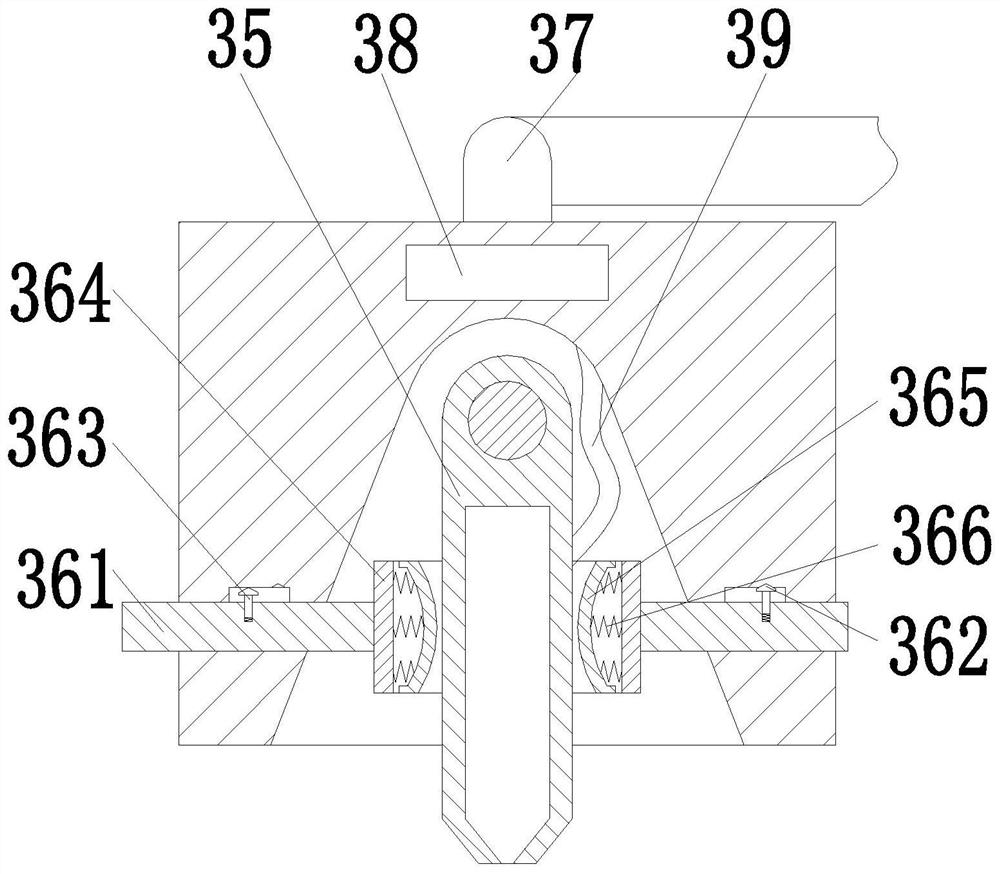

Free swinging device for removing hard yellow mud on surface of codonopsis pilosula and using method

InactiveCN111299263AGood for fallingEffectively eroded and brokenCleaning using liquidsCodonopsis pilosulaMechanical engineering

The invention relates to the technical field of traditional Chinese medicine, in particular to a free swinging device for removing hard yellow mud on the surface of codonopsis pilosula and a using method, and aims to solve the technical problem that after yellow soil is sun-dried, hard blocks are formed and attached to the surface of codonopsis pilosula as well as difficult to simply wash out. Inorder to solve the above technical problem, the free swinging device for removing the hard yellow mud on the surface of codonopsis pilosula is provided. The free swinging device comprises a base, wherein a water tank and a cleaning box are fixedly connected with the top of the base from left to right; a power actuator is fixedly connected with the top of one side of the cleaning box; and the output end of the power actuator penetrates through and extends into the cleaning box. By the adoption of the free swinging device, the hard yellow soil blocks can be effectively eroded and broken; the removal of the hard yellow soil blocks from the surface of codonopsis pilosula can be facilitated; and the problem that after the yellow soil is sun-dried, the hard blocks are formed and attached to thesurface of codonopsis pilosula as well as difficult to simply wash out can be solved.

