Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Small air volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

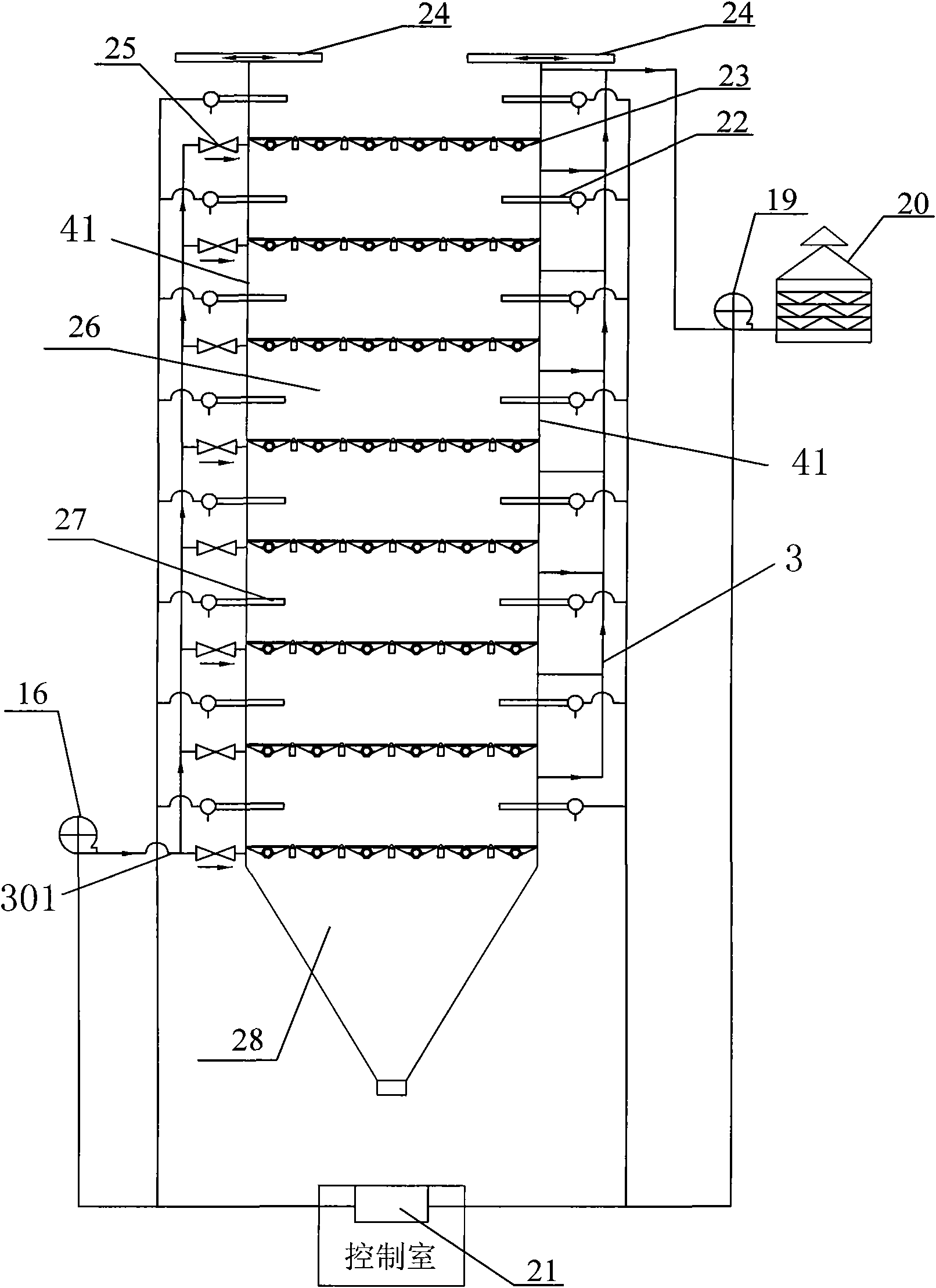

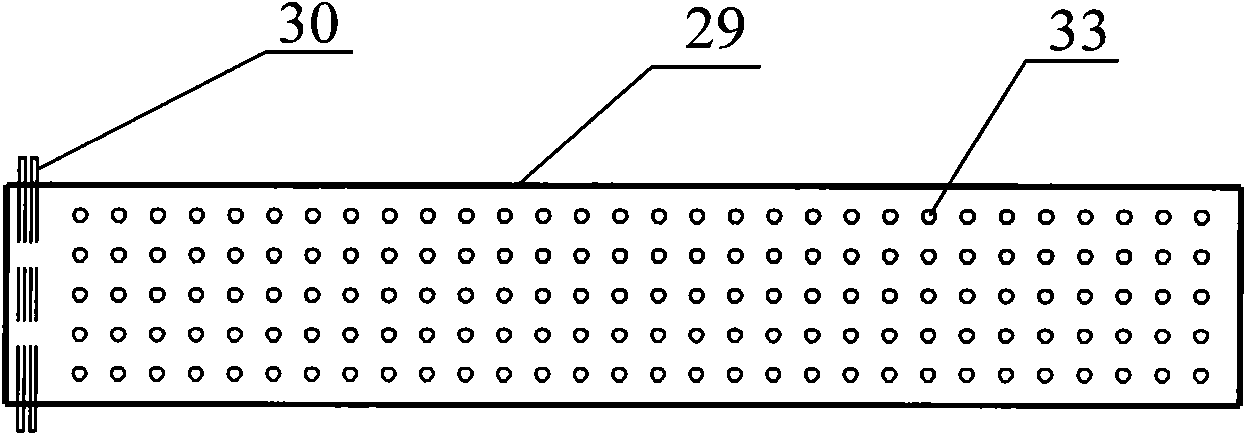

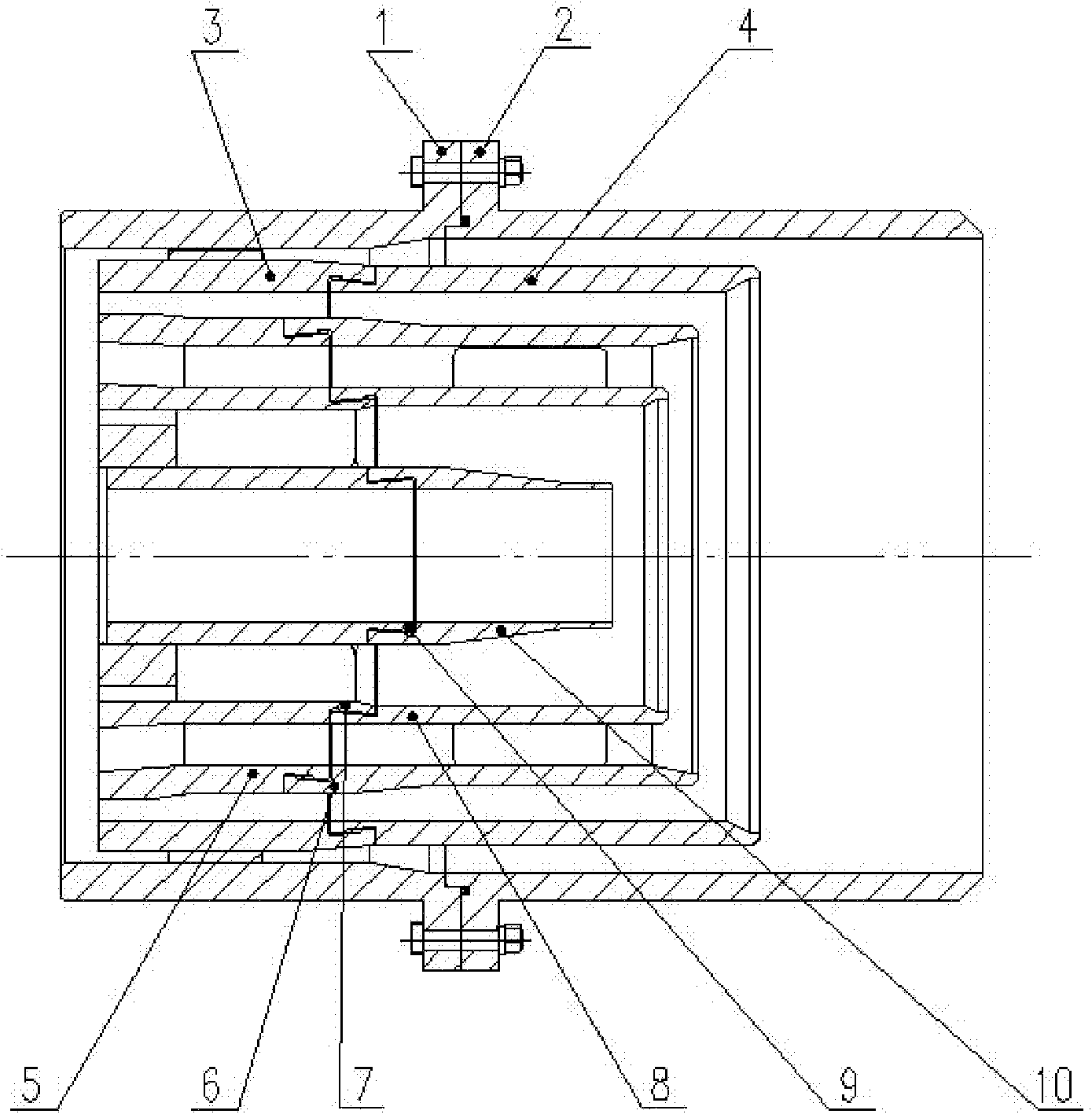

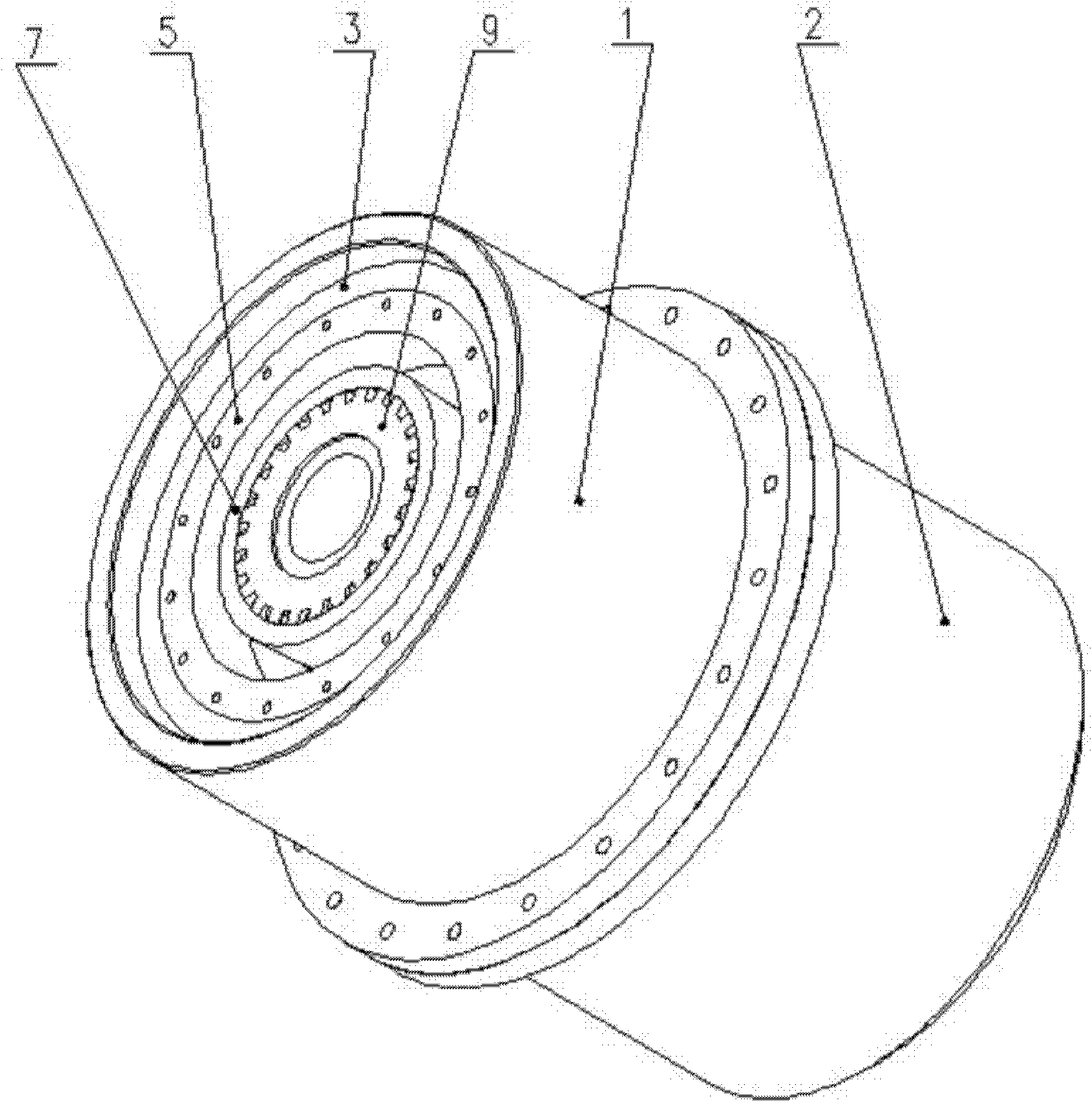

Circulating sludge biological fermentation tank, processing system and processing method

ActiveCN102153388AReduce wind pressureReduce air volumeBio-organic fraction processingSludge treatment by de-watering/drying/thickeningSludgeControl room

The invention discloses a circulating sludge biological fermentation tower which comprises a tower body, an openable tower cover, a storage tank and a plurality of rotatable fermentation devices, wherein the openable tower cover is arranged on the top of the tower body; the storage tank is arranged at the bottom of the tower body; the rotatable fermentation devices are arranged in the tower body in parallel; the fermentation devices divide an inner cavity of the tower body into a plurality of layers of fermentation bins along the axial direction; the lower part of each layer of fermentation device is provided with a ventilating oxygen supply pipeline communicated with a blower; the upper part of each layer of fermentation device is provided with an air outlet pipeline communicated with aninduced draft fan and a monitoring device; the monitoring device is controlled by a control room; and a mechanism for driving the fermentation devices and the tower cover to move, the blower and the induced draft fan are all controlled by the control room. The invention also discloses a circulating sludge biological processing system and a processing method. By the circulating sludge biological fermentation tower, the circulating sludge biological processing system and the processing method, industrial biological fermentation desiccation treatment can be continuously and stably carried out onsludge under the conditions of high efficiency and low energy consumption.

Owner:深圳市如茵生态环境建设有限公司

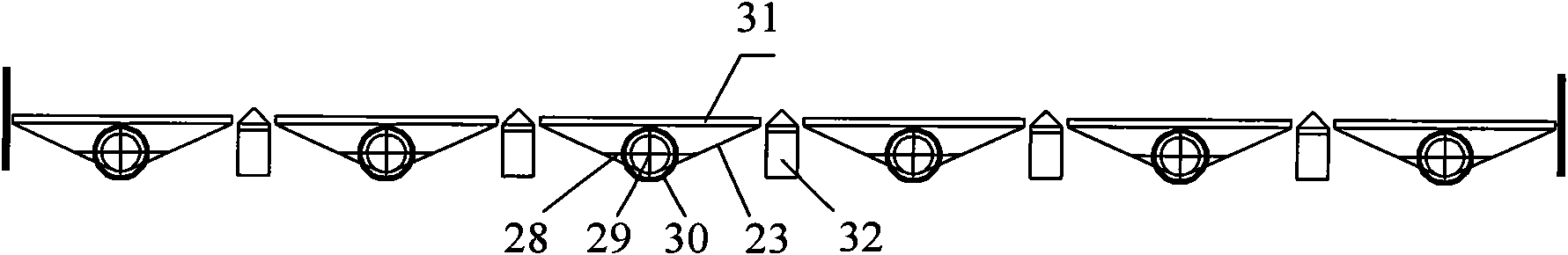

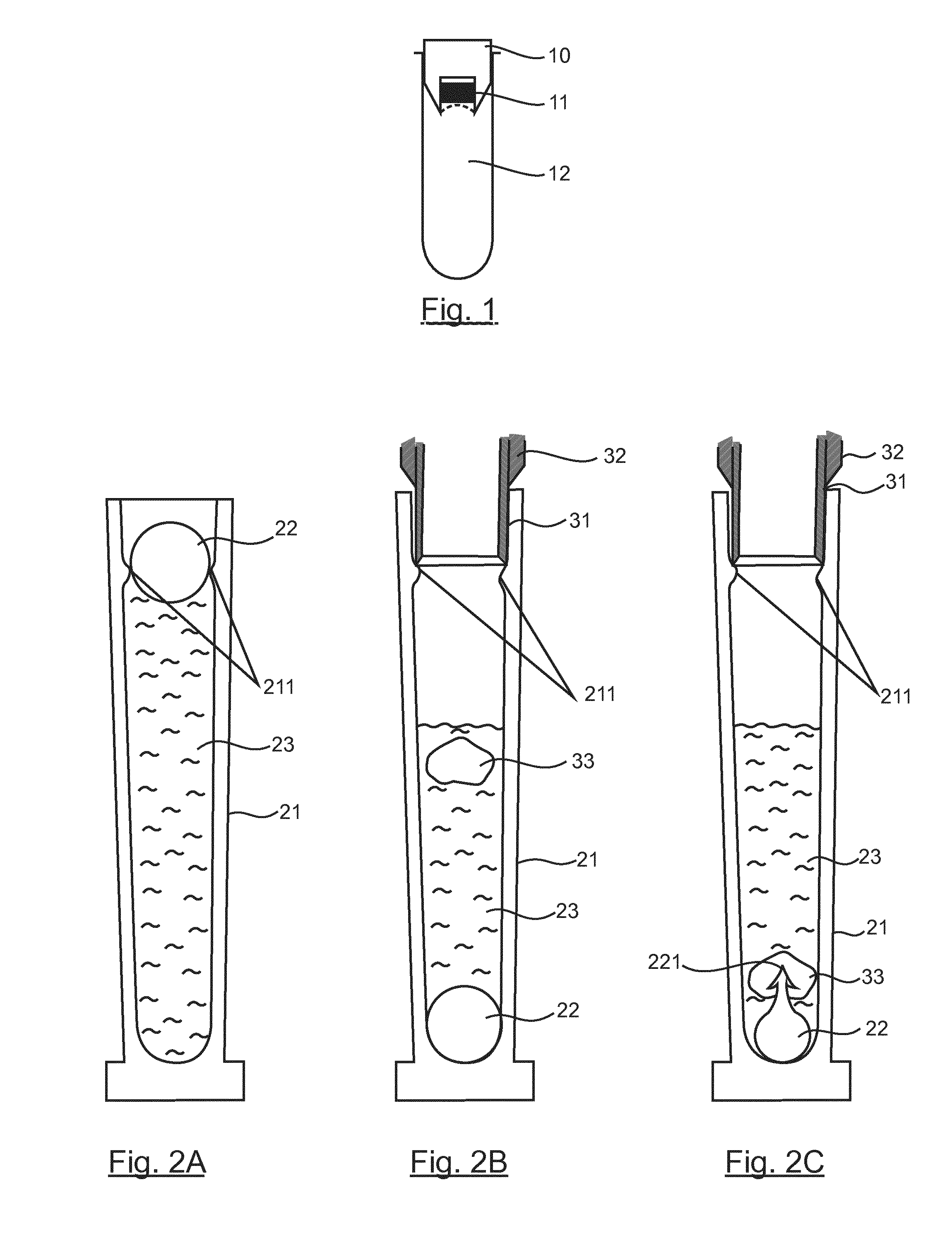

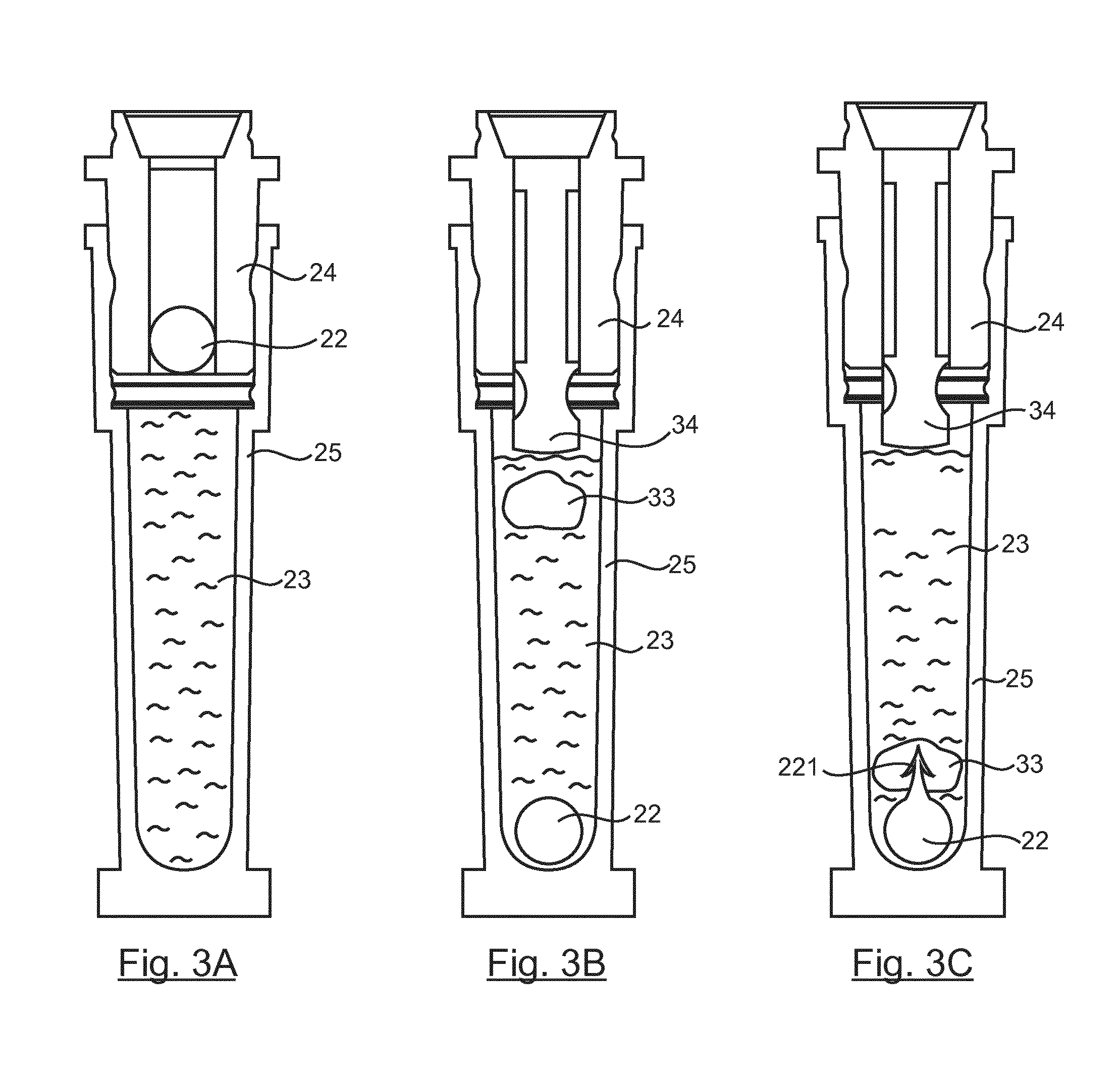

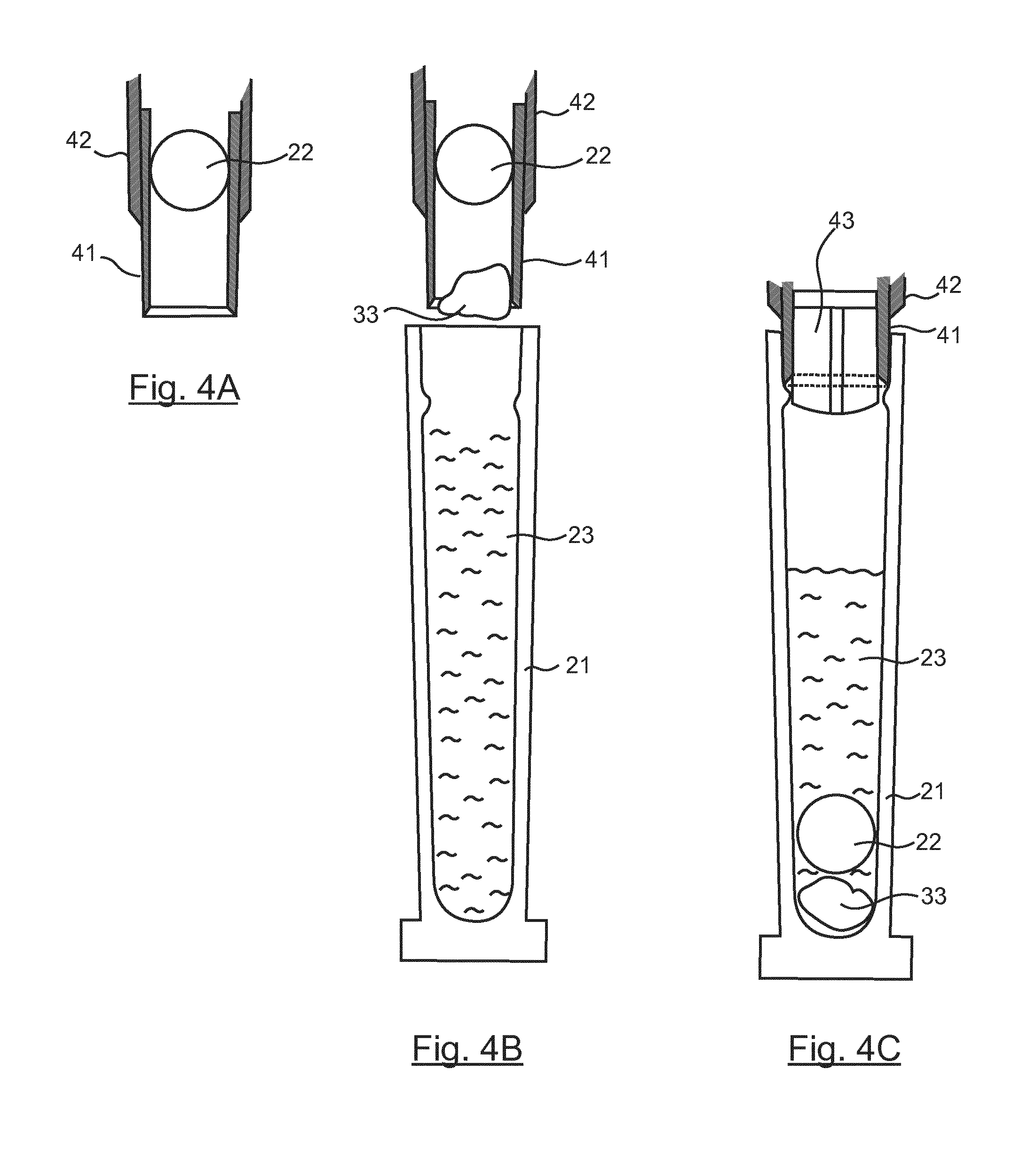

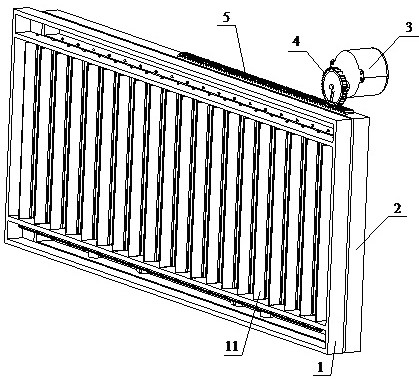

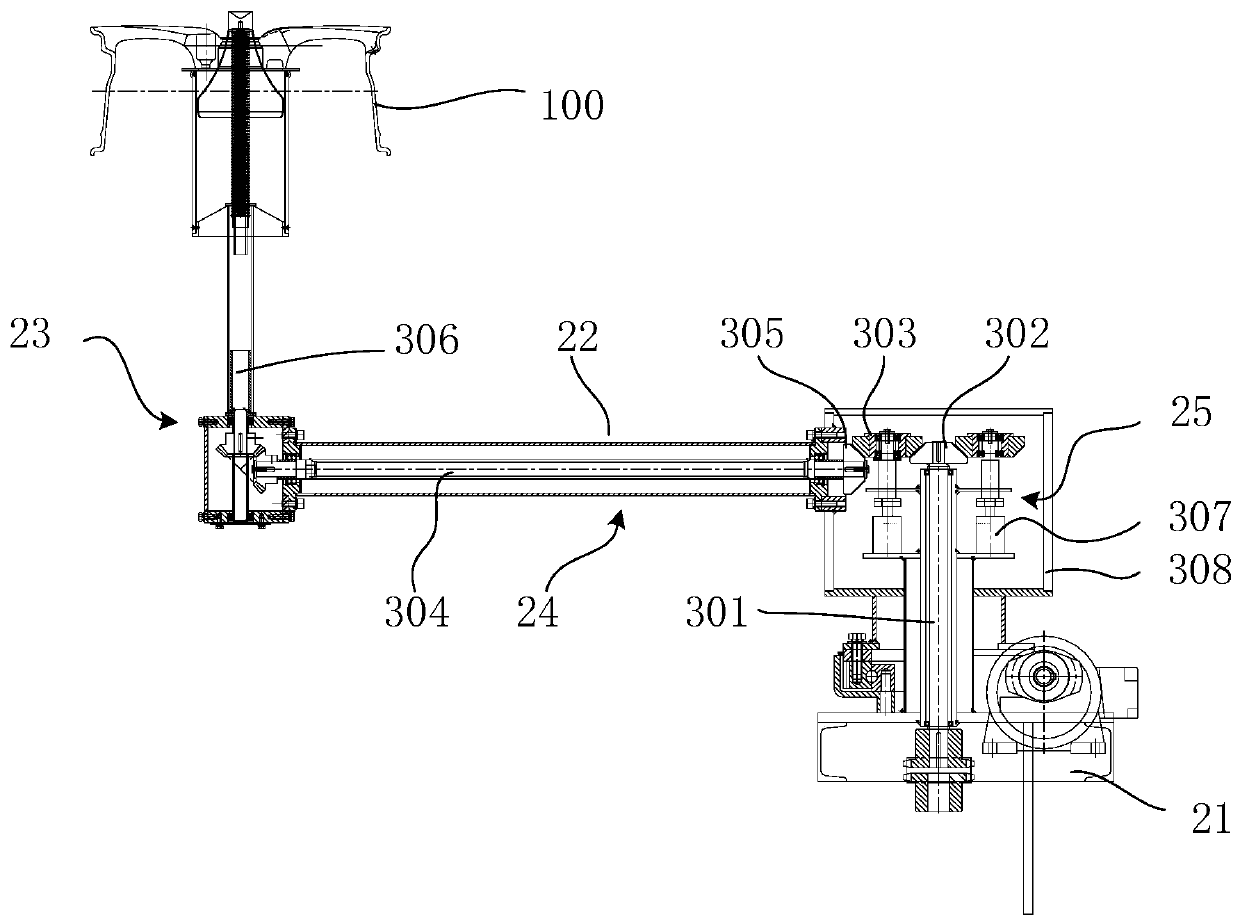

System for collecting at least one sample of animal tissue and corresponding sampling device, storage device, and manufacturing method

InactiveUS20140249449A1Avoid introducingReduce pressureSurgical needlesVaccination/ovulation diagnosticsEngineeringBiomedical engineering

The invention relates to a system for collecting at least one sample of animal tissue, including: a sampling device, including at least one cutting element for cutting off a sample of animal tissue, and a storage device including a receiving tube for receiving said sample. According to the invention, the system includes a weighted element (22) configured so as to assume at least two positions, i.e. a first position which is assumed prior to collecting said sample and in which said weighted element (22) is retained in said sampling device or in said storage device, and a second position which is assumed after said sample is collect and in which said weighted element (22) is free within said tube, said weighted element (22) being pushed inside said tube during said sampling.

