Automatic-control water adding device of dough kneading machine

A technology for dough mixers and water pipes, which is applied to dough mixers, mixing/kneading with vertical installation tools, and structural components of mixing/kneading machines. Difficult to control the amount of water and other problems, to achieve the effect of inhibiting the growth of bacteria, avoiding pollution, and reducing interface holes and defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

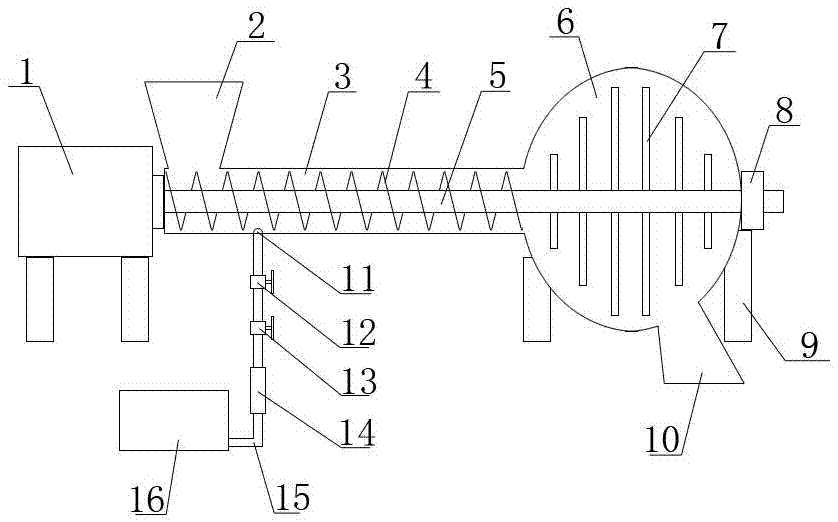

[0020] refer to figure 1 , the present invention includes a delivery pipe 3; one end of the delivery pipe 3 is provided with a feed hopper 2, and the other end communicates with the stirring chamber 6 with a discharge pipe 10; the delivery pipe 3 and the stirring chamber 6 run through A stirring shaft 5; one end of the stirring shaft 5 is connected to the motor 1 through transmission, and the other end is connected to the support seat 9 through the bearing seat 8; The rear portion of the plate 4 and the stirring shaft 5 is provided with the stirring rod 7 located in the stirring chamber 6; There is a shower head 11; the water supply pipe 15 is provided with a flow switch 13 and a flow meter 14 respectively.

[0021] Working principle: Flour enters the conveying pipe 3 from the feeding hopper 2, and the stirring shaft 5 rotates under the drive of the motor 1, thereby pushing the flour forward through the screw ejector plate 4; Under the action of the spray head 11, the water ...

Embodiment 2

[0023] The integrated structure composed of conveying pipe, feeding hopper, mixing chamber and discharging pipe is made of injection molding materials, specifically prepared according to the following process:

[0024] 1) Mix polypropylene, polyvinyl chloride, polyvinyl alcohol, graphene, carbon black and talcum powder evenly according to the mass ratio of 50:30:12:5:2:1, add to the internal mixer, and the internal mixing time is 5 minutes , the banburying temperature is 90°C to obtain the main material;

[0025] 2) Mix nano-titanium dioxide and nano-silver powder in a mass ratio of 2:1 to obtain a mixture, then add it to twice the weight of deionized water, stir well, and then add hexamethylcyclotrisiloxane of the same quality as the nano-silver powder , heated up to 60°C, and ultrasonically treated for 10 minutes to obtain a nanomaterial dispersion;

[0026] 3) Mix borax and silicon nitride evenly at a mass ratio of 2:1, put them into a ball mill tank containing absolute et...

Embodiment 3

[0029] The integrated structure composed of conveying pipe, feeding hopper, mixing chamber and discharging pipe is made of injection molding materials, specifically prepared according to the following process:

[0030] 1) Mix polypropylene, polyvinyl chloride, polyvinyl alcohol, graphene, carbon black and talcum powder evenly according to the mass ratio of 50:30:12:5:2:1, add to the internal mixer, and the internal mixing time is 5 minutes , the banburying temperature is 90°C to obtain the main material;

[0031] 2) Mix nano-titanium dioxide and nano-silver powder in a mass ratio of 2:1 to obtain a mixture, then add it to twice the weight of deionized water, stir well, and then add hexamethylcyclotrisiloxane of the same quality as the nano-silver powder , heated up to 60°C, and ultrasonically treated for 10 minutes to obtain a nanomaterial dispersion;

[0032] 3) Mix borax and silicon nitride evenly at a mass ratio of 2:1, put them into a ball mill tank containing absolute et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com