Powdered coal burner head with high efficiency and low wear

A pulverized coal burner and low-wear technology, which is applied to burners, burners for burning powder fuel, combustion methods, etc., can solve problems such as unreasonable design of head parts and unattainable performance indicators, and achieve a wide range of use. , long service life and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

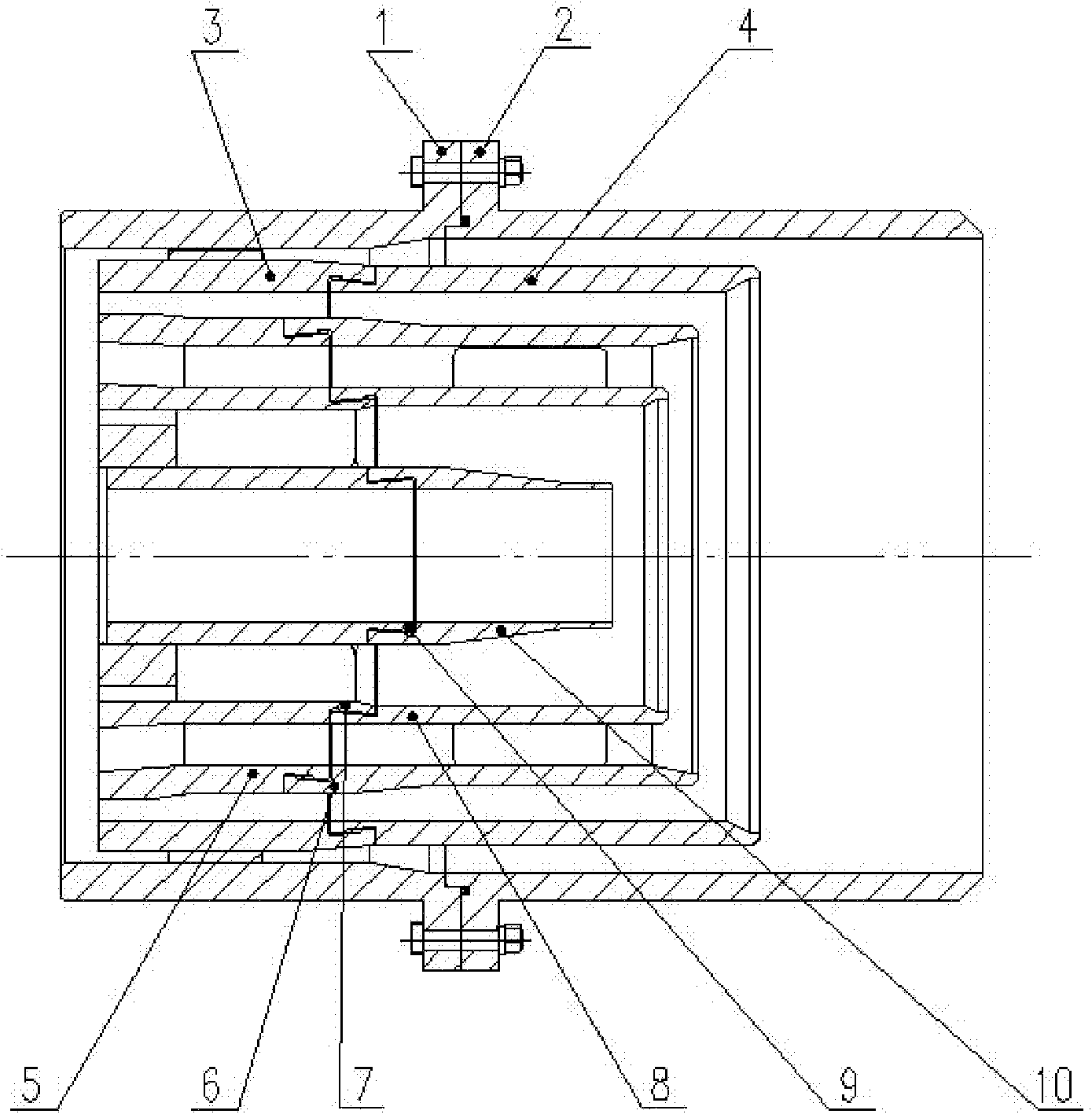

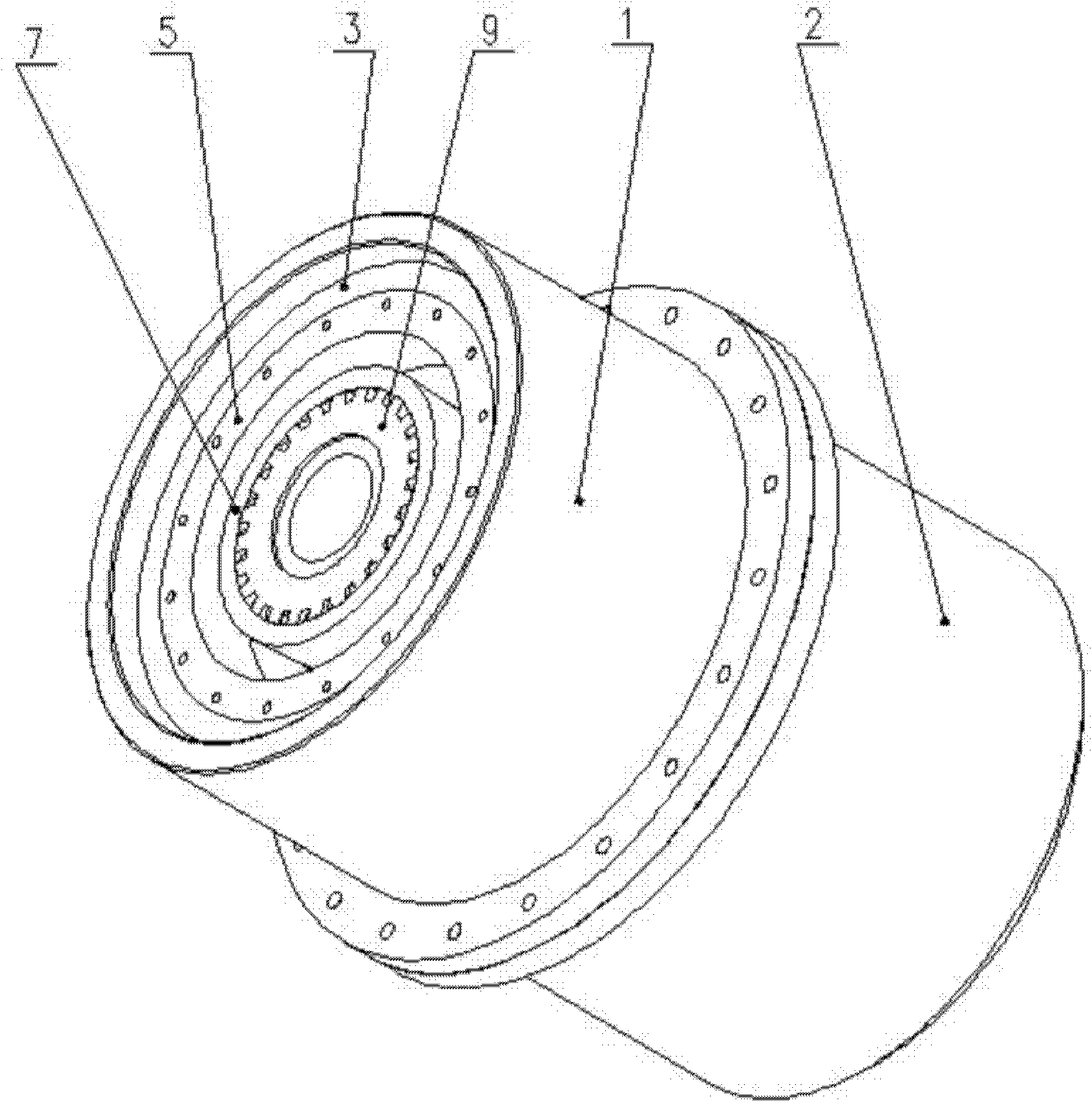

[0016] Embodiment 1 A high-efficiency and wear-free pulverized coal burner head consists of a large head outer cylinder, a middle large outer cylinder, a head outer cylinder, a middle outer cylinder, a head injector, an injector connector, and a head coal burner. It is composed of powder outlet, middle coal powder outlet, head cyclone and cyclone connecting parts. Its characteristics are reflected in that the large outer cylinder of the head and the large outer cylinder of the middle part are connected by means of flange contact surfaces and gaskets through connecting bolts; the outer cylinder of the head and the outer cylinder of the middle part are directly connected by threads; the head injector, its There are 16 circular holes evenly distributed in the circumferential direction of the end surface, and the head injector is directly connected with the injector connector through threads; the outlet of the pulverized coal at the head and the outlet of pulverized coal in the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com