Owner:ALLFLEX EURO SAS

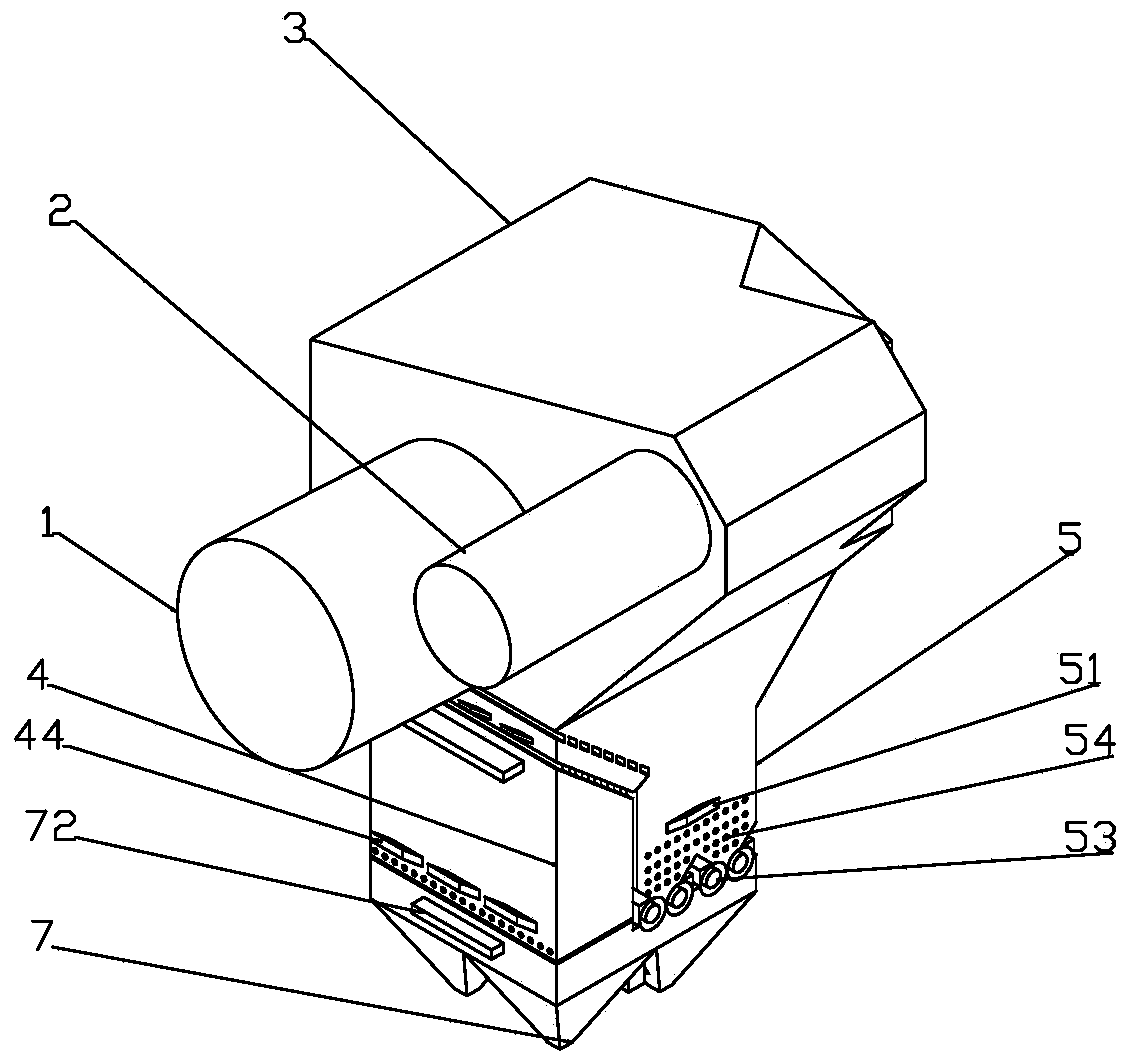

Catalyst unpacking and conveying and dust removing system and method for FCC (Fluid Catalytic Cracking) device

InactiveCN102837863ASolve the problem of energy consumptionSolve the noiseArticle unpackingBulk conveyorsVacuum pumpingAutomatic control

The invention belongs to the technical field of petrochemical engineering, and particularly provides a catalyst unpacking and conveying and dust removing system and method for an FCC (Fluid Catalytic Cracking) device. The catalyst unpacking and conveying and dust removing system comprises a dustproof unpacking system, a lifting system, a dust removing system and an automatic control system. With the adoption of the system and the method provided by the invention, the non-dust unpacking and dense phase automatic conveying of a catalyst can be achieved; the traditional conveying method of steam vacuum pumping is completely removed; and meanwhile, an efficient catalyst dust removing system based on a 316L stainless steel hybrid knitting filtering bag is adopted to replace the traditional cyclone separator; the dust removing efficiency can be increased to 99.99%. The system and the method have the advantages of low catalyst loss and relatively low running cost; and the method is a catalyst conveying and powder dust removing technology with a wide application prospect.

Owner:BEIJING LIKONPEC TECH

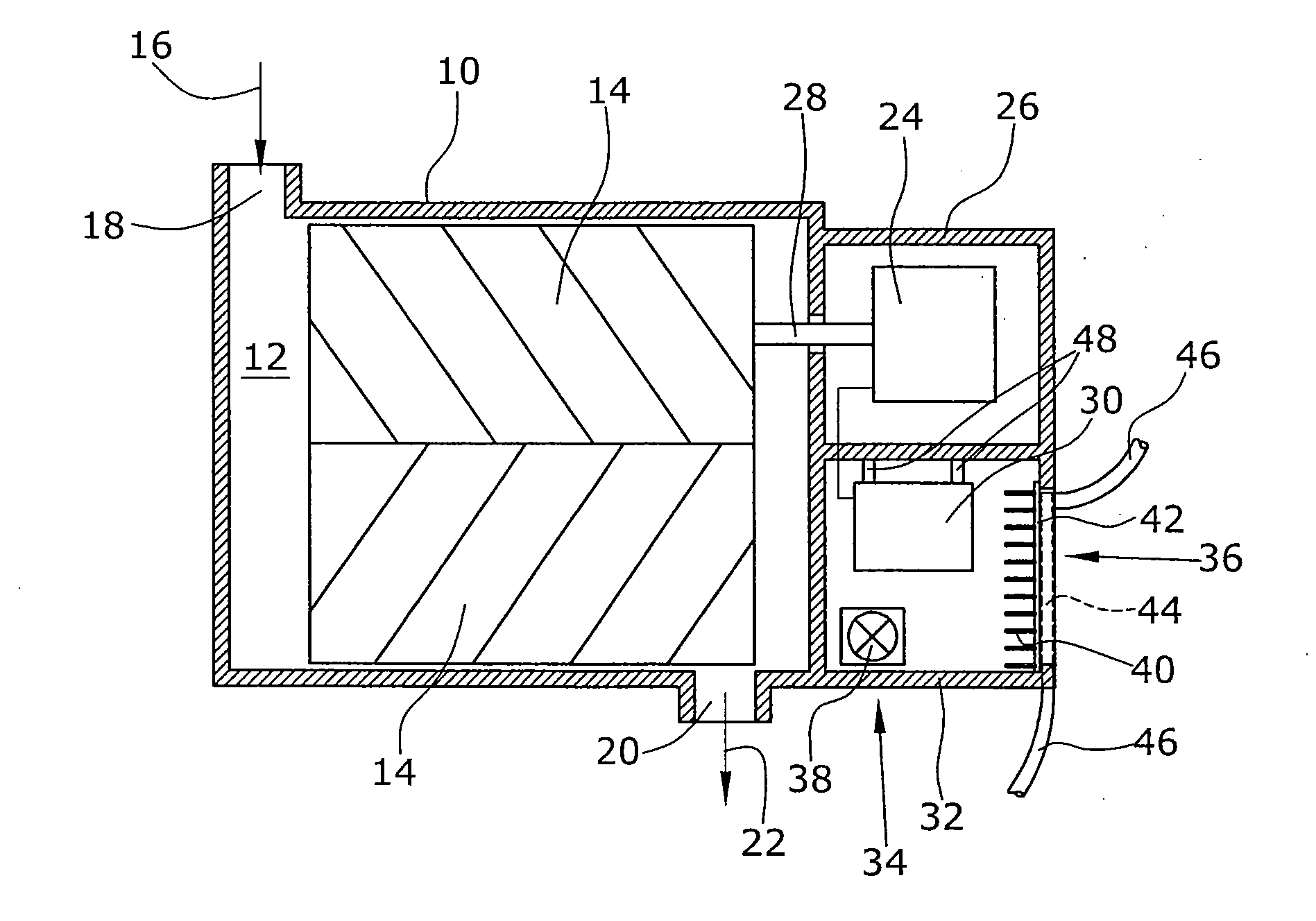

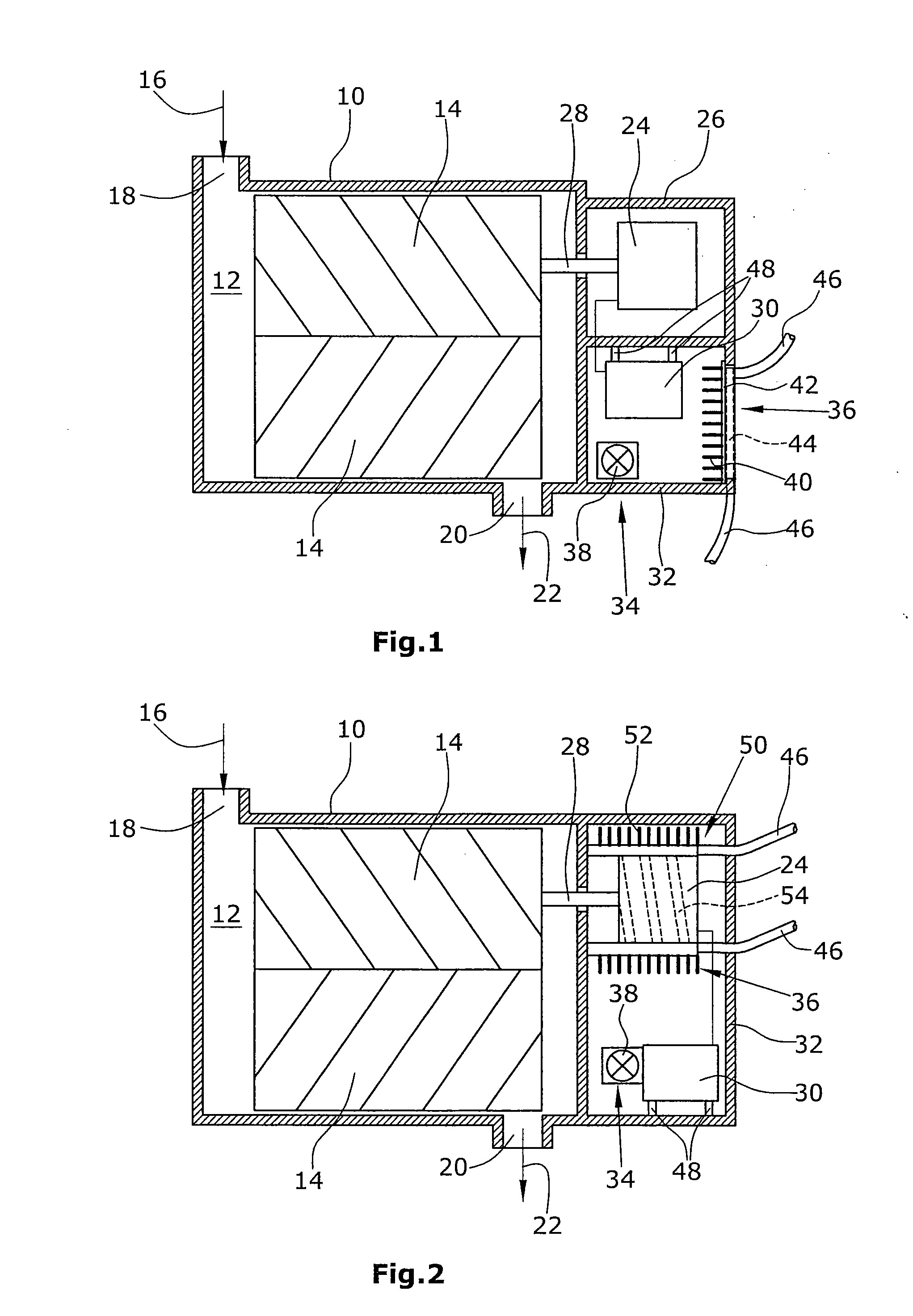

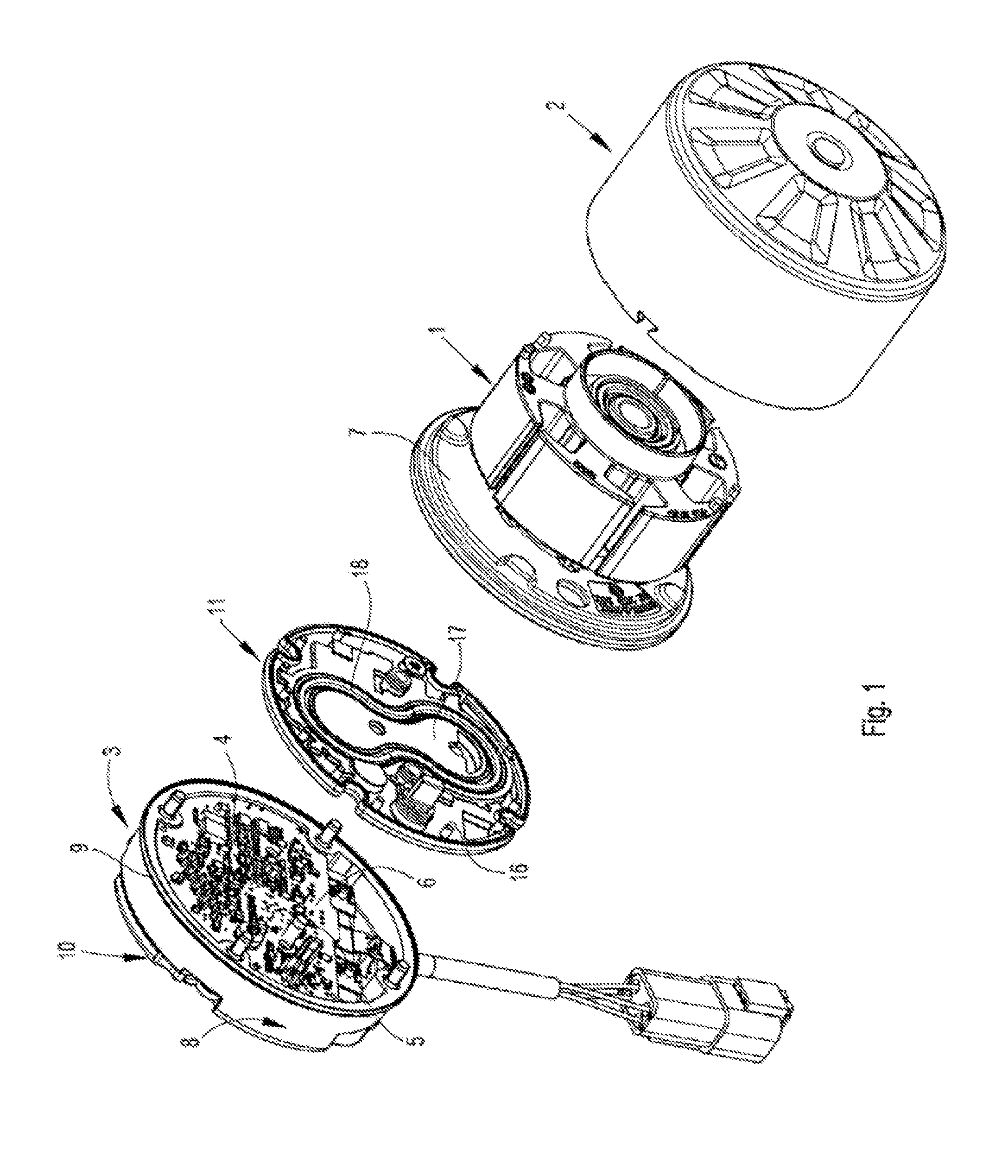

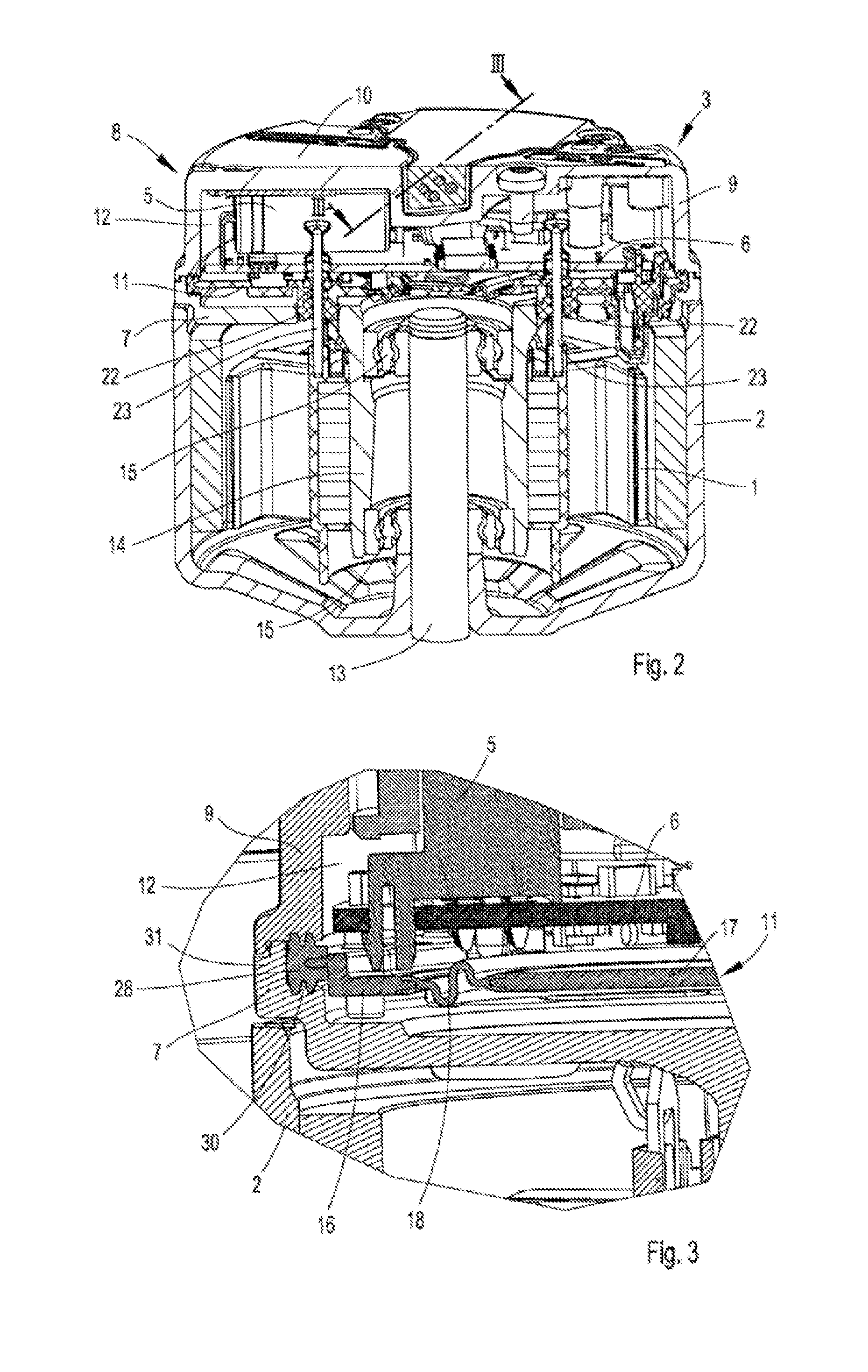

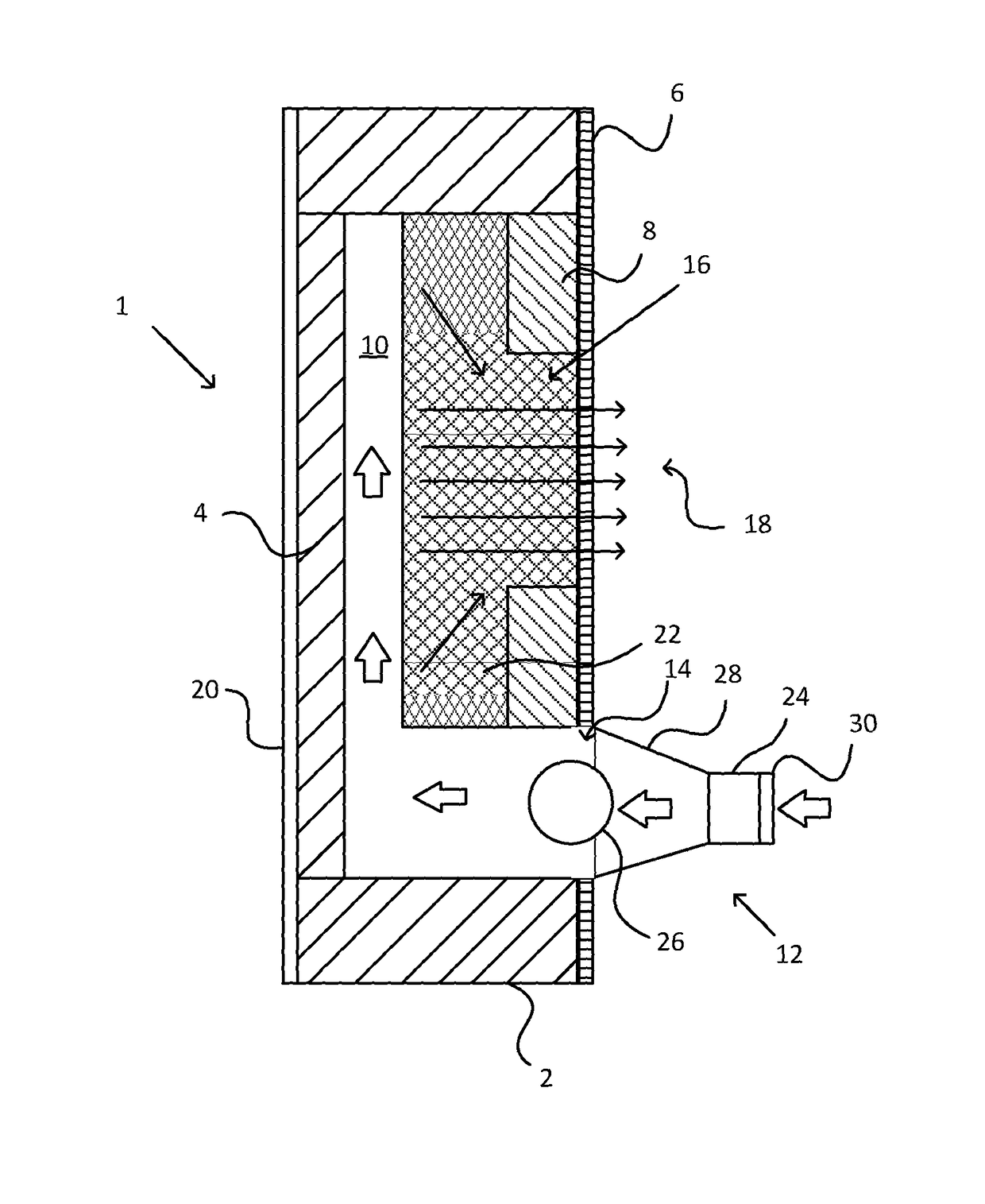

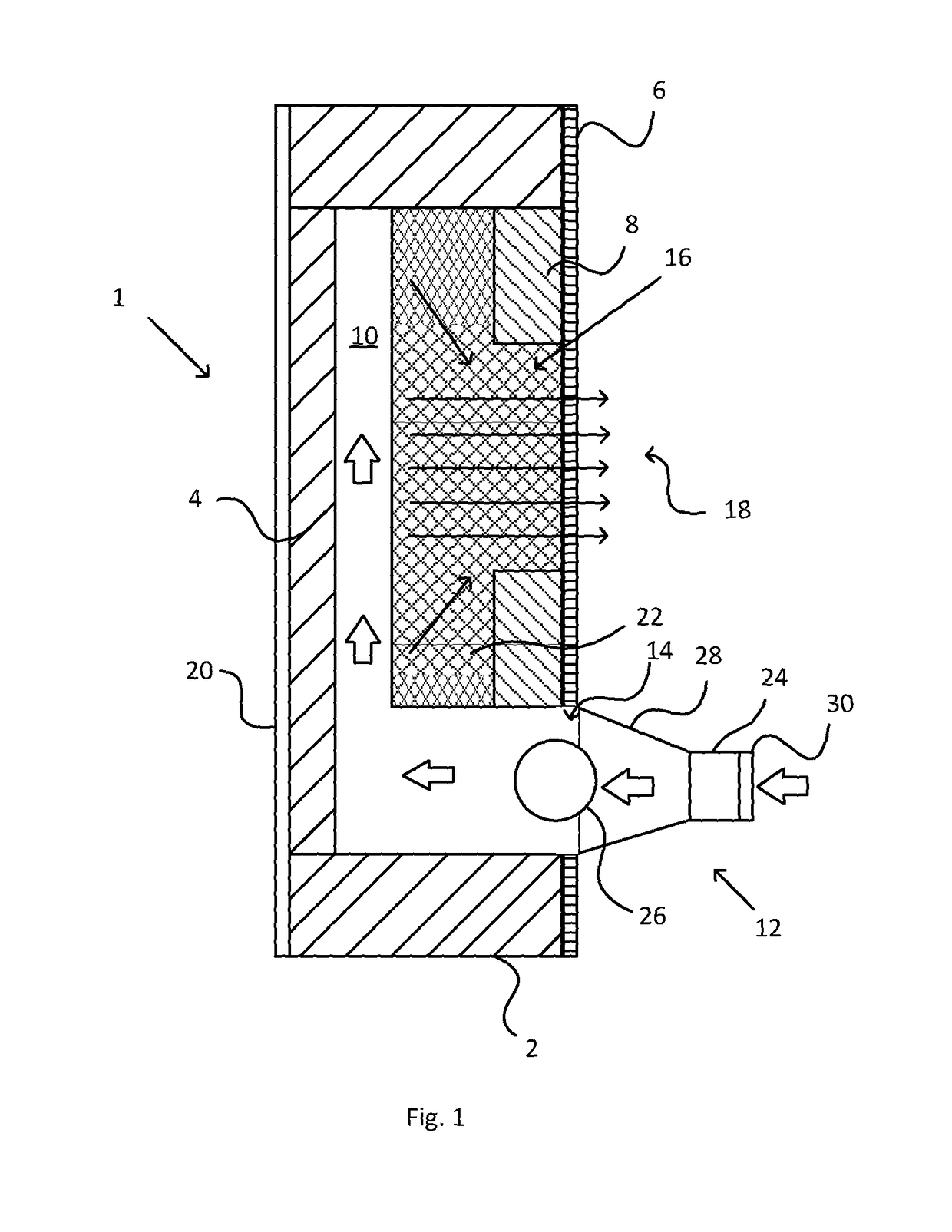

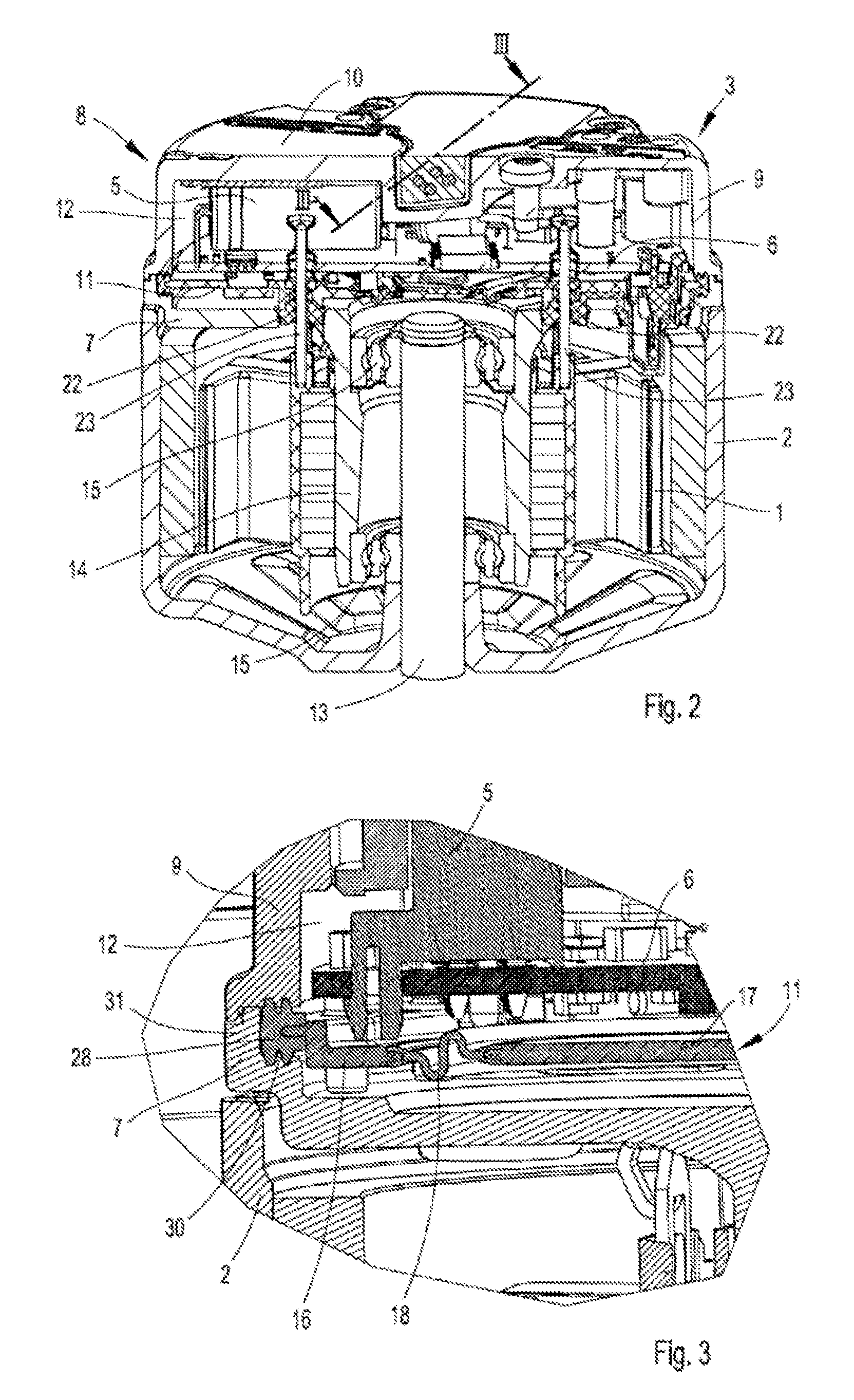

Vacuum pump

ActiveUS20120315165A1Improve cooling effectAvoid vibrationRotary piston pumpsRotary piston liquid enginesFrequency changerPump chamber

