Cleaning device for mechanical part

A technology for cleaning devices and mechanical parts, applied in the direction of dryers, drying gas arrangements, cleaning methods and appliances, etc., can solve the problems of wasting cleaning liquid, high cleaning power of parts, and cost waste, so as to reduce cost waste and improve cleaning quality. High, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

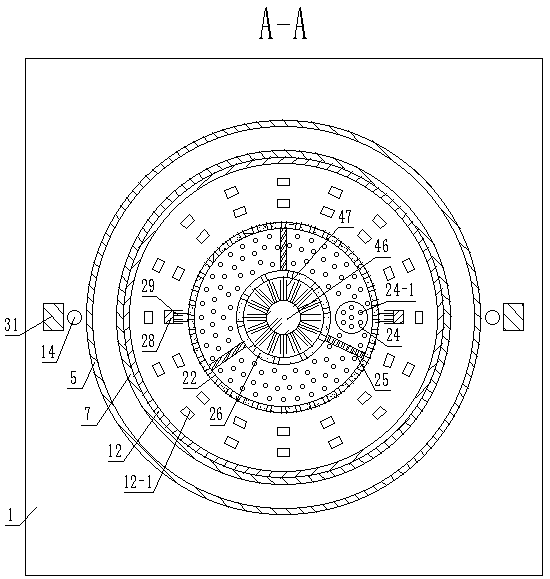

[0034] Such as Figure 1-Figure 9 As shown, a mechanical parts cleaning device includes a base plate 1, a support column A2 is symmetrically fixed on the top surface of the base plate 1, a water tank 3 is fixed on the top surface of the support column A2, and the top surface of the water tank 3 The surface welding is fixed with the cone tube A4 integrally formed with it, the top surface of the cone tube A4 is welded and fixed with the sleeve A5 integrally formed with it, the inside of the cone tube A4 is provided with a cone tube B6, and the inside of the cone tube B6 The side is evenly provided with a plurality of square through holes A6-1, the inside of the sleeve A5 is provided with a sleeve B7, and the side of the sleeve B7 is evenly provided with a plurality of square through holes B7-1, the cone A4 and the cone The bottom surfaces of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com