Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

187results about How to "Simple and reasonable design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

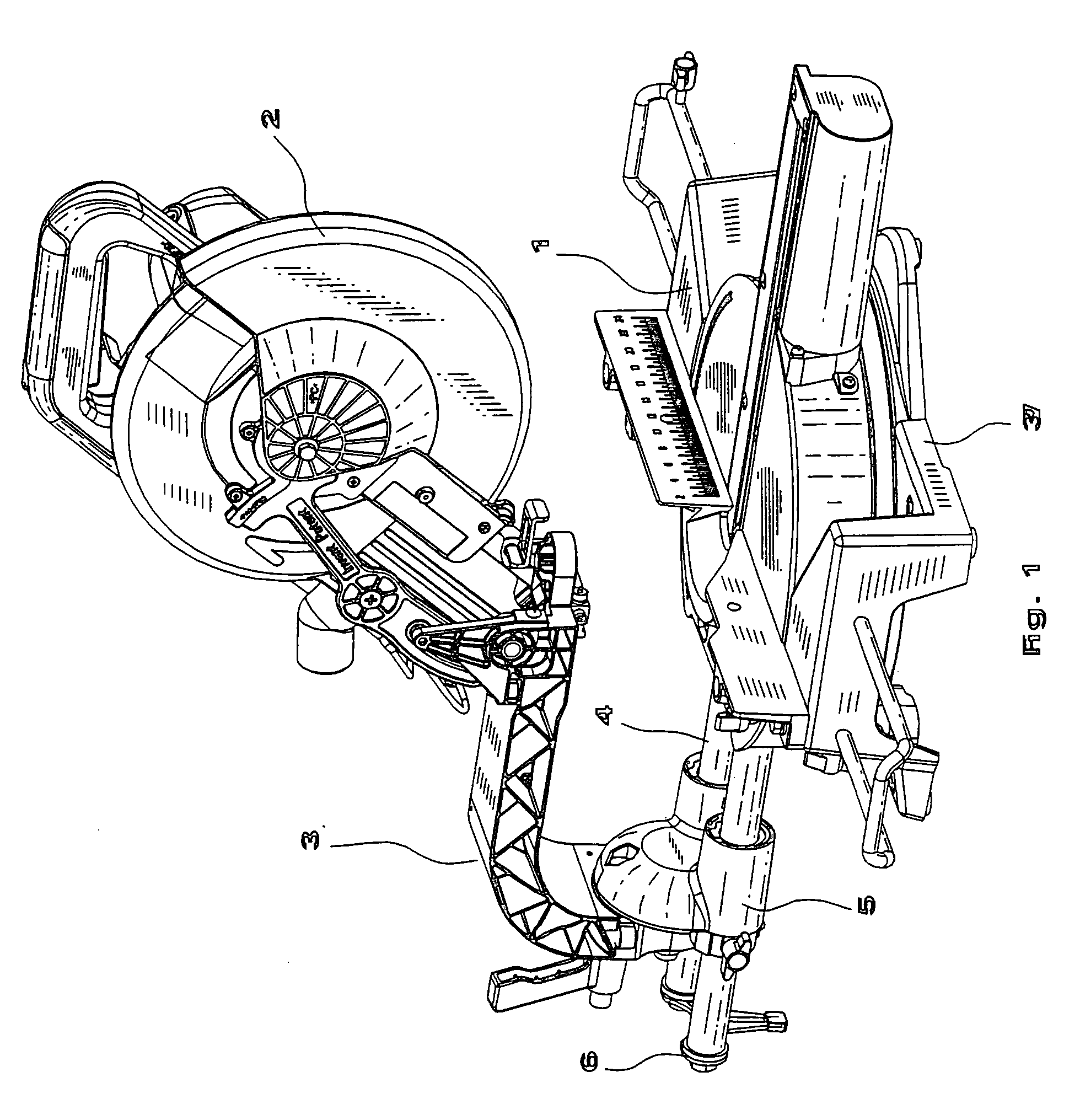

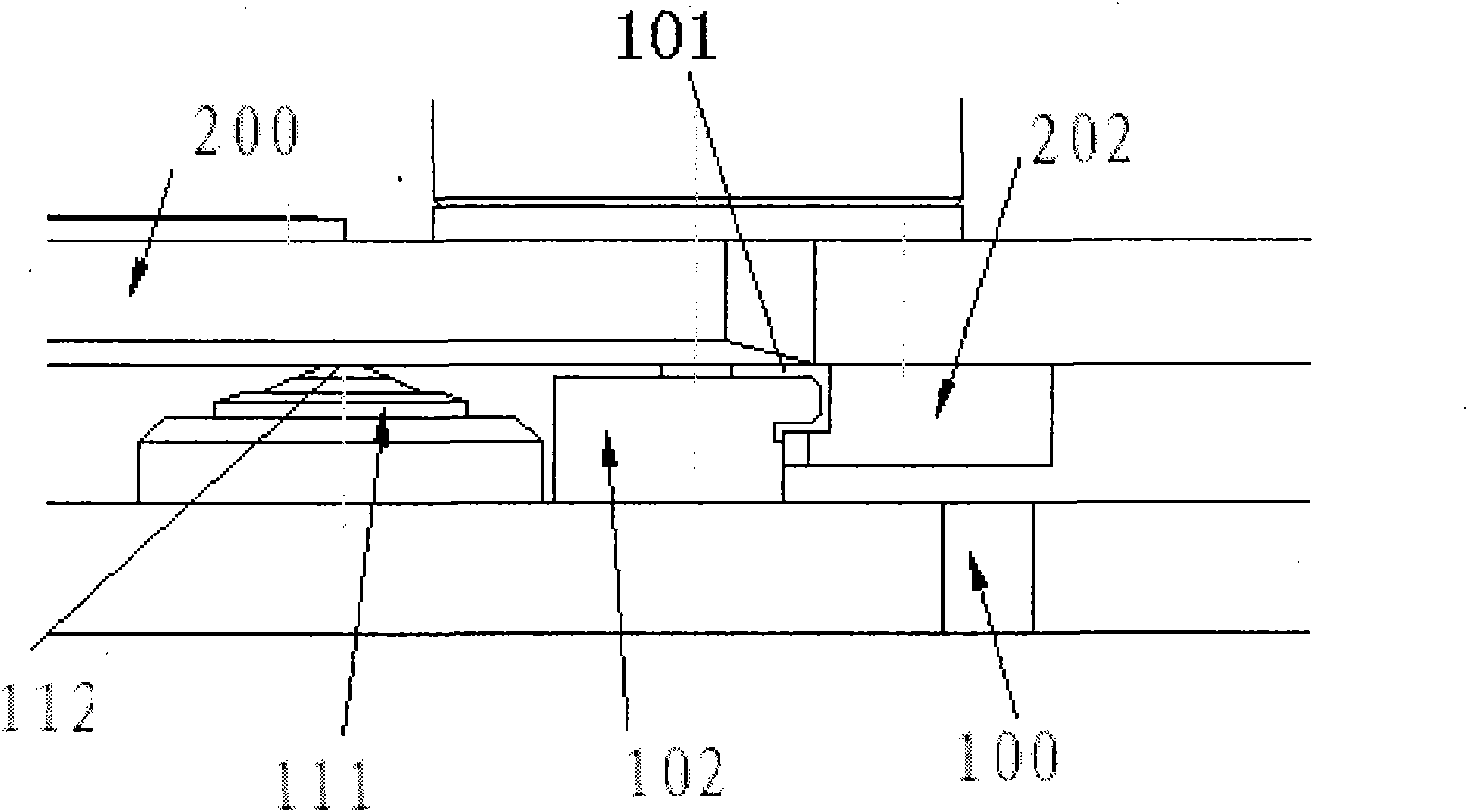

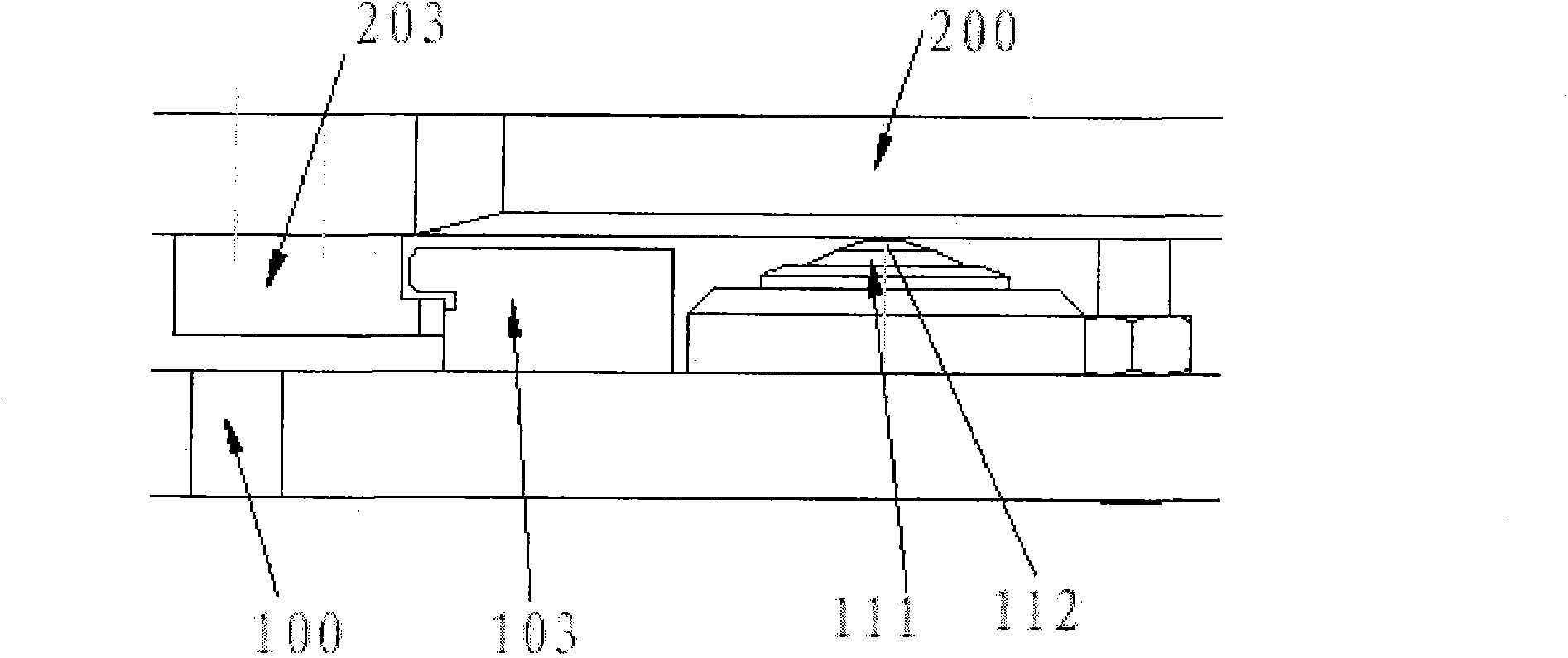

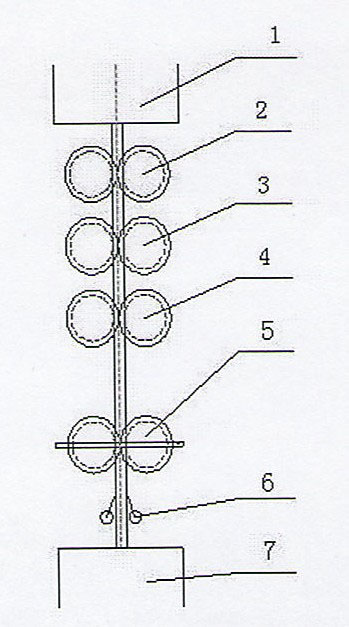

Automatic shoe cover dispenser

InactiveUS20060144879A1Simple and reasonable designLow costApparel holdersCoin-freed apparatus detailsEngineeringHooking