A vacuum pump comprises pumping elements arranged in a pumping chamber. An electric motor drives the pumping element. A frequency inverter is provided for changing the rotational speed of the electric motor. The frequency inverter is arranged in a frequency inverter housing immediately connected to the pump housing. An air cooler and a liquid cooler are arranged in the frequency inverter housing to cool the frequency inverter.

Owner:LEYBOLD HERAEUS GMBH & CO KG

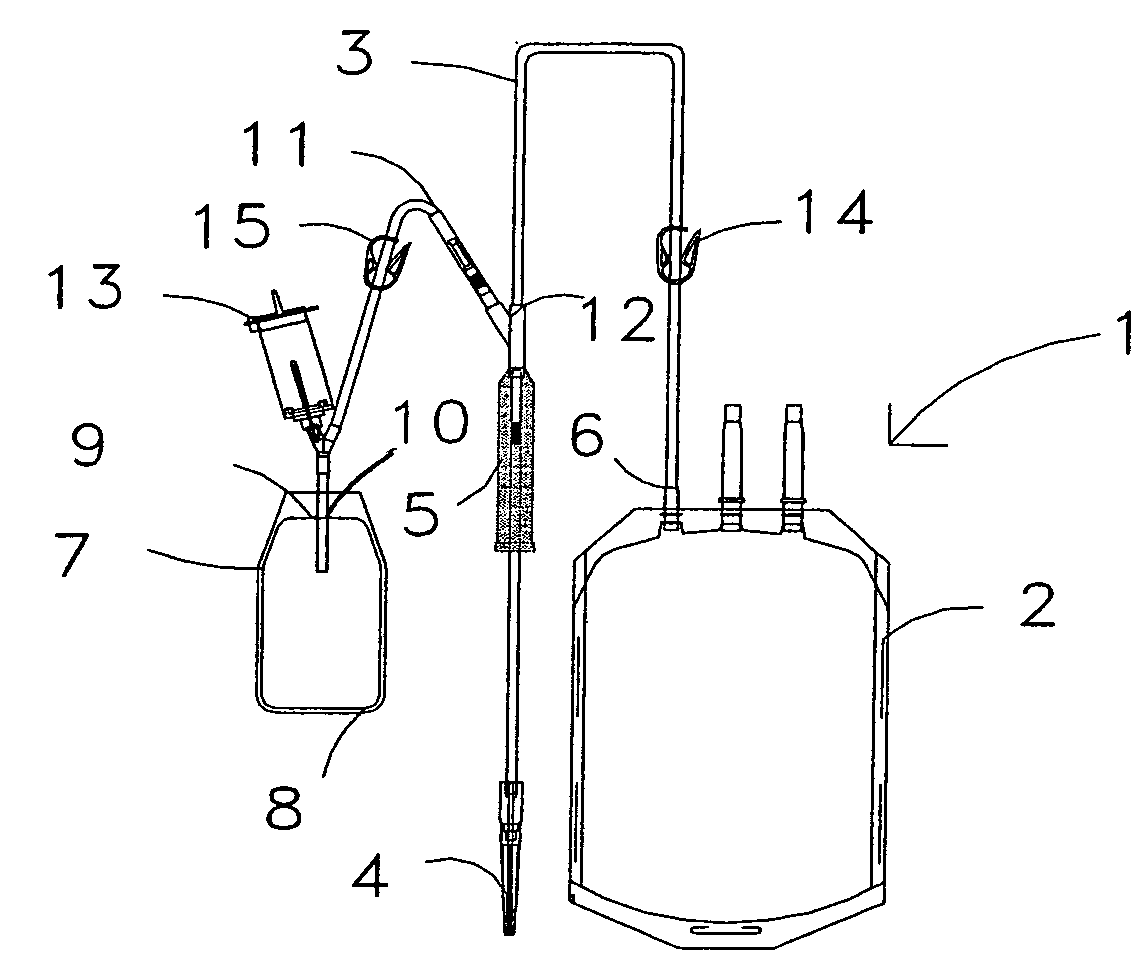

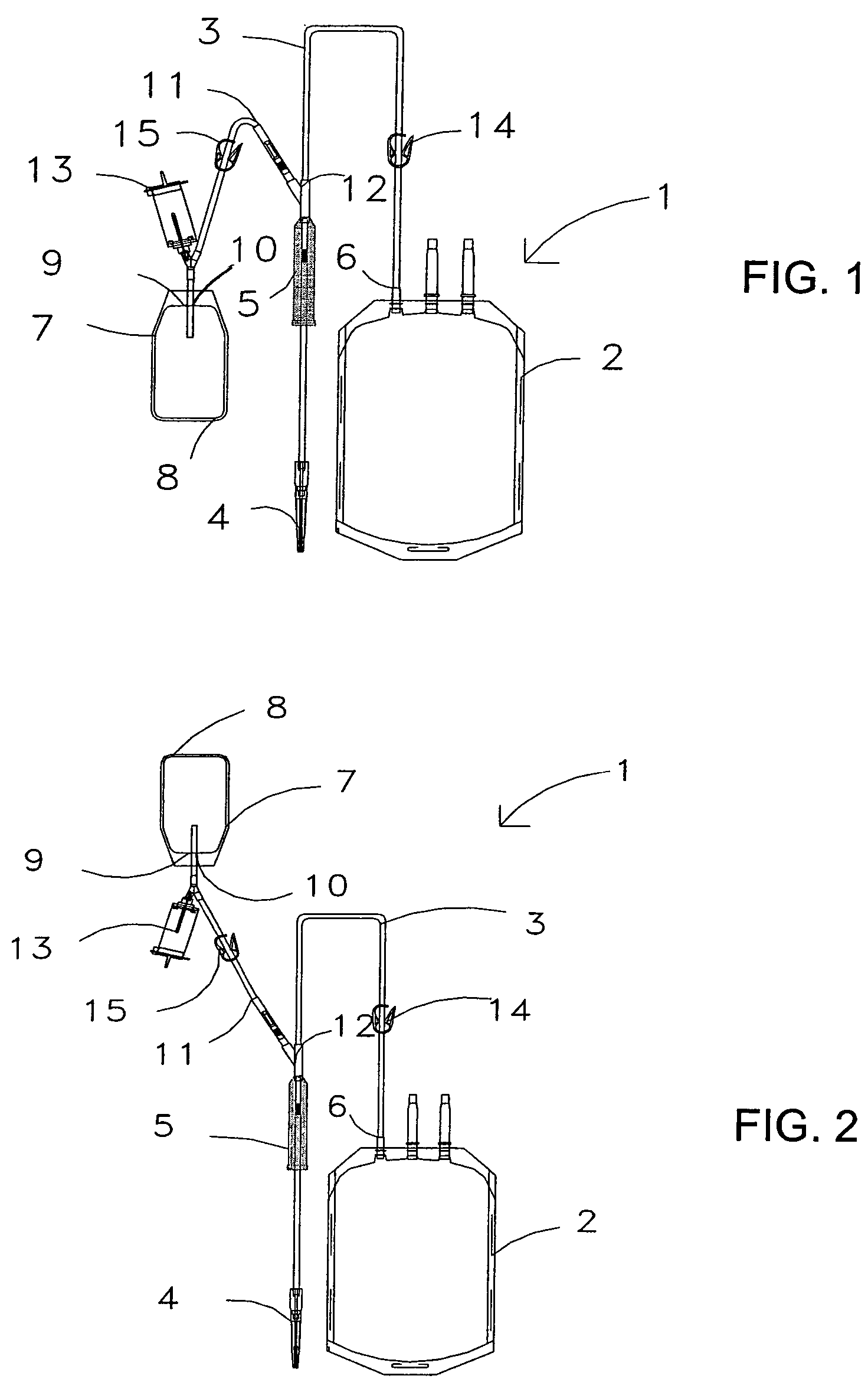

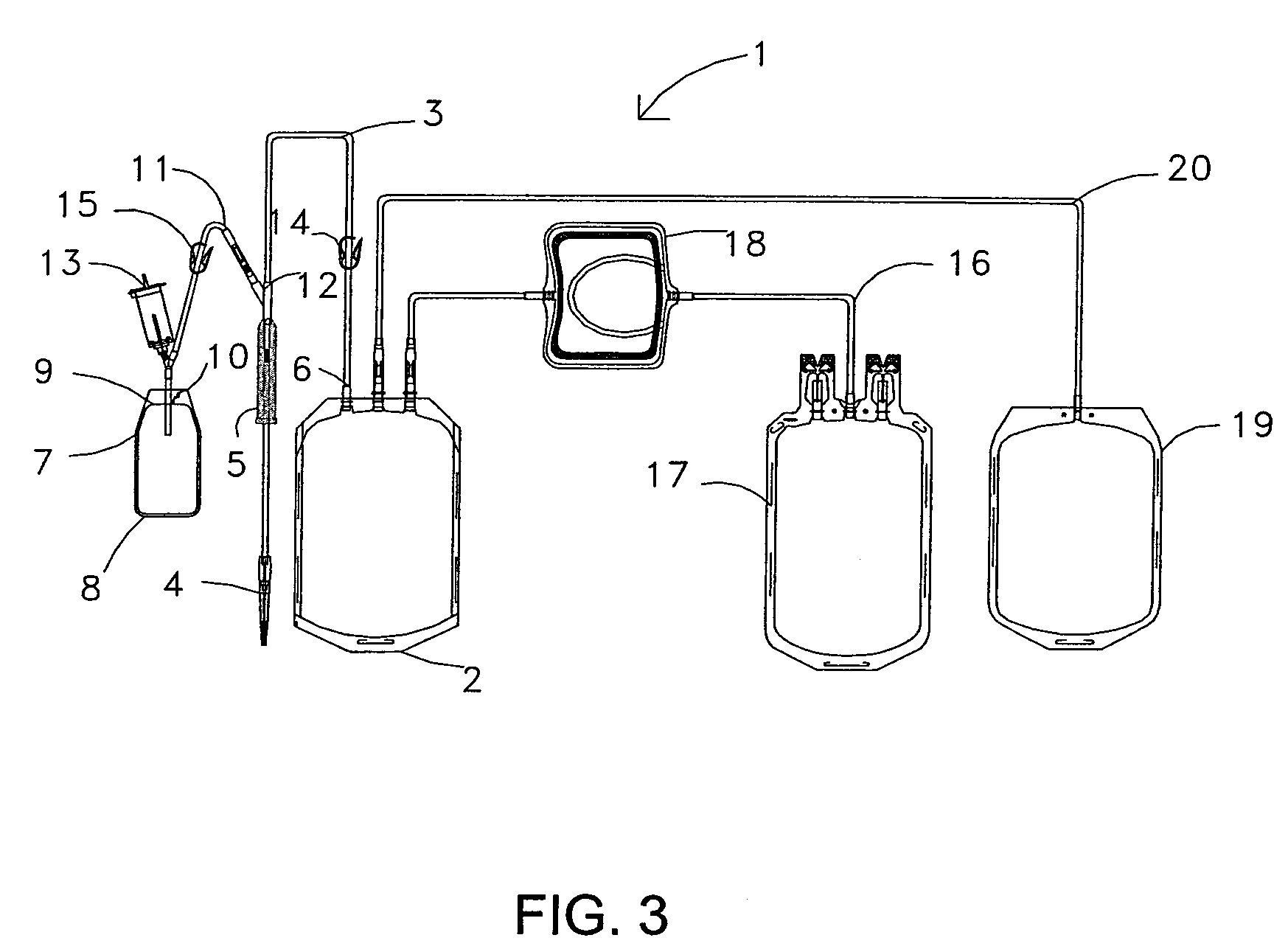

Bag system for collecting and sampling a biological fluid

InactiveUS7306583B2Small air volumeDampens volume of airOther blood circulation devicesDiagnosticsEngineeringBiological fluids

A bag system for the collection and sampling of a biological fluid such as blood is described. The system may include a fluid collection bag and a first tube connected on one end to a collection means and on the other end to the collecting bag. It may also include a flexible sampling bag defining an internal volume having a bottom side and an introduction side which is opposite to the bottom and has an inlet orifice. The system also has a second tube, a first end part of which is connected to the first tube and a second end part of which is inserted in the inlet orifice of the sampling bag, so as to extend inside the sampling bag over a distance of between 25% and 60% of the distance between the bottom and the introduction side of the internal volume of the sampling bag.

Owner:MARCO PHARMA

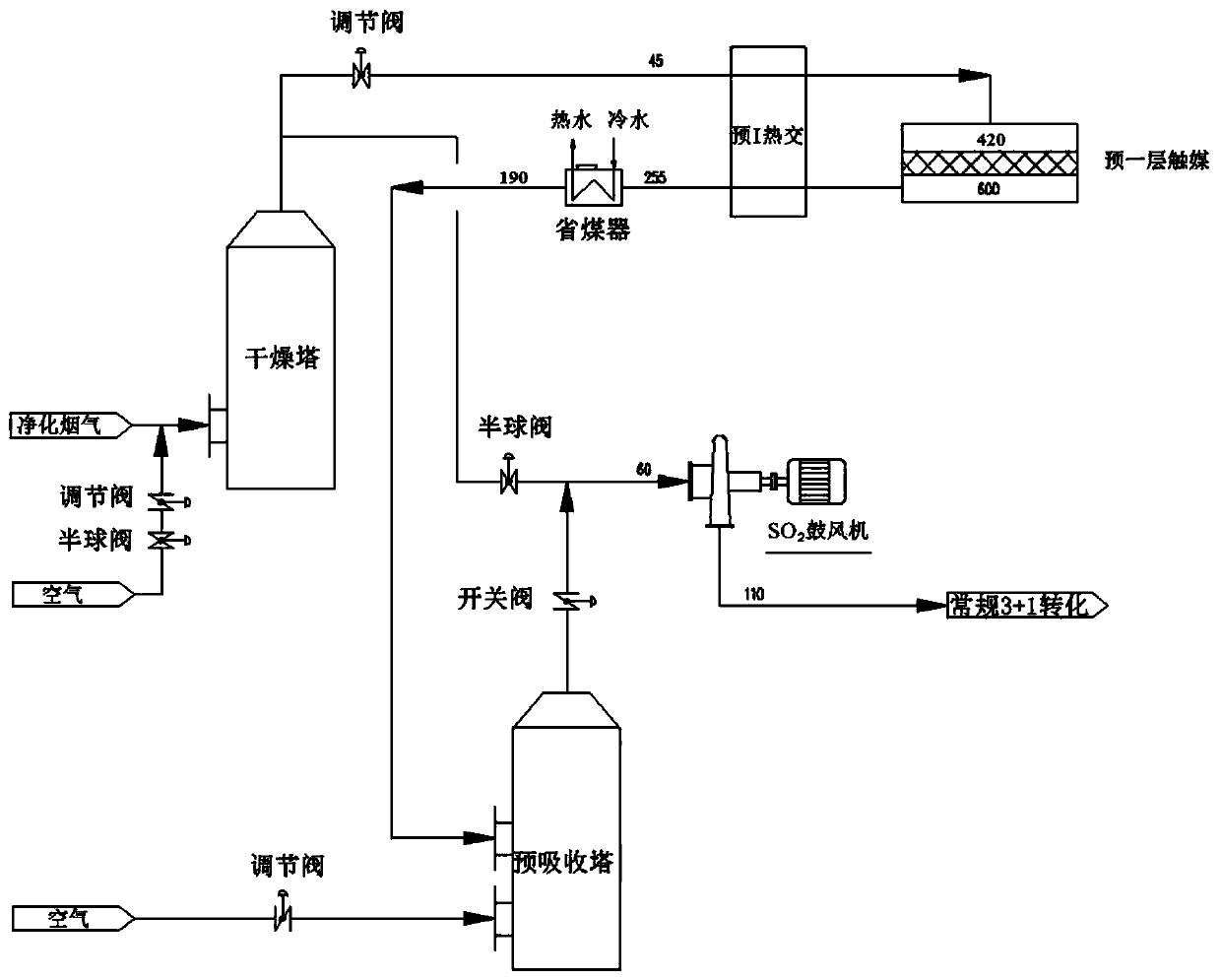

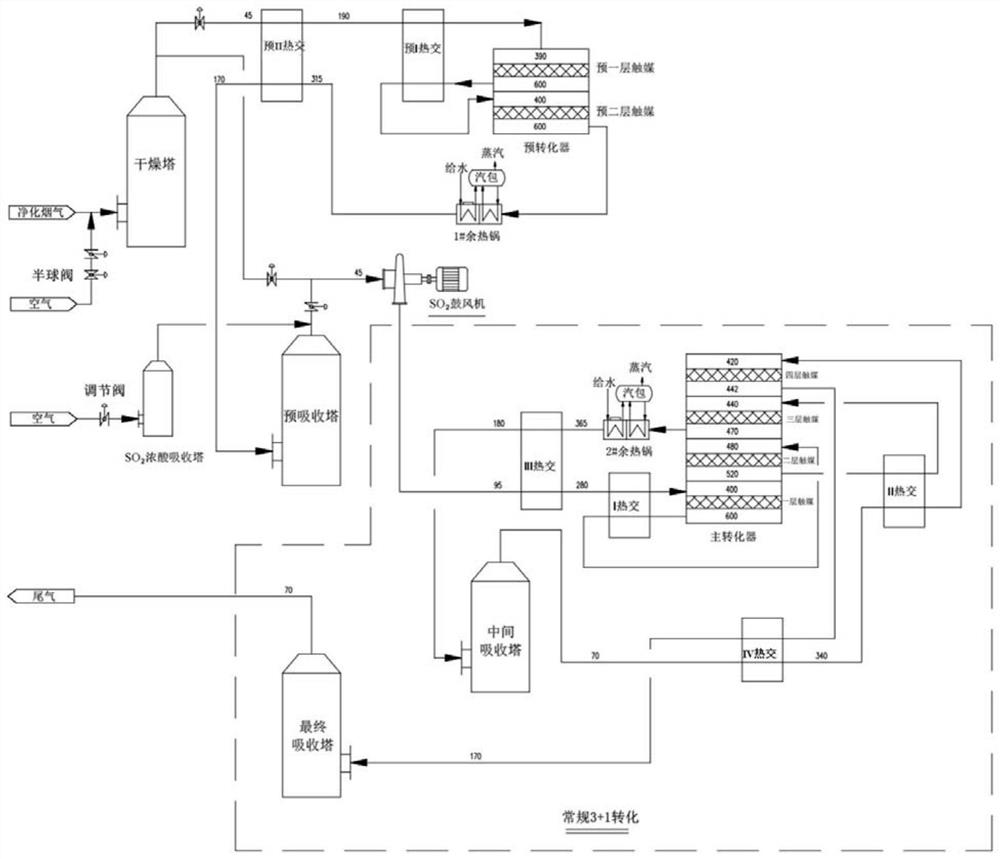

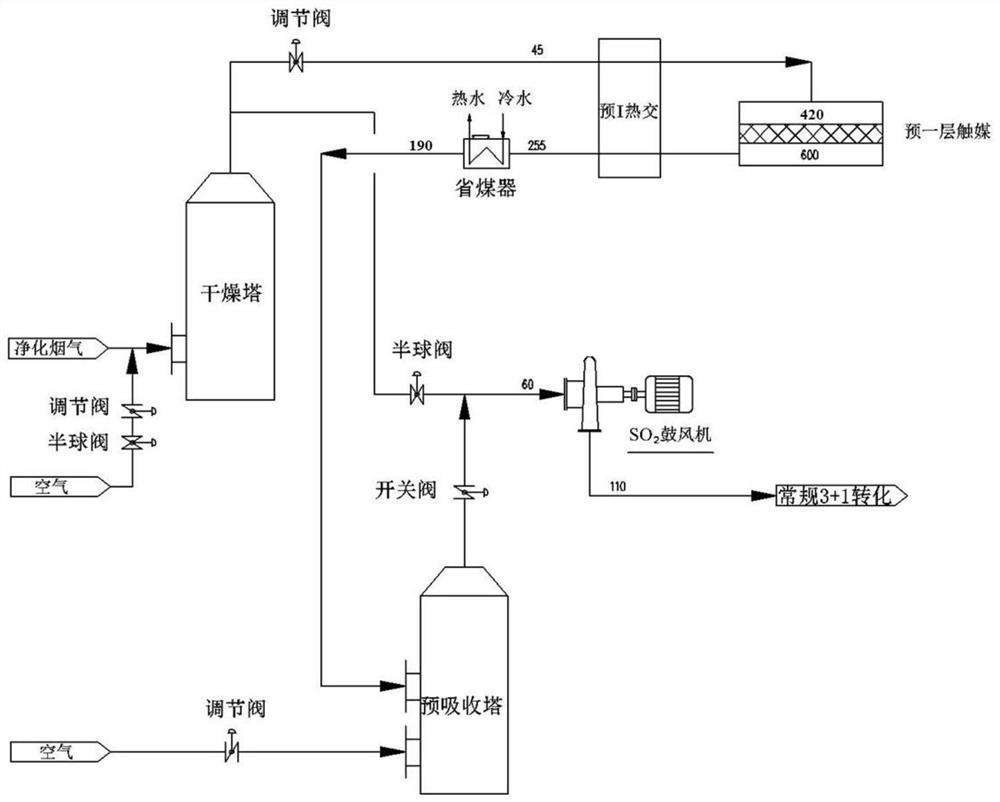

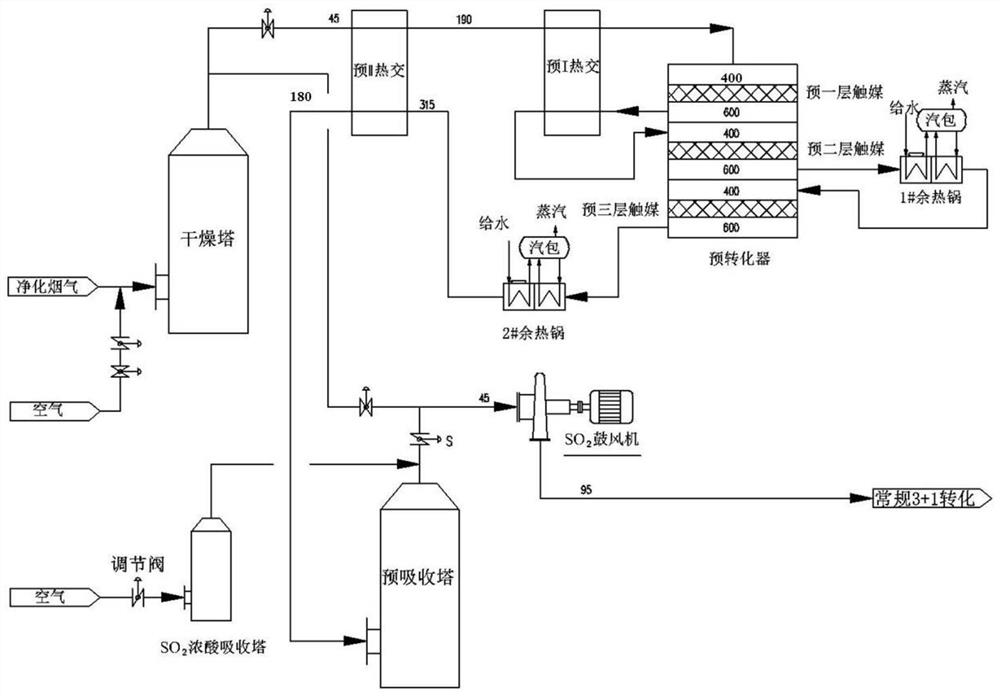

High concentration SO2 conversion acid making technology

ActiveCN109761203AAvoid problems such as complex chain controlHelps control conversion rateSulfur compoundsComing outHigh concentration

The invention discloses a high concentration SO2 conversion acid making technology, and belongs to the technical field of sulfur recycling. The technology comprises the following steps that (1) O2 doped purified wet smoke enters a drying tower to be dehydrated, and then enters a pre-heating exchanger to be heated to preset temperature; (2) the heated purified smoke enters pre-converter catalyst layers to react, SO2 concentration drops by 7% when the smoke passes through each catalyst layer of the pre-converter, and the smoke temperature at the outlet layer is controlled to be lower than 620 DEG C for smoke with arbitrary SO2 concentration at apre-conversion inlet; and (3) the smoke coming out from the pre-converter is cooled to set temperature, first absorption acid making is conducted after the smoke enters a pre-absorption tower, and the smoke absorbing SO3 and with air being distributed enters a traditional SO2 conversion acid making system. The technology is simple, has low requirements on working conditions that equipment such as draught fans and converters need to adapt to, and is a high concentration SO2 conversion technology easy to achieve.

