Olefin polymerization catalyst and preparation and application thereof

A technology for olefin polymerization and catalysts, applied in the field of catalysts, can solve problems such as difficult separation and poor shape of catalyst particles, and achieve the effects of simple preparation method, good particle shape, and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

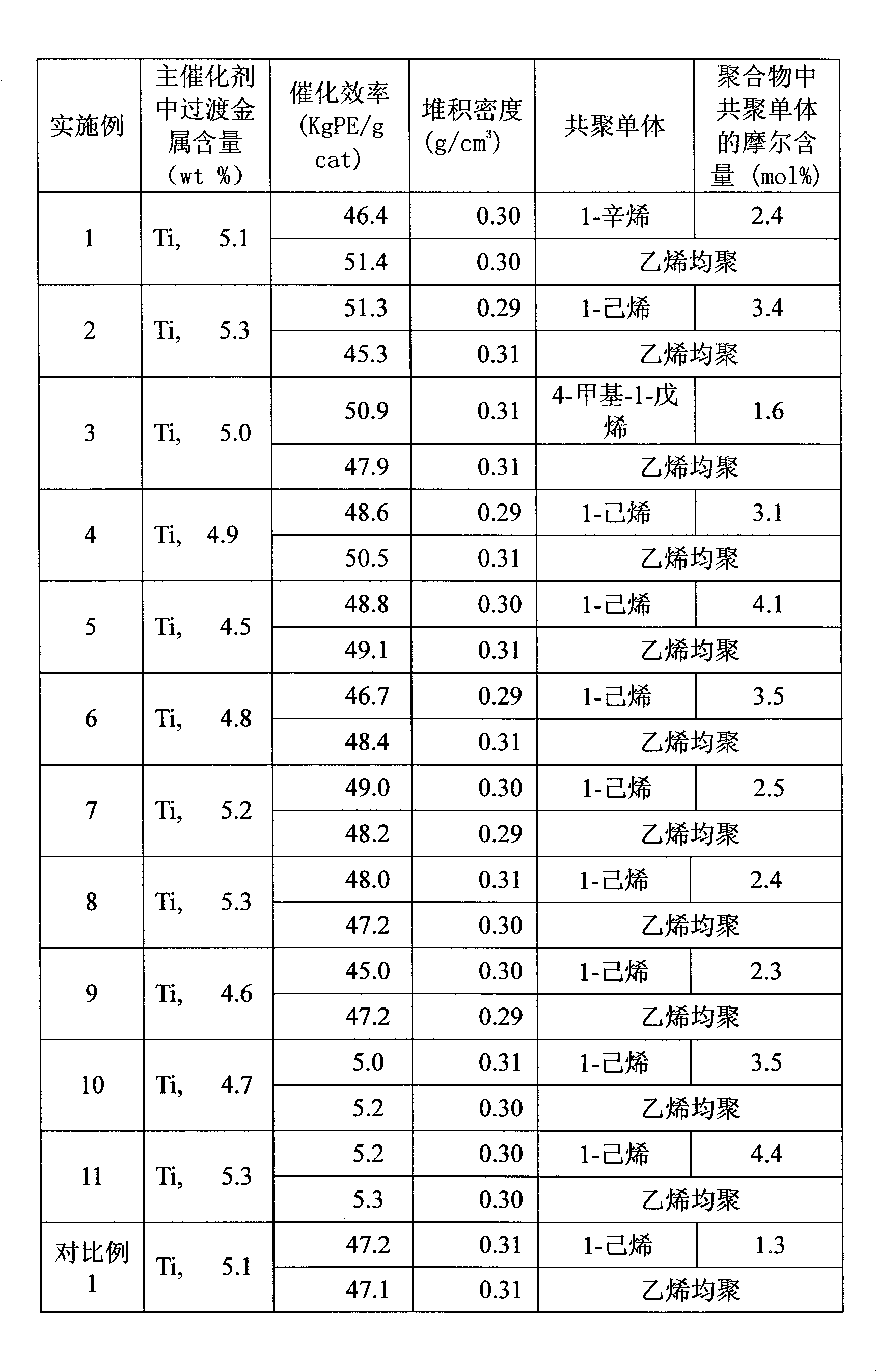

Examples

Embodiment 1

[0033] 1) Preparation of the main catalyst: In the reactor fully replaced by nitrogen, 2 g of magnesium dichloride, 3.5 ml of epichlorohydrin, 5.5 ml of tributyl phosphate, 75 ml of toluene, 15 ml of hexane, and 3.2 ml of ethanol were added successively, and the mixture was stirred. The temperature was raised to 70°C, after the solid was completely dissolved to form a homogeneous solution, the temperature was kept constant for 1h; then the temperature was lowered to -25°C, 58ml of titanium tetrachloride and 3.5ml of diethoxyisopropoxytert-butoxysilane were added dropwise, and the reaction was carried out for 1h. Then, the temperature was kept at -10 °C for 1 h, 0 °C for 1 h, and 20 °C for 1 h, 15 ml of hexane was added, the temperature was raised to a constant temperature of 60 °C, 10 ml of hexane was added, the reaction was carried out for 2 h, the stirring was stopped, the suspension was allowed to stand, and the layers were separated. The supernatant liquid was removed by su...

Embodiment 2

[0037] 1) Preparation of the main catalyst: In the reactor fully replaced by nitrogen, 5 g of magnesium dichloride, 7.5 ml of epichlorohydrin, 10.5 ml of tributyl phosphate, 150 ml of toluene, 10 ml of hexane, and 6.2 ml of ethanol were added successively, and the mixture was stirred. The temperature was raised to 60°C, after the solid was completely dissolved to form a homogeneous solution, the temperature was kept constant for 1 hour; then the temperature was lowered to -25°C, and 40ml of titanium tetrachloride was added dropwise. , add 10ml of hexane, react for 1h, heat up to a constant temperature of 70°C, 10ml of hexane, react for 2h, stop stirring, let the suspension stand, layer, remove the supernatant, wash twice with toluene and twice with hexane , blown dry with nitrogen to obtain the main catalyst component with good fluidity and narrow particle size distribution;

[0038] 2) Ethylene copolymerization: After the 0.5-liter stainless steel autoclave was fully replaced...

Embodiment 3

[0041] 1) Preparation of main catalyst: in the reactor fully replaced by nitrogen, add magnesium dichloride 5g, epichlorohydrin 5ml, tributyl phosphate 10.5ml, toluene 75ml, hexane 15ml successively, and heat up to 60 ℃ under stirring, After the solid was completely dissolved to form a homogeneous solution, the temperature was kept at a constant temperature for 1h; then the temperature was lowered to -25°C, 50ml of titanium tetrachloride was added dropwise, 5g of triethoxy-tert-butoxysilane was added after the dropwise addition, and after the reaction for 1h, the temperature was lowered to -10 ℃ constant temperature for 1h, 0℃ constant temperature for 1h, 0℃ constant temperature for 1h, add 15ml hexane, heat to 50 ℃ constant, add 20ml hexane, warm reaction for 2h, stop stirring, let the suspension stand, stratify, remove the supernatant , washed twice with toluene, twice with hexane, and dried with nitrogen to obtain the main catalyst component with good fluidity and narrow par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com