Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

240results about How to "Rinse thoroughly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

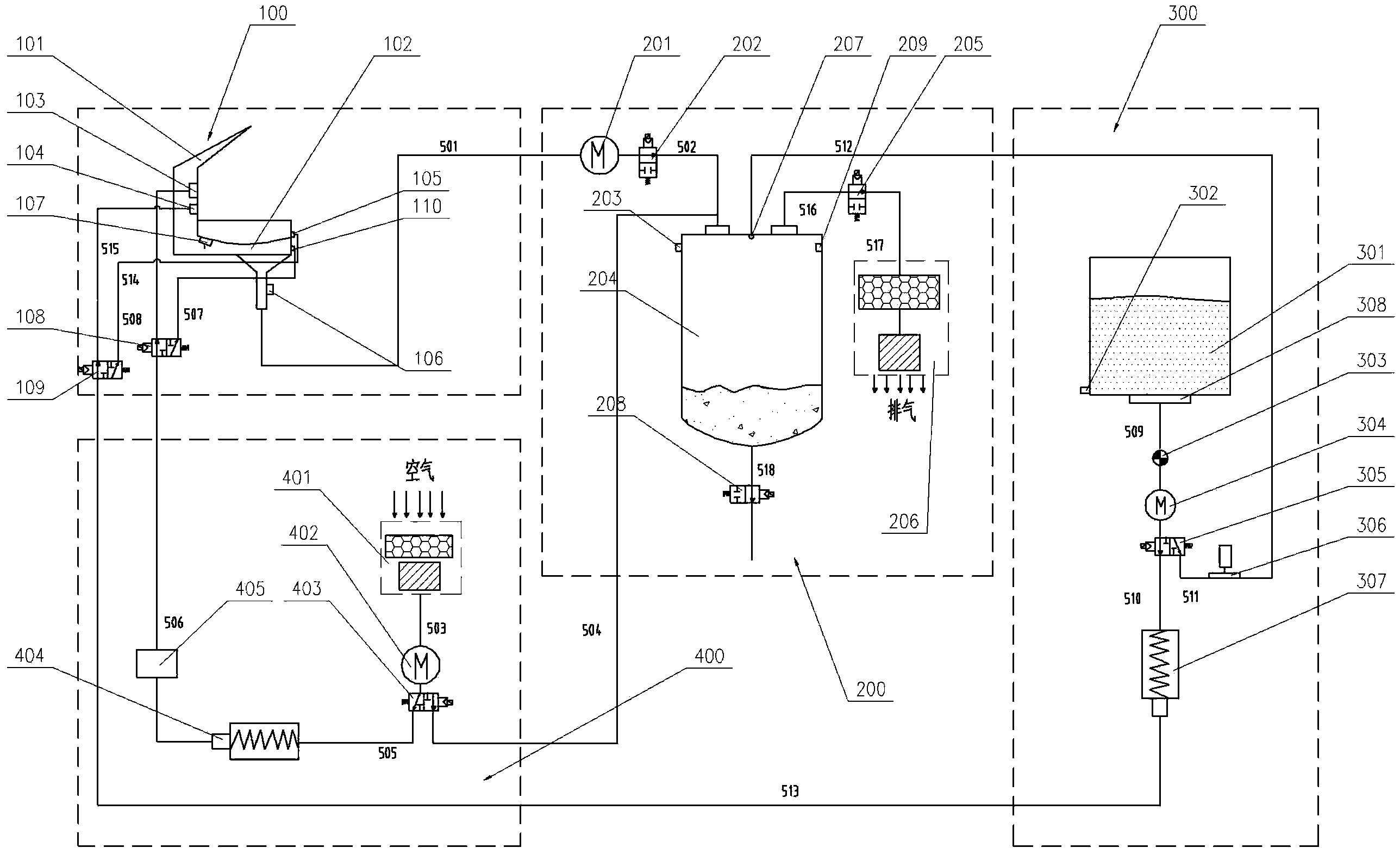

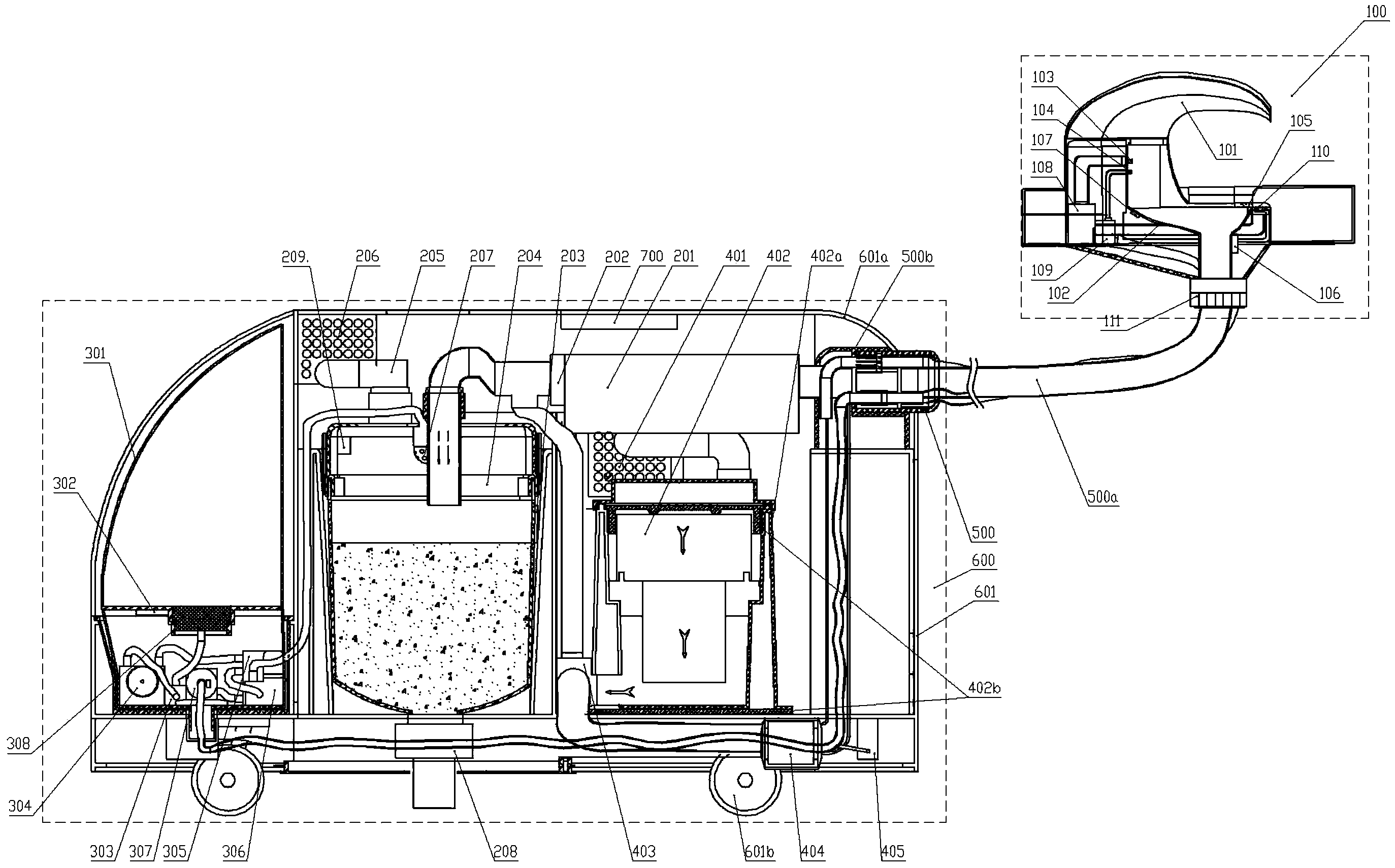

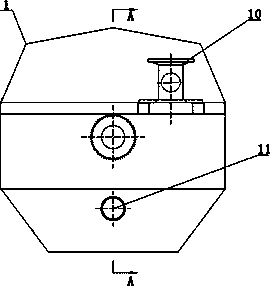

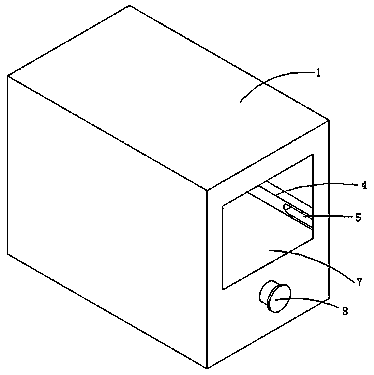

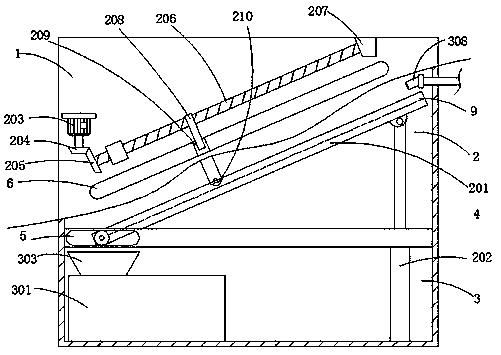

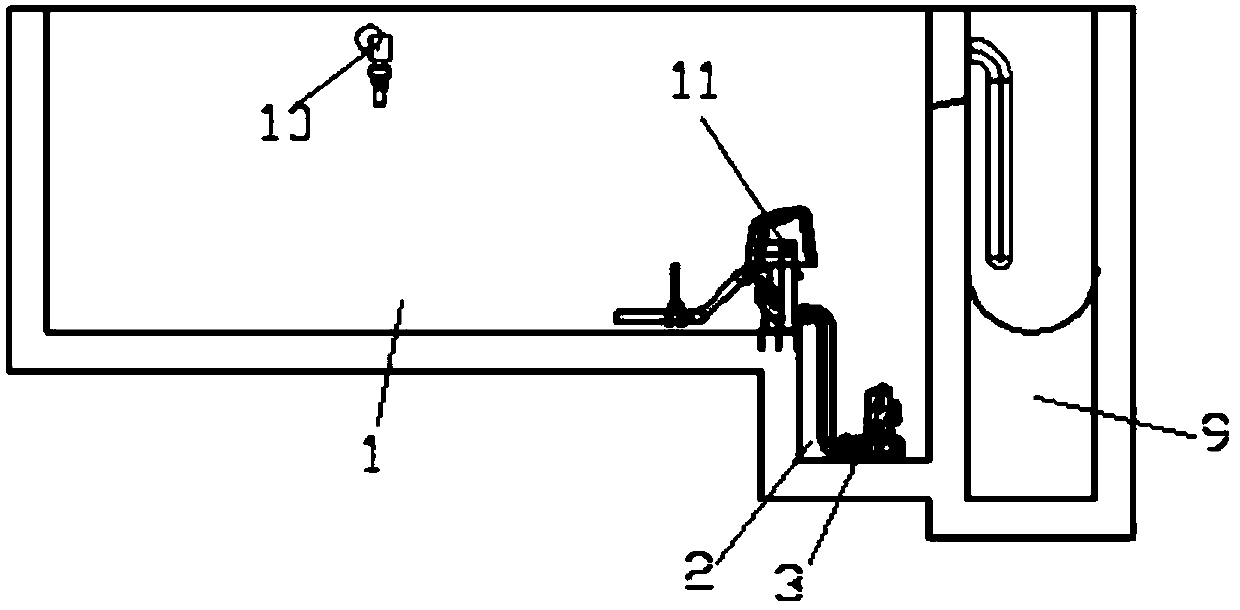

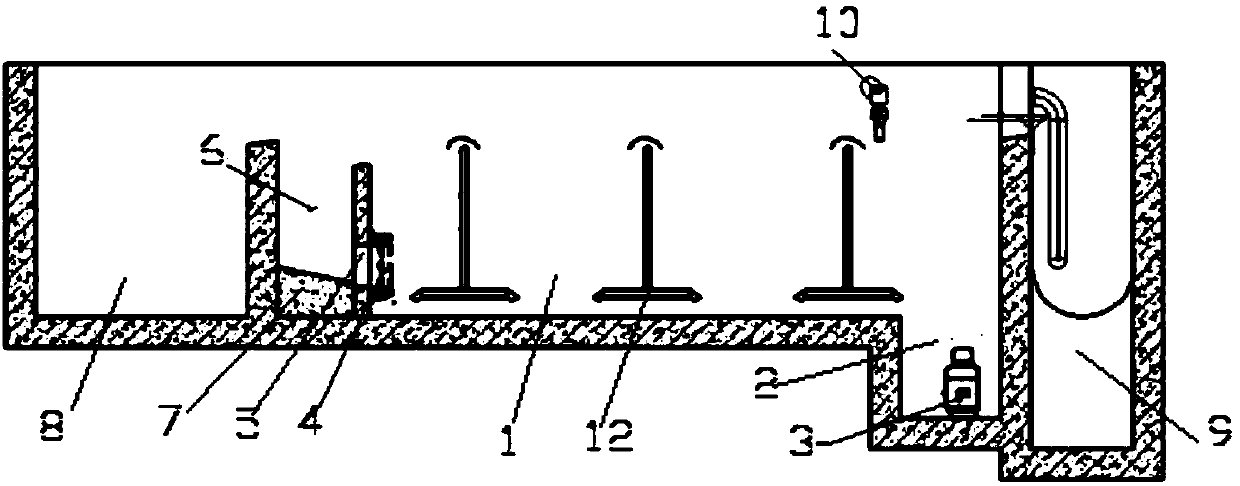

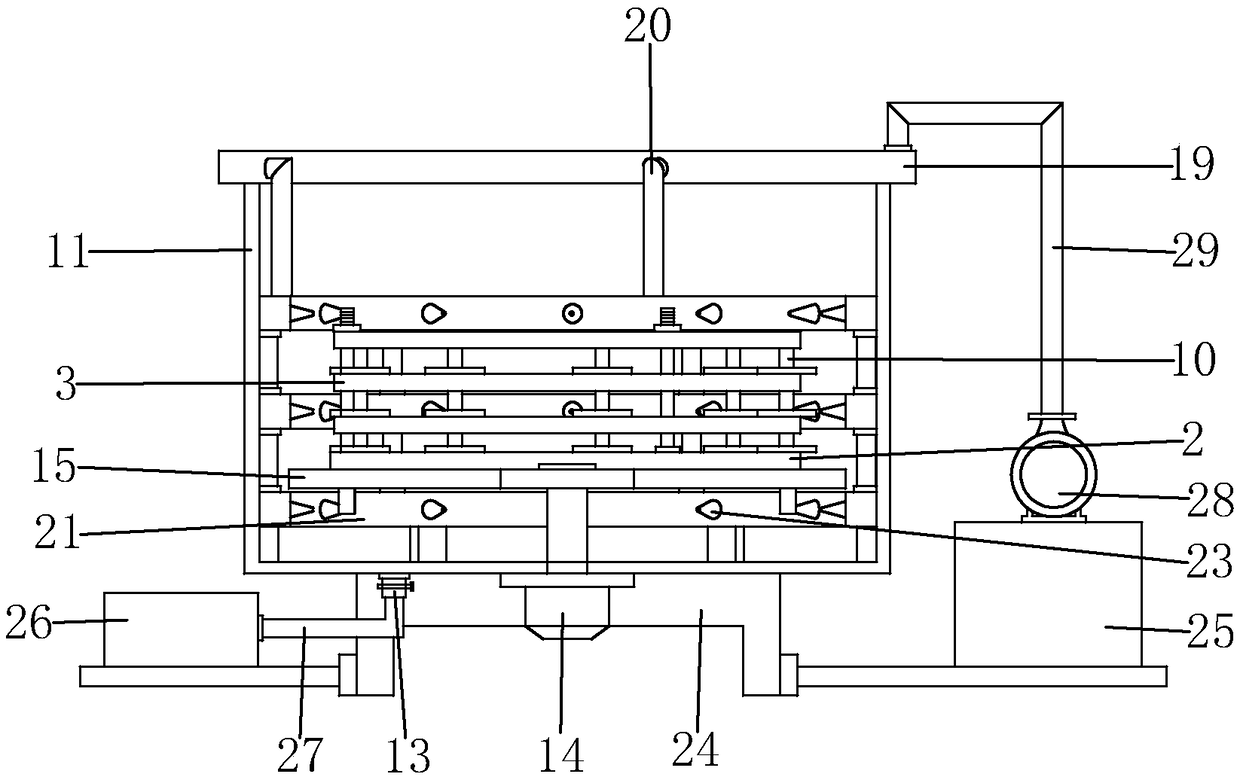

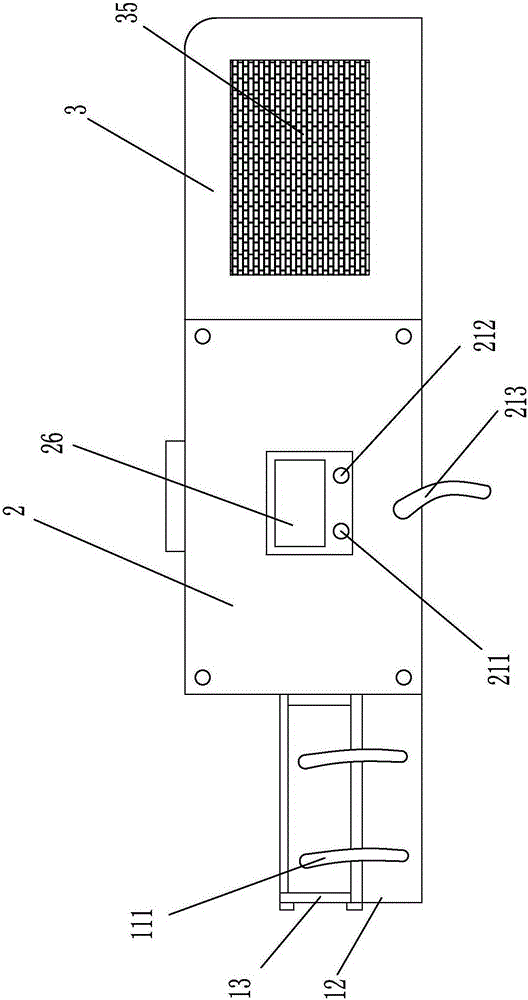

Automatic toilet nursing system

ActiveCN103655094AAchieve energy saving and water saving effectIncrease flushing functionMedical transportAtmosphereSewerage

The invention discloses an automatic toilet nursing system which comprises an excrement receiving assembly, a toilet host assembly and connecting pipelines. The excrement receiving assembly comprises a drying device, a flushing device, an excrement receiving device and a detection device. The drying device and the flushing device are arranged at the upper side of the excrement receiving assembly. The detection device is arranged in the excrement receiving assembly. The toilet host assembly comprises a host machine body, a collecting and evacuating unit, a washing unit, a drying positive-pressure unit and a control unit. The flushing