Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Solve clogged pipes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Melting treatment method for waste incineration flying ash

ActiveCN105562423AReduce volatilityPrevent volatilizationSolid waste disposalResource utilizationCaloric values

The invention relates to a melting treatment method for waste incineration flying ash, and belongs to the technical field of environmental engineering. The treatment method comprises the following steps of carrying out pretreatment on the waste incineration flying ash to form treated flying ash; uniformly mixing the treated flying ash with sludge to form a mixture of the flying ash and the sludge; carrying out solidification and stabilization on the mixture of the flying ash and the sludge to form a solidified body; and carrying out melting treatment on the solidified body. The treatment method can effectively solve the problems that the caloric value in the flying ash is relatively low, and heavy metals in the flying ash are liable to volatilize, so that pipeline blockage in a flying ash conveying process is avoided; and the melting treatment method is good in treatment effect, is low in cost, is free from secondary pollution, and is high in resource utilization.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI +1

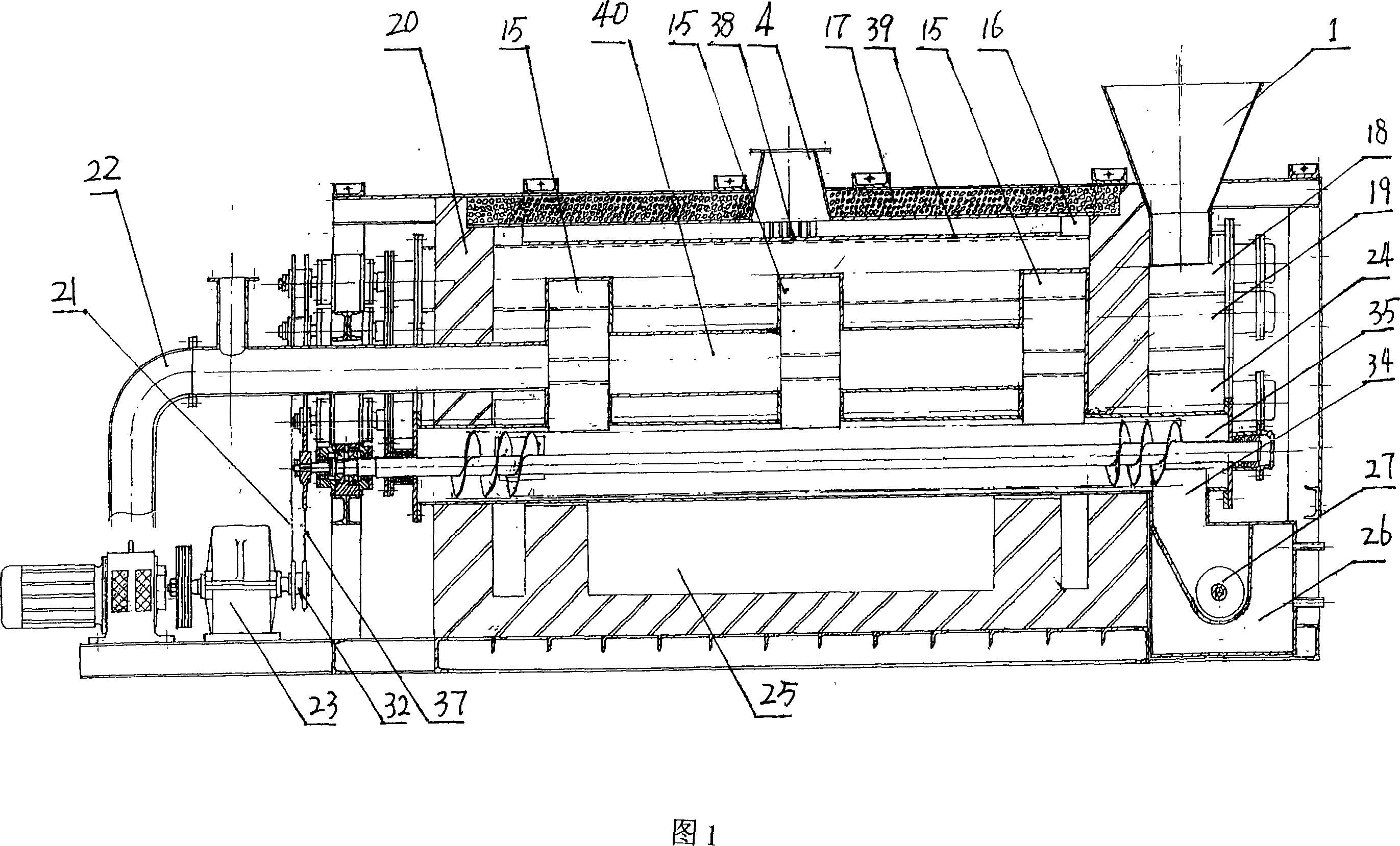

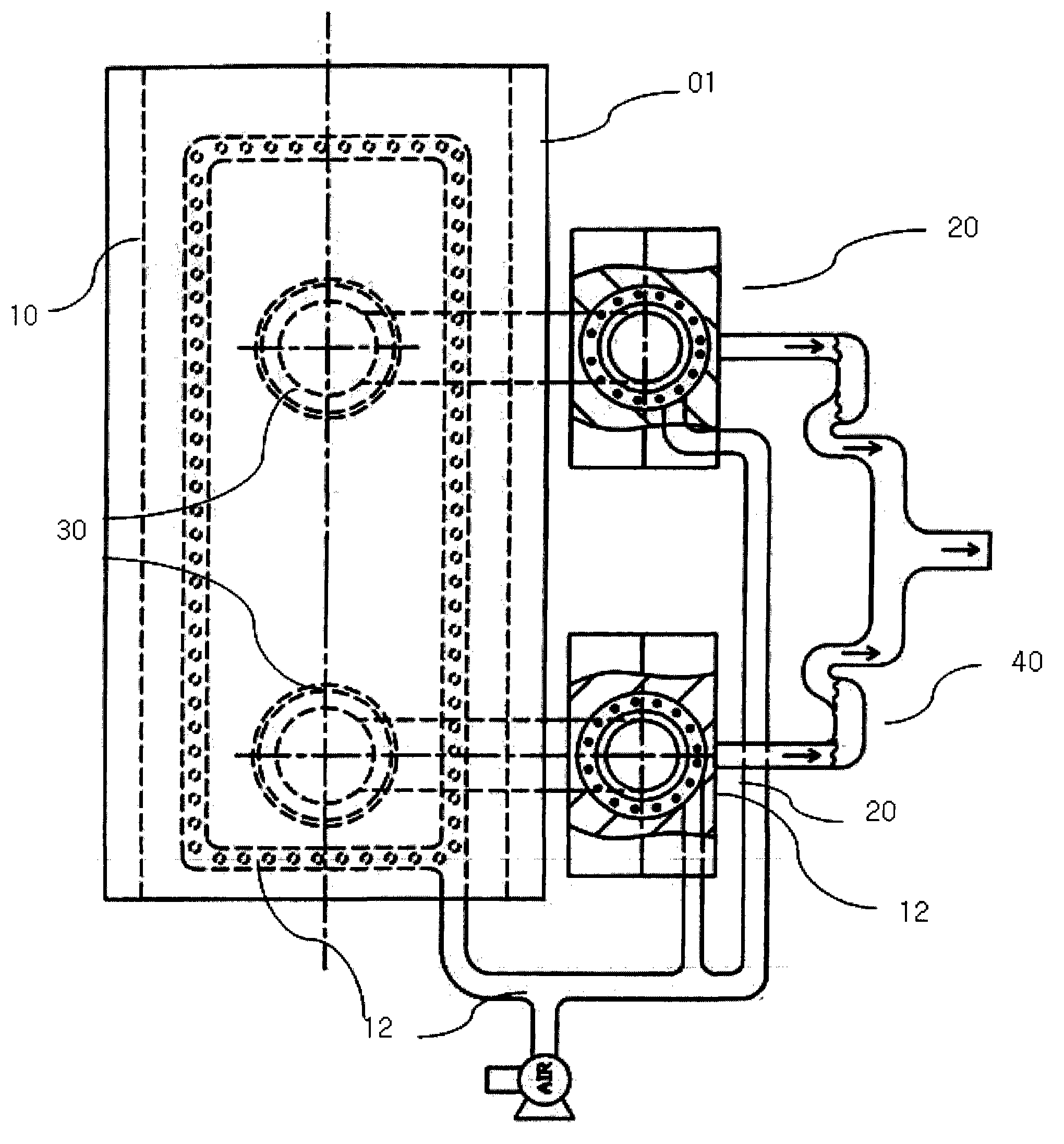

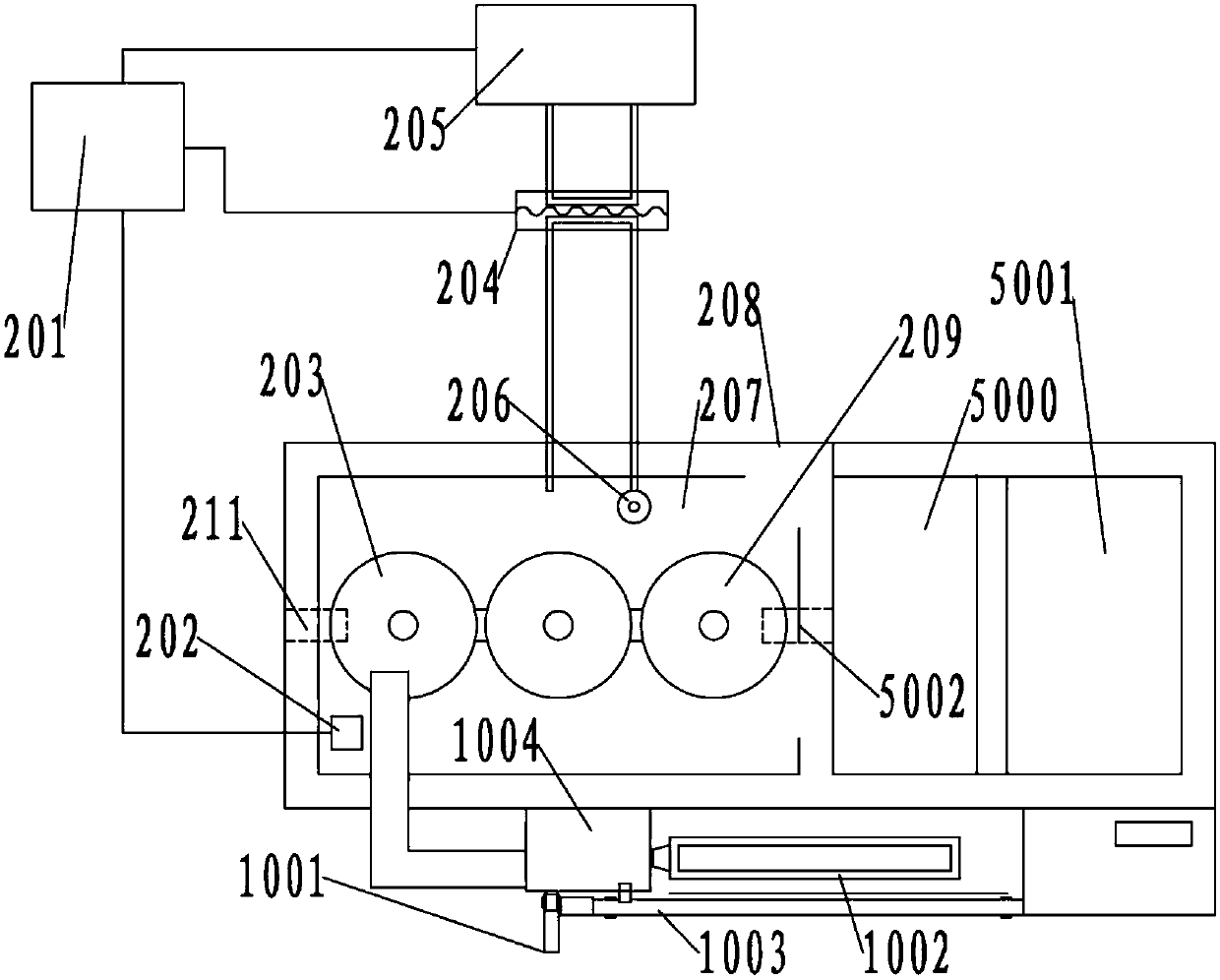

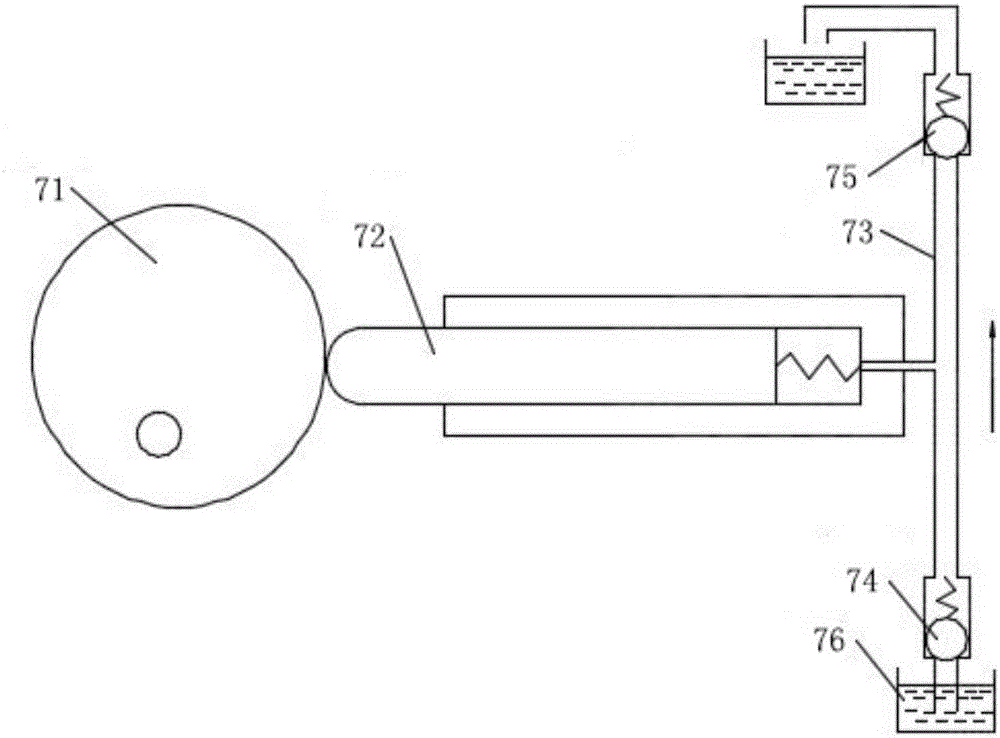

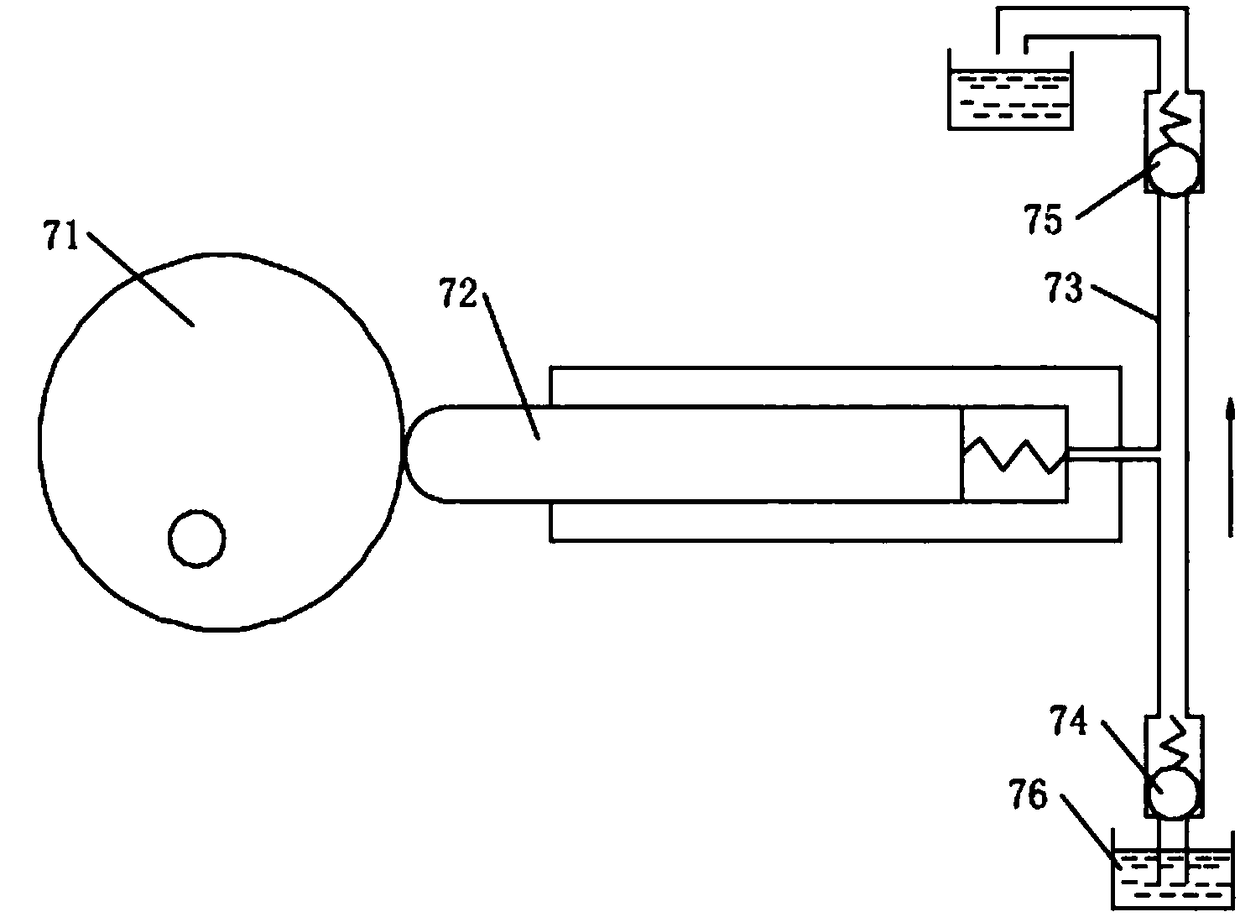

Water-cooled continuous dry distillation type stalk powdered carbon machine

InactiveCN101050370ARegulating pressureStable temperatureBiofuelsSpecial form destructive distillationHigh carbonEngineering

This invention relates to a water-cooling continuous carbonization machine for producing carbon powder from stalk. Multi-stage carbonization pipes are set in a carbonization chamber. A screw conveyer is set in each carbonization pipe. The screw conveyers are connected via double wheels and double chains. The screw conveyers in two carbonization pipes in upper and lower stages have reverse propelling directions. The propelling endpoint of the upper stage carbonization pipe and the propelling start point are through connected via a discharge passage. A gas collection chamber is set in the