Owner:CINF ENG CO LTD

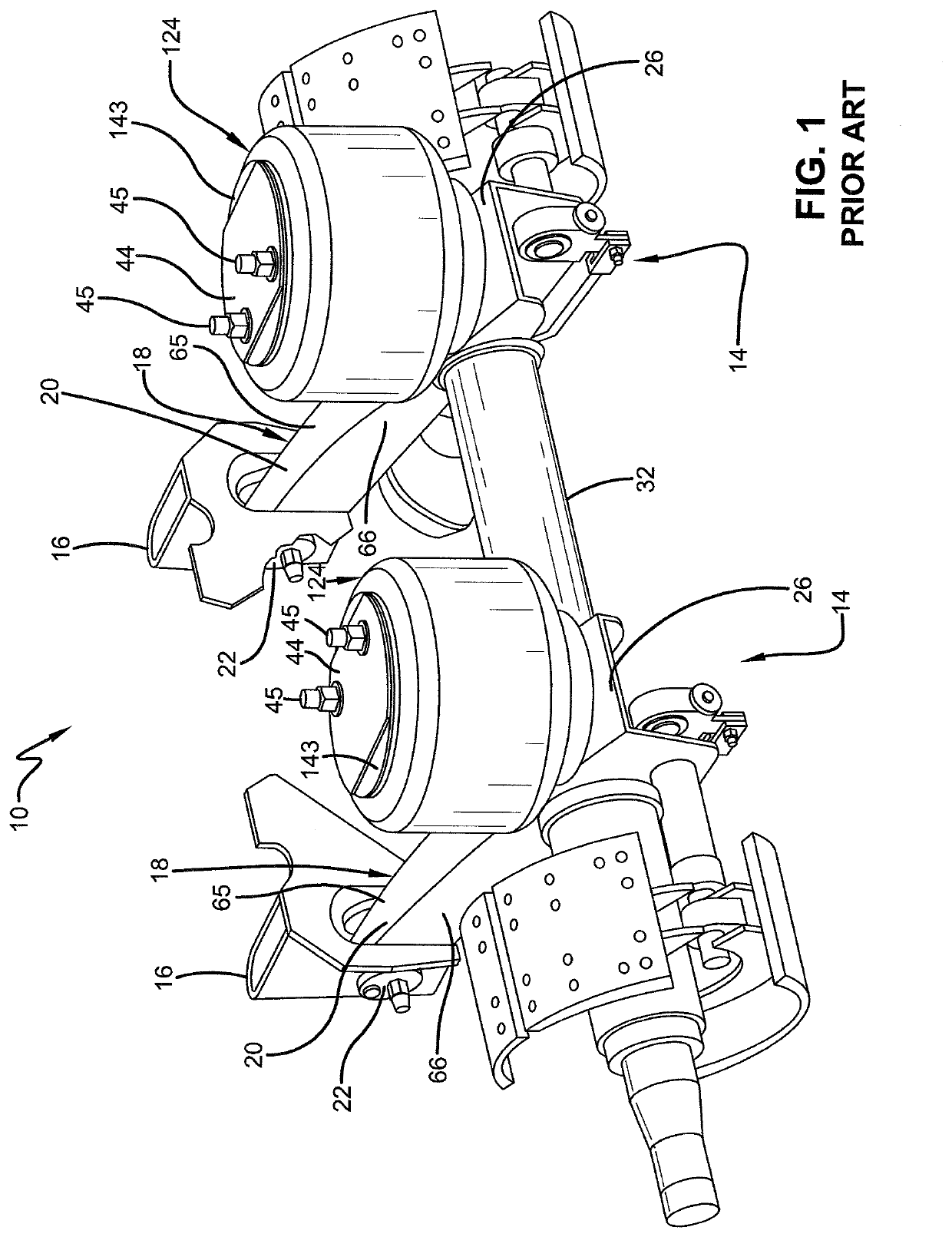

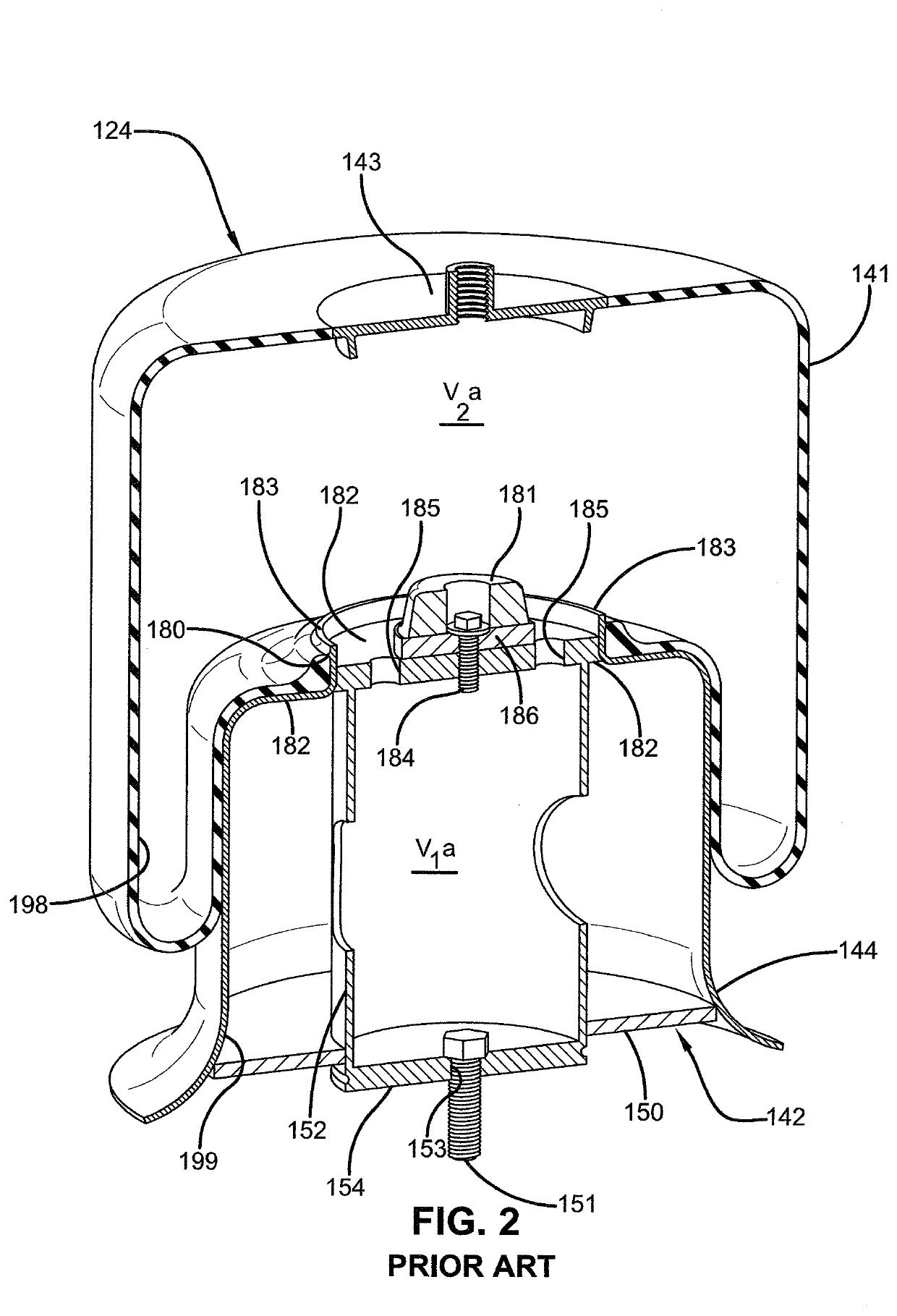

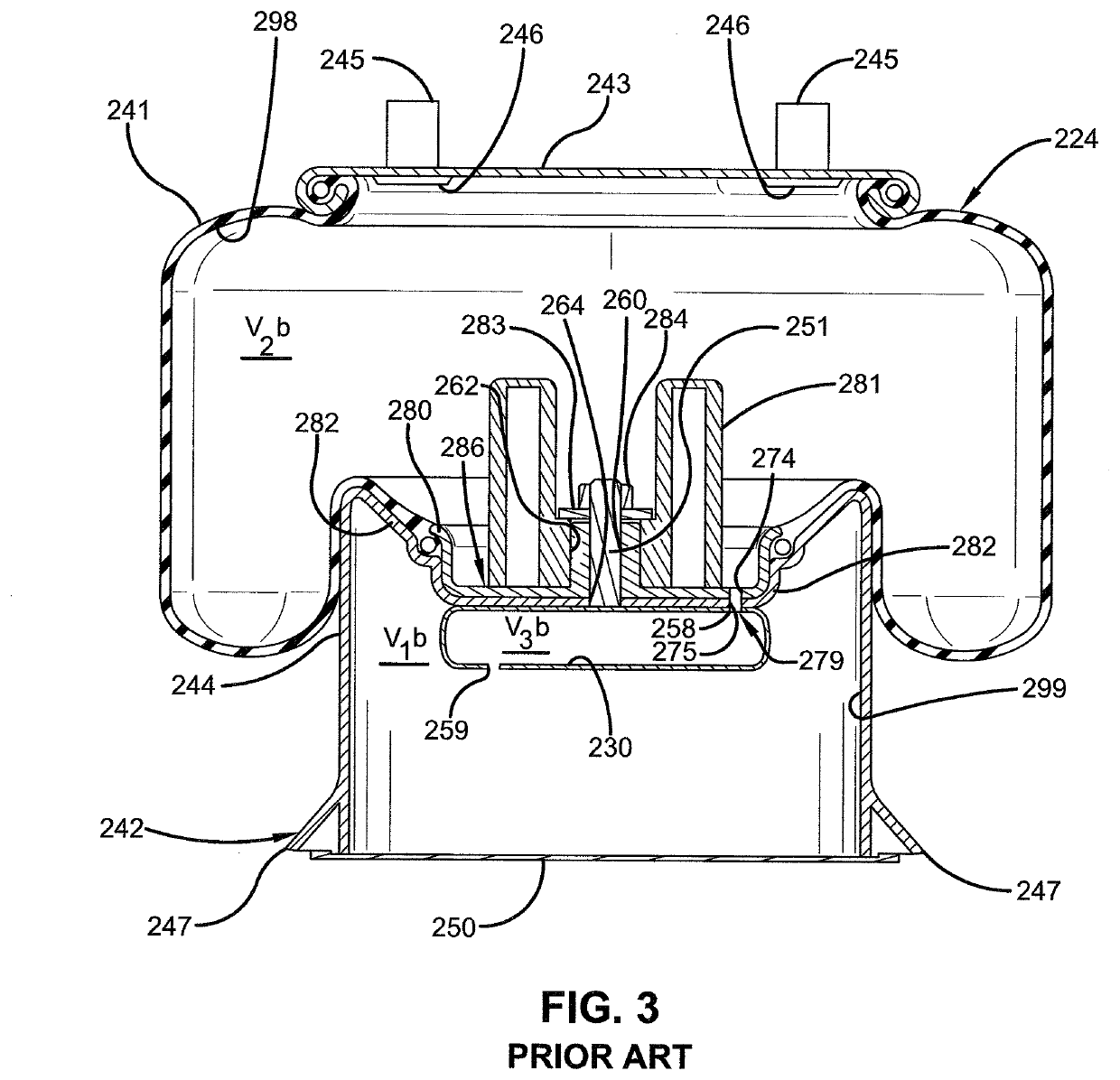

Damping air spring with substantially fixed volume

InactiveUS20190351727A1Reduced frequency dependenceLow costSpringsResilient suspensionsAir springEngineering

An air spring with damping characteristics for a suspension assembly of a heavy-duty vehicle includes a bellows chamber, a piston chamber, an intermediate chamber, and a first and second means for providing restricted fluid communication. The intermediate chamber is disposed at least partially within the bellows chamber and operatively connected to the bellows chamber and the piston chamber. The first means for providing restricted fluid communication is located between the bellows chamber and the intermediate chamber. The second means for providing restricted fluid communication is located between the piston chamber and the intermediate chamber. The first and second means for providing restricted fluid communication provide damping characteristics to the air spring during operation of the heavy-duty vehicle.

Owner:HENDRICKSON USA L L C

Method for stepwise cooling cement clinker

The invention provides a method for stepwise cooling a cement clinker. The method is characterized by comprising steps of (1) first-stage quick cooling; (2) clinker crushing; and (3) second-stage conventional cooling. The cooling method comprises first-stage cooling and second-stage cooling, and the cooling volume of the two cooling stages can be controlled independently, so that the stability of the system is improved, and air mixing among air openings can be avoided; air entering a first-stage cooler is subjected to heat exchange to form high-temperature hot air which is completely used for supplying secondary and tertiary air for a system, wherein the average temperature after the secondary air and the tertiary air are mixed can be more than 1050 DEG C, so that the heat recovery efficiency of the cooler can be over 85 percent; a crushing step is executed before second-stage cooling, so that the contact area of the clinker and cooling air in a second-stage cooler can be increased, the air entering the second-stage cooler is only 0.6-0.8Nm<3> / kg.cl, and the air volume is remarkably reduced; furthermore, the temperature of formed hot air is remarkably increased, so that caloric content in the clinker is recycled as much as possible; and the total cooling air volume in the two cooling stages can be controlled under 1.5Nm<3> / kg.cl, and the total air volume is remarkably reduced.

Owner:SINOMA TECH & EQUIP GRP

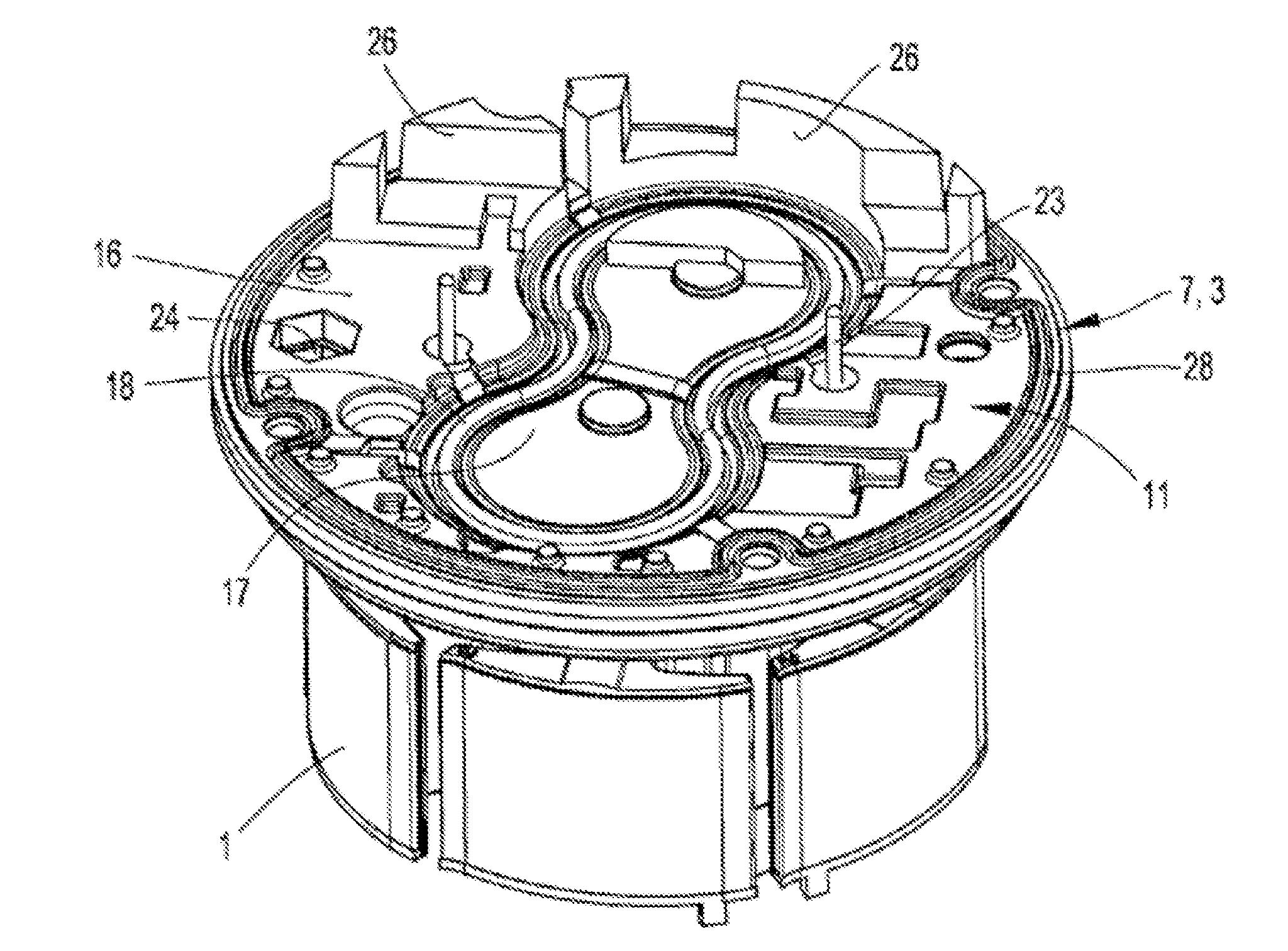

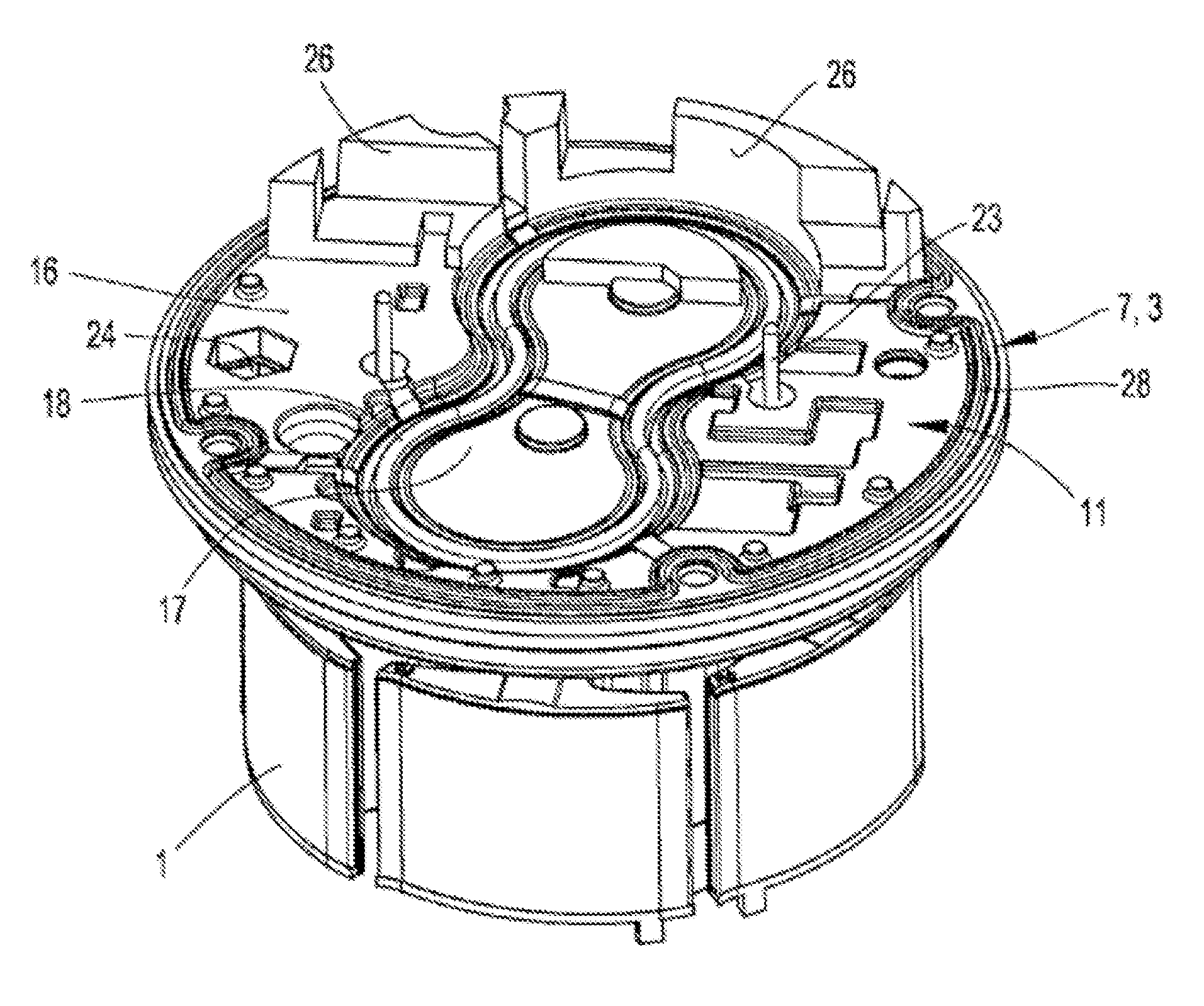

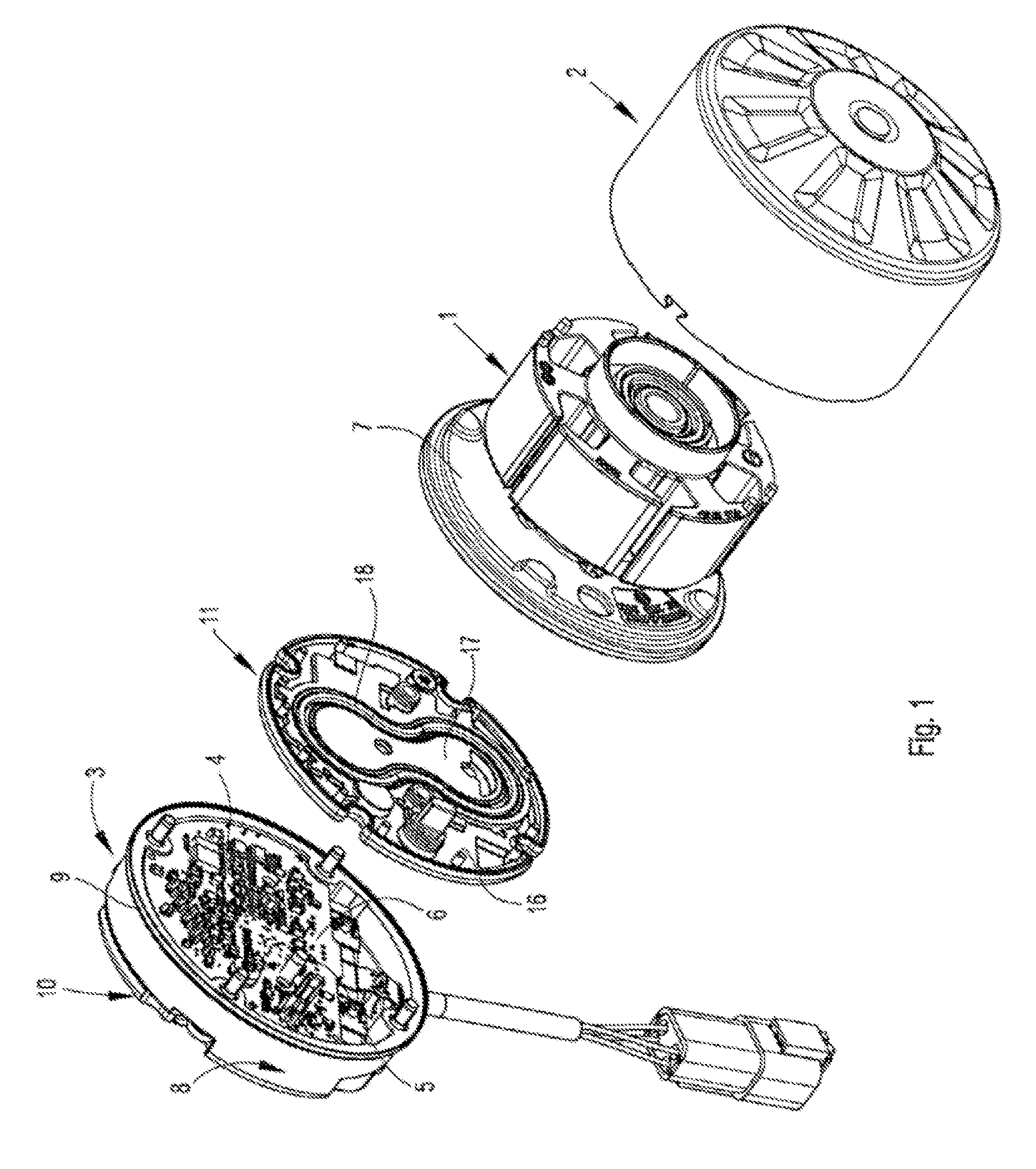

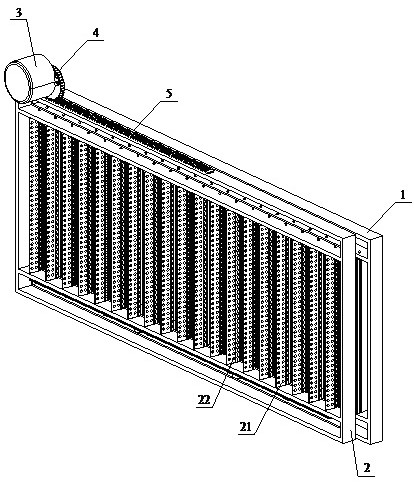

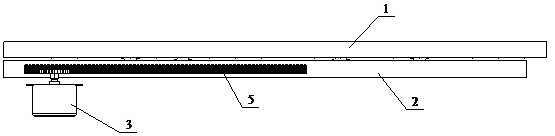

Housing for Accommodating an Electronic Circuit

ActiveUS20140252898A1Small air volumeReduce air volumeAc network load balancingPower oscillations reduction/preventionEngineeringAtmosphere

A housing for receiving an electronic circuit (4) having a plurality of components (5) having a carrier plate (7) and a housing cover (8) including a circumferentially enclosing wall (9) on the carrier plate (7) and a cover part (10) on the wall (9), which cover part (10) lies opposite the carrier plate (7). A volume compensation element (11) is attached on the carrier plate (7) in an interior (12) of the housing cover (8) which is enclosed in a pressure-tight manner from an external atmosphere. The volume compensation element (11) is elastically formed providing a variable volume for compensation of pressure fluctuations in the interior (12), which variable volume occurs with a change in position of the volume compensation element (11) relative to the carrier plate (7). A gap between the volume compensation element (11) and the carrier plate (7) is connected to the external atmosphere.

Owner:EBM PAPST MULFINGEN GMBH & CO KG

Method for preparing elastic and glossy dacron drawing yarns with potential crimps

InactiveCN102912460ACool evenlyHas natural curly propertiesMelt spinning methodsStretch-spinning methodsFiberYarn

The invention relates to a method for preparing elastic and glossy dacron drawing yarns with potential crimps. A glossy polyester melt is used as a raw material. The method comprises the steps of 1, conveying the raw material to a spinning box, and forming melt-shaped fibers after measurement and the filtration of a spinning assembly; 2, after solidifying the melt to as-spun fibers, dividing the fibers into two groups, cooling one group of fibers by a side blowing device, arranging one group of heating devices in front of an air inlet of the side blowing device, arranging one group of steam pipelines in the heating devices, controlling an air temperature between 32 DEG C and 40 DEG C, controlling a side blowing speed at 0.5-0.8 m / s, and conveying the other group of fibers to an air-free device, wherein the length of an air-free zone of a spinneret plate is 150 mm, and the air pressure of a side blower is set to 480-600 pa; and 3, after applying oil with an oil nozzle, respectively combining two groups of filaments with crystallization difference by a pre-interlacer in a one-to-one way, then increasing interlacing points by a first hot godet, a second hot godet and a main interlacer, and finally winding and molding by a winder head.

Owner:张家港欣欣高纤股份有限公司

Combustion-supporting method of rotary cement kiln burner oxygen enrichment device

ActiveCN104048502AIncrease burn rateHigh catalytic efficiencyRotary drum furnacesIndirect carbon-dioxide mitigationRefractoryEngineering

The invention discloses a combustion-supporting method of a rotary cement kiln burner oxygen enrichment device. The rotary cement kiln burner oxygen enrichment device consists of a kiln head outer layer pipeline, a kiln head outer layer air inlet pipe orifice, a kiln head coal layer current pipeline, a kiln head pulverized coal wind current pipeline, a kiln head coal wind pipeline, a kiln head inner wind pipeline, a kiln head inner wind air inlet pipe orifice, a kiln head oil pipeline, an oil nozzle, kiln head refractory concrete and a kiln head oxygen enrichment air flue, wherein the oxygen enrichment air flue is arranged between the kiln head outer layer air inlet pipe orifice and the kiln head inner wind air inlet pipe orifice; an air inlet of oxygen enrichment is preserved in the pipe end of the kiln head oxygen enrichment air flue in the kiln head outer layer air inlet pipe orifice; when the oxygen enrichment in the kiln head outer layer pipeline and the oxygen enrichment in the kiln head inner wind pipeline enter a rotary cement kiln together with pulverized coal wind current simultaneously, the temperature of a combustion field of the rotary cement kiln input with the oxygen enrichment can reach over 1700 DEG C, before free carbon in the combustion field with the temperature of over 1700 DEG C forms black smoke, the free carbon is thoroughly burned, and the free carbon becomes combustive fuel; meanwhile, the clinker catalyst of cement is subjected to oxidation combustion by the input of the oxygen enrichment; when the temperature of the combustion field is over 1700 DEG C, CO in the combustion field is burned, and the emission of NOx is reduced by 35%.