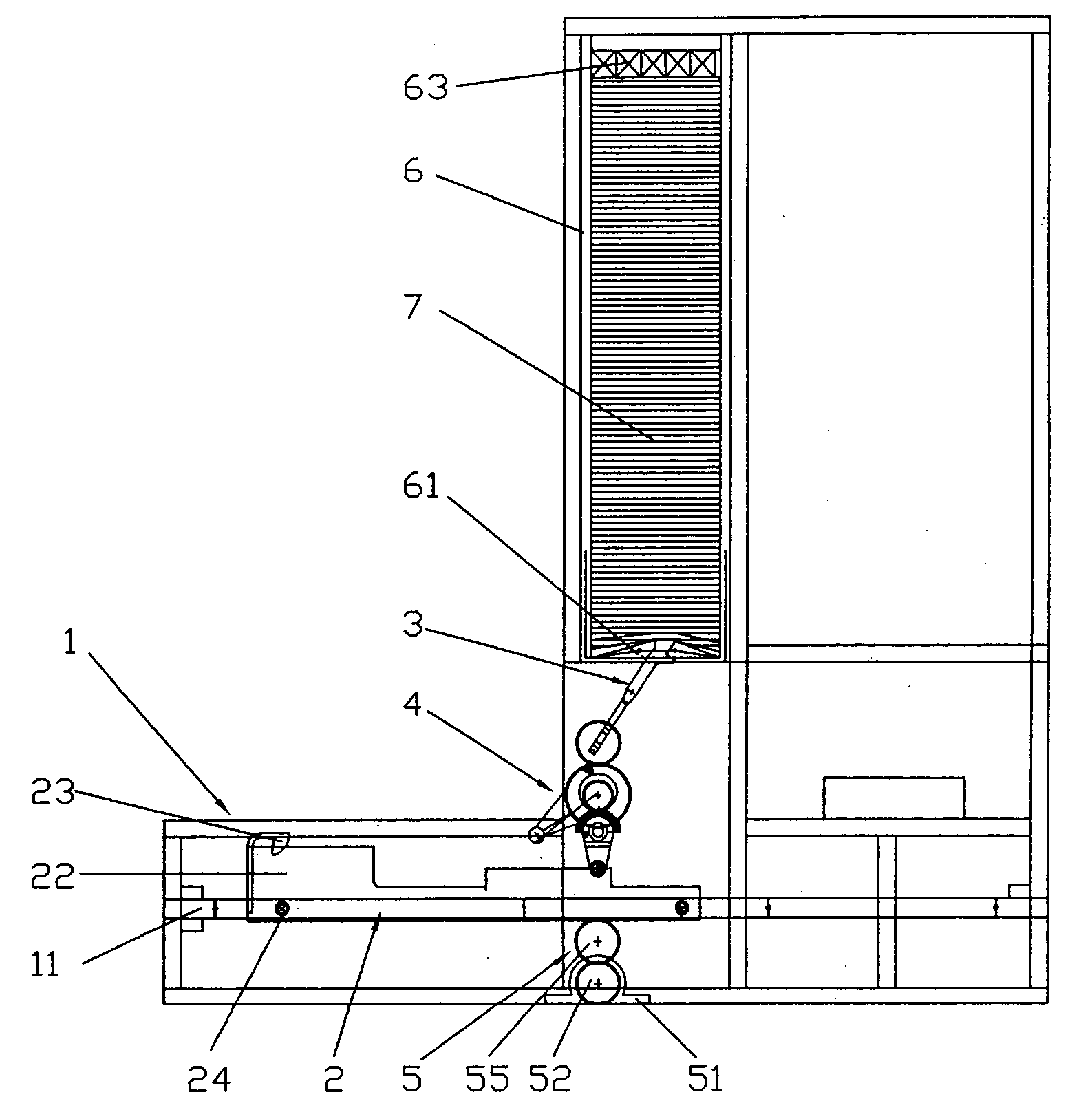

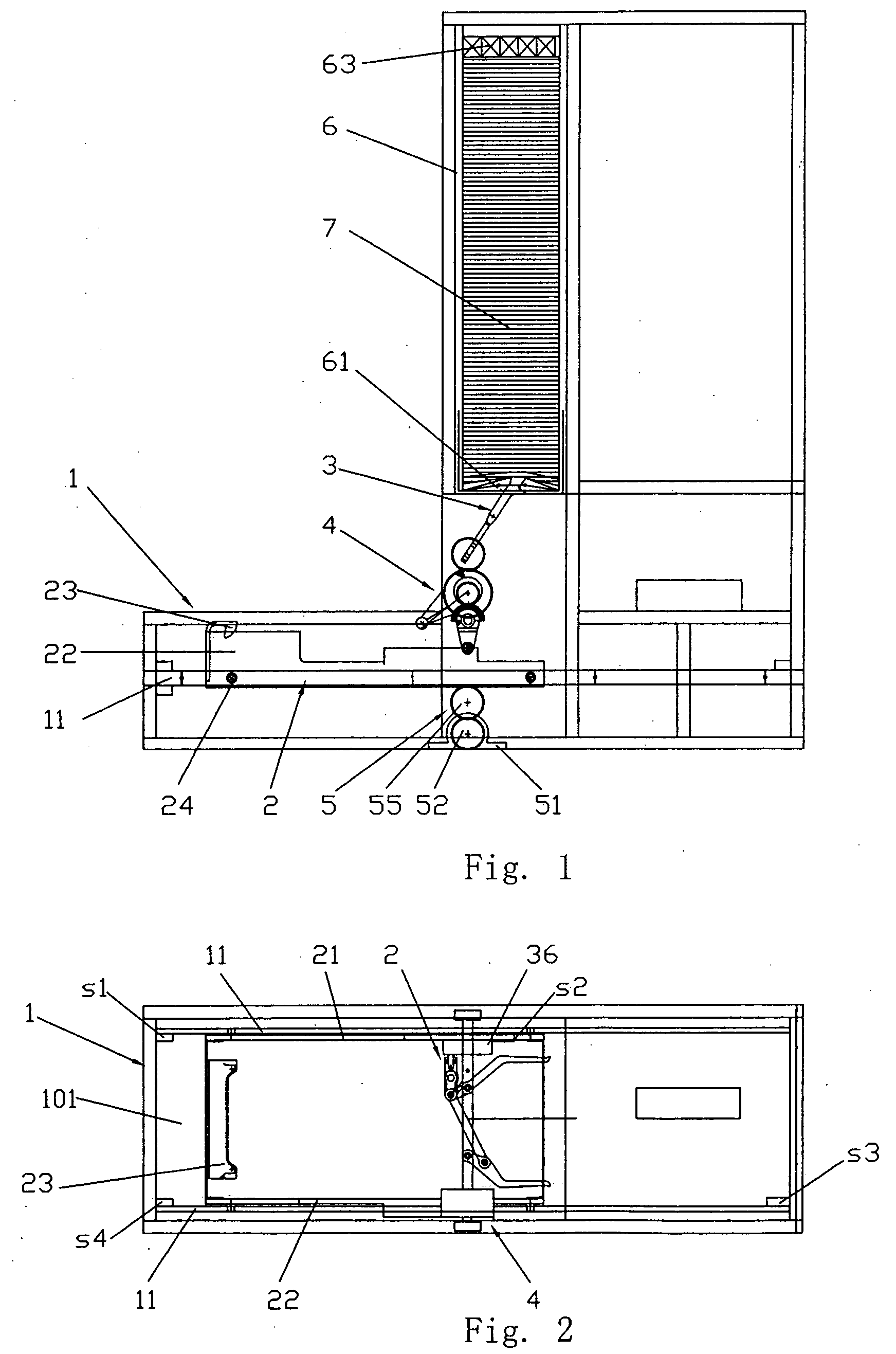

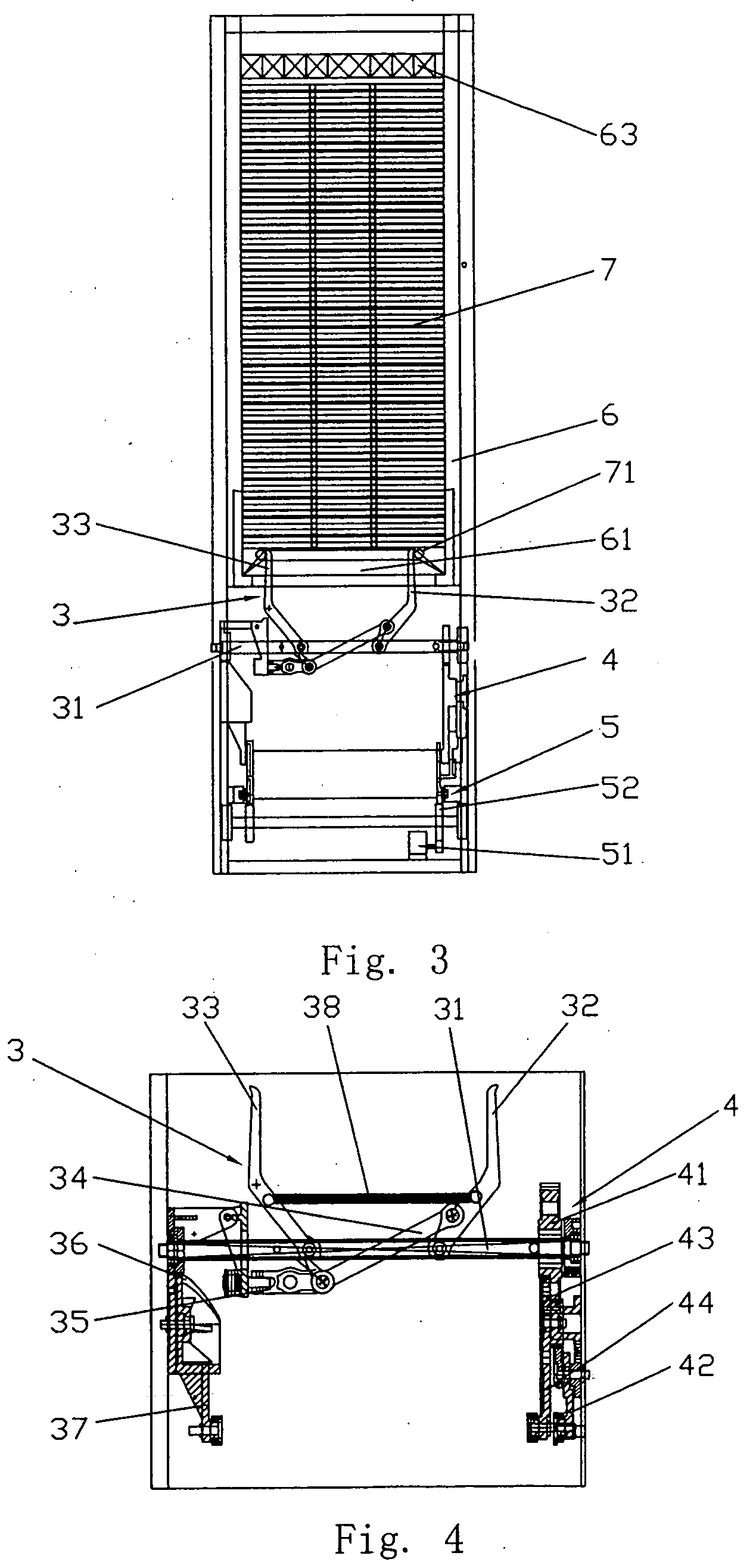

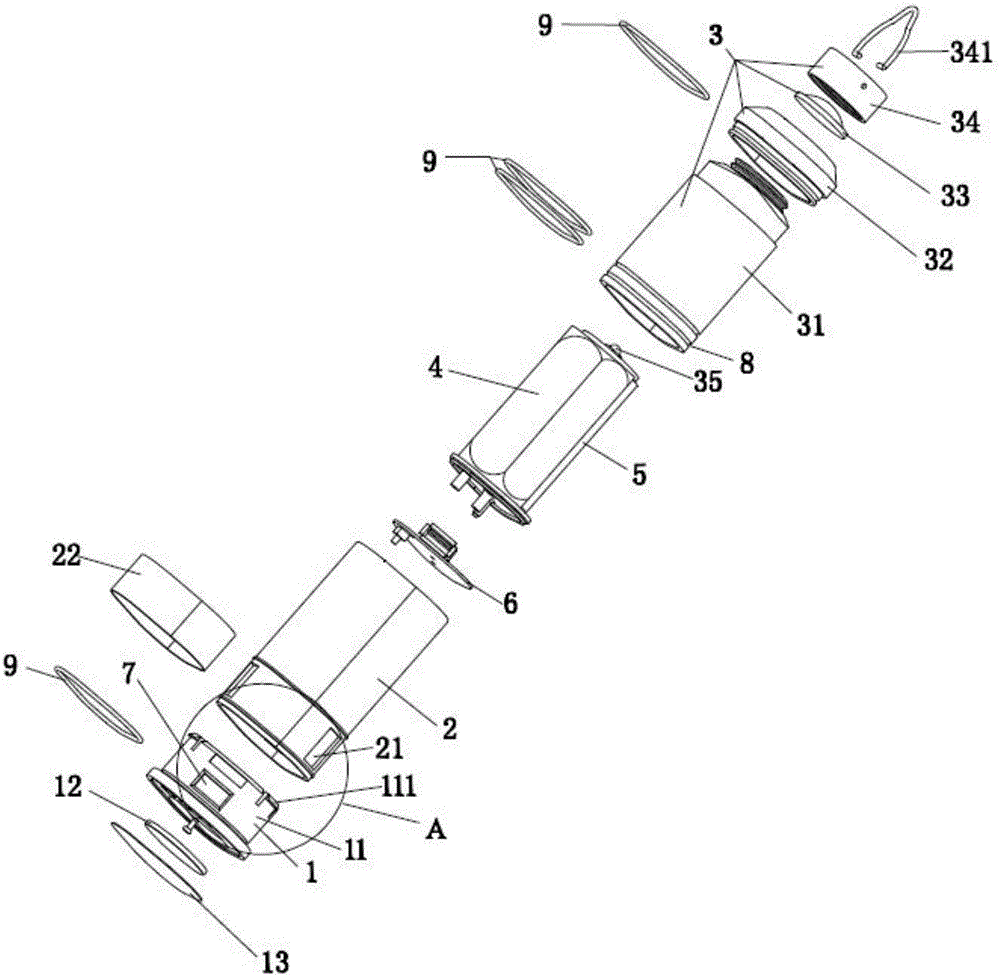

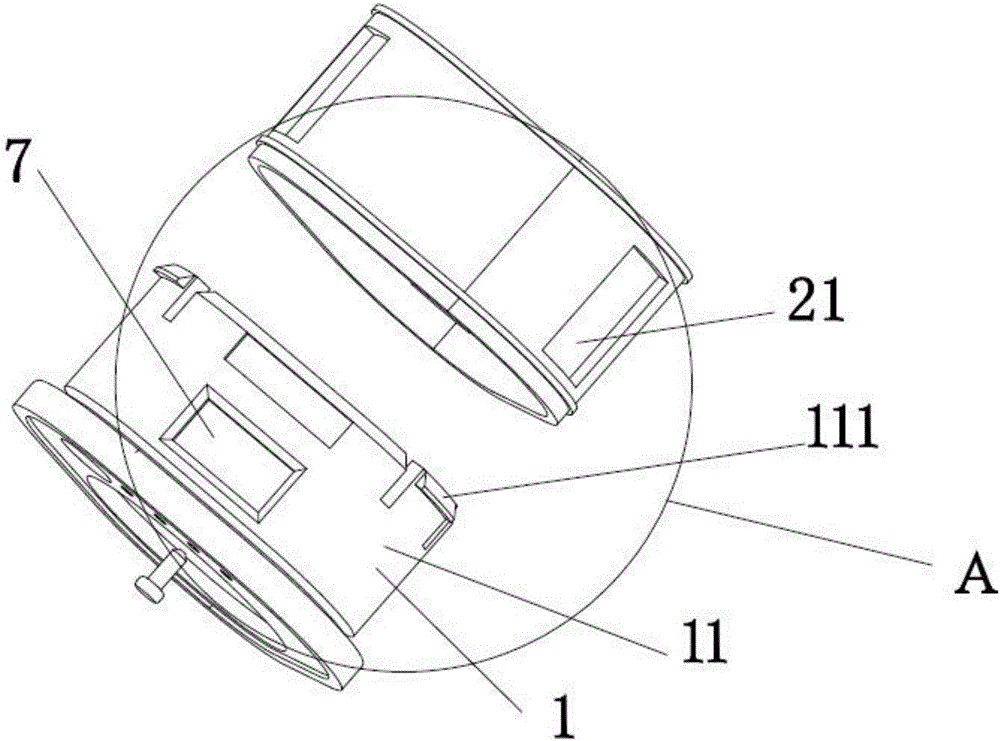

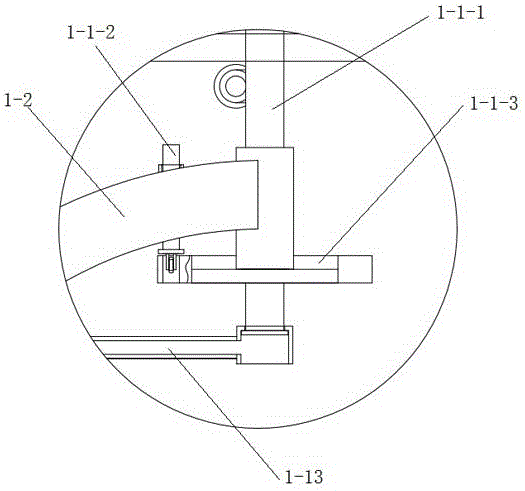

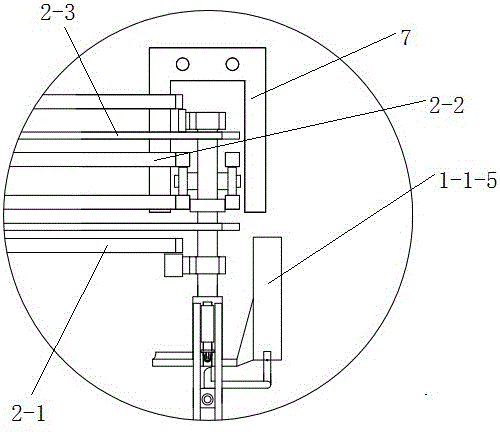

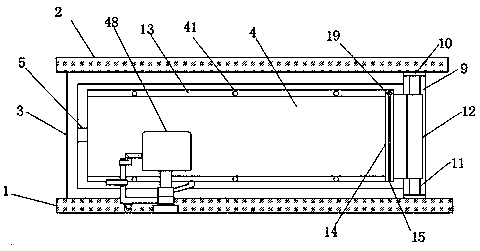

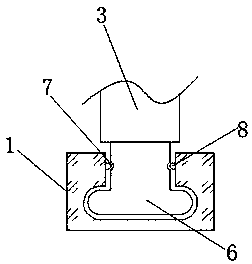

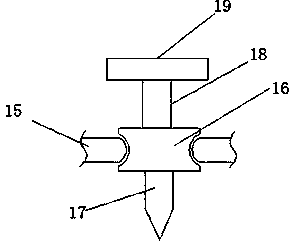

Auto shoe cover dispenser, includes machine body (1), traction and extension mechanism (2), separation and hooking mechanism (3), turning mechanism (4), traction driving mechanism (5), shoe cover box (6). The body of shoe cover box (6) is equipped with shoe cover separating exit, separation and hooking mechanism extends into the shoe cover separating exit to pull out the shoe cover, and the traction and extension mechanism expands it, just put the foot into the stretched shoe cover, and tread out downwards. The advantages of this utility model are, first, its simple and rational structure, strong practicability, safety and reliability, which uses disposable normal shoe cover without special process and technical requirements, thus greatly reducing the costs of perishable items, and affordable to a large quantity of consumers; second, shoe cover dispenser has large capacity and it's also very convenient to install shoe covers, the shoe covers installation quantity can be freely adjusted according to the user's wish, which can reach as high as dozens or even thousands of pairs, while shoe cover dispenser doesn't need to make any adjustment, to be widely used for household needs as well as various locations such as hospitals and scientific research institutes etc.

