Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Rock breaking speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

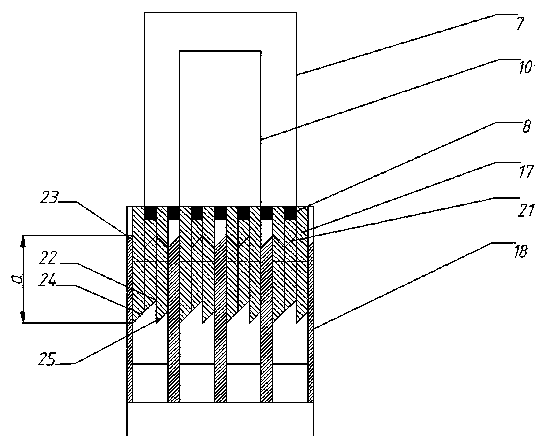

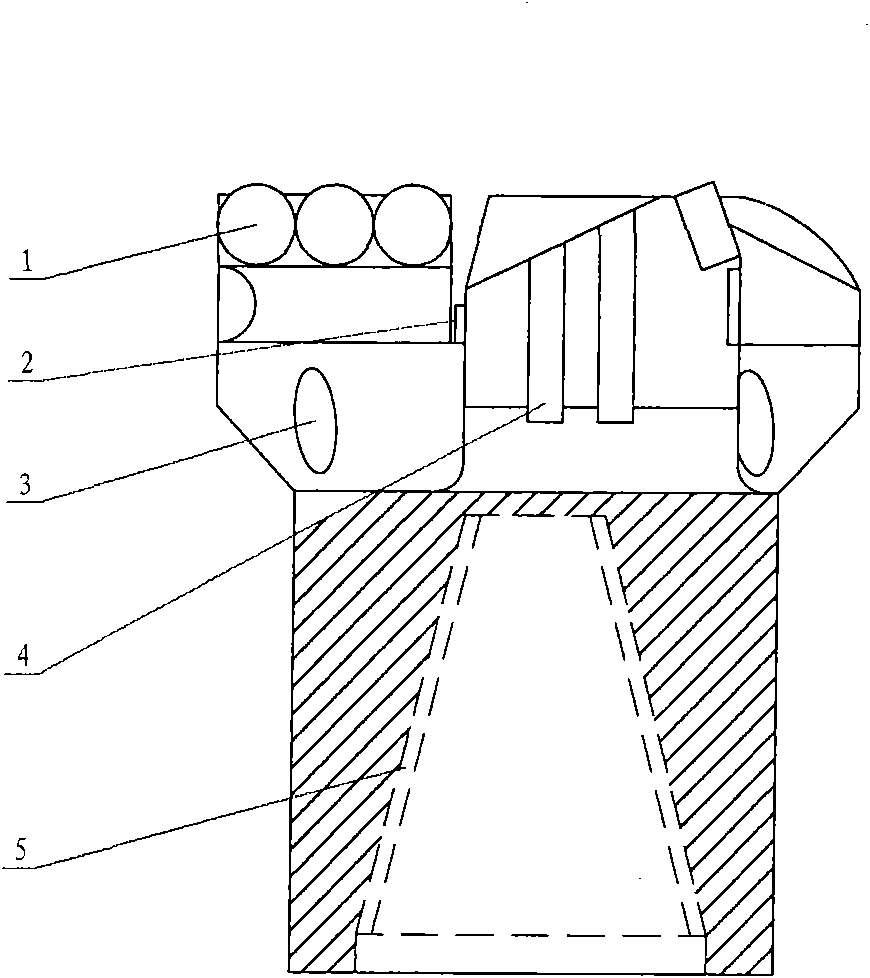

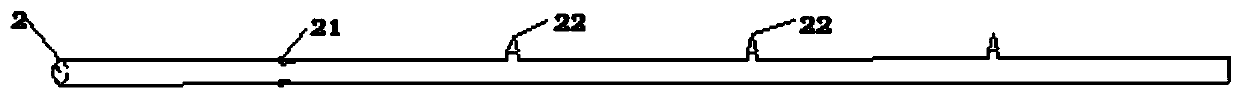

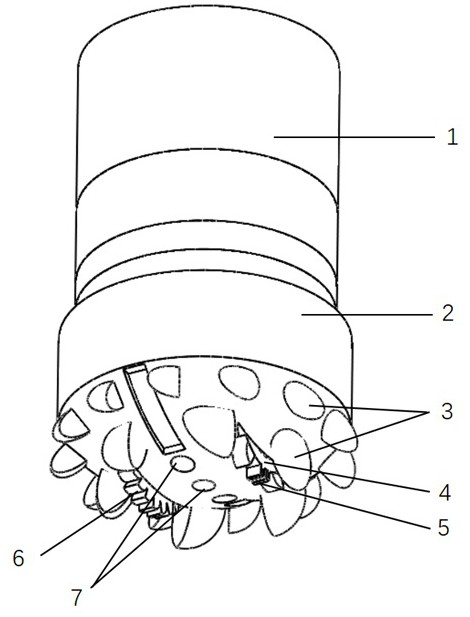

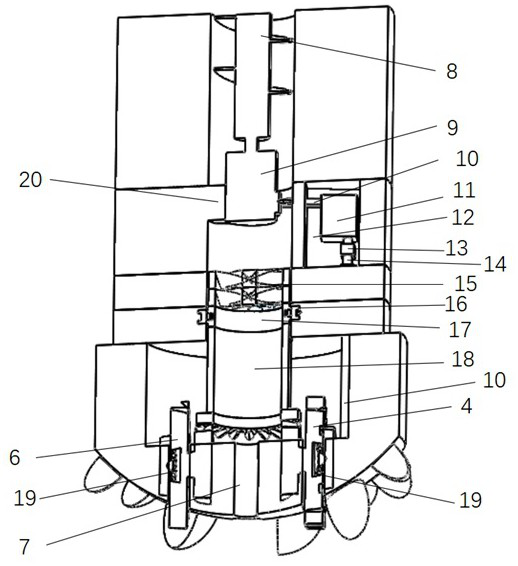

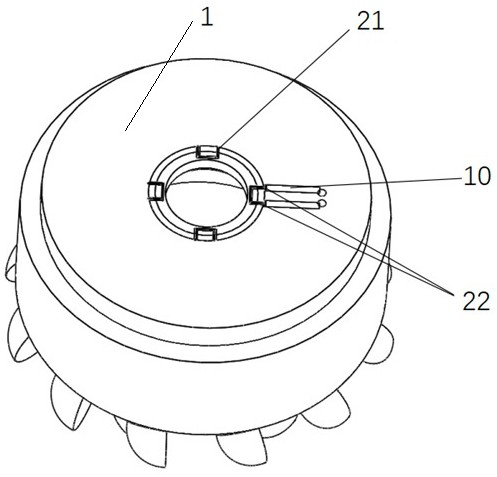

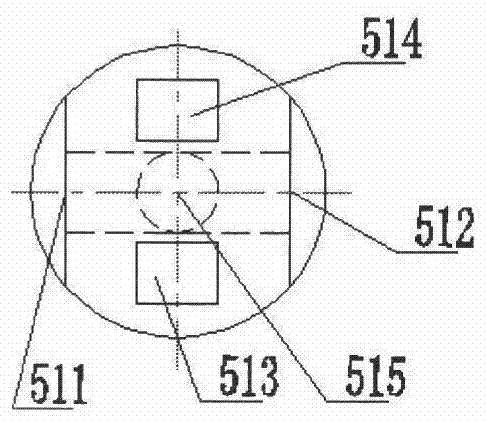

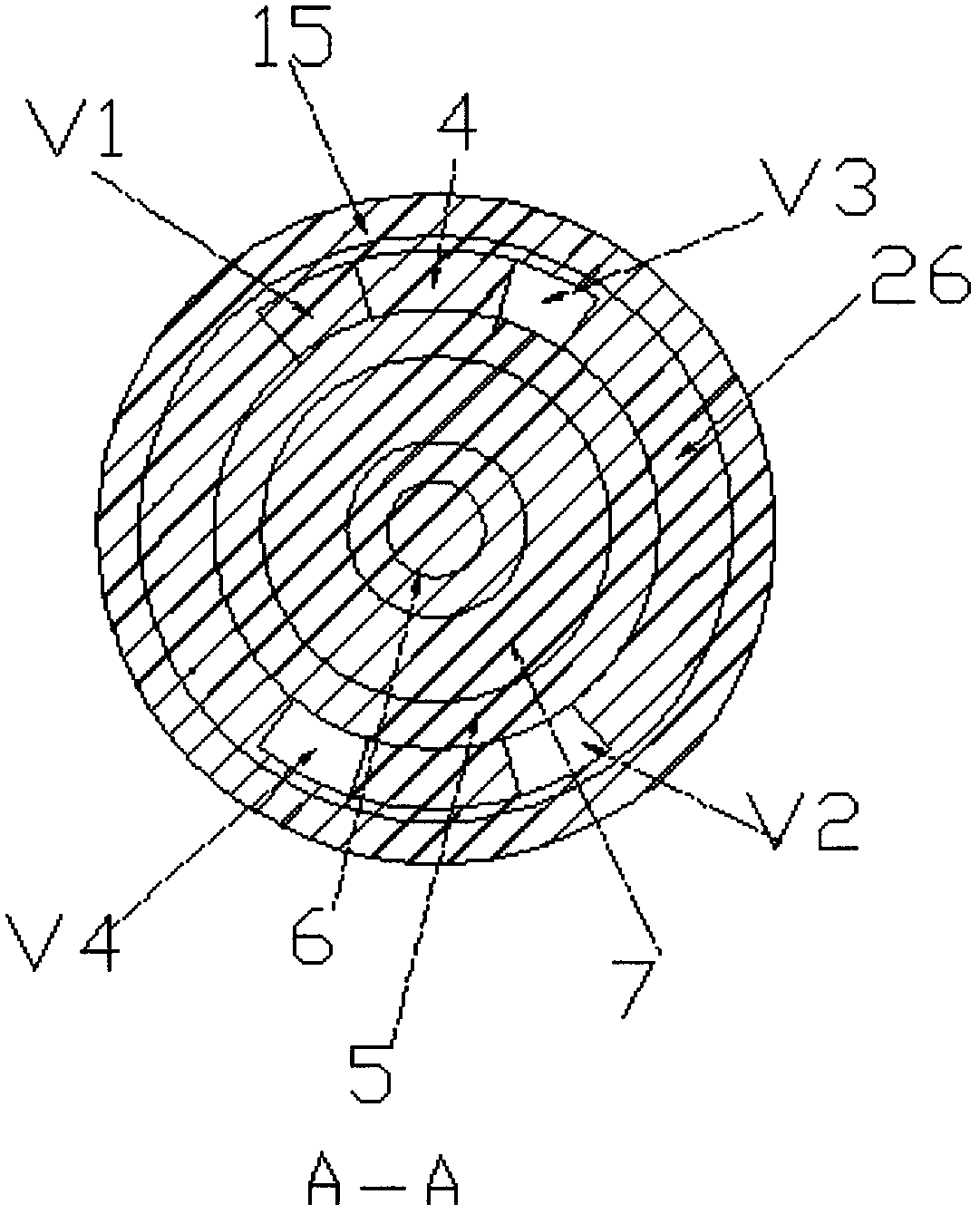

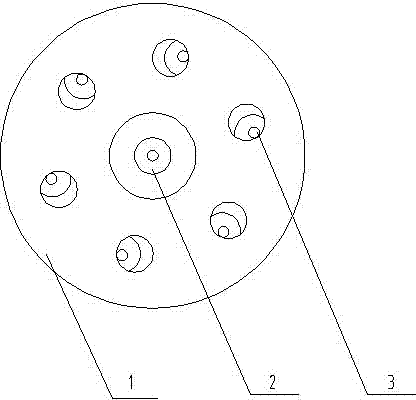

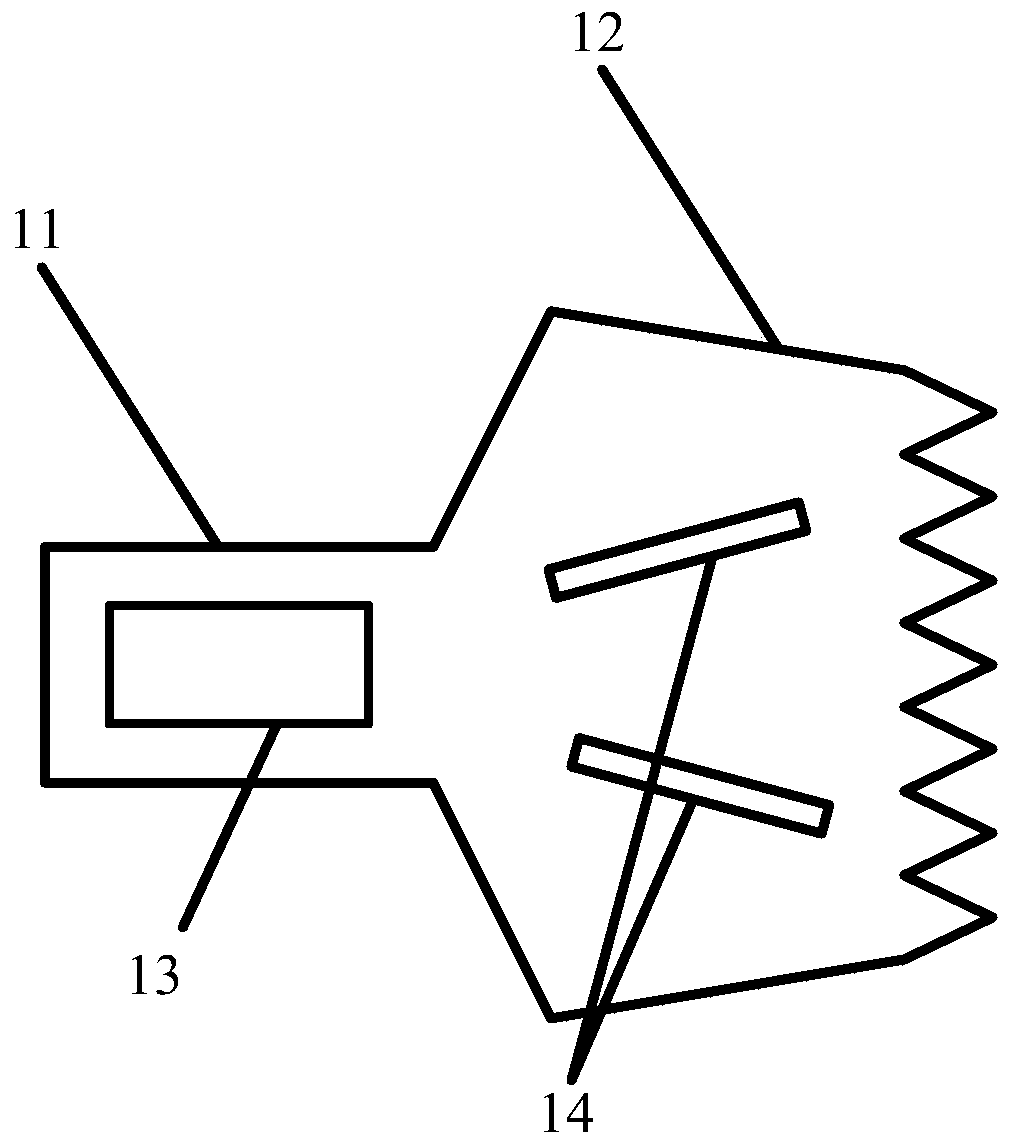

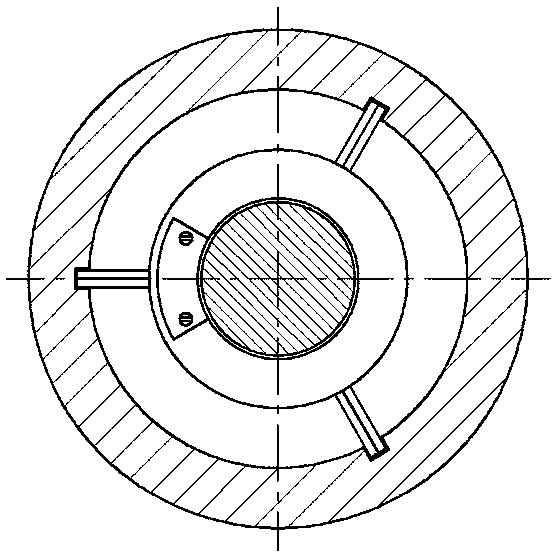

Radial sidetrack drilling rotating self-propelled porous jet flow drill bit