carbonization chamber to recover and recycle residual gas by an injection blower. An adjustment valve and a pressure reducer are set on the air return pipe. A discharge hopper is set in the circulating cooling water tank, and isolated from the circulating cooling water tank to realize dry cooling of carbon powder. The machine can ensure even speed continuous propelling of the raw material. The flue gas can be re-combusted, thus can avoid coal tar harm. The machine has such advantages as high carbonization temperature, no exhaust gas, low labor intensity, high production efficiency and high carbon powder quality.

Owner:赵陆凯

Waste gas washing treatment method and device in polycrystalline silicon industry

ActiveCN103505996ASolve the dangerSolve the hazardDispersed particle separationBuffer tankSpray tower

The invention provides a chlorosilane-containing waste gas washing treatment method and device in a polycrystalline silicon production process. The device comprises a waste gas buffer tank, a chlorosilane-containing waste gas supply pipeline connected with an inlet of the waste gas buffer tank, and a normal waste gas spraying system, an accidental waste system spraying system and an emergency washing system which are connected with an outlet of the waste gas buffer tank. The chlorosilane-containing waste gas is fed into a spray tower and is washed by spraying 10-30 percent of sodium hydroxide. The gas generated after spraying is discharged into atmosphere through a water-sealed tank. According to the method, the problem that hydrogen chloride escapes is effectively solved, the problem that the pipeline is blocked by silicon dioxide generated in the traditional washing process is solved, and harmlessness of environmental protection is realized. According to the device, the chlorosilane waste gas can be effectively and harmlessly treated, escape of hydrogen chloride can be effectively reduced, and sodium silicate generated in the reaction is relatively convenient to remove.

Owner:BEIJING HANGHUA ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

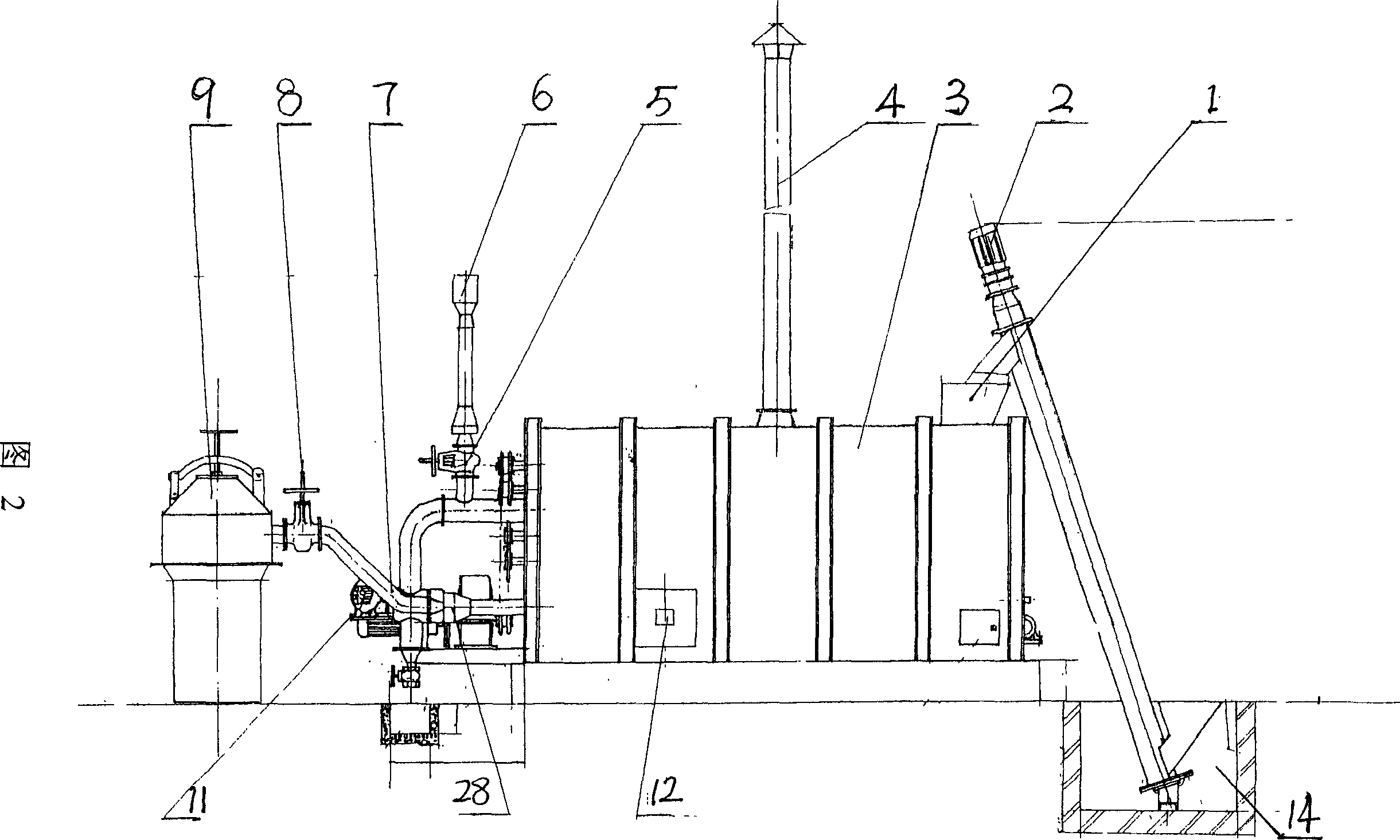

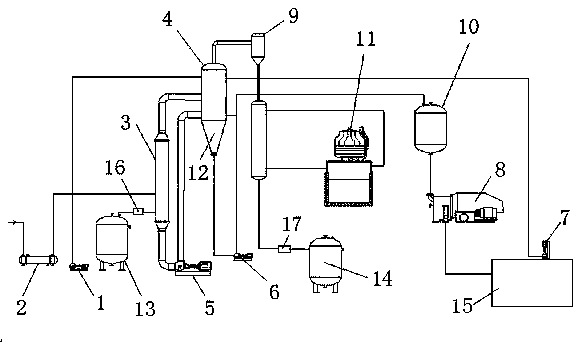

Integrated multifunctional chimney-free low-carbon gas boiler

InactiveCN105402709ASolve clogged pipesAdd automatic decoking deviceSteam boilersSteam boilers componentsCycloneTar