Owner:HU QUANXI

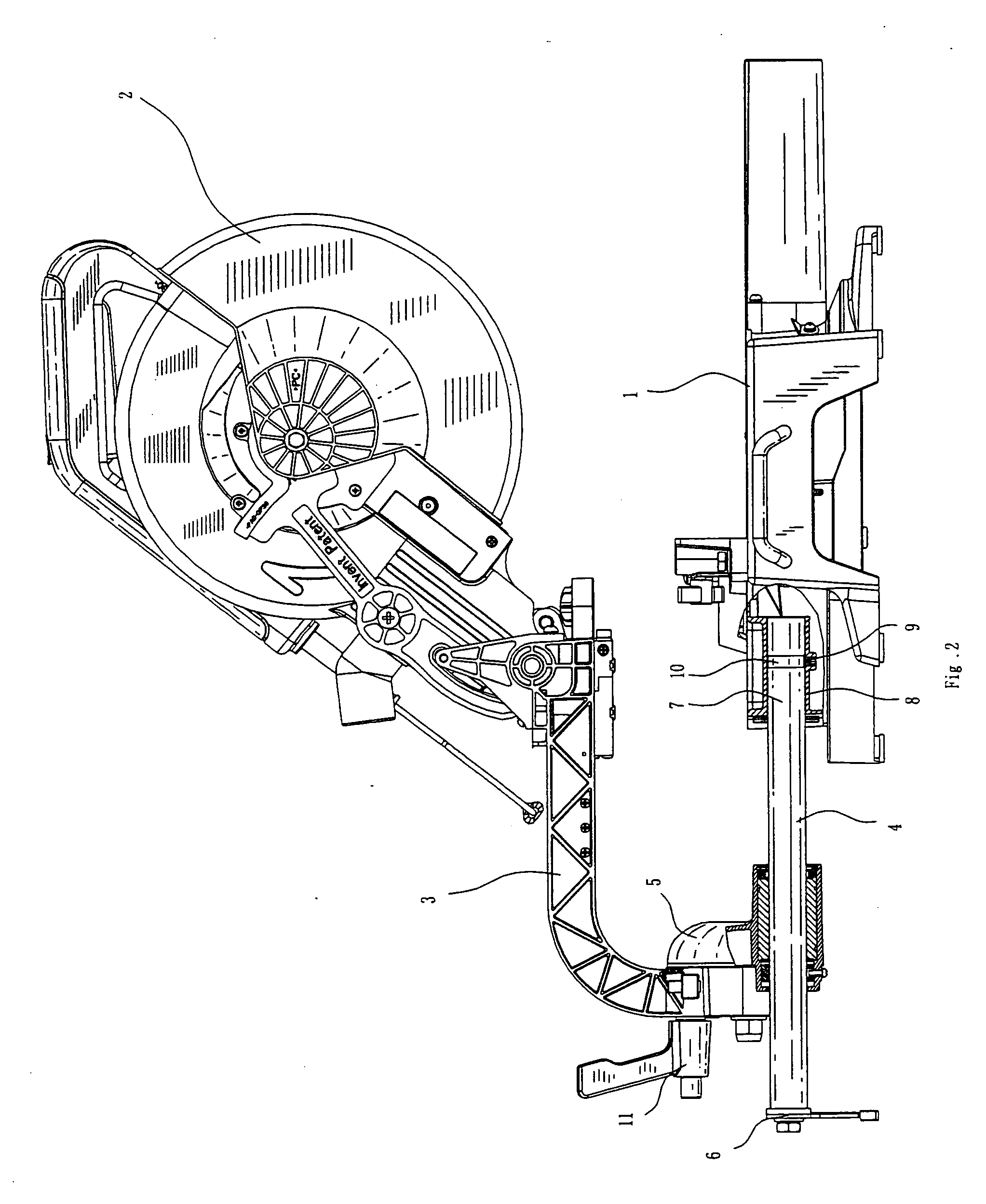

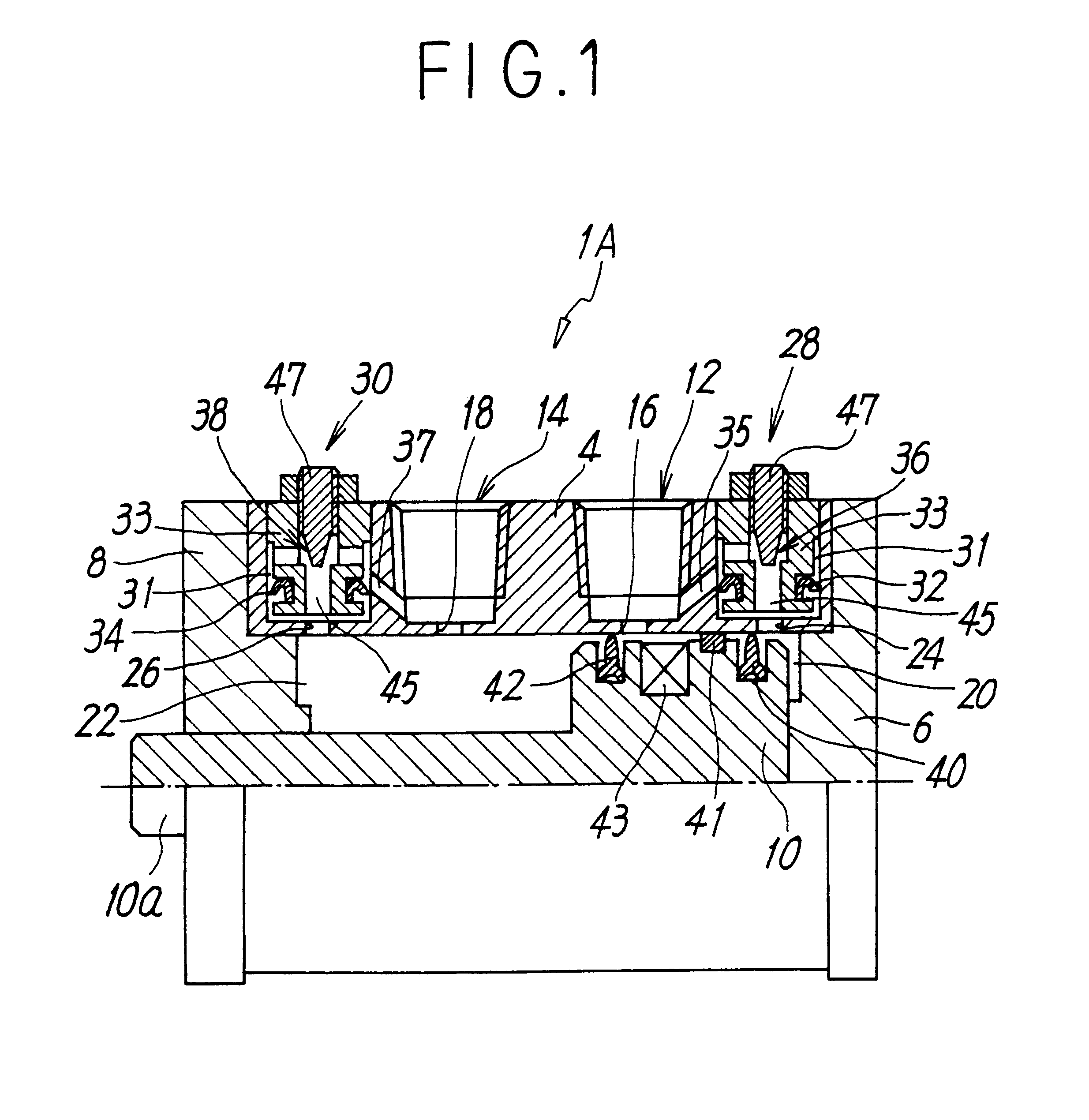

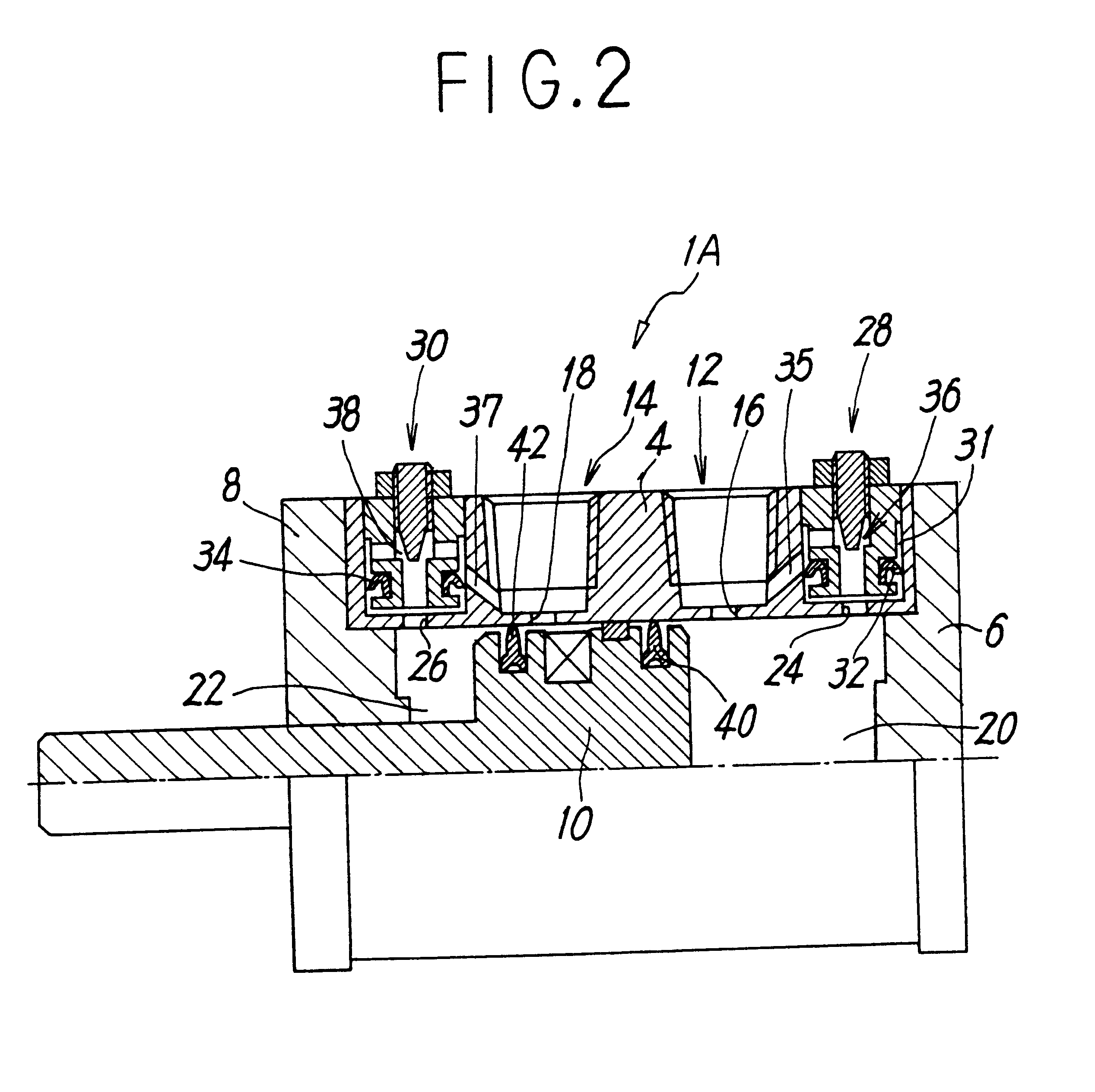

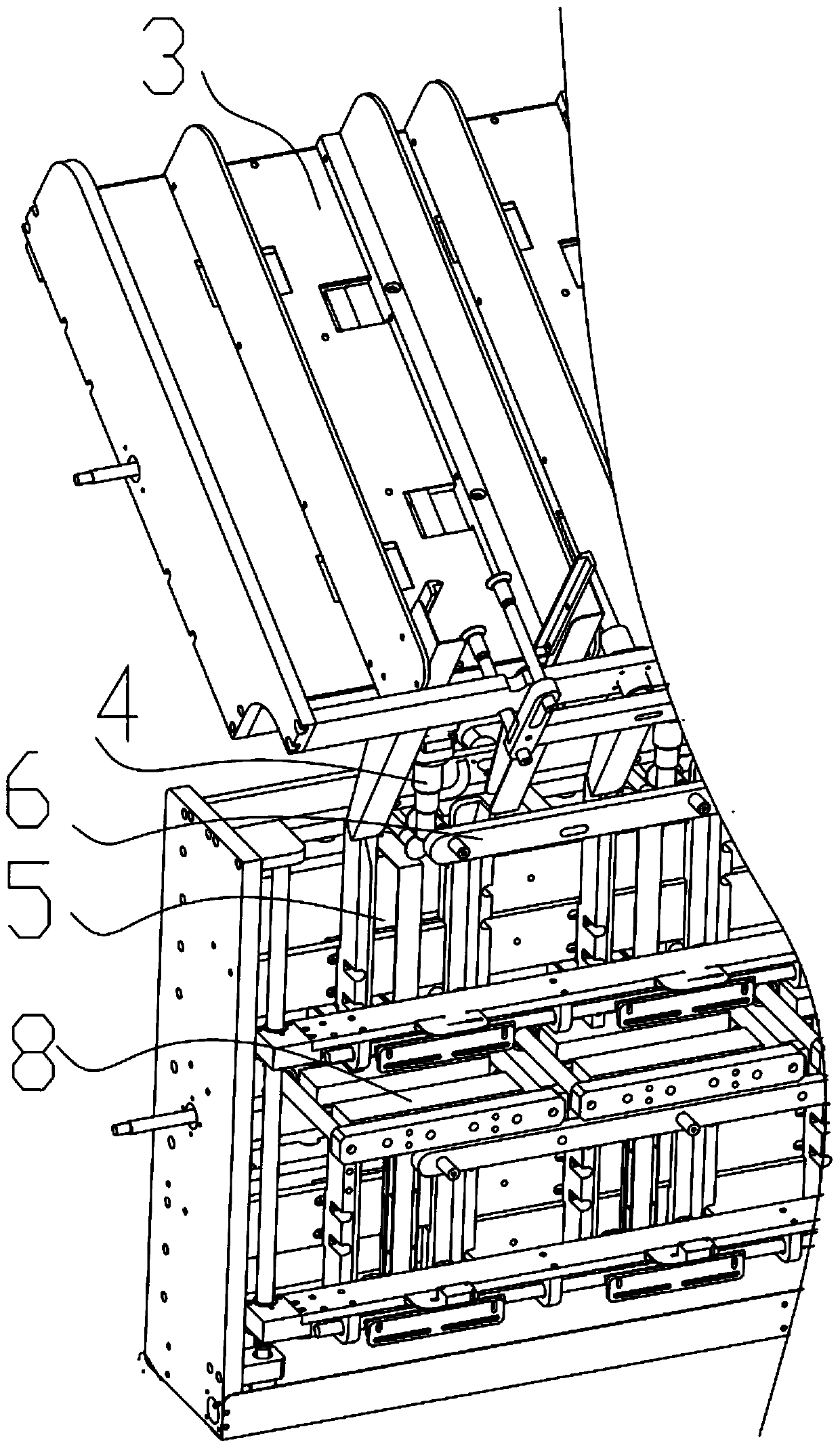

Electric miter saw

InactiveUS20070074611A1Efficient use ofExpand the cutting rangeMetal sawing devicesGuide fencesBall bearingEngineering

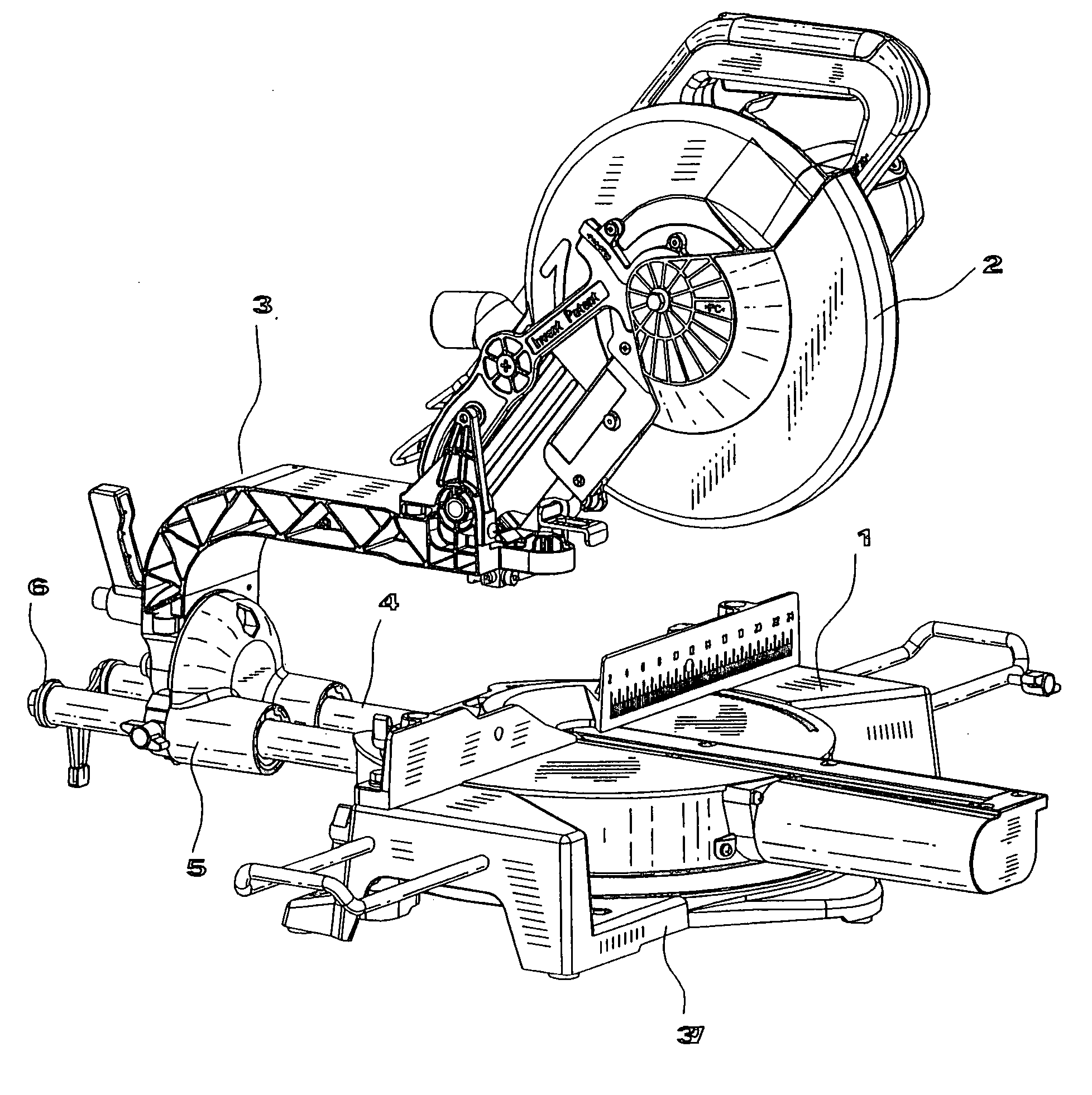

An electric miter saw includes a base, a cutting table, a cutting member and a link arm. The cutting table is mounted on the base. The upper portion of the link arm is connected to a cutting member with the cutting saw blade driven by a motor. The lower portion of the link arm is connected to the upper portion of a supporting member and secured by a threaded central bolt. The linear ball bearing is mounted in the inner aperture of the supporting member, which is slidably connected to the slide rod by a linear ball bearing. At the outer end of the slide rod is mounted a position limit socket. The inner end of the slide rod is connected and secured beneath the cutting table via a releasable securing configuration mentioned above. A flexible blade guard is also provided.

Owner:NIG BO YANG MING ELECTRIC TOOLS

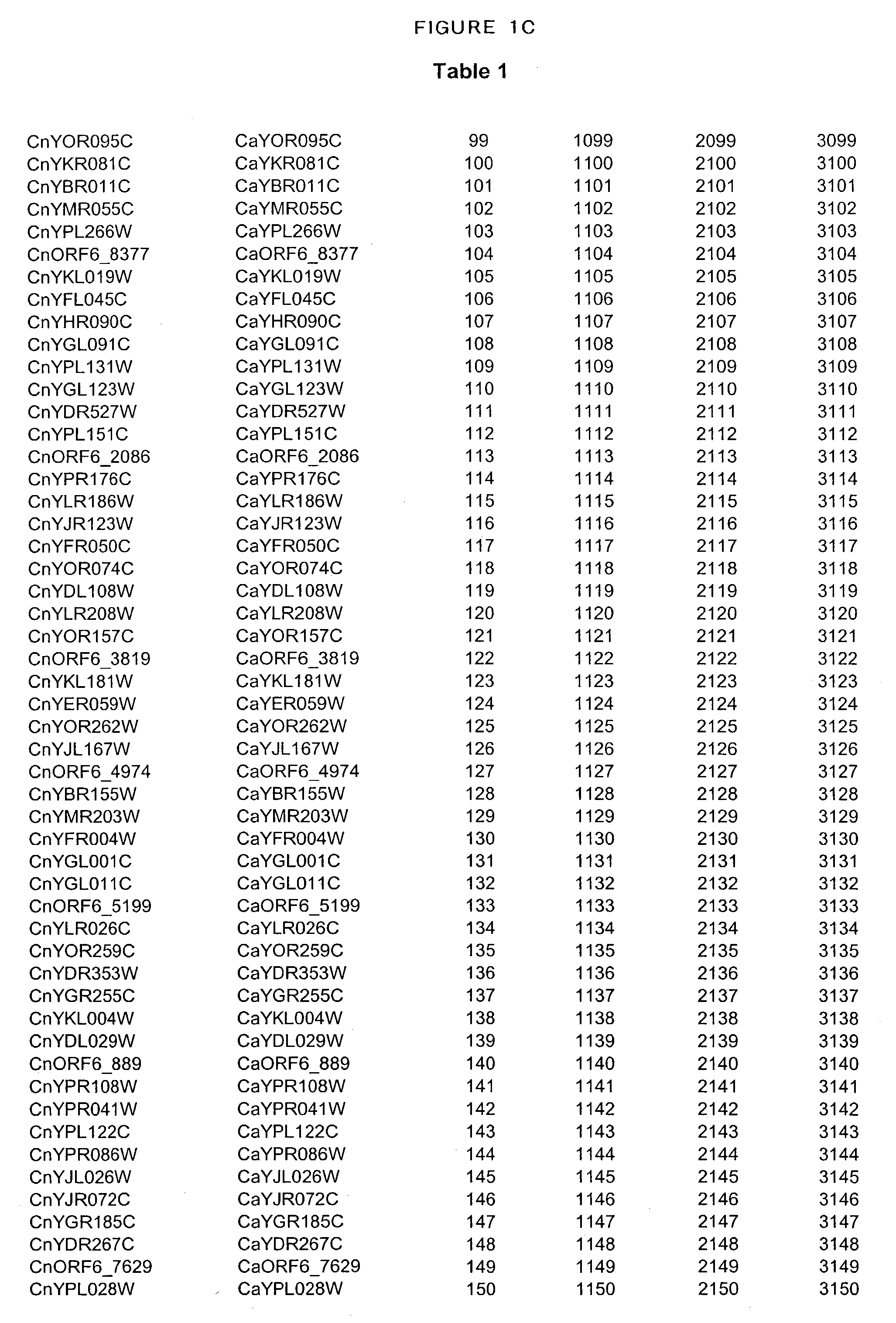

Identification of essential genes of cryptococcus neoformans and methods of use

InactiveUS20040014955A1Simple and reasonable designSugar derivativesMicrobiological testing/measurementBiotechnologyVirulent characteristics

The present invention provides C. neoformans genes that are essential and are potential targets for drug screening. The nucleotide sequence of the target genes can be used for various drug discovery purposes, such as expression of the recombinant protein, hybridization assay and construction of nucleic acid arrays. The uses of proteins encoded by the essential genes, and genetically engineered cells comprising modified alleles of essential genes in various screening methods are also encompassed by the invention. The present invention also provides methods and compositions that enable the experimental determination as to whether any gene in the genome of Cryptococcus neoformans is essential, and whether that gene is required for virulence or pathogenicity. The identification of essential genes and those genes critical to the development of virulent infections, provides a basis for the development of screens for new drugs against C. neoformans.

Owner:MERCK & CO INC

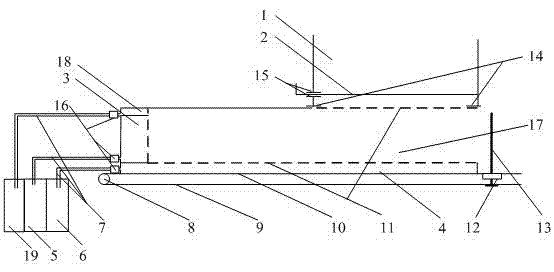

Device and method for simultaneously testing water seepage and drainage capacities of asphalt mixture

InactiveCN102507410ASimple designSimple and reasonable designPermeability/surface area analysisTest sampleStructural engineering

The invention discloses a device and a method for testing the rutting performance of asphalt mixture which is applied to mountainous highways. The device comprises an upper bearing platform which is connected with a loading system, and a lower bearing platform which is connected with a test sample; the lower end of the upper bearing platform is provided with loading pressing heads; the device is characterized in that: four sloped surfaces, which are sloped along the circumferential direction, are arranged on the upper end face of the lower bearing platform; number of the loading pressing heads is the same as that of the sloped surfaces; and the end face of each loading pressing head is matched with the sloped surface of the lower bearing platform. The device and the method disclosed by the invention can test the rutting performance of asphalt mixture under different longitudinal slope conditions, are convenient for optimization of the asphalt mixture and simple in operation, and do not need large special equipment.