The invention relates to a radial sidetrack drilling rotating self-propelled porous jet flow drill bit, which mainly comprises a casing, a rotating drill bit body, a gear type slide ring type combined seal, an opening sealing screw, steel balls and the like, wherein a water inlet is processed at the tail end of the casing; a backward spray nozzle is processed on the casing; a forward spray nozzle and a center spray nozzle are processed on the rotating drill bit body; semicircular grooves are respectively processed in the casing and the rotating drill bit body; the steel balls are placed in the grooves formed between the casing and the rotating drill bit body; the rotating drill bit body is positioned through the steel balls and can rotate around the self axial line; the gear type slide ring type combined seal is adopted between the rotating drill bit body and the casing; through holes are formed at the lateral side of the casing; the steel balls are placed into the grooves through the through holes; and after the steel balls are placed into the grooves, the through holes are sealed through the opening sealing screws. The radial sidetrack drilling rotating self-propelled porous jet flow drill bit can effectively solve the problems of poor jet flow drill bit reaming capability, poor rock breaking hole smooth roundness, bent tracks of hydraulic jet hoses and the like of the hydraulic jet radial sidetrack drilling tiny drill hole technology, and can be widely applied to the hydraulic jet radial horizontal well technology.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Laser drilling device

InactiveCN102322216AIncrease drilling speedShorten the drilling cycleDrilling machines and methodsAir compressionInlet channel

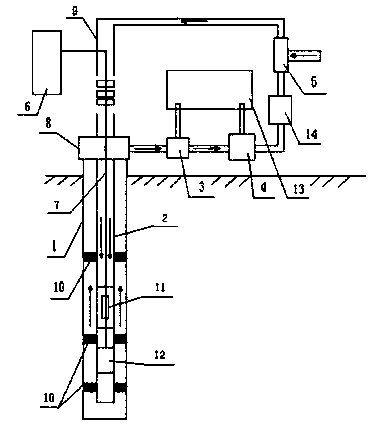

The invention relates to a laser drilling device, comprising a ground part and an underground part, wherein in an underground pit shaft, a communicated duct extends downwards into the pit shaft from the ground and reaches the bottom of the pit shaft; an MWD (Measurement While Drilling) guide instrument and a laser are arranged in the duct; a cable extends downwards into the pit shaft and is connected with the MWD guide instrument and the laser respectively; a stabilizer is arranged in an annular cavity between the duct and the pit shaft; a sleeve head is arranged at the pit opening on the ground; the duct is connected to an air outlet hole of an air compression booster station through the sleeve head so as to form an air inlet channel; the pit shaft is connected with the sleeve head through a superficial sleeve; the sleeve head is connected with another duct; and the another duct is connected to the air inlet hole of the air compression booster station after passing through a sand remover, a dust remover and a liquid-gas separator so as to form a circulation channel for dust removal, purification and boosting. The laser drilling device disclosed by the invention has high drilling speed, saves the drilling cycle and improves the drilling benefits.