The invention discloses an integrated multifunctional chimney-free low-carbon gas boiler which comprises a vertically arranged cylindrical boiler body, wherein the boiler body is composed of an ash cabin and a gasification chamber; the gasification chamber and the ash cabin are combined up and down to form a biomass gasifier; a boiler is installed on the upper side of the gasification chamber of the boiler body; a feeding device is installed at the top part of the gasification chamber; a burning machine is installed on one side of the boiler; and the top part of the gasification chamber is also connected with a pipeline which is beneficial to supplying produced gas to the burning machine. According to the integrated multifunctional chimney-free low-carbon gas boiler disclosed by the invention, fuel is fed from the top part of the gasification chamber through the feeding device; the biomass gasifier is used for gasifying the fuel into gas firstly, smoke dust and tar of flammable gas produced by gasification are removed by a high-temperature cyclone dust collector, the flammable gas is fired to burn through the burning machine, and the heat is provided for the boiler to produce steam.

Owner:GUANGDONG HUINENG XINYUAN TECH CO LTD

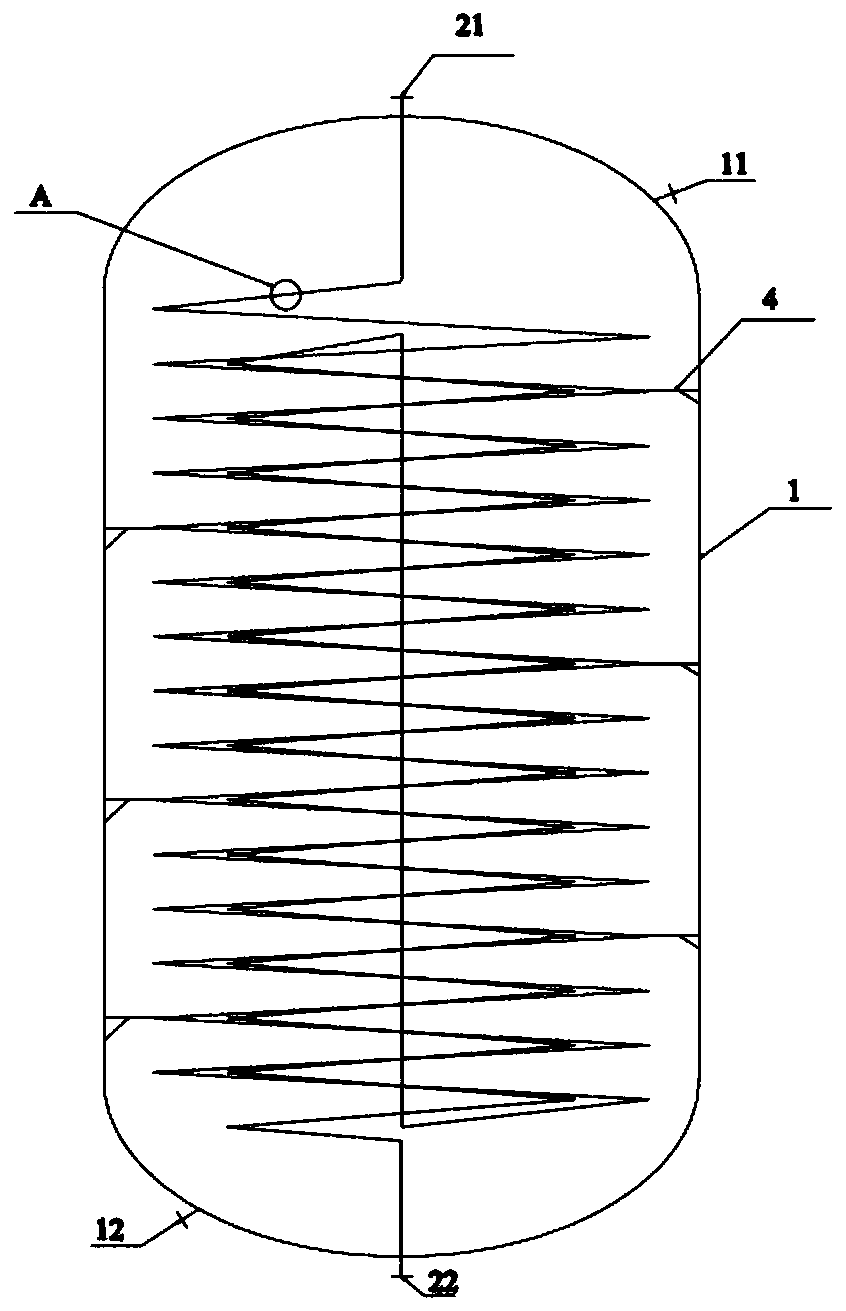

Vertical type tubular reactor for deenergization and alkali hydrolysis of TNT (Trinitrotoluene)

ActiveCN107855090AAchieve continuous operationImprove processing efficiencyChemical/physical/physico-chemical stationary reactorsFeed devicesEngineeringHydrolysis

The invention provides a vertical type tubular reactor for deenergization and alkali hydrolysis of TNT (Trinitrotoluene). The vertical type tubular reactor comprises a heat insulation tube, wherein the heat insulation tube is internally connected with a disc-shaped alkali hydrolysis reaction tube through a fixed bracket; the disc-shaped alkali hydrolysis reaction tube is spirally arranged in the heat insulation tube; a spiral shaft and the heat insulation tube are coaxially arranged; an alkali liquid spraying pipe is embedded into the disc-shaped alkali hydrolysis reaction tube; the alkali liquid spraying pipe and the disc-shaped alkali hydrolysis reaction tube are coaxially arranged; a plurality of micro-pores are formed in the alkali liquid spraying pipe; the heat insulation tube is vertically arranged; a heat insulation medium adopts heat insulation water; the heat insulation water enters from a bottom water inlet of the heat insulation tube and then is discharged from a top water outlet; the disc-shaped alkali hydrolysis reaction tube is a TNT alkali hydrolysis reaction region; the TNT enters from a top feeding opening of the disc-shaped alkali hydrolysis reaction tube and alkali liquid is sprayed out from the alkali liquid spraying pipe; after reaction, the TNT is discharged from a discharging opening formed in the bottom of the disc-shaped alkali hydrolysis reaction tube;a flowing direction of heat insulation water is opposite to the flowing direction of a reaction solution in the disc-shaped alkali hydrolysis reaction tube. By adopting the vertical type tubular reactor, the treatment efficiency of abandoned propellant and explosive is improved; meanwhile, the safety is improved.

Owner:XI AN JIAOTONG UNIV +1

Fermentation device and microbial fermentation decomposition treatment method thereof

InactiveCN103230921ADecomposition helpsGuaranteed cleanlinessSolid waste disposalOil and greaseMicroorganism

The invention relates to a fermentation device and a microbial fermentation decomposition treatment method thereof. Specifically, treatment is carried out directly at a food waste generation site, food waste is placed into a specially set stirring and heating apparatus to perform decomposition by means of microorganisms that can decompose food waste at high speed, and then the left materials are separated from holes of different sizes. The treatment device treats the food waste into liquid through microorganisms, and according to differences of microorganism species, decomposition temperature, air injection amount and time, the decomposition degrees can also be different. However, the common feature lies in that, after particles pass through a filter screen disposed in front of a fermentation decomposition tank outlet and are dispersed, they are discharged in a suspension liquid state. The suspension liquid comprises 90% of water and the balance animal or vegetable oil. The solid state component is composed of microorganisms, ferment discharged after microbial fermentation, and the particles passing through the filter screen. The particles can be regarded as food fragments cut according to certain size.

Owner:BEIJING SHIENDE ENVIRONMENTAL PROTECTION TECH

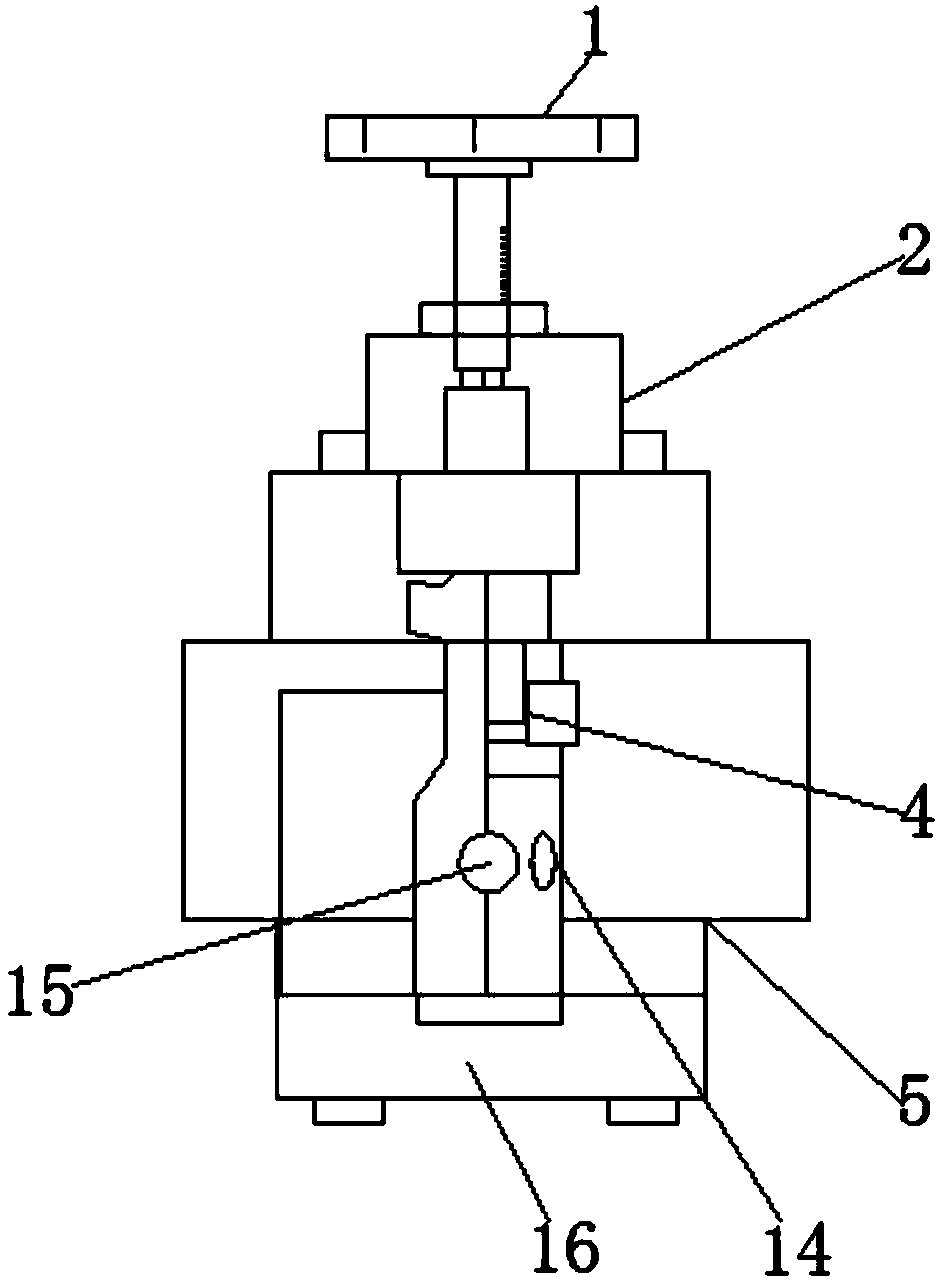

Method for treating blockage of regulating valve at entrance of urea spray gun in urea ammonia production system