Owner:杨喜兰

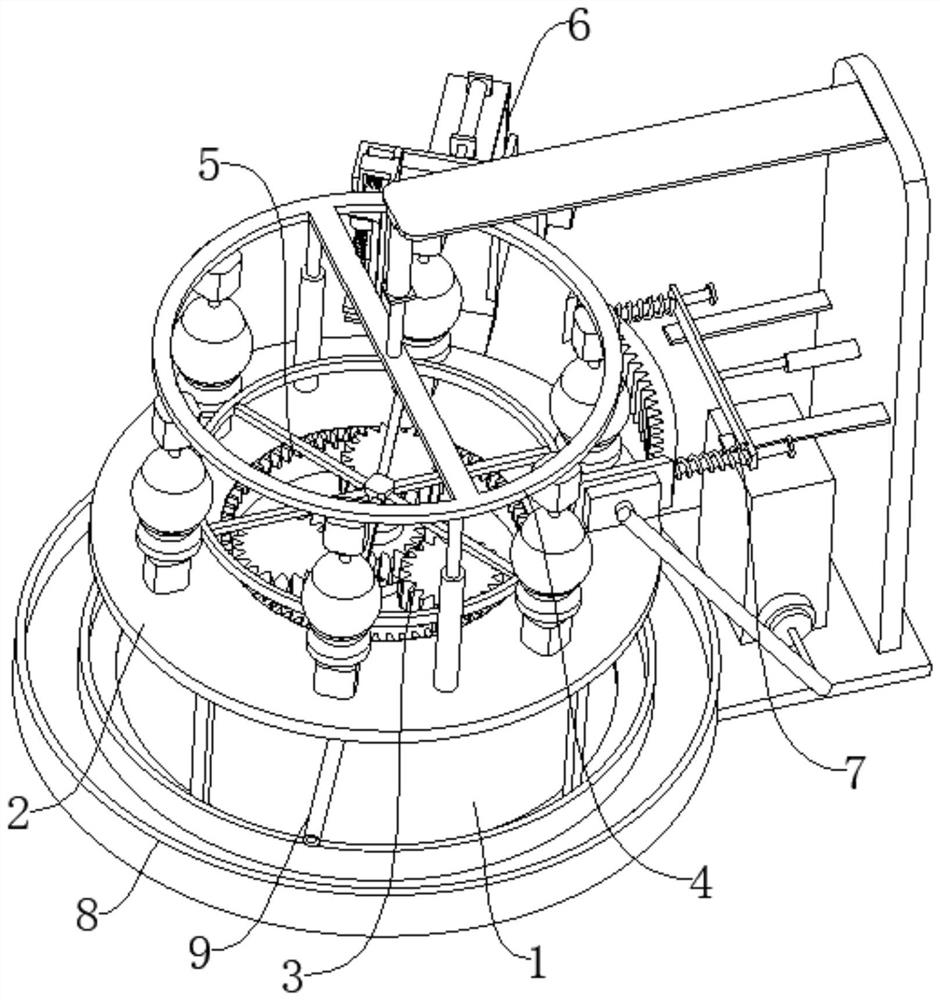

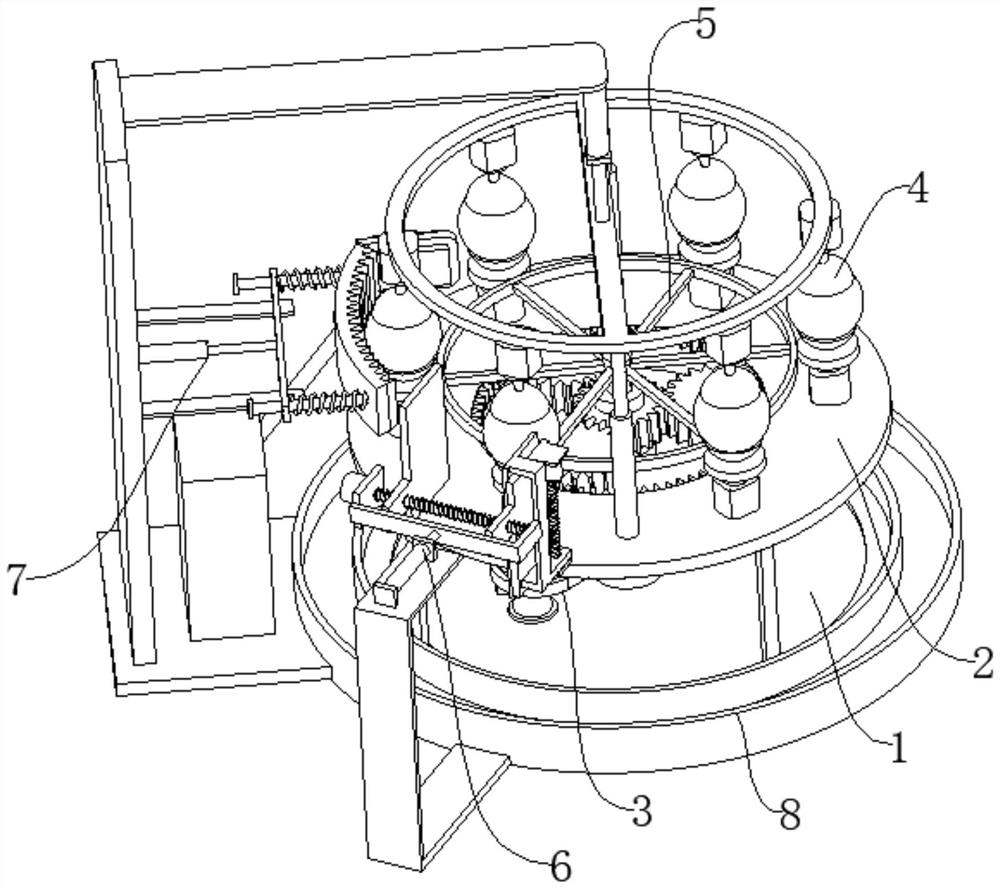

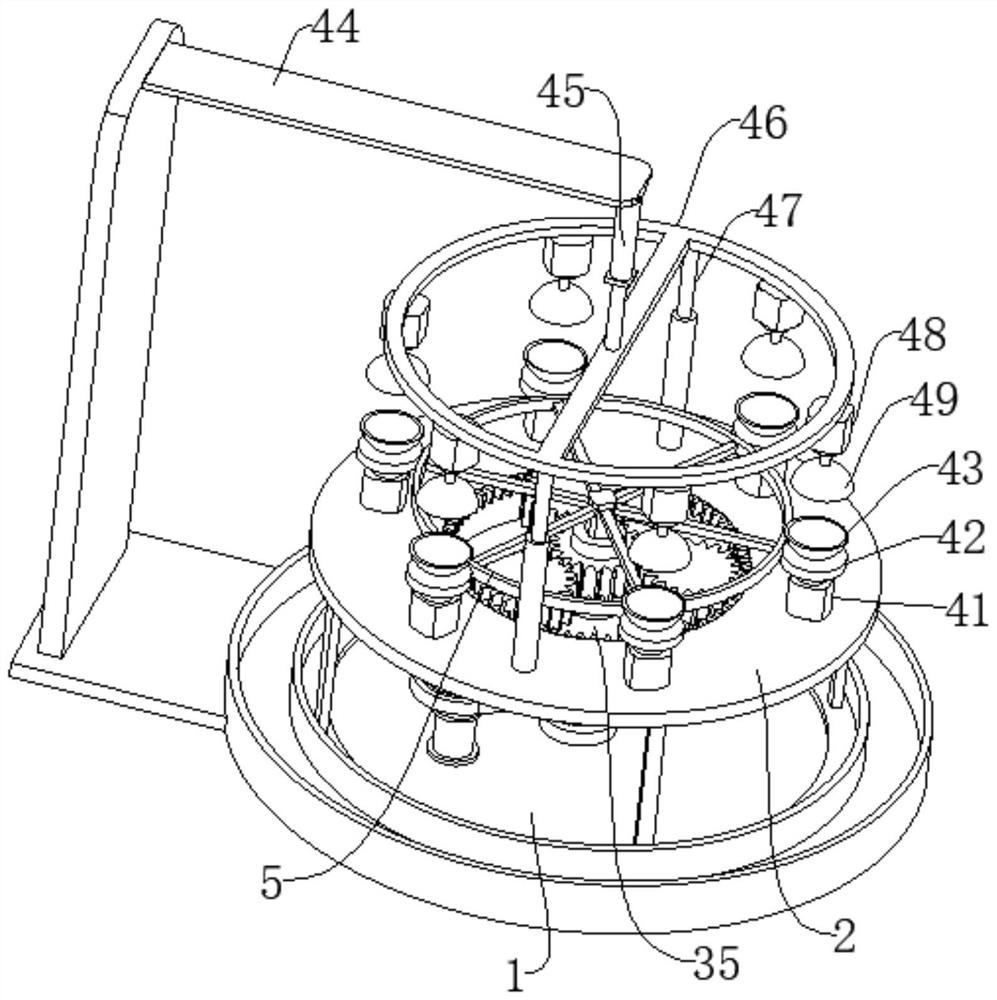

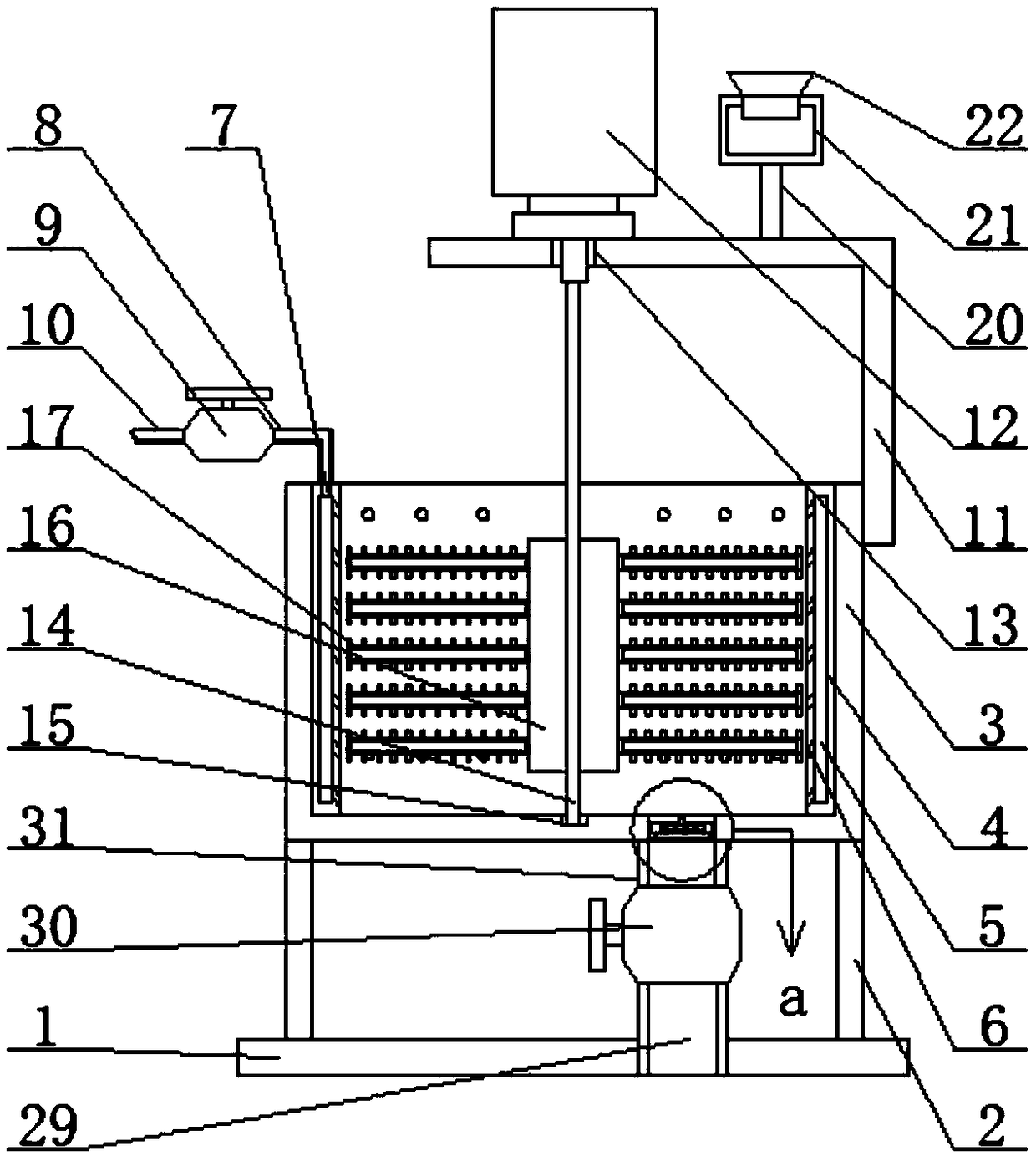

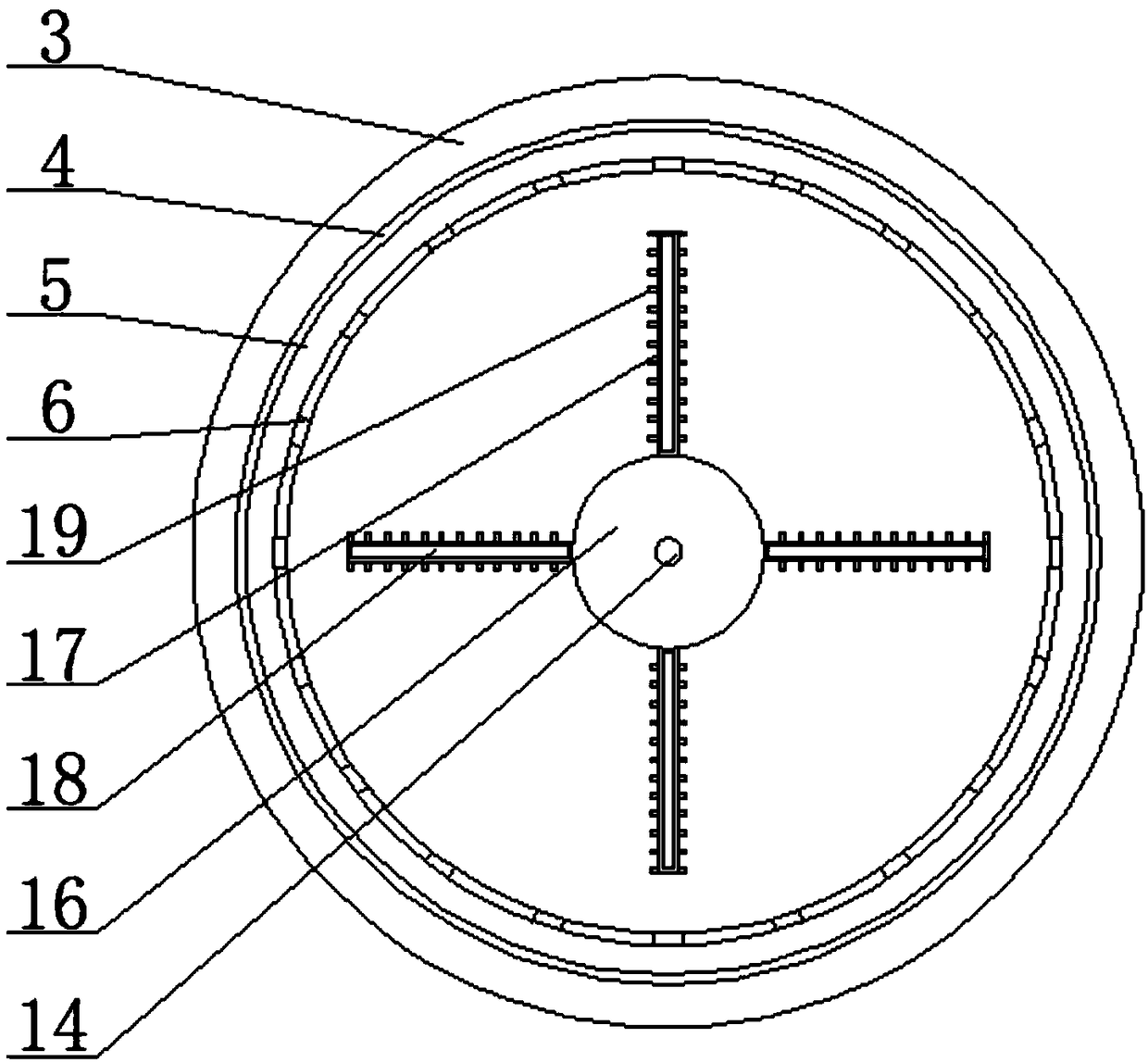

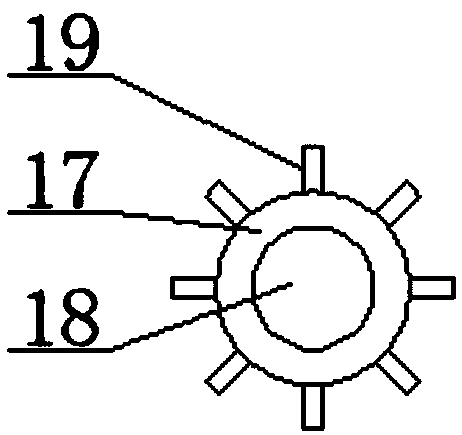

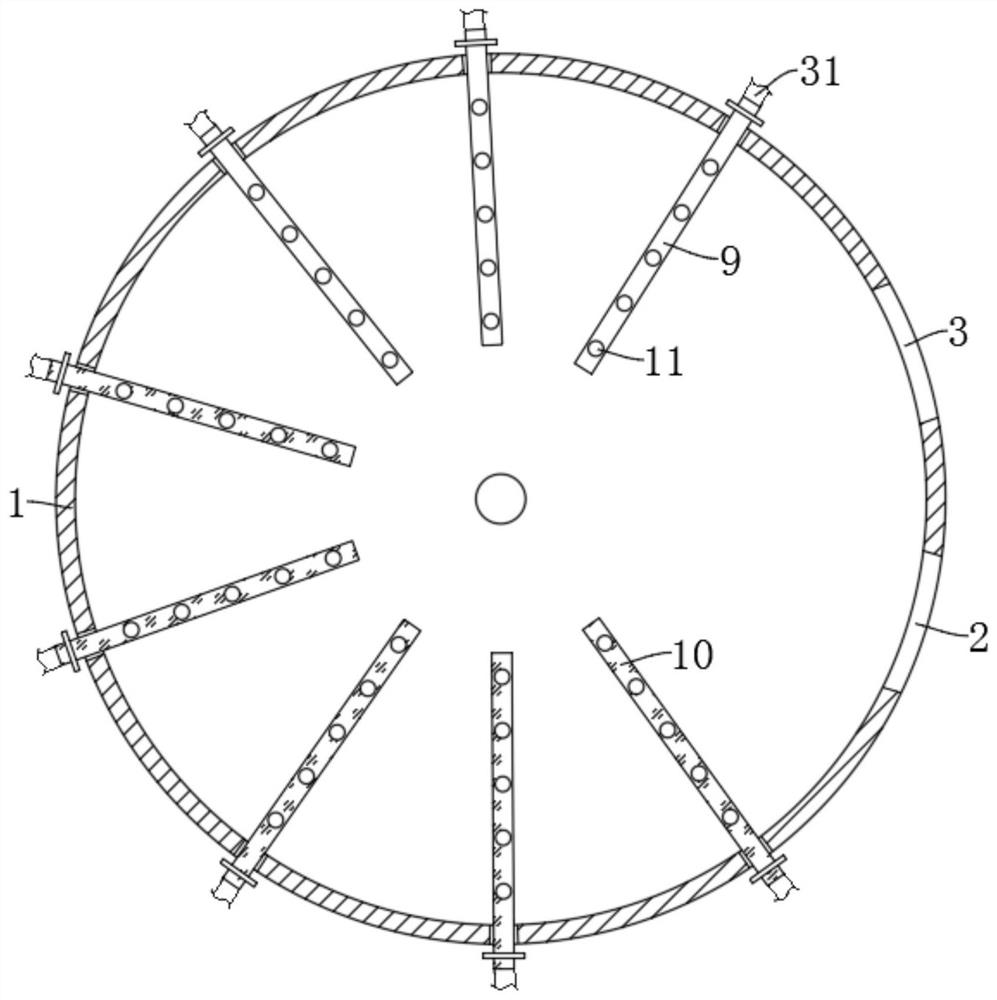

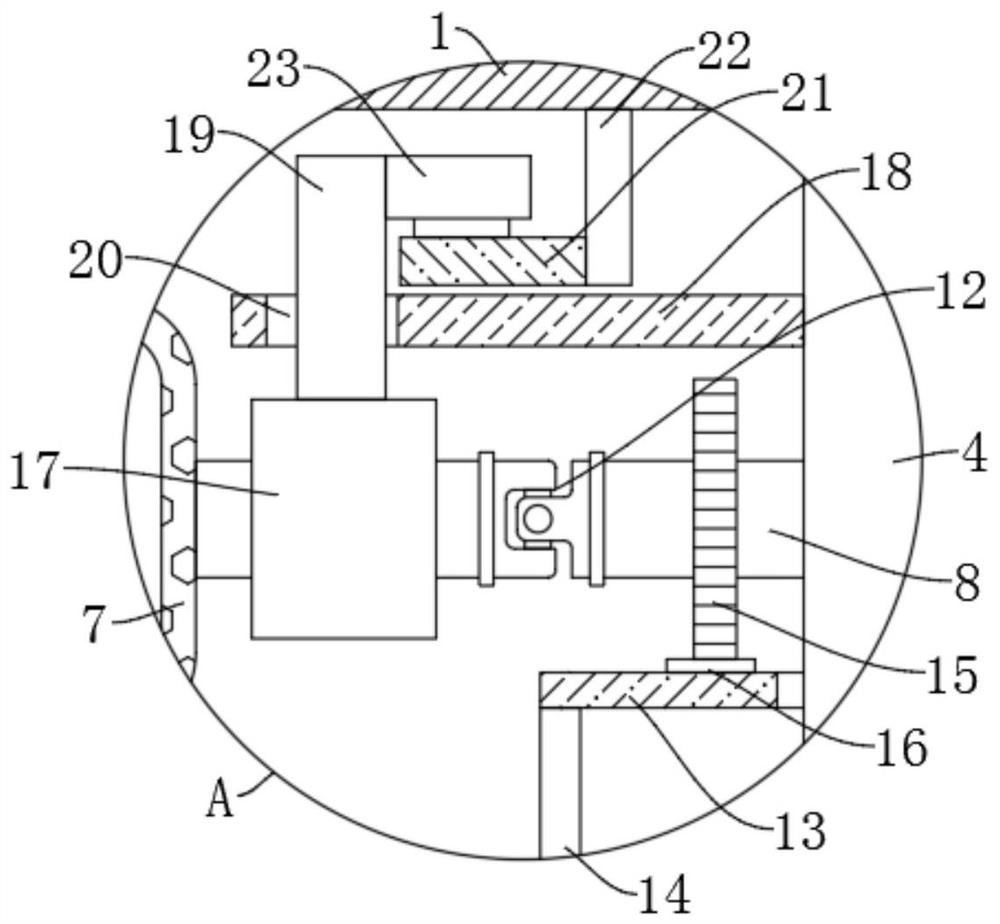

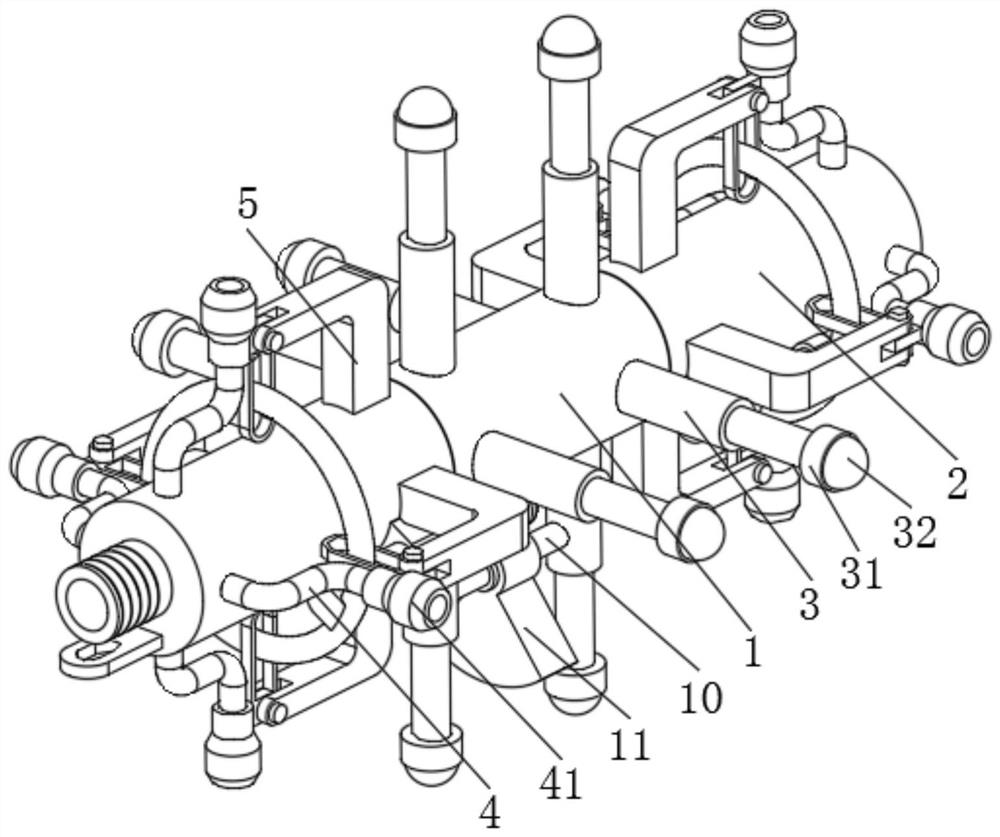

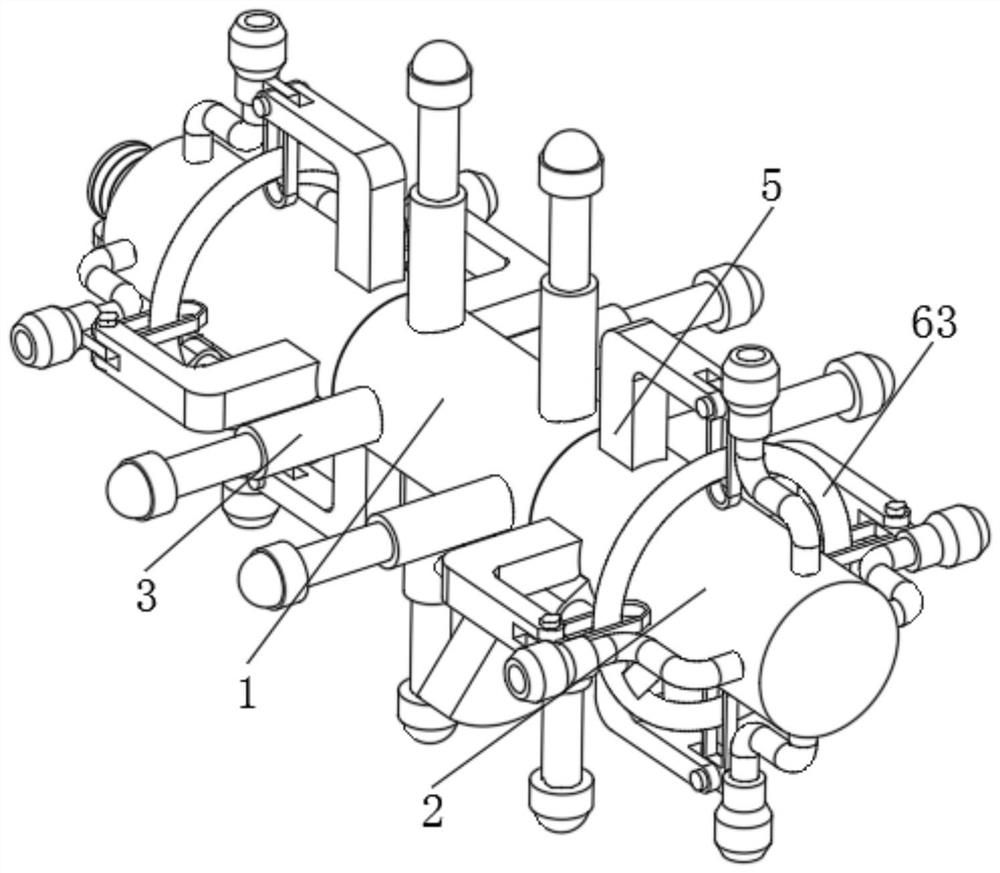

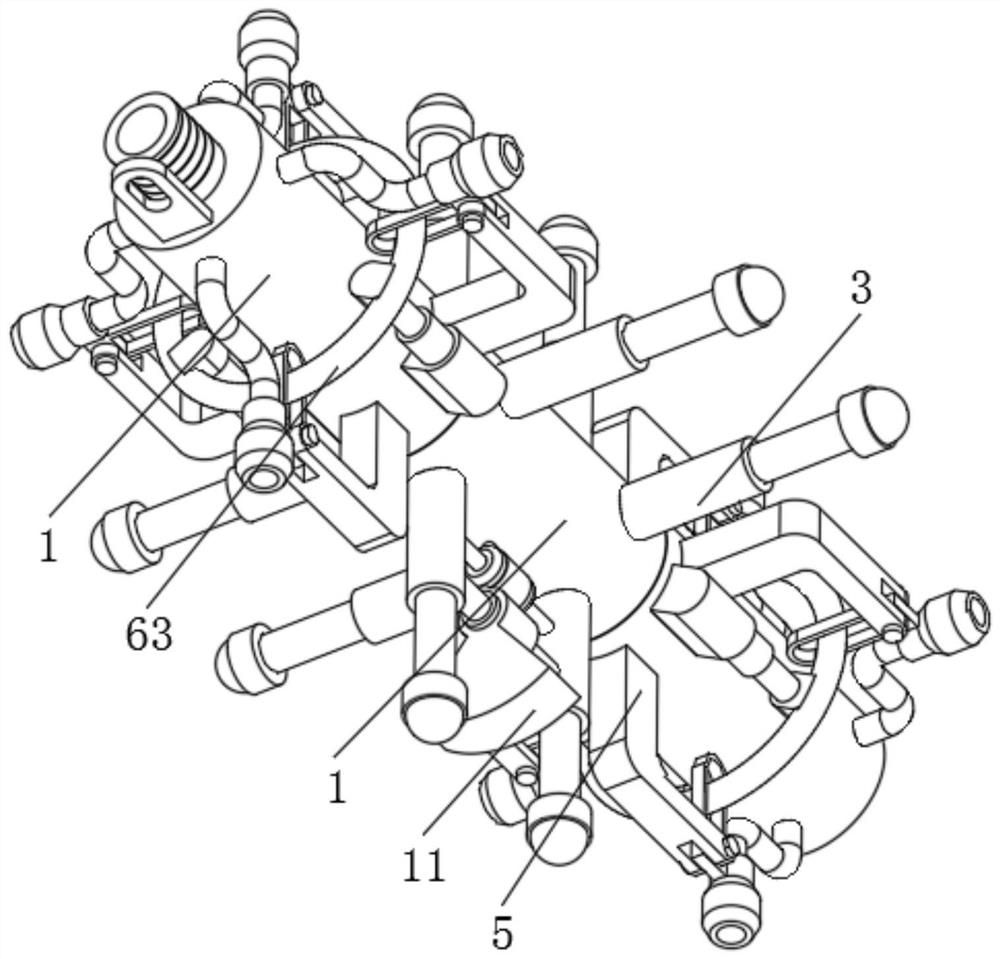

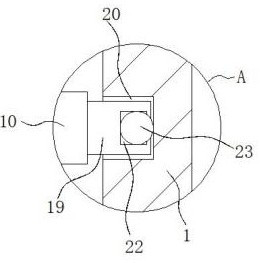

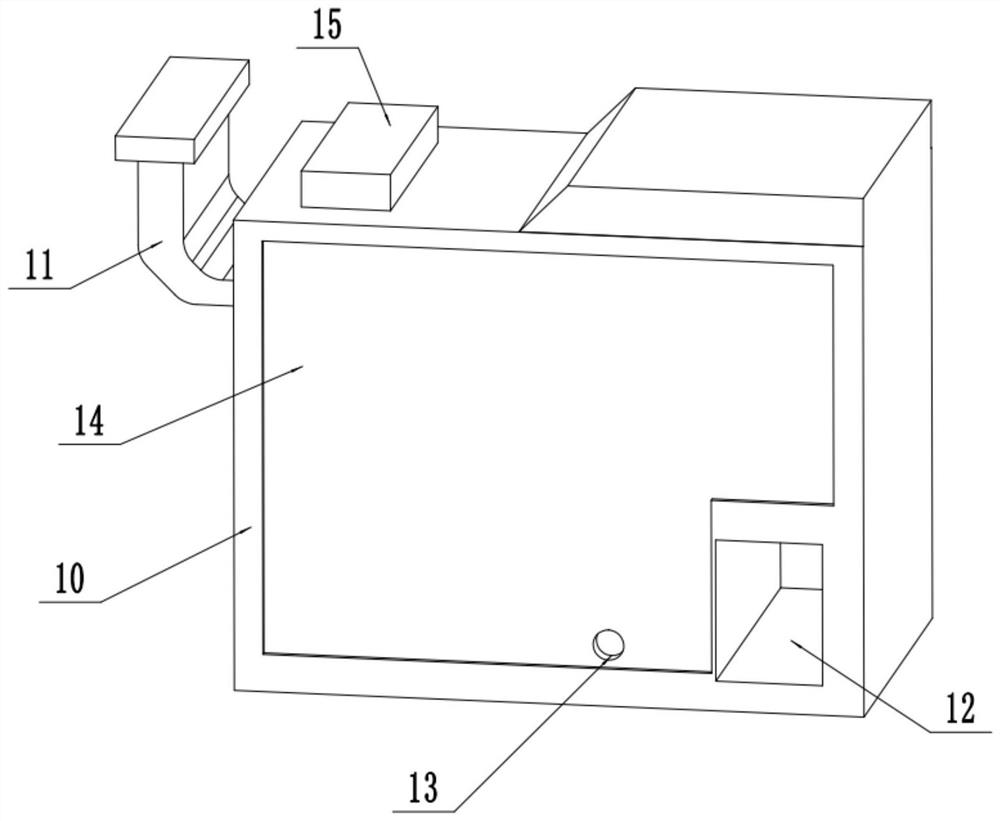

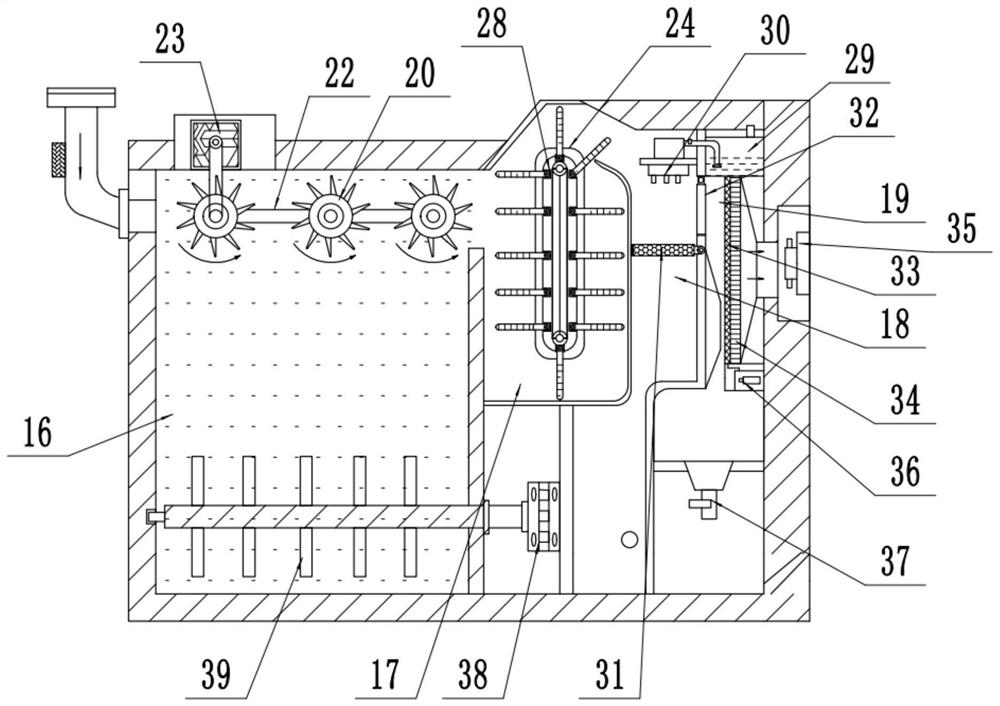

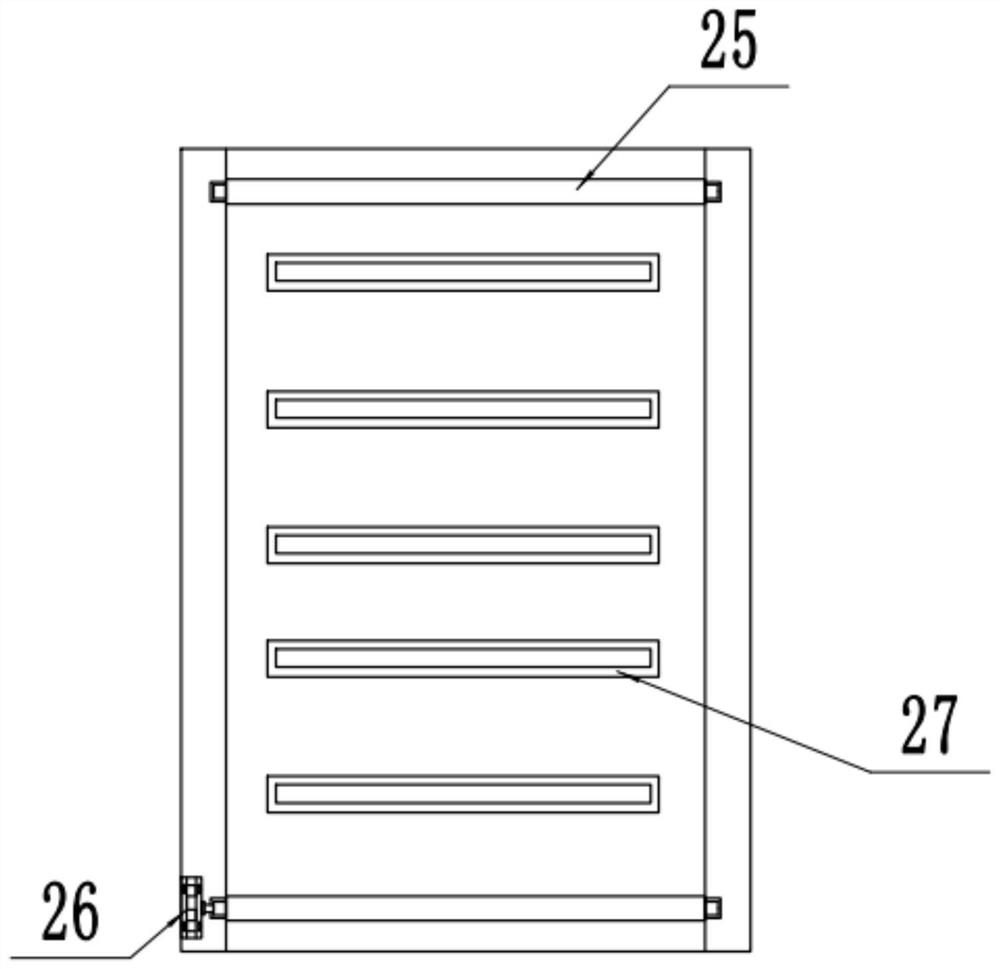

Automatic reversing and cleaning device of spherical catalyst for coke oven flue gas desulfurization

ActiveCN113500027AFull rinseEasy to cleanCatalyst regeneration/reactivationCleaning using toolsPtru catalystEngineering

The invention discloses an automatic reversing and cleaning device of a spherical catalyst for coke oven flue gas desulfurization. The device comprises a base and an annular rotating plate rotationally connected to the top of the base, wherein a driving mechanism used for driving the rotating plate to rotate is arranged at the top of the base, a fixing mechanism used for fixing the spherical catalyst is arranged above the rotating plate, a cleaning mechanism and a reversing mechanism are arranged on one side of the base, the cleaning mechanism sprays water to clean the catalyst, the reversing mechanism reverses the cleaned spherical catalyst, and the fixing mechanism comprises a plurality of first fixing seats fixed to the top of the rotating plate and evenly distributed, rotating discs rotationally connected to the tops of the first fixing seats, containing seats rotationally connected to the tops of the rotating discs, a mounting frame fixed to one side of the base, and a first air cylinder mounted on the mounting frame and vertically arranged. The cleaning device is capable of automatically reversing the catalyst, free of cleaning dead angles, good in cleaning effect, high in automation degree and convenient to use.