Owner:NORTHEAST GASOLINEEUM UNIV

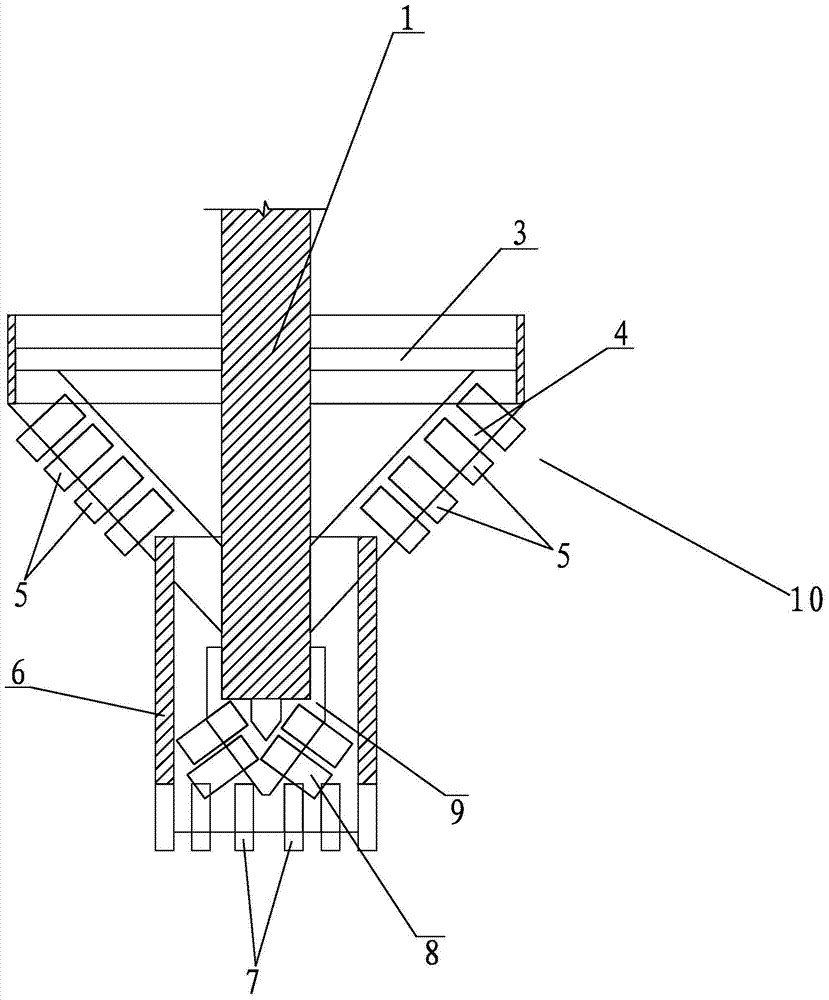

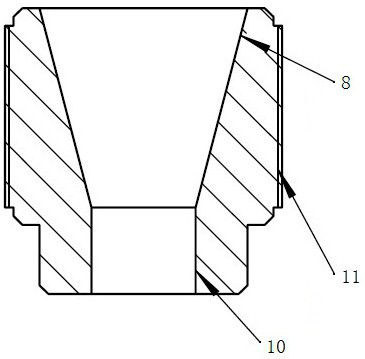

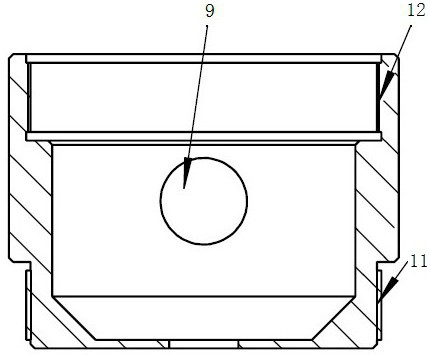

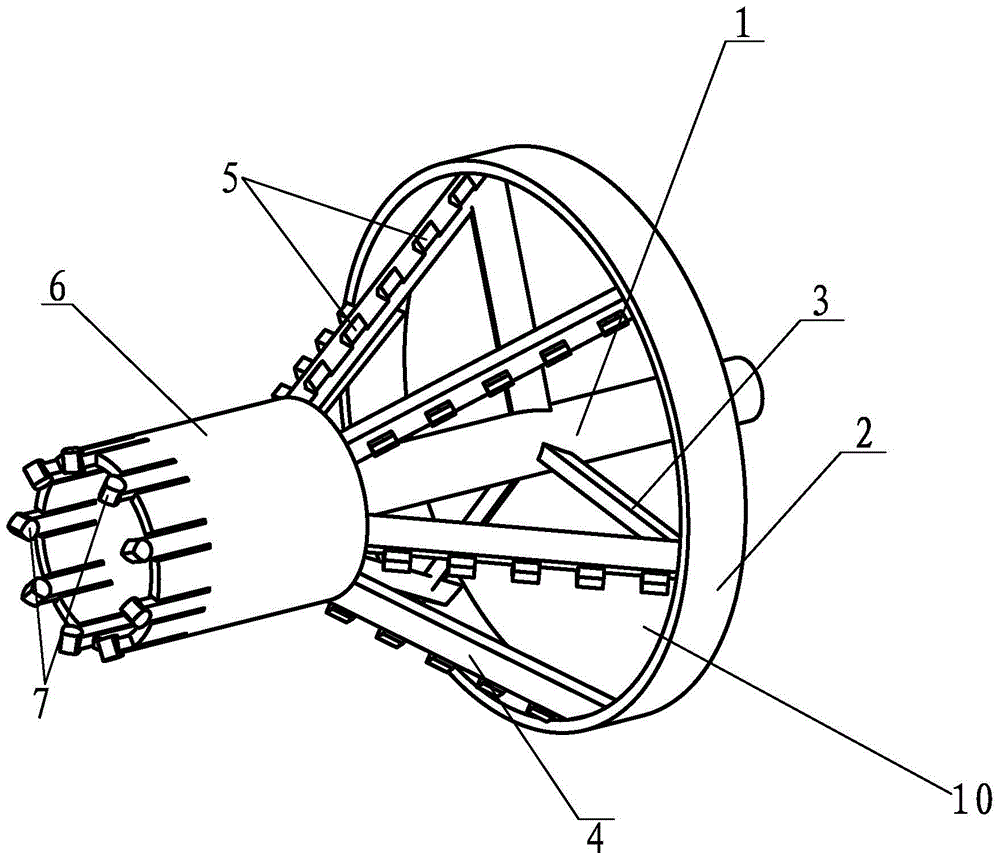

Driving retractable combination drill bit

InactiveCN105156039ATake advantage ofMeet drilling requirementsDrill bitsWell drillingPolycrystalline diamond

The invention relates to a driving retractable combination drill bit which mainly comprises a drill bit body, a well drilling liquid accommodating space, a well drilling liquid channel, a drill bit barrel, a compressive block, limiting stoppers, protruded rib plates in walls, a rotary retractable block, a retractable column, PDC (polycrystalline diamond compact) cutter wings and a cone. The PDC cutter wings are peripherally arranged along the outer wall of the drill bit body to form a central hollow groove; the retractable column which is positioned inside the drill bit barrel axially penetrates the central hollow groove, and the cone is fixedly arranged at the tail end of the retractable column; the retractable column can axially move up and down under the control of a retractable device; a hollow flow channel is axially fixedly connected onto the PDC cutter wings; the well drilling liquid accommodating space is jointly formed by the upper end surface of the compressive block and the side walls of the drill bit body; the protruded rib plates in the walls are peripherally arranged along the inner side of the drill bit barrel at intervals, and the limiting stoppers can axially move in slide grooves. The driving retractable combination drill bit has the advantages that merits of PDC drill bits and cone drill bits are sufficiently utilized, and accordingly the driving retractable combination drill bit is high in rock breaking speed and efficiency and long in service life under soft and hard staggered stratum conditions.