device is connected with the washing unit through the washing pipeline. The excrement receiving assembly is connected with the collecting and evacuating unit through the sewage inlet pipeline. The drying device is connected with the drying positive-pressure unit through the drying pipeline. The collecting and evacuating unit is connected with the drying positive-pressure unit through the positive-pressure pipeline. The collecting and evacuating unit is communicated with the external environment through the sewage discharging pipeline and communicated with a toilet or a sewer. The collecting and evacuating unit is connected with the external atmosphere through the exhausting pipeline. The detection device, the washing unit and the drying positive-pressure unit are respectively connected with the control unit through circuits.

Owner:CRRC SHANDONG CO LTD

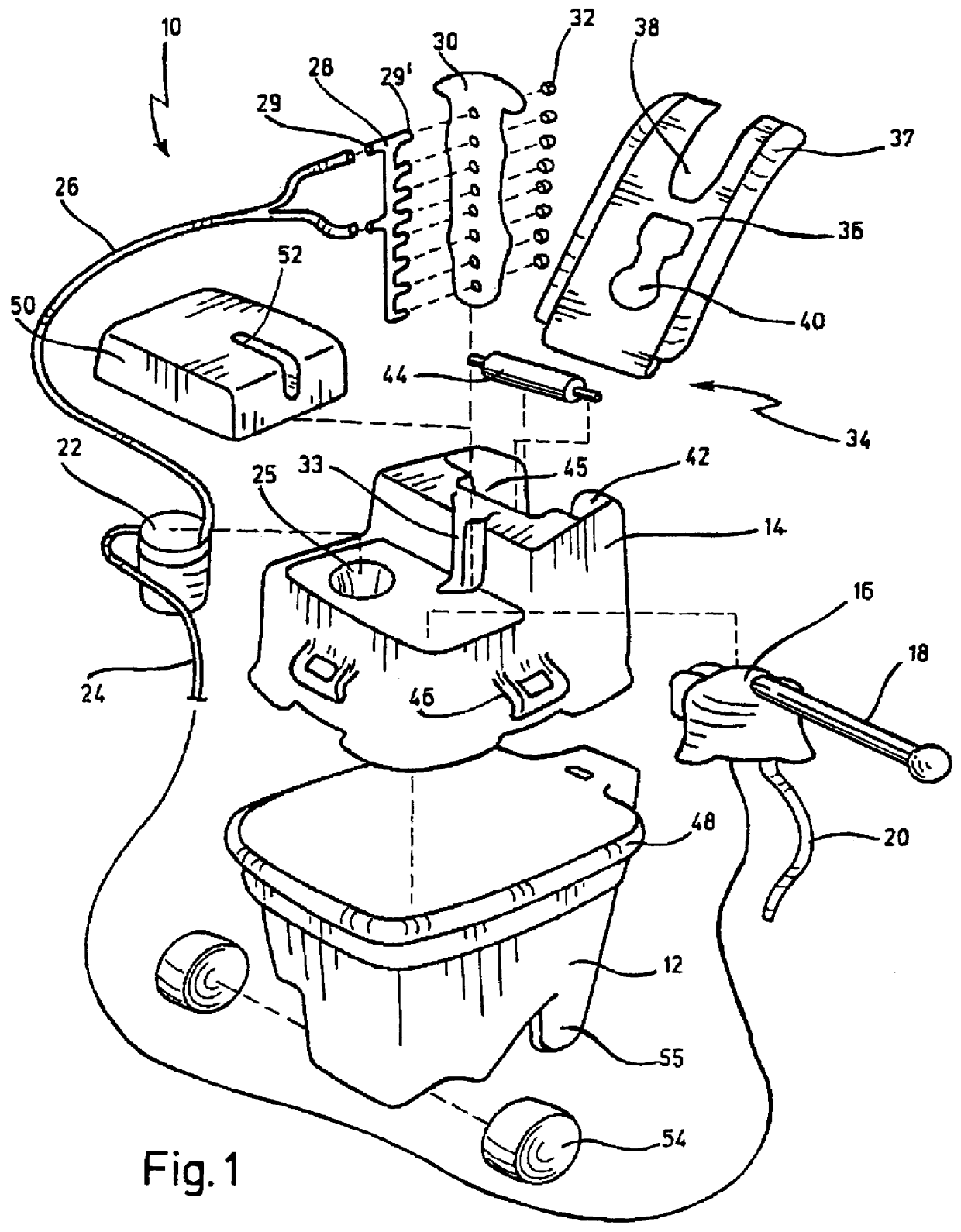

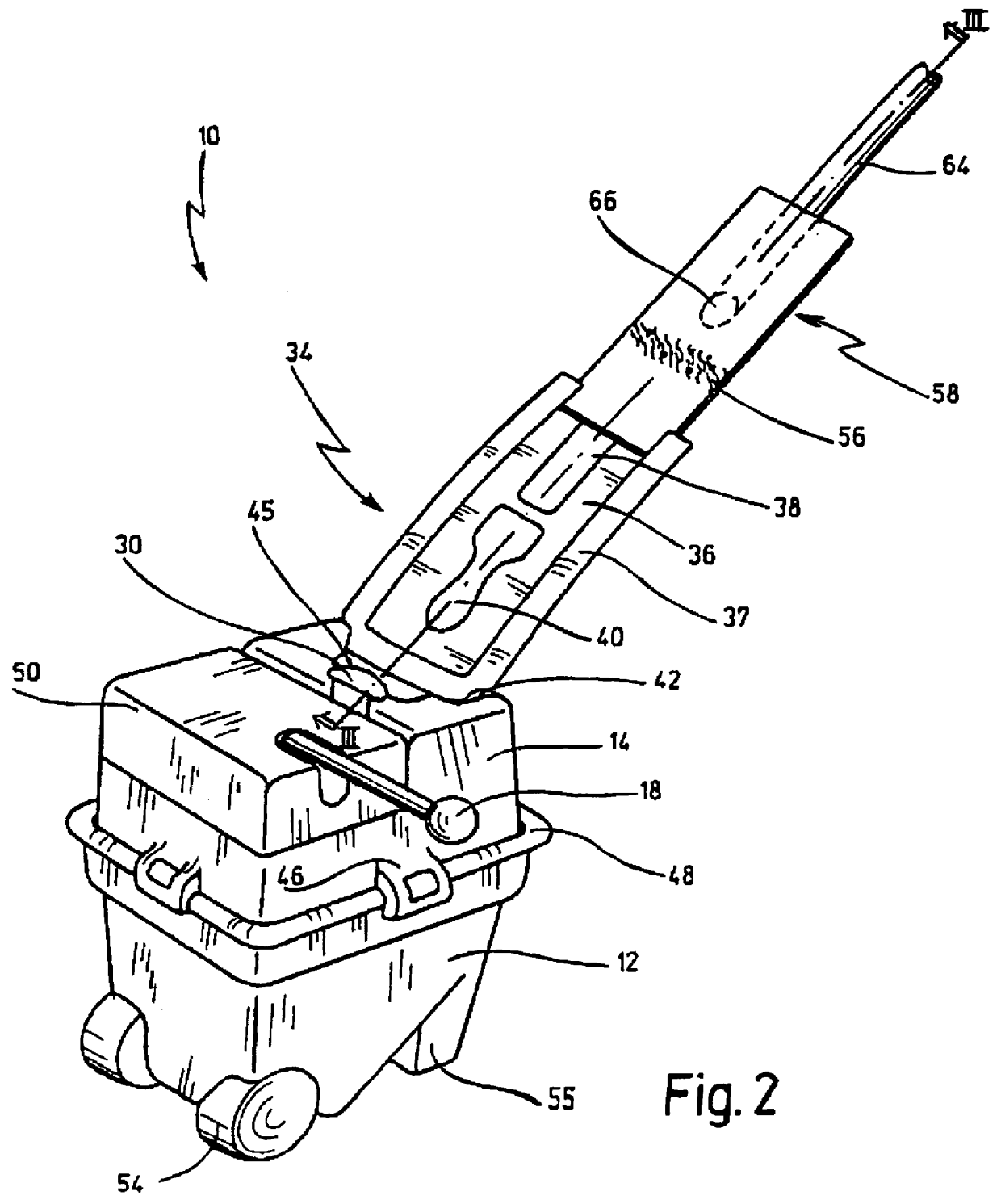

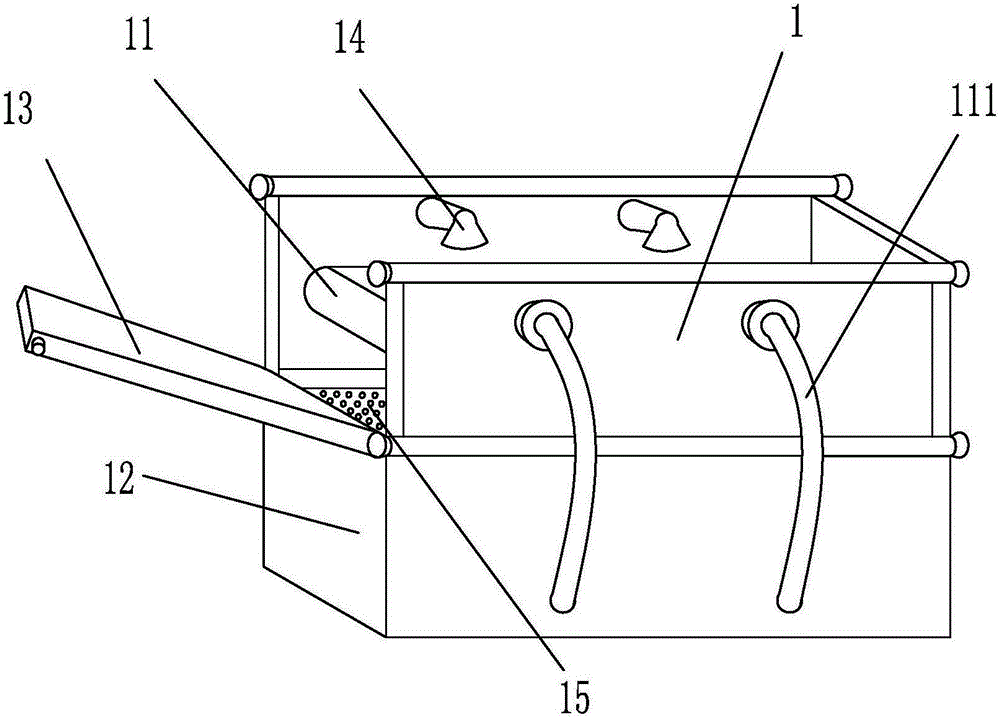

Rinsing system

A container (10) for use in rinsing out dirt from a cleaning cloth comprises a compartment (12) adapted to hold water, means for providing fresh water, a structure (34) adapted to receive the cleaning cloth to be rinsed, and at least one nozzle (32) for supplying water free of dirt onto the cleaning cloth (FIG. 1).