Owner:河南嘉和节能科技有限公司

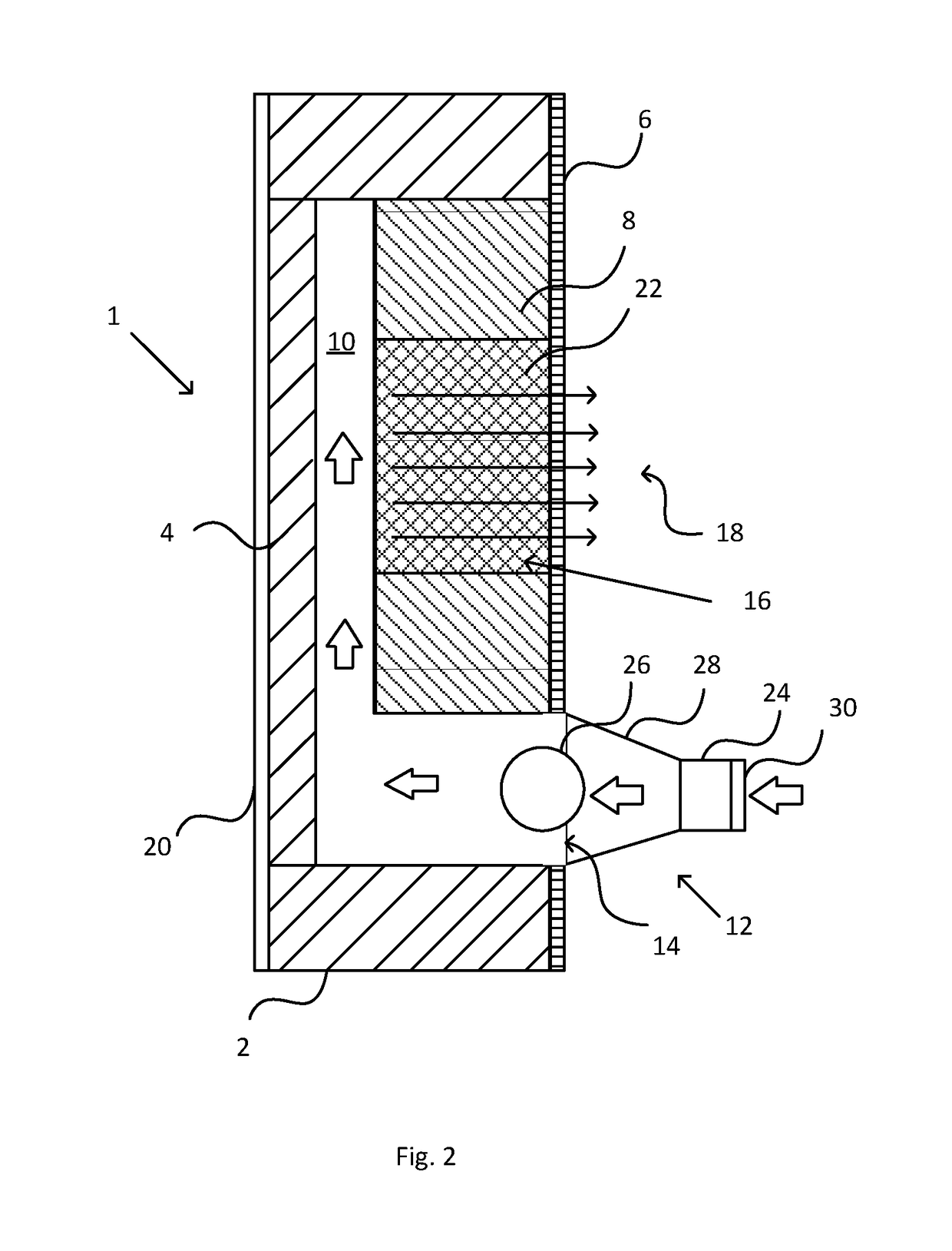

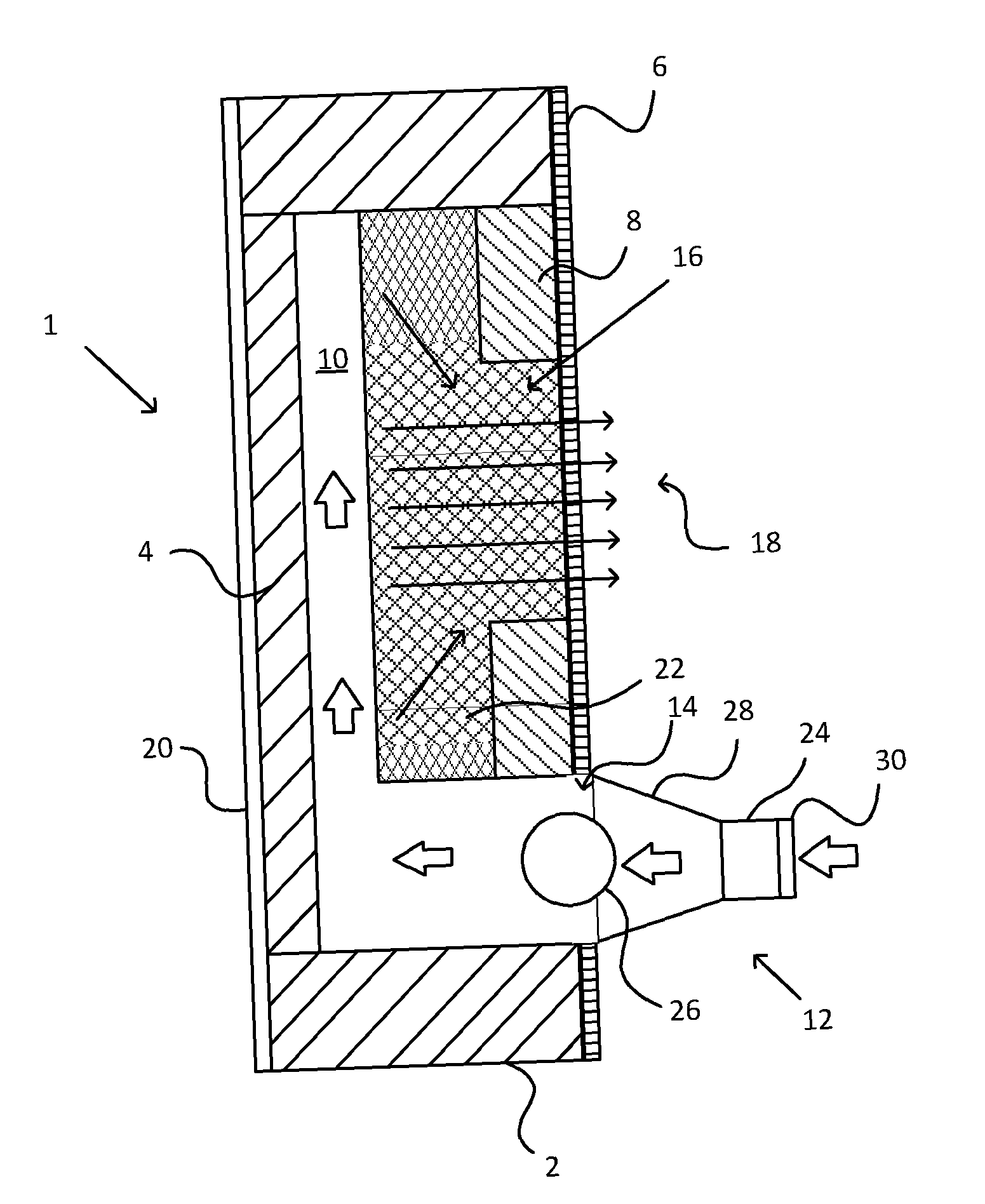

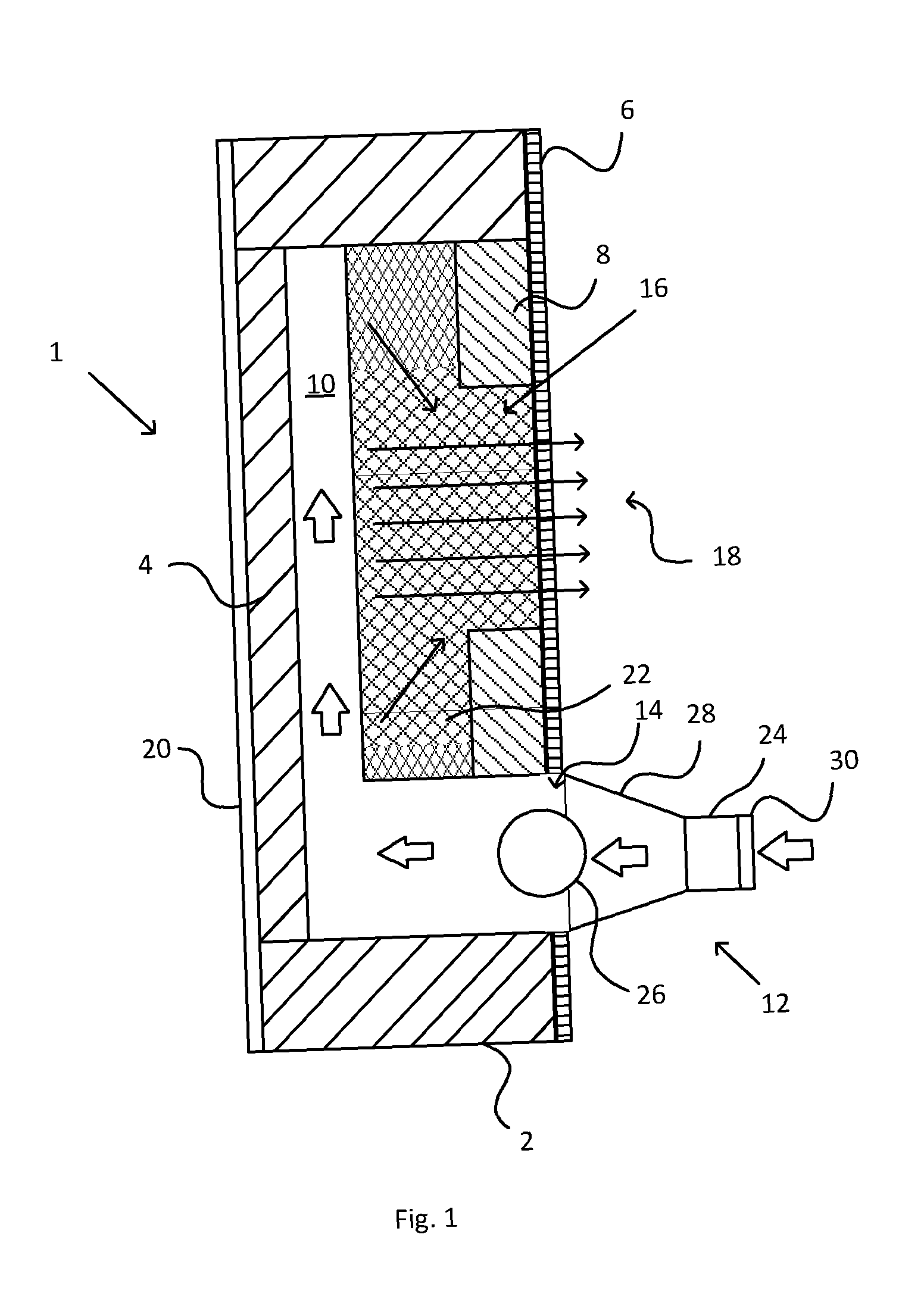

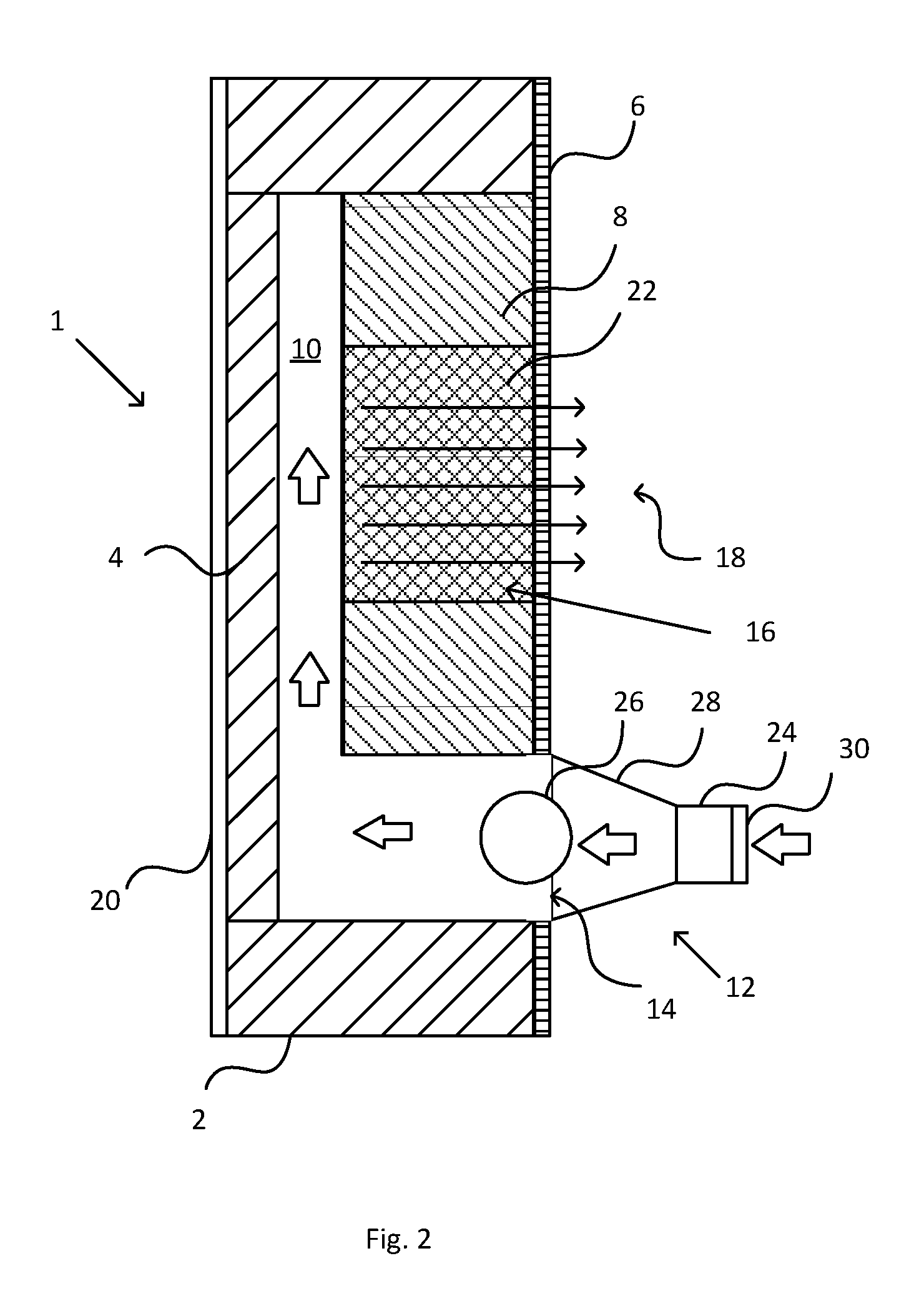

Sound dampening device

ActiveUS10034550B2Improve the indoor environmentEfficient sound dampeningNoise suppressionBedsEngineering

Owner:ARTEX LTD

Sound dampening device

ActiveUS20160066699A1Improve indoor environmentImprove the indoor environmentSofasNoise suppressionEngineering

Owner:ARTEX LTD

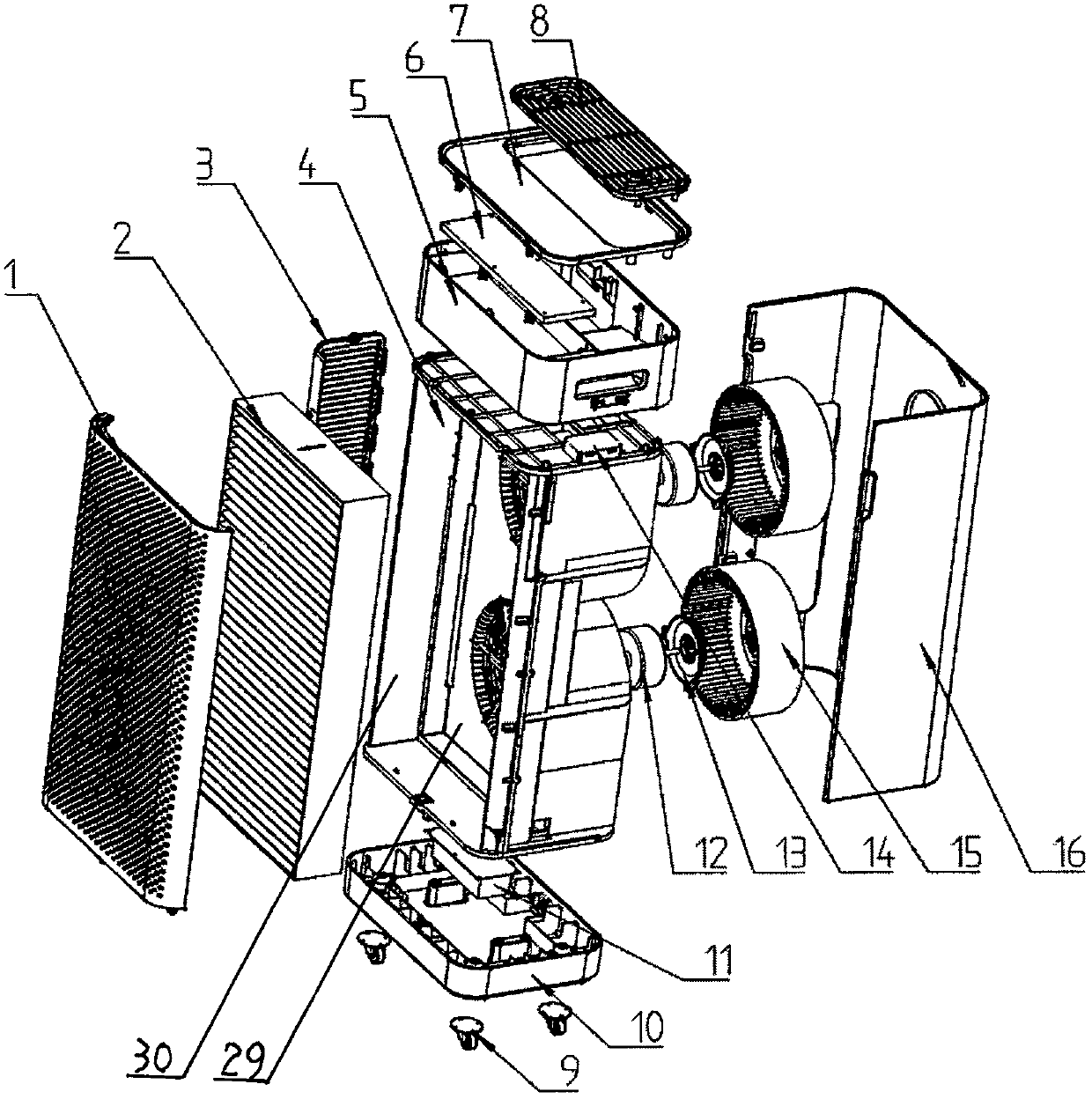

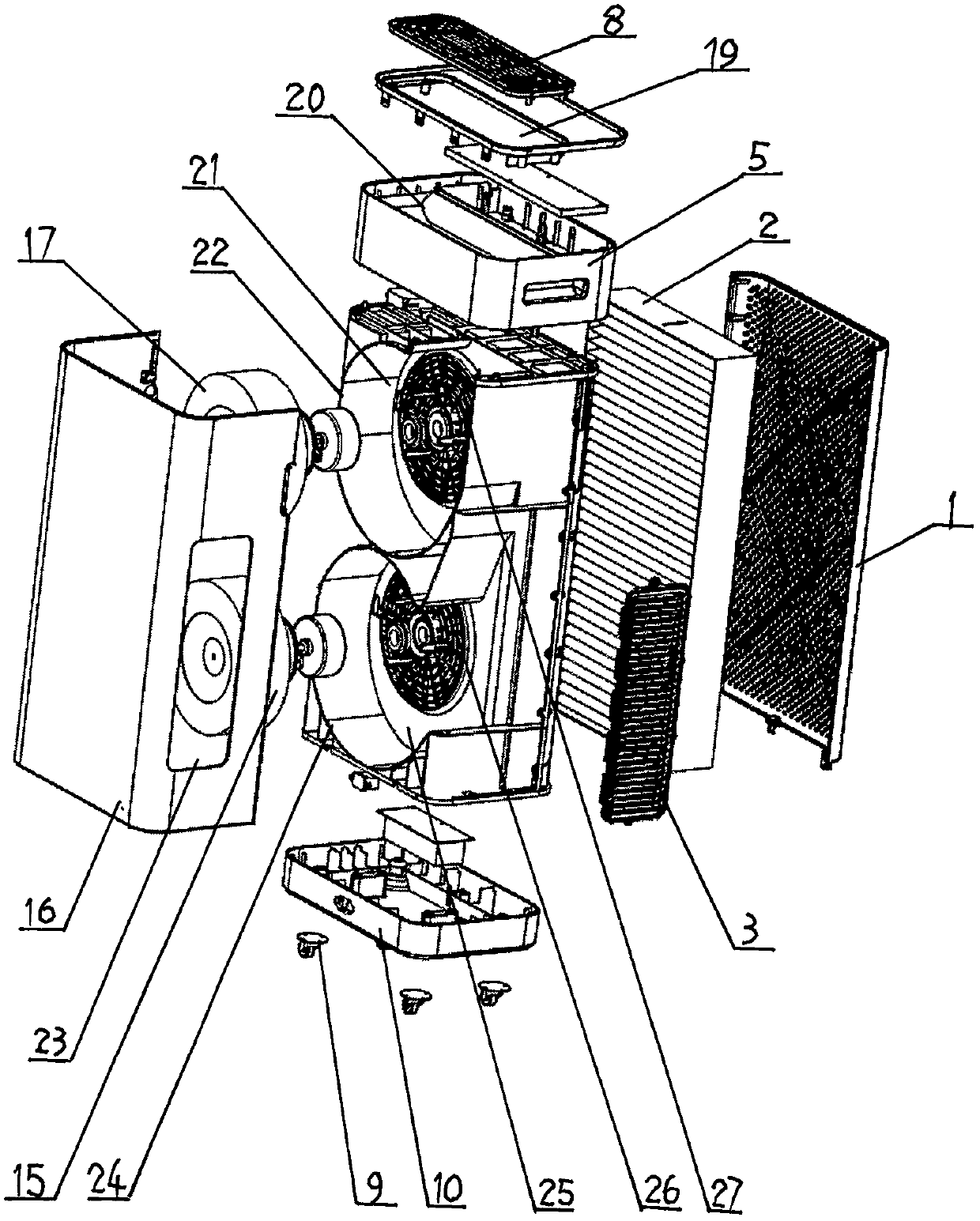

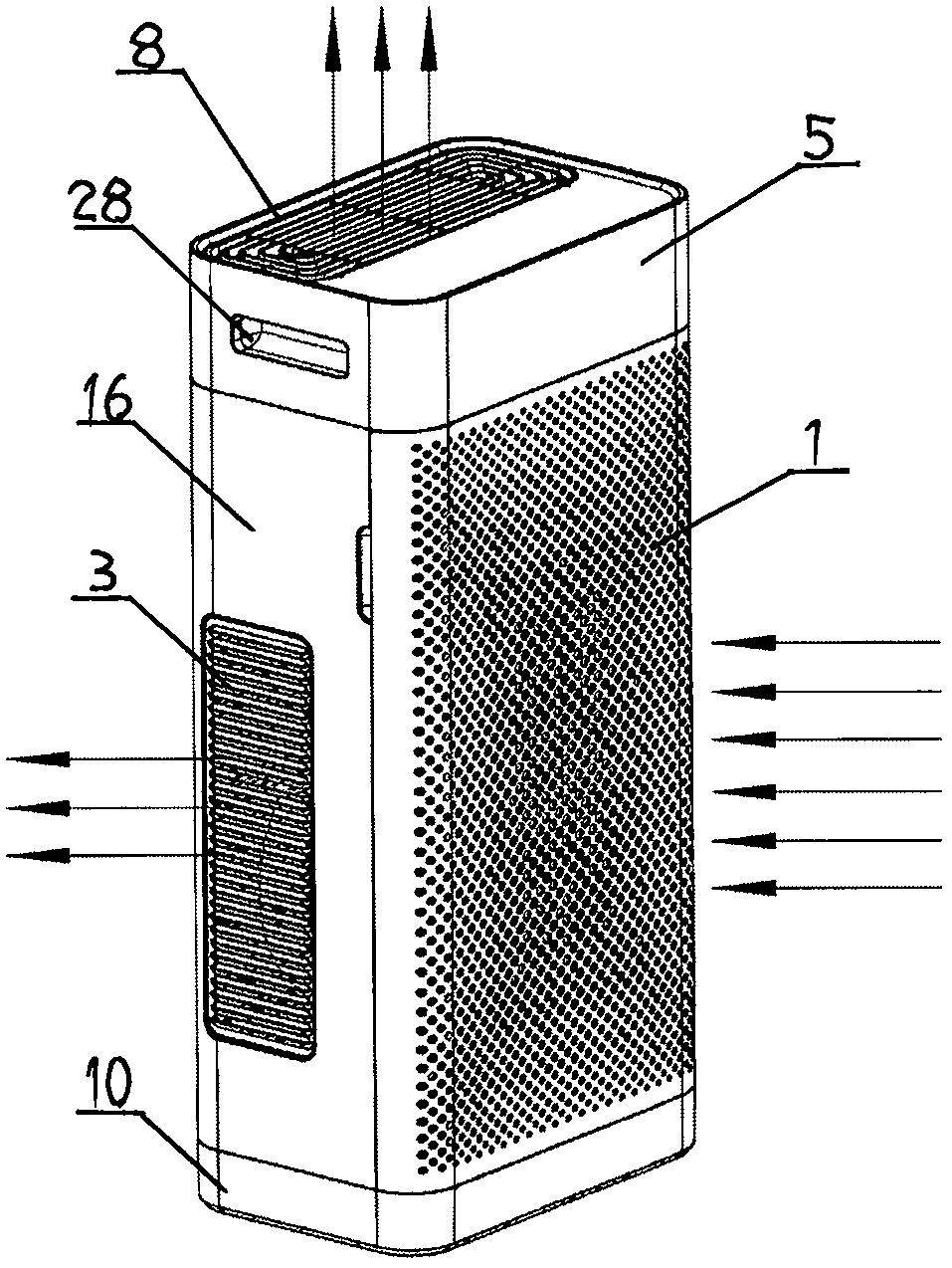

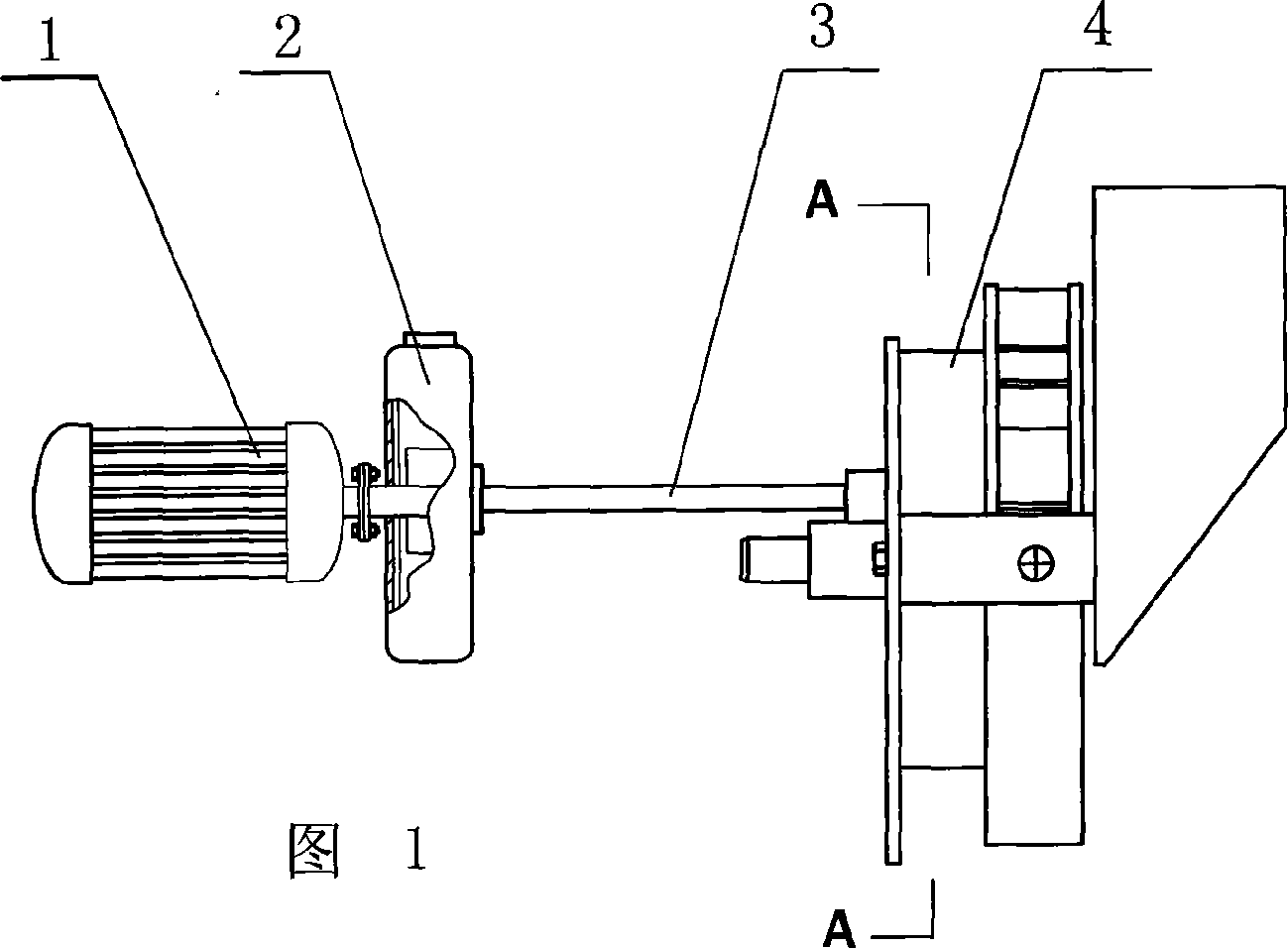

Household air purifier

PendingCN107726469AReasonable designImprove purification efficiencyMechanical apparatusLighting and heating apparatusAir volumeEngineering

The invention belongs to a household air purifier. The household air purifier consists of a machine body, a weak current plate and a strong current plate, wherein an upper centrifugal wind wheel and alower centrifugal wind wheel are separately driven by an upper motor and a lower motor; an Archimedean spiral upper partition board is arranged at the upper part in the rear space of the machine bodyaround the upper centrifugal wind wheel; space between the Archimedean spiral upper partition board and the periphery of the upper centrifugal wind wheel forms an Archimedean spiral upper air duct; an upper air outlet of the Archimedean spiral upper air duct is located at the upper end of the machine body; an Archimedean spiral lower partition board is arranged at the lower part in the rear spaceof the machine body around the lower centrifugal wind wheel; space between the Archimedean spiral lower partition board and the periphery of the lower centrifugal wind wheel forms an Archimedean spiral lower air duct; and a lower air outlet of the Archimedean spiral lower air duct is located at the side end of the machine body. The household air purifier has the advantages of small size, small air losses, large air output, reasonable filter design, high purifying efficiency, no noise, convenient and rapid filter material change, smooth air supply, high purifying efficiency and great use effect.

