Coal-based methanol-ether fuel additive based on chemical by-products and application thereof

A coal-based alcohol ether and by-product technology, applied in the field of fuel additives, can solve the problems of micro-toxicity, open flame, high heat and flammability, insufficient coal combustion, environmental damage, etc., to reduce the amount of cold air entering and ensure stable combustion , Improve the effect of particle shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

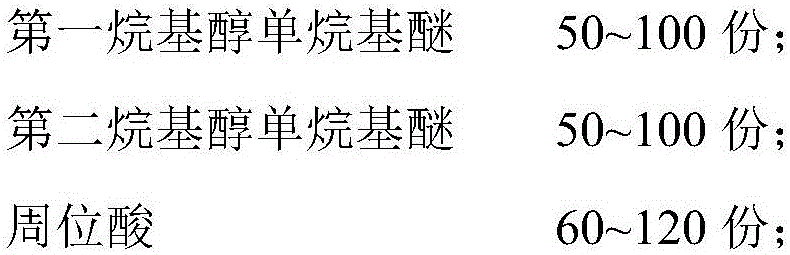

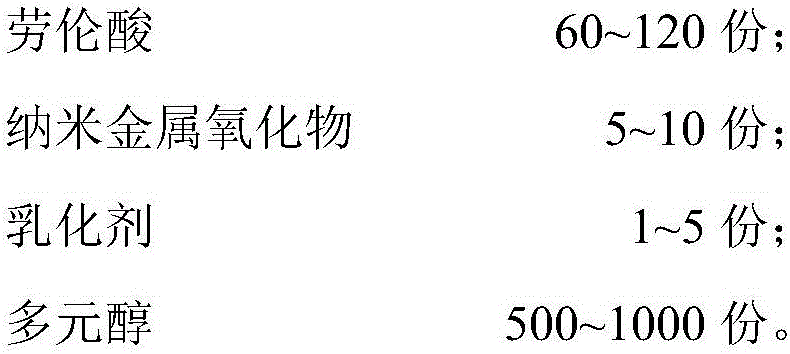

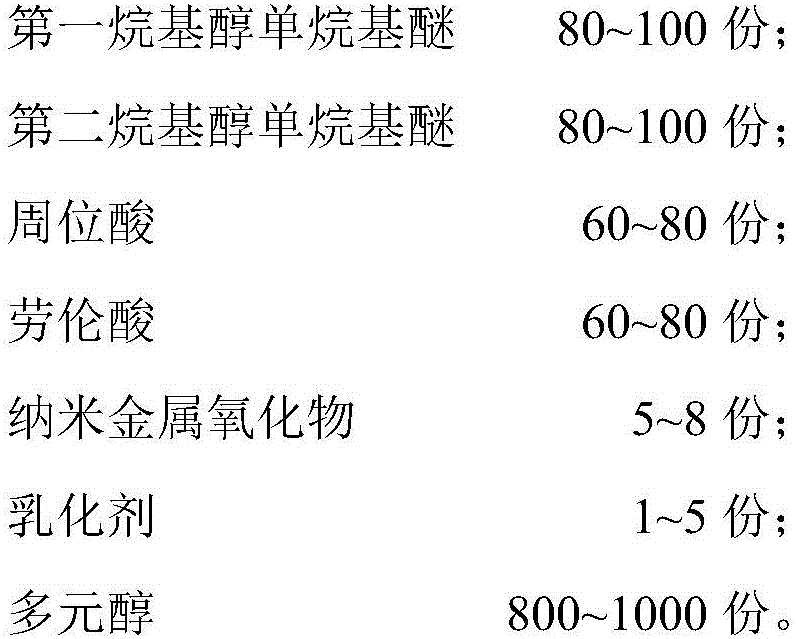

[0021] The above-mentioned preparation method of the coal-based alcohol ether fuel additive based on chemical by-products comprises the following steps:

[0022] (1) the described polyhydric alcohol of formula quantity is equally divided into four groups, the described emulsifier of formula quantity is equally divided into three groups;

[0023] (2) The first alkyl alcohol monoalkyl ether and the second alkyl alcohol monoalkyl ether of the formula quantity are dissolved in two groups of polyols respectively to form the first ether solution and the second ether solution;

[0024] (3) Dissolve the laurentic acid and periacid of formula quantity in water respectively to form periacid solution and laurentic acid solution (usually 1~5mol / L), then mix the first ether solution with the The peri-acid solution and the laurentic acid solution are subjected to dehydration-esterification (using the existing dehydration-esterification method) reaction, and then respectively add a group of ...

Embodiment 1

[0030] This embodiment provides a coal-based alcohol ether fuel additive based on chemical by-products. Its raw material formula includes the following components in parts by weight: 50 parts of diethylene glycol monomethyl ether, 100 parts of tetraethylene glycol monononyl ether 60 parts, 60 parts of peri acid, 120 parts of laurenic acid, 10 parts of nano-titanium dioxide, 5 parts of emulsifier OP-10, 1000 parts of ethylene glycol.

[0031] The method for above-mentioned coal-based alcohol ether fuel additive, it may further comprise the steps:

[0032] (1) The ethylene glycol of formula quantity is equally divided into four groups, and the emulsifier of formula quantity is equally divided into three groups;

[0033] (2) The first alkyl alcohol monoalkyl ether and the second alkyl alcohol monoalkyl ether of the formula quantity are dissolved in two groups of polyols respectively to form the first ether solution and the second ether solution;

[0034] (3) Dissolve the laurent...

Embodiment 2

[0039] This embodiment provides a coal-based alcohol ether fuel additive based on chemical by-products. Its preparation method is consistent with that in Example 1, except that its raw material formula includes the following components in parts by weight: pentaethylene glycol 100 parts of monomethyl ether, 50 parts of tetraethylene glycol lauryl ether, 50 parts of peri-acid, 60 parts of laurenic acid, nano La 2 o 3 5 parts, 1 part of emulsifier OP-10, 500 parts of propylene glycol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com