Owner:BOWMAN DAVID ALAN

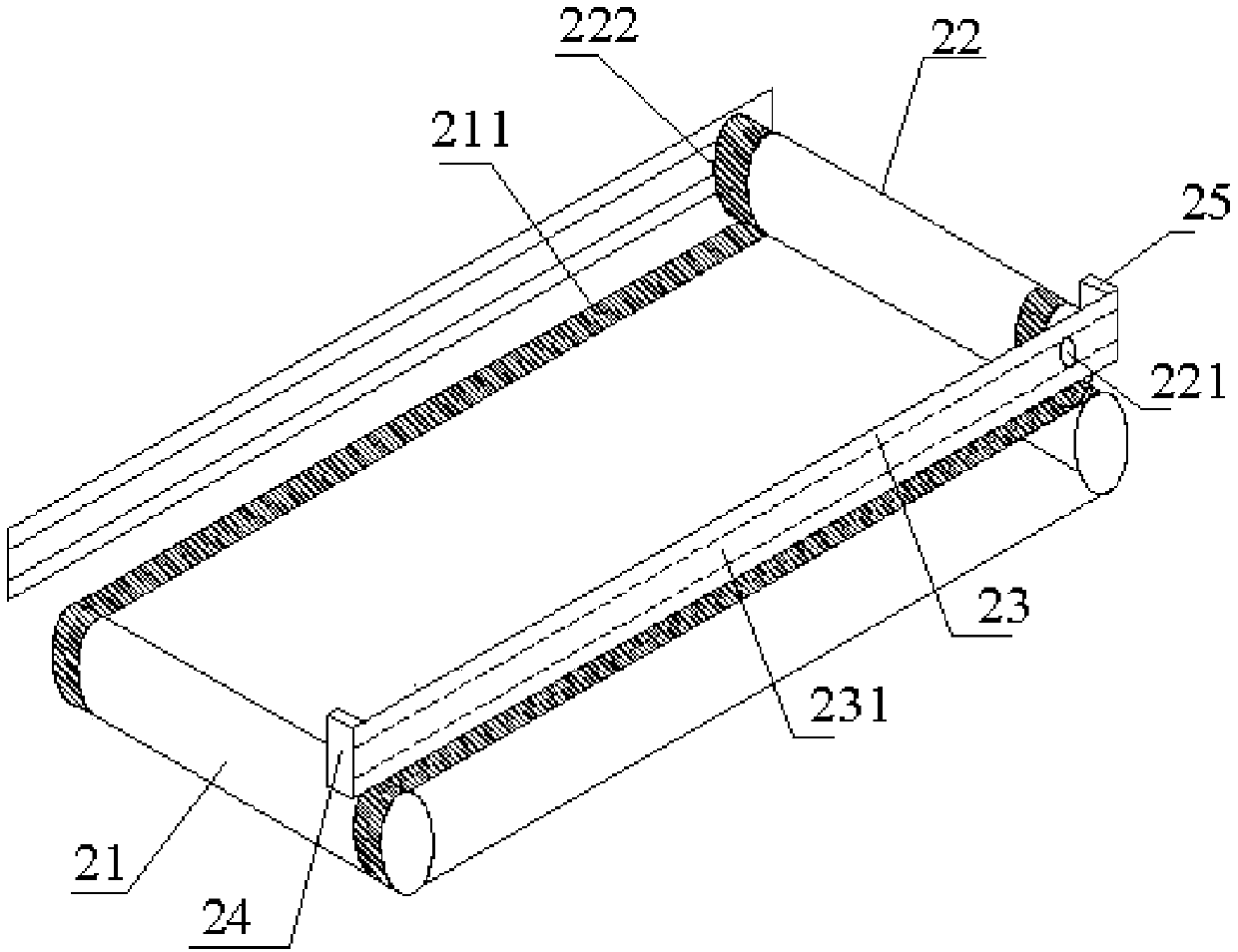

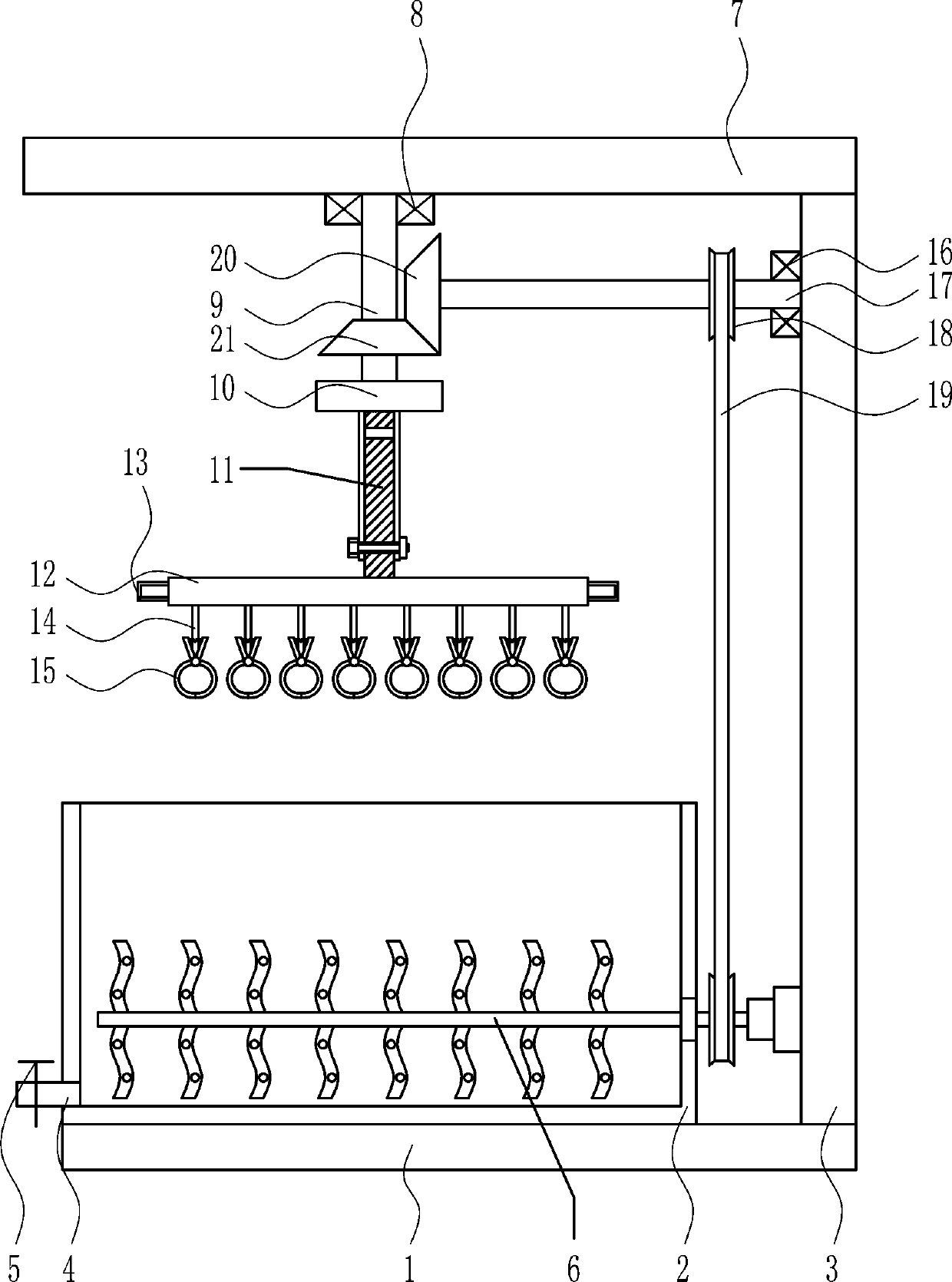

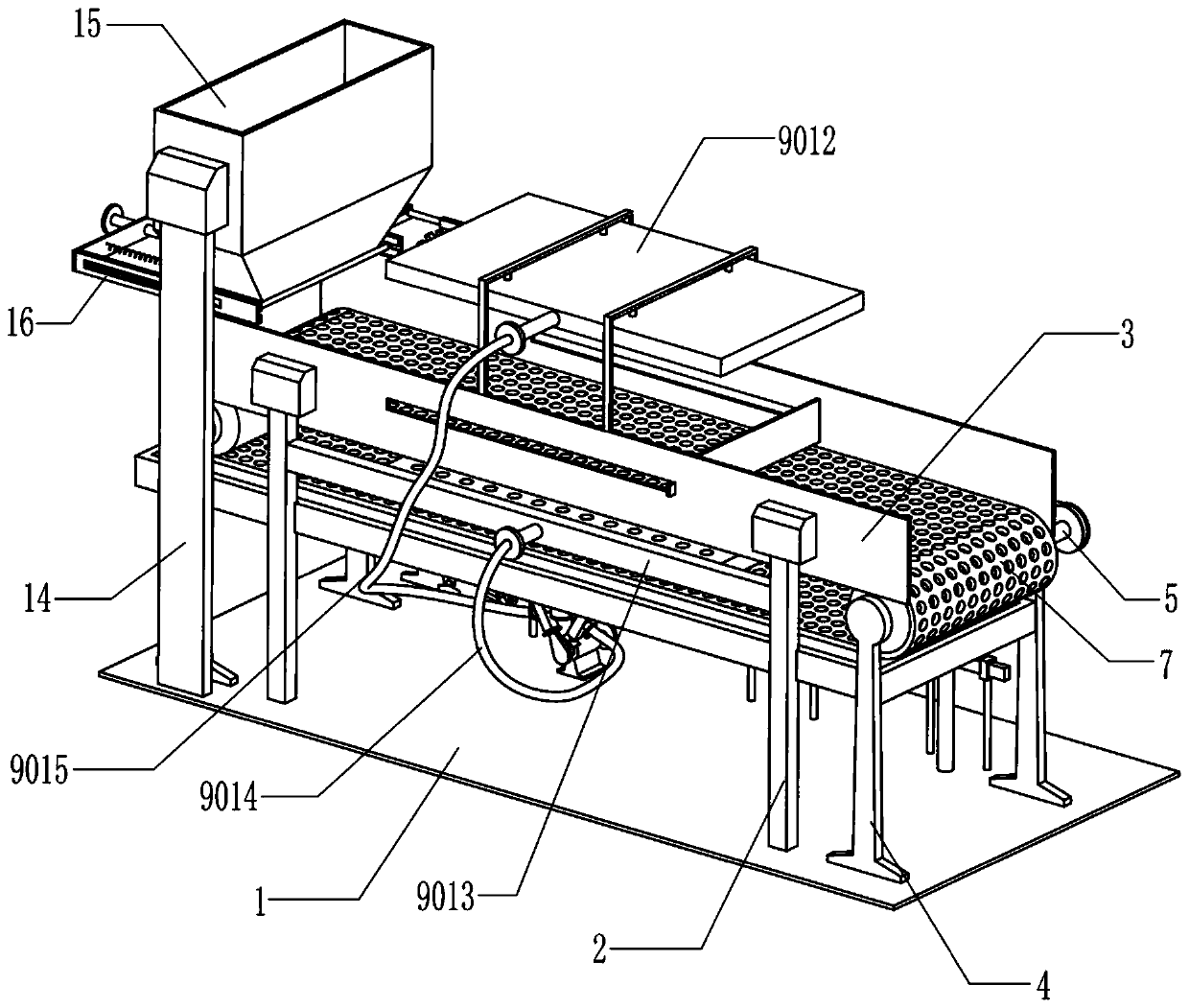

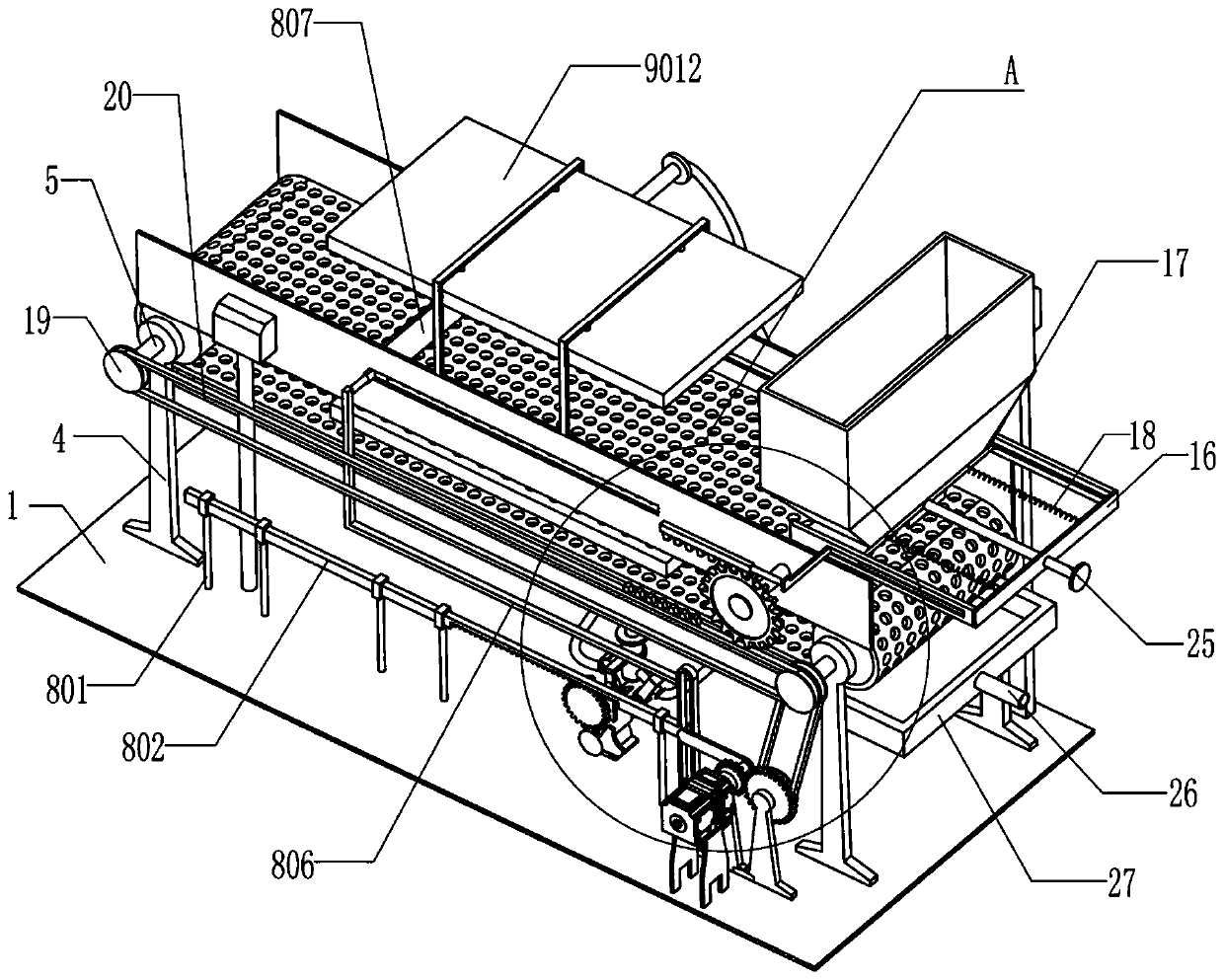

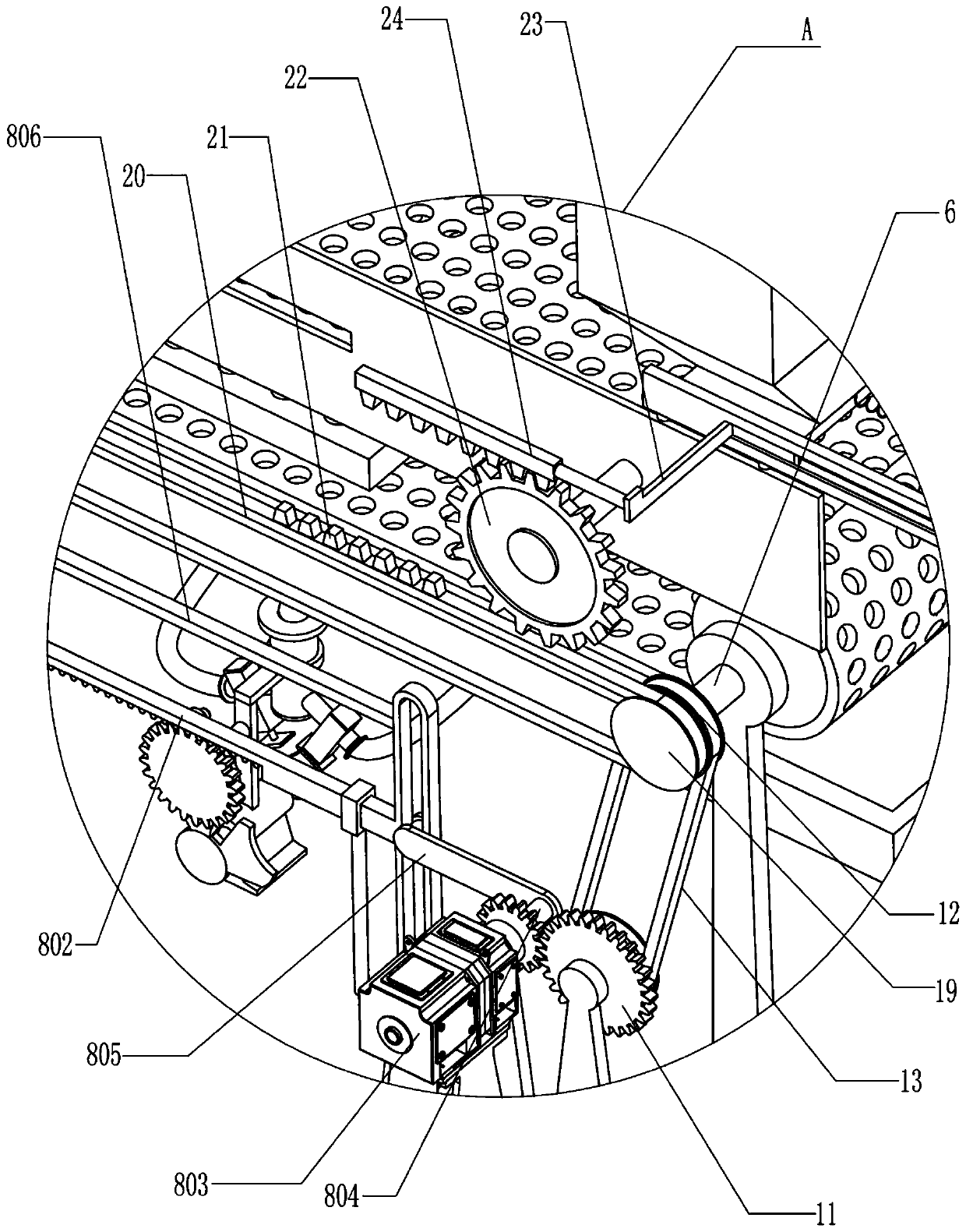

Cleaning and drying device

InactiveCN108380599ARinse thoroughlySimple structureHollow article cleaningDrying gas arrangementsWater dischargeOutput device

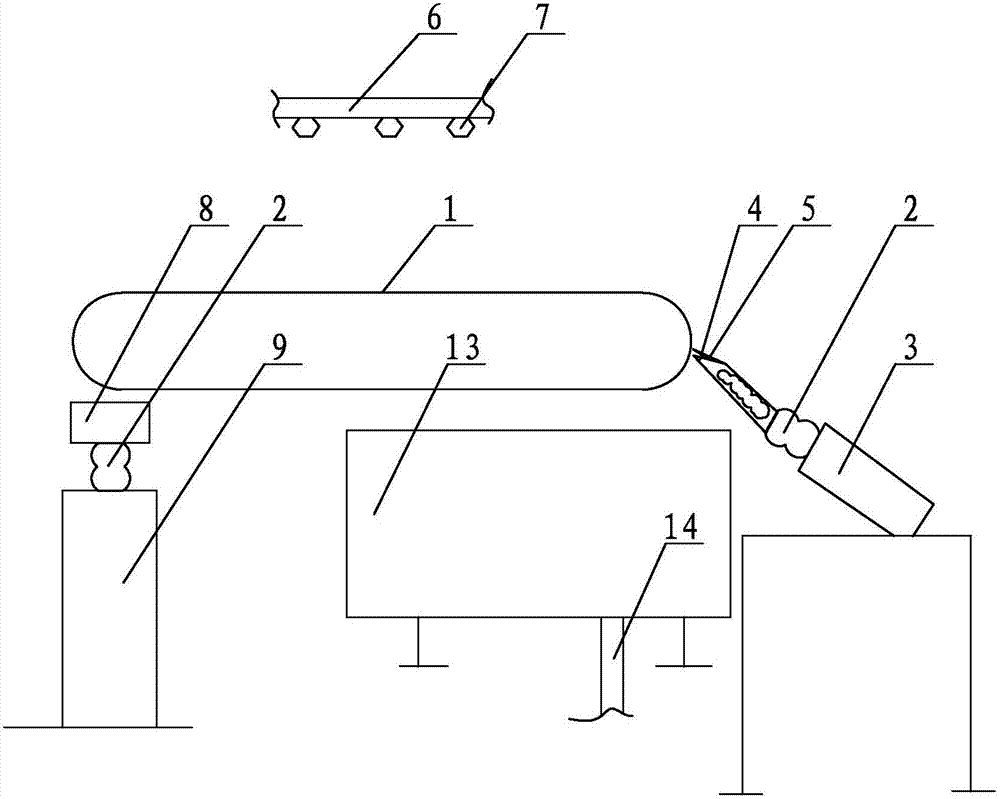

The invention relates to the technical field of tube product cleaning, in particular to a cleaning and drying device of a cylindrical tube. The cleaning and drying device of the cylindrical tube comprises a conveyer belt, a feeding device, a material outputting device, a cleaning device, a drying device and a material collecting frame. The material outputting device comprises a first supporting frame, a hopper and a material outputting mechanism used for outputting the tubes in the hopper. The first supporting frame is erected on the conveyer belt. The hopper and the material outputting mechanism are installed on the first supporting frame. The feeding device is located beside the first supporting frame. The conveying face of the conveyer belt is provided with a plurality of locating jigsand water discharging through holes. The cleaning device and the drying device are both located at one end of the conveyer belt. The other end of the conveyer belt is provided with a lead screw sliding table and a drive mechanism. The lower section of the conveyer belt is provided with a waste water collecting box. The material collecting frame is located under the material outlet end of the conveyer belt. The cleaning and drying device is simple in structure, high in automation degree and capable of thoroughly flushing the outer surfaces of the tubes and then directly drying the tubes and improves the production efficiency.

Owner:成都菲斯普科技有限公司

Inclined plate separate film biological reactor

InactiveCN101215024ALow infrastructure costLow running costTreatment using aerobic processesWater/sewage treatment bu osmosis/dialysisPorosityEngineering

The invention relates to a sloping-plate-independent membrane bioreactor, which comprises a biological contact oxidation region and a membrane separation region, wherein the two regions are separated by a plurality of sloping plates which are arrayed homogeneously and vertically and are placed horizontally and vertically, the top portion of the first sloping plate of the sloping plates is inundated in sewage, active porosity is left between the lowest sloping plate body and a baseboard of the membrane separation region, thereby achieving the hydraulic circulation between the membrane separation region and the biological contact oxidation region. The invention is capable of achieving pumpless circulation and reducing membrane pollution level of membrane bioreactor simultaneously.

