Silencing structure suitable for drying air duct of washing machine and washing machine

A washing machine and air duct technology, applied in the field of noise reduction of the air duct of the washing machine, can solve the problem of high noise of the whole machine, and achieve the effects of solving the noise, improving the airflow pulsation noise, and improving the user experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

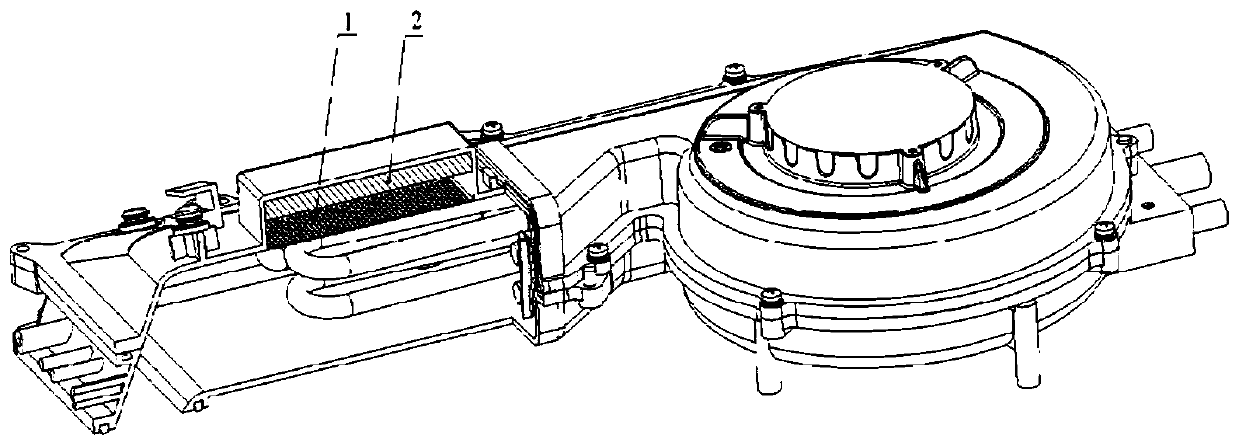

[0027] Such as figure 1 As shown, in this embodiment, a sound-absorbing structure suitable for the drying air duct of the washing machine is disclosed. The sound-absorbing structure can be arranged on the drying air duct located downstream of the fan. The air outlet is connected, and the air outlet of the drying air duct is connected with the drying barrel, and the noise in the air duct and the noise of the fan can be eliminated by being arranged at this place. Specifically, the noise reduction structure includes: an outwardly protruding cavity formed on the upper wall of the drying air duct, a micro-perforated plate 1 sealed at the mouth of the cavity, and a micro-perforated plate located at the rear side of the micro-perforated plate (cavity One side inside) and the sound insulation layer 2 laid on the inner wall of the cavity at a predetermined distance from the micro-perforated plate.

[0028] In this embodiment, the laying direction of the micro-perforated plates is para...

Embodiment 2

[0039]In this embodiment, a washing machine with noise reduction function is disclosed. The washing machine includes: a drying air duct, a fan and a drying drum, wherein the drying fan and the drying drum are connected through the drying air duct, and the drying air duct adopts The sound-absorbing structure in embodiment 1.

[0040] During the drying process of the washing machine, the fan of the drying system is always running at high speed, and the noise of the fan motor and the air flow noise of the air duct are particularly prominent. The technical solution in the present invention starts to improve the structure of the drying air duct, and adopts new sound-absorbing materials to reduce the noise of the drying system from the transmission path and improve the quiet comfort of the whole machine.

[0041] The present invention will be further described in detail below in combination with specific embodiments.

[0042] Such as figure 1 As shown, the drying air duct in the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com