Owner:安徽紫朔环境工程技术有限公司

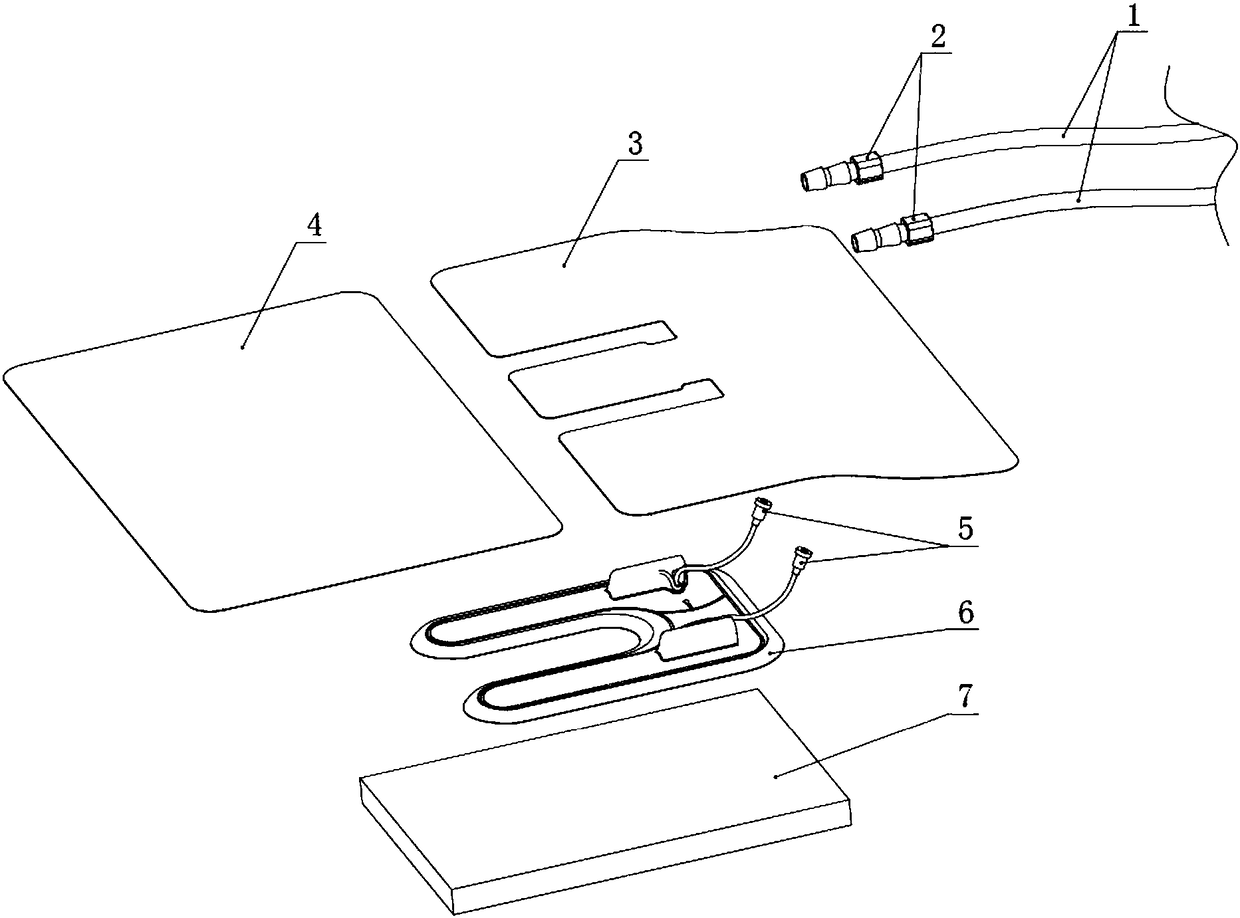

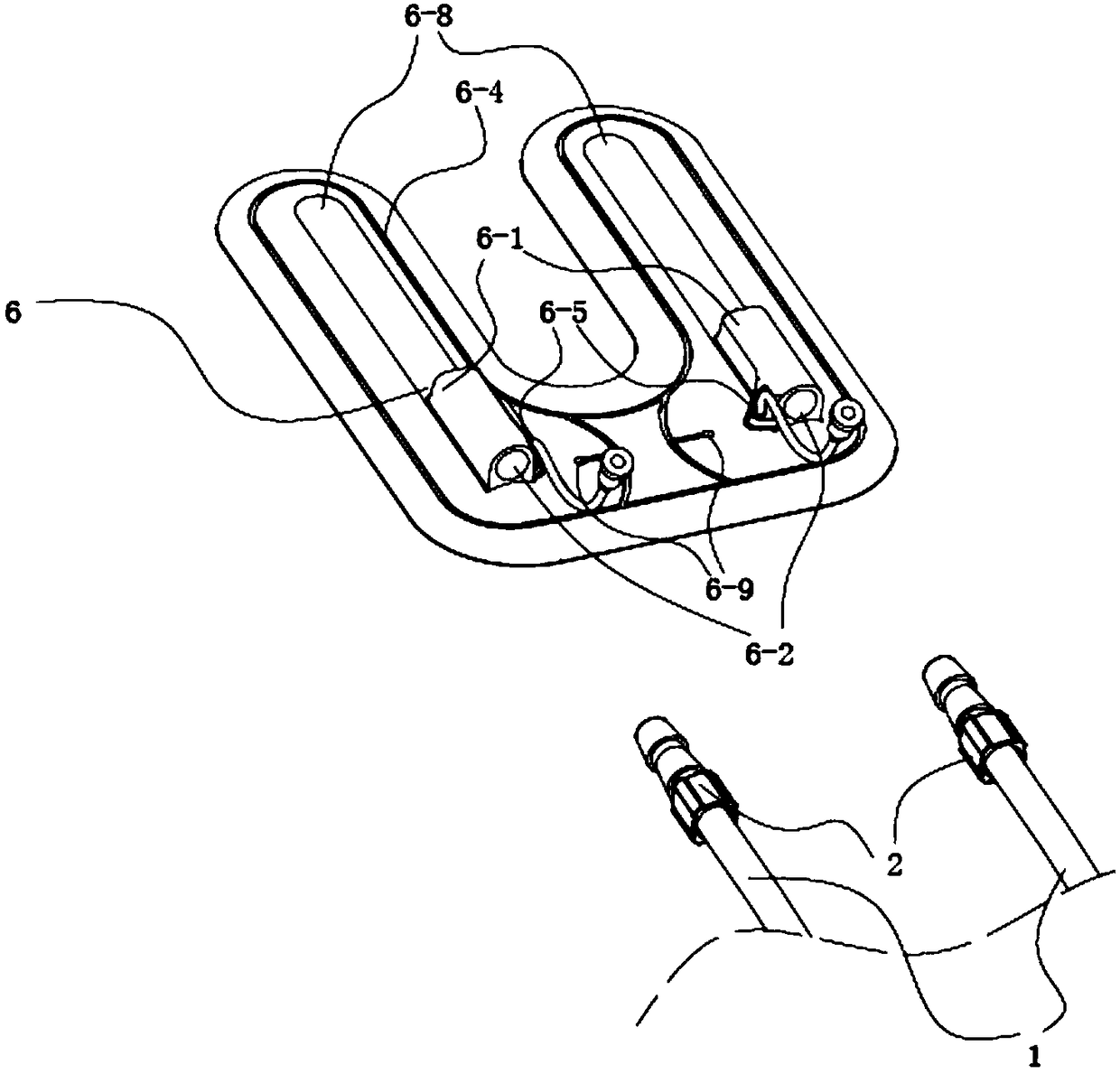

Embedded-type vacuum sealing drainage device for comprehensive washing

PendingCN108378988ASolve indentationEffective flushingMedical devicesAdhesive dressingsWound skinBody contact

The invention discloses an embedded-type vacuum sealing drainage device for comprehensive washing. The embedded-type vacuum sealing drainage device comprises a lower surface and a porous foam body contacting with the wound skin surface of a patient. A flow guide connector is arranged on the upper side of the porous foam body, and is provided with a flow guide channel, a washing channel and a catheter support base. The front end, connected with a liquid collection bottle, of an external drainage pipe is fixed to the catheter support base through a pagoda-shaped joint, and is communicated with the drainage channel. An external washing pipe connected with an external washing liquid storage container is fixed to the catheter support base, and is communicated with the washing channel. A medicalfilm arranged on the upper side of the flow guide connector seals the flow guide connector, the porous foam body and the skin of the patient. The embedded-type vacuum sealing drainage device has theadvantages that exudates of a to-be-drained region is drained actively, continuously and efficiently through external negative pressure, the wound surface is enabled to be in a zero-gathering environment, and secondary absorption of organism toxin is reduced; sponge and the wound surface are washed comprehensively and continuously by washing liquid, and indentations are avoided without reduction of drainage effect when the wound surface is treated for a long time.