Owner:SHANGHAI UNIV

Water sample pre-treatment system for automactically monitoring sandy river water quality

InactiveCN1474186AIncrease the sedimentation areaReduce sedimentation heightPreparing sample for investigationWater/sewage treatmentSample waterWater quality

The computerized water sample pre-treatment system for automatically monitoring sandy river water quality includes computerized central controller, submersed water pump in river, water flow bufferingpond connected to the submersed water pump, inclined pipe deposition pond connected to the bottom of the water flow buffering pond, laminar current deposition pond connected to the water overflow edge of the inclined pipe deposition pond, intermediate water tank connected to the laminar current deposition pond via valve, pressurizing water pump and solid-liquid separator, sampling water tank connected to the intermediate water tank via valve, pressurizing water pump, filter and pipeline, monitoring instrument connected to the sampling water tank, and automatic sampler with the sampling water tank via valve. The present invention can eliminate silt effectively and set reasonable operation parameters and is suitable for sample water supply for automatic water quality monitoring instrument.

Owner:水利部国家环境保护局黄河流域水资源保护局 +1

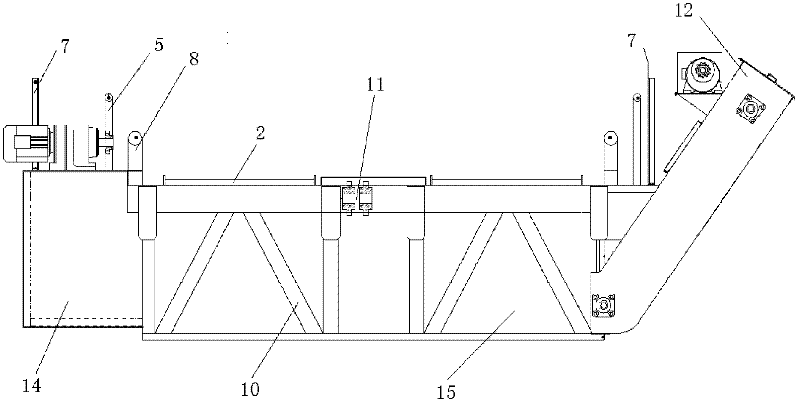

Automatic cleaning system for conveyer belt

The invention relates to a cleaning device of a conveying device or a storing device and in particular relates to an automatic cleaning system for a conveyer belt. The system comprises a conveyer belt and plastic scraper blades. The plastic scraper blades are arranged on one end of the conveyor belt; the direction of the plastic scraper blades is opposite to the transmission direction of the conveyor belt; the plastic scraper blades are connected to a scraper blade driving assembly through an air spring; a pressure sensor is arranged between the air spring and the plastic scraper blades; the plastic scraper blades comprise a primary scraper blade and a secondary scraper blade; the primary and secondary plastic scraper blades are of integrated structures; non-bearing portions of the primary and secondary plastic scraper blades are of hollowed structure; a spray pipe is correspondingly arranged above the conveyor belt and is connected to a rotating assembly; a nozzle is arranged on the spray pipe corresponding to the conveyor belt; sponge is arranged on the other end of the conveyor belt; sponge is connected to a sponge driving assembly through the air spring; and the pressure sensor, the scraper blade driving assembly, the sponge driving assembly and the rotating assembly are connected to a controller. The automatic cleaning system provided by the invention can prevent the conveyor belt from being damaged while the cleaning effect of the scraper blades is guaranteed.