Owner:HOHAI UNIV

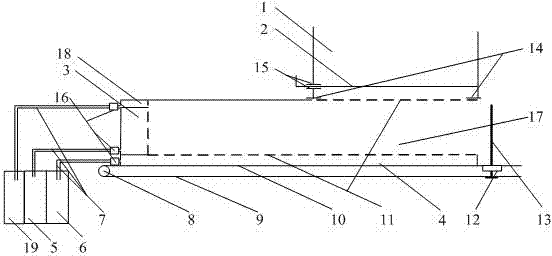

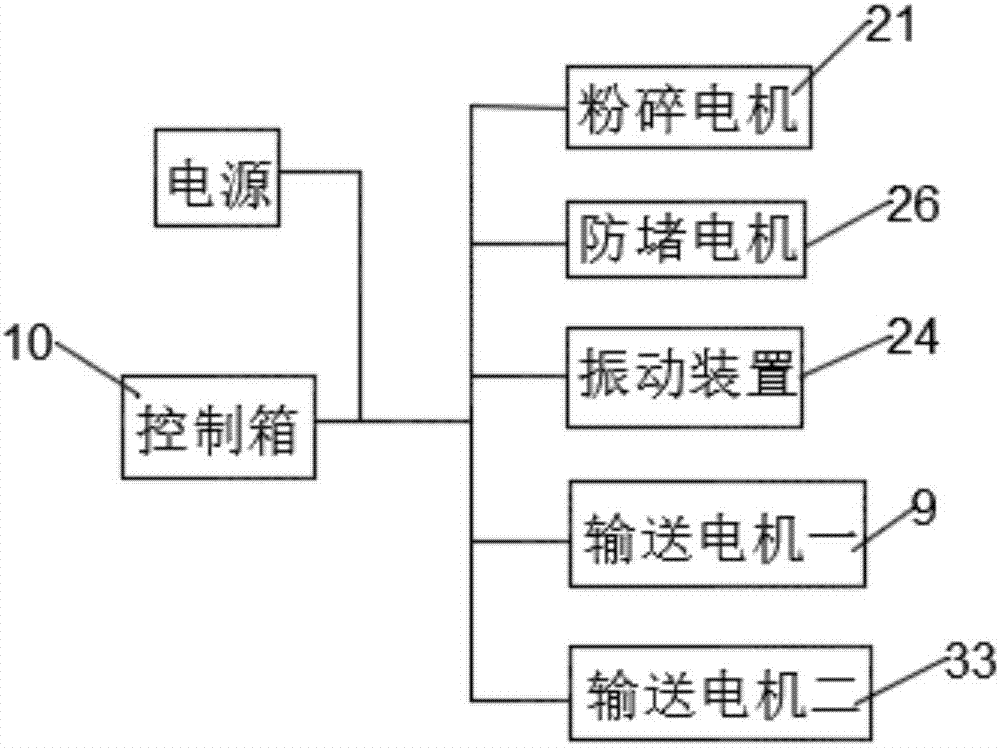

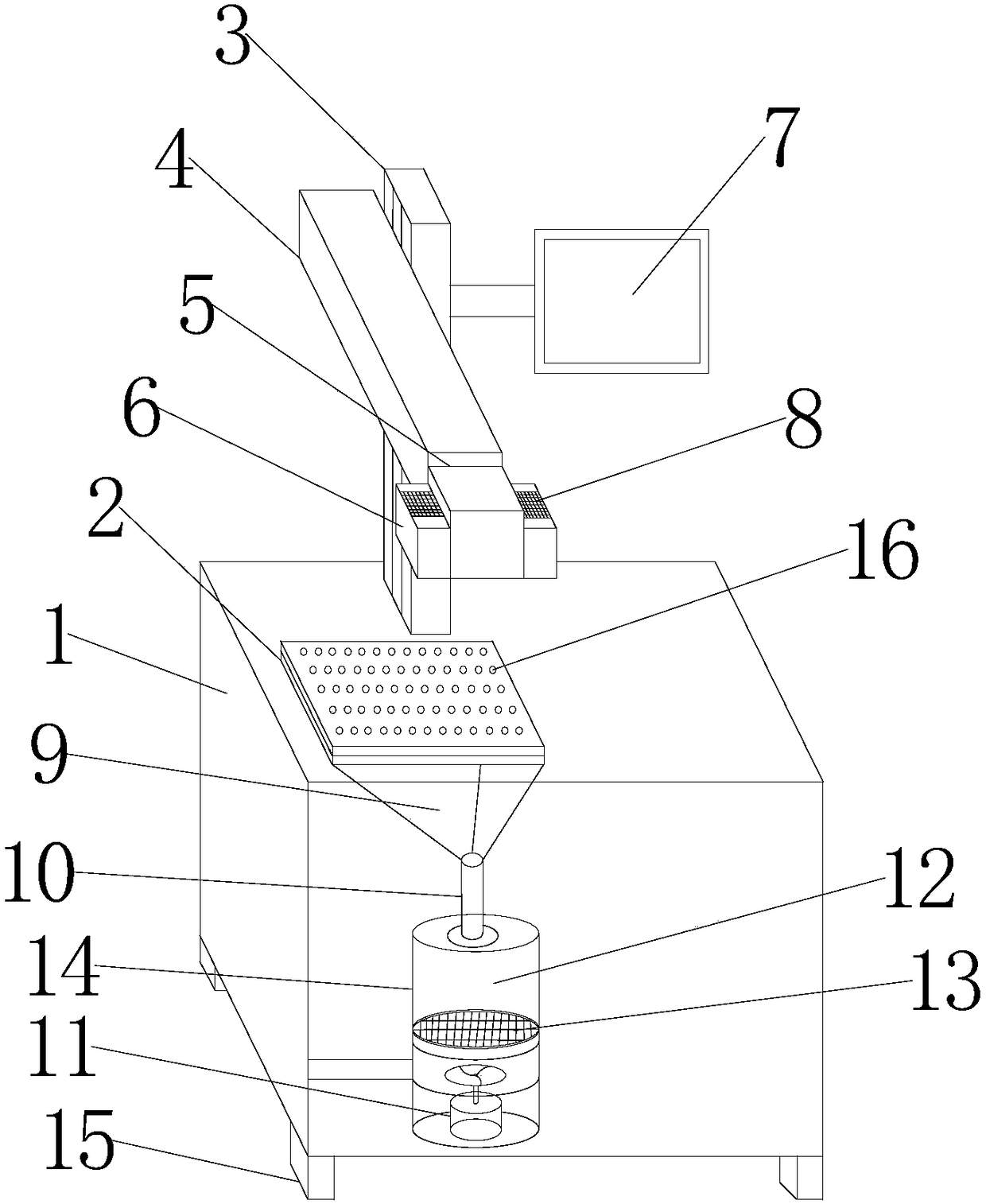

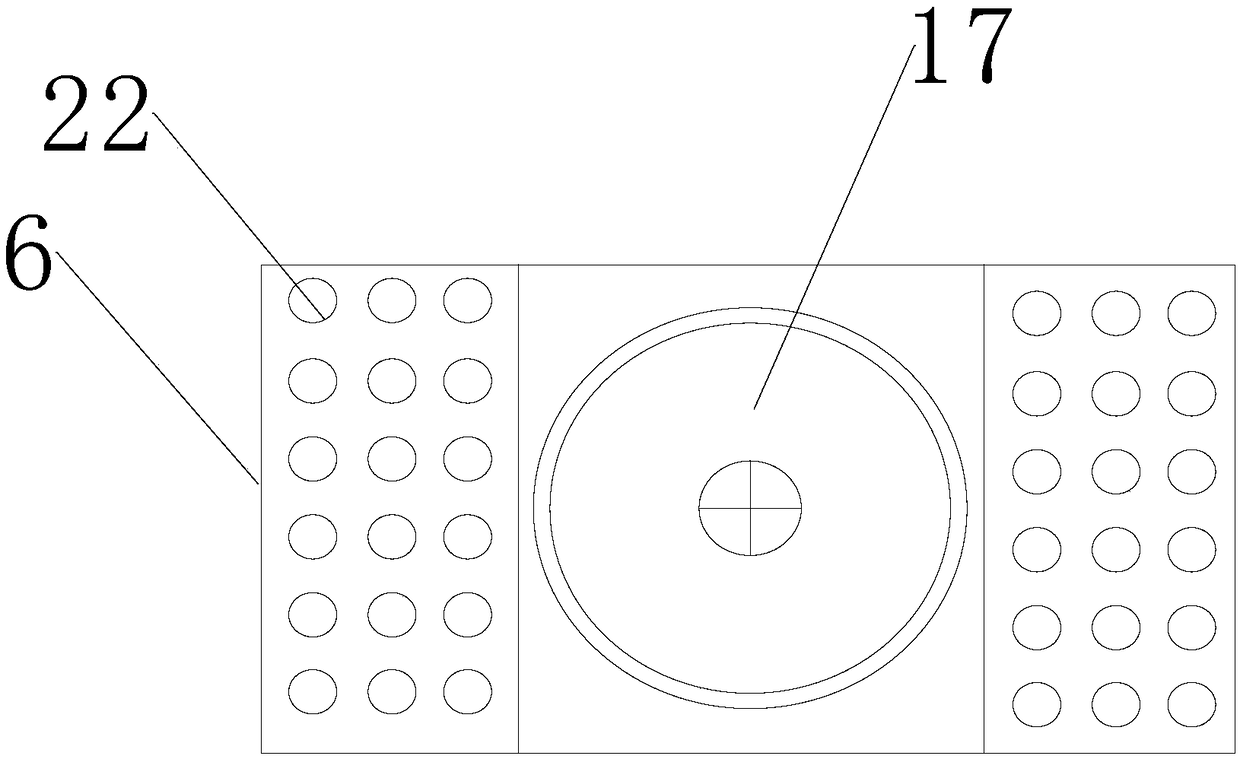

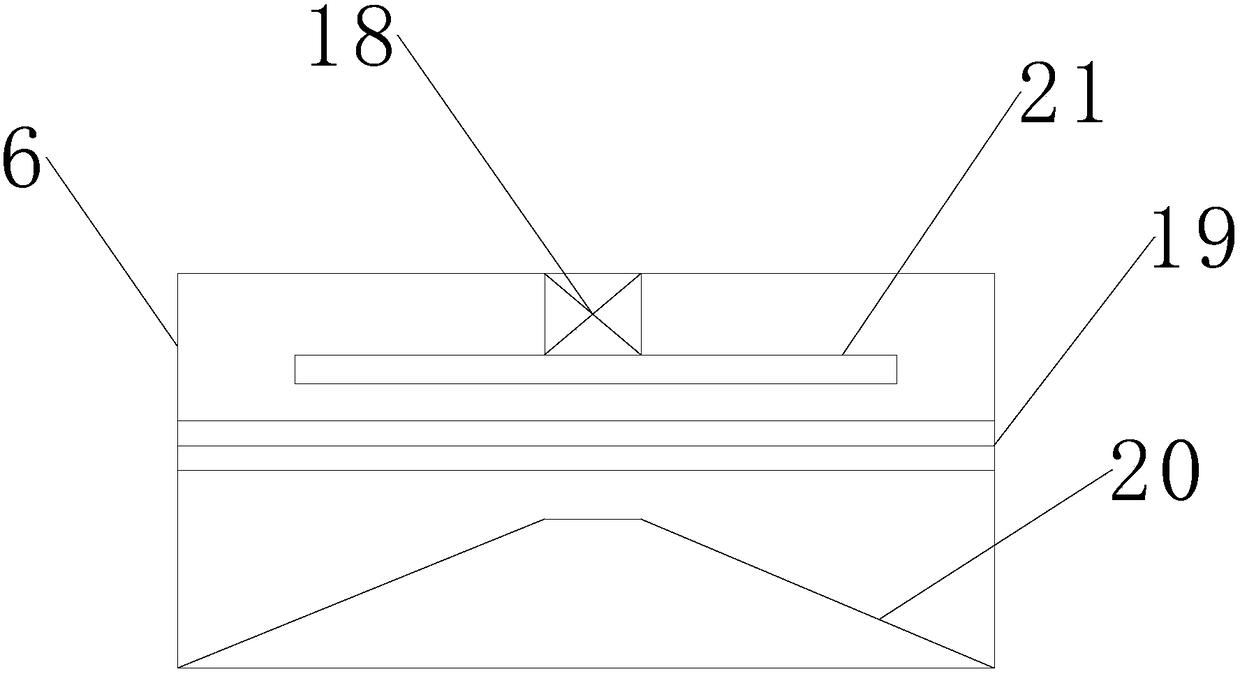

Crushing, stirring and lifting device for construction

InactiveCN107127038ASimple and reasonable designEasy to operatePackagingGrain treatmentsQuality assuranceBuilding material

The invention discloses a crushing and stirring lifting device for building construction, which comprises a bottom frame, a shock-absorbing layer and a base. A second crushing box is provided, the lower end of the second crushing box is provided with a feeding channel, the lower end of the feeding channel is provided with a first conveying cylinder, the right end of the first conveying cylinder is provided with a conveying port, and the lower right end of the conveying port is provided with a second Two delivery cylinders. This device realizes double crushing and mixing of building materials, ensures the quality of material crushing and mixing, and realizes the lifting of materials from low to high, which brings great convenience to construction and can greatly reduce the labor intensity of workers , which is conducive to improving the efficiency of construction. The shock absorbing mechanism and the shock absorbing layer have a good shock absorbing and buffering effect, which can reduce the vibration caused by the equipment during operation, protect the device, and prolong the service life of the device. .

Owner:蔡政伟

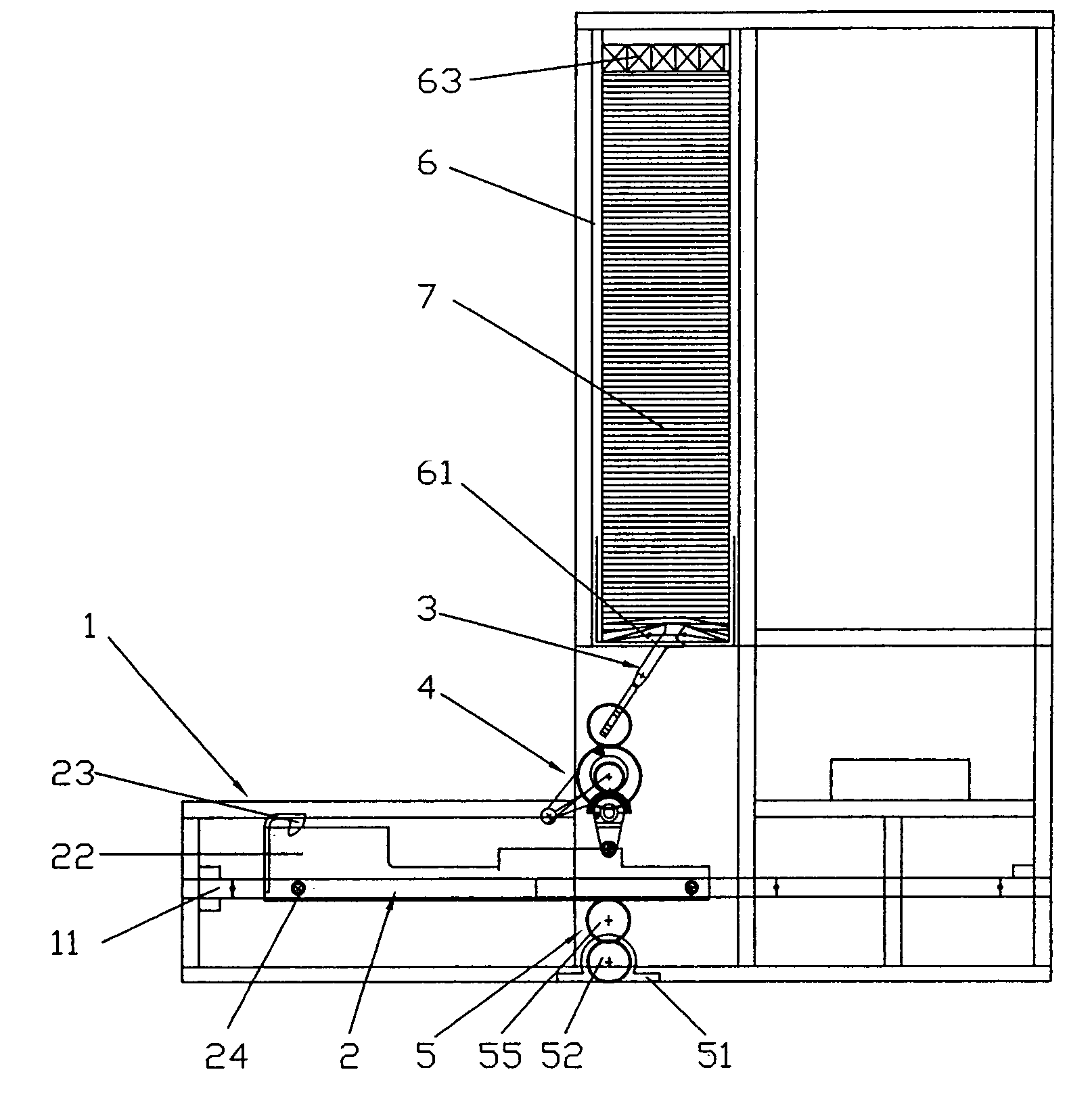

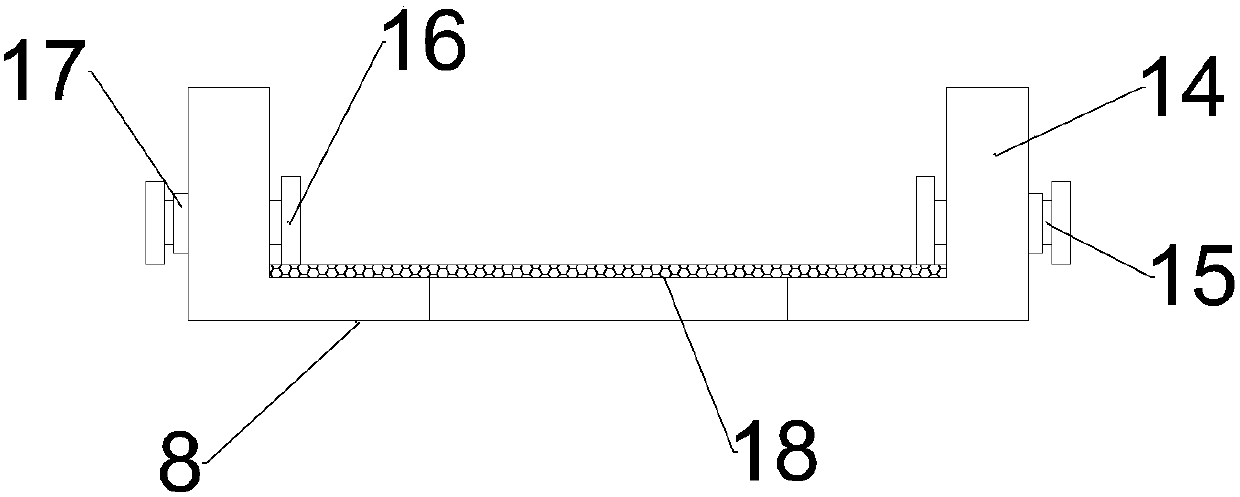

Automatic shoe cover dispenser

InactiveUS7448521B2Simple and reasonable designLow costApparel holdersSolesDisposable shoe coverEngineering

An automatic shoe cover dispenser that includes a machine body, a traction and extension mechanism, a separation and hooking mechanism, a turning mechanism, a traction driving mechanism, and a shoe cover box. The body of the shoe cover box is equipped with a shoe cover separating exit. The separation and hooking mechanism extends into the shoe cover separating exit to pull out the shoe cover, and the traction and extension mechanism expands the shoe cover so that one merely has to insert a shoed foot into the stretched shoe cover with the tread of the shoe facing downwards. The advantages of the invention include its simple and rational structure, strong practicability, safety and reliability, and the use of a normal disposable shoe cover without special process and technical requirements, thus greatly reducing the costs of perishable items, and being affordable to a large quantity of consumers. In addition, the shoe cover dispenser has large capacity and allows for very convenient installation of shoe covers. The shoe cover installation quantity can be freely adjusted as desired and can reach a rate as high as dozens or even thousands of pairs of shoe covers before the shoe cover dispenser might need to be adjusted. The shoe cover dispenser can be widely used for household needs as well as various locations such as hospitals and scientific research institutes etc.

Owner:HU QUANXI

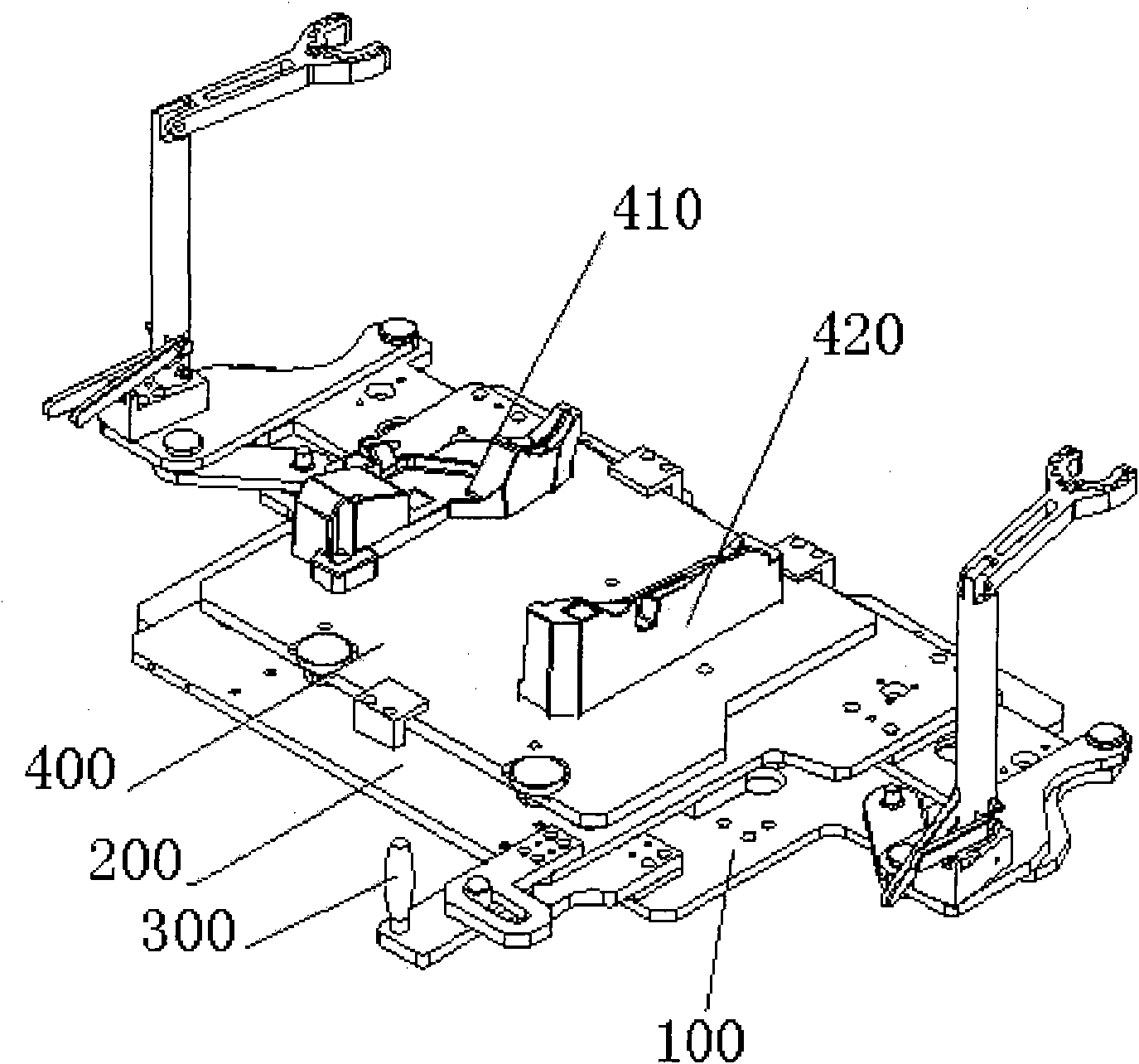

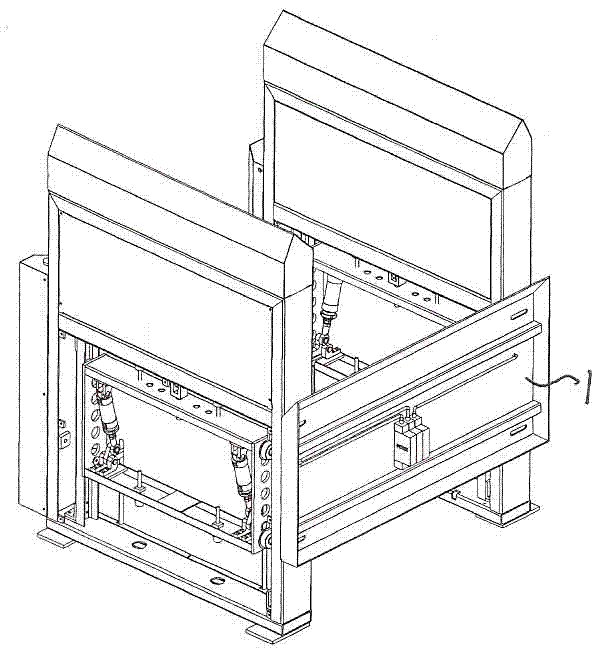

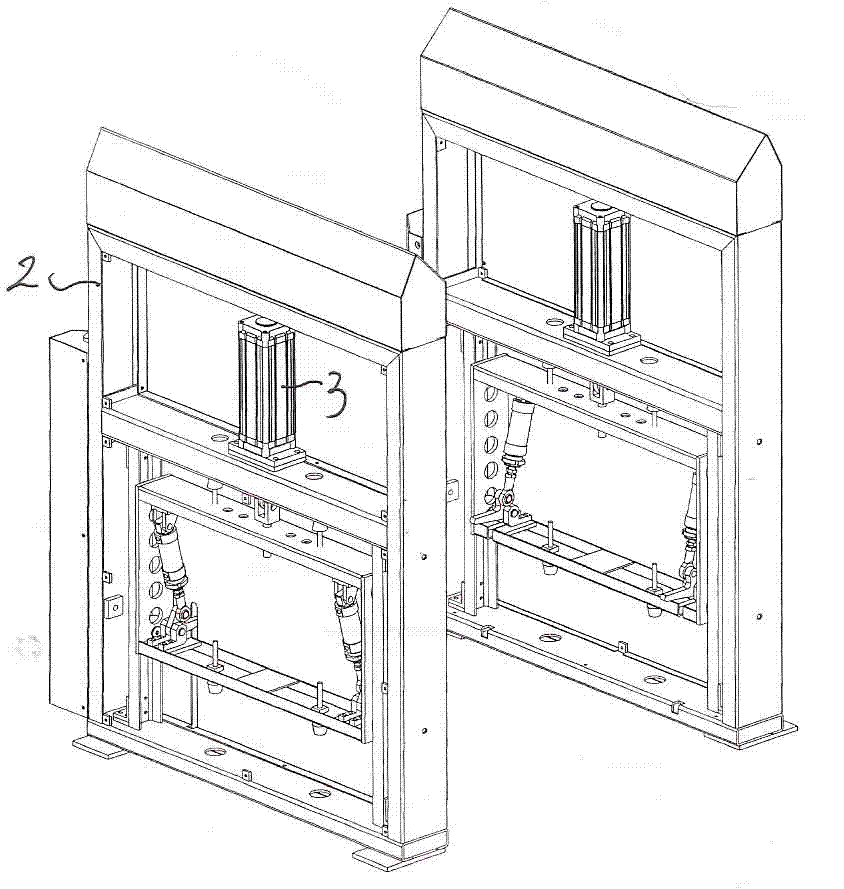

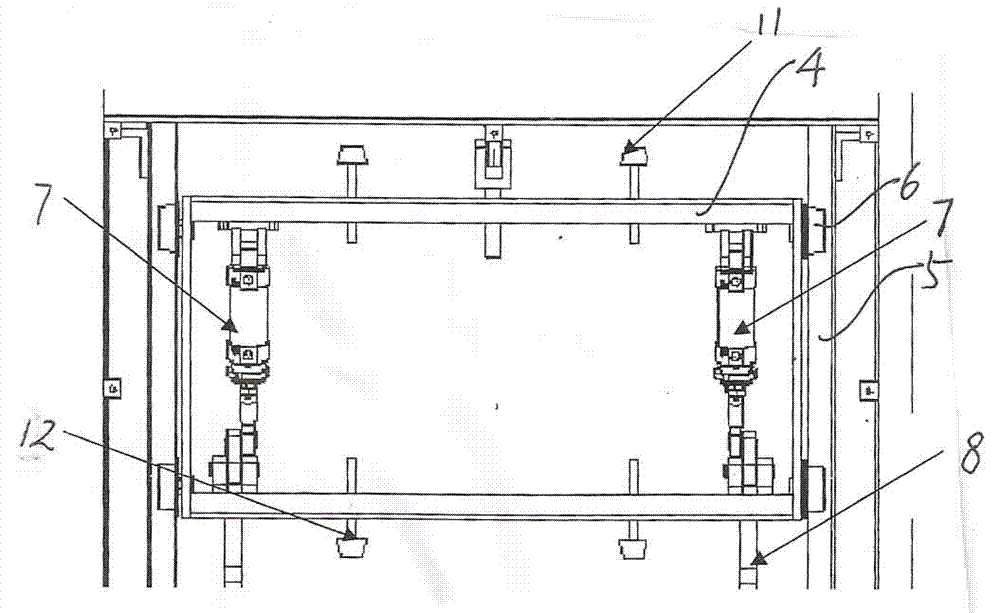

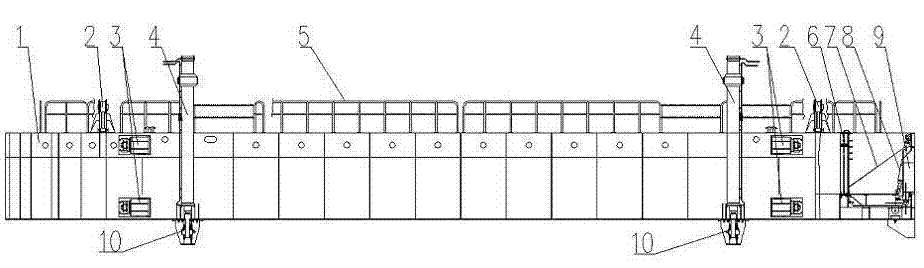

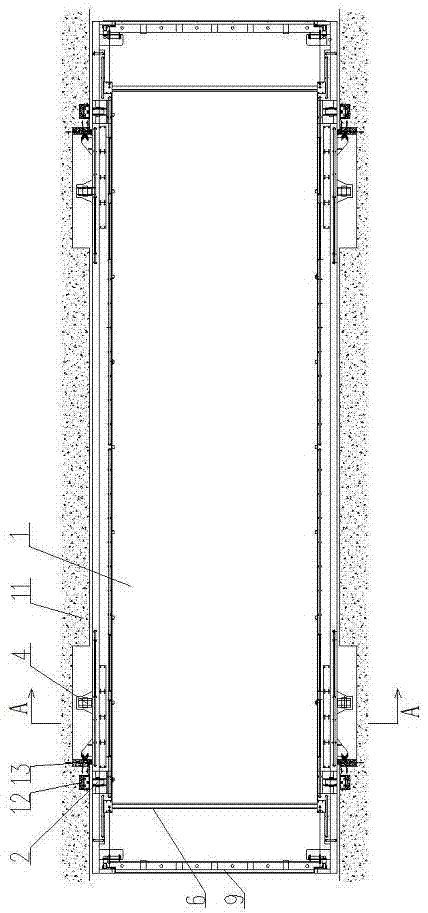

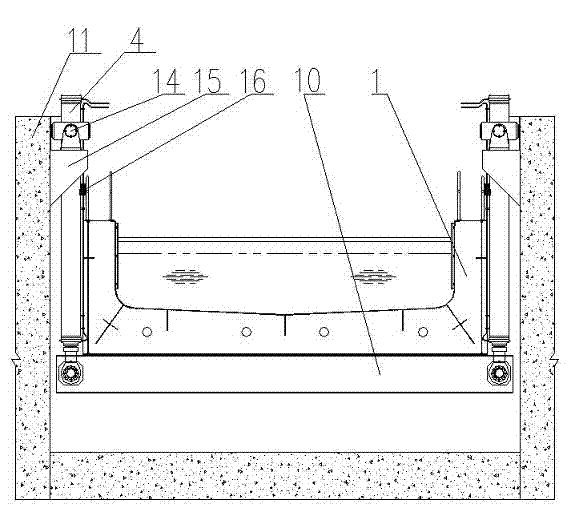

Rapid positioning platform based on collinear flexible assembly of a plurality of power assemblies

