Cleaning and drying device for chrysanthemum tea processing

A drying device, chrysanthemum tea technology, applied in heating device, liquid cleaning method, drying, etc., can solve the problems of chrysanthemum tea quality decline, low degree of automation, affecting processing efficiency, etc., and achieve high overall work efficiency and drying Fast speed and high cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

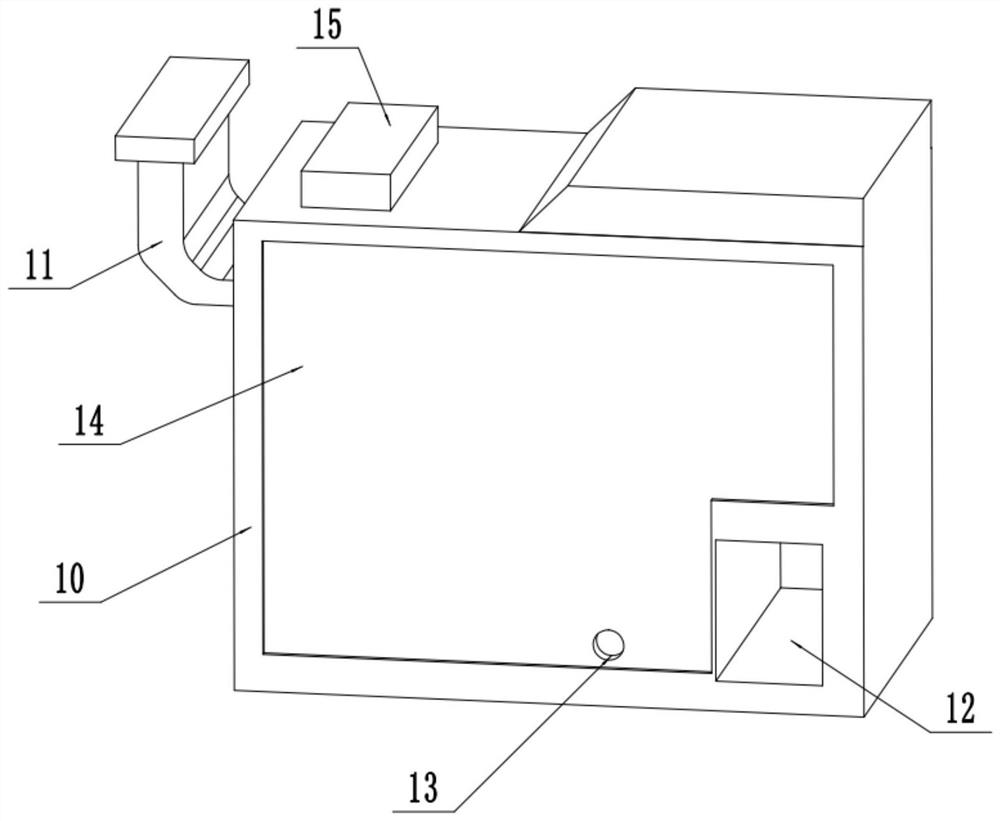

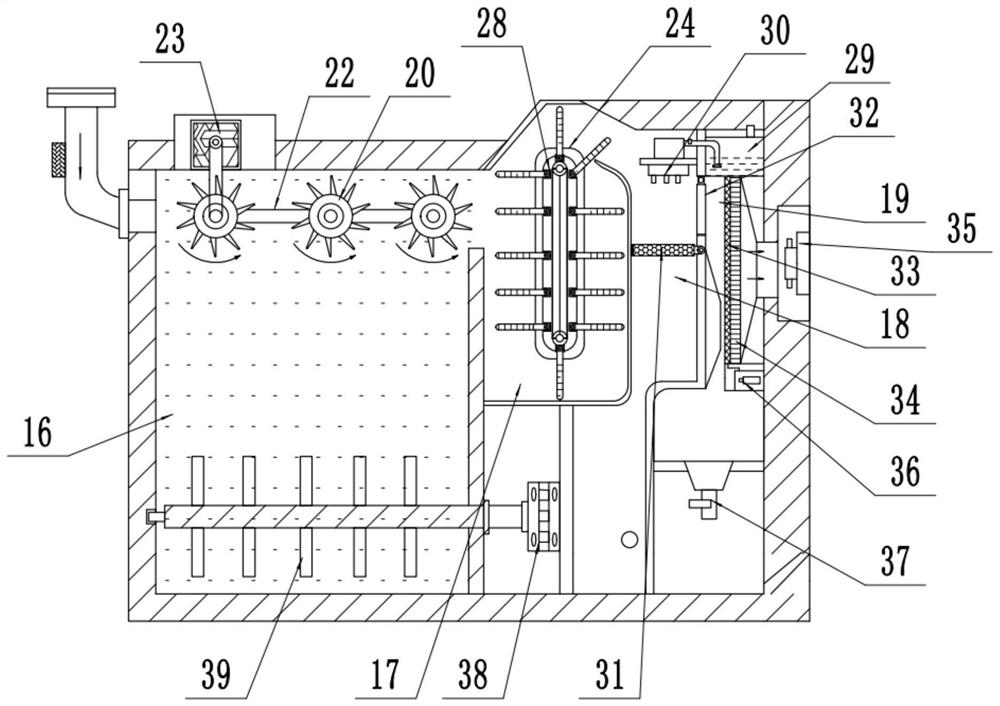

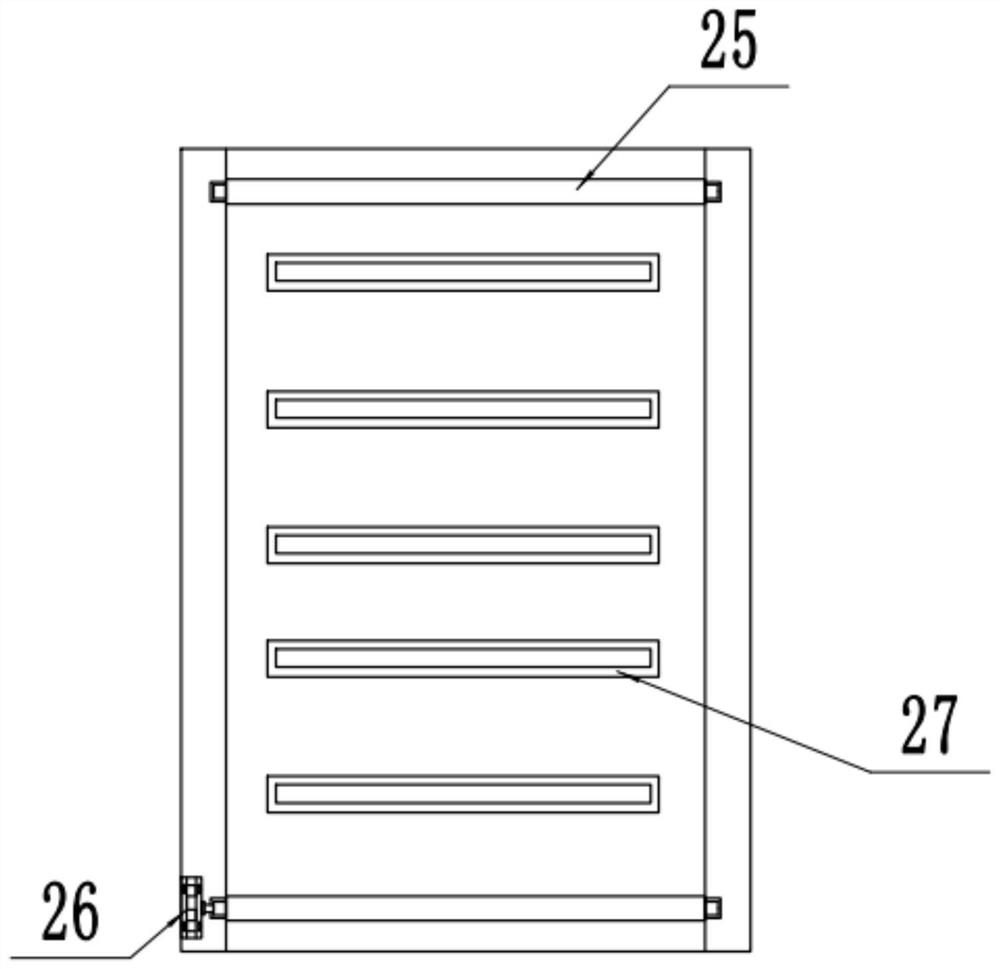

[0023] see Figure 1-4 , a cleaning and drying device for processing chrysanthemum tea, comprising a box body 10, a feed pipe 11, and a discharge bin 12; Material pipeline 11, the front side of box body 10 is provided with the glass window 14 that is convenient to observe internal working state, and the inside left side of box body 10 is provided with the rinsing tank 16 that is fully filled with clear water that communicates with the bottom end of feed pipeline 11, By inputting the chrysanthemum tea to be cleaned into the feed pipeline 11, and then entering the rinsing tank 16 for rinsing, since the chrysanthemum tea and the particulate impurities contained in the chrysanthemum tea are different in quality, the chrysanthemum tea in the rinsing tank 16 will float in the At the top of the rinsing tank 16, dust particles, impurities, etc. drop to the bottom of the rinsing tank 16 under the effect of gravity. The right side of the top of the rinsing tank 16 is connected with a g...

Embodiment 2

[0027] On the basis of Embodiment 1, the bottom of the rinsing tank 16 is provided with a set of horizontal stirring shafts, the left end of the stirring shaft is connected to the inside of the rinsing tank 16 in rotation, and the right side is rotatably connected to the right side of the rinsing tank 16. The stirring motor 38 fixed inside the casing 10 below the transfer bin 17, the outer surface of the stirring shaft is evenly fixed with multiple groups of stirring blades 39 for accelerating the rinsing strength of the chrysanthemum tea in the rinsing pool 16. It is convenient to improve the probability of falling of dust impurities attached to the chrysanthemum tea by arranging the stirring blade 39 inside the rinsing tank 16 .

[0028] The working principle of the present invention is: when in use, firstly, the chrysanthemum tea to be treated is input into the rinsing pool 16 through the feed pipe 11, and then soaked and rinsed in the rinsing pool 16 to remove most of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com