Owner:SHANDONG HUALIAN MINING

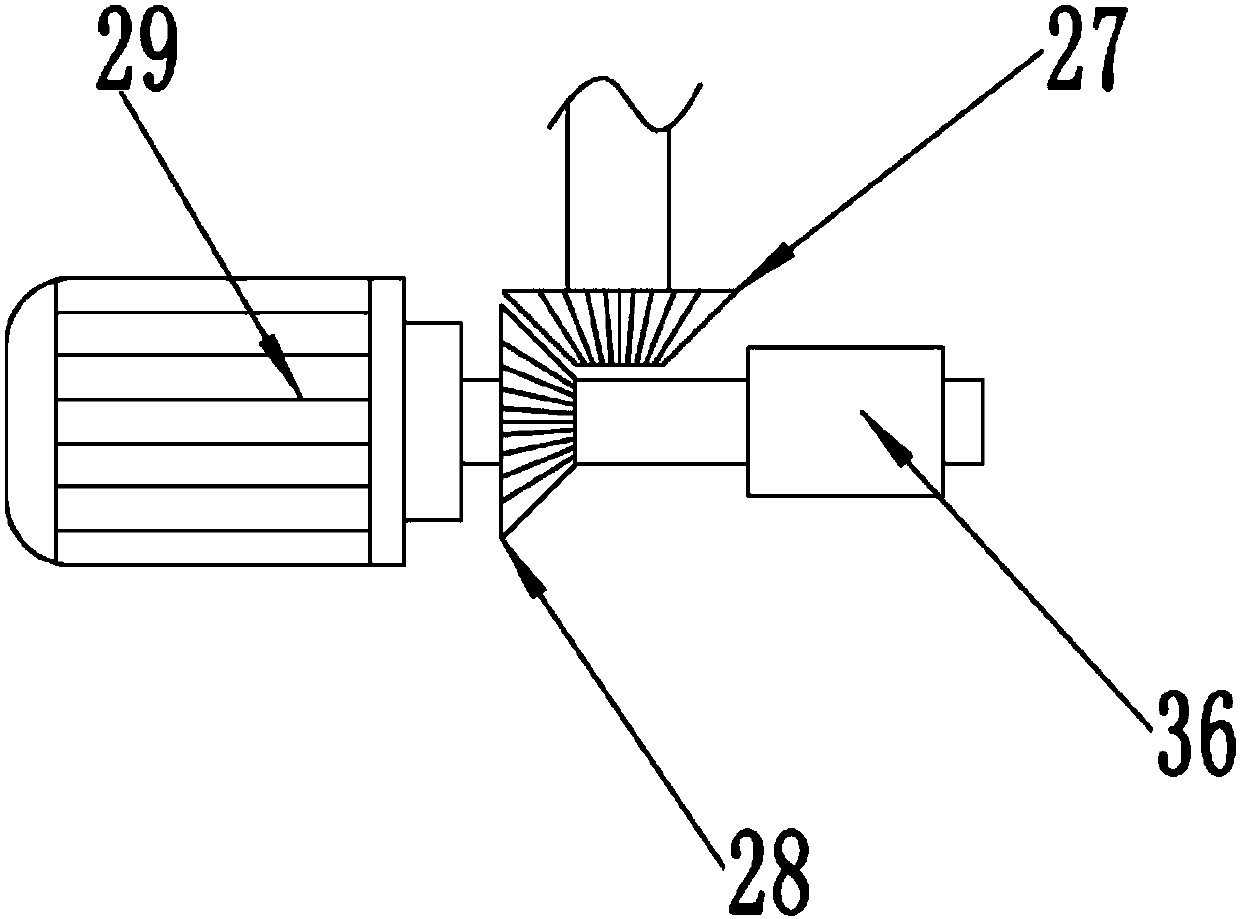

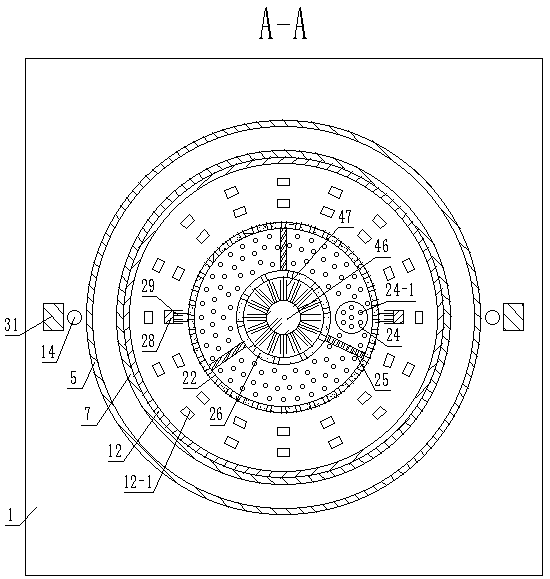

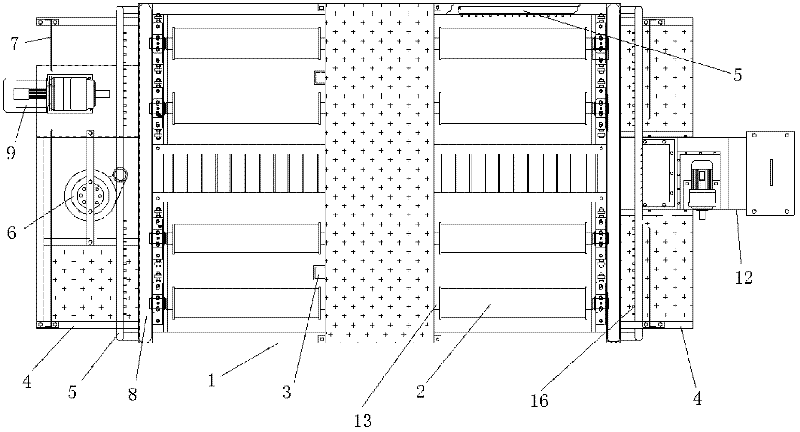

Drum type micro-filtering machine

ActiveCN104190142AReduce energy consumptionReduce laborMoving filtering element filtersControl systemWater level

The invention provides a drum type micro-filtering machine which comprises a housing, a filtering barrel with a filtering net, a backwashing device, a control system and a motor, wherein the filtering barrel is located in the housing, a rotary bracket of the filtering barrel is fixedly connected with the housing, the backwashing device is arranged between the filtering barrel and the housing; the control system comprises a water level sensor arranged in the filtering barrel and a control device assembly arranged outside the housing. By adopting an automatic water level detection function, by virtue of a water level difference, the rotation of the filtering barrel and the starting of backwashing are controlled, the advantages of reducing energy consumption and labor force are achieved; the drum type micro-filtering machine is economic and applicable, simple to operate, and low in production and operation costs.

Owner:杭州启程生态环境工程有限公司

Shredded peduncle dipping type material feeding process

The invention relates to a cabo processing method in the tobacco industry, which comprises the steps of cabo steeping, steam heating, cabo storing, chopping, fountain feeding, drying and swelling, wherein the fountain charging is replaced by impregnated charging, the cabo is fully immersed into the steeping liquor added by feed liquid, dewatering the steeped cabo to next stage (drying and swelling).

Owner:蚌埠卷烟厂

Efficient pipe cleaner

InactiveCN106694477ASimple structureReasonable designHollow article cleaningDrying gas arrangementsEngineeringIn degree

The invention provides an efficient pipe cleaner which comprises a steel pipe storage hopper, a transmission unit, a leaching unit, a blow-drying unit and a washing liquor circulating and demagnetizing unit, wherein a pipe outlet adaptive to a stainless steel pipe is formed in the bottom of the steel pipe storage hopper; an elastic plate connected with a controller is arranged in the pipe outlet; stainless steel pipe fixing slots are distributed in the surface of a conveyor belt at equal distance; the outer surface of a drive roller and the outer surface of a driven roller are rotatably connected with the stainless steel pipe; the leaching unit and the blow-drying unit are arranged above the transmission unit in parallel in sequence; the washing liquor circulating and demagnetizing unit comprises a water collecting slot, a demagnetizing box, a magnetic rotary disc and a liquor outlet pipe; and the liquor outlet pipe is vertically arranged at the left side in the demagnetizing box. The efficient pipe cleaner is relatively high in degree of automation; a pipe fixing slot is formed in the surface of the conveyor belt, so that the stainless steel pipe can be kept to rotate in a conveying process, and therefore, the cleaning effect is more complete. The demagnetizing box can recycle washing liquor, so that production cost is reduced.

Owner:天津俊海科技有限公司

Method for processing waste water of acid leaching and deironing of potassium feldspar

ActiveCN103482784ANeutralize sournessShort processing timeMultistage water/sewage treatmentPotassium feldsparK feldspar

The invention relates to a method for processing waste water of acid leaching and deironing, in particular to a method for processing waste water of acid leaching and deironing of potassium feldspar. The processing method comprises the steps of carrying out acid leaching and deironing on the potassium feldspar, flushing the potassium feldspar after acid leaching and deironing are carried out, and processing flushing fluid used for flushing the potassium feldspar. The method has the advantages that bluestones and quicklime serve as a processing agent, cost is low, operation is easy, and the processing time is short; as the flushing fluid is recycled in the whole system, no waste water is drained in the whole system, and zero drain of the waste water is achieved.

Owner:青岛立人环保科技有限公司 +1

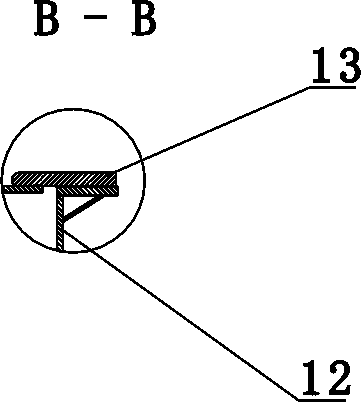

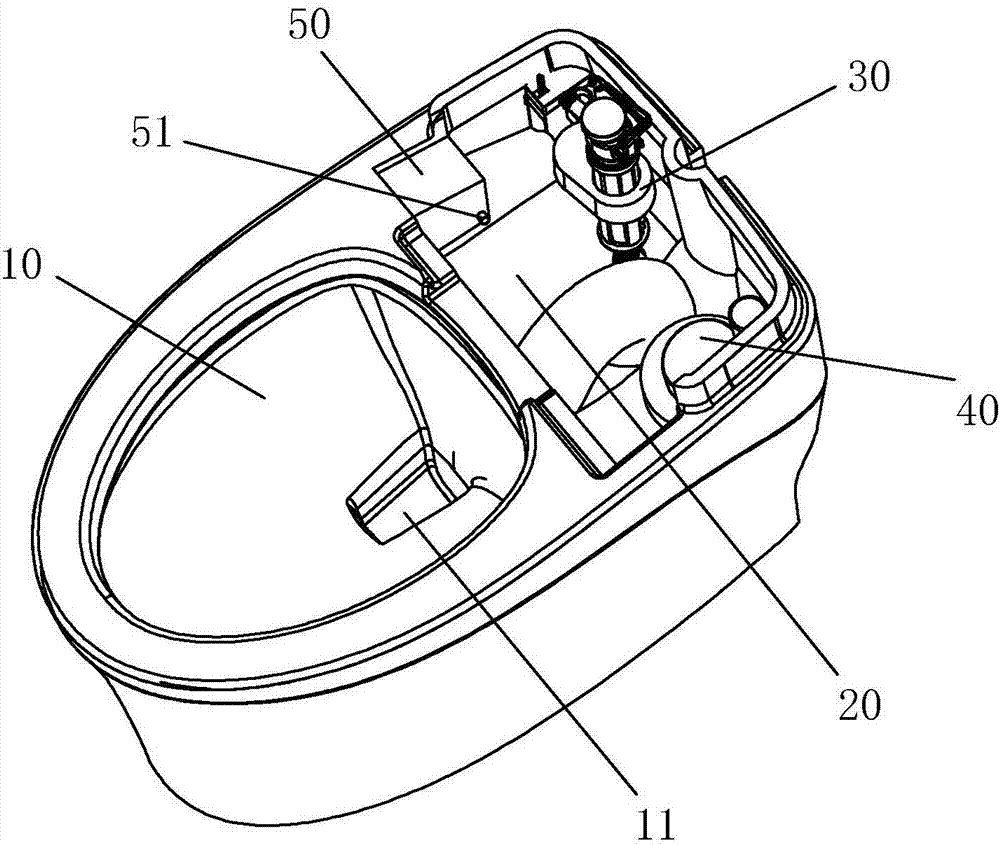

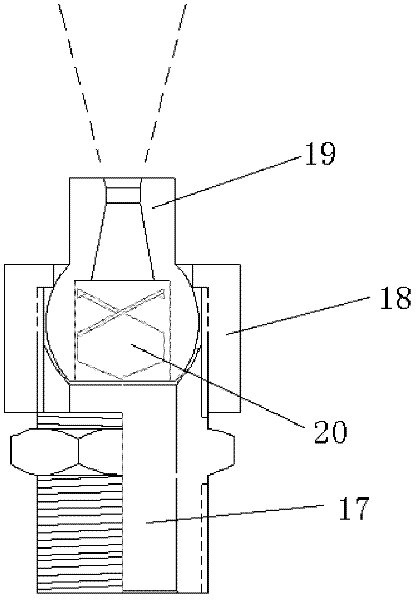

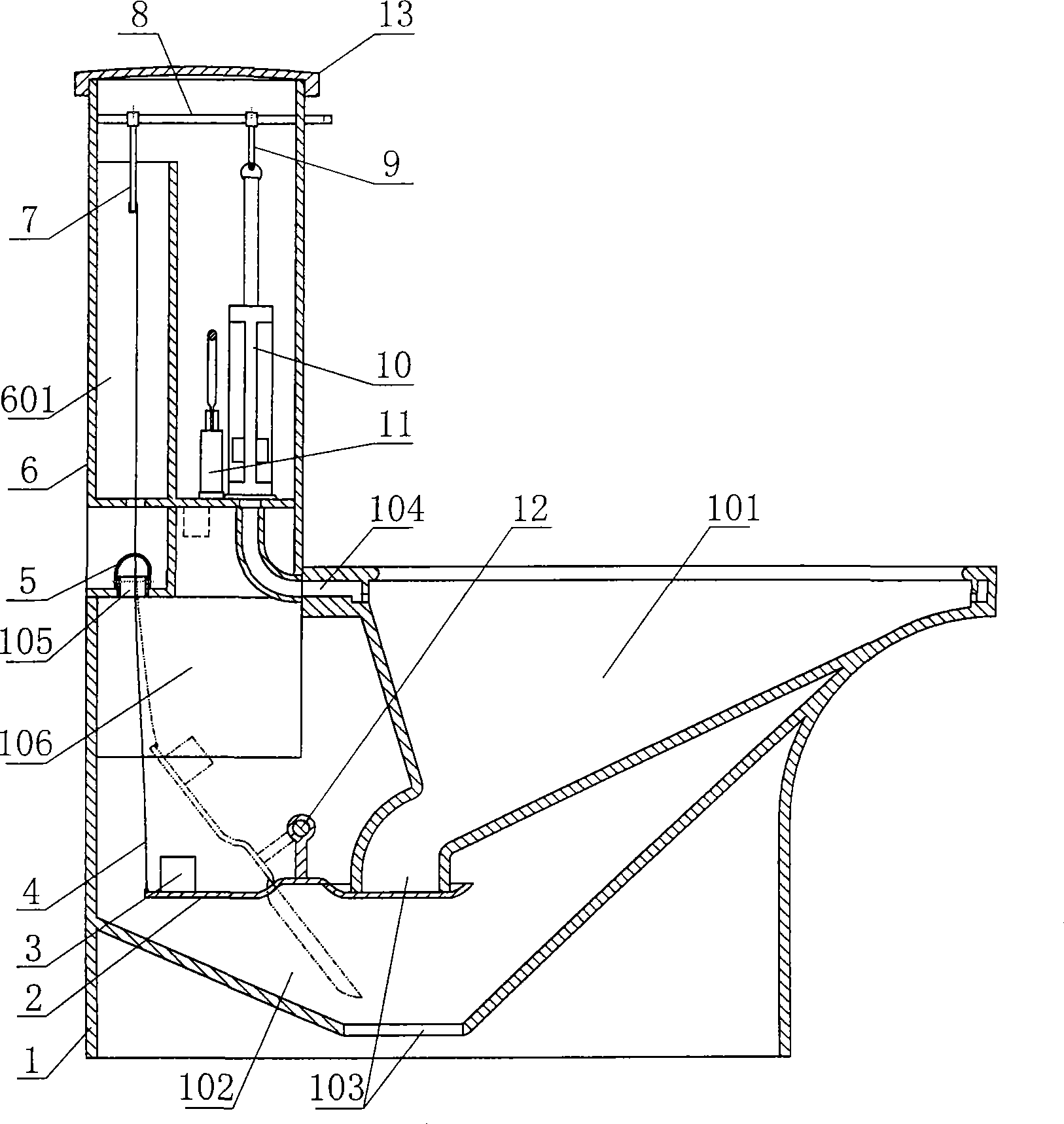

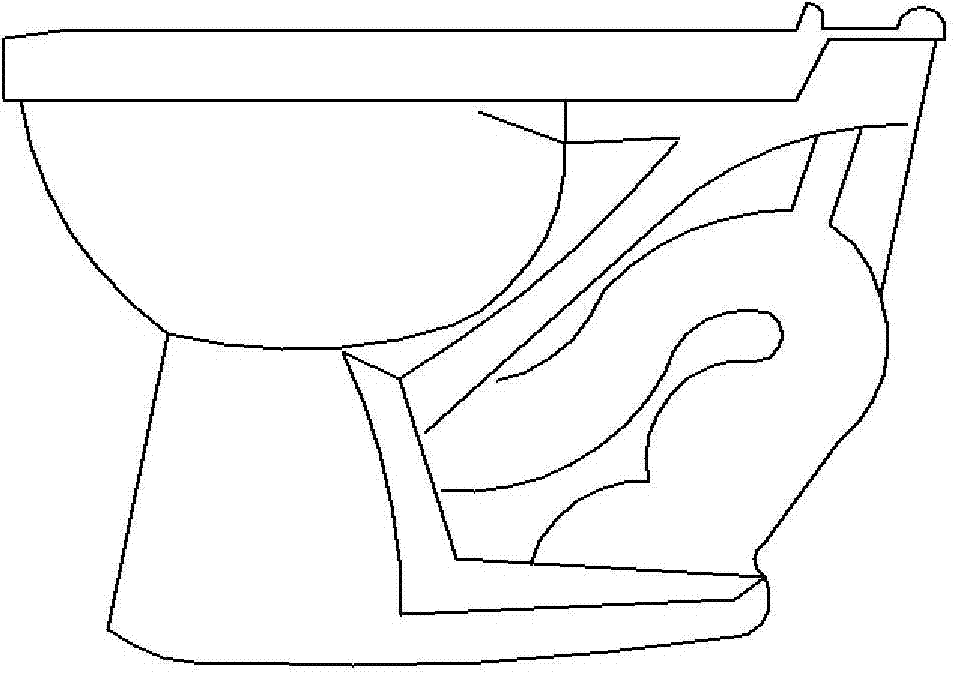

Low-pressure flushing system for intelligent toilet bowl

InactiveCN107130669AOutstanding and Beneficial Technical EffectsRinse thoroughlyFlushing devicesLavatory sanitoryWater sourceSprayer

