Two-component silicone encapsulant and its preparation method and application

A silicone and encapsulant technology, used in adhesives, non-polymer adhesive additives, semiconductor devices, etc., can solve the problems of poor mixing uniformity, affecting product appearance and light efficiency, and uncontrollable glue output. Good clarity and stability, avoids adhesive lamination problems, easy to mix and homogeneous results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] Specifically, the preparation method of alkoxy-modified polydimethylsiloxane comprises the following steps:

[0047] Mix side vinyl silicone oil, solvent and catalyst, then add alkoxysilane, keep the reaction temperature at 50℃~70℃ for 5h~7h.

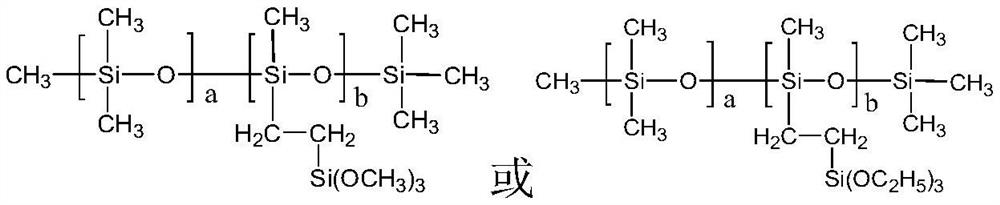

[0048] Further, the alkoxysilane is selected from trimethoxysilane or triethoxysilane. Specifically, its reaction formula can be expressed as follows:

[0049]

[0050]In one specific example, the viscosity of the alkoxysilane-modified polydimethylsiloxane is 500 cP to 1500 cP. Specifically, the viscosity of the alkoxysilane-modified polydimethylsiloxane includes but is not limited to: 500cP, 550cP, 600cP, 700cP, 800cP, 900cP, 950cP, 1000cP, 1150cP, 1200cP, 1300cP, 1400cP, 1450cP, 1500cP .

[0051] In one specific example, the 1,2-bisalkoxysilylethane is selected from the group consisting of 1,2-bistrimethoxysilylethane and 1,2-bistriethoxysilylethane at least one. Preferably, 1,2-bisalkoxysilylethane is selected from 1,2...

Embodiment 1

[0072] The present embodiment provides a two-component silicone encapsulant for the potting of flexible LED light strips, the composition of which is as follows:

[0073]

[0074] The preparation method of the above-mentioned two-component silicone encapsulant is as follows:

[0075] (1) Preparation of component A: add hydroxyl-terminated polydimethylsiloxane (107 glue) and methyl MQ silicone resin into a planetary mixer, and mix for 20 minutes to obtain component A;

[0076] (2) Preparation of component B: Ethoxysilane-modified polydimethylsiloxane, 1,2-bismethoxysilylethane, γ-aminopropyltriethoxysilane, dilaurin Dibutyltin acid is added to the planetary mixer and mixed for 15min until uniform, that is, component B is obtained.

Embodiment 2

[0078] The present embodiment provides a two-component silicone encapsulant for the potting of flexible LED light strips, the composition of which is as follows:

[0079]

[0080] The preparation method of the above-mentioned two-component silicone encapsulant is as follows:

[0081] (1) Preparation of component A: add hydroxyl-terminated polydimethylsiloxane (107 glue) and methyl MQ silicone resin into a planetary mixer, and mix for 20 minutes to obtain component A;

[0082] (2) Preparation of component B: methoxysilane-modified polydimethylsiloxane, 1,2-bismethoxysilylethane, N-βaminoethylγ-aminopropyltrimethoxy Silane and dibutyltin diacetate were added to the planetary mixer, and mixed for 15 minutes until uniform, that is, component B was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com