Method for cleaing molten steel for continuous casting tundish by air curtain retaining wall method

A continuous casting tundish and gas curtain retaining wall technology, which is applied in the field of steelmaking and continuous casting, can solve the problems of secondary pollution and insignificant removal effect of small inclusions, save gas source, reduce secondary pollution, and achieve good effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

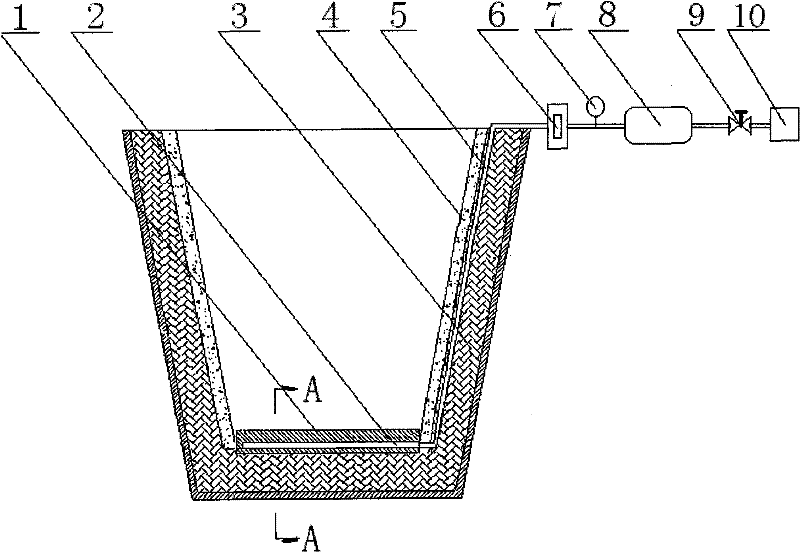

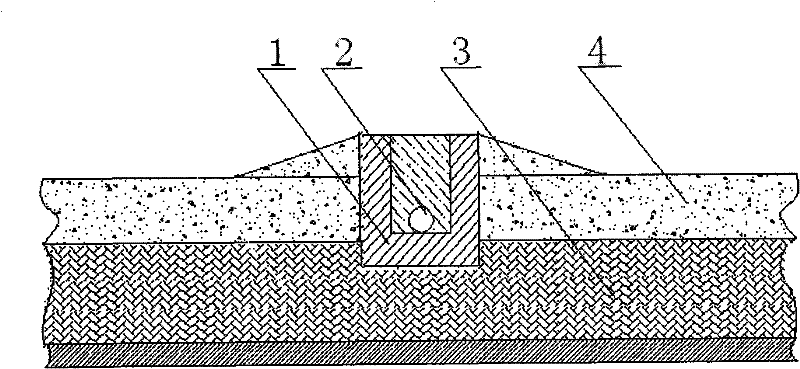

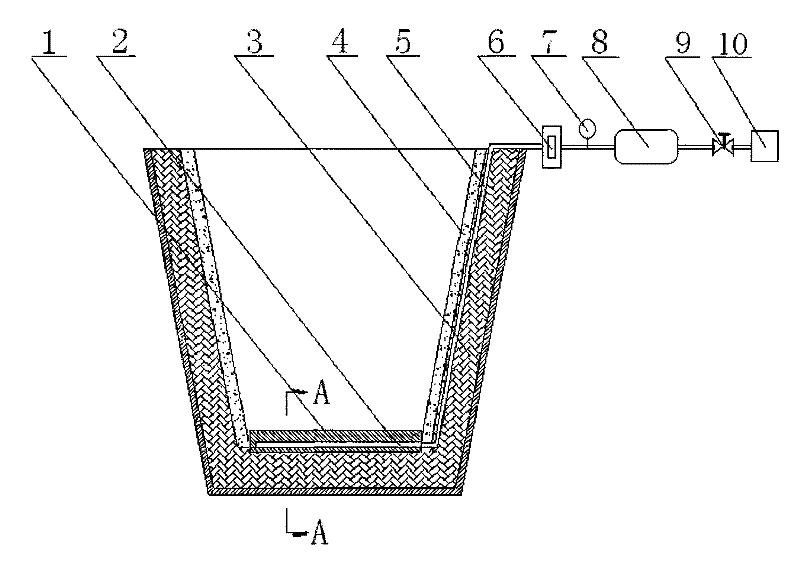

[0015] A method for cleaning molten steel in continuous casting tundish air curtain retaining wall, such as figure 1 Shown: Slots are made on the bottom of the tundish and the permanent layer 3 near the side wall of the air source, and the breathable brick 1 is embedded in the groove of the permanent layer 3 at the bottom of the tundish. The upper air-permeable surface of the breathable brick 1 is as follows figure 2 The working layer 4 that is slightly higher than the bottom of the tundish is shown; the groove of the permanent layer 3 near the side wall of the gas source is embedded in the groove of the permanent layer 3, and one end of the argon connecting pipe 5 is connected to the breathable brick embedded in the groove at the bottom of the tundish The air-permeable chamber 2 of 1 communicates, and the other end of the argon gas connection 5 protrudes upward along the permanent layer 3 groove of the side wall and passes through the flow meter 6, pressure gauge 7, buffer ga...

Embodiment 2

[0020] A method for cleaning molten steel in continuous casting tundish air curtain retaining wall, such as figure 1 Shown: Slots are made on the bottom of the tundish and the permanent layer 3 close to the side wall of the gas source, the ventilating brick 1 is embedded in the groove at the bottom of the tundish, and the upper ventilating surface of the ventilating brick 1 is flush with the working layer 4 built on the bottom of the tundish . The air permeability of the air brick is 25-40μm 2 , the width of the upper air-permeable surface is 50-60mm; the groove depth of the permanent layer 3 at the bottom of the tundish is 10-15mm, the groove width is 90-100mm, and the groove length is the same as the width of the working layer 4 at the bottom of the tundish; The groove depth of the permanent layer 3 on the side wall of the source is 10-15 mm, the groove width is 10-15 mm, and the groove length is the distance from the bottom of the tundish to the edge of the tundish.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com