The invention belongs to the technical field of toilet bowls, and relates to a low-pressure flushing system for an intelligent toilet bowl. The low-pressure flushing system comprises a close-stool with a water tank, a water inlet component and a water outlet component are mounted in the water tank, a flushing tank is arranged at the upper edge of the close-stool, an outlet of the flushing tank is positioned on the inner surface of the upper edge of the close-stool, a water inlet of the flushing tank is positioned in the water tank or on the rear outer surface of the close-stool, a water pump is mounted in the water tank, a water outlet of the water pump is connected with a flushing sprayer, the flushing sprayer is positioned in the outlet of the flushing tank at the upper edge of the close-stool, a water inlet of the water pump is communicated with an inner cavity of the water tank through a guide pipe or connected with a guide pipe which can be externally connected with a water source, or the water outlet of the water pump is connected with the water inlet of the flushing tank, and a flushing port is formed in the outlet of the flushing tank. The low-pressure flushing system has the advantages that tap water or low-pressure water in the water tank is pressurized by the water pump and then performs thorough high-pressure flushing on the inner wall of the close-stool, and the low-pressure flushing system is applicable to high-grade, medium-grade and low-grade toilet bowls.

Owner:浙江星星便洁宝有限公司

Water saving type multi-stage potato cleaning device

ActiveCN107625170AExtend the movement timeImprove cleaning efficiencyClimate change adaptationFood treatmentWater savingWater resources

The invention discloses a water saving type multi-stage potato cleaning device which comprises a bottom plate, a bracket, a water tank, a conveyer belt, a cleaning sleeve and a cleaning cavity, wherein the bracket is fixedly mounted at the upper end of the bottom plate; a feeding hopper is arranged on the bracket; the conveyer belt is arranged below the feeding hopper; a water ejection tube is arranged above the conveyer belt; the upper end of the water ejection tube is communicated with a water sucking pump through a water guide tube; the water sucking pump is communicated with the bottom ofthe left side of the water tank through the water guide tube; the water tank is arranged on the base; a water collection disc is arranged at the upper end of the water tank; the bottom of the water collection disc is communicated with the water tank through a guide tube; the cleaning sleeve is arranged on the right side of the conveyer belt; the right side of the cleaning sleeve is rotationally connected with a material guide tube; the lower end of the material guide tube is communicated with the cleaning cavity. The water saving type multi-stage potato cleaning device is novel in design and high in automation degree; due to multi-stage cleaning, the potato cleaning effect is improved, potatoes can be thoroughly cleaned with high efficiency; meanwhile due to water circulation, the water resource is greatly saved, and very good practicability is achieved.

Owner:中科星河(山东)智能科技有限公司

Cleaning device for mechanical part

InactiveCN108311448AEasy to washEasy to cleanDrying gas arrangementsCleaning using toolsEngineeringMechanical engineering

The invention discloses a cleaning device for a mechanical part. The cleaning device comprises a bottom plate, supporting column bodies A are symmetrically fixed to the top surface of the bottom plate; a water tank is arranged on the top surfaces of the supporting column bodies A, the top surface of the water tank is welded with a cone cylinder A which is integrally formed with the water tank, anda sleeve A which is integrally formed with the cone cylinder A is welded and fixed on the top surface of the cone cylinder A; a cone cylinder B is arranged in the cone cylinder A, and multiple squarethrough holes A are uniformly formed in the side surface of the cone cylinder B; a sleeve B is arranged in the sleeve A, multiple square through holes B are uniformly formed in the side surface of the sleeve B; and the conical cylinder A is fixedly connected to the bottom surface of the conical cylinder B through an annular plate A. According to the cleaning device, the part can be cleaned from all directions, the surface of the part is washed more uniformly and thoroughly, and the multiple parts can be washed at one step, the cleaning efficiency is high, a proper amount of flushing can be performed according to the dirt accumulation degree of the part, so that the good cleaning effect is achieved; and meanwhile, the probability that the part is rusted, damaged or stained again in the transportation process is reduced, and the cleaning device is high in use efficiency and is very practical and reliable.

Owner:DONGGUAN KAILEDI NUMERICAL CONTROL SCI & TECH CO LTD

Environment-friendly waste gas treatment equipment

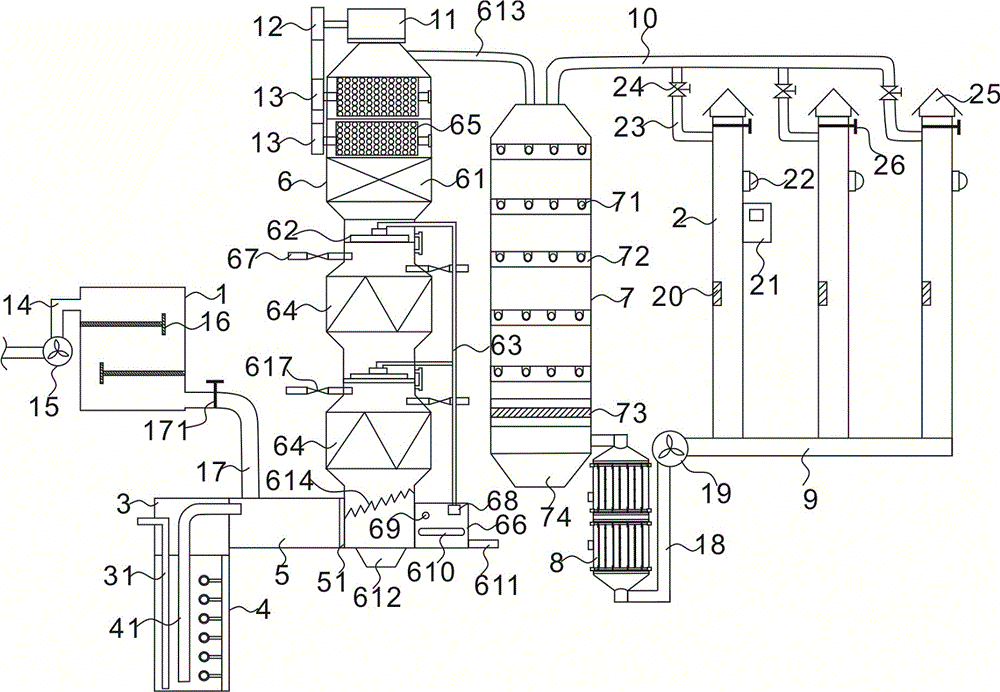

ActiveCN106215658AConserve waterReduce impactCombination devicesGas treatmentIonEnvironmental resistance

The invention discloses environment-friendly waste gas treatment equipment. The environment-friendly waste gas treatment equipment comprises a rectifier, a reaction cavity, a purification tower, an ultraviolet reaction tower, an electrostatic dust collector, an exhaust gear and a waste gas detection system which are all communicated in sequence, the purification tower comprises a purification device and a filter device, and the filter device is located above the purification device; the purification is communicated with the ultraviolet reaction tower through a second circulation pipe, and one side of the reaction cavity is communicated with a low-temperature ion generator; a bent plate is arranged at the bottom of the purification device, flushing pipes are connected to two sides of the purification device, venturi pipes are mounted on the corresponding flushing pipes, multiple sets of ultraviolet lamps are arranged in the ultraviolet reaction tower, and a filter is arranged at the bottom of the ultraviolet reaction tower; the electrostatic dust collector comprises a dust collection plate and a corona pin; the exhaust gear comprises an exhaust manifold and multiple exhaust branches, and the waste gas detection system comprises a controller, a gas sensor and an alarm. By the arrangement, problems that existing waste gas treatment is poor in purification effect and incomplete in purification and service life of the equipment is short can be solved.

Owner:深圳市东荣环保科技有限公司

Chicken house manure cleaning device

InactiveCN110881420AA hygienic environment is conducive toReduce manure cleaning costsBird housingsAnimal scienceEnvironmental geology

The invention provides a chicken house manure cleaning device and relates to the field of poultry breeding equipment. The chicken house manure cleaning device comprises a chicken cage, a cleaning mechanism and a flushing mechanism, an extensible rod is fixedly connected at the bottom of an inner cavity of the chicken cage, one end of a bottom plate is slidably connected on a sliding groove througha rotating shaft while the other end of the same is hinged at the top of the extensible rod, a through groove is formed in the chicken cage, two connection blocks are positioned above the through groove, a screw rod is rotatably connected between the connection blocks, a sliding rod is connected on the screw rod in a threaded manner, and a cleaning roller is rotatably connected between connectionplates. Through the cleaning mechanism, angle of a bottom plate is adjusted to enable the bottom plate to incline, and the cleaning roller driven by the screw rod on the outer side is also utilized to repeatedly clean the bottom plate; through the flushing mechanism, water is provided cyclically for flushing to clean the bottom plate more thoroughly, in this way, sanitary environment of a chickenhouse is enabled to be conducive to growth of chickens, manure cleaning cost is lowered, and breeding benefit is increased.

Owner:五莲德瑞达牧业机械有限公司

Apparatus for washing vagina

InactiveCN101366608APrevent overflowPrevent backflowEnemata/irrigatorsBathroom accessoriesWastewaterEngineering

The invention relates to a vagina rinse apparatus, which comprises a solution bottle, a suction pressure water bag and a rinse probe, wherein a check valve is arranged between the solution bottle and the suction pressure water bag; another check valve is arranged between the suction pressure water bag and the rinse probe; a joint of the suction pressure water bag and the rinse probe is provided with a wastewater retaining sheet; and the rinse probe is provided with a cut seam. The rinse apparatus has the advantages that liquid medicine can not flow back to the suction pressure water bag from the rinse probe or flow back to the solution bottle from the suction pressure water bag; when the water bag is squeezed, a cut stretches to allow water to flow out, and when the squeezing is stopped, the cut automatically closes; meanwhile, the rinse apparatus is wide in rinse surface, and prevents water from rushing into a cervix so as to cause endometritis and then pelvic inflammation; as the wastewater retaining sheet covers labia majora, a closed cavity is formed in a vagina, and the water pressure in the vagina increases during rinse, so as to unfold and thoroughly rinse vaginal plica; the liquid medicine is kept for a while after rinse, so as to bring the efficacy of the liquid medicine into play; and in addition, the rinse apparatus can prevent the liquid medicine from overflowing from the lower ends of the labia majora on two sides and polluting hands.

Owner:SHANGHAI NEW JIEER CLEANING PRODS

Soybean milk making method of rapid soybean milk maker

ActiveCN102771575AAvoid wastingReduce wasteBeverage vesselsMilk substitutesHigh concentrationWater resources

The invention relates to a soybean milk making method of a rapid soybean milk maker. The soybean milk making method at least comprises the steps: injecting the water of capacity V1 in a small-space smasher at a time, and heating the water in the small-space smasher through a heating device, draining the heated water to a milk receiving cup and mixing the milk in the milk receiving cup. Compared with the prior art, the residue of high-concentration milk / paste in the small-space smasher can be reduced, so that waste is avoided; furthermore, the water resources for cleaning at later stage can be effectively reduced, and the waste of water resources can also be reduced.

Owner:JOYOUNG CO LTD

Chicken cage frame

InactiveCN107836374ARinse thoroughlyAccurately control the amount of feedCleaning using liquidsBird housingsEngineeringLimit switch

The invention relates to the technical field of chicken raising equipment, in particular to a chicken cage frame. The chicken cage frame comprises a frame body, railings are arranged on the two opposite sides of the frame body, the bottom of the frame body is a net surface, and chicken excrement can be discharged from the frame body through the net surface. A cleaning device is arranged below theframe body, the cleaning device includes an excrement transport belt, a cleaning cylinder and fixed plates, the fixed plates are fixedly connected to both sides of the frame body and are located on the same sides of the railings, the fixed plates are slidably connected to the cleaning cylinder, and there are two fixed plates. Limit switches are arranged at both ends of one of the fixed plates, gear rings are arranged at both ends of the cleaning cylinder, tooth strips are arranged at both ends of the excrement transport belt, and the gear rings and the tooth strips are engaged with each other.The two railings are correspondingly provided with water supply devices and feeding devices. The cleaning device, the water supply devices and the feeding devices are controlled by a PLC. The chickencage frame can automatically cleaning the chicken excrement and can automatically feed water to chickens and feed the chickens.