Owner:台州绿之源环保股份有限公司

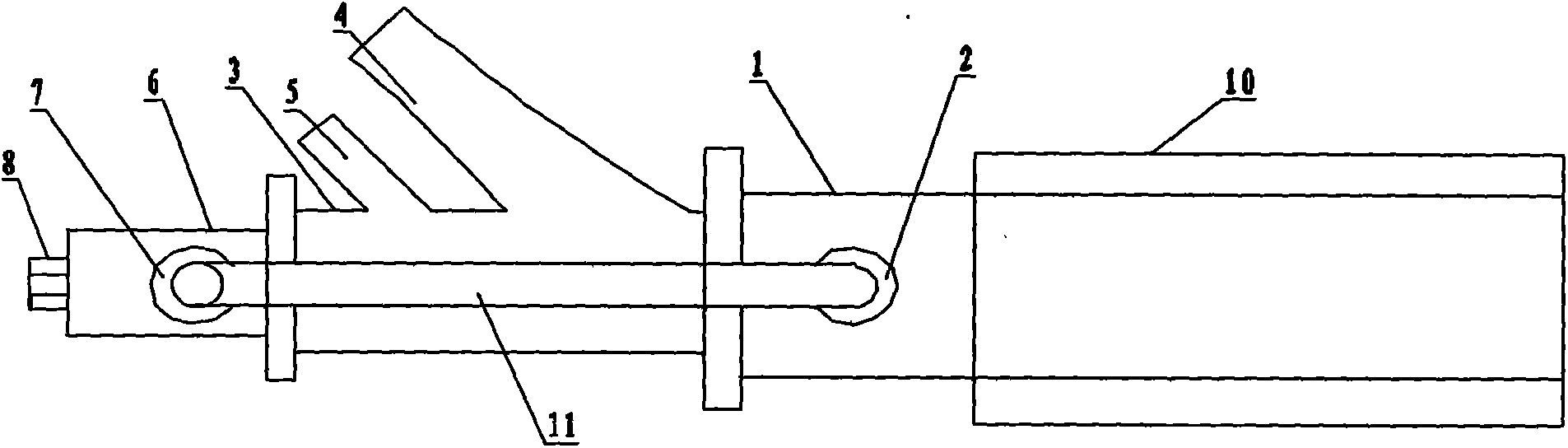

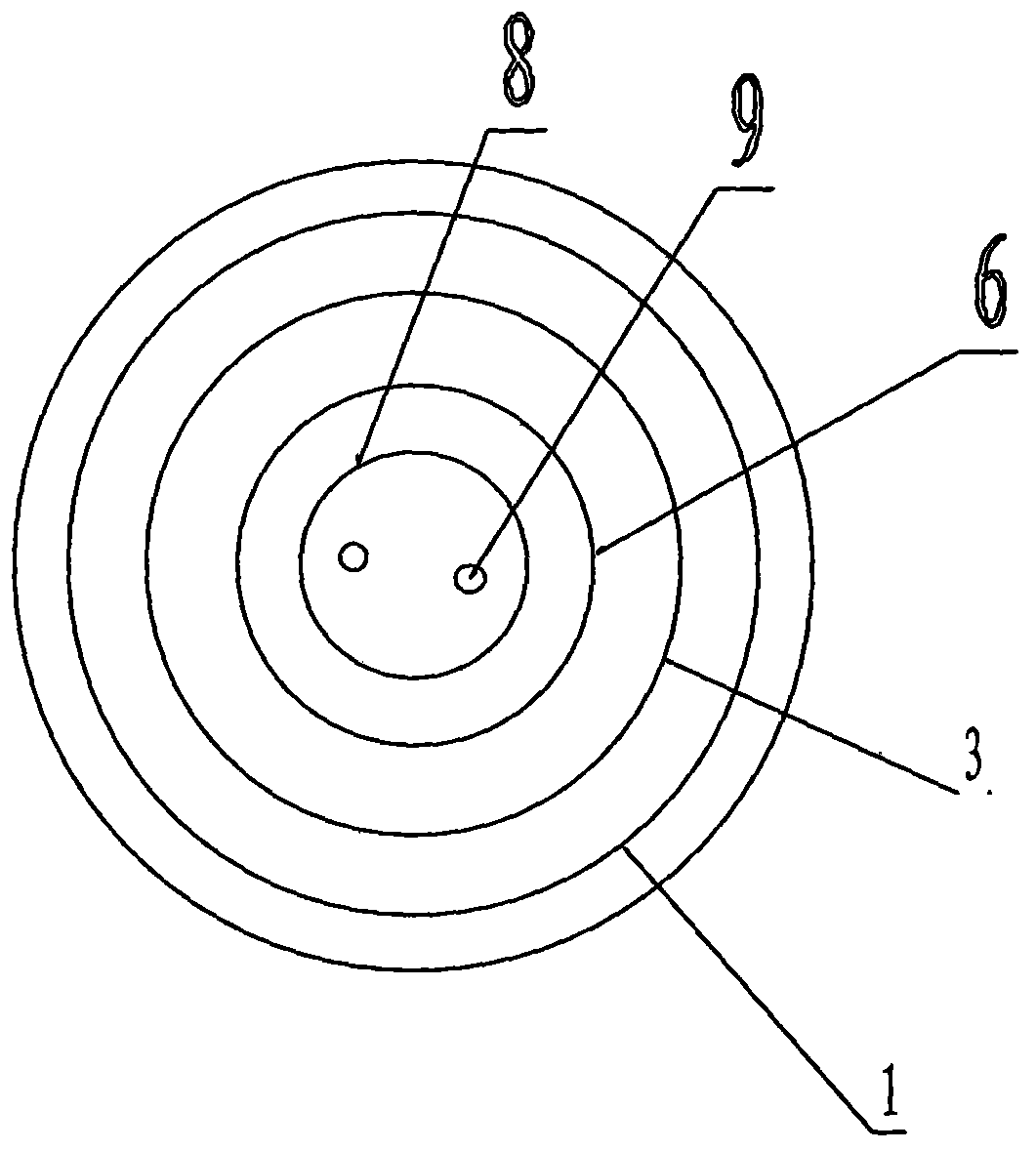

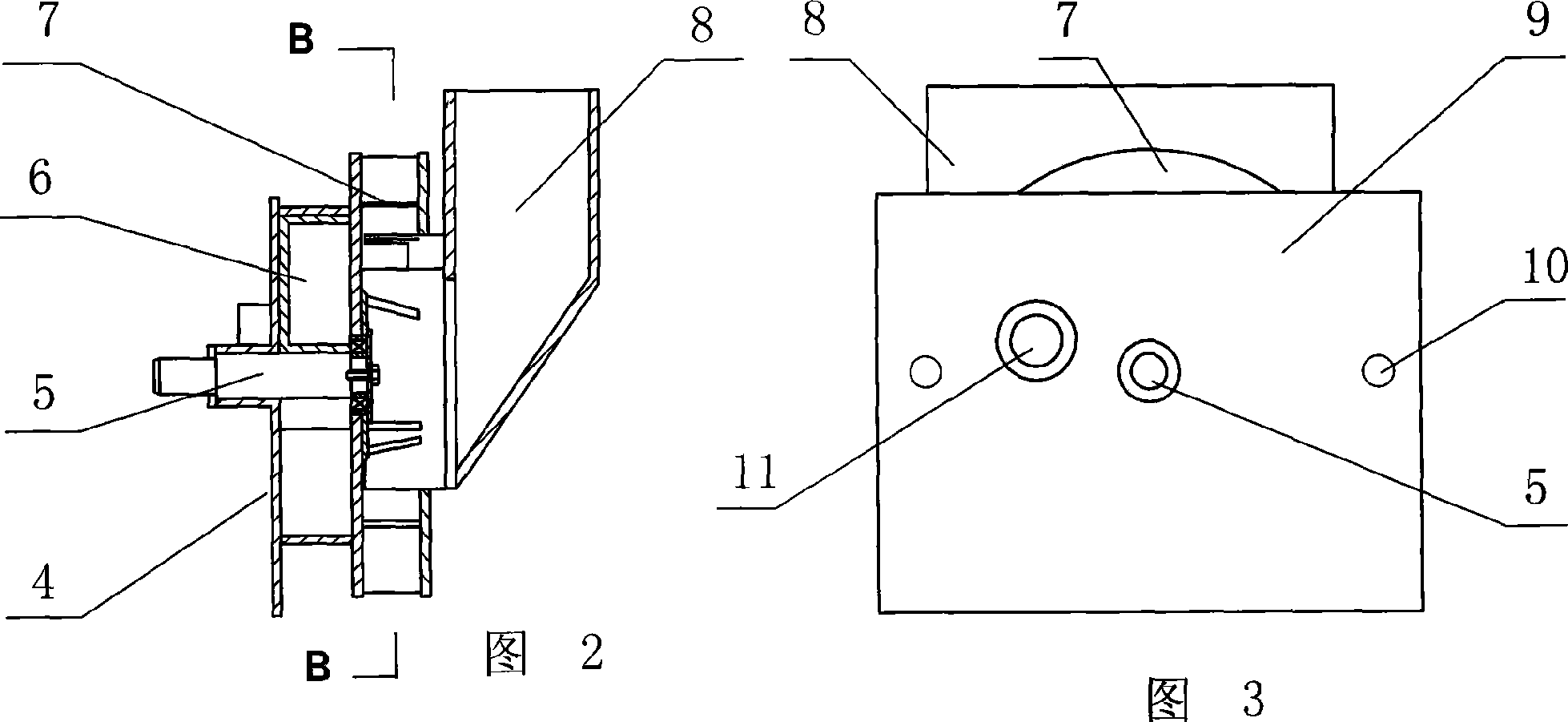

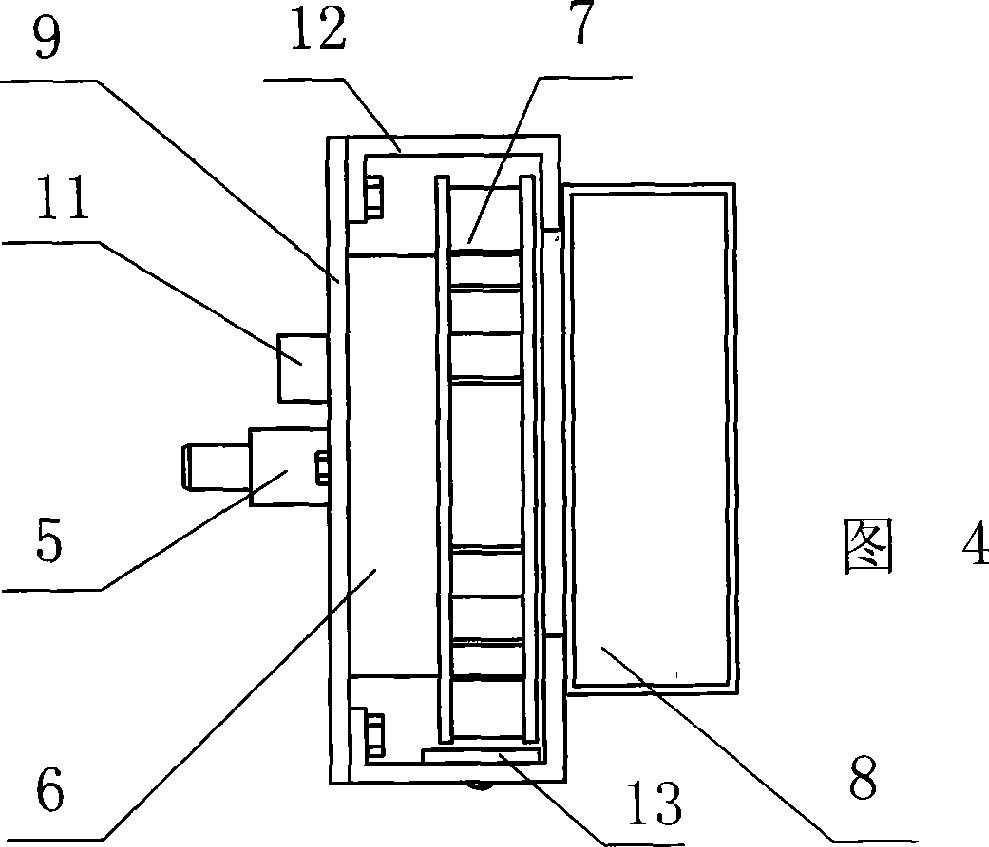

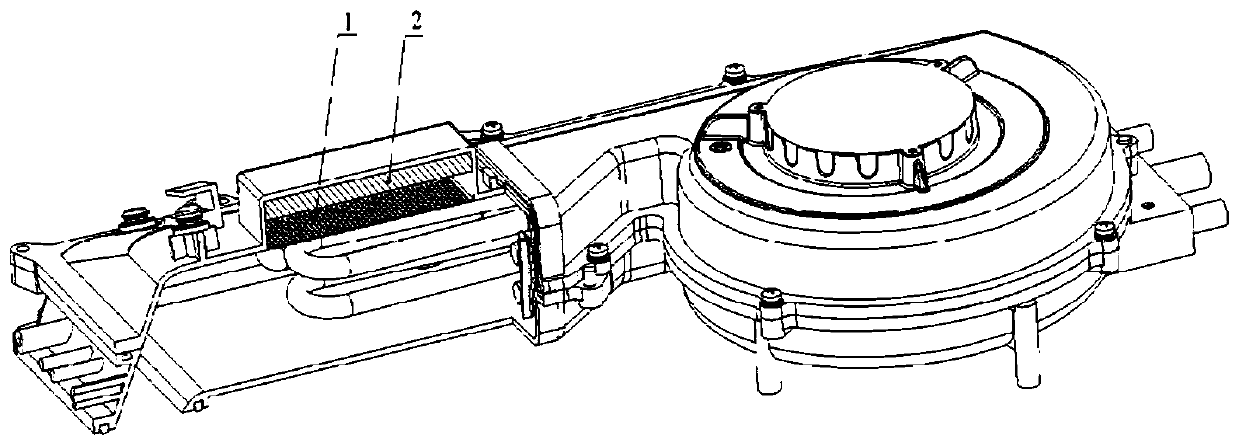

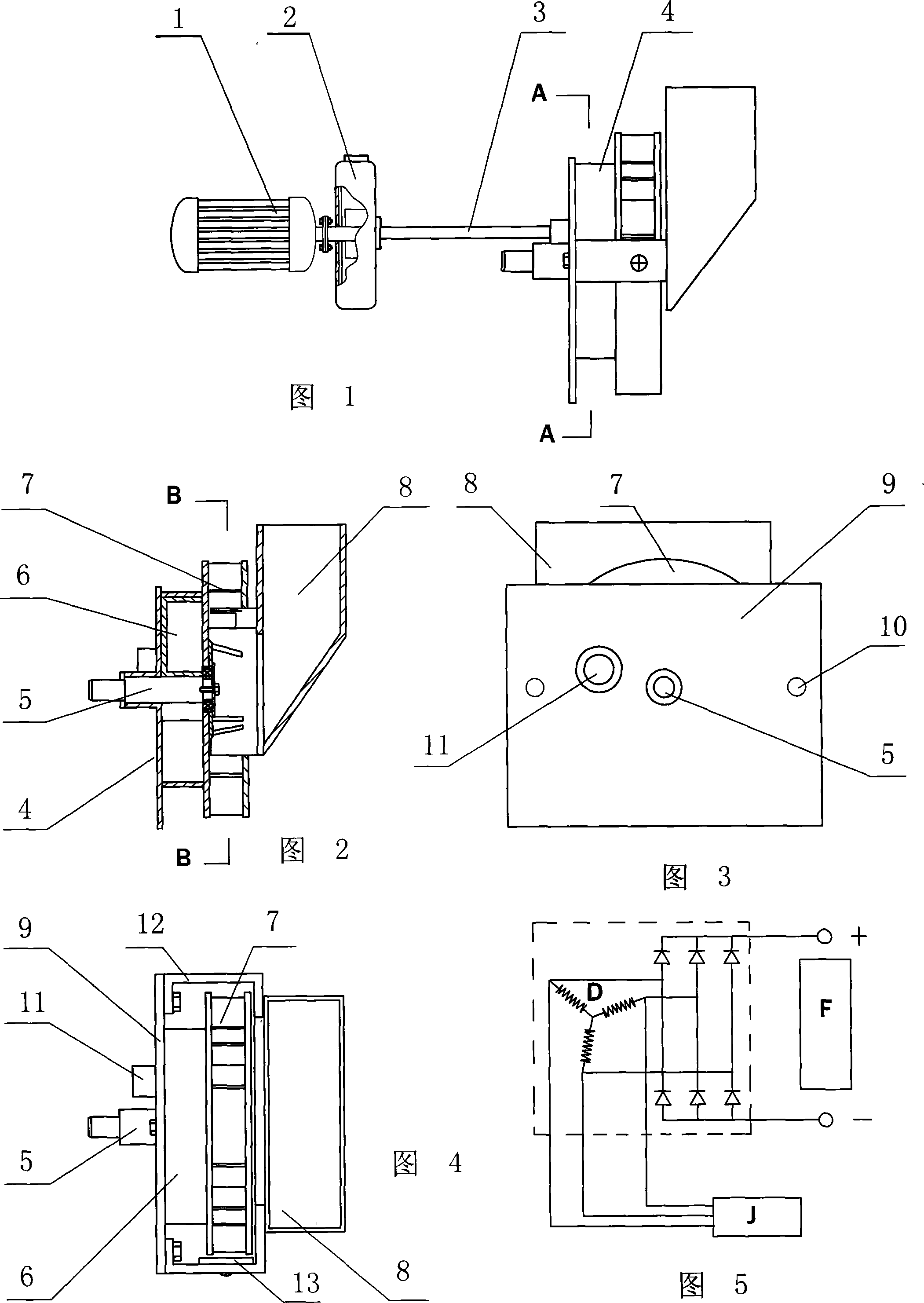

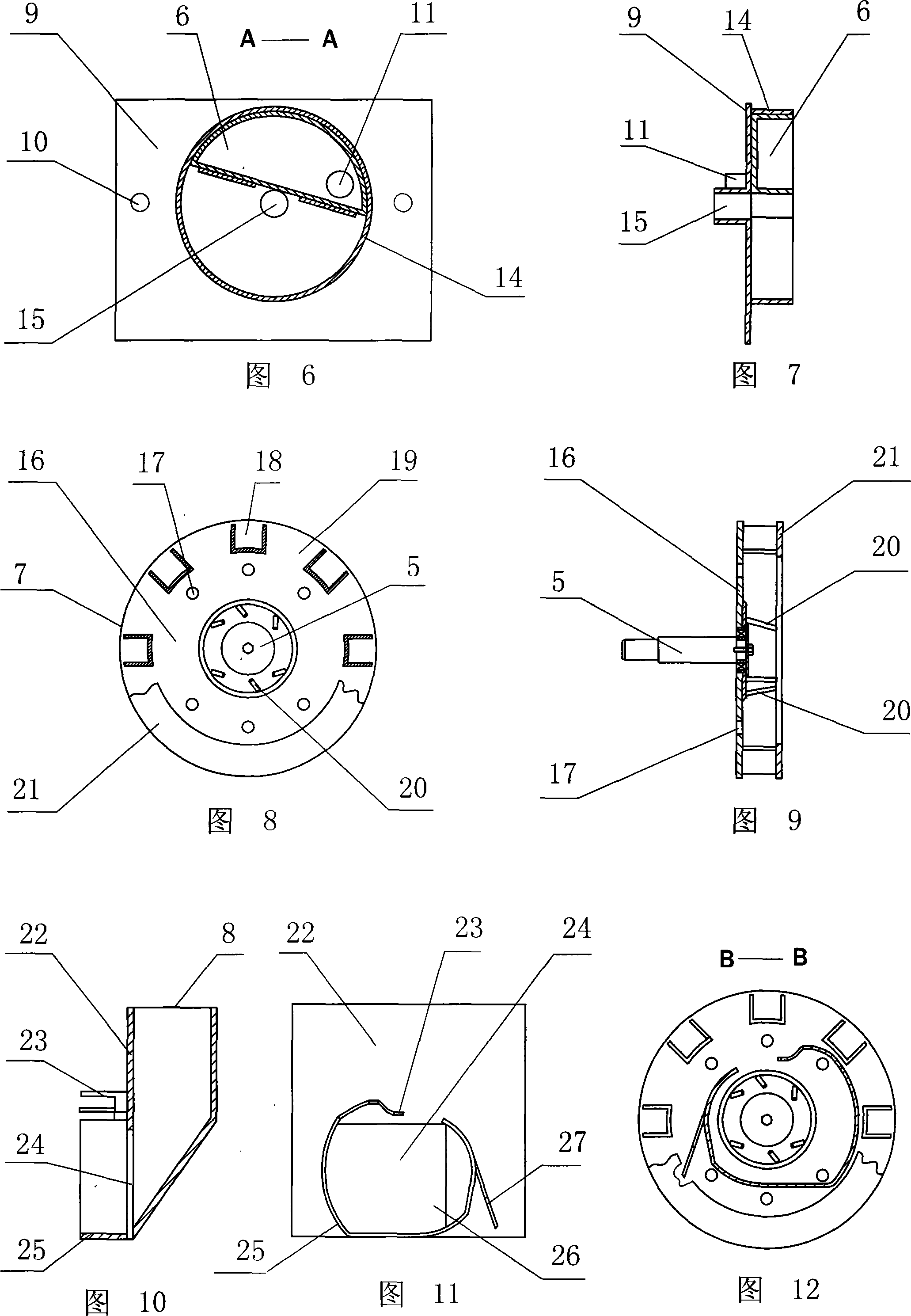

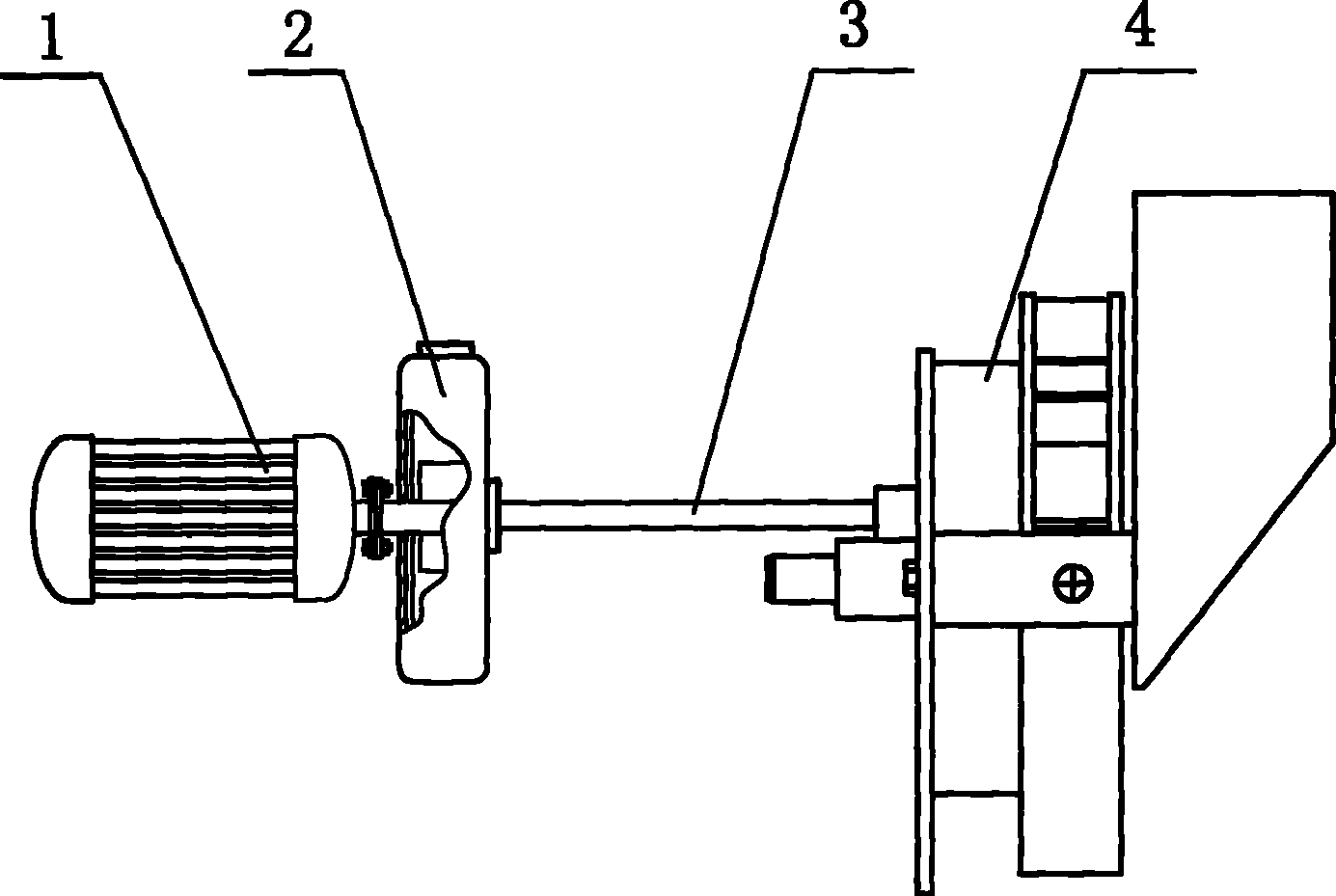

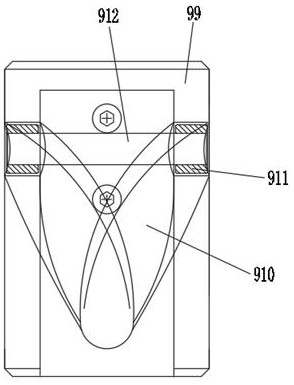

Electrically driven sucking precise seeder

InactiveCN101066016ASave spaceReduce the number of suction holesSeed depositing seeder partsRegular seed deposition machinesSeederFarm machine

The present invention relates to agricultural machine assembly, and is especially one kind of electrically driven sucking precise seeder suitable for seeding corn and other crops. The present invention has a reduced induction chamber, a crescent part of the suction disc opposite to the induction chamber, and at most one half of covered sucking holes in the suction disc. Compared with available technology, the present invention has the advantages of reduced required wind rate, low power consumption of the blower and capacity of using the tractor power generator as power source for precise seeding job.