Owner:WUHAN VSD MEDICAL SCI & TECH CO LTD

Fully automatic processing device for vegetable cleaning production

The invention discloses a fully automatic processing device for vegetable cleaning production. The fully automatic processing device comprises a bottom plate; supporting columns are fixedly connectedto the two sides of the upper end of the bottom plate; and a cylinder is fixedly connected to the upper ends of the supporting column. A circular ring is fixedly installed at the inner wall of the cylinder; an annular inner cavity is formed inside the circular ring; oblique holes are formed uniformly and annularly in the inner wall inside the annular inner cavity; and a water inlet hole is formedin the upper side of the annular inner cavity. A right-angle pipe member is fixedly connected to the upper port of the water inlet hole; a stop valve is fixedly connected to the left port of the right-angle pipe member; and a water pipe is fixedly connected to the water inlet port of the stop valve. With the oblique holes arranged uniformly, vegetables added into the upper side and the lower sideinside the cylinder can be washed with the good effect; with protrusions in contact with the vegetable, mud on the vegetables can be swept down quickly and thus the mud cleaning effect on the surfacesof the vegetables is good; and large impurities in vegetable washing water also can be cleaned away.

Owner:GUANGZHOU RESTAURANT GRP LIKOUFU FOOD +1

Surface treatment device for lithium battery after processing forming

InactiveCN112382796AIncrease frictionFull rinseNon-aqueous electrolyte cellsRotary stirring mixersEngineeringStructural engineering

The invention discloses a surface treatment device for a lithium battery after processing forming. The device comprises a device frame, a centralizing pool and an outer frame body. A bearing seat is arranged at the upper end of the device frame, rollers are connected through a first chain, the rear end of the roller on the right side is connected with a first rotating shaft through a second chain,the centralizing pool is arranged below the device frame. The rear ends of the stirring rods are connected with second rotating shafts, the second rotating shafts are connected through a synchronousbelt, the outer frame body is arranged on the outer side of the device frame, the lower end of the first hydraulic telescopic rod is connected with a sweeping mechanism, and a drying box is arranged on the outer frame body. According to the surface treatment device for a lithium battery after processing forming, the sweeping mechanism is pushed to make contact with the lithium battery under the action of a first hydraulic telescopic rod, the surface of the lithium battery can be swept through a brush roller and flushed through cleaning liquid, and meanwhile, a second hydraulic telescopic rod pushes a wiping mechanism to make contact with the lithium battery and wipes and cleans the surface of the lithium battery through a wiping roller and flushes clean water, and cleaning effect is guaranteed.

Owner:江苏超聚新能源科技有限公司

Surgical instrument cleaning device

ActiveCN113208747AImprove flushing effect and efficiencyQuick rinseDrying solid materials without heatDiagnosticsElectric machinerySurgical instrument

The invention discloses a surgical instrument cleaning device, and belongs to the field of medical treatment. The surgical instrument cleaning device comprises a cleaning box; a placing opening and a fetching opening are adjacently arranged on a side wall of the cleaning box; a rotating shaft is rotationally connected between the upper inner wall and the lower inner wall of the cleaning box; a motor is fixedly mounted at the upper end of the cleaning box; the output end of the motor is connected with the rotating shaft in a meshed mode through two first gears; a plurality of cylindrical mesh enclosures are circumferentially distributed in the cleaning box; a plurality of water spraying pipes and gas ejecting pipes are fixedly mounted at the inner top of the cleaning box; spraying heads are arranged at the lower ends of the gas ejecting pipes and the lower ends of the water spraying pipes; the cylindrical mesh enclosures are connected with a rotating shaft through autorotation mechanisms; and the plurality of gas ejecting pipes are connected with the rotating shaft through cylinder mechanisms. The surgical instrument cleaning device disclosed by the invention can be conveniently and effectively cleaned, and has higher inclination efficiency; and moreover, the surgical instruments can be air-dried.

Owner:HUNAN PROVINCIAL TUMOR HOSPITAL

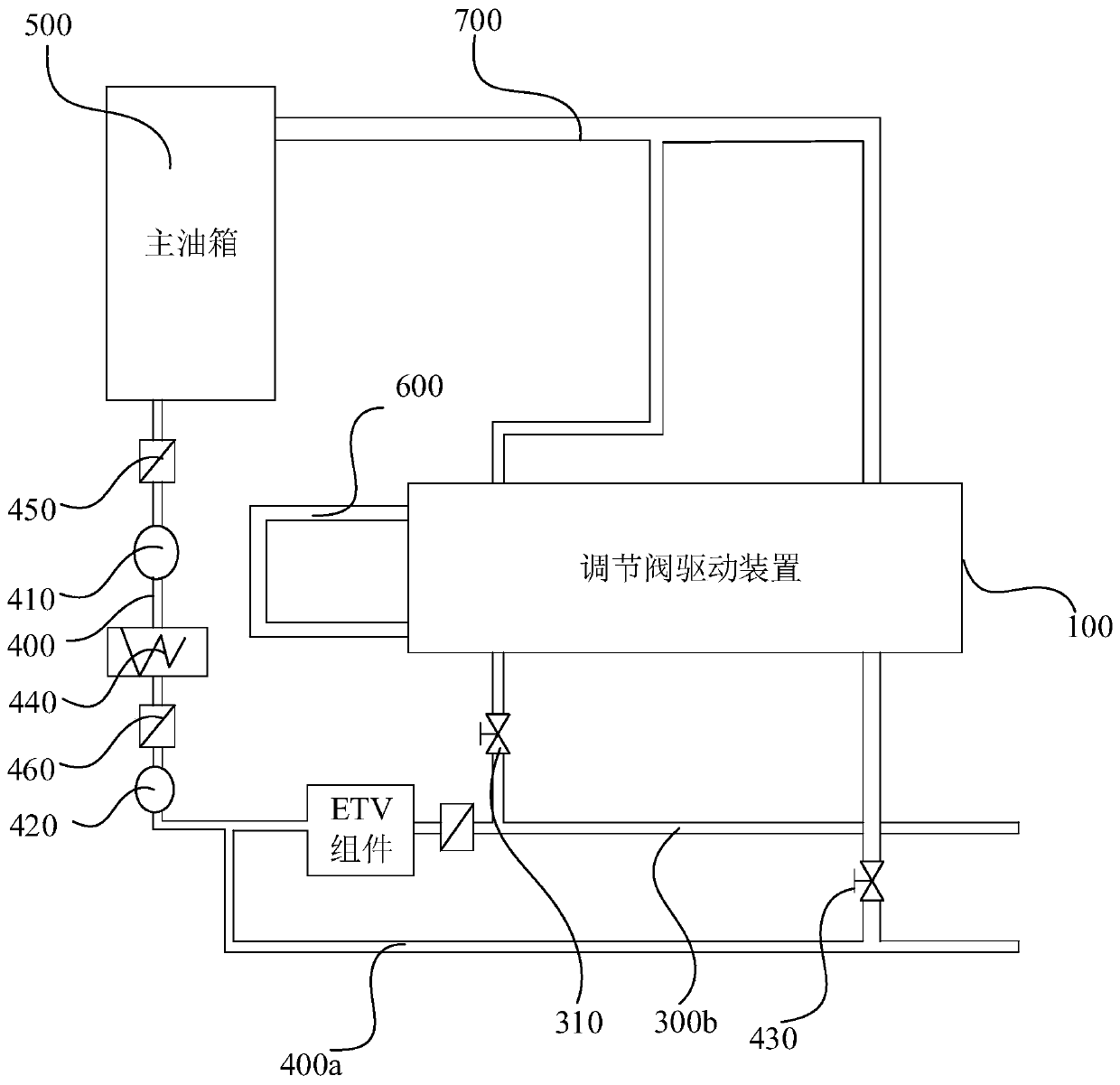

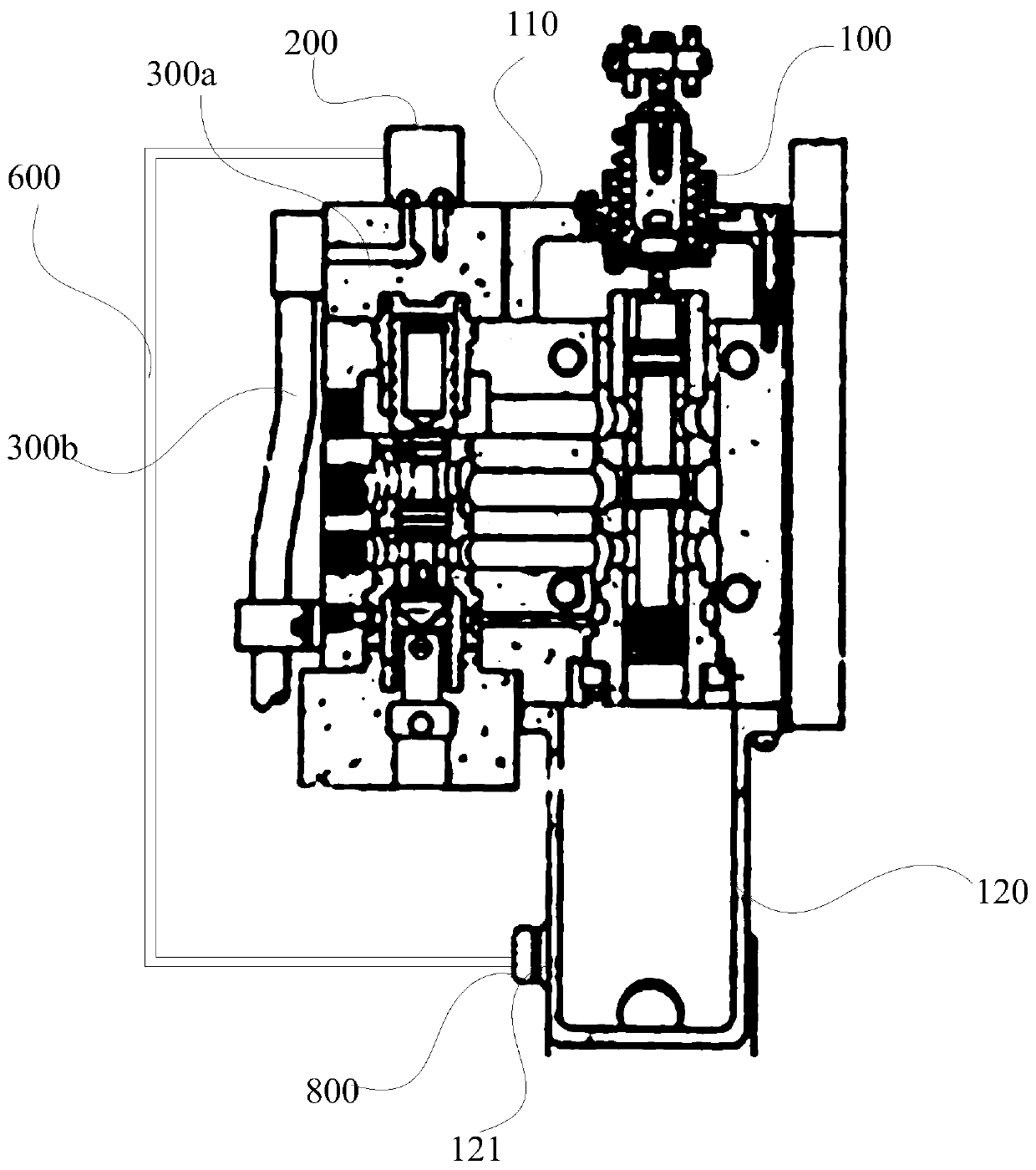

Flushing method of nuclear power station steam turbine adjusting oil system

ActiveCN110153112AReduce in quantityReduce the risk of oil spill accidentsHollow article cleaningIsolation valveNuclear power

The invention relates to a flushing method of a nuclear power station steam turbine adjusting oil system. The flushing method includes the steps that a header block is provided, the header block is connected with an adjusting valve drive mechanism device, a drainage pipeline is arranged in the header block, an oil inlet and an oil outlet are formed in the two ends of the drainage pipeline separately, the oil inlet of the drainage pipeline communicates with a protective oil branch pipe in the adjusting valve drive mechanism device, and the protective oil branch pipe in the adjusting valve drivemechanism device communicates with an oil tank through a protective oil mother pipe and a power oil pipe in sequence; a flushing hose is provided, one end of the flushing hose communicates with the oil outlet of the drainage pipeline, and the end, away from the header block, of the flushing hose communicates with the oil tank through an oil return pipe; and a pump is started, a power oil isolating valve is switched off, protective oil in the oil tank sequentially passes through a system mother pipe, the protective oil mother pipe, the protective oil branch pipe, the drainage pipeline in the header block, the flushing hose and the oil return pipe to flow back to the oil tank, and therefore protective oil flushing is completed. The risk of oil leakage accidents is reduced, and the flushingefficiency is improved.

