Drum type micro-filtering machine

A microfilter and drum-type technology, which is applied in the field of water treatment, can solve the problems of high energy consumption and heavy weight, and achieve the effects of long service life, pressure reduction and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

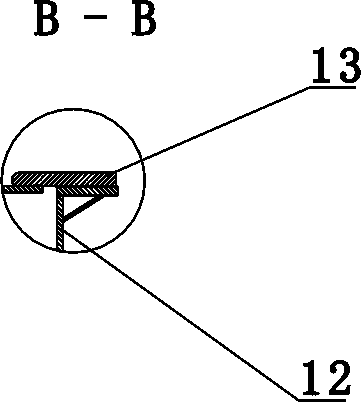

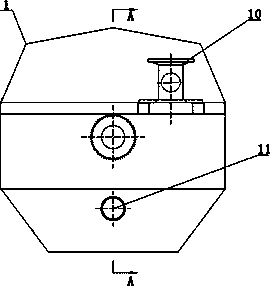

[0034] figure 1 It is the left view of the drum type microfiltration machine in one embodiment of the present invention, figure 2 yes figure 1 A sectional view along line A-A, image 3 yes figure 2 The sectional view along the E-E line, Figure 5 yes image 3 The partially enlarged schematic diagram along the line B-B in . combine figure 1 , figure 2 , image 3 and Figure 5 It can be seen that the rotary drum microfilter of this embodiment includes: a housing 1, a filter bucket 4, a motor 10, a backwashing device and a control system.

[0035] Wherein the shell 1 is a container of filtered water, and the polygonal bucket is selected, wherein the cross-section of the bottom is trapezoidal, which is easy to clean and has no dead ends.

[0036] The material of the housing 1 can be selected to have certain strength and corrosion resistance,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com