Owner:GUANGXI ZHEYUAN AGRI SCI & TECH CO LTD

An engineering vehicle automatic washing machine

ActiveCN102294991AQuick rinseRinse thoroughlyCleaning apparatus for vehicle exteriorsControl systemHuman environment

The invention relates to an automatic flushing machine for an engineering vehicle, comprising a flushing nozzle, a rack, a slurry collecting pool, a water tank, an automatic slurry extractor and a sensing control system, wherein the flushing bed of the rack is at least provided with two sets of parallel roller groups; each set of roller groups is respectively composed of two lateral rollers whichare mutually parallel and are arranged into one row; two sets of parallel roller groups are at least correspondingly provided with a pressure sensor; and the pressure sensor is installed between two rollers of one set of roller groups. The automatic flushing machine provided by the invention has the advantages of high flushing efficiency and low cost, is environmentally-friendly and is durable inuse, pollution on roads by the construction field is drastically reduced, and city human environment is improved.

Owner:武汉瑞丽森智能设备有限公司

Rainwater regulation and storage device

The invention discloses a rainwater regulation and storage device. The rainwater regulation and storage device comprises a regulation and storage pool, as well as a stirring device and a flushing device which are arranged in the regulation and storage pool, wherein the stirring device is used for stirring rainwater in the regulation and storage pool, the flushing device is used for flushing the bottom of the regulation and storage pool, a water collecting pit is formed in the bottom of one side of the regulation and storage pool, and a submersible sewage pump is arranged in the water collecting pit. For the rainwater regulation and storage device, the phenomenon that sediment forms sludge and hardened matters at the bottom of the regulation and storage pool can be effectively avoided, so that the regulation and storage effects of the rainwater regulation and storage device are ensured.

Owner:WUHAN SHENGYU DRAINING SYST

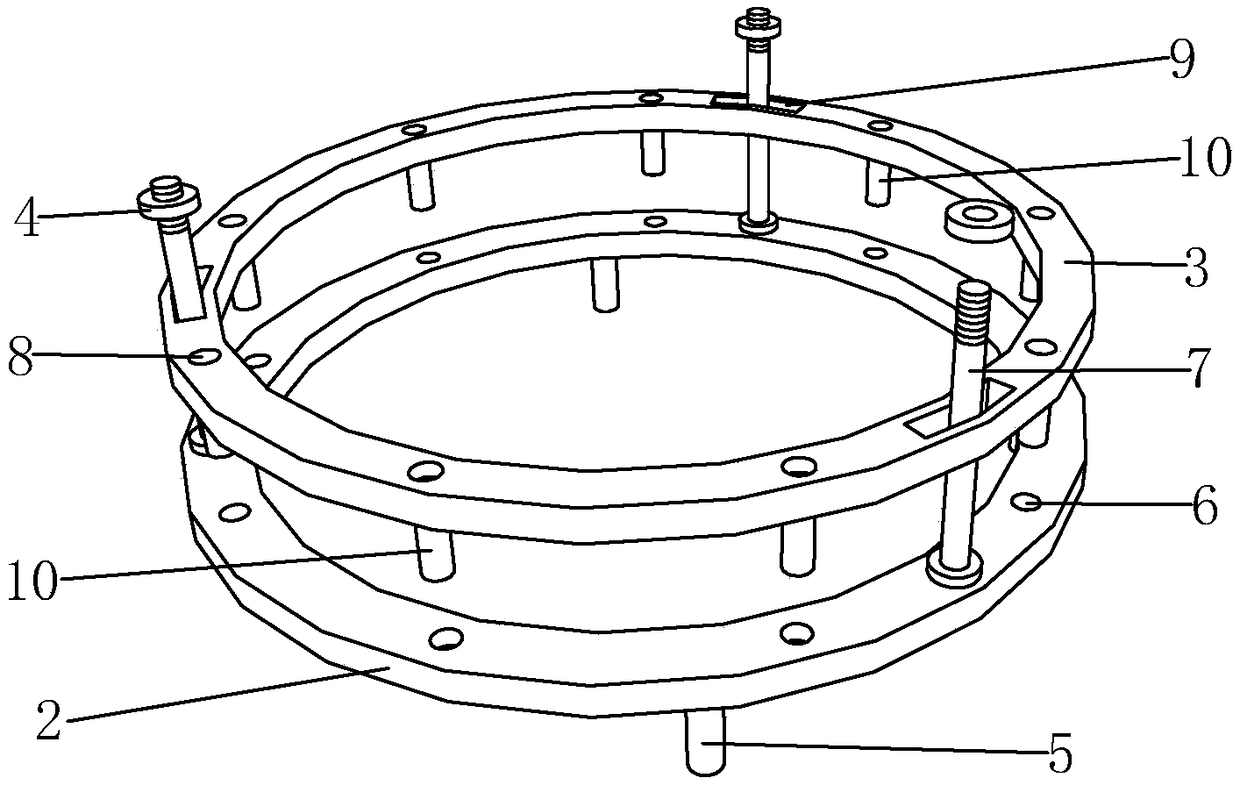

Permanent magnetic separation column suitable for strongly or weakly magnetic minerals

The invention belongs to the field of magnetic separation columns and particularly relates to a permanent magnetic separation column suitable for strongly or weakly magnetic minerals. Permanent magnetic systems are adopted, the magnetic field intensity can be adjusted within 1,600-16,000 Gs, and an inner permanent magnetic field mechanism and an outer permanent magnetic field mechanism which are in spiral distribution and movement are arranged simultaneously meet the requirement for production of big or small magnetic separation columns; fed water and minerals in a mineral separation chamber conduct inversely spiral upward movements to separate concentrate from tailing more radically, so that the concentrate grade is further improved; concentrate particles conduct obliquely downward slow movement under dual actions of the magnetic field and the dead weight, so that the tailing missing amount is reduced; and the permanent magnetic separation column is simple in structure, stable and reliable, low in water consumption, high in equipment output, and is simultaneously suitable for separation of such strongly-magnetic minerals as magnetite and such weakly-magnetic minerals as hematite, limonite and siderite.

Owner:唐竹胜

Metal bearing cleaning method

ActiveCN109332278AImprove connection strengthIncreased connection contact areaCleaning using liquidsCleaning methodsEngineering

The invention discloses a metal bearing cleaning method. The metal bearing cleaning method comprises the following steps that (a) a cleaning frame is assembled; (b) installation is carried out in place; (c) preliminary cleaning is carried out; (d) secondary cleaning is carried out; (e) deep cleaning is carried out; (f) drying is carried out; and (g) storage is carried out. The metal bearing cleaning method has the advantages of being simple in operation, easy to control, large in cleaning amount, good in cleaning effect, comprehensive, thorough and high cleaning quality, improves cleaning efficiency, and being capable of achieving phased cleaning,.

Owner:蓝山县太平湘发机械铸造有限公司

Direct-flushing water-saving toilet seat

InactiveCN101487289AAvoid pollutionGood for healthWater closetsFlushing devicesWater useWater saving

A straight-flushing water-saving closetool comprises a closestool body and a water tank. A water feeding control component and a water draining valve are arranged inside the water tank. The closestool is characterized in that the closestool body can be divided into a stool-receiving cavity and an isolating cavity; a sewage draining outlet is respectively arranged on the lower parts of the stool-receiving cavity and the isolating cavity; a sealing support plate is articulated inside the isolating cavity; the front part of the sealing support plate appears as a disc shape which blocks the closetool draining outlet at the lower end of the stool-receiving cavity; a weight-balancing part is arranged at the rear part of the sealing support plate; a rotary shaft, one end of which is threaded through the water tank, is arranged on the upper part of the water tank; the lead-out end of the rotary shaft is provided with a handle; the front part of the rotary shaft is connected by a link rod with a piston rod of a draining valve; and the rear part of the rotary shaft is connected with the rear end of the sealing support-plate by the link rod and a pulling rope. The closestool has the advantages that the structure is simple; the use is convenient; the straight-flushing is realized and the water-using quantity is low and the water saving capability is good; the flushing effect is clean and complete; after the flushing is completed, the disc mouth at the front part of the sealing support plate can contain a little clean water to realize the water sealing with good sealing effect so as to avoid the air pollution and be beneficial to body health.

Owner:潘一兵

Automobile part washing device

InactiveCN108031678ARealize alternate flushingRinse thoroughlyCleaning using liquidsEngineeringScrew thread

The invention belongs to the technical field of automobile parts, and particularly discloses an automobile part washing device. The automobile part washing device comprises a base, a washing gun, andtwo rotating seats arranged on the two sides of the base; a rotating motor, a part bearing seat and a limiting frame are sequentially arranged at the middle part of the base from the bottom up; firstwashing holes are formed in the bottom of the part bearing seat; the rotating motor is sleeved with a first gear; each rotating seat is rotationally connected with a lifting wheel engaged with the first gear; the limiting frame is connected with the first gear through springs; the centers of the lifting wheels are in threaded connection with a left lifting rod and a right lifting rod correspondingly; the thread pitch of the right lifting rod is greater than that of the left lifting rod; the left lifting rod is fixedly connected with an annular frame; the head of the washing gun faces towards the part bearing seat; the middle part of the washing gun is hinged to the right lifting rod; and the bottom end of the washing gun is hinged to the annular frame. The automobile part washing device isthorough in washing and easy and simple to operate.

Owner:重庆冠亨汽车配件有限公司

Plastic mould after-use washing equipment

InactiveCN107599252ARinse thoroughlyStir wellDrying gas arrangementsCleaning using liquidsEngineeringMechanical engineering

The invention relates to washing equipment, in particular to plastic mould after-use washing equipment. The plastic mould after-use washing equipment comprises a bottom plate, a washing box, a first support, a water outlet pipe, a valve, a stirring mechanism, a top plate, a first bearing seat and the like. The washing box and the first support are arranged on the bottom plate, the first support islocated on the right portion of the washing box, the water outlet pipe is arranged on the lower portion of the left side of the washing box, and the valve is arranged on the water outlet pipe; and the stirring mechanism is arranged on the lower portion of the interior of the washing box, the top plate is arranged at the top of the first support, and the first bearing seat is arranged in the middle of the top plate. According to the plastic mould after-use washing equipment, the effects that the washing efficiency of plastic moulds is high, and the plastic moulds can be washed cleanly are achieved, when needing to collect impurities left in water, people can put a screen frame into the washing box before the plastic moulds are washed, and therefore the screen frame can collect the impurities falling from the plastic moulds.

Owner:JINGMEN KUNPENG TECH DEV

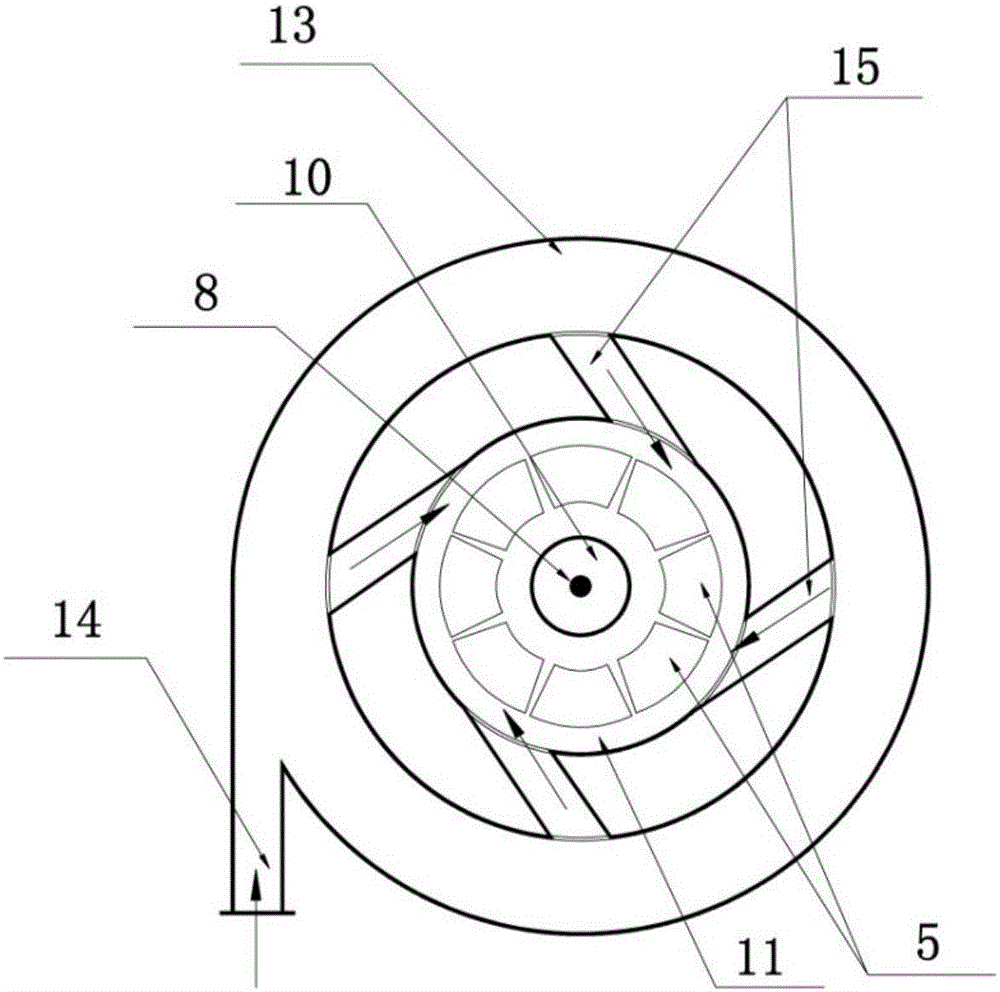

Cleaning device for plane glass

InactiveCN105170543AAvoid pollutionEasy to cleanDrying gas arrangementsCleaning using toolsEngineeringCentrifugal fan

The invention discloses a cleaning device for plane glass. The cleaning device for plane glass comprises a water soaking mechanism, a scouring chamber and a drying chamber. The scouring chamber is located between the water soaking mechanism and the drying chamber. The water soaking mechanism comprises a water soaking box, a cleaning base and a cleaning liquid collecting box. The cleaning base comprises a moving mechanism, a fixing plate and a push-out mechanism. The moving mechanism is arranged at the lower end of the fixing plate. The push-out mechanism is arranged in a fixed groove and comprises a supporting plate and a lifting base. The lifting base is fixed to the lower end of the supporting plate. The scouring chamber comprises a cleaning brush, a conveying roller and a telescopic arm. The conveying roller penetrates the space between the scouring chamber and the drying chamber. A heating shaft and a centrifugal fan are arranged in the drying chamber. The centrifugal fan is arranged on the outer side of the heating shaft. The cleaning device for plane glass is high in practicability, not only is stability improved when the cleaning device works, but also the cleaning effect is guaranteed, operation is facilitated in the whole process, the effect is obvious, and work efficiency is improved.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

Efficient water-saving toilet bowl

The invention provides an efficient water-saving toilet bowl which comprises a flushing pipeline, a blow-off pipeline, an ejection pipeline and a barrel cylinder. The flushing pipeline is composed of a water inlet, a water distribution pipe, a flushing pipeline inlet, a flushing pipeline and a flushing opening, wherein water flows into a water tank through the water inlet, enters the flushing pipeline after being distributed by the water distribution pipe, and enters the barrel cylinder through the flushing opening for flushing. The blow-off pipeline is composed of a blow-off opening and a blow-off pipe. The blow-off pipe is communicated with the blow-off opening located in the bottom of the barrel cylinder. Water flushing the barrel cylinder enters the blow-off pipe for blow-off, the blow-off pipe is in a bent S shape. The ejection pipeline is composed of a water inlet, a water distribution pipe, an ejection pipe inlet, an ejection pipe and an ejection hole, wherein water flows into the water tank through the water inlet, enters the ejection pipe inlet after being distributed by the water distribution pipe, then passes through the ejection pipe, produces jet water flow at the ejection hole in the tail end of the ejection pipe, and produces the siphonage under the strong water pressure effect.