ActiveCN101642904ASimple and reasonable designLow investment costMetal-working hand toolsFlexible MechanismsMarine engineering

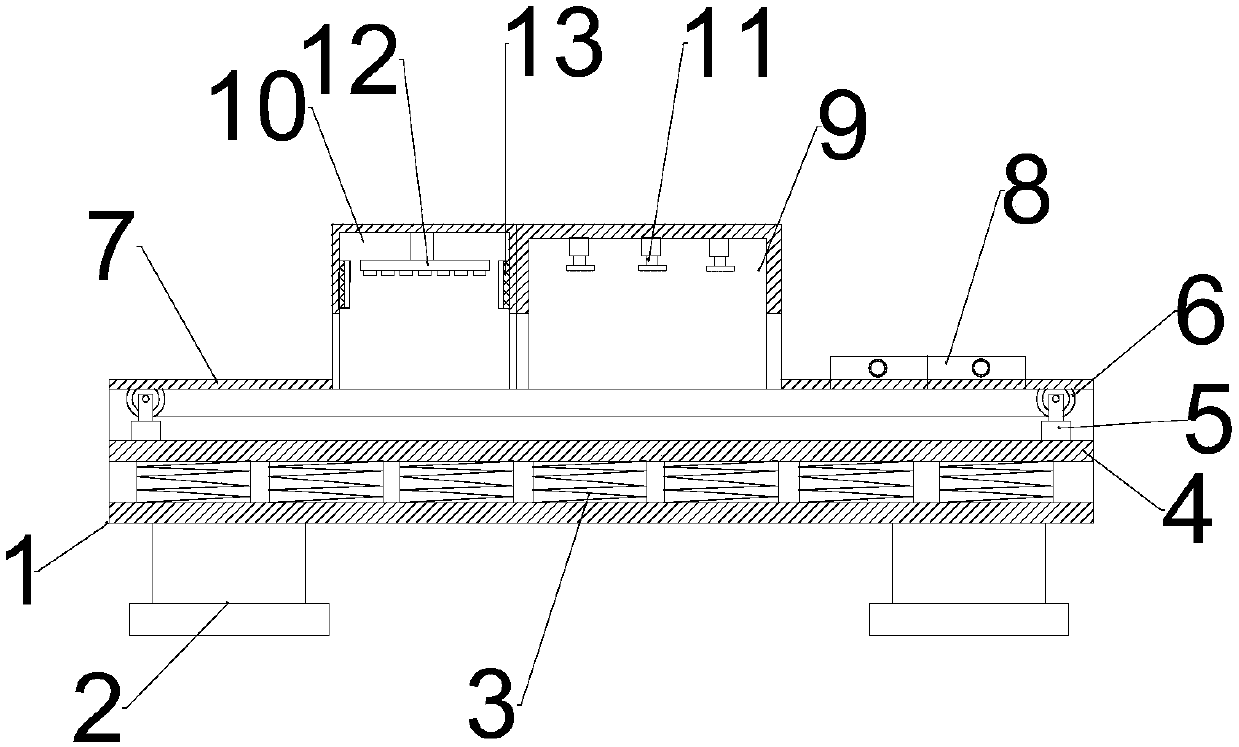

The invention discloses a rapid positioning platform based on collinear flexible assembly of a plurality of power assemblies, which comprises a fixed soleplate, a movable soleplate capable of linearlymoving is arranged on the fixed soleplate, a floating soleplate is supported on the movable soleplate, and an engine positioning module pin shaft and a gearbox positioning module pin shaft are arranged on the floating soleplate; a replaceable engine positioning module is connected with the engine positioning module pin shaft, and a replaceable gearbox positioning module is connected with the gearbox positioning module pin shaft. The rapid positioning platform adopts a modularized design method to achieve reasonable and simple design of an assemblage positioning system of the power assemblies,not only greatly reducing the tool investment cost, but also greatly improving the collinear flexible production capability of different products; the rapid positioning platform has flexible mechanism motion, rapid and reliable transposition, rapid and accurate module replacement, long service life and convenient maintenance, and is particularly suitable for the mass and collinear flexible assemblage of serial plurality of series of vehicle types of power assemblies and vehicle bodies.

Owner:DONGFENG PEUGEOT CITROEN AUTOMOBILE

Air cylinder with cushion mechanism

InactiveUS6279451B1Simple and reasonable designShorten the lengthServomotor componentsServomotorsCushioningCheck valve

A small-sized and inexpensive air cylinder with a cushion mechanism having a simple structure is provided. Therefore, discharge outlets for discharging cushioning air are disposed in positions closer to ends of the stroke than the openings of the ports in the cylinder tube, respectively, and check valves and throttling mechanisms are arranged in parallel between discharge outlets and ports, respectively. On the outer peripheral surface of the piston, one of the piston packing rings is disposed in one position which does not pass through the opening of the port while another of the piston packing rings is disposed in another position which passes through the opening but does not pass through discharge outlet, when the piston reaches the terminal ends of the stroke.

Owner:SMC CORP

Automatic pallet machine

ActiveCN102730422ASave human effortReduce manufacturing costStacking articlesDe-stacking articlesElectrical controlEngineering

The invention discloses an automatic pallet machine, comprising a left lifting mechanism and a right lifting mechanism. Guiding apparatuses are arranged in the front of the left and right lifting mechanisms, and rear support plates are arranged at the back of the left and the right lifting mechanisms, wherein the rear support plate is used to connect the left lifting mechanism and the right lifting mechanism and restrict the pallet in place. The machine provided in the invention has the following advantages that: the structure of the machine is reasonable, forward operation can be adopted for task of pallet removing, and reverse operation can be used for pallet stacking and pallet settling in a warehouse; the mechanical structure of the machine is simple and portable, the operation is convenient and easy to learn, and the machine occupies a small area; and positioning precision is greatly improved by adopting electrical control. According to the above advantages, the product can greatly minimize manpower of enterprise and reach a final purpose that reduces production cost of the enterprise. The machine provided in the invention is suitable for splitting of various pallets, and the machine can be widely applied in industries of daily chemicals, medicine, foodstuff, beverage, warehouse and the like.

Owner:NANTONG UNIVERSAL MACHINERY

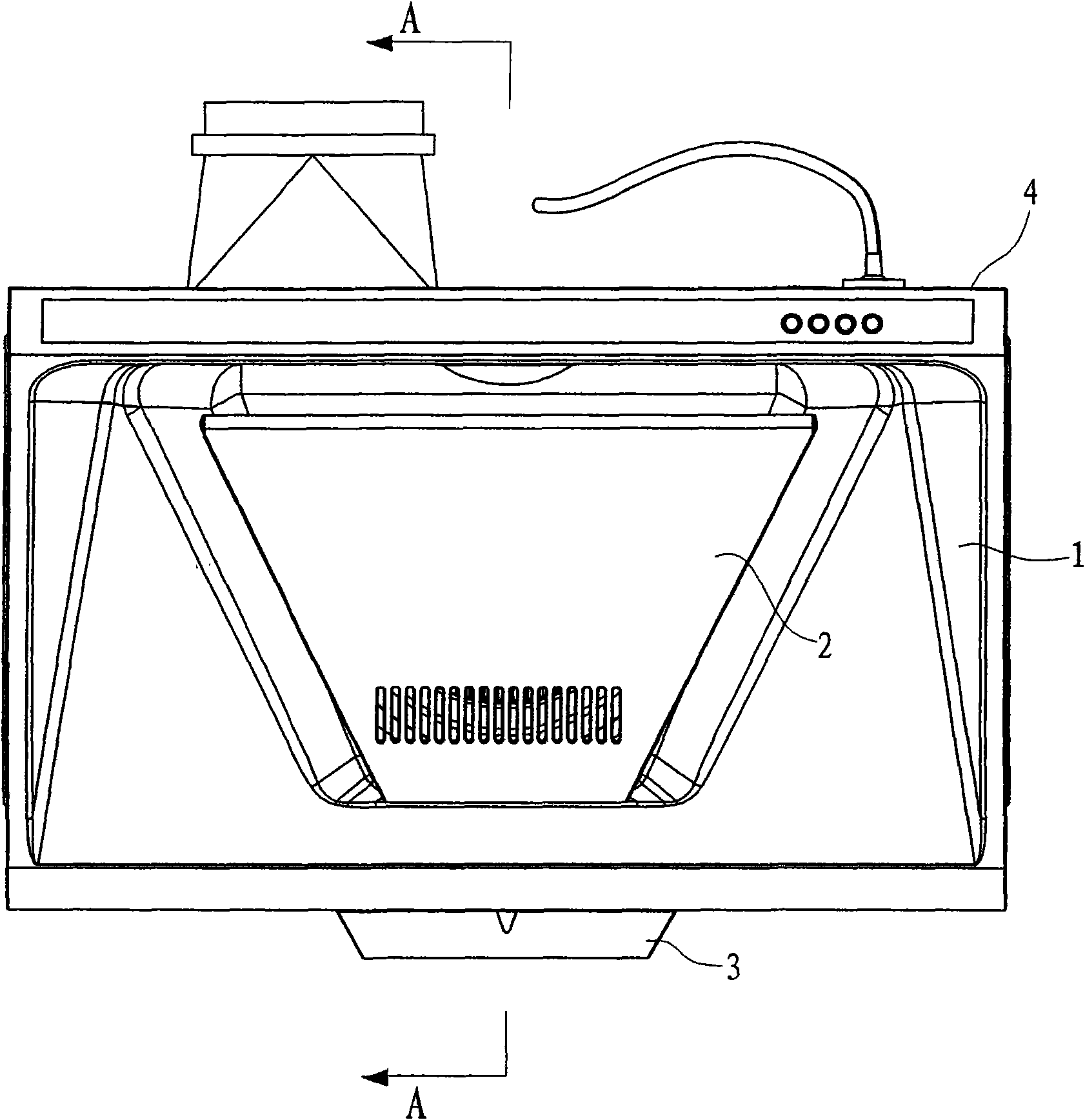

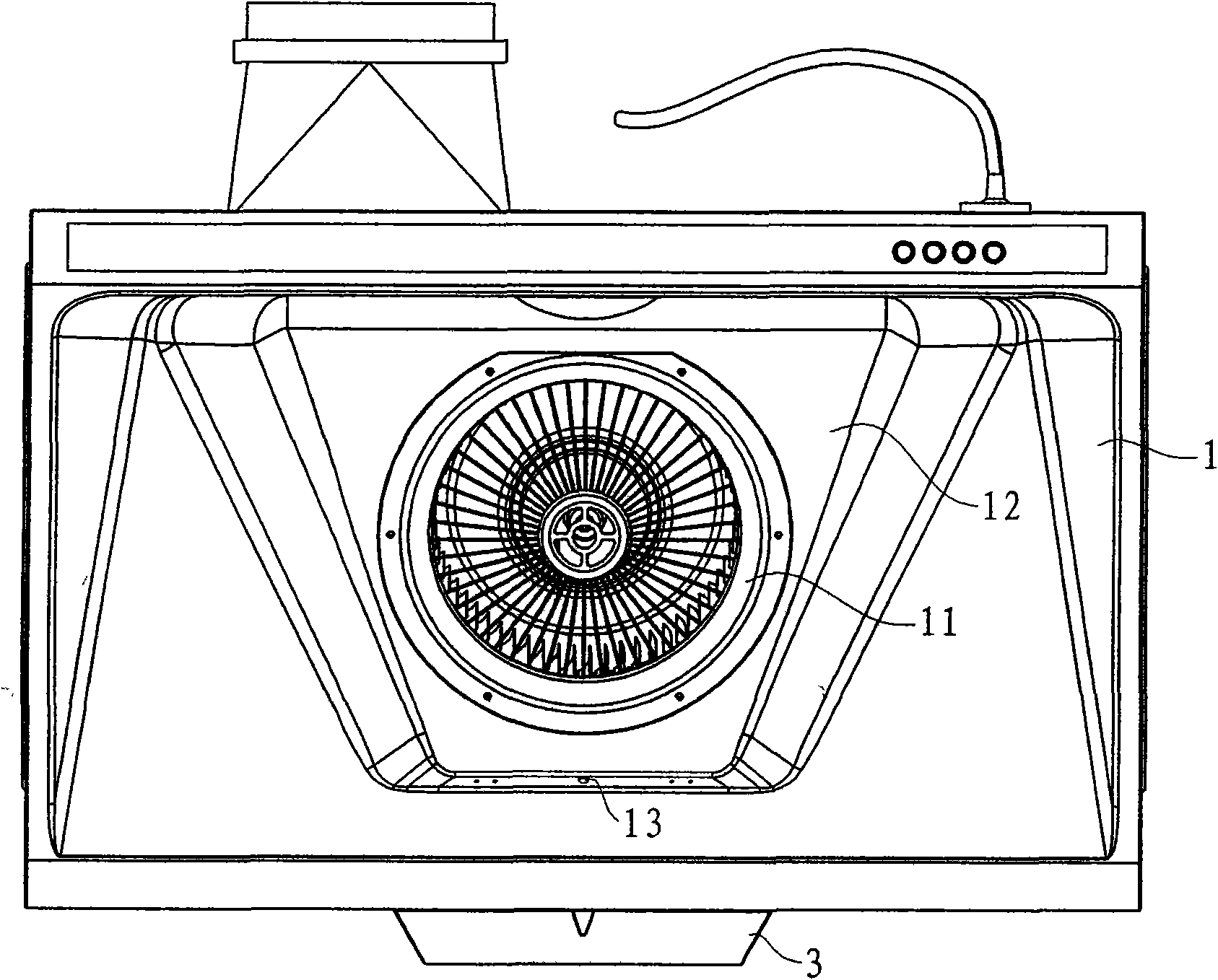

Oil collecting structure of range hood

ActiveCN101650048ANo blockageSimple and reasonable designDomestic stoves or rangesLighting and heating apparatusEngineeringPetroleum engineering

The invention discloses an oil collecting structure of a range hood, comprising a gas collecting hood and an oil collecting cup arranged at the bottom of the gas collecting hood. The oil collecting structure is characterized in that a groove is formed in the middle of the front end of the gas collecting hood, the bottom of the groove is provided with oil-dripping holes, the lower end of the back of the gas collecting hood is provided with a smooth arc flow guiding surface for catching the oil droplets from the oil-dripping holes, and the oil collecting cup is arranged below of the flow guidingsurface for receiving oil blots from the flow guiding surface. Compared with the prior art, the invention has advantages that the accumulated oil blots enter the flow guiding surface from the oil-dripping holes, and then flow into the oil collecting cup, the flow guiding surface integrated with the gas collecting hood is used for collecting oil, the integral design is simple, reasonable and effective without the match of extra hosepipes, so that an oil collecting system is not blocked.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

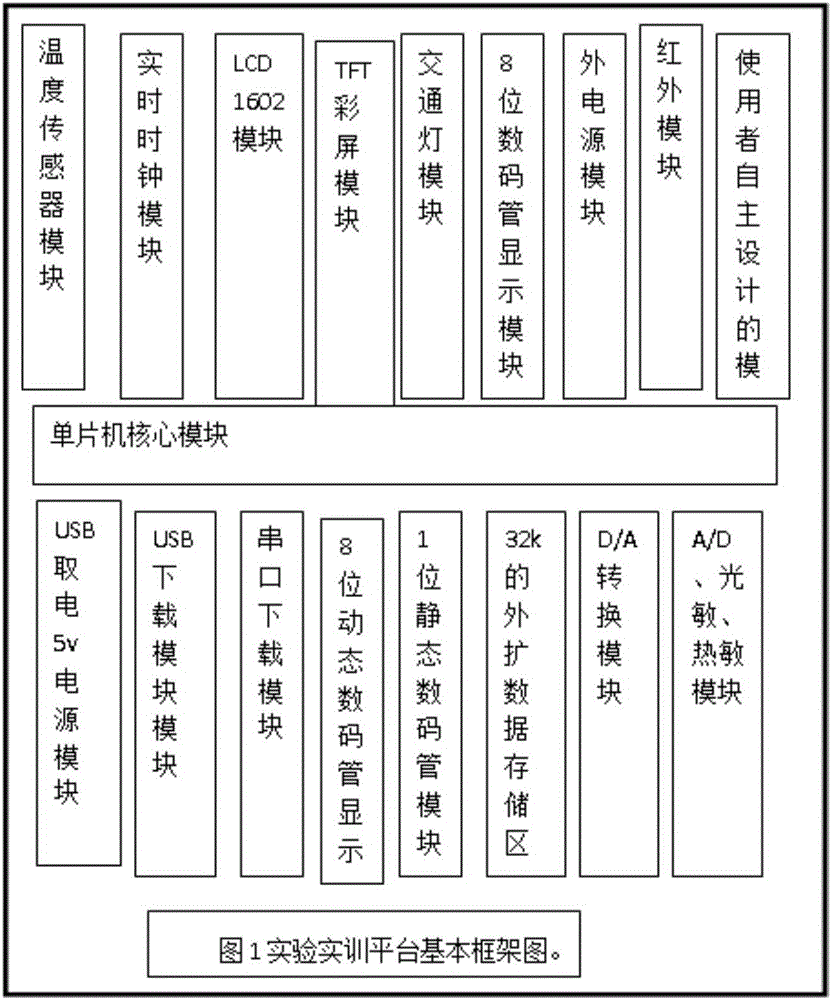

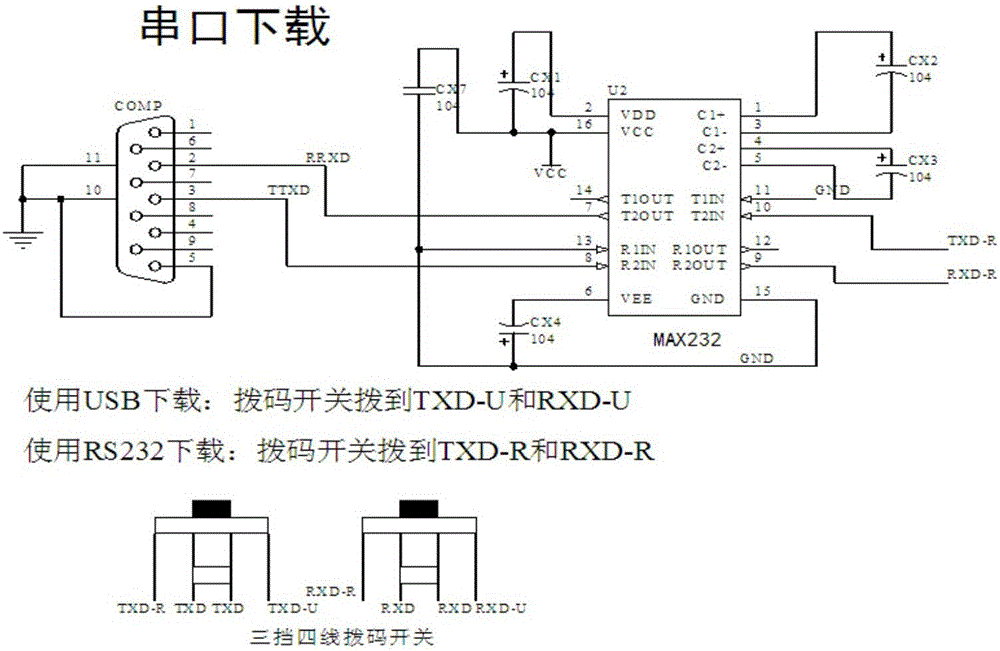

Single-chip microcomputer modularization experiment training system and method based on virtual simulation platform

InactiveCN105913739AEasy to writeEasy and intuitive to writeEducational modelsMicrocontrollerSimulation

The invention discloses a single-chip microcomputer modularization experiment training system and method based on a virtual simulation platform. The system comprises a virtual simulation part and an experiment box training part. The virtual simulation part comprises a plurality of virtual simulation experiment circuits matched with each experiment module of an experiment box; and integral virtual simulation experiment circuits formed by combination of different experiment modules and matched with the experiment box. The experiment box training part comprises an IC locking socket, and a single-chip microcomputer minimum system module, a nixie tube display module, an LED indication lamp, a power supply module, a USB downloading module, a serial port downloading module, a data storage module, a data conversion module, a clock module and an autonomous exploitation module are respectively arranged on the IC locking socket. The single-chip microcomputer modularization experiment training system and method have the advantages that virtual simulation of software is utilized, there is no need to repeatedly download a debugging program on a practical hardware circuit, the time is saved, the loss of the equipment is avoided, and the service lifetime of the equipment is prolonged.