InactiveCN104495872ASolve clogged pipesImprove denitrification efficiencyDispersed particle separationAmmonia preparation/separationFlue gasAmmonia production

The invention discloses a method for treating blockage of a regulating valve at an entrance of a spray gun in a urea ammonia production system. The method for treating the blockage of the regulating valve at the entrance urea spray gun in the urea ammonia production system comprises the following steps: comprehensively determining that blockage is caused by virtue of low urea solution flow of a urea solution regulating valve according to show value of a flow meter and experience, taking down the urea flow regulating valve (2), and washing a valve element of the urea flow regulating valve (2) with water at the temperature of 80-100 DEG C; mounting one compressed air hose between a compressed air inlet pipe (6) and a urea flow regulating valve outlet pipe (7), opening a compressed air inlet valve (4), and purging with compressed air at 0.2-0.6MPa; adjusting a position of an interface at one end of the compressed air hose from the urea flow regulating valve inlet pipe (7) to a urea flow regulating valve outlet pipe (8), and sweeping according to a previous operation step; and then repeating operation in the second step. The method for treating the blockage of the regulating valve at the entrance urea spray gun in the urea ammonia production system has the advantages that the problem that a pipeline and a valve are blocked by crystallized urea can be solved, flue gas denitrification efficiency is improved, and practicability is strong.

Owner:DATANG TAIYUAN CO GENERATION POWER PLANT

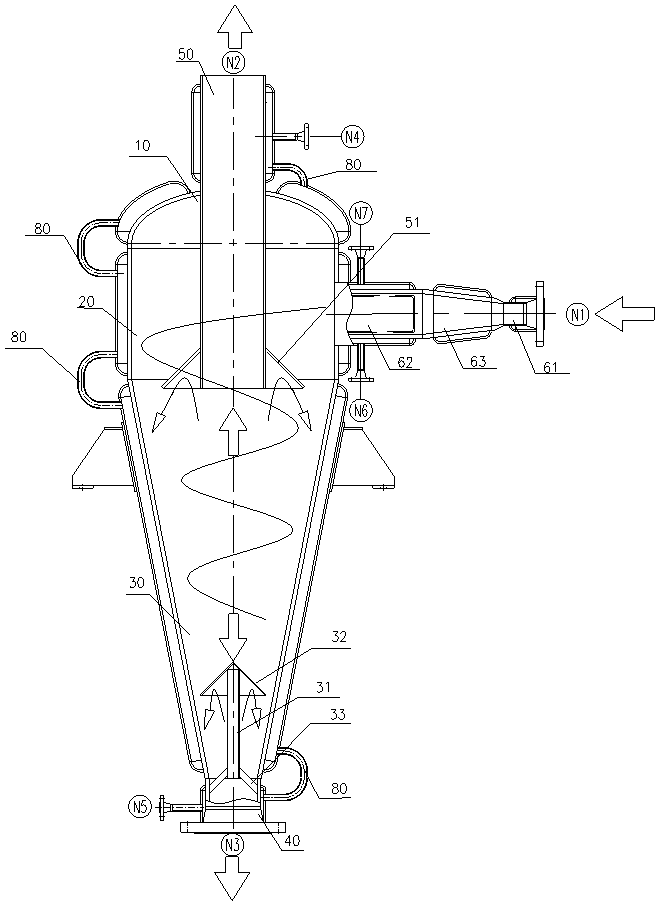

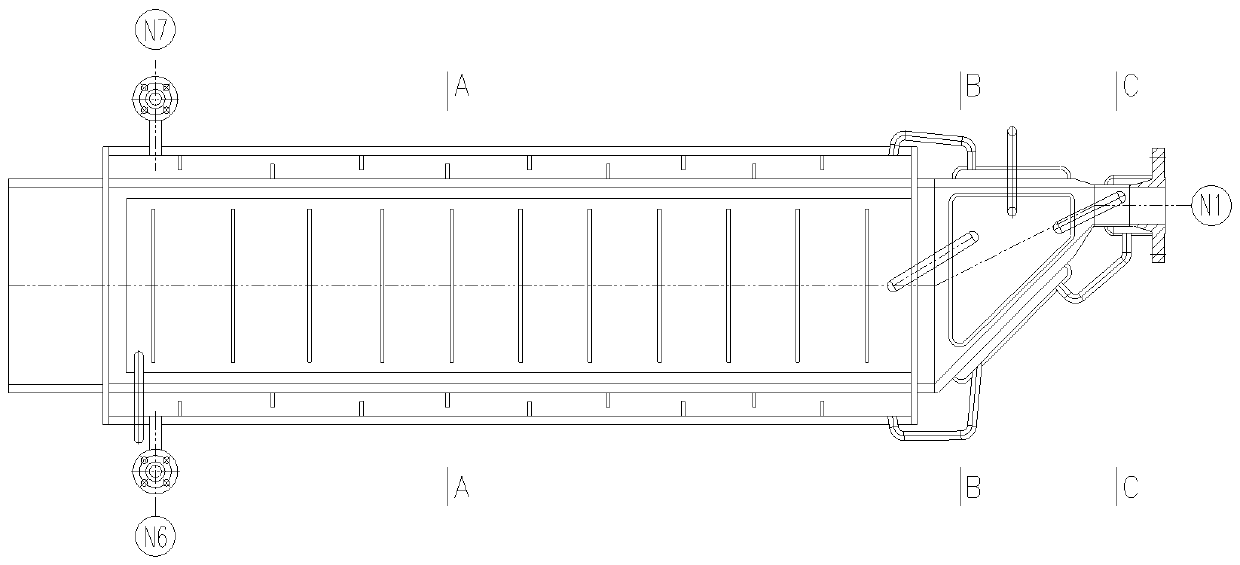

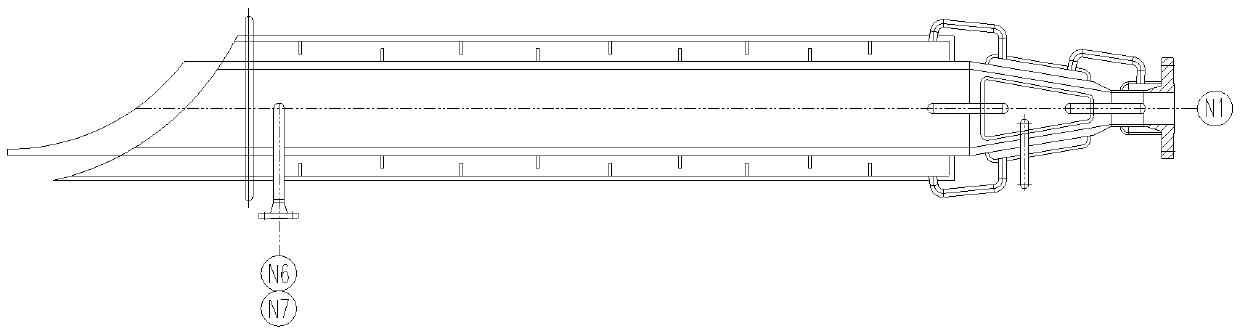

High-freezing-point medium gas-liquid separator with labyrinth-type gas inlet pipe heat-preserving device

ActiveCN109603316AImprove liquiditySolve the stickinessDispersed particle separationCycloneVapor–liquid separator

The invention relates to the technical field of gas-liquid separation devices in chemical engineering equipment, specifically to a high-freezing-point medium gas-liquid separator with a labyrinth-typegas inlet pipe heat-preserving device. The high-freezing-point medium gas-liquid separator successively comprises an elliptical seal head, a cyclone drum body and a cyclone cone body from top to bottom, wherein the elliptical seal head, the cyclone drum body, the cyclone cone body, a liquid discharging pipe and an exhaust pipe located at the exterior of the elliptical seal head are respectively sleeved by a heat-preserving sleeve to form heat-preserving cavities; a connecting circular pipe is arranged between adjacent heat-preserving cavities; a tangential gas inlet pipeline is arranged at one side of the drum body of the cyclone drum body and comprises a gas inlet circular pipe, a cone pipe and a rectangular pipe; four side surfaces of the cone pipe are respectively provided with a conepipe heat-preserving chamber; and four side surfaces of the rectangular pipe are respectively provided with a rectangular pipe heat-preserving chamber. According to the invention, heat-conductive oilenters from the heat-conductive oil inlet of a gas inlet pipe, respectively passes through the heat-preserving chambers located on four side surfaces of the cone pipe, the circular pipe heat-preserving chamber and the heat-preserving chambers located on four side surfaces of the rectangular pipe, and finally flows out from the heat-conductive oil outlet of the gas inlet pipe.

Owner:EAST CHINA ENG SCI & TECH

Device and method for preparing hydrogen-rich gas based on pyrolysis gas conversion of double fluidized beds

ActiveCN114044490APyrolysis gas sensible heat is wasted highTar condenses and precipitates to block the pipelineHydrogen separation using solid contactEnergy inputCatalytic reformingWater vapor

The invention discloses a device and method for preparing hydrogen-rich gas based on pyrolysis gas conversion of double fluidized beds. The device comprises a pyrolyzing furnace, a circulating fluidized bed, and a catalytic reactor, a superheater, a high-temperature dust remover, a waste heat boiler, an intercooler, a fan and a hydrogen-rich gas storage tank which are sequentially connected with the pyrolyzing furnace, and a cyclone dust collector, a high-temperature heat exchanger and a superheater which are sequentially connected with the circulating fluidized bed. A process route for preparing hydrogen-rich gas through catalytic reforming of tar water vapor under a high-temperature condition is adopted, and waste heat recovery is carried out through a combined mode of the superheater and the waste heat boiler, so that a mode of spraying ammonia water for quenching and electrically capturing tar is avoided; the problems that sensible heat of high-temperature pyrolysis gas is wasted, tar is condensed and separated out to block a pipeline, the pyrolysis gas amount is small and the hydrogen content is small are solved, heat needed by the device and high-temperature steam needed by reforming reaction both come from the circulating fluidized bed boiler side, steam or energy does not need to be supplemented externally, and the purposes of energy utilization and material utilization of the whole device are optimal are achieved.