Owner:CHINA GENERAL NUCLEAR POWER OPERATION +2

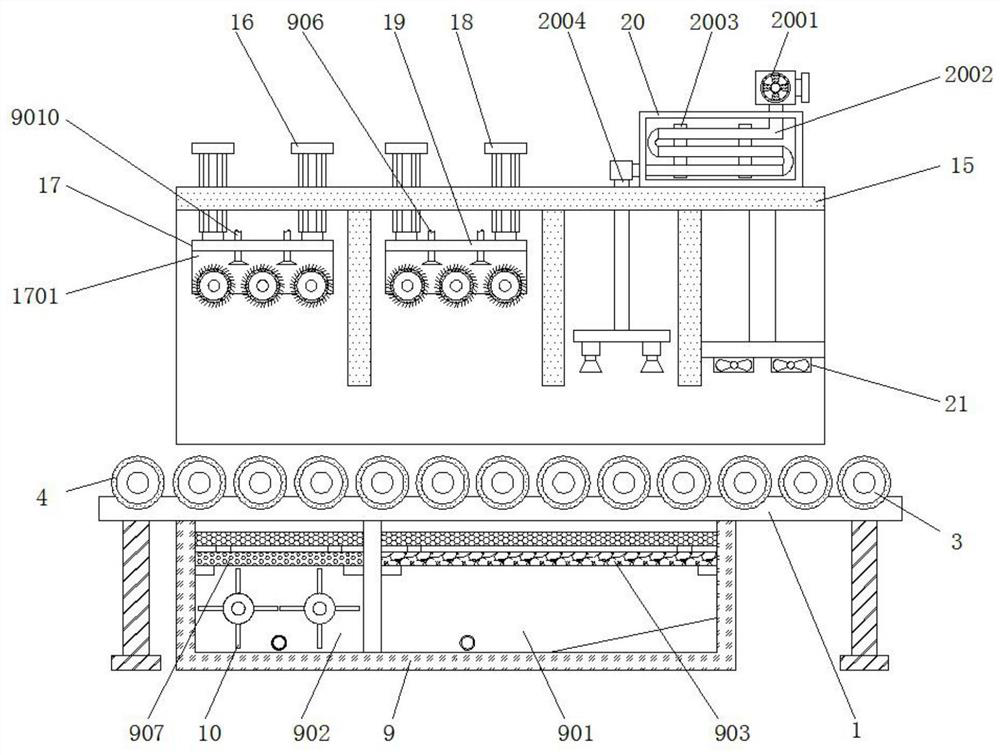

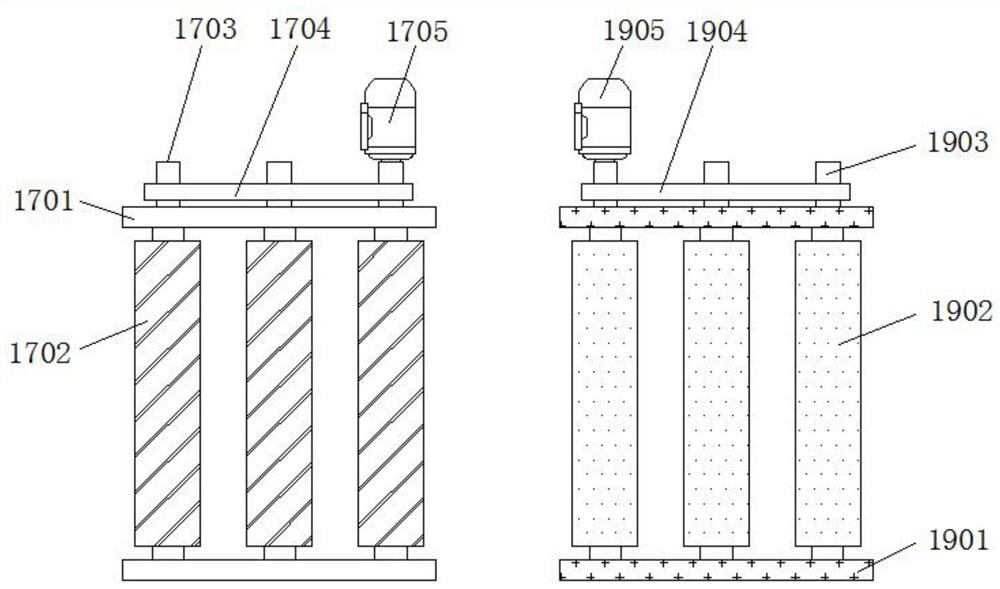

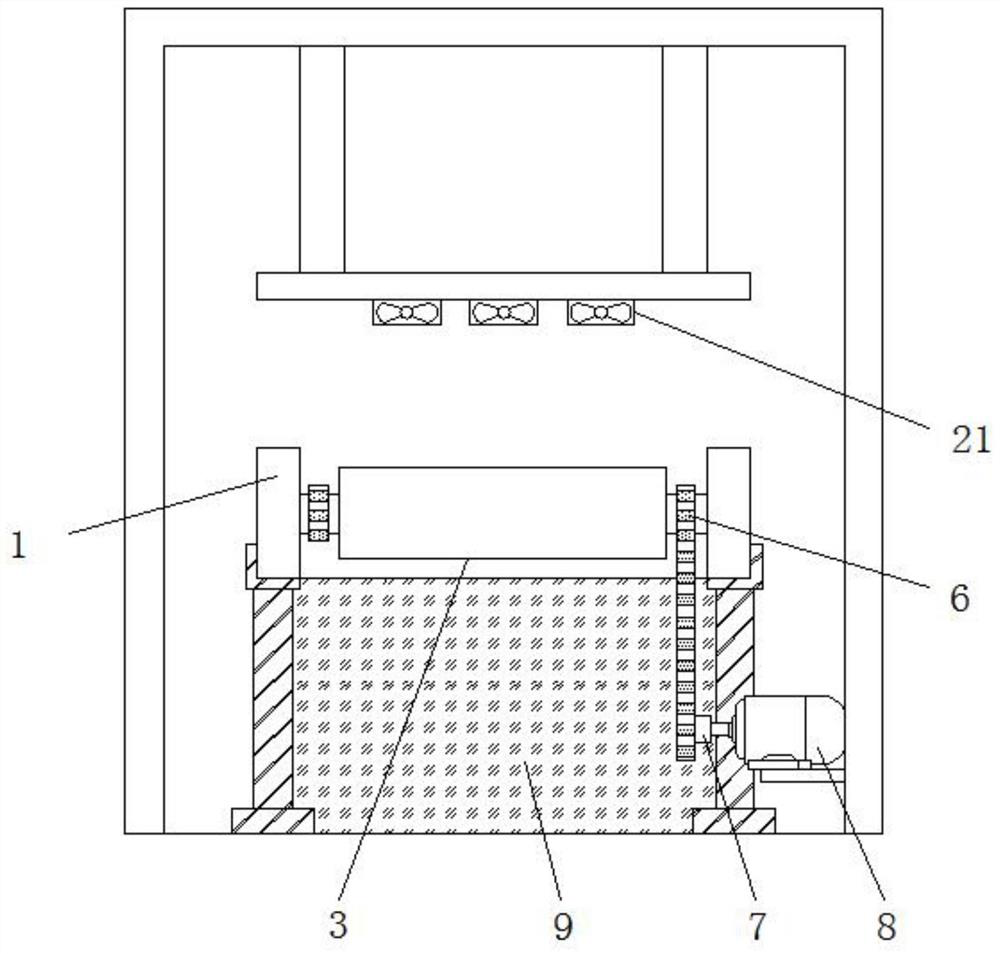

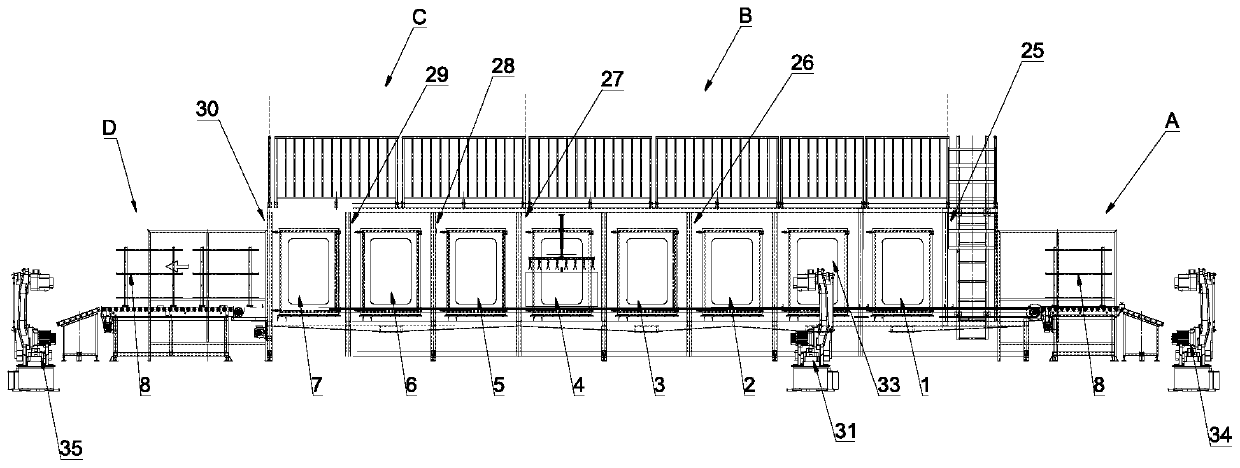

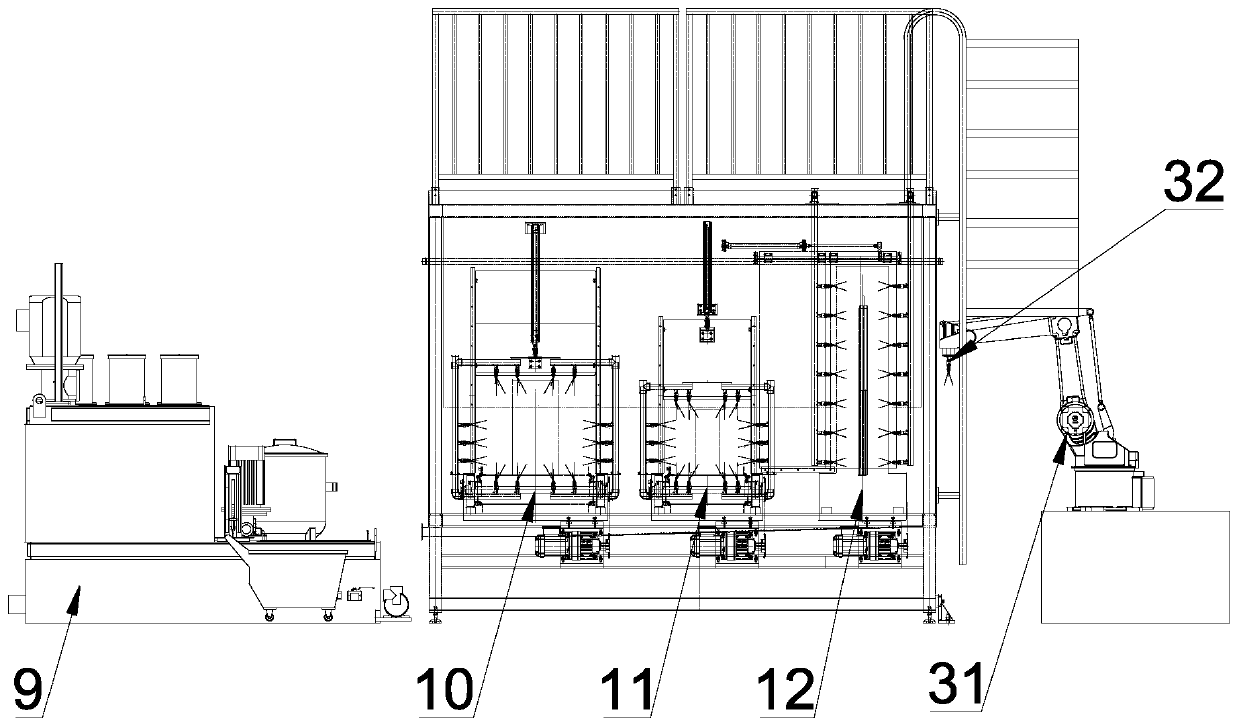

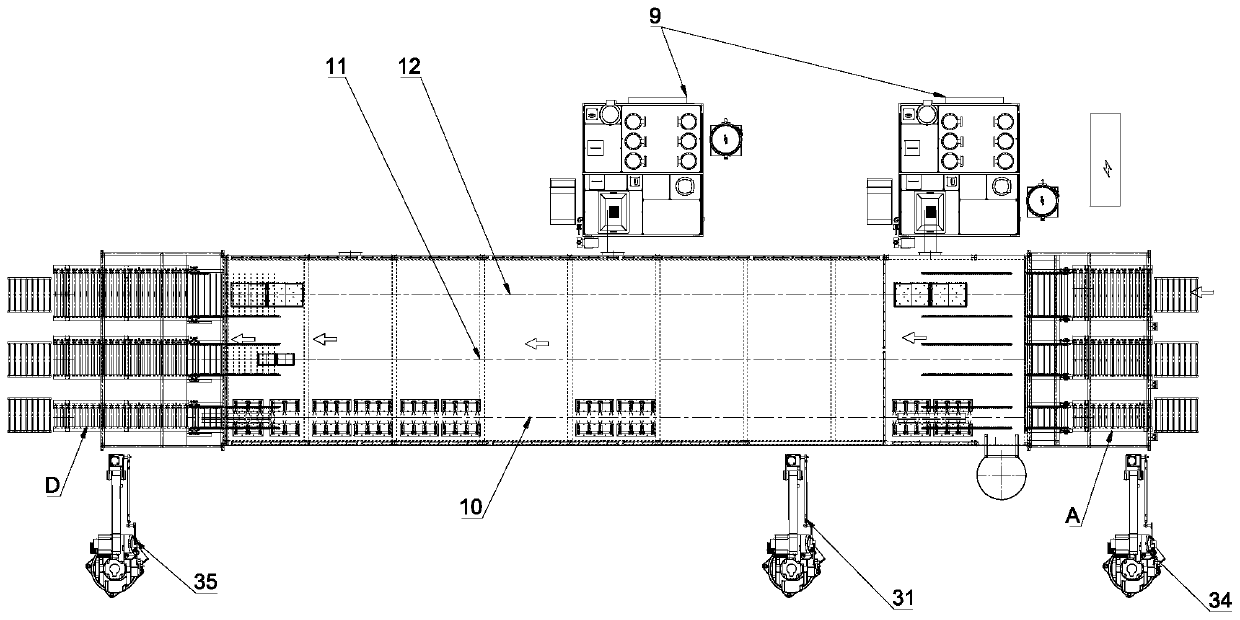

Robot intelligent feed box cleaning production line and system

PendingCN110449430AImprove cleaning qualityImprove cleaning efficiencyHollow article cleaningDrying gas arrangementsEngineeringHigh pressure

The invention discloses a robot intelligent feed box cleaning production line and system. The cleaning production line comprises a feeding module, a water scrubbing module, a drying module, a discharging module and a conveying module; the water scrubbing module comprises a first washing device and a second washing device, each of the first washing device and the second washing device comprises multiple cleaning assemblies, the multiple cleaning assemblies are arranged in the moving direction of a feed box, and each cleaning assembly comprises a frame and multiple water spray nozzles arranged on the frame; the drying module comprises a high-pressure blow-drying device and a high-temperature blow-drying device; and each of the high-pressure blow-drying device and the high-temperature blow-drying device comprises multiple blowing assemblies, the multiple blowing assemblies are arranged in the moving direction of the feed box, and each blowing assembly comprises a bracket and multiple blast nozzles arranged on the bracket. The feed box can be cleaned automatically, and improvement of the cleaning quality and the cleaning efficiency of the feed box is facilitated.

Owner:GUANGZHOU YUEYAN INTELLIGENT EQUIP CO LTD

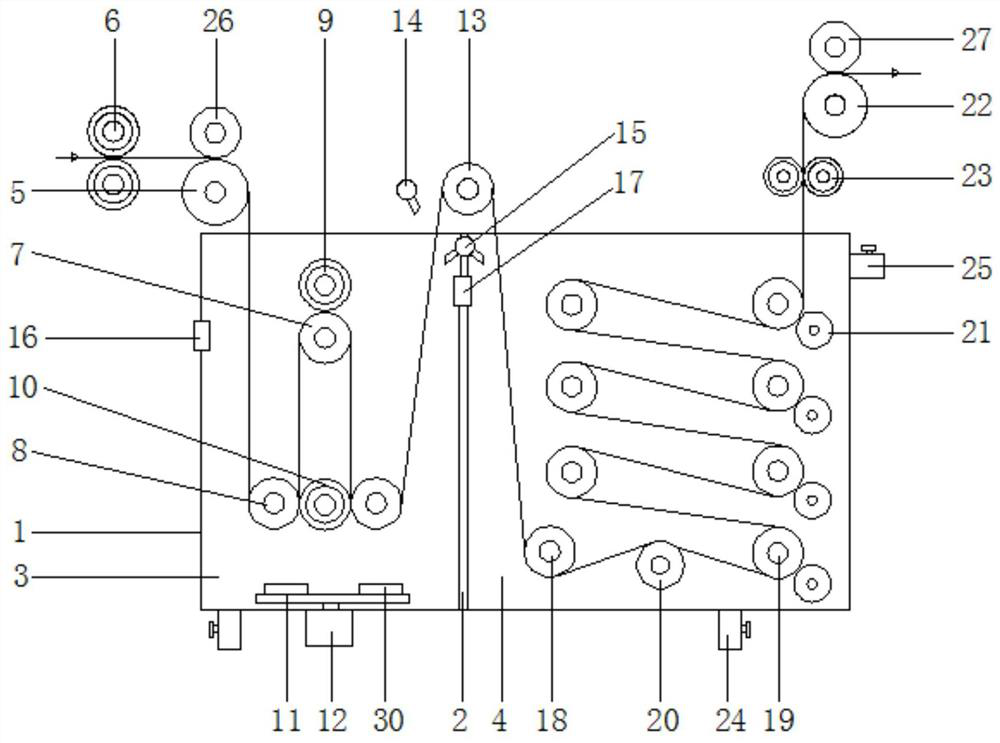

Conveyance device and method for conveying workpieces through treatment area

ActiveCN103796937AEasy to eliminateFlexible controlCharge manipulationConveyor partsEngineeringMechanical engineering

Owner:DUERR SYST GMBH

Cleaning device for oil smoke purification equipment

PendingCN109865597AAvoid wastingQuick cleanCleaning using liquidsElectrodes cleaningWater sprayUltrasonic generator

The invention discloses a cleaning device for oil smoke purification equipment. The cleaning device comprises a protection rack, a shell, a base, a filtering tank and a cleaning tank, wherein the shell is welded with the top of the base, a partition plate is welded with the shell, a motor is fixedly arranged at one side of the partition plate, the cleaning tank is arranged in the shell, a liquid storage box is connected with one side of the cleaning groove by a pipeline, a fixture is welded with one side of the shell, the filtering tank is welded with the bottom of the base, a water pump is connected with one side of the filtering tank by a hose, and an output end of the water pump is connected with a water spraying rack at an inner wall of the shell by a connection pipe. The filtering tank is arranged, a cleaning liquid can be repeatedly used, the waste of the cleaning liquid is prevented, the cost is reduced, and the environmental-friendly efficiency of the device is improved; and byarranging an ultrasound wave generator, the cleaning efficiency of the device can be improved, a filtering core can be rapidly cleaned, oil dirt in a corner of the filtering core can be cleaned, andthe cleaning effect of the filtering core is ensured.

Owner:REED XINXIANG ROAD INC

Efficient water washing tank

InactiveCN111926480AImprove cleaning efficiencySimple structureMechanical cleaningPressure cleaningDust controlWater resources

The invention relates to an efficient water washing tank. The tank includes a tank body, a vertical separating plate is connected with an inner chamber of the tank body, a pre-washing tank and a rinsing tank are formed on the left and right sides of the vertical separating plate respectively, a feeding guide roll is connected with the left side of the top of the pre-washing tank in a rotating mode, two dust removal rolls are arranged on the left side of the feeding guide roll, the dust removal rolls are connected in an attaching mode, an upper cloth guide roll and two lower cloth guide rolls are connected with the top and the bottom of an inner chamber of the pre-washing tank respectively in a rotating mode, the two lower cloth guide rolls are arranged in parallel, and an upper scrubbing roll is connected with the top of the upper cloth guide roll in an attaching mode. According to the efficient water washing tank, the structure is simple, the stability and reliability can be achieved,the cleaning capacity is strong, the cleaning efficiency is high, fabric can be pre-washed, washed, and rinsed fully, the effect of washing can be improved, through the arrangement of the pre-washingtank and the rinsing tank, the fabric can be pre-washed, dirt on the surface of the fabric can be removed, then washing can be carried out fully, so that the cleaning is cleaner, the utilization of water resources can be improved, and a wide application prospect can be achieved.

