Permanent magnetic separation column suitable for strongly or weakly magnetic minerals

A technology of weak magnetic and magnetic separation columns, applied in the field of magnetic separation columns, can solve the problems of large tailing, many electrical failures, large water consumption, etc., and achieve the effect of improving the concentrate grade, large equipment capacity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

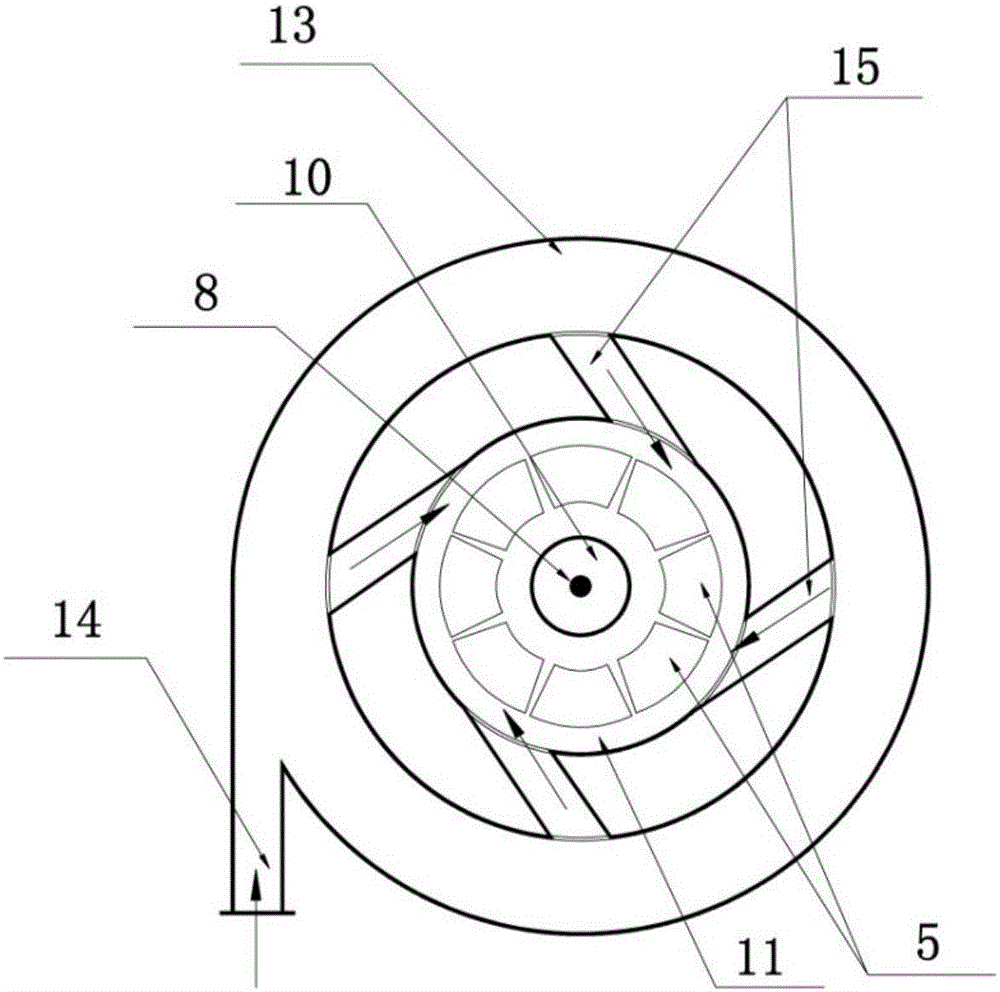

[0023] A permanent magnet magnetic separation column suitable for strong magnetic minerals or weak magnetic minerals, including a cylinder 1 with an open top, an overflow box 2 installed on the top of the cylinder 1, and a concentrate installed at the bottom of the cylinder 1 The bucket 3 is special in that the top of the cylinder 1 passes through the middle of the bottom wall of the overflow tank 2, and the bottom wall of the overflow tank 2 is provided with a tailings outlet 4, and the cylinder 1 The bottom wall of 1 is provided with a concentrate leakage hole 5 for communicating with the concentrate hopper 3, and the bottom of the concentrate hopper 3 is provided with a concentrate outlet 6, and an impeller feeder is installed on the concentrate outlet 6 7. The cylinder body 1 is fixedly installed with a central rotating shaft 8 extending along the central axis direction, and the top end of the central rotating shaft 8 is fixed on the top wall of the overflow box 2, on the o...

Embodiment 2

[0026] A permanent magnet magnetic separation column suitable for strong magnetic minerals or weak magnetic minerals, including a cylinder 1 with an open top, an overflow box 2 installed on the top of the cylinder 1, and a concentrate installed at the bottom of the cylinder 1 The bucket 3 is special in that the top of the cylinder 1 passes through the middle of the bottom wall of the overflow tank 2, and the bottom wall of the overflow tank 2 is provided with a tailings outlet 4, and the cylinder 1 The bottom wall of 1 is provided with a concentrate leakage hole 5 for communicating with the concentrate hopper 3, and the bottom of the concentrate hopper 3 is provided with a concentrate outlet 6, and an impeller feeder is installed on the concentrate outlet 6 7. The cylinder body 1 is fixedly installed with a central rotating shaft 8 extending along the central axis direction, and the top end of the central rotating shaft 8 is fixed on the top wall of the overflow box 2, on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com