Single-effect forced-circulation evaporation system for hazardous waste treatment liquid and operation method of single-effect forced-circulation evaporation system

A technology for forced circulation evaporation and liquid treatment, applied in chemical instruments and methods, water/sewage multi-stage treatment, heating water/sewage treatment, etc. Timely release and other problems to achieve the effect of continuous feeding and discharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

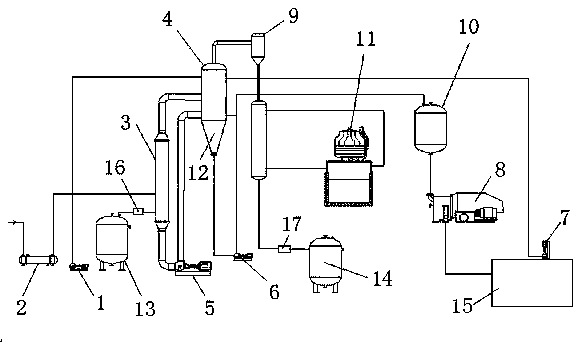

[0018] Such as figure 1 As shown, the single-effect forced circulation evaporation system for hazardous waste treatment liquid of the present invention mainly includes a heater 3 , a separator 4 and a thickening tank 10 . The heater 3 adopts a steam heater, and is connected with the steam source through the sub-cylinder 2, and a steam valve is arranged on the connecting pipeline. An intake valve can be set on the connection pipeline between the heater 3 and the sub-cylinder 2. There is a safety valve on the top of the sub-cylinder 2, and when the steam pressure reaches the set pressure, the safety valve will automatically release the pressure to ensure the safe operation of the device. The heater 3 is also connected to the steam condensed water storage tank 13, and a steam condensed water pump 16 can be arranged on the connecting pipeline to collect and store the steam condensed water.

[0019] The separator 4 is provided with a top liquid outlet, an upper feed port, an uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com