Owner:SHANDONG NORMAL UNIV

Manufacturing technology of long-length jointless mineral insulation cable

InactiveCN102496422ASimple and reasonable designEasy to manufactureInsulating conductors/cablesMagnesiumOxide

The invention, which belongs to a cable manufacturing technology field, relates to a manufacturing technology of a long-length jointless mineral insulation cable. The above technology comprises the following steps that: (1) 12-16% H2SO4 and tap water are successively used to clean a copper strip through a cleaning machine, the cleaned copper strip is dried at a temperature of 35-45 DEG C, and then the dried copper strip enters into a moulding roller so as to perform pipe forming; a tension force alignment copper rod flows into a stainless steel set core pipe and a special magnesium oxide powder is filled while the copper rod is entering into the stainless steel set core pipe, and silicone oil is injected into the special magnesium oxide powder in the set core pipe; (2) argon arc welding continuous welding is performed to the pipe moulding copper strip, and then continuous cycle rolling and annealing are performed. A production period is short. Product manufacturing cost is low. High-pressure resistant and insulation properties are good. A cable production length is long.

Owner:BAOSHENG SCI & TECH INNOVATION

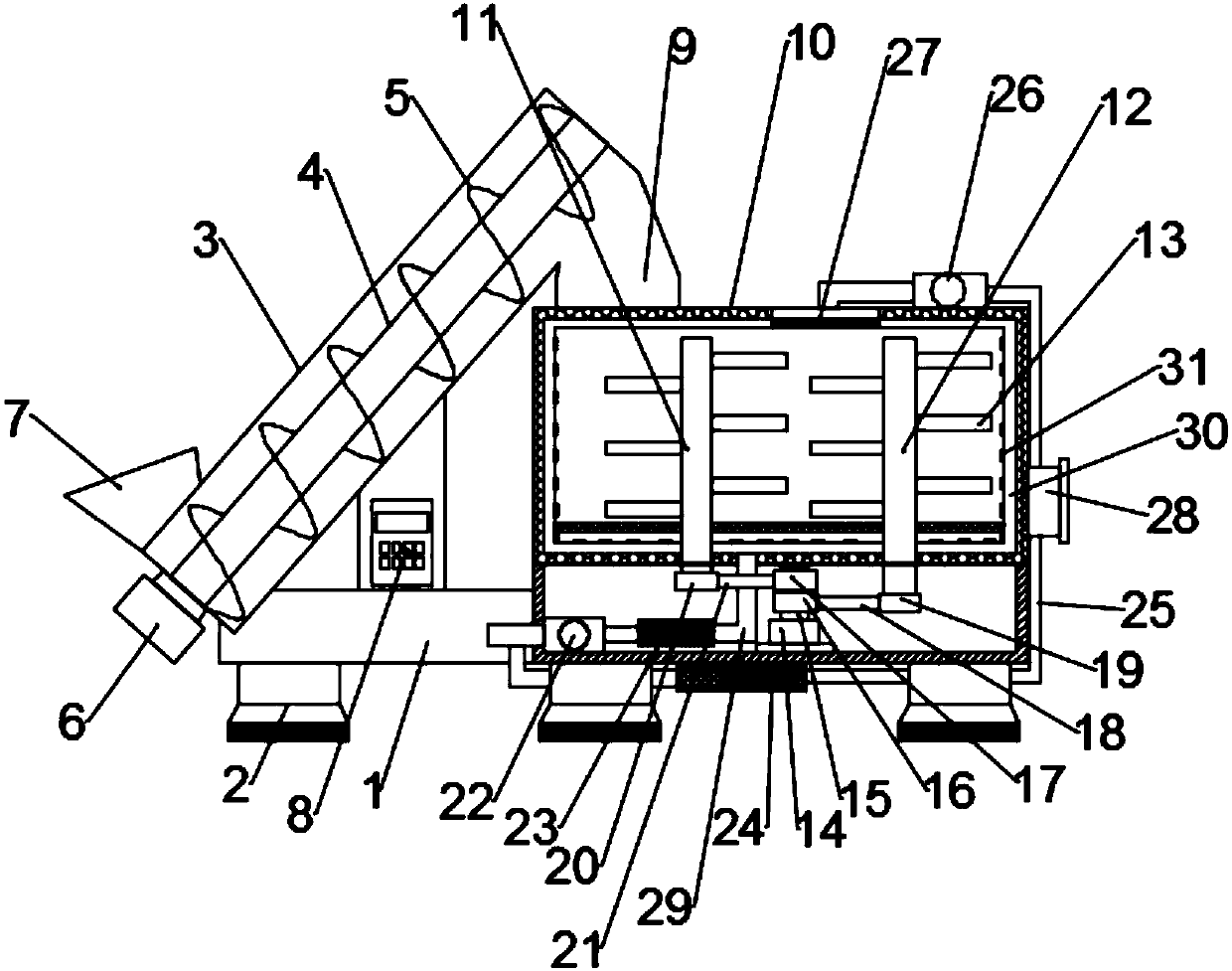

Dust collection environment-friendly marking machine

InactiveCN108080797ASimple and reasonable designEasy to operateGas treatmentDispersed particle filtrationElectric machineryImpeller

The invention discloses a dust collection environment-friendly marking machine which comprises a cabinet, a dust collector and purification boxes. The dust collector is arranged in the cabinet. A dustcollecting barrel is arranged at the upper end in the dust collector. A locating plate is arranged at the upper end of the cabinet. Multiple dual-purpose locating holes are formed in the locating plate. The purification boxes are arranged on the two sides of a marking box, exhaust holes are formed in the upper ends and the lower ends of the purification boxes, and a filter layer is arranged in each purification box. The dust collection environment-friendly marking machine is simple and reasonable in structural design, convenient and fast to use and operate and high in practicality; during work, the machine is stable and balanced under the action of supporting legs; through a supporting column and a laser launcher, precise locating is achieved; a motor drives an impeller to generate suction force; waste is sucked away by the dual-purpose locating holes to be stored in the dust collecting barrel, and a working table face is clean and tidy; small motors in the purification boxes drive fans to generate suction force, and smoke dust and other harmful gas are sucked into the purification boxes; and through filtering of the filter layers, diffusion of harmful smoke dust is avoided, the health of operators is guaranteed, and the working efficiency is improved.

Owner:XINGUANG NUMERICAL CONTROL TECH

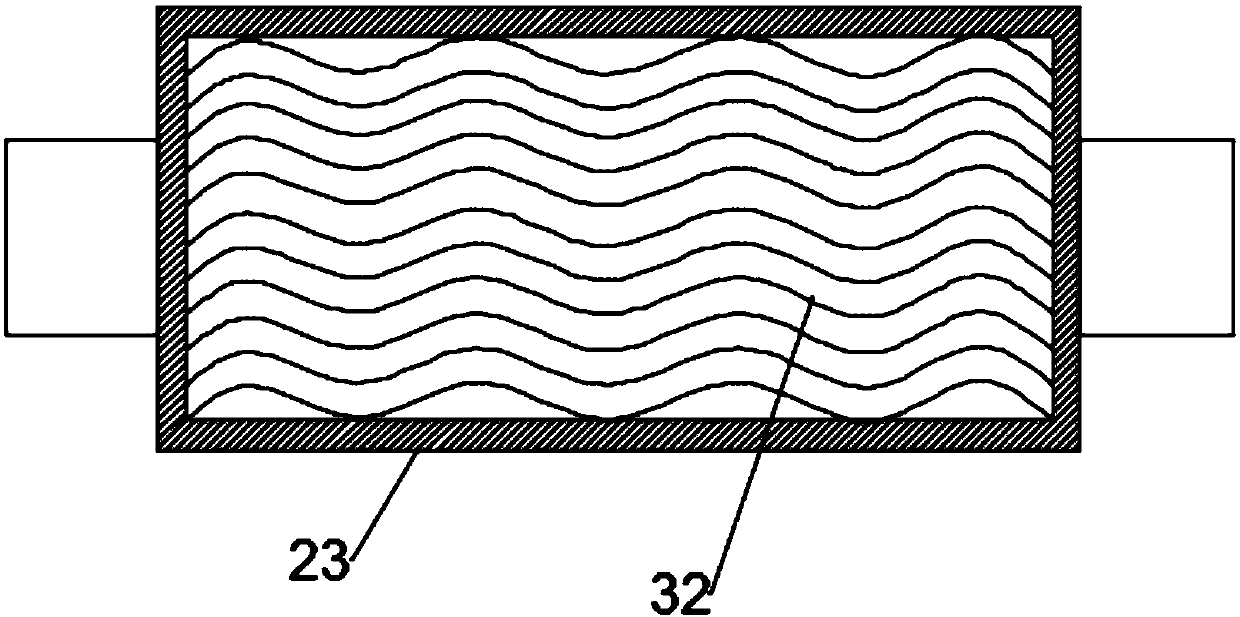

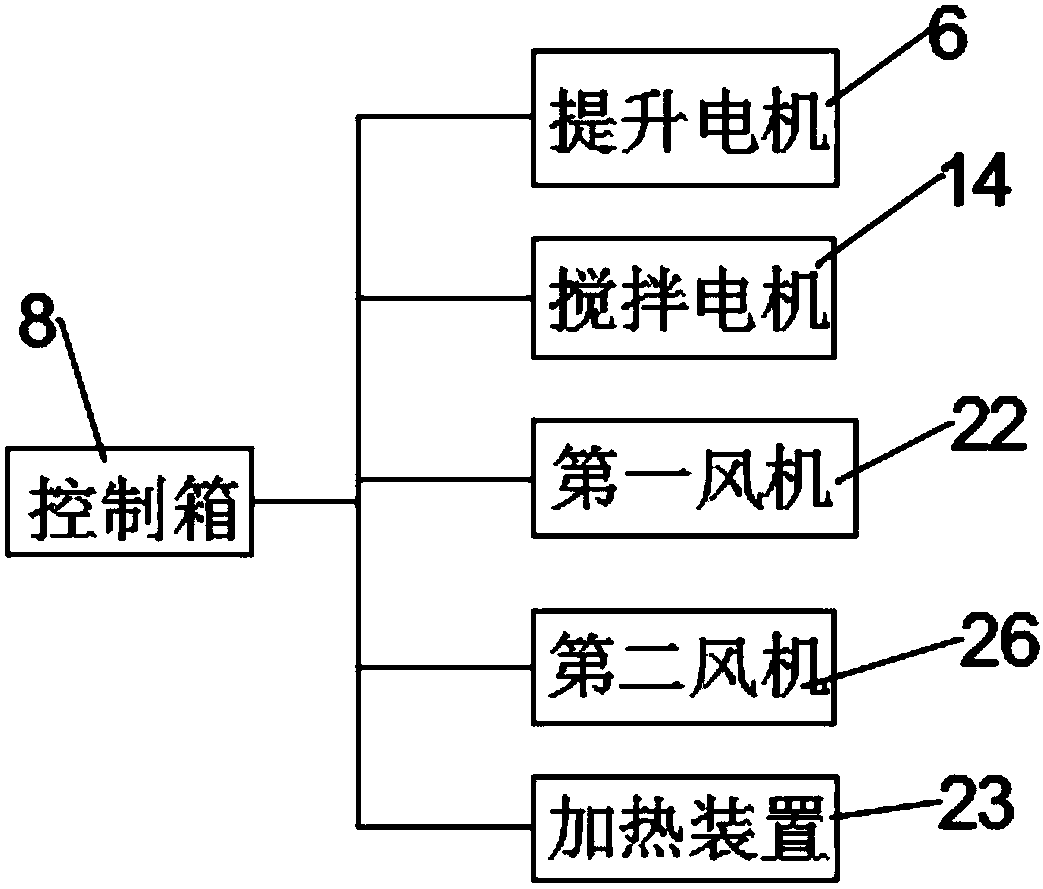

Drying equipment capable of facilitating feeding and applicable to corn processing

InactiveCN107940942ASimple and reasonable designEasy to operateDrying gas arrangementsDrying machines with non-progressive movementsFixed frameEngineering

The invention discloses drying equipment capable of facilitating feeding and applicable to corn processing. The drying equipment comprises a feeding fixing frame, bases and a feeding barrel; a first rotating shaft is arranged in the feeding barrel; a spiral lifting mechanism is arranged on the first rotating shaft; a lifting motor is arranged at the lower end of the first rotating shaft; a discharging channel is arranged on the upper right side of the feeding barrel; and a drying box is arranged at the lower end of the discharging channel. The drying equipment is simple and reasonable in structural design as well as convenient and quick to use and operate; the spiral lifting mechanism is driven by the lifting motor to rotate to lift corn, the corn enters the drying box through the discharging channel, air is blown into the drying box continuously by the aid of a first fan and becomes dried hot air after being heated by a heating device, a plurality of air spraying holes are formed in an annular air spraying pipe on the inner wall of the drying box and spray the dried hot air in different directions, and thus the drying efficiency can be improved.

Owner:房立洲

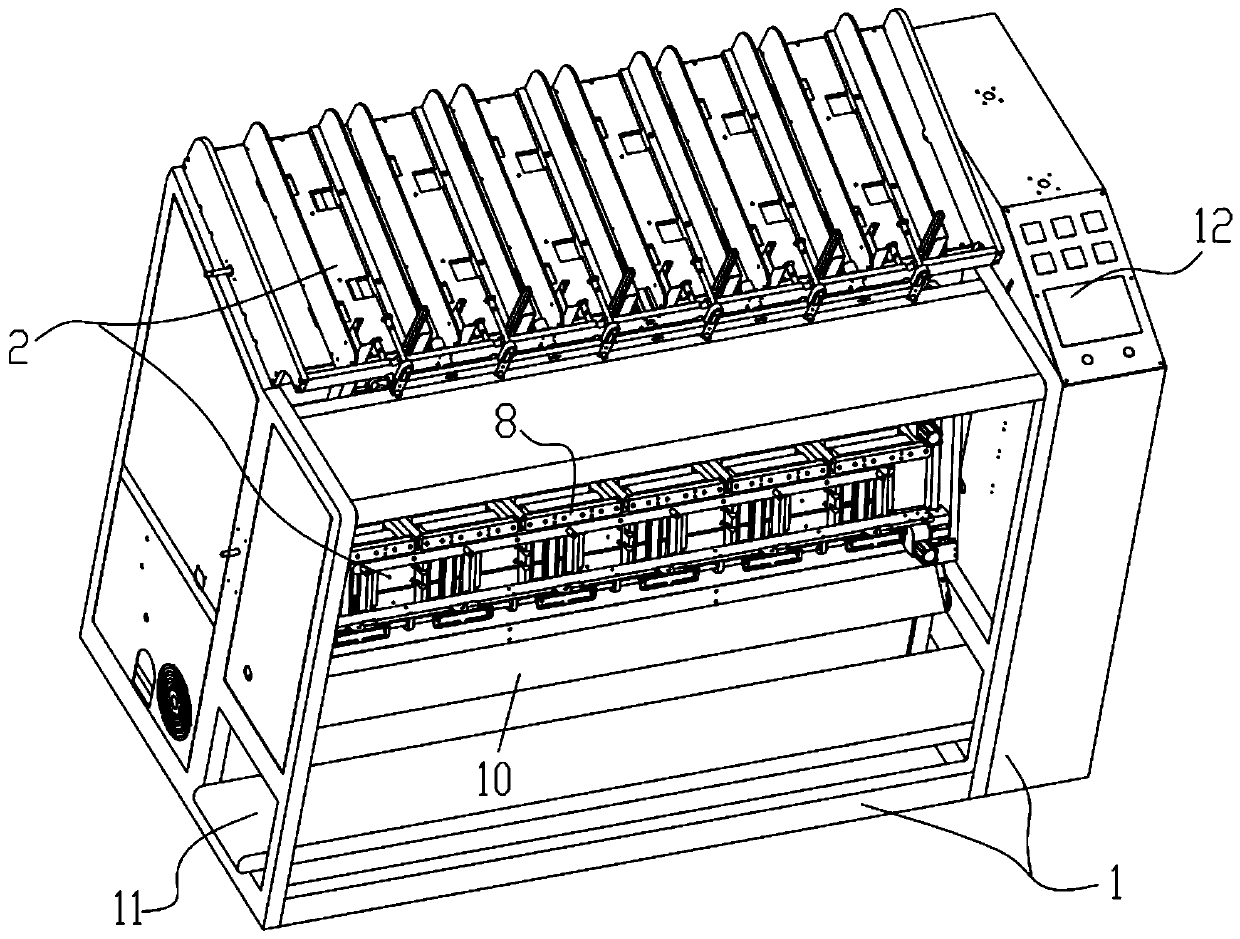

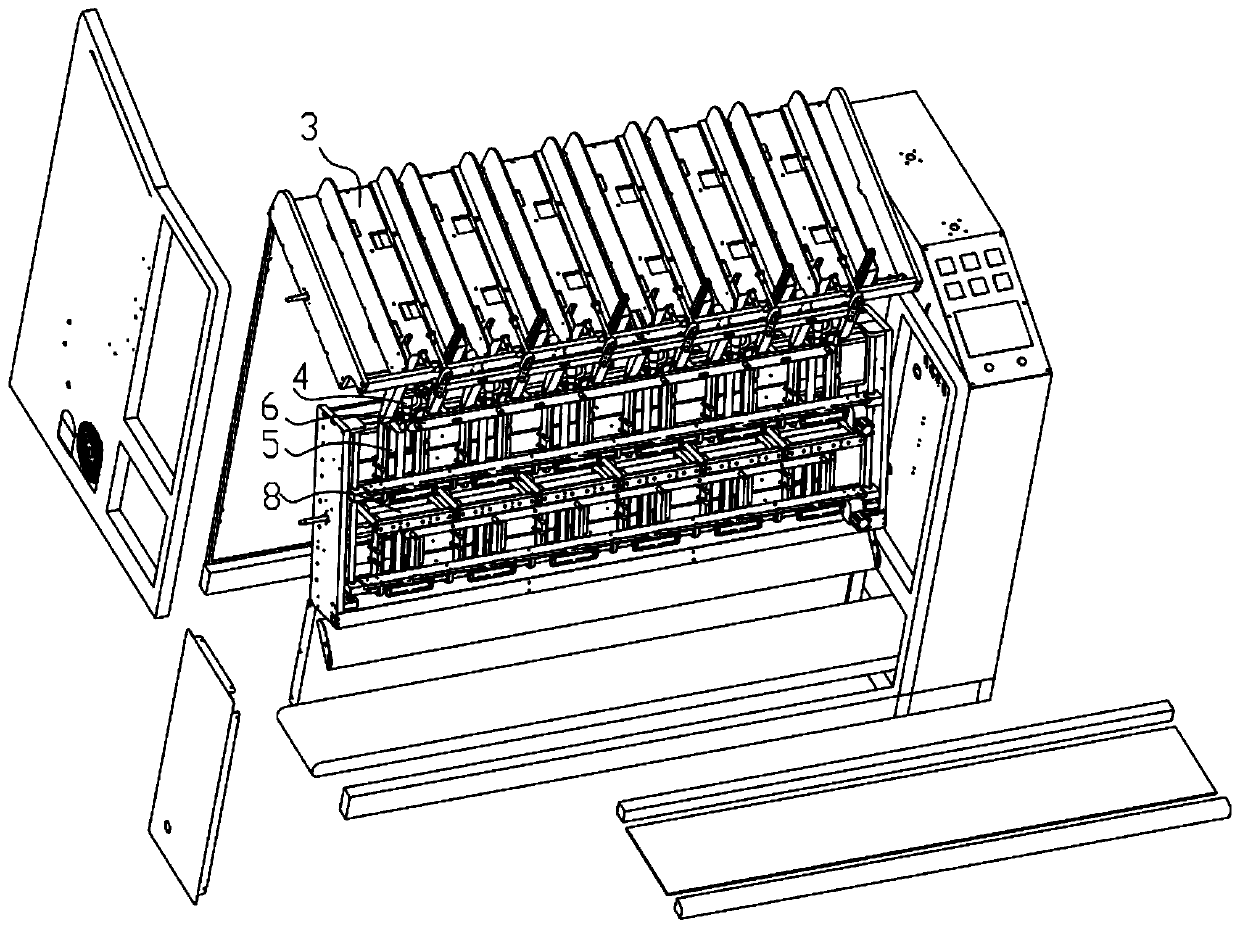

Automatic facial mask packaging machine

PendingCN110979873AReduce the probability of mask wrinklesAvoid stickingWrapper twisting/gatheringLiquid materialEngineeringFacial mask

The invention discloses an automatic facial mask packaging machine, which comprises a rack, a packaging line unit, a bag collecting assembly and a control panel, wherein a plurality of rows of packaging line units are arranged on the rack side by side; each packaging line unit comprises a bag conveying assembly, a filling assembly, a bag opening assembly, a conveying channel and a heat sealing mechanism which are sequentially arranged from top to bottom; and the bag collecting assembly is arranged at the bottom part of each packaging line unit. The automatic facial mask packaging machine is simple and reasonable in design, is stable in operation, can complete the filling and sealing processes of packaging bags can automatically, efficiently and smoothly, effectively prevents the packagingbags from adhering to the heat sealing mechanism, and can suck and remove the packaging bags adhering to the heat sealing mechanism.