Owner:吴江新生喷织有限责任公司

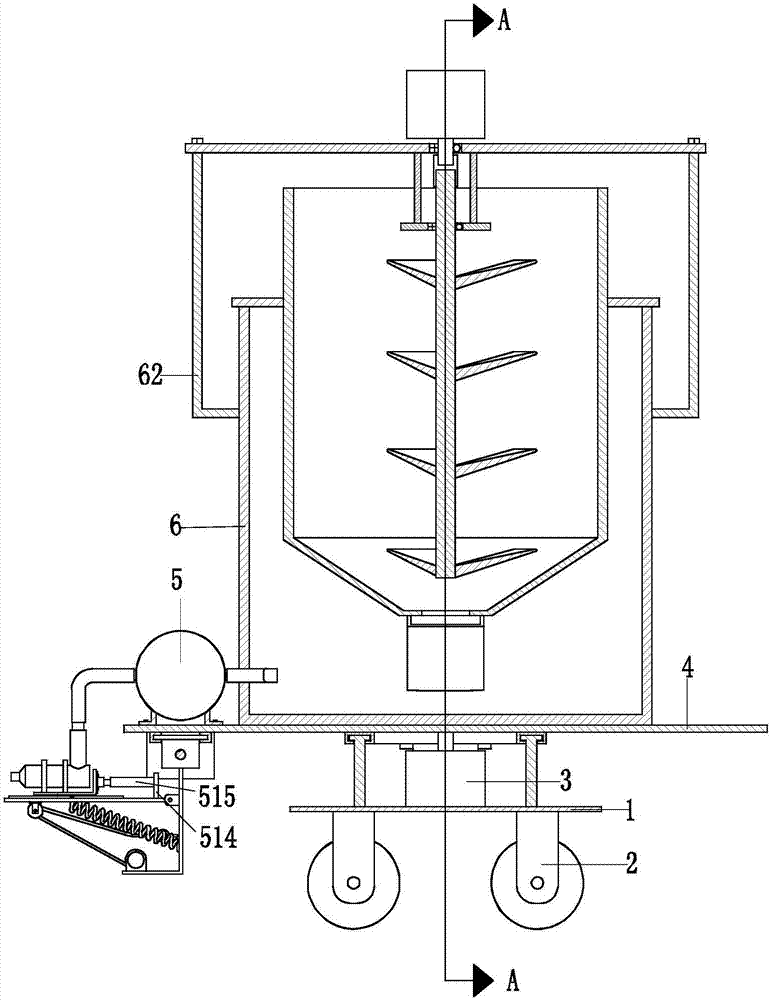

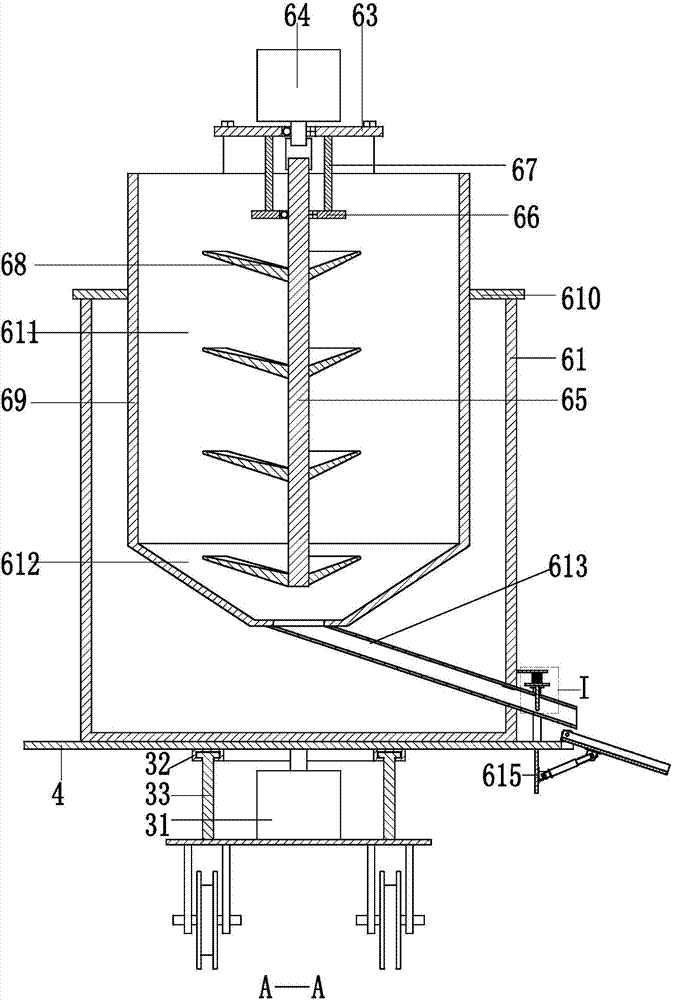

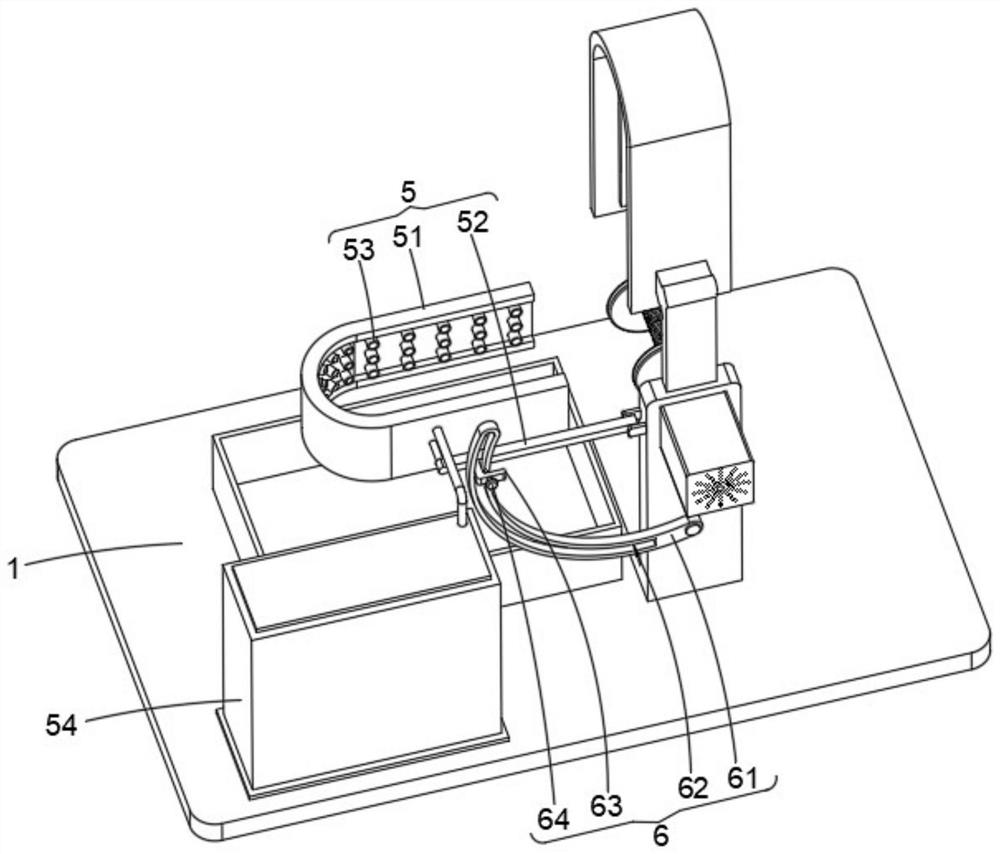

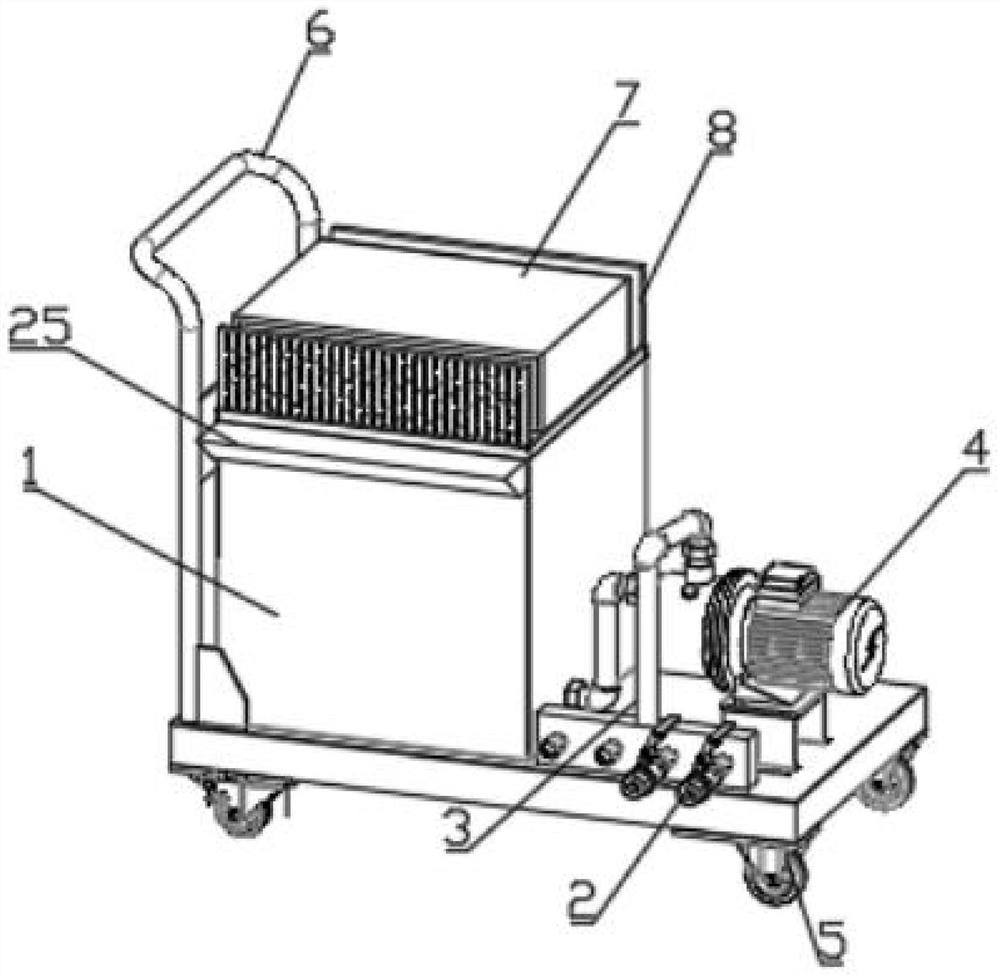

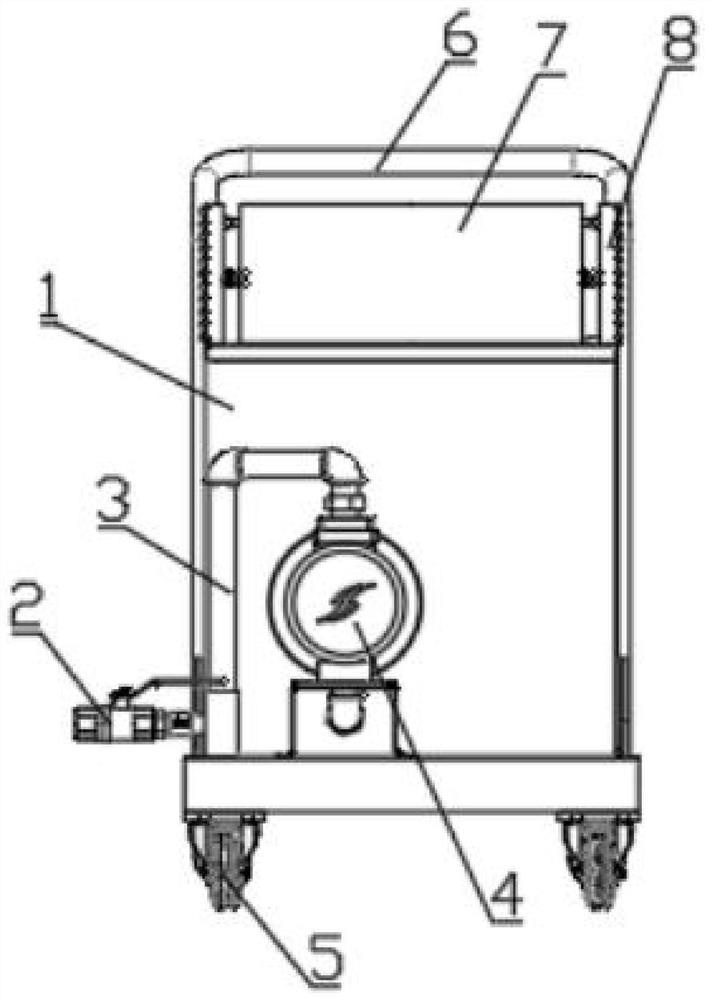

Live pig breeding feeder special flushing feeding machine

InactiveCN107135972APlay a supporting rolePlay an auxiliary roleAnimal feeding devicesHollow article cleaningPig breedingEngineering

The invention relates to a special washing feeder for pig breeding troughs. A bottom plate is provided with a walking wheel at the lower end of the bottom plate, a rotating device is mounted on the upper end of the bottom plate, a supporting plate is mounted on the upper end of the rotating device, and a flushing device is mounted on the front end of the supporting plate. A stirring and feeding device is arranged in the middle of the upper end of the feeder, and the rotating device, the flushing device and the stirring and feeding device cooperate with each other to complete the process of automatic flushing and quantitative feeding of the pig trough. The present invention can solve the need to manually feed the live pigs at regular intervals in the existing live pig breeding process, to manually rinse the live pig trough before feeding the live pigs, to manually re-stir the food materials before feeding the live pigs, and to manually control the use of tools. The food is put into pig troughs of different sizes, and the troughs are manually washed, which has problems such as poor stability, low accuracy, high labor intensity, and low work efficiency. The functions of automatic flushing and quantitative feeding of pig troughs can be realized.

Owner:安庆米锐智能科技有限公司

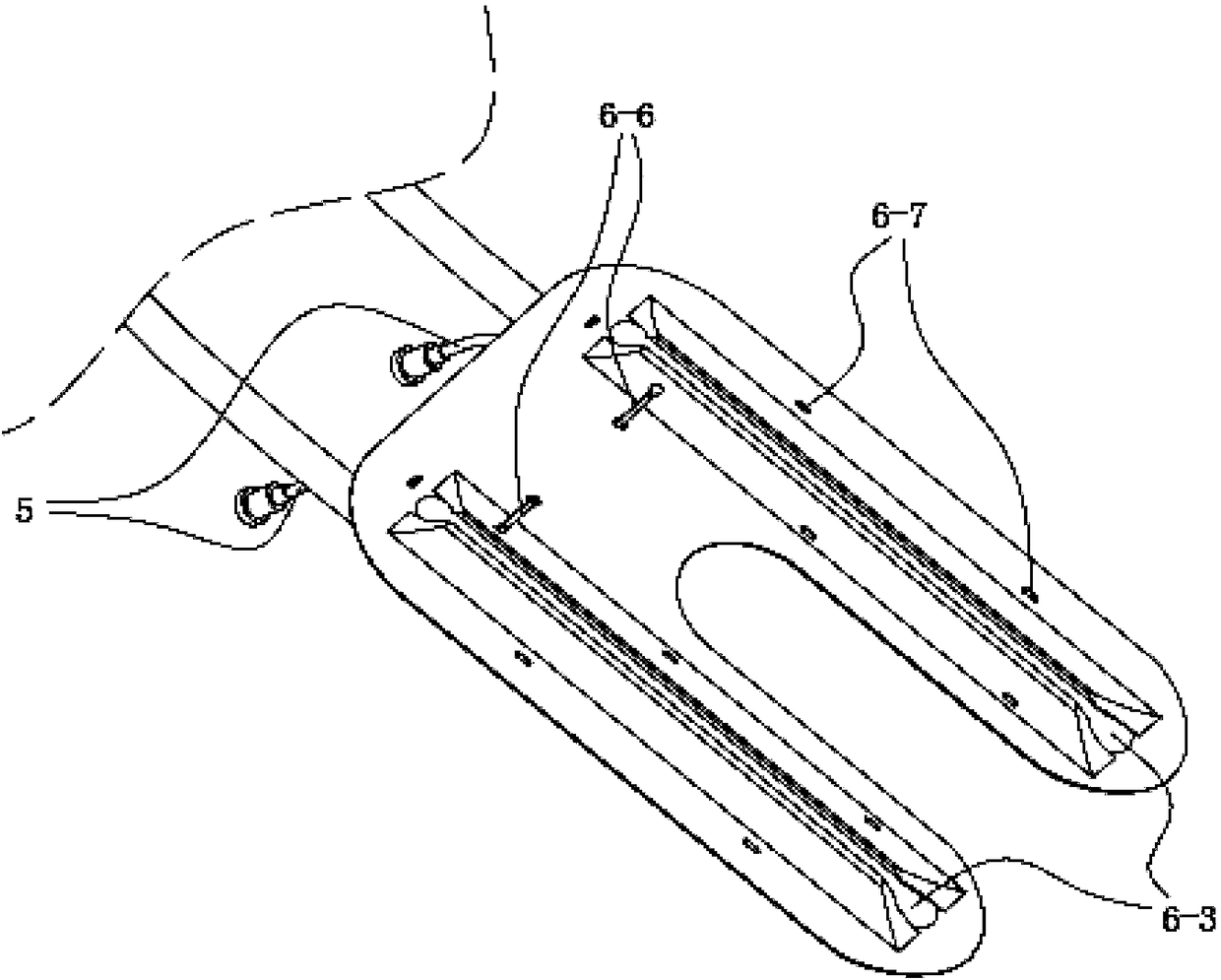

Pipeline robot for inclined pipeline cleaning

ActiveCN112696560AImprove cleaning effectEasy to cleanNon-rotating vibration suppressionHollow article cleaningEngineeringStructural engineering

The invention discloses a pipeline robot for inclined pipeline cleaning. The pipeline robot comprises a main pipeline, wherein auxiliary supporting pieces are evenly arranged on the peripheral side of the main pipeline, a balance weight swing assembly is arranged on the side face of the auxiliary supporting piece located on the lower side of the main pipeline, adjusting pipes are rotationally arranged at the two ends of the main pipeline respectively, hoses are evenly distributed on the circumferential side face of the end, away from the main pipeline, of each adjusting pipe, high-pressure spray heads are arranged at the ends, away from the adjusting pipes, of the hoses, and vertical plates are arranged on the side faces of the high-pressure spray heads. According to the pipeline robot for inclined pipeline cleaning, high-pressure sprayed water can be adjusted according to the spraying angle to clean the pipeline, the pipeline robot can be driven to move in the pipeline at different angles through the counter-acting force of the high-pressure sprayed water, the pipeline robot can walk in the pipeline conveniently, and damage to the robot can be avoided; and meanwhile the pipeline robot can clean different parts of the pipeline and is good in cleaning effect, easy to operate and convenient to use.