Owner:慕生活智能电器有限公司

Ultrahigh cleaning process for semiconductor parts

PendingCN114256107ARemove completelyWash thoroughlyDrying gas arrangementsSemiconductor/solid-state device manufacturingAcid etchingMetallurgy

The invention discloses an ultrahigh cleaning process for semiconductor parts, and relates to the technical field of cleaning of semiconductor parts. Comprising the following steps: S1, degreasing and cleaning; s2, filtering and cleaning for the first time; s3, soaking in hot water; s4, soaking in an alkaline etching tank; s5, filtering and cleaning for the second time; s6, soaking in an acid etching tank; s7, filtering and cleaning for the third time; s8, soaking in a pickling tank; s9, filtering and cleaning for the fourth time; s10, performing high-pressure flushing treatment; s11, hot water ultrasonic cleaning; s12, filtering and cleaning for the fifth time; s13, carrying out blow-drying treatment; and S14, high-temperature drying. The ultrasonic degreasing agent tank is arranged for cleaning the aluminum alloy parts, then hot water soaking, alkali etching tank soaking, acid etching tank soaking, high-pressure flushing treatment and hot water ultrasonic cleaning are sequentially carried out, and first-time filtering cleaning, second-time filtering cleaning, third-time filtering cleaning, fourth-time filtering cleaning and fifth-time filtering cleaning are matched; therefore, dust particles, metal ions, oil stains and smudginess of the parts are removed.

Owner:合肥升滕半导体技术有限公司

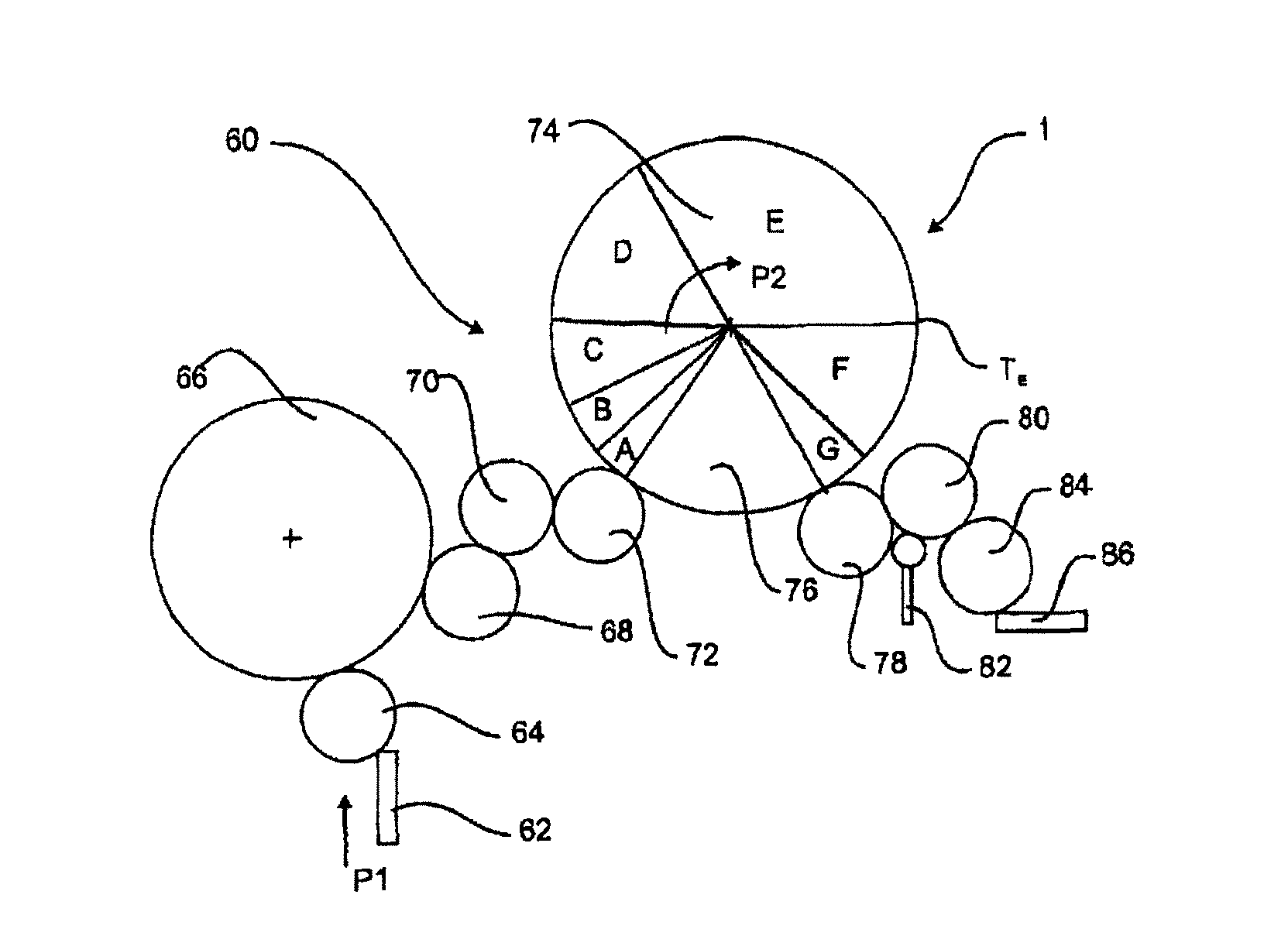

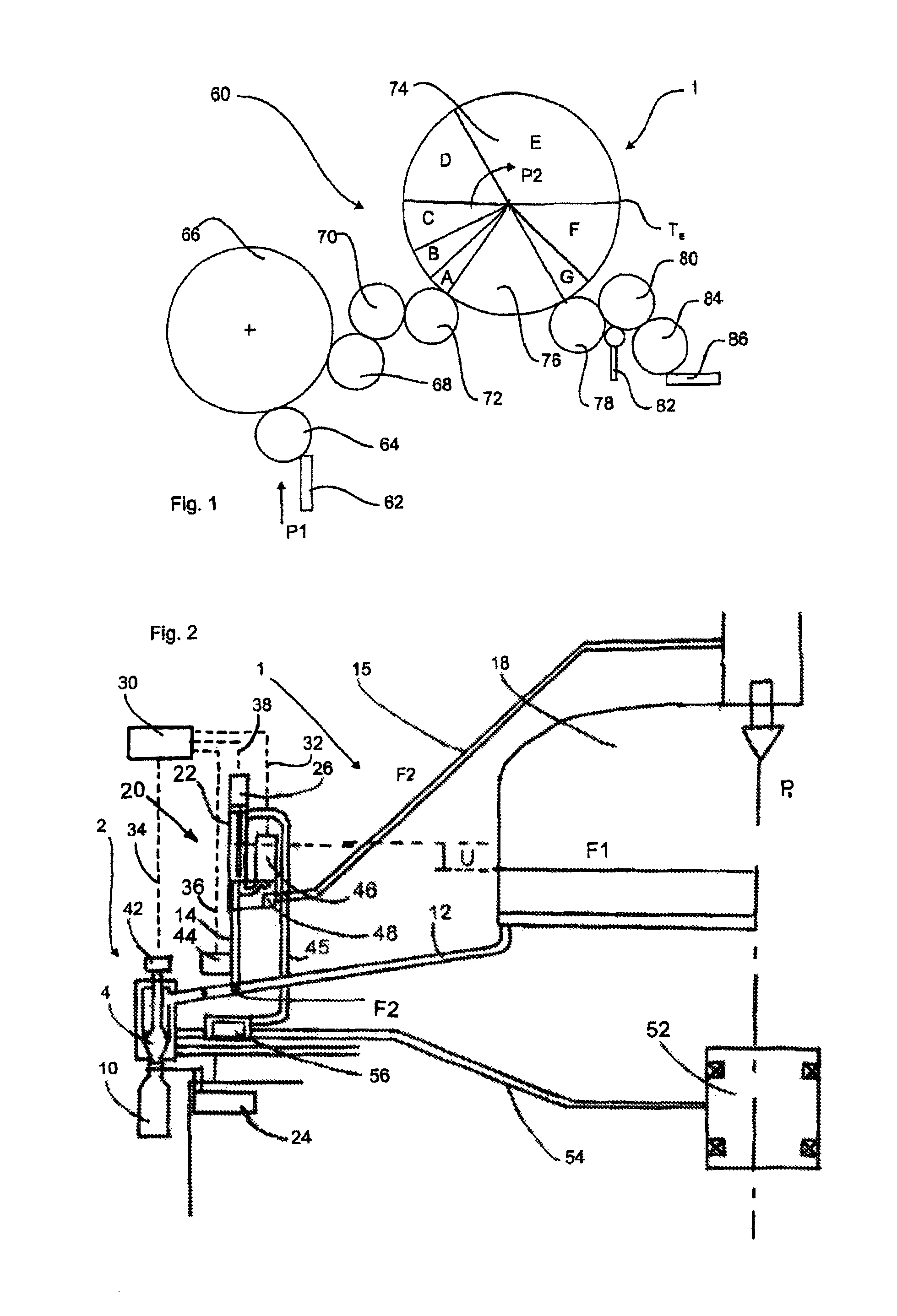

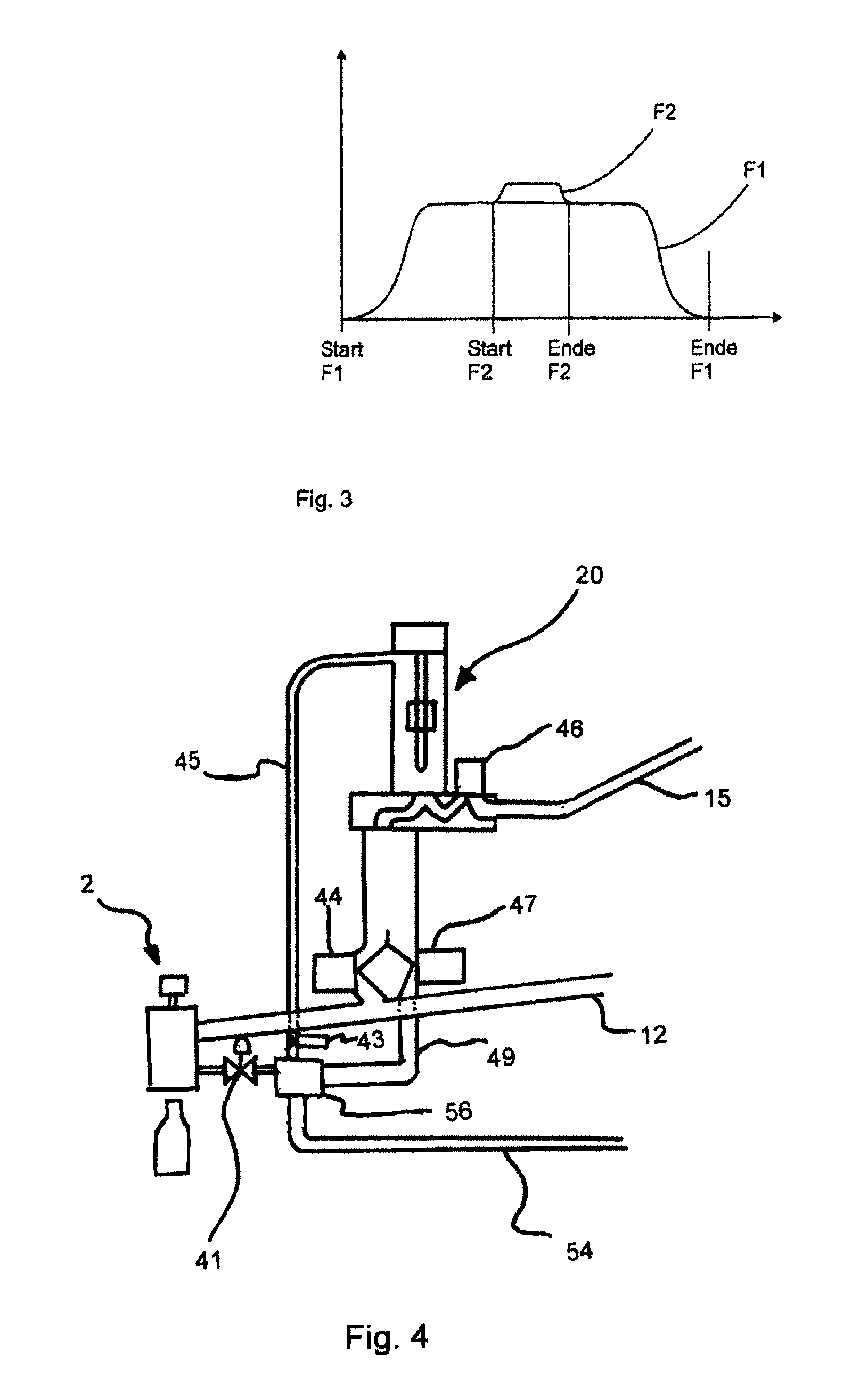

Apparatus for filling containers with multicomponent liquids

Owner:KRONES AG

Multi-face washing equipment for broken glass for glass production

ActiveCN111570373AMeeting Hygiene NeedsFull rinseWater/sewage treatmentFlexible article cleaningConveyor beltGlass production

The invention relates to the technical field of glass processing, in particular to multi-face washing equipment for broken glass for glass production. The multi-face washing equipment for the broken glass for the glass production can spread and disperse the broken glass before washing a large amount of the broken glass, so that each piece of the broken glass can be washed, the upper and lower sides of the broken glass can be washed, and the recycled broken glass can better meet the secondary recycling sanitary standard. According to the technical scheme, the multi-face washing equipment for the broken glass for the glass production comprises a bottom plate, support plates, a limit plate, a support seat, a first transmission roller, a second transmission roller, a mesh conveyor belt and thelike. A plurality of supporting plates are fixedly installed on one side of the bottom plate. Broken glass piles on the mesh conveyor belt can firstly be spread and dispersed, so that each piece of the broken glass can be washed, and the upper and lower sides of the broken glass can be washed completely and thoroughly.

Owner:SUZHOU YUQIAN INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com