Owner:广州市伟东机械科技有限公司

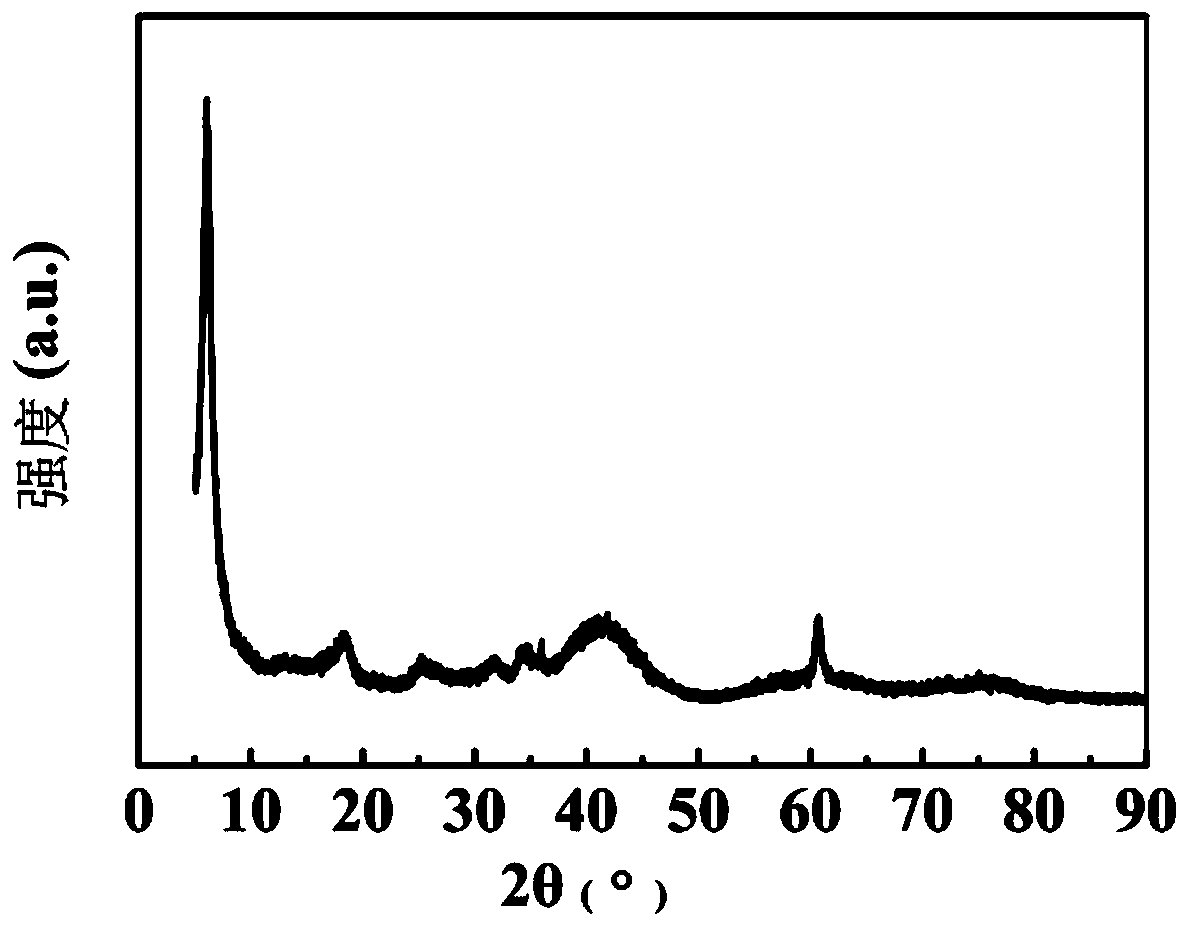

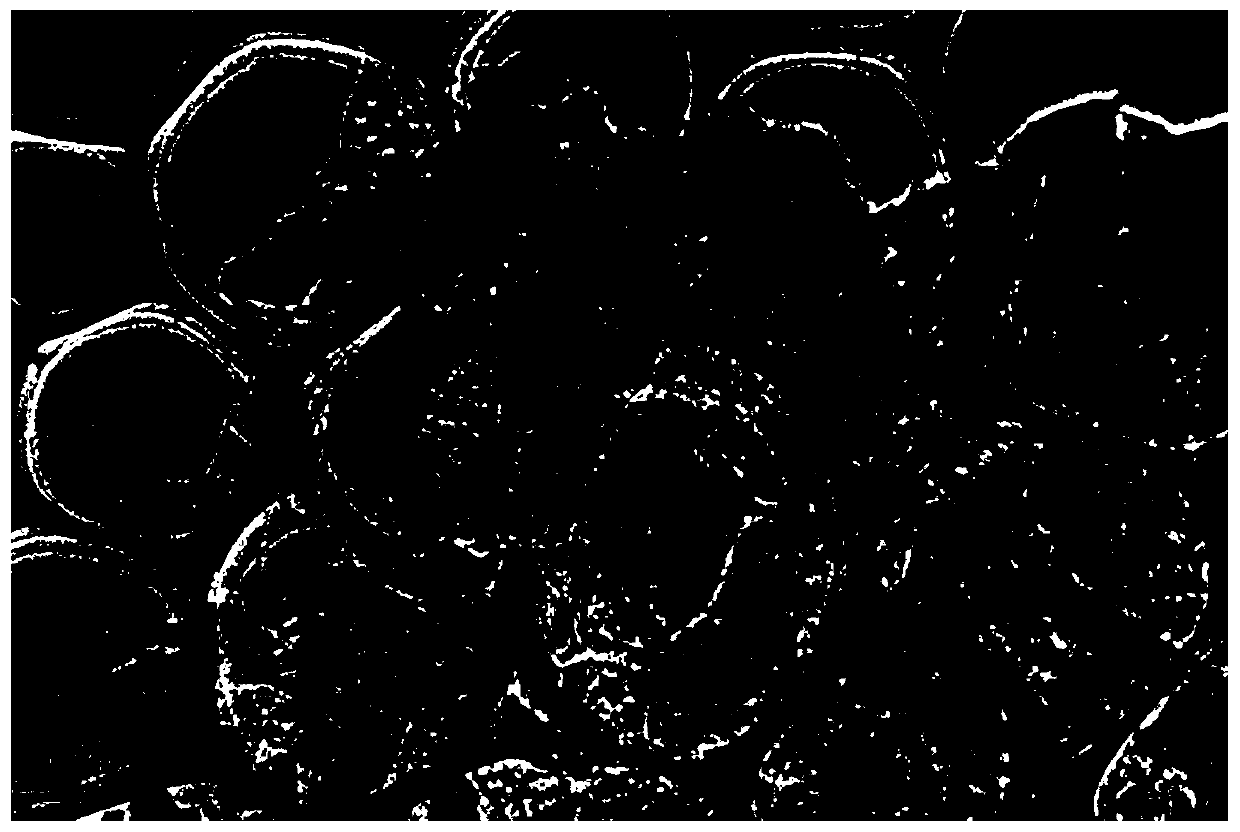

Large-size MXene nanosheet rich in oxygen functional groups as well as preparation method and application thereof

ActiveCN110615440ASolve the problem of small lateral size (2-5 microns)Fast conductionMaterial nanotechnologyTitanium carbideUltra Low Temperature FreezerFreeze-drying

The invention discloses a large-size MXene nanosheet rich in oxygen functional groups as well as a preparation method and an application thereof, and relates to an MXene nanosheet as well as a preparation method and an application of the MXene nanosheet. The invention aims to solve the problem that the transverse size of the MXene nanosheet prepared by the existing method is small. The large-sizeMXene nanosheet being rich in oxygen functional groups is formed by stacking a plurality of few-layer MXene nanosheets. The preparation method comprises the following steps: 1, centrifuging a two-dimensional MXene nanosheet suspension to obtain a muddy precipitate; 2, adding deionized water into the muddy precipitate, stirring the slurry, freezing the slurry in an ultra-low temperature refrigerator at -80 DEG C, and finally freeze-drying in a freeze dryer to obtain a freeze-dried product; and 3, placing the freeze-dried product into a solvent for carrying out ultrasonic treatment. The invention discloses applications of the large-size MXene nanosheet as an electrode material of a supercapacitor or a lithium ion battery. According to the preparation method, the large-size MXene nanosheet rich in oxygen functional groups can be obtained.

Owner:HARBIN NORMAL UNIVERSITY

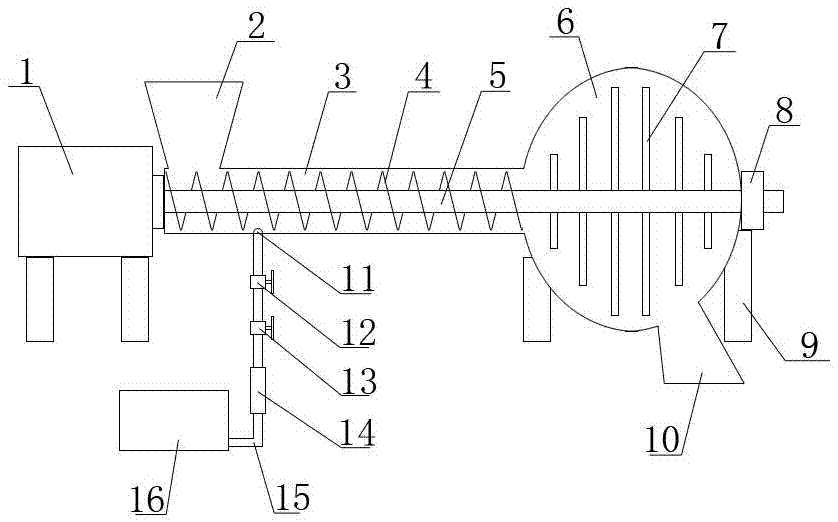

Automatic-control water adding device of dough kneading machine

InactiveCN106889132AHigh tensile strengthImprove bending abilityMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsAutomatic controlSprayer

The invention discloses an automatic-control water adding device of a dough kneading machine. The automatic-control water adding device comprises a conveying pipe, a feeding hopper is arranged at one end of the conveying pipe, the other end of the conveying pipe is communicated with a stirring cavity with a discharging pipe, a stirring shaft penetrates the conveying pipe and the stirring cavity, and one end of the stirring shaft is in transmission connection with a motor while the other end of the same is connected with a supporting seat; a spiral pushing plate is arranged on the front portion of the stirring shaft, a stirring rod is arranged on the rear portion of the stirring shaft, the conveying pipe is communicated with a water adding pipe with a gate valve, a sprayer is arranged at a position where the conveying pipe is communicated with the water adding pipe, and a flow switch and a flow meter are arranged on the water adding pipe. Flour enters the conveying pipe from the feeding hopper, is mixed and stirred with water in the process of being conveyed, is stirred well for the second time when passing the stirring cavity and is discharged finally through the discharging pipe; water injection quantity and flowing speed are controlled through the flow switch and the flow meter, and water incoming quantity can be adjusted according to different flour and different stirring speeds; the stirring rod in the stirring cavity can flail and stir the flour for well mixing.

Owner:SHANDONG YUHUANG GRAIN & OIL FOOD

Device for recycling nitric acid from waste liquor containing copper nitrate and use method of device

InactiveCN104085865AConcentration controllableImprove the distillation effectWater/sewage treatment by heatingCopper sulfatesDistillationCopper nitrate

The invention discloses a device for recycling nitric acid from waste liquor containing copper nitrate. Repeated addition of concentrated sulphuric acid or adoption of a reverse extraction technology is not needed, cost and space occupied by equipment are saved, operation steps are simplified, resource optimization is realized, design is simple and reasonable, and control is easy. The device for recycling nitric acid from the waste liquor containing copper nitrate comprises a concentrated sulphuric acid storage tank and an acid pickling waste liquor storage tank and is characterized in that a metering pump is respectively arranged at the outlet of the bottom of each of the concentrated sulphuric acid storage tank and the acid pickling waste liquor storage tank and is respectively communicated to the inner cavity of a heating unit, a heating wire is arranged in the inner cavity of the heating unit, a crystal outlet pipeline is arranged at the bottom of the heating unit, a distillation flask and a rectifying unit are sequentially arranged at the outlet in the upper part of the heating unit, the outlet in the upper part of the distillation flask is communicated with the inlet in the lower part of the rectifying unit, the outlet in the upper part of the rectifying unit is externally connected with an inner cavity inlet in the upper part of a condensation unit, an inner cavity outlet in the lower part of the condensation unit is connected to the lower part of a nitric acid finished product tank by virtue of a guide pipe, and flowing cold water is filled in the outer cavity of the condensation unit.

Owner:KUNSHAN MINGKUAN ENVIRONMENTAL & ENERGY SAVING TECH CO LTD

Full-hydraulic-lifting type ship lifter

ActiveCN103614995ACompact structureSimple and reasonable designVertical ship-liftingOperations securityMarine engineering

The invention relates to a full-hydraulic-lifting type ship lifter. The full-hydraulic-lifting type ship lifter comprises a ship reception chamber, a horizontal gate, an anti-collision device, two tower columns, locking devices, jacking and guiding devices, main lift cylinders, chamber bottom support beams, locking seats and guide rails, wherein the chamber bottom support beams are mounted at the bottom of the ship reception chamber; one ends of the main lift cylinders are connected with the tower columns, and the other ends of the main lift cylinders are connected with the end parts of the chamber bottom support beams; the locking devices are mounted on two sides of the top of the ship reception chamber, and the locking seats are mounted on the tower columns; the jacking and guiding devices are mounted on two sides of the ship reception chamber, one ends of the jacking and guiding devices are connected to the ship reception chamber, the other ends of the jacking and guiding devices are connected to the guide rails, and the guide rails are mounted on the tower columns. According to the full-hydraulic-lifting type ship lifter, the ship reception chamber is supported by the chamber bottom support beams, so that the loading condition of the ship reception chamber is definite, the stress, rigidity and operation security of the structure are good; as multiple cylinders are synchronously driven, lifted and locked, the ship reception chamber smoothly works and is securely locked; the full-hydraulic-lifting type ship lifter is simple and reasonable in integral structure and low in investment cost.

Owner:杭州国电机械设计研究院有限公司

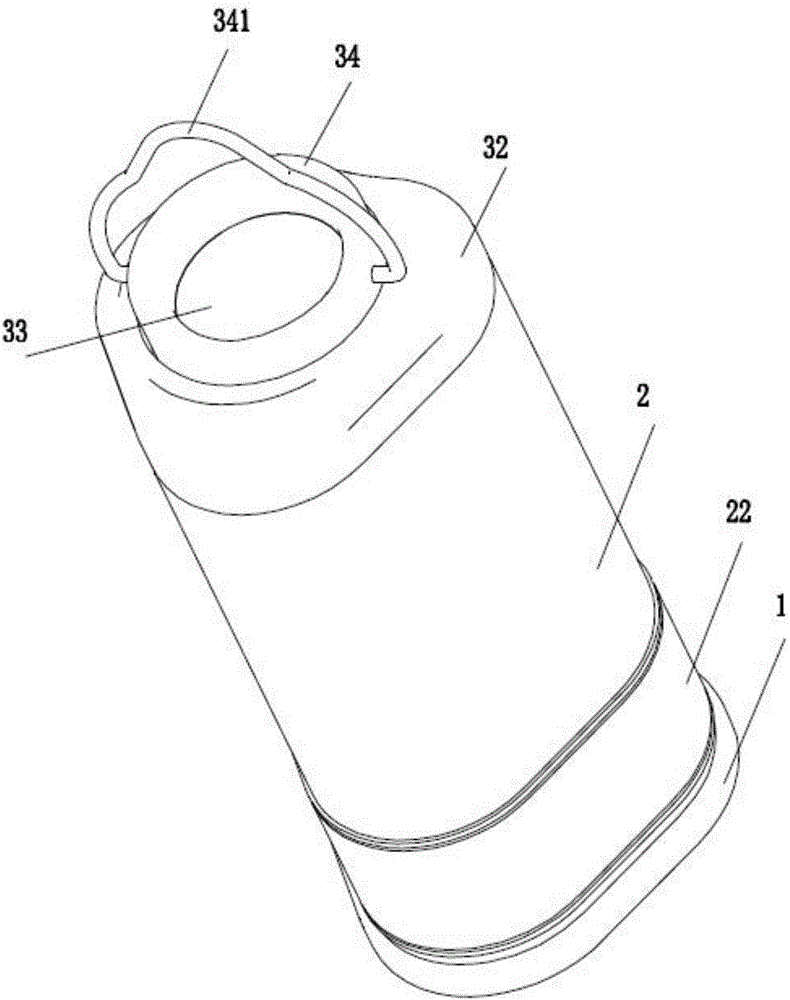

Telescopic type multifunctional camping lamp

InactiveCN106090693AWith sun protectionWith UV protectionLighting support devicesElectric circuit arrangementsEngineeringLED lamp

The invention discloses a telescopic type multifunctional camping lamp which comprises a base, a shell, a lamp holder assembly and a built-in storage battery, wherein the shell is a column body with a cavity inside and openings in two ends; the size and the shape of the base are matched with those of the end surface of the shell; the upper end of the base is movably connected with the lower end of the shell; the upper end of the shell is movably connected with the lamp holder assembly; the storage battery is arranged in the inner cavity of the shell; the lamp holder assembly comprises a side lampshade, a lamp cover, a front lampshade, a lamp holder and an LED bulb; the side lampshade is a column body with a cavity inside and openings in two ends; the shape of the side lampshade is similar to that the shell, but the size of the side lampshade is slightly smaller than that of the shell; the side lampshade is inserted into the inner cavity of the shell and can be movably connected with the shell; the base comprises a pluggable end; convex clamping claws are arranged at the edge of the outer wall of the pluggable end; and grooves connected with the clamping claws in a matched manner are formed in the lower end of the shell. The telescopic type multifunctional camping lamp adopts a three-joint telescopic structure, and one joint and another joint are connected through built-in limiting fasteners and inverted-pulling type structures, so that the design is reasonable and convenient.

Owner:浙江启皓光电有限公司

Corridor elevator

ActiveCN106044460ASimple and reasonable designThe overall structure is simple and reliableElevatorsBuilding liftsDirect currentHandrail

The invention discloses a corridor elevator. The corridor elevator comprises a track group arranged along a moving direction of stair handrails, a cross shaft chain penetrating through the track group, a driving mechanism for dragging the cross shaft chain to operate along a track and a hoisting rod seat hoisted on the tail end of the cross shaft chain; the track group comprises a main track located in the middle, two auxiliary tracks located at one side of the main track and two straight tooth racks located at the other side of the main track; and the cross shaft chain penetrates through the main track. By adopting the split structure of a direct current motor and the hoisting rod seat, the structure of the hoisting rod seat is simplified, the hoisting rod seat is hoisted in the track group and can be automatically folded and rotated, such that the corridor space is greatly saved; the track and the racks adopt a standard part assembly manner, such that the corridor elevator is suitable for a staircase of various structures and is easy and feasible to measure and mount, a dual insurance safety device is adopted, accidents in operation are avoided, and a safety coefficient is improved.