Owner:YANTAI ENG & TECH COLLEGE YANTAI TECHNICIAN INST

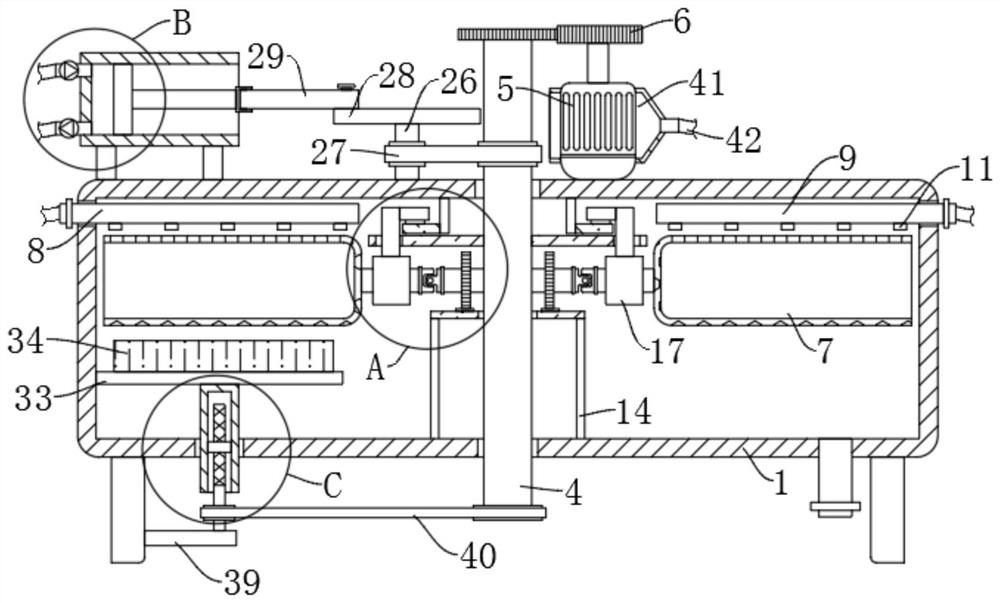

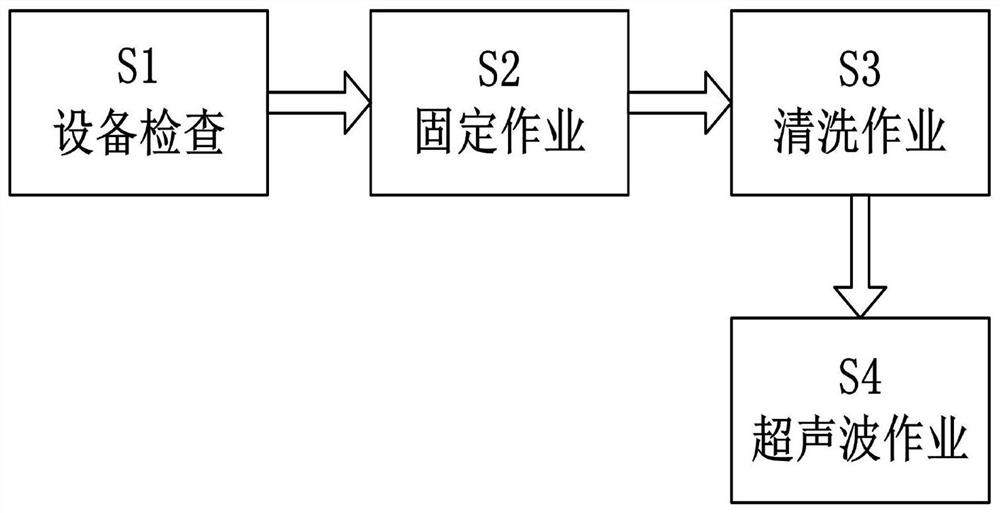

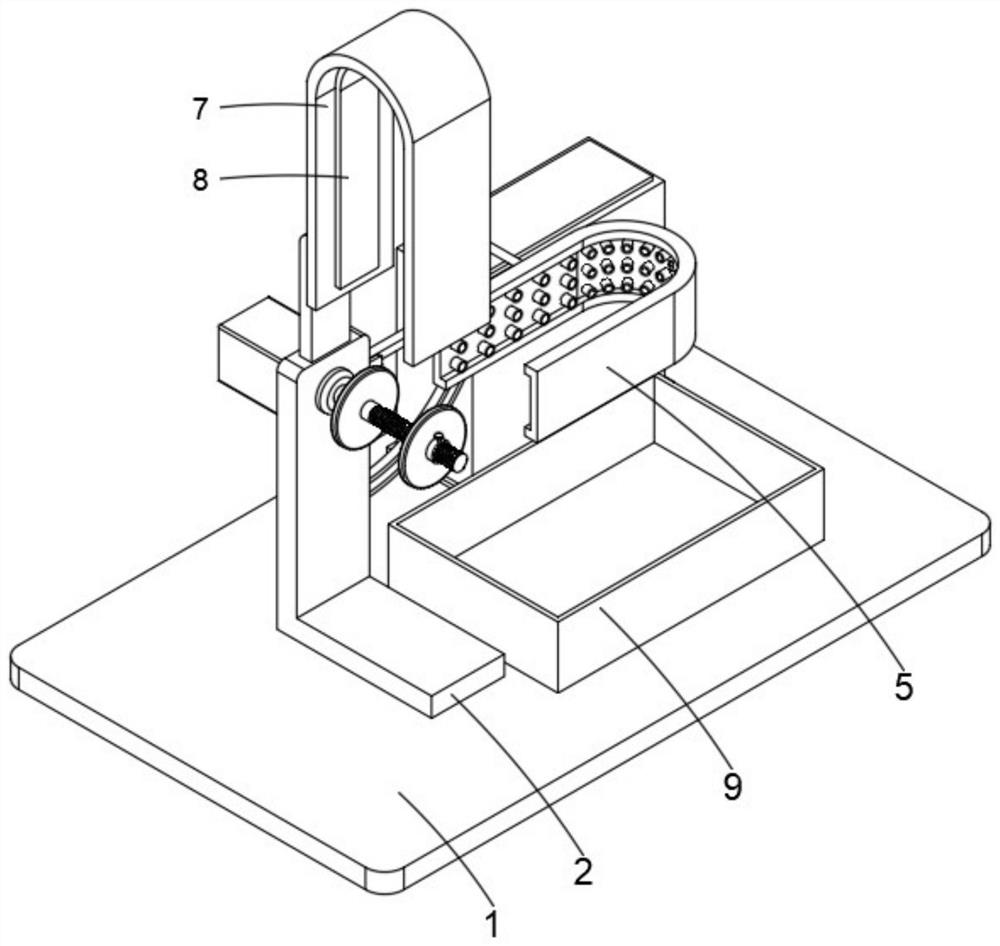

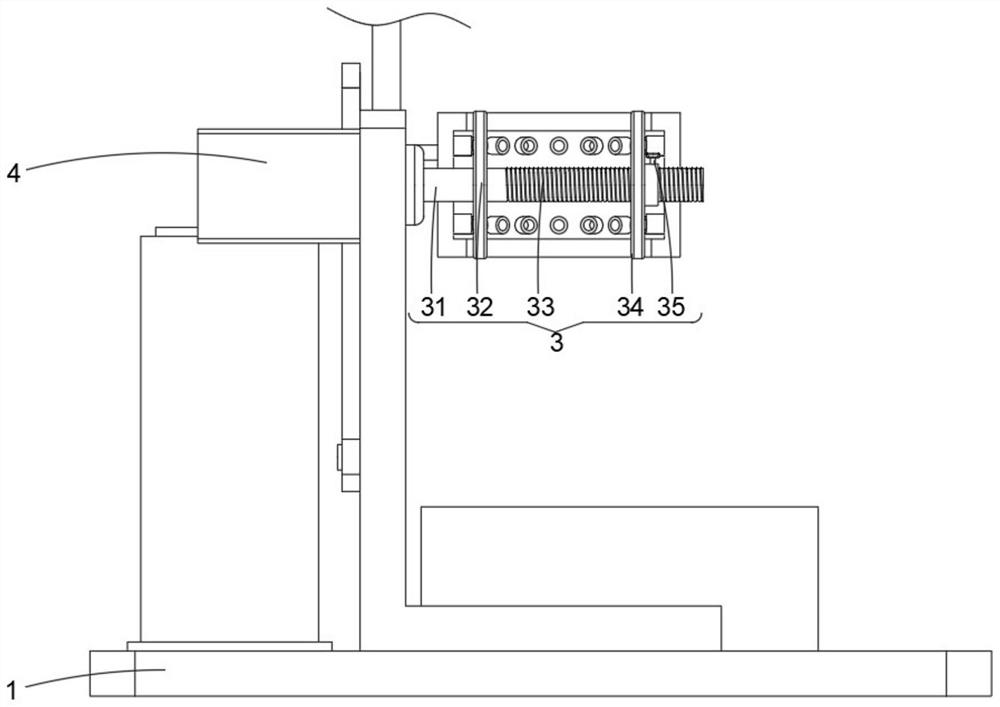

Ultrasonic cleaning method for aluminum alloy die casting

The invention relates to an ultrasonic cleaning method for an aluminum alloy die casting. The method uses ultrasonic cleaning equipment. The ultrasonic cleaning equipment comprises a cleaning frame, clamping units, a cleaning unit and ultrasonic transmitters. The clamping units are arranged on the inner walls of the left and right ends of the cleaning frame. The cleaning unit is arranged on the inner wall of the rear end of the cleaning frame. The ultrasonic transmitters are arranged on the inner wall of the lower end of the cleaning frame. The method adjusts the angle of a spray water gun anda movable spray water gun, so that the washing process of a runner is more comprehensive, the workload of ultrasonic cleaning is reduced, and the problem that the water flow can only be sprayed on afixed point on the outer surface of the aluminum alloy die casting during the washing process is solved. The method clamps and fixes the runner according to the structural characteristics of the runner, and drives the runner to flip, thereby improving the efficiency of washing and ultrasonic cleaning.

Owner:SHENZHEN KAIDELI DIE CASTING CO LTD

Cleaning equipment used before automobile tire recovery treatment

The invention provides cleaning equipment used before automobile tire recovery treatment. The cleaning equipment used before automobile tire recovery treatment comprises a bottom plate, a flusher andan adjuster, wherein an L-shaped supporting frame used for bearing an automobile tire is fixedly installed on the bottom plate, a tire fixing piece used for fixing the automobile tire is installed onthe L-shaped supporting frame, and the flusher is installed on the L-shaped supporting frame; and the flusher comprises a U-shaped cleaning plate, a mounting frame, spray heads and a water storage tank, wherein the plurality of spray heads distributed at equal intervals are fixedly mounted on the inner wall of the U-shaped cleaning plate, the U-shaped cleaning plate is fixedly erected on the sidewall of the L-shaped supporting frame through the horizontally-arranged mounting frame, a water inlet in the U-shaped cleaning plate is fixedly connected with a water outlet of the water storage tankthrough an elastic guide pipe, the water storage tank is fixedly installed on the bottom plate, and the adjuster is installed on the L-shaped supporting frame. The cleaning equipment used before automobile tire recovery treatment has the advantages of being comprehensive in cleaning, high in efficiency and convenient to operate.