Owner:浙江百能科技有限公司

Single-effect forced-circulation evaporation system for hazardous waste treatment liquid and operation method of single-effect forced-circulation evaporation system

PendingCN108409019ASolve clogged pipesSmooth feedingWater/sewage treatment by centrifugal separationWater contaminantsCirculator pumpEvaporation

The invention relates to a single-effect forced-circulation evaporation system for hazardous waste treatment liquid and an operation method of the single-effect forced-circulation evaporation system.The system comprises a heater and a separator, a discharge opening of the heater is connected with a heating opening of the separator, a circulating opening of the separator is connected with a feed opening of the heater through a forced-circulation pump, a feed opening of the separator is connected with a feeding pump, a returning opening of the separator is connected with a mother liquid tank, aliquid outlet in the top of the separator is connected with a gas-liquid separation demister which is connected with a condenser, the condenser is connected with an effluent storage tank, a conical discharging pipe is arranged at the bottom of the separator, and is connected with a discharge pump, the discharge pump is connected with a thick kettle, and is connected with the returning opening ofthe separator, the thick kettle is connected with a centrifugal machine, the centrifugal machine is connected with the mother liquid tank. When the single-effect forced-circulation evaporation systemis in operation, the hazardous waste treatment liquid is circulated between the heater and the separator, and solid salt is collected through centrifuging at last. Continuous feeding and discharging are realized, the crystallized solid salt can be discharged in time, and blockage of pipelines is avoided.

Owner:济南云水腾跃环保科技有限公司

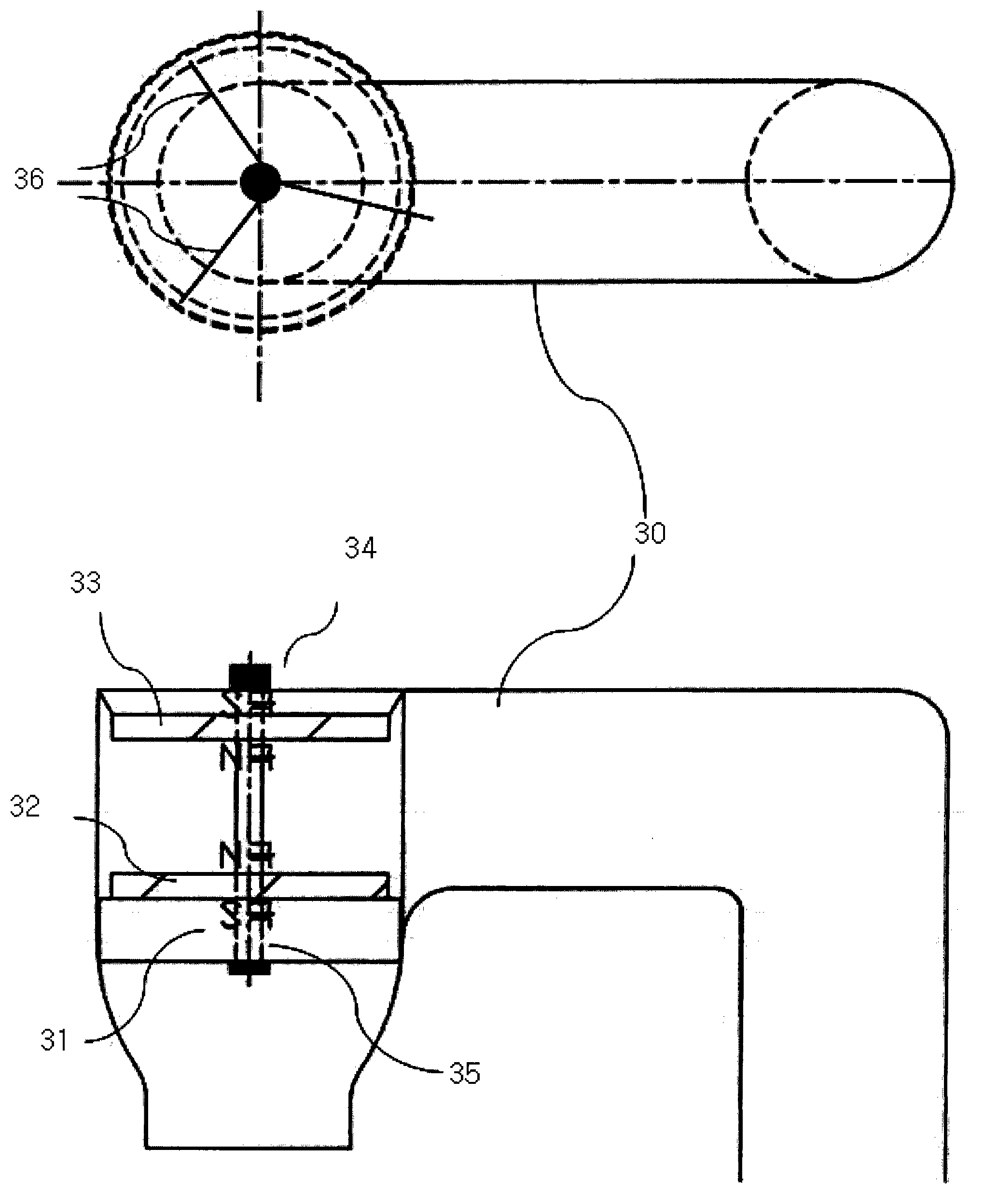

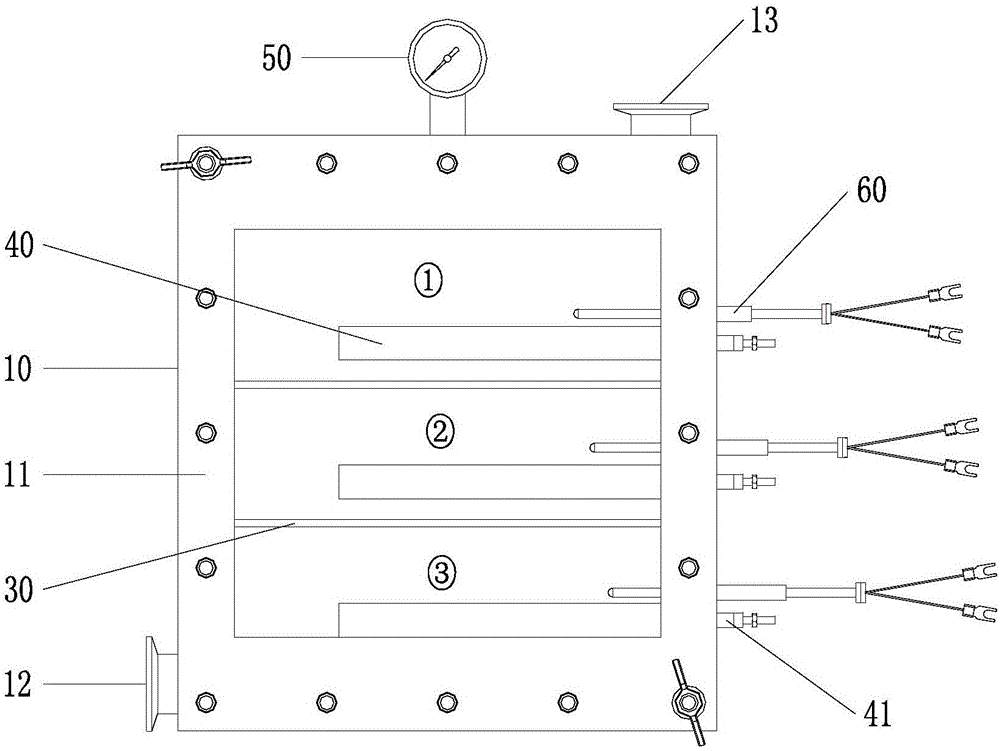

Multilevel heating apparatus and method for high-salt waste water supercritical water oxidation system

ActiveCN109319861APrecise positioningPrecise location of blockageSpecific water treatment objectivesWater/sewage treatment by heatingInorganic saltsChemical industry

The invention discloses a multilevel heating apparatus and method for a high-salt waste water supercritical water oxidation system, which belongs to the technical fields of chemical industry and environmental protection. The multilevel heating apparatus is formed by serially connecting a plurality of heating units, wherein each heating unit comprises a long straight pipe, a slide-rail pipeline heater, a thermometer and a pressure gauge, the heating units are connected by virtue of short straight pipes, and the heating unit is provided with parts such as a detachable insulating sleeve, an ultrasonic pipeline scale remover, a filter and an auxiliary material inlet. The conventional heating apparatus is divided into a plurality of heating units, the defects of the conventional electric heaterthat the heating pipes are intensively distributed and no additional operation space is provided can be solved, and conditions are provided for adding a pipeline filter, the ultrasonic pipeline scaleremover and a chemical inlet. When the high-salt waste water is heated, the crystallization blockage position of inorganic salts can be precisely positioned by virtue of temperature and pressure measure points, so that the scale can be removed on purpose by independently using or jointly using multiple means.

Owner:XI AN JIAOTONG UNIV

Environment-friendly sewage treatment device for solving sewage discharge blockage

InactiveCN112456681ASolve drain blockageReduce wasteSpecific water treatment objectivesTreatment involving filtrationSewage treatmentMechanical engineering

The invention relates to the technical field of sewage treatment, and discloses an environment-friendly sewage treatment device for solving sewage discharge blockage, which comprises a device main body, a rotating part is arranged in the device main body, the right side of the rotating part is movably connected with a movable part, the upper part of the movable part is movably connected with an extrusion rod, and the left side of the rotating part is provided with an incomplete gear; and the lower portion of the movable piece is movably connected with a sliding rail, and an elastic bag is arranged on the left of the sliding rail. According to the device, a driving device drives the rotating part to rotate anticlockwise, the upper portion of the movable part moves leftwards to drive the extrusion rod to move leftwards, the lower portion of the movable part drives the sliding rail to move leftwards and rightwards so as to extrude the elastic bag, the extrusion rod moves leftwards to extrude the lower portion of a pushing part, and the upper portion of the pushing part moves upwards to drive a fixing plate to move upwards;the fixing plate drives a filtering plate to move up when the fixing plate moves upwards, and impurities filtered on the filtering plate enter a filtering box along with the opening, so that large impurities in the sewage are filtered, and the problem that the impurities in the sewage block a pipeline is solved.

Owner:温州哥邦度信息科技有限公司

Wet dicyandiamide pneumatic conveying device

InactiveCN111306895ASimplify the delivery processReduce labor intensityDrying solid materials with heatDrying gas arrangementsStructural engineeringProcess engineering

The invention discloses a wet dicyandiamide pneumatic conveying device which comprises a Roots blower, a heater and a quantitative stock bin, wherein an outlet silencer is arranged at the outlet of the Roots blower; an air outlet is formed in in the outlet silencer and is connected with the heater; the upper part of the quantitative stock bin is connected with a shaftless screw conveyer; a feedinghole is formed in the top of the quantitative stock bin; a pneumatic gate valve B is arranged at the lower part of the quantitative stock bin and is connected with a direct blowing rotary feeding valve arranged at the lower part; the direct blowing rotary feeding valve is connected with an exhaust pipeline below; the front end of the exhaust pipeline is connected with a hot-blast air inlet pipe;the exhaust pipeline is connected with a dissolving kettle arranged on the rear; a discharging pipe and a warehouse top reversing valve are arranged between the exhaust pipeline and the dissolving kettle; and a warehouse top exhaust pipe is arranged on the top of the dissolving kettle. During the actual using process, the wet dicyandiamide pneumatic conveying device adopts the quantitative conveying method to solve the problems about material adhesion to a wall and unsmooth discharging and to also solve the problem that the material blocks the pipeline to enable the production process to be smooth.