Owner:吴慧勇

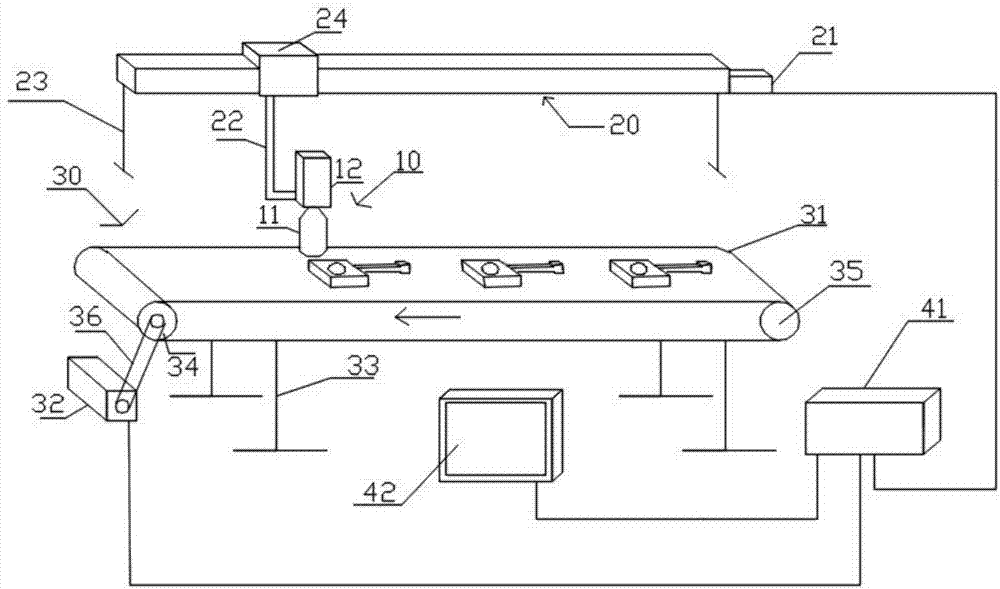

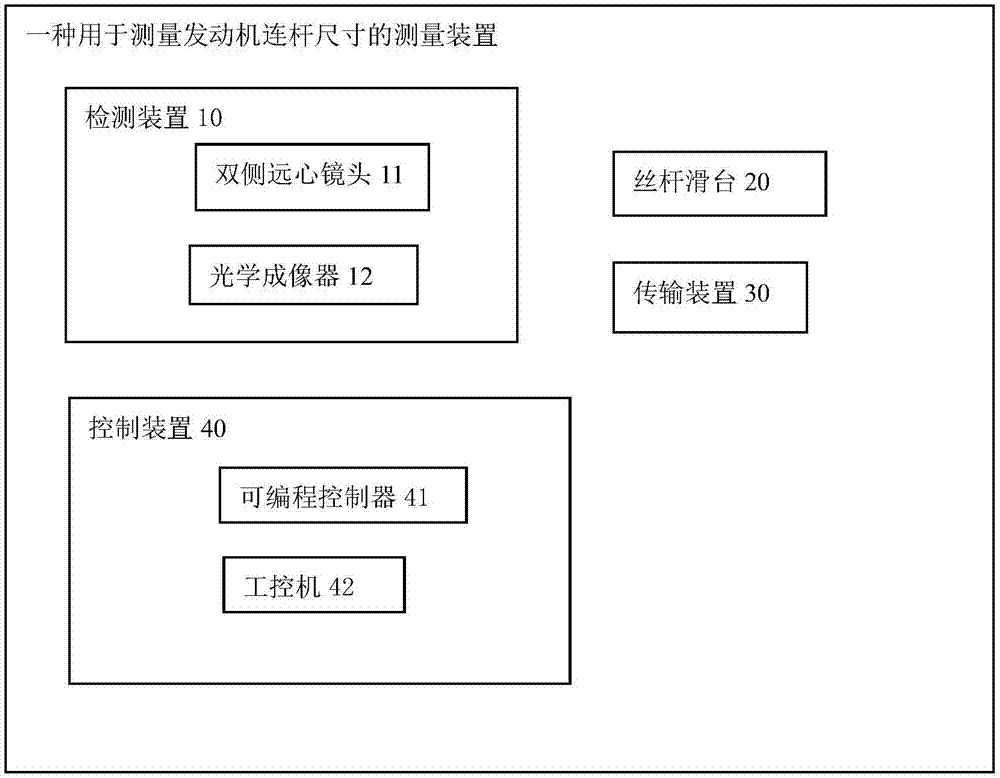

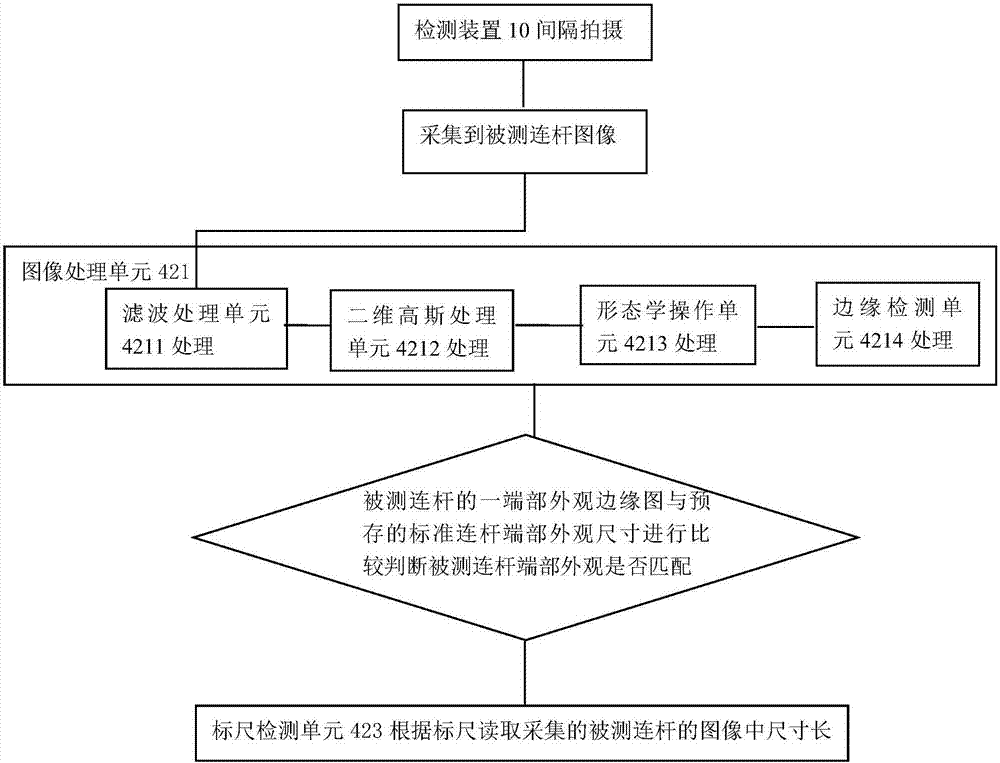

Engine connecting rod dimension measuring device and method based on machine vision

PendingCN107957245ASolve efficiency problemsSolve the defect of high false positive rateUsing optical meansMachine visionFrequency conversion

The invention discloses an engine connecting rod dimension measuring device based on machine vision; the measuring device is featured by comprising the following units: a detection unit comprising a bi-telecentric lens with a scale and an optical imager, wherein the bi-telecentric lens is mechanically connected with the lens of the optical imager through a C-type interface; a screw rod slide way including a servo motor, wherein the detection unit is fixed on the screw rod slide way through a support bolt, the servo motor drives the detection unit to linearly axially move from the initial position of the screw rod slide way to another terminal position; a transmission unit including a conveyer belt and a frequency conversion motor, wherein the frequency conversion motor intermittently runsto transfer to-be-tested rods one by one; a control unit including a programmable controller and an industrial control computer.

Owner:JIANGSU HONGBAO FORGING

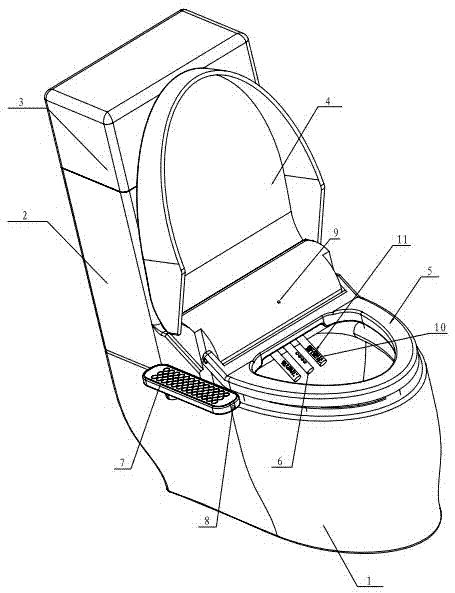

Closestool with physical therapy function and work method thereof

InactiveCN105442681ASimple structureSimple and reasonable designBathroom coversLavatory sanitoryElectricityEngineering

The invention relates to a closestool with a physical therapy function and a work method thereof. The closestool comprises a closestool seat, a water tank, a water tank cover, a closestool cover and a closestool ring. A water inlet pipe in the water tank is communicated with a flushing rod for flushing the anus through a filter, the flushing rod is arranged at the top of the closestool seat and extends downwards into the closestool seat in an inclined mode, and the flushing rod is internally provided with a heater; the upper end of the side wall of the closestool seat is further provided with an operation keyboard, the front end of the operation keyboard is provided with a first infrared sensor, and the inner wall of the bottom of the closestool cover is further provided with a second infrared sensor; the two sides of the flushing rod are each provided with a blowing rod, a plurality of infrared LED lamps are evenly embedded in the peripheral sides of the blowing rods, and one end of each blowing rod extends outside the closestool seat to be communicated with a small-size fan; the first infrared sensor, the second infrared sensor, the heater, the infrared LED lamps and the small-size fan are electrically connected with the operation keyboard. According to the closestool with the physical therapy function and the work method thereof, the flushing rod and the blowing rod are utilized to achieve the functions of flushing, antiphlogosis, blood activation and sterilization of the anus, and the physical therapy effect is achieved.

Owner:FUZHOU PINXING TECH DEV

Domestic sewage material filtering device

ActiveCN107746158AShort processSmall footprintFatty/oily/floating substances removal devicesTreatment using aerobic processesEngineeringTherapeutic effect

The invention discloses a domestic sewage material filtering device, and belongs to the technical field of domestic sewage treatment. The domestic sewage material filtering device comprises two relatively large box bodies (a solid impurity filtering box and an organic matter cleaning box), a connecting pipe and an oil liquid filtering box, wherein the connecting pipe is used for connecting the solid impurity filtering box and the organic matter cleaning box; the oil liquid filtering box is arranged on the connecting pipe; the solid impurity filtering box is separated into a large solid filtering region and a small solid filtering region by a separation plate; a rotating blade group and a first rotating cylinder of a windmill structure are arranged in the large solid filtering region; fixedcutter teeth and blade cutter teeth which are matched are arranged at one side of a first fixed cylinder body and rotating blades; first through holes are formed in the side wall of the first rotating cylinder; the first rotating cylinder is filled with active carbon; a second rotating cylinder and rotating fan blades are arranged in a small solid filtering cavity; reticular metal filled with quartz sand and zeolite is arranged between the rotating fan blades; third through holes are formed in the side wall of the second rotating cylinder; the domestic sewage material filtering device is alsoprovided with a solid accommodating box and a water body accommodating box. The domestic sewage material filtering device has the advantages that the design is reasonable and is optimized; the structure is compact; the occupied space is relatively small; the work flow process is short; the treatment efficiency is high; the treatment effect is better.

Owner:徐州宇之阳市场营销策划有限公司

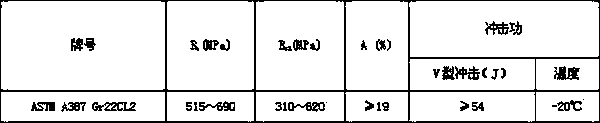

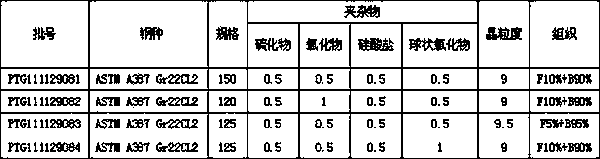

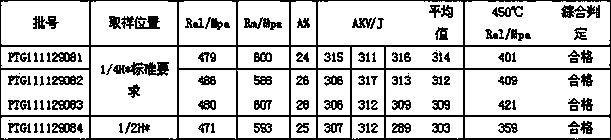

Cr-Mo ASTM A387 Gr22CL2 pressure vessel steel and production method thereof

The invention provides a limit-thickness Cr-Mo ASTM A387 Gr22CL2 pressure vessel steel and a production method thereof. The Cr-Mo ASTM A387 Gr22CL2 pressure vessel steel comprises the following chemical components in percentage by mass: 0.08-0.16 wt% of C, 0.20-0.50 wt% of Si, 0.30-0.60 wt% of Mn, at most 0.015 wt% of P, at most 0.005 wt% of S, 0.020-0.060 wt% of Als, 2.0-2.5 wt% of Cr, 0.9-1.1 wt% of Mo and the balance of Fe and residual element. The production method comprises the following steps: pretreatment of high-quality molten iron and KR molten iron, 120t top / bottom blown converter, argon blowing by Ar station, LF (ladle furnace) refining, VD (vacuum degasser) vacuum degassing, water-cooled die casting, dead soaking pit heating, 3800mm rolling mill, ACC laminar cooling, straightening, cooling in pile, heat treatment, finishing, outer inspection, flaw detection and warehousing. The steel plate is cast by a 48t water-cooled ingot die, so the cooling and solidifying time is shortened by 1 / 3 as compared with the conventional foundry ingot die, the defect of severe loosening or segregation at the center of the steel ingot is reduced or avoided, and the internal quality of the steel plate is improved.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

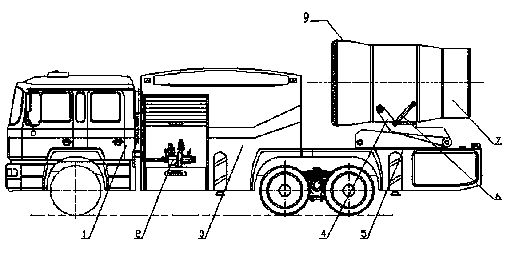

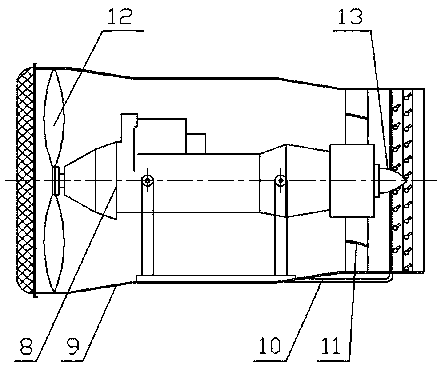

Strong wind smoke exhaust fire vehicle with air fan driven by aero-engine

The invention discloses a strong wind smoke exhaust fire vehicle with an air fan driven by an aero-engine. The fire vehicle comprises a vehicle, a water tank, a water pump, an elevating mechanism, a rotating mechanism and a pitching mechanism. Pitching of a ventilating duct is controlled through the pitching mechanism. An aero-turboprop engine, an air fan, a fairing and a rectiblock are arranged in the ventilating duct. The ventilating duct is sleeved at the outer side of the aero-turboprop engine. The air fan is arranged on the output shaft of the aero-turboprop engine. The fairing is arranged in the shell body of the ventilating duct through the rectiblock. The ventilating duct, the aero-turboprop engine, the air fan and the fairing are arranged on the same axis. The ventilating duct and the aero-turboprop engine are arranged on the support of the elevating mechanism. The decommissioned aero-turboprop engine with small size, light weight, large power and high reliability is used for driving the air fan, thus the input power is increased to above 2000KW, the air speed at the outlet of the air fan is 90m / s, the air quantity reaches above 600000 m<3> / h, and the air flow injection distance is more than 100m. The fire vehicle is a smoke exhaust fire vehicle with the largest air mass flow in domestic.

Owner:JIANGSU KAWEI SPECIAL PURPOSE VEHICLE MFG

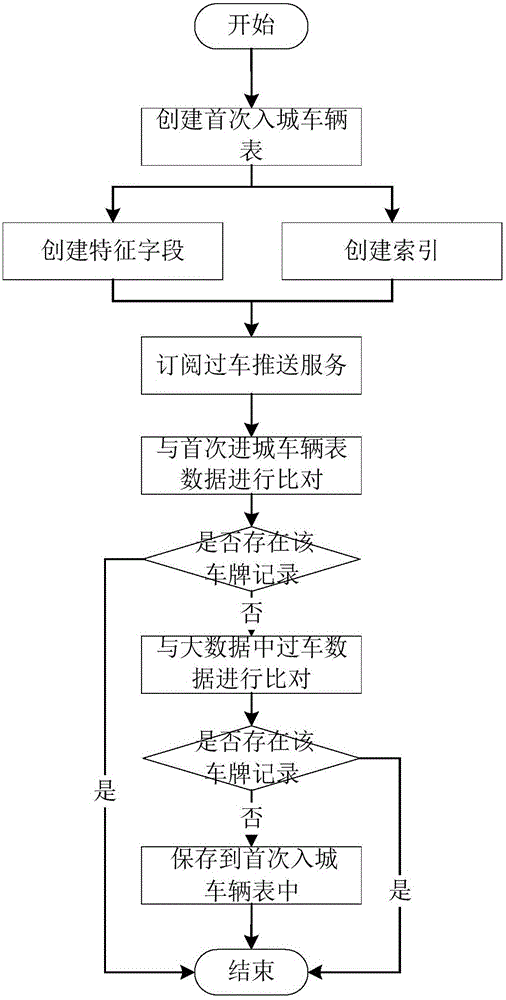

Discrimination method for vehicles entering city for the first time

InactiveCN105868368AImprove scalabilityReduce loadOther databases queryingSpecial data processing applicationsTelecommunicationsMessage oriented middleware

The invention belongs to the field of analysis of checkpoint vehicle padding information data, and particularly relates to a discrimination method for vehicles entering a city for the first time. The method comprises the following steps that 1, a list of vehicles entering the city for the first time is built in a database, wherein the list can be updated in good time; 2, a list structure is built according to vehicle features needing to be collected, and indexes are built according to a primary key and independent license plate numbers; 3, message-oriented middleware is set to receive timely checkpoint vehicle passing data having access to each platform; 4, data obtained by the message-oriented middleware each time is compared with the data in the list of the vehicles entering the city for the first time in time; 5, the data obtained by the message-oriented middleware each time is compared with vehicle passing data in big data; the comparison processes in the step 4 and the step 5 are repeated. The rapid, efficient and accurate online information retrieval purpose can be achieved with low cost, and the system burden rate can be effectively reduced.

Owner:ANHUI SUN CREATE ELECTRONICS

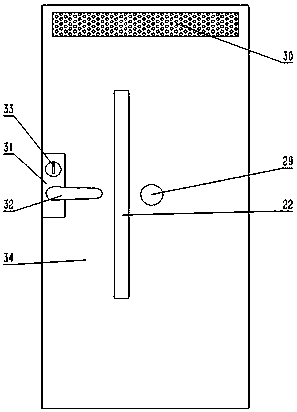

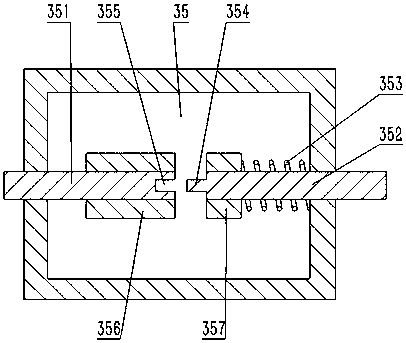

Anti-theft door monitoring device

ActiveCN108547560ASimple and reasonable designEasy to operateClosed circuit television systemsSpecial door/window arrangementsProtective glassesAnti theft

The invention discloses an anti-theft door monitoring device. The anti-theft door monitoring device comprises a transmission chamber, an upper sliding block, a camera, a motor base and a power supplyswitch; the motor base is arranged at the top of the transmission chamber, a first motor is arranged in the motor base, a first lead screw is arranged on the lower portion of the first motor, and theupper sliding block and a lower sliding block are arranged on the first lead screw in a sleeving mode; a sliding rail is arranged on the right side of the upper sliding block, the camera is arranged on the upper portion of the sliding rail, fixing blocks are arranged at the upper end and the lower end of the right side of the transmission chamber correspondingly, and protective glass is arranged on the right sides of the fixing blocks and fixedly connected with the right sides of the fixing blocks; and the power supply switch is arranged on the upper right portion of the transmission chamber,the transmission chamber is arranged in an anti-theft door, and the protective glass is arranged in the front side wall of the anti-theft door. The anti-theft door monitoring device is simple and reasonable in structural design, operation is convenient and fast during using, and practicability is quite high; and according to the anti-theft door monitoring device, the camera can be driven by the motor to conduct scan and shoot, thus the whole body of a thief is shot, the defect that the shooting range of the camera is not wide can be made up, and the situation that judgment is influenced due toincomplete shooting pictures is prevented.

Owner:浙江神将门业有限公司

Guide rail sliding-type drawing board device

ActiveCN108497774ASimple and reasonable designLow costDrawing desksOther artistic work equipmentsEngineeringDrawing board

The invention discloses a guide rail sliding-type drawing board device, which comprises a guide rail I and a guide rail II, wherein a sliding clamping plate is arranged between the guide rail I and the guide rail II; a drawing board is arranged in the sliding clamping plate; the drawing board is connected to the sliding clamping plate via a fastening shaft; sliding strips are each arranged at thetop end and the bottom end of the sliding clamping plate; the sliding strips are similar to T-shaped structures; a plurality of grooves are symmetrically formed in two sides of the sliding strips; elastic convex points, which are matched with the grooves, sleeve in the grooves; the elastic convex points are arranged on the inner walls of the guide rail I and the guide rail II; and a cavity, whichis laterally opened, is formed in one side of the sliding clamping plate. In comparison with the prior art, a piece of drawing paper, which is drawn, can be paved on the drawing board, so that cost isreduced and user's labor is saved; a user, who implements large-scale drawing, can not move around to adjust the drawing board back and forth and just needs to adjust the drawing board as required, so that the design breaks limitation of conventional drawing boards.

Owner:YANTAI NANSHAN UNIV

Efficient wooden door paint spraying equipment with drying function

InactiveCN107774488ASimple and reasonable designEasy to operatePretreated surfacesCoatingsFixed frameEngineering

The invention discloses efficient wooden door paint spraying equipment with a drying function. The efficient wooden door paint spraying equipment comprises a fixing bottom frame, fixing bases and a damping device. A support plate is arranged at the upper end of the damping device, fixing frames are arranged on the upper sides of the left end and the right end of the support plate, turning wheels are arranged at the upper ends of the fixing frames, conveying devices are arranged at the upper ends of the turning wheels, a paint spraying chamber is arranged at the upper end of the support plate,and a drying chamber is arranged on the left side of the paint spraying chamber. The efficient wooden door paint spraying equipment has the advantages that the efficient wooden door paint spraying equipment is used for paint spraying work on wooden doors, the wooden doors required to be processed are arranged in fixing devices at first, limit screws and fixing nuts can rotate, accordingly, each wooden door can be fixed to a position between two fixing blocks, the efficient wooden door paint spraying equipment can be conveniently and quickly operated, and the wooden doors can be stably fixed; the wooden doors can be driven by the turning wheels to be fed into the paint spraying chamber at first, the paint spraying work can be carried out on the wooden doors, a plurality of air spray nozzlesare uniformly arrayed, accordingly, the paint spraying efficiency and the paint spraying uniformity can be improved, the surfaces of the wooden doors can be flat, and the quality of the processed wooden doors can be improved.

Owner:蚌埠抒阳自动化设备制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com