Owner:赵亚超

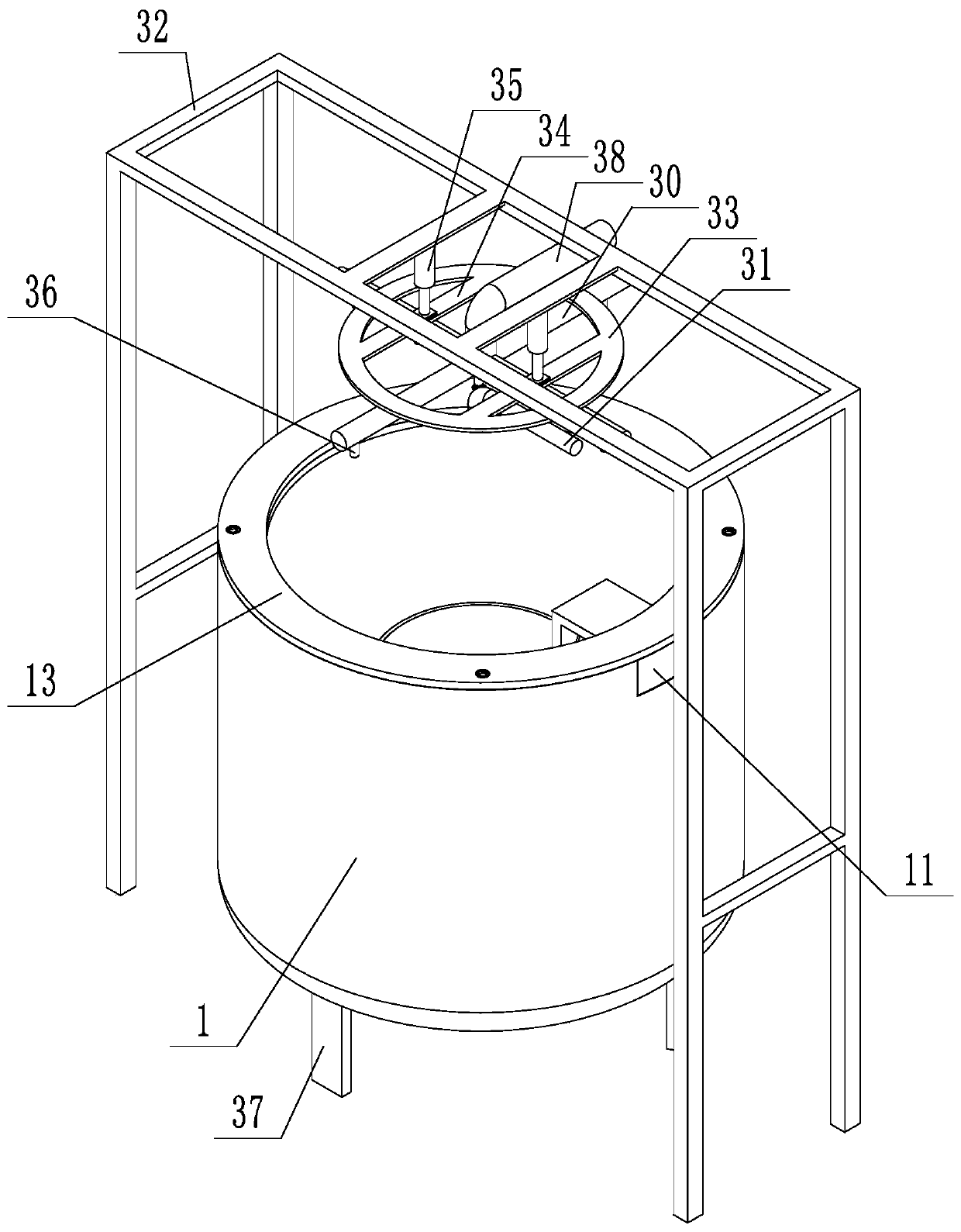

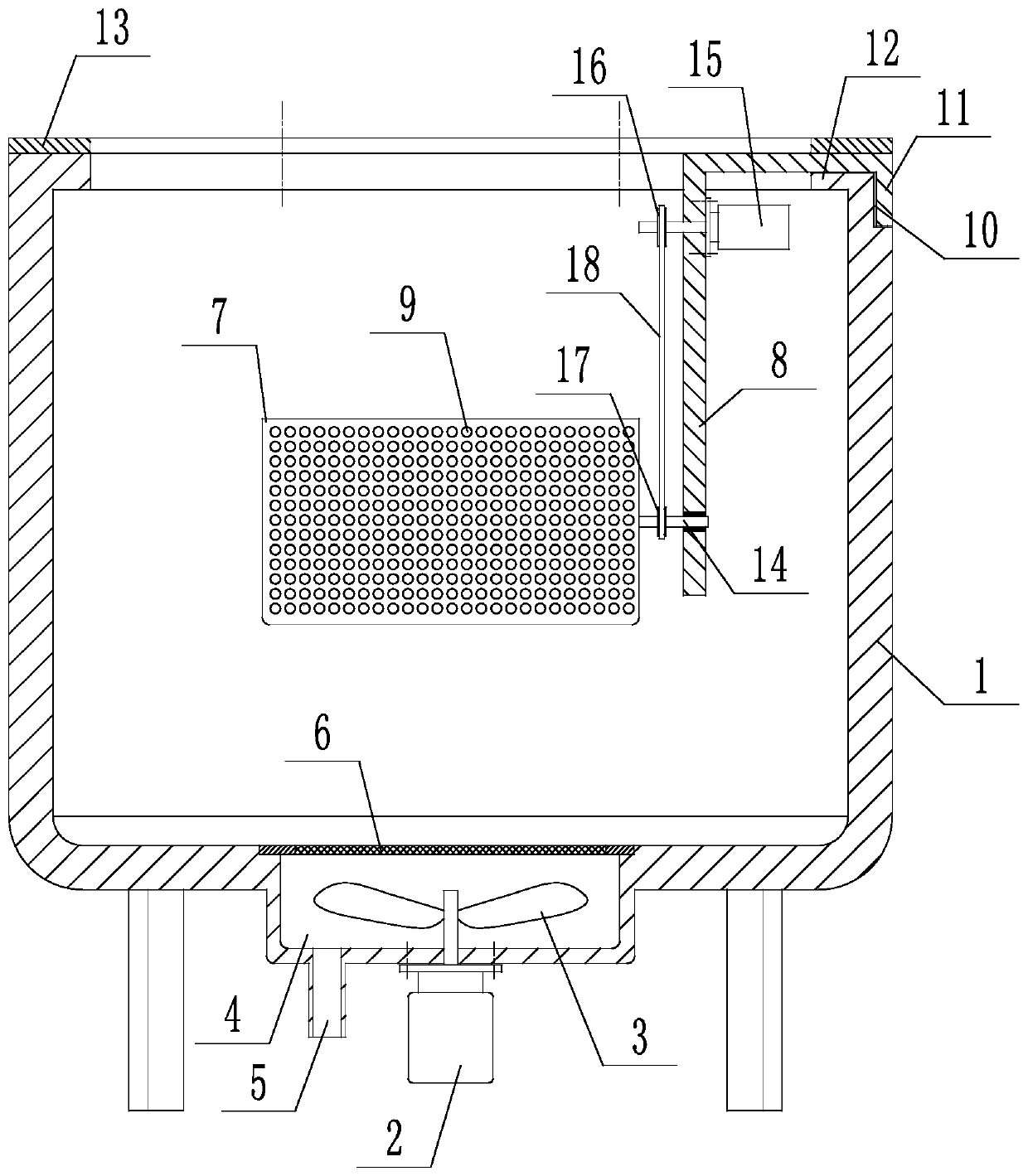

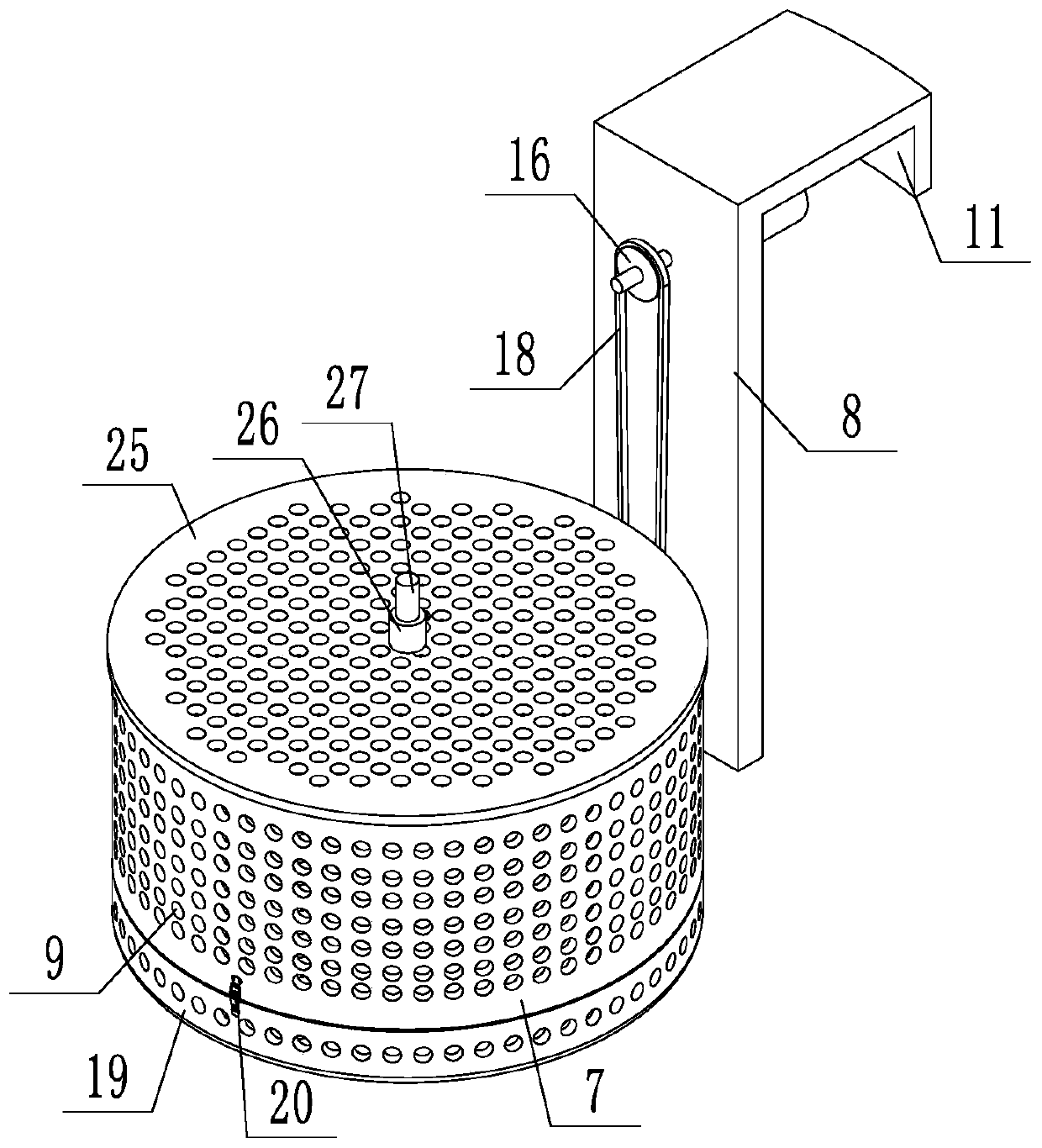

Sampling bottle cleaning device for microorganism sampling

ActiveCN110076156AAchieve cleaningHigh degree of automationHollow article cleaningCleaning using liquidsMicroorganismDistilled water

The invention discloses a sampling bottle cleaning device for microorganism sampling. A cleaning barrel, a stirring mechanism, a sampling bottle fixing mechanism and a cleaning mechanism are included;the stirring mechanism is located below the cleaning barrel; the sampling bottle fixing mechanism is located in the cleaning barrel; the cleaning mechanism is located above the cleaning barrel; a sampling bottle is fixed through the sampling bottle fixing mechanism which is installed in the cleaning barrel; cleaning liquid is added in the cleaning barrel, then the stirring mechanism makes the cleaning liquid flow, and the sampling bottle is cleaned; after the cleaning liquid is used for cleaning the sampling bottle, the cleaning liquid flows out; then an acidic or alkaline solution is sprayedout of the cleaning mechanism, the sampling bottle is cleaned; stirring by the stirring mechanism is used in cooperation while cleaning is performed; the cleaning mechanism is used for spraying out clean water and distilled water to wash the sampling bottle in sequence; cleaning of the sampling bottle is achieved; the automation degree is high; and a plurality of sampling bottles can be cleaned at the same time, efficiency is high, and the labor intensity is lowered.

Owner:INST OF QUALITY STANDARDS & TESTING TECH FOR AGRO PROD OF SHANDONG ACADEMY OF AGRI SCI

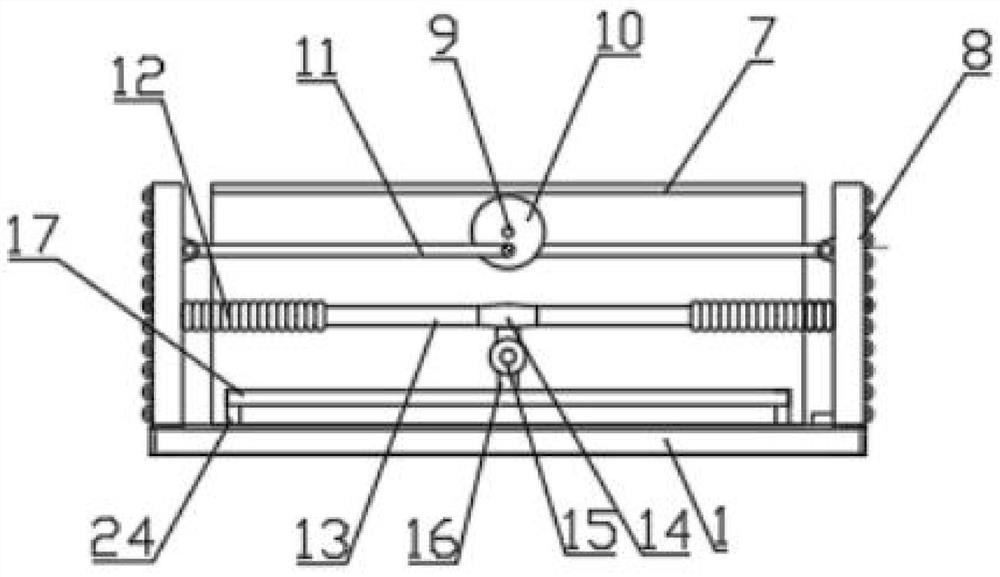

Rinsing and washing machine for poultry breeding, and use method of rinsing and washing machine

InactiveCN111700003AIncrease the sprayed areaEasy to moveRotary stirring mixersTransportation and packagingElectric machineryAnimal science

The invention discloses a rinsing and washing machine for poultry breeding, and a use method of the rinsing and washing machine. The rinsing and washing machine is characterized by comprising a rinsing box body, a spraying mechanism and a stirring mechanism, wherein the top surface of the rinsing box body is provided with the spraying mechanism, the top surface of the rinsing box body is equippedwith a fixing plate, the spraying mechanism is located on the fixing plate, spraying plates are movably installed on two sides of the top surface of the rinsing box body respectively, the side walls,away from the fixing plate, of the spraying plates are evenly provided with multiple groups of spraying holes, an output end of a double shaft motor is connected with a turntable, positions, away fromthe center of the circle, of the turntable are connected with movable rods, and the other ends of the movable rods are movably connected with the side walls of the spraying plates. The rinsing and washing machine can rinse breeding rooms on two sides at the same time, and the spraying plates can be rotated to adjust an angle during rinsing, so that a spraying area is greatly increased, and the breeding rooms can be completely rinsed. In addition, the rinsing mechanism is convenient to move through a handle and rotating wheels, so that the rinsing mechanism has strong flexibility, and can disinfect the breeding rooms at the same time.

Owner:安徽亳诚农牧科技股份有限公司

Water-saving type steel belt cleaning device

InactiveCN108722976AFull rinseRinse thoroughlyCleaning using toolsCleaning using liquidsSteel beltEngineering

The invention discloses a water-saving type steel belt cleaning device. The water-saving type steel belt cleaning device comprises a cleaning tank, wherein supporting plates are separately welded to the front and the rear of the upper surface of the cleaning tank; guiding rolls are separately mounted at the left end and the right end of the upper surface of the cleaning tank; a water drainage tubewhich communicates with the cavity of the cleaning tank are arranged at the bottom of the right side surface of the cleaning tank; a water drainage valve is arranged on the water drainage tube; a transmission roll mounting column is welded to the inside of the cleaning tank; and a transmission roll is mounted on the transmission roll mounting column through a bearing. By arrangement of a washingbox which replaces a sprayer, the upper surface and the bottom surface of a cleaned steel belt are washed by the washing box, a steel belt is washed comprehensively, moreover, water is injected into the washing box by only one water inlet tube, the steel belt is washed by flowing of water in the washing cavity, therefore, water can be fully utilized, the utilization rate of the water is increased,by arrangement of bristles, the surface of the steel belt can be brushed and washed, and the steel belt can be cleaned thoroughly.

Owner:扬州道明智控科技有限公司

Dull polish machine capable of preventing dust from flying

InactiveCN113043102AAvoid flyingConvenient cycle sprayGrinding drivesGrinding work supportsMachineGrinding wheel

The invention relates to the technical field of glass processing equipment, and discloses a dull polish machine capable of preventing dust from flying. The dull polish machine comprises a dull polish cylinder, hydraulic rods are symmetrically and fixedly connected to the inner wall of the dull polish cylinder, the other ends of the hydraulic rods are fixedly connected with L-shaped clamping plates, arc-shaped cover plates corresponding to the L-shaped clamping plates are connected to the outer side wall of the dull polish cylinder through hinges, the arc-shaped cover plates are connected with the dull polish cylinder through lock catches, a cross rod is fixedly connected to the inner wall of the dull polish cylinder, a rotating rod is arranged on the cross rod in a penetrating mode, the rotating rod and the cross rod are rotationally connected through a bearing, a linkage mechanism is installed between the rotating rod and the dull polish cylinder, a rotating disc is fixedly connected to the bottom end of the rotating rod, an electric push rod is fixedly installed on the lower surface of the rotating disc, and the other end of the electric push rod is fixedly connected with a grinding wheel. In the dull polish process of glass, generated dust can be comprehensively flushed, so that the harm of the dust to a human body is effectively avoided.

Owner:蒋凯

Cleaning and drying device for chrysanthemum tea processing

InactiveCN112044845AFull rinseIncrease cleaning powerPre-extraction tea treatmentCleaning using liquidsProcess engineeringEnvironmental geology

The invention relates to the technical field of chrysanthemum tea processing and discloses a cleaning and drying device for chrysanthemum tea processing. The cleaning and drying device comprises a boxbody, a feeding pipeline and a discharging bin. A rinsing pool filled with clear water and communicating with the bottom end of the feeding pipeline is arranged on the left side in the box body, a set of transfer bin communicates with the right side of the top of the rinsing pool, and multiple sets of shifting rollers used for shifting chrysanthemum tea floating on the water surface in the rinsing pool rightwards into the transfer bin are arranged at the inner top of the rinsing pool from left to right at equal intervals. A set of vertical conveying plates are arranged in the transfer bin, the right side of the transfer bin communicates with a flushing bin, the right side of the flushing bin is connected with a drying bin used for drying chrysanthemum tea through a partition plate, and awaste liquid discharging pipe used for discharging waste water is forwards arranged at the bottom of the flushing bin. A set of heating plates which are vertically arranged to be of a latticed structure are arranged on the right side of the interior of the drying bin.

Owner:XUZHOU UNIV OF TECH

Pig house with ground having cleaning function

InactiveCN108464245AAdjustable positionFull rinseAnimal housingCleaning using liquidsEngineeringScrew thread

The invention relates to the technical field of pig-raising equipment, and particularly relates to a pig house with a ground having a cleaning function. The pig house comprises a rectangular house; the house is mounted on a ground; the front face of the house is provided with an outlet; a door is hinged in the outlet; the ground at one side, close to the outlet, of the house is provided with a dirt collecting box; a grid plate is arranged on the top surface of the dirt collecting box; a sewage discharge pipe is connected at the bottom of the dirt collecting box; a top plate is horizontally arranged above the house; two sides of the bottom face of the top plate are both connected with the side walls of two sides of the house through connecting plates; a horizontally arranged screw rod is mounted at the middle part of the bottom face of the top plate; two ends of the screw rod are both connected with the top plate through first connecting rods; two adjusting pipes are in threaded connection with the screw rod. The pig house has the advantages of simple structure and convenient operation, the inner part of the pig house can be effectively cleaned, and the practical use is facilitated.

Owner:成都酷爱睿工业产品设计有限公司

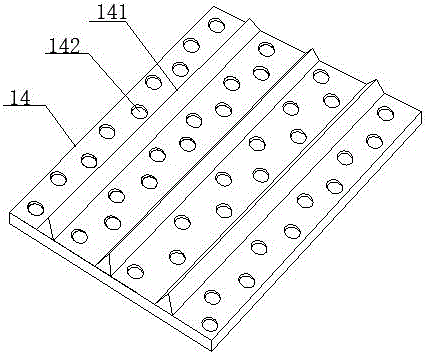

Cleaning device for spinneret plate machining

InactiveCN112410895AImprove cleaning efficiencyFull rinseSpinnerette packsStructural engineeringMachining

The invention discloses a cleaning device for spinneret plate machining. The cleaning device comprises a conveying device, side walls and a top wall, two clamping turnover mechanisms are fixed to theside walls, each clamping turnover mechanism comprises a clamp, a connecting rod, a hydraulic telescopic rod, a rotating seat, a rotating rod and a guide rail, one side face of each clamp is fixedly connected with the corresponding rotating seat, one ends of the rotating rods are rotationally connected with the rotating seats, and the other ends of the rotating rods are rotationally connected withthe connecting rods; the connecting rods are hinged to the side walls, one ends of the hydraulic telescopic rods are fixedly connected with the side walls through supporting seats, the other ends ofthe hydraulic telescopic rods are hinged to the clamps, the guide rails are fixedly connected with the side walls, and the inner side walls of the guide rails are slidably connected with the hydraulictelescopic rods; and two cleaning mechanisms are arranged on the upper portions of the two clamping turnover mechanisms correspondingly, and the two cleaning mechanisms are both connected to the lower end face of the top wall. The cleaning device for spinneret plate machining is high in cleaning efficiency and thorough in cleaning.

Owner:JIANGSU BIAOLI PRECISION MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com