Manufacturing technology of long-length jointless mineral insulation cable

A technology of mineral insulated cable and manufacturing process, which is applied in the direction of cable/conductor manufacturing, conductor/cable insulation, circuit, etc., which can solve the problems of cable production length restriction, long cable production cycle, and increased electrical hidden dangers, etc., and achieves one-time inspection High qualification rate, easy guarantee of structure, size and concentricity, and reduced manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

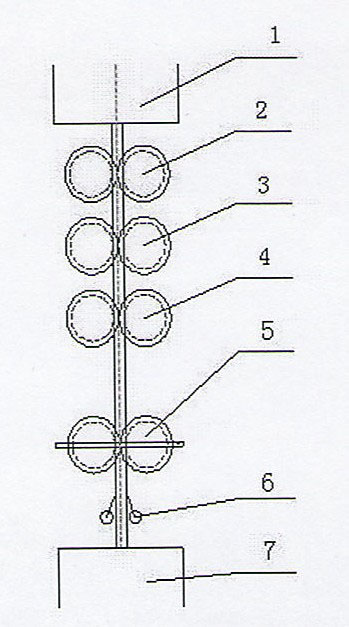

Image

Examples

Embodiment Construction

[0027] A manufacturing process of a large-length non-joint mineral insulated cable, comprising the following steps:

[0028] (1) Use 12-16% H successively through the washing machine 2 SO 4 1. Clean the copper strip with tap water, dry the cleaned copper strip at 35-45°C, and the dried copper strip enters the forming roll for tube forming; the tension-aligned copper rod (conductor) flows into the fixed core tube, and the copper The rod enters the stainless steel fixed core tube and is filled with special magnesium oxide powder at the same time. Silicone oil is injected into the special magnesium oxide powder in the fixed core tube. There is no need for any moisture removal treatment before silicone oil injection. The special magnesium oxide powder contains more than 94% of MgO. The rest is SiO 2 , CaO, Fe 2 o 3 The magnesia powder that can be added with silicon oil flows into the copper sheath through the fixed core tube. The length of the stainless steel fixed core tube i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com