Owner:NINGXIA JIAFENG CHEMICALS CO LTD

Oil sewage cut-off valve

InactiveCN107754434AReasonable structureAchieve regulationSpindle sealingsOperating means/releasing devices for valvesSpool valveOil retention

The invention discloses an oil pollution retaining valve, which comprises a handwheel, a top cover, a guide sleeve, a valve core, a valve body, an angle adjustment ruler, a filter element adjustment ruler, a valve cavity, a coarse filter membrane, a fine filter membrane, a water inlet, and a water outlet , core cavity, sewage outlet, oil outlet and bottom cover, the upper end of the valve body is provided with a hand wheel, the valve core is provided below the hand wheel; the angle adjustment ruler is provided on the hand wheel; the valve body is provided with The valve cavity, the valve core is installed in the valve cavity, the lower end of the valve body is provided with a bottom cover; one side of the valve body is provided with a water inlet. The oil pollution shut-off valve realizes the adjustment of the position of the filter port through the set angle adjustment ruler and the filter element adjustment ruler, thereby realizing the filtration of oily sewage with different densities; through the set sewage outlet and oil outlet, it realizes the pollution control Oil cleanup. The oil pollution retaining valve solves the problems of dirty oil corrosion and pipeline blockage, and has the advantages of convenient use, reasonable structure and good sewage discharge effect.

Owner:HEFEI HONGRUN ENVIRONMENTAL PROTECTION TECHCO

A steady-state device and method for industrially synthesizing hydrogen sulfide gas

The invention discloses a steady-state device and method for industrially synthesizing hydrogen sulfide gas. The device comprises a liquid sulfur storage and transportation unit, an H2 input unit, anH2S synthesis unit, an H2S purification unit and an H2S cooling and storage unit. The liquid sulfur storage and transportation unit and the H2 input unit are respectively connected with the H2S synthesis unit, the H2S purification unit is connected with the H2S synthesis unit, and the H2S cooling and storage unit is connected with the H2S purification unit. According to the invention, the continuity, stability and system intrinsic safety of industrial production are taken as starting points, hydrogen and sulfur are taken as raw materials, and the long-period steady-state production of high-purity hydrogen sulfide is realized through process configuration. The device and the technology disclosed by the invention have the characteristics of few system byproducts, strong energy-saving and environment-friendly properties, low unit consumption of a hydrogen sulfide product, excellent system operation economy and the like.

Owner:CHANGSHA HASKY ENVIRONMENTAL PROTECTION TECH DEV CO LTD

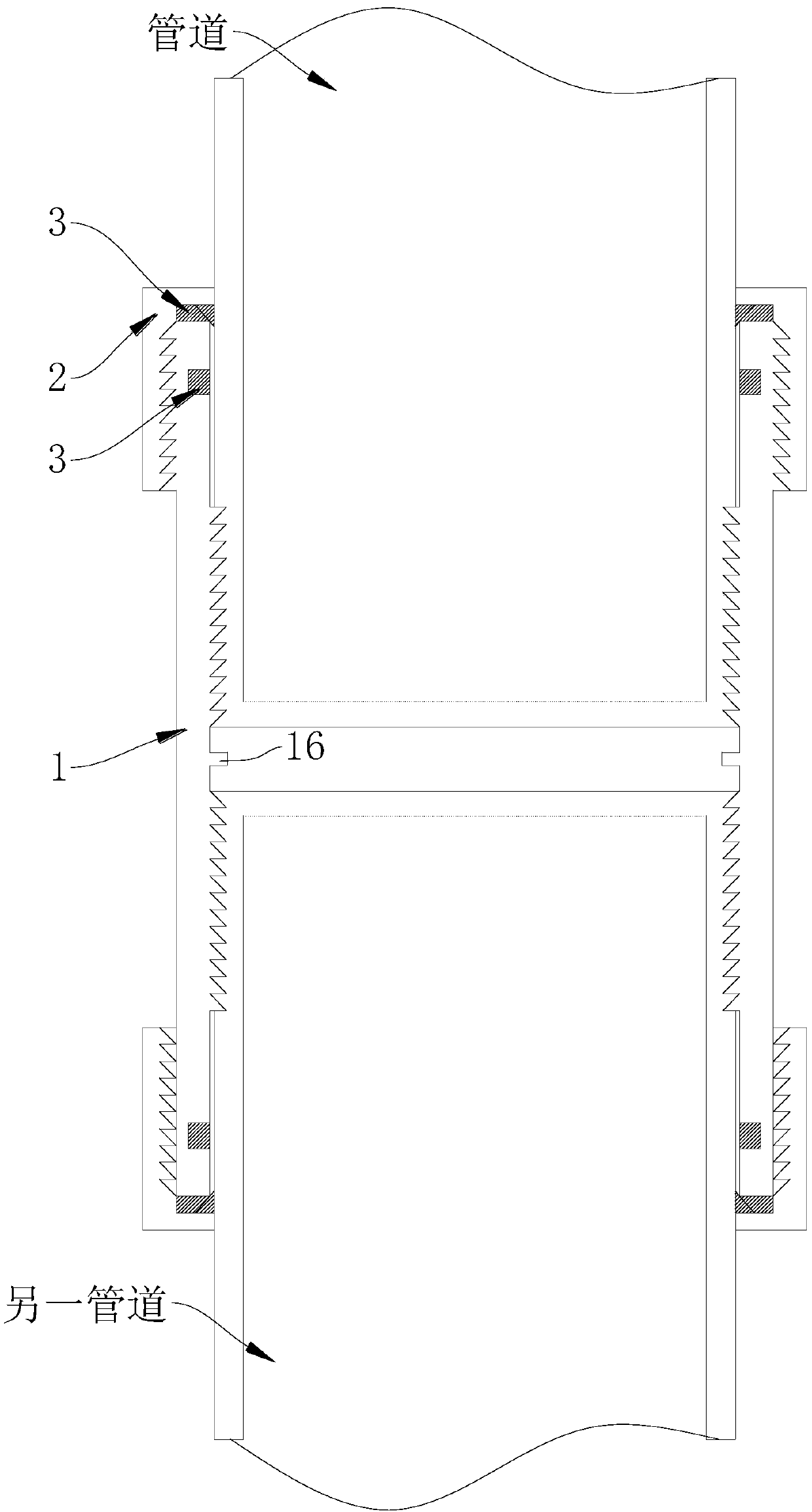

Pipe fitting

InactiveCN109667997AFirmly connectedEasy to disassembleJoints with sealing surfacesSiphonsPipe fittingWater quality

The invention discloses a pipe fitting. The pipe fitting comprises a pipe body, a sealing part and a screw cap, wherein outer threads are arranged on the outer wall of the pipe body, first internal threads are arranged on the inner wall of the pipe body, the first internal threads are used for connecting a pipeline, the screw cap is provided with second internal threads, the external threads are in threaded fit with the second internal threads so as to make the sealing part press the outer wall of the pipeline, and then seal a gap between the inner wall of the pipe body and the outer wall of the pipeline. According to the pipe fitting, installing and disassembly are convenient, the maintenance is easier, in addition, the problems of water quality pollution caused by using a liquid raw material belt and inconvenient disassembly and maintenance are avoided, meanwhile, usage of a polytetrafluoroethylene raw material is also avoided, so that the phenomenon that the inner wall of the pipeline is blocked by the polytetrafluoroethylene raw material is avoided.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

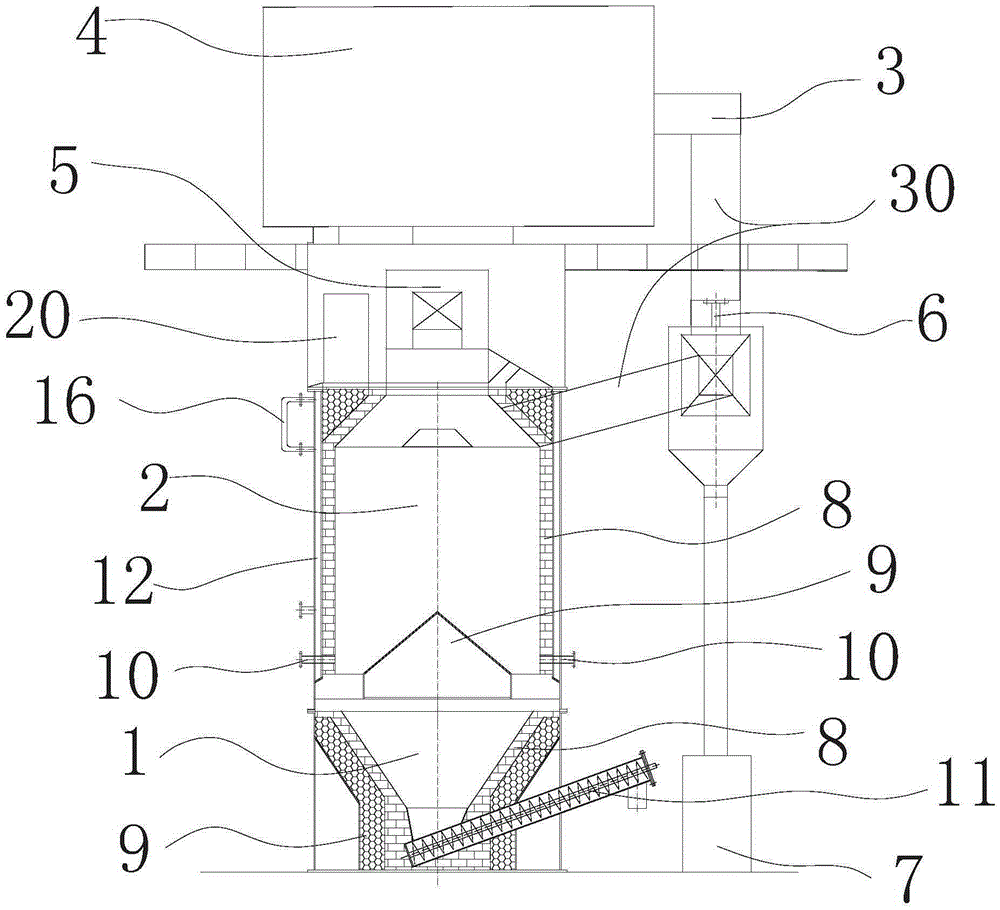

Special tank for storage and fermentation of organic garbage before digestion of hermetia illucens and use method

ActiveCN112812958ASolve the problem of slurry material stuck valveSolve stuck valve problemBioreactor/fermenter combinationsBiological substance pretreatmentsHermetiaProcess engineering

The invention relates to a special tank for storage and fermentation of organic garbage before digestion of hermetia illucens and a use method, integrates storage and fermentation, and belongs to the technical field of environment-friendly equipment for recycling and harmless utilization of the organic waste. According to the technical scheme, the special tank consists of a valve rod assembly (1), a tank body (2), a discharging auger assembly (3) and a breeding disc operation platform (4). The special tank has the beneficial effects that storage and fermentation conditions are provided for complex materials at the same time, the problem that the complex materials block a pipeline and the tank body is well solved, adaptability to the materials is good, material pretreatment equipment can be omitted, the materials can be put into the tank body for fermentation after being simply smashed directly through a shredding machine and the like without sorting, investment is reduced, the production efficiency is improved, the production cost is saved, the labor intensity of operators is reduced, the automation degree is high, operation is easy, mounting is convenient, the appearance is attractive, the labor cost of hermetia illucens breeding is greatly reduced, and the labor environment of the operators is improved.