Owner:全莉平

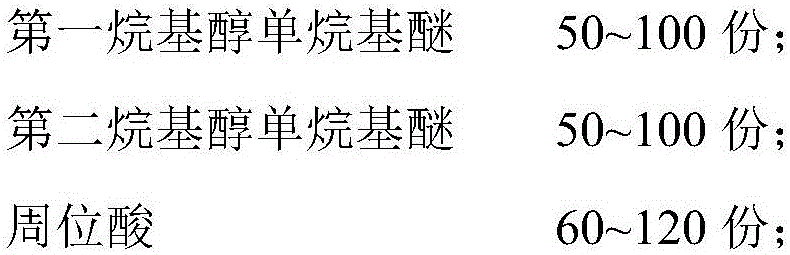

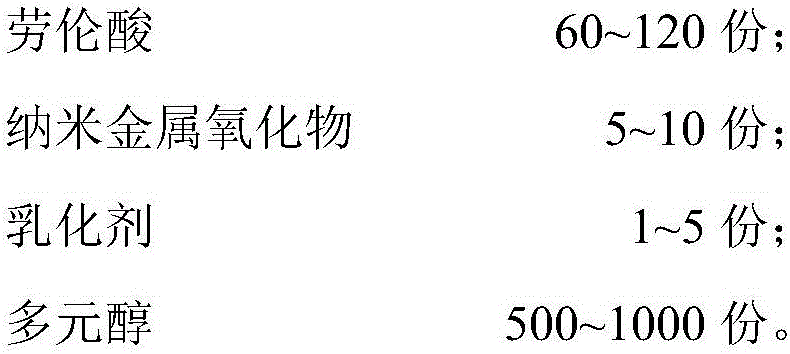

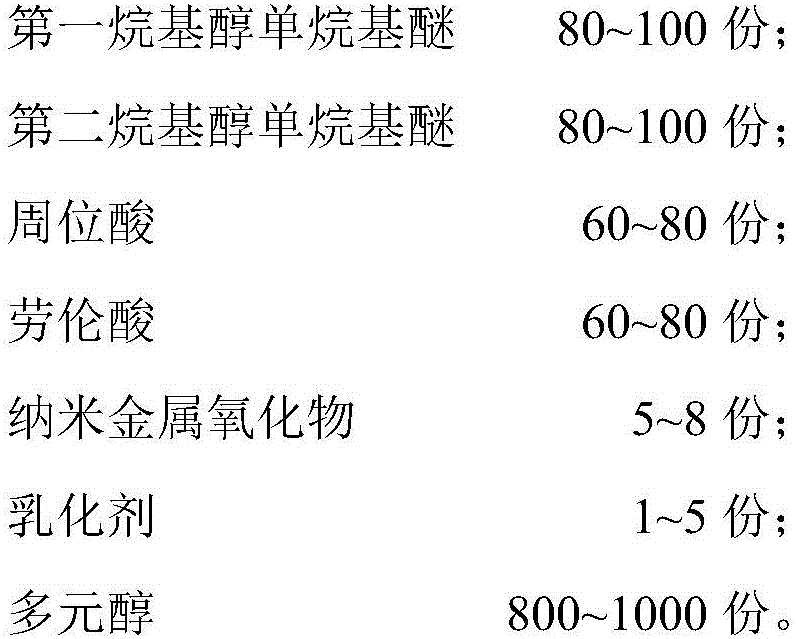

Coal-based methanol-ether fuel additive based on chemical by-products and application thereof

The invention relates to a coal-based methanol-ether fuel additive based on chemical by-products and application thereof. The raw material formula comprises the following components in parts by weight: 50-100 parts of a first alkyl alcohol monoalkyl ether, 50-100 parts of a second alkyl alcohol monoalkyl ether, 60-120 parts of peri-acid, 60-120 parts of Laurent's acid, 5-10 parts of nanocrystalline metal oxides, 1-5 parts of an emulsifier and 500-1000 parts of polyhydric alcohols. With the adoption of a specific formula, particle morphology of pulverized coal can be improved, flowing smoothness of the pulverized coal in a pulverized coal injection process is promoted, and stable pulverized coal combustion is guaranteed, so that the air amount of a primary air fan can be reduced, the cold air entry quantity is reduced, and the aims of saving coal and reducing nitrogen are achieved; and moreover, the fuel additive has the advantage of wide adaptability, can be applied to cement plants, power plants and other industries in which coal serves as main fuel, and is applicable to different coal types such as fault coal, blind coal, bituminous coal and high-sulfur coal.

Owner:ANHUI ZHENGJIE HIGH TECH MATERIALS CO LTD BY SHARE

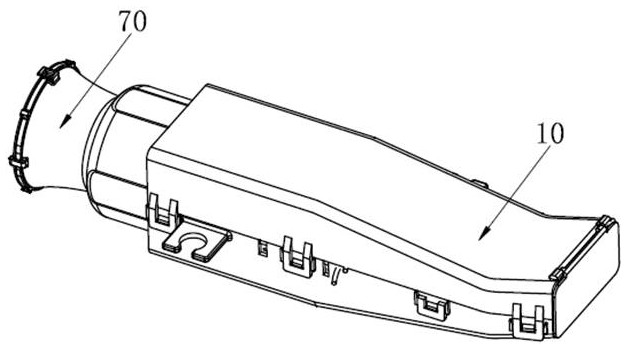

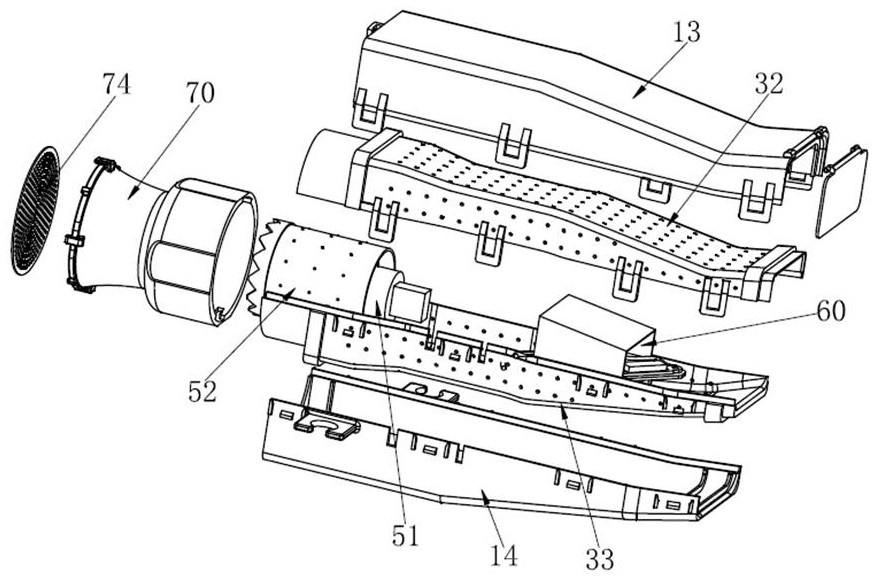

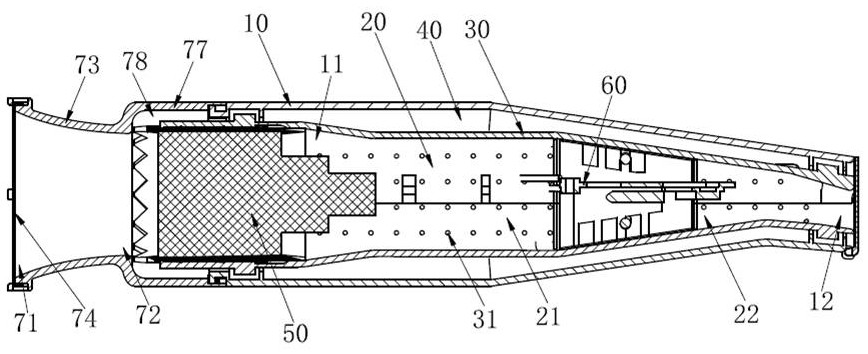

Silencing structure suitable for drying air duct of washing machine and washing machine

InactiveCN110894669AImprove noiseSolve the problem of loud noise during workTextiles and paperLaundry driersMicro perforated plateLaundry washing machine

The invention provides a silencing structure suitable for a drying air duct of a washing machine. The silencing structure is arranged on the drying air duct located at the downstream part of a fan; anair inlet of the drying air duct is connected with an air outlet of the fan; an air outlet of the drying air duct is connected with a drying barrel; the silencing structure comprises an outwards protruding cavity formed in the upper wall surface of the drying air duct, a micro-perforated plate sealed at a cavity opening of the cavity and a sound insulation layer located on the rear side of the micro-perforated plate and laid on the inner wall of the cavity in a manner of keeping a preset interval from the micro-perforated plate. The invention further provides the washing machine provided withthe silencing structure.

Owner:GREE ELECTRIC APPLIANCES INC

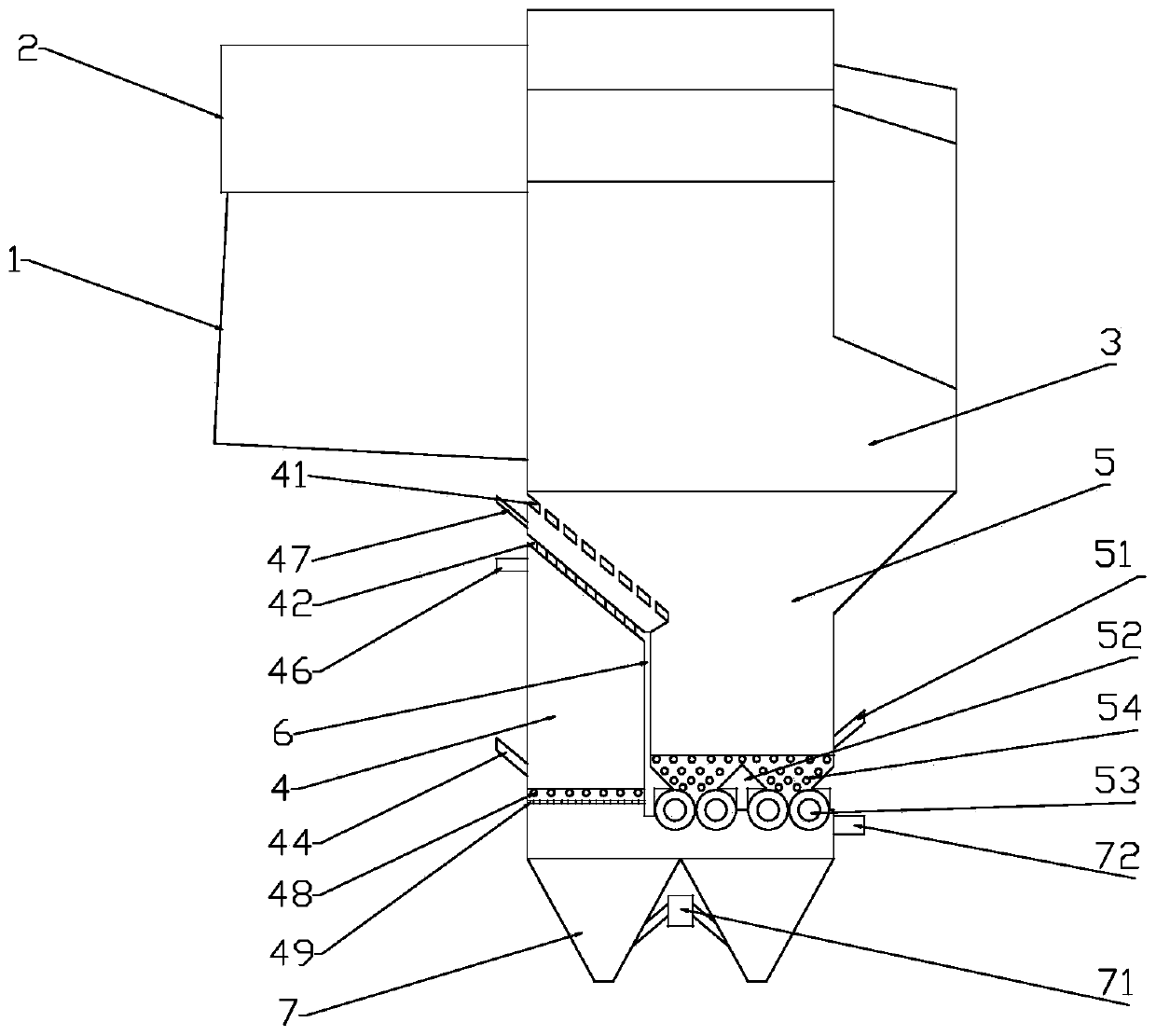

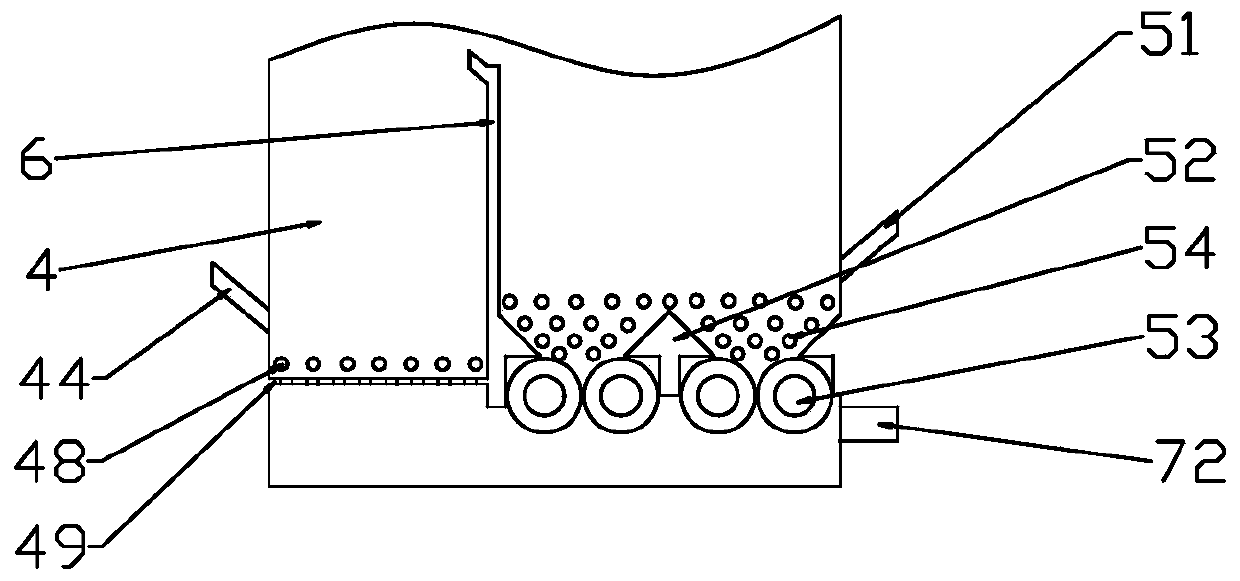

Vertical cement clinker grate-type particle grading cooler and cooling method

The invention belongs to the field of cement sintering equipment, and particularly relates to a vertical cement clinker grate-type particle grading cooler. The upper layer of the cooler is a wicket cover; a fine material cooling area is arranged on the lower part, close to one side of a rotary kiln, of the wicket cover, a coarse material cooling area is arranged on one side of the fine material cooling area, and the fine material cooling area and the coarse material cooling area are separated through a separating cooling wall; a two-stage screening grate plate for filtering clinkers is arranged at the upper end of the fine material cooling area in an inclined mode; a secondary cooling area for secondary cooling of all falling materials are arranged on the lower layer of the cooler, the secondary cooling area comprises a plurality of material falling ash buckets arranged at the bottom end of the cooler, and the cooled clinkers are finally collected through the material falling ash buckets into a drag chine conveyor on the lower part of the cooler. According to the vertical cement clinker grate-type particle grading cooler, the clinkers are cooled respectively in grades, the good heat exchange effect can be achieved, meanwhile the material layer obstruction of the clinkers is lowered, and the purposes of energy saving and consumption reduction are achieved; and the process of countercurrent flow of the clinkers and air for two times is achieved, and the cooling effect is good.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

Housing for accommodating an electronic circuit

ActiveUS9153971B2Small air volumeReduce air volumeAc network load balancingElectric powerEngineeringAtmosphere

A housing for receiving an electronic circuit (4) having a plurality of components (5) having a carrier plate (7) and a housing cover (8) including a circumferentially enclosing wall (9) on the carrier plate (7) and a cover part (10) on the wall (9), which cover part (10) lies opposite the carrier plate (7). A volume compensation element (11) is attached on the carrier plate (7) in an interior (12) of the housing cover (8) which is enclosed in a pressure-tight manner from an external atmosphere. The volume compensation element (11) is elastically formed providing a variable volume for compensation of pressure fluctuations in the interior (12), which variable volume occurs with a change in position of the volume compensation element (11) relative to the carrier plate (7). A gap between the volume compensation element (11) and the carrier plate (7) is connected to the external atmosphere.

Owner:EBM PAPST MULFINGEN GMBH & CO KG

Air outlet mechanism of electronic toilet stool drying device and drying device

PendingCN113737907AImprove experienceNoise isolationLavatory sanitoryDomestic applicationsStructural engineeringToilet

The invention discloses an air outlet structure of an electronic toilet stool drying device. The structure comprises a shell and an air outlet channel formed in the shell, and an air inlet and an air outlet are formed at two ends of the shell. A first separator is inwards arranged in the shell along the air outlet channel; and the first separator and the inner wall of the shell form a closed cavity. By means of the closed cavity formed by the first separator and the inner wall of the shell, a noise generated in the device can be effectively isolated, and the user experience is improved.

Owner:XIAMEN AXENT

Powder coating sheet material automatic feeding mechanism

InactiveCN103285989AGuaranteed efficiencyGuaranteed inhalationGrain treatmentsManufacturing technologyEngineering

The invention discloses a powder coating sheet material automatic feeding mechanism, relates to the field of machinery, and in particular relates to the manufacture technical field of an automatic feeding mechanism. The powder coating sheet material automatic feeding mechanism provided by the invention comprises a material receiving hopper comprising an upper part columnar hopper body and a lower part conical material hopper body; the lower end of the lower part conical material hopper body is matched and connected with a feeding machine; the outlet of the feeding machine is connected with a material charge pipe; an outlet end of the material charge end is provided with an air classification mill; the air classification mill is provided with a material intake pipe; and an outlet end of the material intake pipe is connected with the material intake pipe. According to the powder coating sheet material automatic feeding mechanism, sheet materials can be directly delivered into the air classification mill for milling without being transported manually; the production working procedures are reduced; the labor force is reduced; the production efficiency is improved; meanwhile the problem that materials are polluted and wasted when sheet materials can fall on the ground due to manual material charge is solved.

Owner:扬州三川实业有限公司

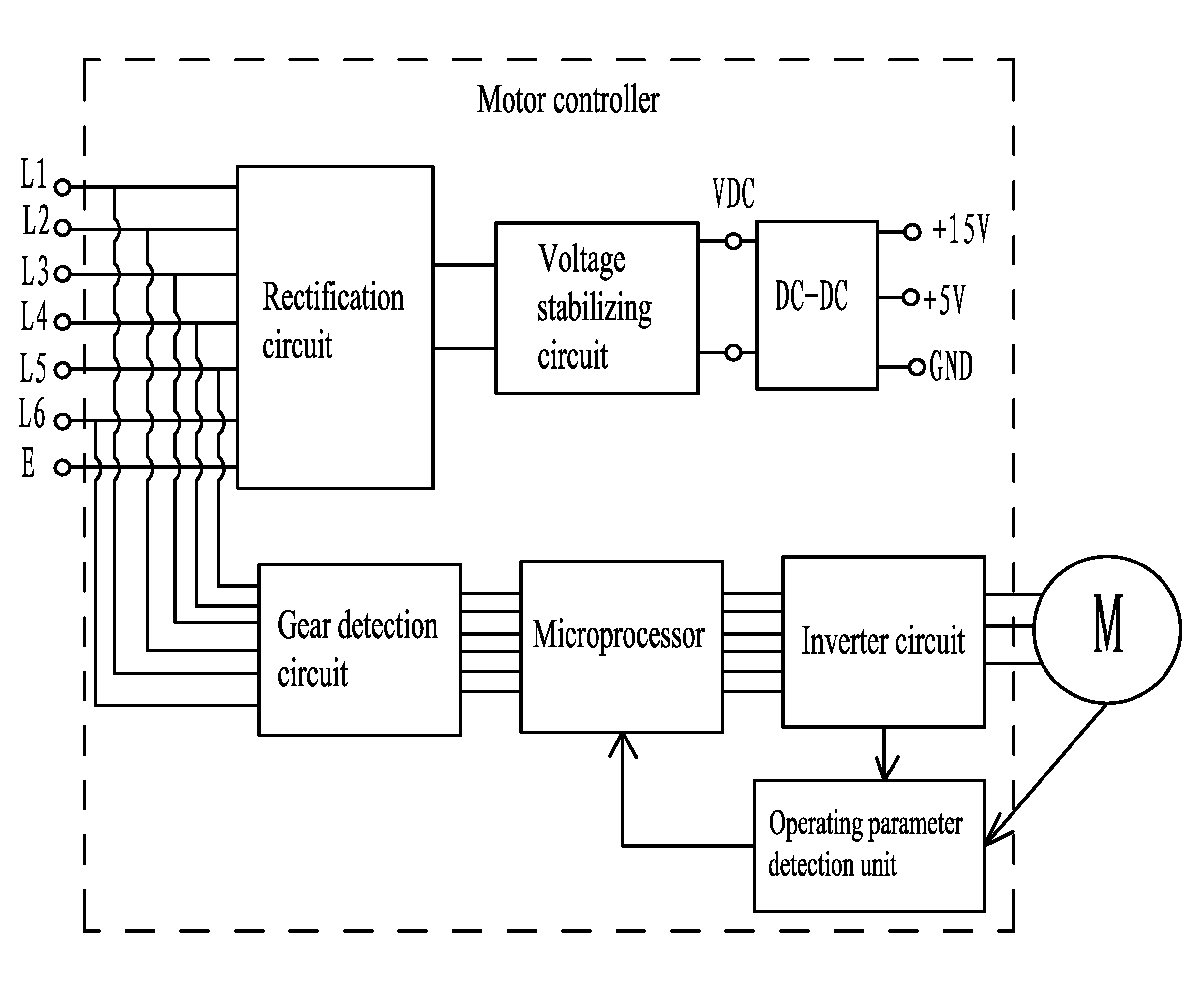

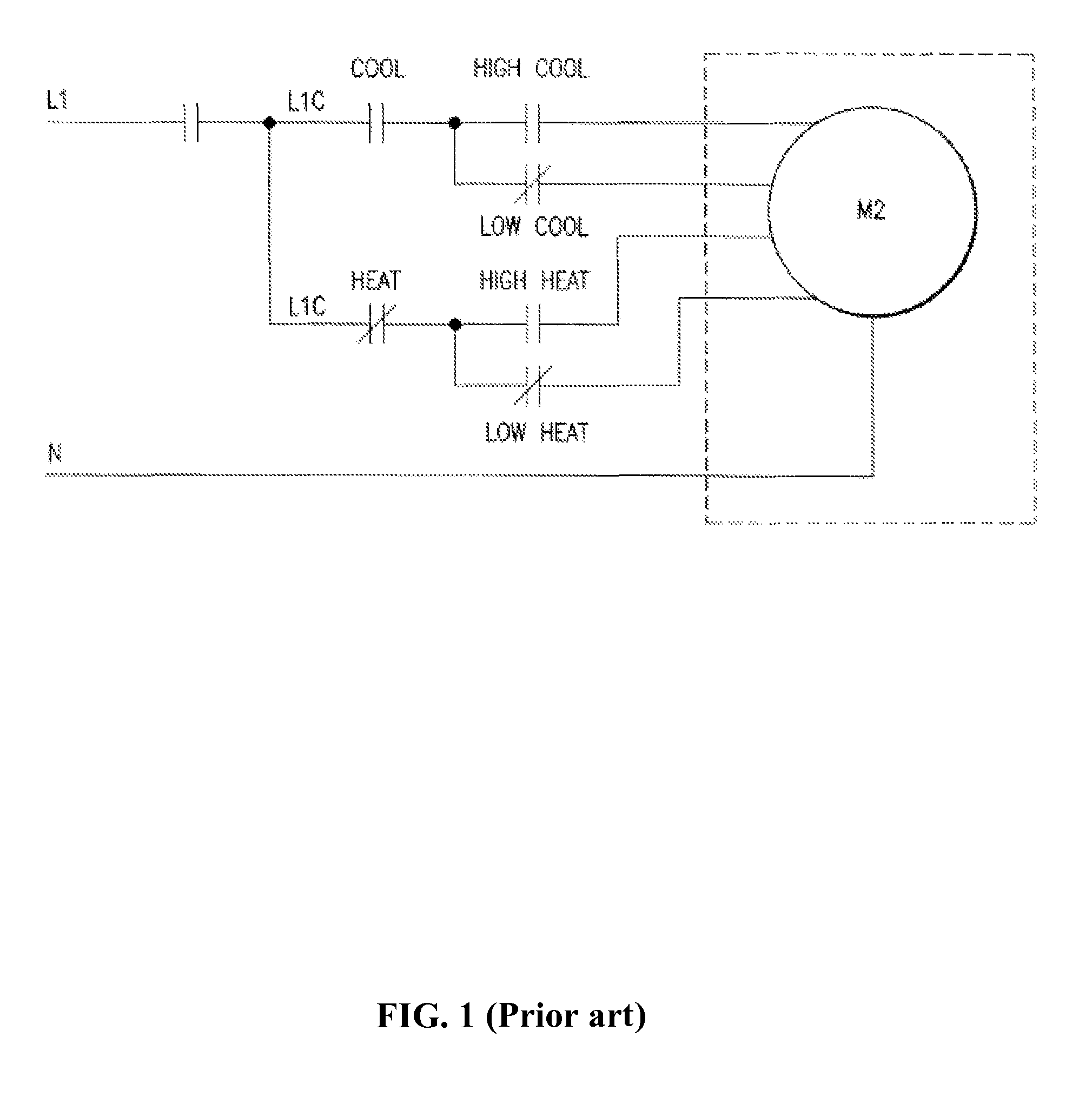

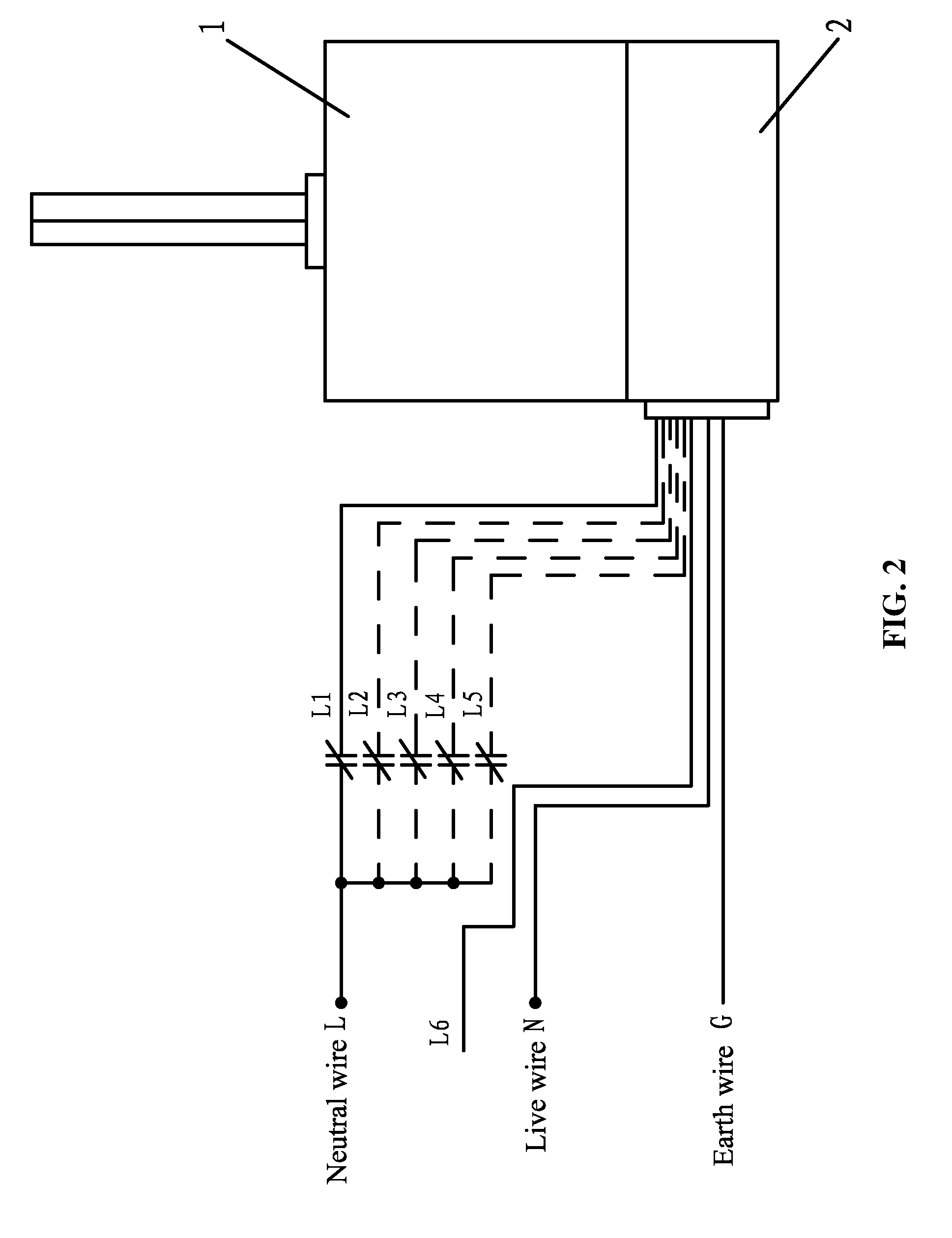

Method for correcting torque for substituting permanent-split capacitormotor by electronically-commutated motor

ActiveUS9369070B2Easy to adaptHigh control precisionElectric motor controlSingle motor speed/torque controlStable stateElectric machine

A method for correcting torque including: presetting rotational speed of each gear by corresponding gear input lines of a microprocessor; providing a mechanism to select one rotational speed set; electing N power points within a range of the rated power, acquiring a set of torque data corresponding to each set of the rotational speed at each power point, and storing a total 2×N sets of torque data; allowing the motor to enter the torque correction mode; recording a steady torque Tadj when the motor operates in a steady state; and comparing the steady torque Tadj with a maximum gear torque Tmax, and selecting the set of torque data to which T[M]max belongs when the steady torque Tadj satisfies the relationship: 110%×T[M−1]max<Tadj≦110%×T[M]max, M=1, 2, . . . , N; when M=1, T0max=0.

