Full-hydraulic-lifting type ship lifter

A lifting type, full hydraulic technology, applied in the field of ship lifts and full hydraulic lift type ship lifts, can solve the problems such as the structural design is not simple and reasonable, the lifting speed of the ship lift is slow, and the lifting speed is not well overcome, etc. Compact, simple and reasonable overall structure, simple and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0031] Example.

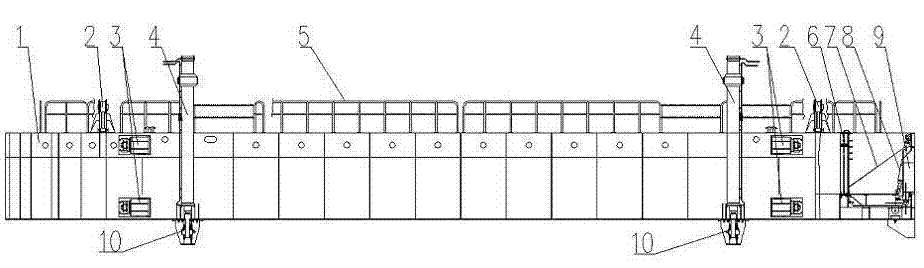

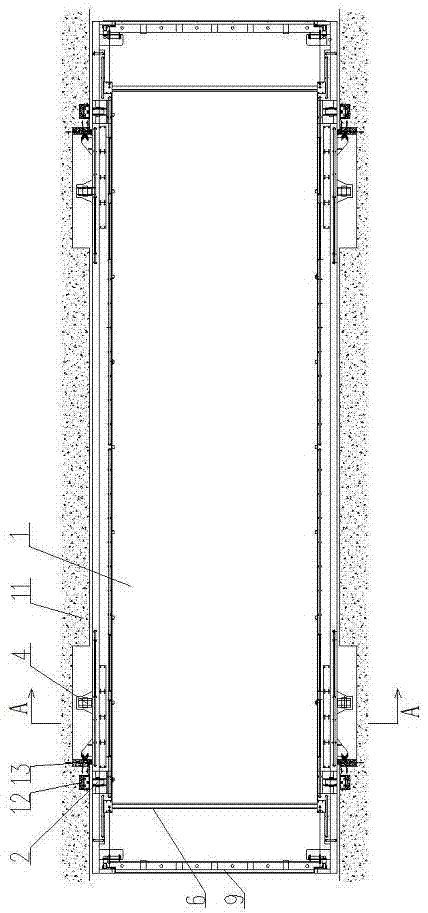

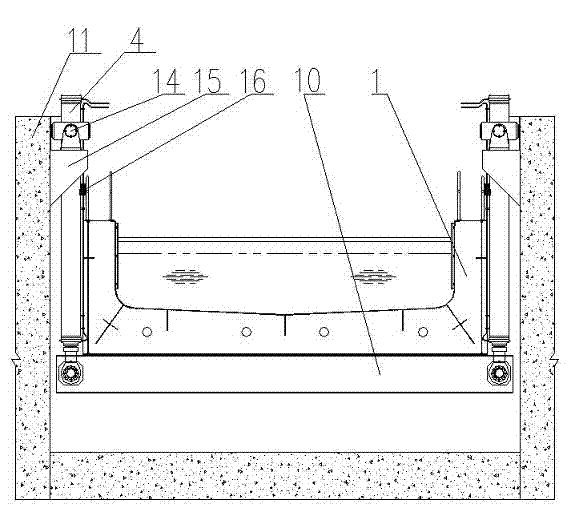

[0032] see Figure 1 to Figure 4, this embodiment includes a ship bearing compartment 1, a lock spindle device 2, a top tightening guide device 3, a main lifting cylinder 4, a guardrail 5, an anti-collision device 6, a steel wire rope 7, a reclining door 8, a recumbent door cylinder 9, and a bottom Backing beam 10, tower column 11, spindle lock seat 12, guide rail 13, oil cylinder hinge seat 14, corbel column 15, explosion-proof valve 16.

[0033] In this embodiment, the ship-bearing compartment 1 is located between two tower columns 11; there are two support beams 10 at the bottom of the compartment, and the two support beams 10 at the bottom of the compartment are symmetrically arranged at the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com