Owner:四川蜀凤梧环保科技有限公司 +1

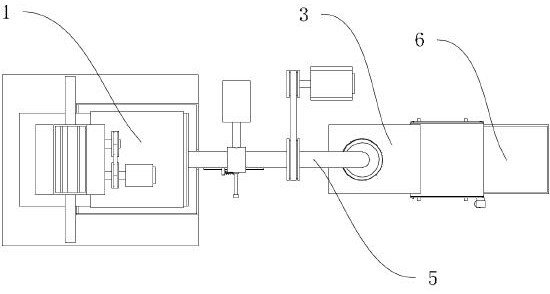

Rotary stripping type soil multi-stage screening machine for land investigation based on photoelectric sensing

ActiveCN113856875AImprove grinding efficiencySolve clogged pipesSievingScreeningSoil scienceEngineering

The invention discloses a rotary stripping type soil multi-stage screening machine for land investigation based on photoelectric sensing. The rotary stripping type soil multi-stage screening machine for land investigation based on photoelectric sensing comprises an air pressure pushing type rotary screening device, an extrusion type pneumatic cleaning type pre-crushing device, a gravity driving type elastic screening device, a double-roller grinding device, an anti-blocking type material conveying device and an auxiliary transferring and collecting device. The invention belongs to the technical field of sample screening, particularly relates to the rotary stripping type soil multi-stage screening machine for land investigation based on photoelectric sensing, which is simple in structure and high in system efficiency. An air pressure pushing type rotary screening device is creatively provided on the basis of the intermediary principle and the air pressure and hydraulic structure principle, air flow is used as an intermediary to push soil particles to quickly and efficiently pass through a screening barrel, and the function that the air flow periodically pushes a soil sample is achieved by means of the magnetic attraction principle under the condition that no sensor is involved, so that the problems that an existing screening tool is low in screening efficiency and low in precision are effectively solved.

Owner:青州市大森机械有限公司 +1

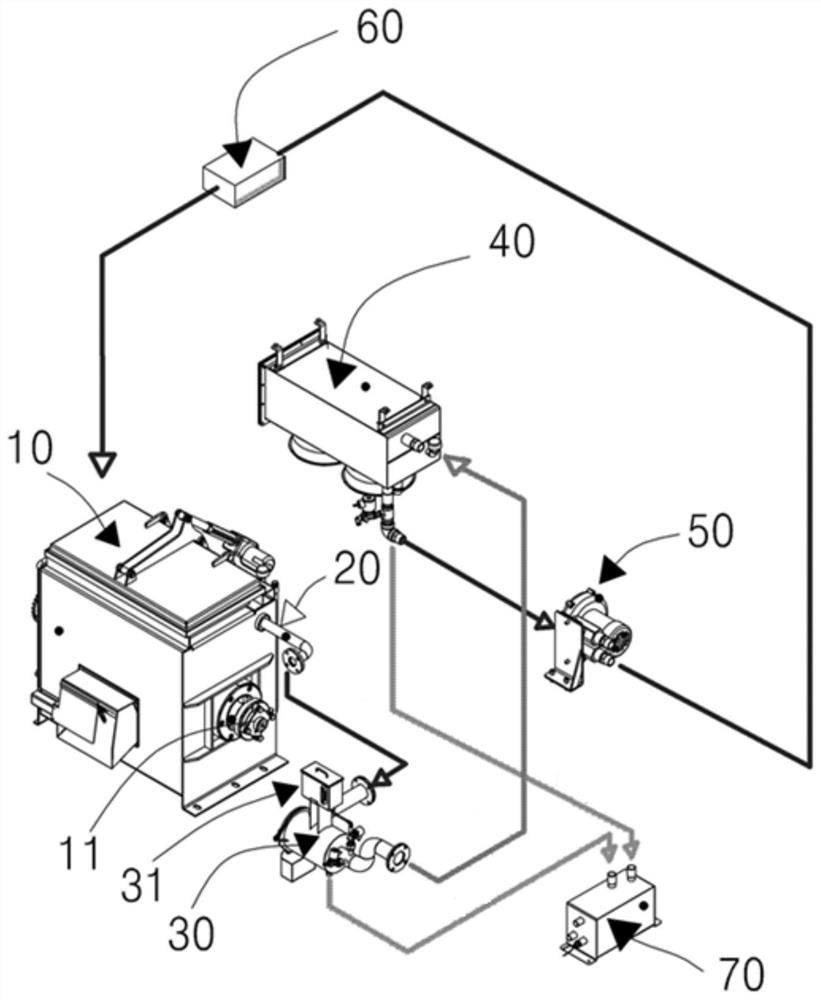

Sand, gravel and pulp-water separating recycling and temperature control system

ActiveCN107754443ATemperature controlStable temperatureTransportation and packagingRotary stirring mixersTemperature controlControl system

The invention relates to a sand, gravel and pulp-water separating recycling and temperature control system. The system comprises a pulp-water automatic stirring storage unit with pulp-water placed ina container, a sand, gravel and pulp-water separating system used for separating sand, gravel and pulp-water, a temperature control system which is arranged for heat exchange of pulp-water in the pulp-water automatic stirring storage unit, a clear water replenishment system used for replenishing clear water for heat exchange to the temperature control system, and a linkage stable-pressure water supply device which is communicated with the pulp-water automatic stirring storage unit through a pipeline in a pulp-water recycling system. Pulp-water separated through a sand, gravel and pulp-water separating system is communicated with an inlet in the container of the pulp-water automatic stirring storage unit through a pulp-water outlet pipeline. The system of the invention is reasonably designed, has a compact structure, and is convenient to use.

Owner:邢台建工商品混凝土有限公司

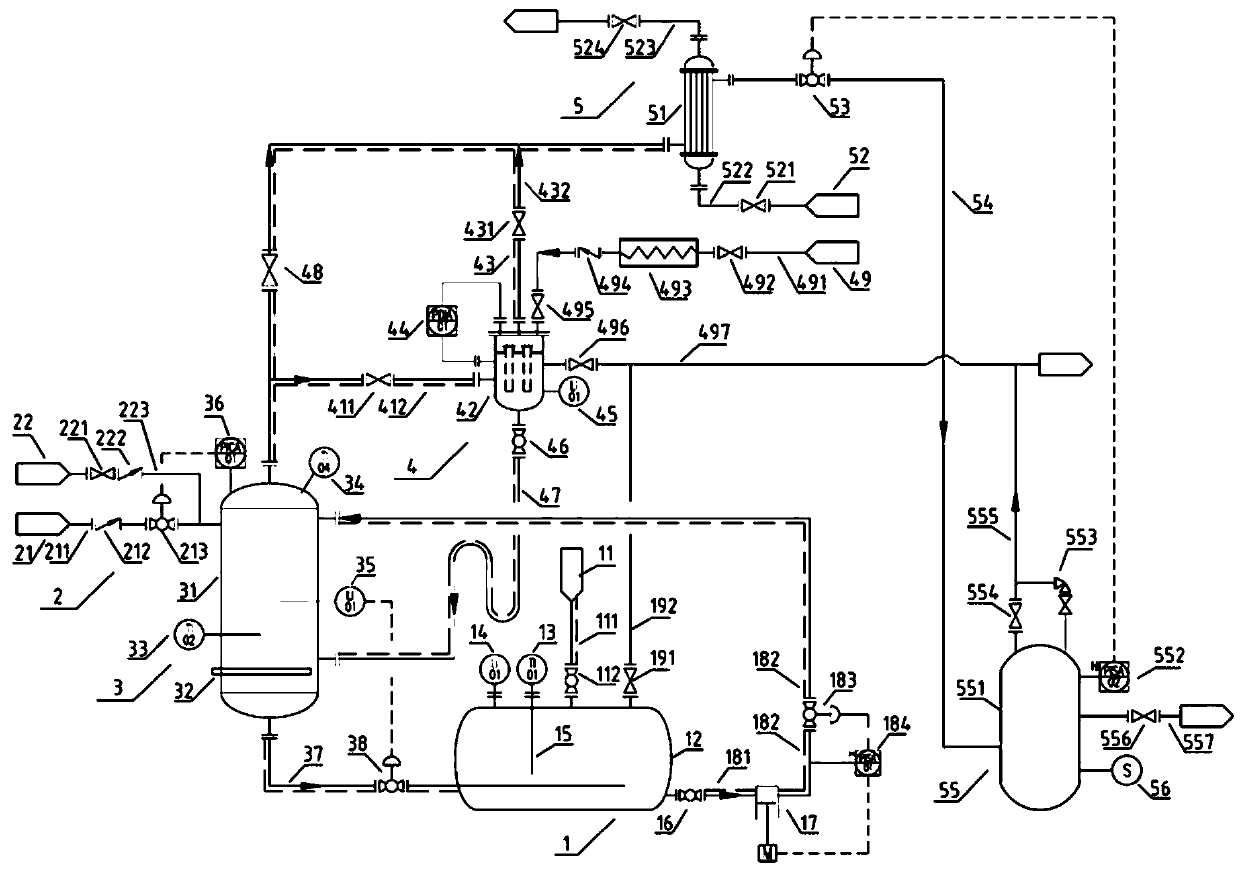

Steady-state device and method for industrially synthesizing hydrogen sulfide gas

The invention discloses a steady-state device and method for industrially synthesizing hydrogen sulfide gas. The device comprises a liquid sulfur storage and transportation unit, an H2 input unit, anH2S synthesis unit, an H2S purification unit and an H2S cooling and storage unit. The liquid sulfur storage and transportation unit and the H2 input unit are respectively connected with the H2S synthesis unit, the H2S purification unit is connected with the H2S synthesis unit, and the H2S cooling and storage unit is connected with the H2S purification unit. According to the invention, the continuity, stability and system intrinsic safety of industrial production are taken as starting points, hydrogen and sulfur are taken as raw materials, and the long-period steady-state production of high-purity hydrogen sulfide is realized through process configuration. The device and the technology disclosed by the invention have the characteristics of few system byproducts, strong energy-saving and environment-friendly properties, low unit consumption of a hydrogen sulfide product, excellent system operation economy and the like.

Owner:CHANGSHA HASKY ENVIRONMENTAL PROTECTION TECH DEV CO LTD

Self-adaptive pipeline cleaning device with pipeline dredging function

InactiveCN112044886AImprove efficiencyAccelerated corrosion softeningHollow article cleaningEngineeringStructural engineering

The invention discloses a self-adaptive pipeline cleaning device with a pipeline dredging function. The self-adaptive pipeline cleaning device comprises a pipeline cleaning device body, wherein the pipeline cleaning device body is provided with a regulating and controlling box; two power devices are fixedly connected to the regulating and controlling box in an up-down symmetrical mode; each powerdevice comprises a direction rotating block; each direction rotating block is rotationally connected with a supporting rod; an adjusting cavity is formed in each supporting rod; and an adjusting sliding block is connected in each adjusting cavity in a sliding mode. According to the self-adaptive pipeline cleaning device with the pipeline dredging function, the power devices are arranged, the powerdevices carry out inner diameter calibration work on a pipeline before entering the pipeline, so that the size of the device is changed, then the efficiency of the device is higher, and meanwhile, the cleaning effect is better; and meanwhile, the device is provided with a blockage dredging device, when complete blockage is detected, a linkage mechanism is started to fix the device, meanwhile, thedredging device is used for carrying out force-generating dredging, acid spraying is carried out at the same time, and corrosion softening of concrete is accelerated.