Owner:ZHONGSHAN BROAD OCEAN

Electrically driven sucking precise seeder

InactiveCN101066016BSave spaceReduce the number of suction holesSeed depositing seeder partsRegular seed deposition machinesEngineeringDynamo

The present invention relates to agricultural machine assembly, and is especially one kind of electrically driven sucking precise seeder suitable for seeding corn and other crops. The present invention has a reduced induction chamber, a crescent part of the suction disc opposite to the induction chamber, and at most one half of covered sucking holes in the suction disc. Compared with available technology, the present invention has the advantages of reduced required wind rate, low power consumption of the blower and capacity of using the tractor power generator as power source for precise seeding job.

Owner:全莉平

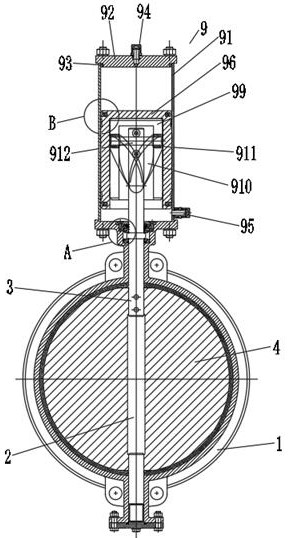

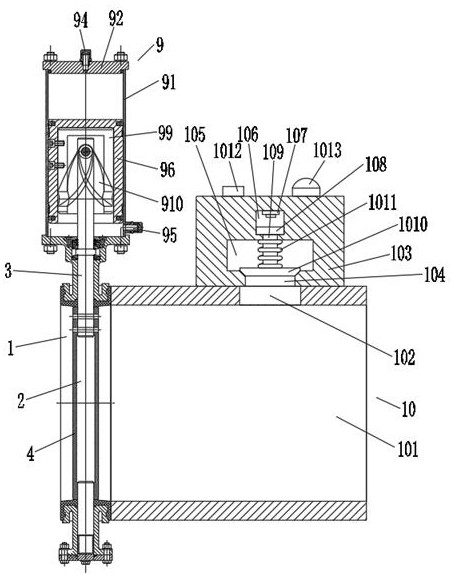

Pneumatic holder type butterfly valve

InactiveCN112483665ASmall air volumeAvoid damageOperating means/releasing devices for valvesLift valveNumerical controlGas cylinder

The invention discloses a pneumatic holder type butterfly valve which comprises a valve body, wherein the bottom of the inner wall of the valve body is rotatably connected to a lower valve shaft; thetop of the lower valve shaft is connected to an upper valve shaft through a connecting pin. A twisting sleeve twists to drive a rotary rod to rotate, so that the upper valve shaft and the lower valveshaft are driven to rotate, and thus, a valve plate is driven to rotate until linear motion is converted into rotational motion, and opening and closing of the butterfly valve are accomplished; and meanwhile, the volume of a gas cylinder is small, number of pistons is small, friction resistance is small, torque is small, parts are fewer, and opening-closing is flexible; after a numerical-control machine tool appears, the pneumatic holder type butterfly valve has the advantages of being low in production cost, compact in structure, attractive in appearance, and the like; besides, a pressure alarm mechanism can be arranged for detecting pressure inside a pipeline and the valve body; after the pressure reaches a pre-warning value, warning prompt is emitted, so that the pipeline and the valvebody are prevented from being damaged, and thus, actual use is facilitated.

Owner:ANHUI TONGDU FLOW TECH

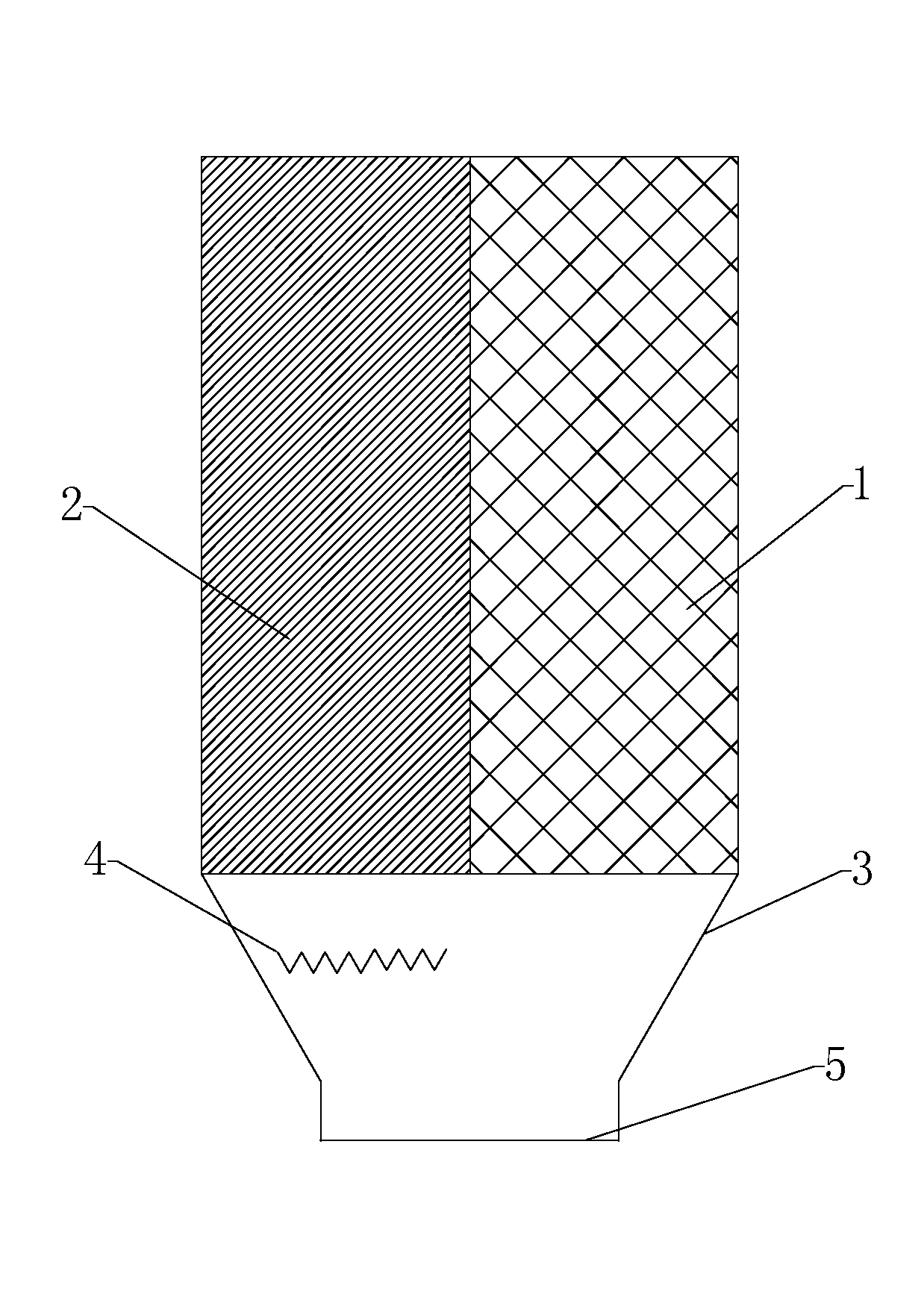

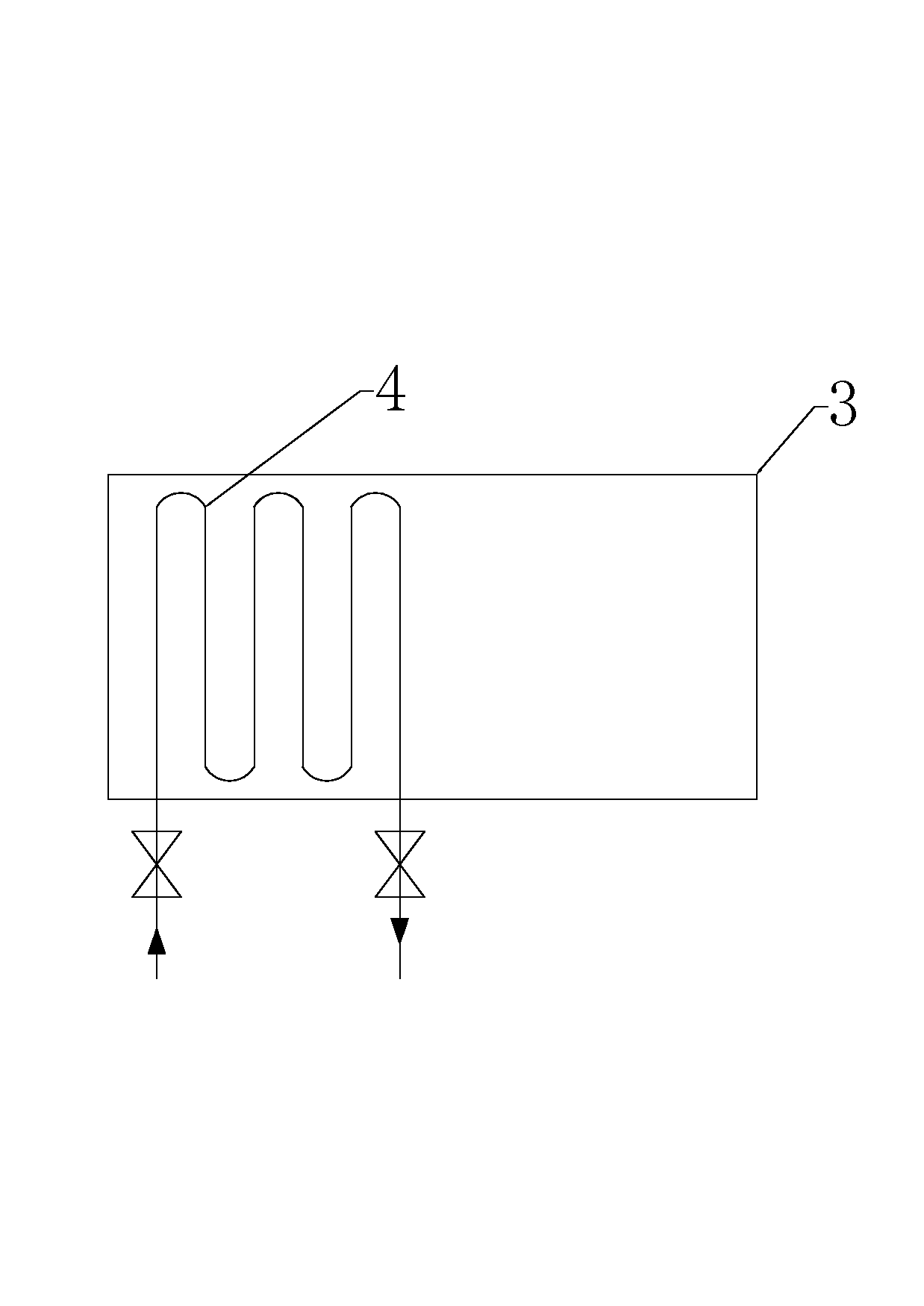

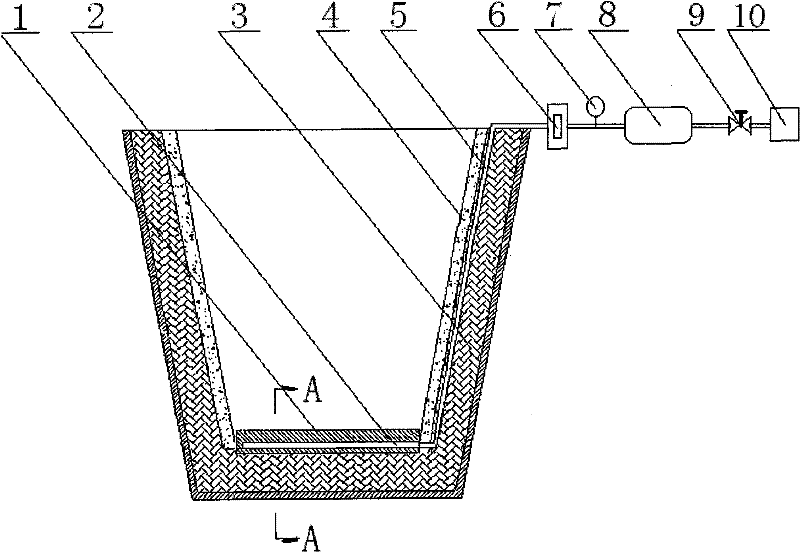

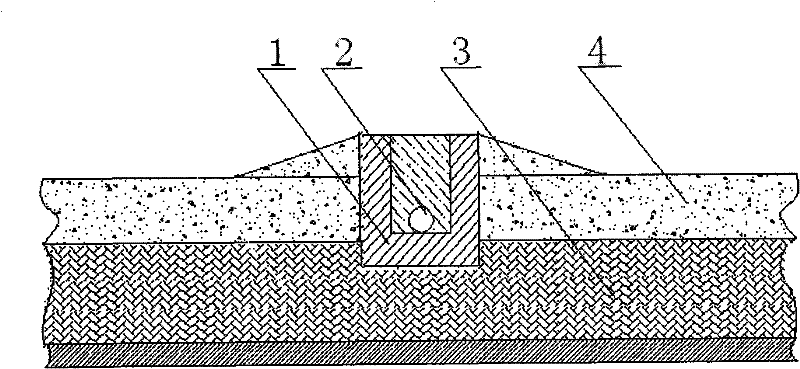

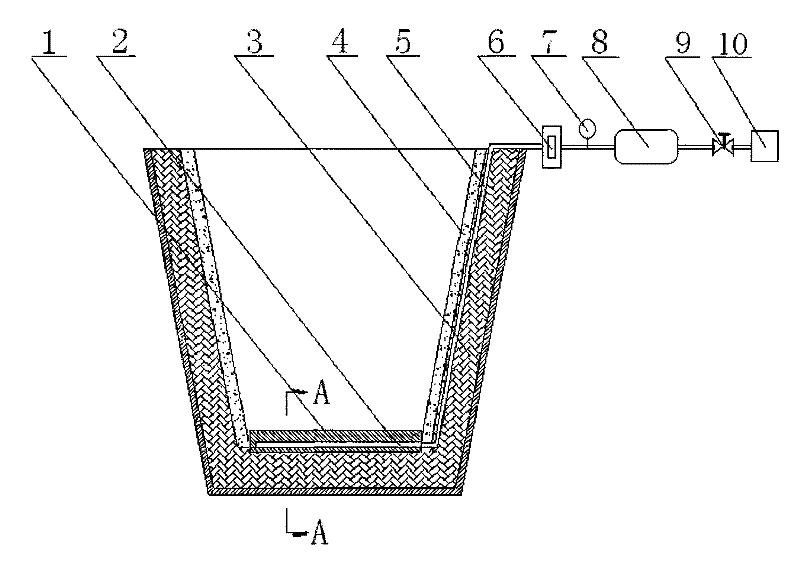

Method for cleaing molten steel for continuous casting tundish by air curtain retaining wall method

The invention relates to a continuous casting method of pouring box air curtain retaining wall clean molten steel. The adopted technical proposal is as follows: slotting a permanent layer (3) on the bottom of the pouring box and a permanent layer (3) close to the lateral wall of an air source, embedding an air brick (1) in the slot of the permanent layer (3) at the bottom of the pouring box with the upper ventilation surface of the air brick (1) paralle and level to or a little higher than a working layer (4) built at the bottom of the pouring box; embedding an argon connecting pipe (5) in theslot of the permanent layer (3) close to the lateral wall of the air source with one end of the argon connecting pipe (5) communicated with a ventilation chamber (2) of the air brick (1) embedded inthe slot on the bottom of the pouring box and the other end thereof extending upward along the slot of the permanent layer (3) close to the lateral wall and being connected with an argon source (10) through a flow meter (6), a pressure gauge (7), a buffering air tank (8) and a valve (9) outside the pouring box; and adopting smearing material to infill the construction gaps for embedding the air brick (1) and the argon connecting pipe (5). The method is conducive to eliminating inclusion due to collided growth, can improve the flow characteristic of molten steel and eliminate minute non-metallic inclusion, and effectively improves the purity of molten steel.

Owner:WUHAN UNIV OF SCI & TECH

Air outlet component of indoor unit, indoor unit and control method thereof

ActiveCN107328072BImprove air efficiencySmall air volumeMechanical apparatusSpace heating and ventilation safety systemsAir volumeControl engineering

Provided is an indoor unit air outlet assembly, comprising at least two layers of swing blade sets having identical swing blade rotational directions, wherein the at least two layers of swing blade sets are arranged successively front to back, each layer of swing blade set comprises multiple swing blades, and the minimum gap front to back of swing blades in two adjacent layers of swing blade sets is no greater than a pre-set gap.Further provided are an indoor unit having the indoor unit air outlet assembly and a method of controlling same. Use of the indoor unit air outlet assembly, the indoor unit and the method of controlling same means that while guaranteeing the air supply distance, air output resistance is reduced as much as possible, optimising air supply distance and the volume of air output.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

A combustion-supporting method for an oxygen-enriched device of a cement rotary kiln burner

ActiveCN104048502BIncrease burn rateHigh catalytic efficiencyRotary drum furnacesIndirect carbon-dioxide mitigationRefractoryEngineering

The invention discloses a combustion-supporting method of a rotary cement kiln burner oxygen enrichment device. The rotary cement kiln burner oxygen enrichment device consists of a kiln head outer layer pipeline, a kiln head outer layer air inlet pipe orifice, a kiln head coal layer current pipeline, a kiln head pulverized coal wind current pipeline, a kiln head coal wind pipeline, a kiln head inner wind pipeline, a kiln head inner wind air inlet pipe orifice, a kiln head oil pipeline, an oil nozzle, kiln head refractory concrete and a kiln head oxygen enrichment air flue, wherein the oxygen enrichment air flue is arranged between the kiln head outer layer air inlet pipe orifice and the kiln head inner wind air inlet pipe orifice; an air inlet of oxygen enrichment is preserved in the pipe end of the kiln head oxygen enrichment air flue in the kiln head outer layer air inlet pipe orifice; when the oxygen enrichment in the kiln head outer layer pipeline and the oxygen enrichment in the kiln head inner wind pipeline enter a rotary cement kiln together with pulverized coal wind current simultaneously, the temperature of a combustion field of the rotary cement kiln input with the oxygen enrichment can reach over 1700 DEG C, before free carbon in the combustion field with the temperature of over 1700 DEG C forms black smoke, the free carbon is thoroughly burned, and the free carbon becomes combustive fuel; meanwhile, the clinker catalyst of cement is subjected to oxidation combustion by the input of the oxygen enrichment; when the temperature of the combustion field is over 1700 DEG C, CO in the combustion field is burned, and the emission of NOx is reduced by 35%.

Owner:河南嘉和节能科技有限公司

a high concentration so 2 conversion acid production process

ActiveCN109761203BAvoid problems such as complex chain controlHelps control conversion rateSulfur compoundsHigh concentrationFlue gas

The invention discloses a high concentration SO 2 The conversion acid production process belongs to the technical field of sulfur recovery, and comprises the following steps: (1) mixed with O 2 The purified wet flue gas enters the drying tower for dehydration, and then enters the preheat exchanger to raise the temperature to a predetermined temperature; (2) the purified flue gas after heating enters the catalyst layer of the pre-reformer to react, and the flue gas passes through the catalyst layers of the pre-reformer, SO 2 Concentrations were all decreased by 7%, for any SO at the pre-reforming inlet 2 concentration of flue gas, the flue gas temperature in the outlet layer is controlled to be lower than 620°C; (3) the flue gas from the pre-reformer cools down to the set temperature, and then enters the pre-absorption tower for the first absorption to make acid, after absorbing SO 3 And with the flue gas after the wind, enter the traditional SO 2 Conversion acid system; the invention has a simple process and does not have high requirements for the working conditions of fans, converters and other equipment, and is an easy-to-implement high-concentration SO 2 conversion process.

Owner:CINF ENG CO LTD

Powdered coal burner head with high efficiency and low wear

InactiveCN101839479BReduce wearSolution to short lifePulverulent fuel combustion burnersCombustionEngineering

The invention relates to a powdered coal burner head with high efficiency and low wear, which belongs to the cement technical field. The powdered coal burner head is characterized in that the powdered coal burner head is of a component structure and sequentially comprises a head large outer drum, a middle large outer drum, a head outer drum, a middle outer drum, a head ejector and a head swirler from outside to inside, the head large outer drum is connected with the middle large outer drum, the head outer drum is connected with the middle outer drum, the circumference of the end plane of the head ejector is evenly provided with round holes, a head powdered coal outlet is directly connected with a middle powdered coal outlet through threads. The head swirler is provided with a swirl channel. The invention has the advantages of simple structure, compact assembly, saving energy, reducing consumption, full combustion, high efficiency, little abrasion, flexible adjustment, convenient maintenance, safe operation, high device running rate, long service life and extensive use range.

Owner:TIANJIN CEMENT IND DESIGN & RES INST +1

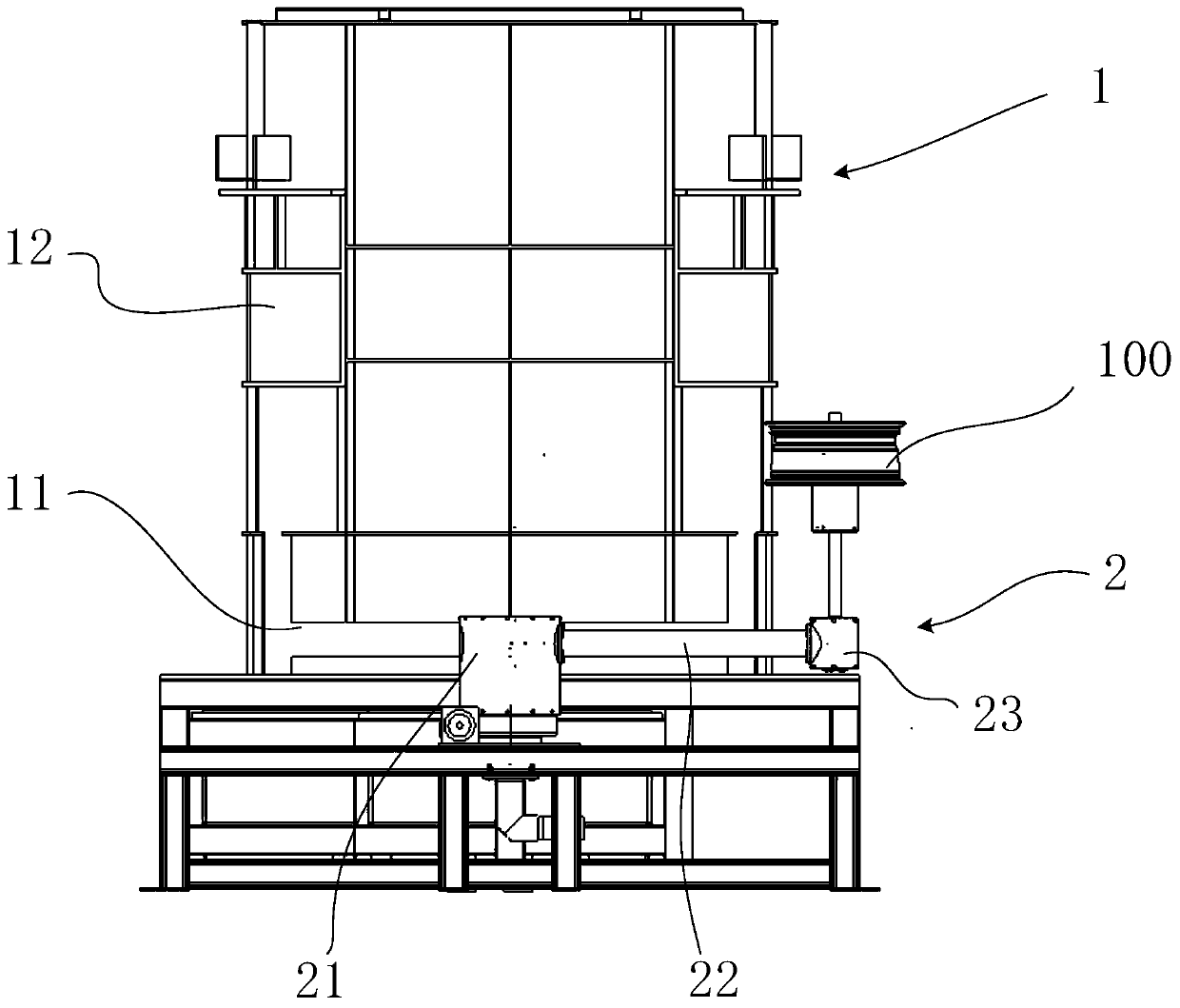

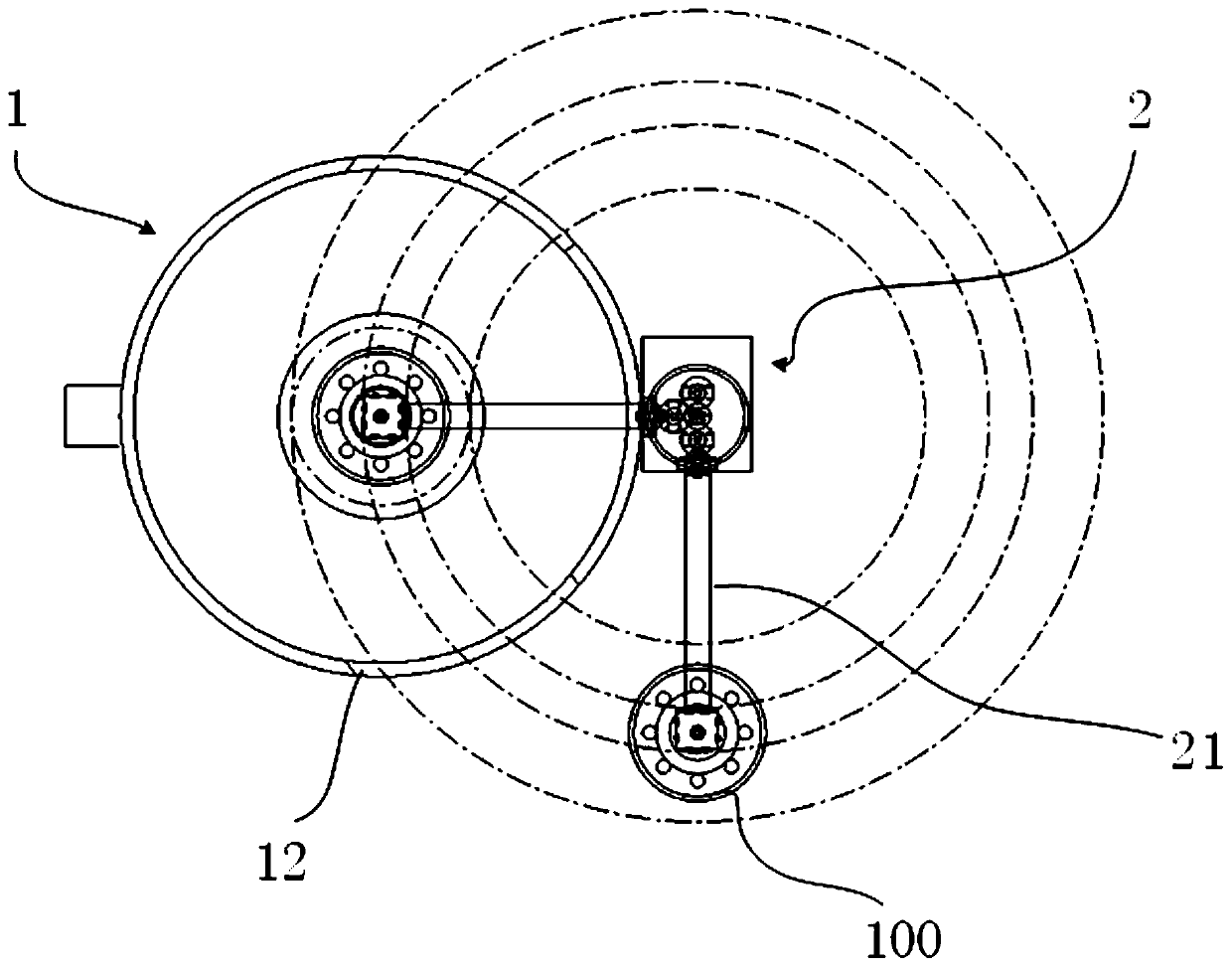

Spraying operation device and method

The invention discloses a spraying operation device and method. The spraying operation device comprises a shell and a rotation mechanism located at the outer portion of the shell. The rotation mechanism comprises a rotation body and at least two arm parts, wherein the rotation body rotates around one axis and is located on the outer side of the shell, one ends of the arm parts are provided with supporting parts for containing to-be-sprayed components, and the arm parts and the supporting parts can be driven by the rotation mechanism to automatically get in and out of the shell from notches anddoor bodies. The spraying operation device further comprises the door bodies, wherein the door bodies can be in a closed state when one supporting part is located in the shell and is in a spraying state. According to the provided spraying operation device and method, the spraying operation device can have the small waste gas amount, and the enterprise waste gas treatment cost is greatly reduced.

Owner:昆山敬德科技工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com