Owner:福州晋安区格撕图科技有限公司

A method for melting and processing waste incineration fly ash

The invention relates to a melting treatment method for waste incineration flying ash, and belongs to the technical field of environmental engineering. The treatment method comprises the following steps of carrying out pretreatment on the waste incineration flying ash to form treated flying ash; uniformly mixing the treated flying ash with sludge to form a mixture of the flying ash and the sludge; carrying out solidification and stabilization on the mixture of the flying ash and the sludge to form a solidified body; and carrying out melting treatment on the solidified body. The treatment method can effectively solve the problems that the caloric value in the flying ash is relatively low, and heavy metals in the flying ash are liable to volatilize, so that pipeline blockage in a flying ash conveying process is avoided; and the melting treatment method is good in treatment effect, is low in cost, is free from secondary pollution, and is high in resource utilization.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI +1

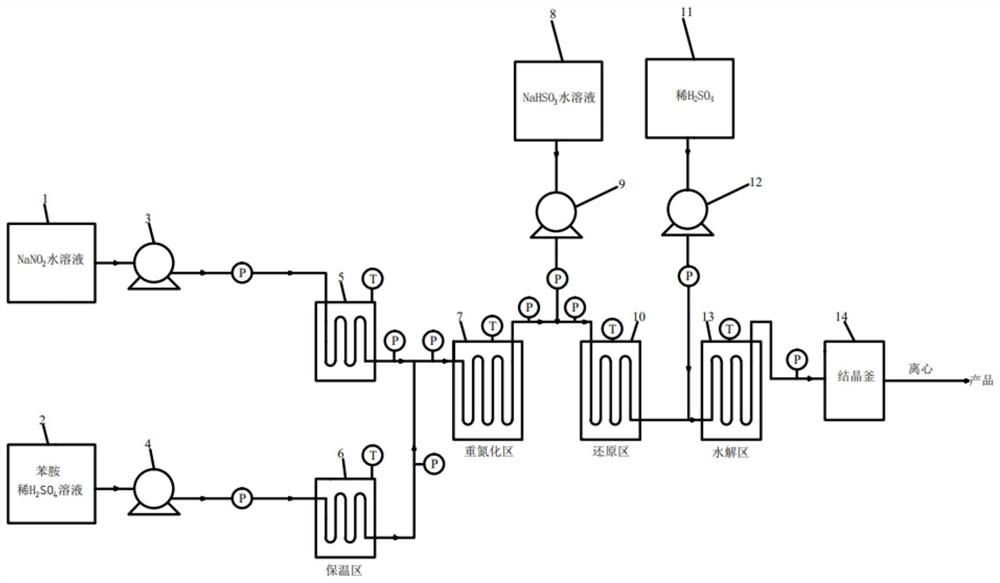

Process for preparing phenylhydrazine sulfate by continuous method

PendingCN112707842AImprove operational efficiencyImprove operational safetyHydrazine preparationPhenylhydrazineSulphate salt

The invention discloses a process for preparing phenylhydrazine sulfate by a continuous method, which comprises the following steps: reducing a phenyl diazonium salt solution by using a NaHSO3 solution to generate phenylhydrazine sulfate, the molar ratio of diazonium salt to NaHSO3 being 1: (2.5-5.5); and respectively pumping a phenyl diazonium salt solution and a sodium hydrogen sulfite solution into a pipeline reactor by a metering pump under the condition that the mixing temperature is 5-30 DEG C, controlling the temperature of the pipeline reactor in a sectional manner, performingfront stagecontrolling at 50-80 DEG C for retention time of 5-10 minutes, adding a dilute sulphuric acid solution into a reaction pipeline, performing rear stage controlling at 80-100 DEG C forretention time of 15-25 minutes, then introducing into a crystallization kettle, cooling to 0-5 DEG C, crystallizing, and centrifuging. A continuous method is used for replacing traditional intermittent operation, the operation efficiency and safety are greatly improved, workshops are saved, equipment investment is reduced, energy consumption is reduced, and manpower is reduced.

Owner:NANTONG ACETIC ACID CHEM +1

Oxalic acid conveying device

ActiveCN106225486ASolve the problem of entering the degreasing furnaceAchieve complete gasificationCharge manipulationWaste heat treatmentOxalateEngineering

The invention discloses an oxalic acid conveying device. The oxalic acid conveying device comprises a box, a box cover and a plurality of separation plates. The box is formed by an upper side plate, a lower side plate, a left side plate, a right side plate and a rear side plate in a surrounded mode. The box cover covers a front side box opening of the box in a seal mode. The separation plates are arranged up and down and welded in the box. The box is divided into a plurality of areas by the separation plates. A heating plate is installed in each area. A gas inlet connector used for leading in nitrogen gas is arranged in the position, close to the bottom end, of the left side plate or the right side plate of the box. The separation plates are provided with ports for ventilation. A gas outlet connector is arranged on the upper side plate and is provided with a gas channel used for communicating with a furnace liner reaction cavity of a debinding furnace. According to the designed oxalic acid conveying device, supply of a gas oxalic acid catalyst is achieved, thus the debinding furnace decomposes polyformaldehyde through gas oxalic acid as the catalyst, the problem that oxalic acid can enter the debinding furnace after sublimation in the catalytic debinding process is solved, so that conveying supply can also be completed without the usage of compressed air.

Owner:SHENZHEN SINTERZONE TECH CO LTD

A treatment method for the clogging of the inlet regulating valve of the urea spray gun in the urea ammonia production system

InactiveCN104495872BSolve clogged pipesImprove denitrification efficiencyDispersed particle separationAmmonia preparation/separationFlue gasAmmonia production

The invention discloses a method for treating blockage of a regulating valve at an entrance of a spray gun in a urea ammonia production system. The method for treating the blockage of the regulating valve at the entrance urea spray gun in the urea ammonia production system comprises the following steps: comprehensively determining that blockage is caused by virtue of low urea solution flow of a urea solution regulating valve according to show value of a flow meter and experience, taking down the urea flow regulating valve (2), and washing a valve element of the urea flow regulating valve (2) with water at the temperature of 80-100 DEG C; mounting one compressed air hose between a compressed air inlet pipe (6) and a urea flow regulating valve outlet pipe (7), opening a compressed air inlet valve (4), and purging with compressed air at 0.2-0.6MPa; adjusting a position of an interface at one end of the compressed air hose from the urea flow regulating valve inlet pipe (7) to a urea flow regulating valve outlet pipe (8), and sweeping according to a previous operation step; and then repeating operation in the second step. The method for treating the blockage of the regulating valve at the entrance urea spray gun in the urea ammonia production system has the advantages that the problem that a pipeline and a valve are blocked by crystallized urea can be solved, flue gas denitrification efficiency is improved, and practicability is strong.

Owner:DATANG TAIYUAN CO GENERATION POWER PLANT

Oxalic acid delivery device

ActiveCN106225486BSolve the problem of entering the degreasing furnaceAchieve complete gasificationCharge manipulationWaste heat treatmentOxalateOXALIC ACID DIHYDRATE

The invention discloses an oxalic acid conveying device. The oxalic acid conveying device comprises a box, a box cover and a plurality of separation plates. The box is formed by an upper side plate, a lower side plate, a left side plate, a right side plate and a rear side plate in a surrounded mode. The box cover covers a front side box opening of the box in a seal mode. The separation plates are arranged up and down and welded in the box. The box is divided into a plurality of areas by the separation plates. A heating plate is installed in each area. A gas inlet connector used for leading in nitrogen gas is arranged in the position, close to the bottom end, of the left side plate or the right side plate of the box. The separation plates are provided with ports for ventilation. A gas outlet connector is arranged on the upper side plate and is provided with a gas channel used for communicating with a furnace liner reaction cavity of a debinding furnace. According to the designed oxalic acid conveying device, supply of a gas oxalic acid catalyst is achieved, thus the debinding furnace decomposes polyformaldehyde through gas oxalic acid as the catalyst, the problem that oxalic acid can enter the debinding furnace after sublimation in the catalytic debinding process is solved, so that conveying supply can also be completed without the usage of compressed air.

Owner:SHENZHEN SINTERZONE TECH CO LTD

Crushing equipment for preventing sludge blockage

PendingCN111921638AFully brokenReduce volumeSludge treatment by de-watering/drying/thickeningGrain treatmentsSludgeProcess engineering

The invention relates to crushing equipment for preventing sludge blockage. The crushing equipment comprises a spiral conveyor and a sludge dryer, wherein a crushing device is connected between the spiral conveyor and the sludge dryer; the crushing device comprises a housing, and a crushing and stirring cavity is formed in the housing; and a stirring and crushing mechanism for crushing sludge is rotatably connected in the crushing and stirring cavity. The crushing equipment is simple in structure and convenient and practical. By arranging the crushing device between the spiral conveyor and thesludge dryer, the crushing device crushes sludge fully, so that the volume of the sludge is decreased, the sludge is prevented from being agglomerated massively, and a condition of easy blockage of the sludge entering an inlet of the dryer when relatively humid or easily agglomerated sludge is conveyed is avoided.

Owner:上海立泉环境科技有限公司

Food waste dry matter decrement dryer re-utilizing vapor produced during drying

ActiveCN113048752ALow manufacturing costReduce power consumptionHollow article cleaningDrying gas arrangementsDry matterIngested food

The invention relates to a food waste dry matter decrement dryer. When food waste is crushed and dried, remaining, accumulation and solidification of the food waste can be prevented, and blocking of equipment and pipelines due to fine powder can be prevented, and meanwhile, the exhausted vapor is recycled, so that energy conservation is achieved and prevention of odor exhaustion is achieved. The food waste dry matter decrement dryer comprises a drying device, a primary dust filter which is used for filtering foreign matter in the vapor produced in a drying device, a secondary dust filter which is used for filtering remained impure substances in the vapor which is not filtered by the primary dust filter, a condensation device, and a circulating device which is used for drying the food waste. The secondary dust filter comprises a cleaning device, and the cleaning device is used for supplying a detergent and water to the interior and removing the fine powder and oil content contained in the vapor produced during drying; the pipelines which are connected with the secondary powder filter and the condensation device are prevented from being blocked because of the dust and the oil content; and a stirring and crushing device which is used for stirring and crushing the food waste accommodated in the main body is arranged in the drying device.

Owner:株式会社盖亚

A kind of vertical tubular reactor for the hydrolysis of tnt deenergized base

ActiveCN107855090BAchieve continuous operationImprove processing efficiencyChemical/physical/physico-chemical stationary reactorsFeed devicesEngineeringHydrolysis

The invention provides a vertical type tubular reactor for deenergization and alkali hydrolysis of TNT (Trinitrotoluene). The vertical type tubular reactor comprises a heat insulation tube, wherein the heat insulation tube is internally connected with a disc-shaped alkali hydrolysis reaction tube through a fixed bracket; the disc-shaped alkali hydrolysis reaction tube is spirally arranged in the heat insulation tube; a spiral shaft and the heat insulation tube are coaxially arranged; an alkali liquid spraying pipe is embedded into the disc-shaped alkali hydrolysis reaction tube; the alkali liquid spraying pipe and the disc-shaped alkali hydrolysis reaction tube are coaxially arranged; a plurality of micro-pores are formed in the alkali liquid spraying pipe; the heat insulation tube is vertically arranged; a heat insulation medium adopts heat insulation water; the heat insulation water enters from a bottom water inlet of the heat insulation tube and then is discharged from a top water outlet; the disc-shaped alkali hydrolysis reaction tube is a TNT alkali hydrolysis reaction region; the TNT enters from a top feeding opening of the disc-shaped alkali hydrolysis reaction tube and alkali liquid is sprayed out from the alkali liquid spraying pipe; after reaction, the TNT is discharged from a discharging opening formed in the bottom of the disc-shaped alkali hydrolysis reaction tube;a flowing direction of heat insulation water is opposite to the flowing direction of a reaction solution in the disc-shaped alkali hydrolysis reaction tube. By adopting the vertical type tubular reactor, the treatment efficiency of abandoned propellant and explosive is improved; meanwhile, the safety is improved.

Owner:XI AN JIAOTONG UNIV +1

Method for preventing hematoxylin from blocking pipe

The invention relates to methods for preventing hematoxylin from blocking pipes, particularly to a method for preventing the hematoxylin from blocking a pipe on biological slice production dyeing equipment. The method is characterized in that a pipe opening of a hematoxylin conveying pipe is closed and blocked by the residual liquid water in a water conveying pipe. According to the method for preventing the hematoxylin from blocking the pipe, the method is simple, the production cost is low, the operation is simple and easy, the problem that the pipe is blocked due to the hematoxylin oxide crystallization can be solved, the pipe dredging work during boot-up is reduced, the convenience is brought to the work of the operators, and the damage to the equipment can be avoided.

Owner:HUBEI HUAPING MEDICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com