Owner:SOUTHWEST PETROLEUM UNIV

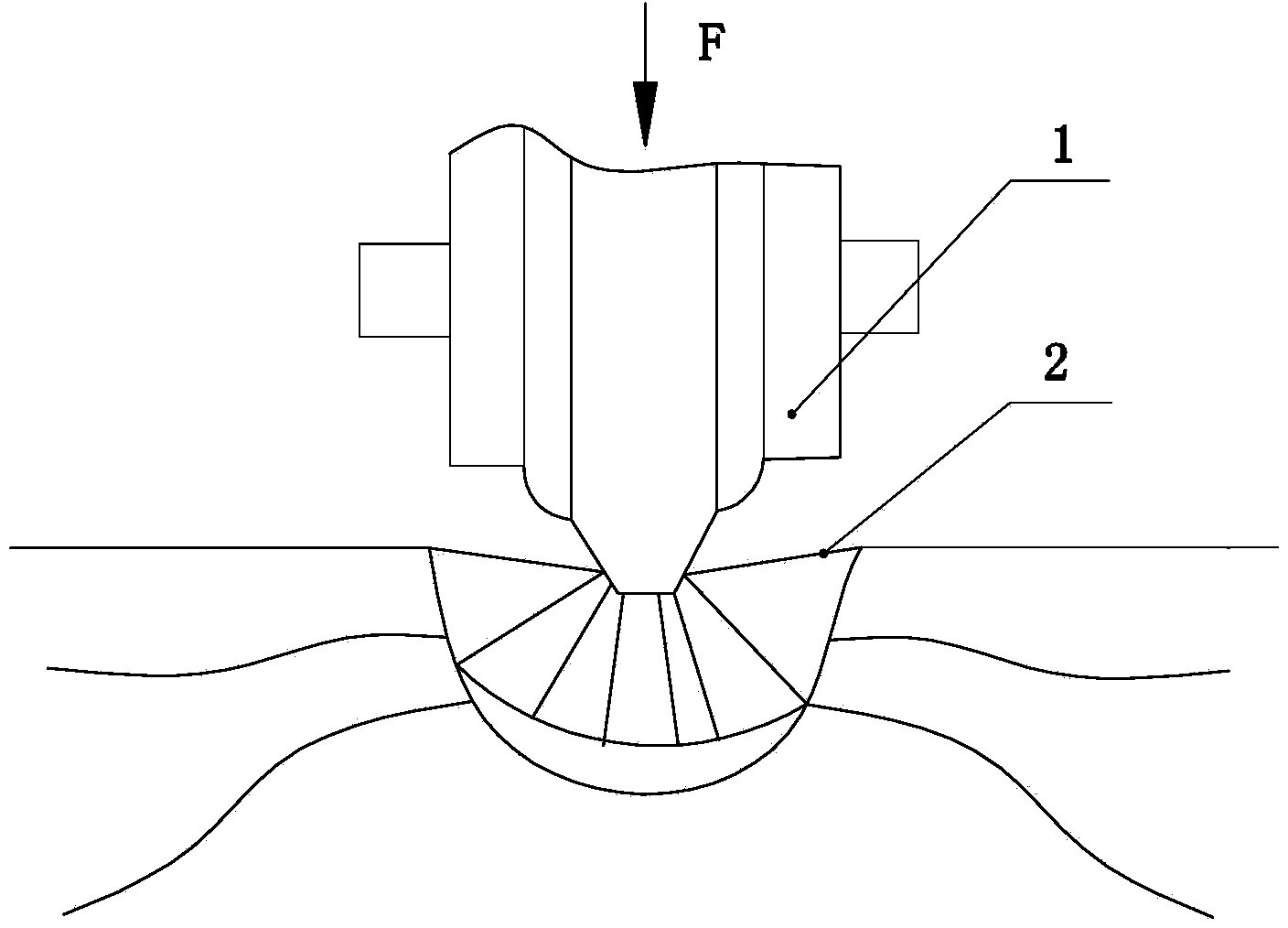

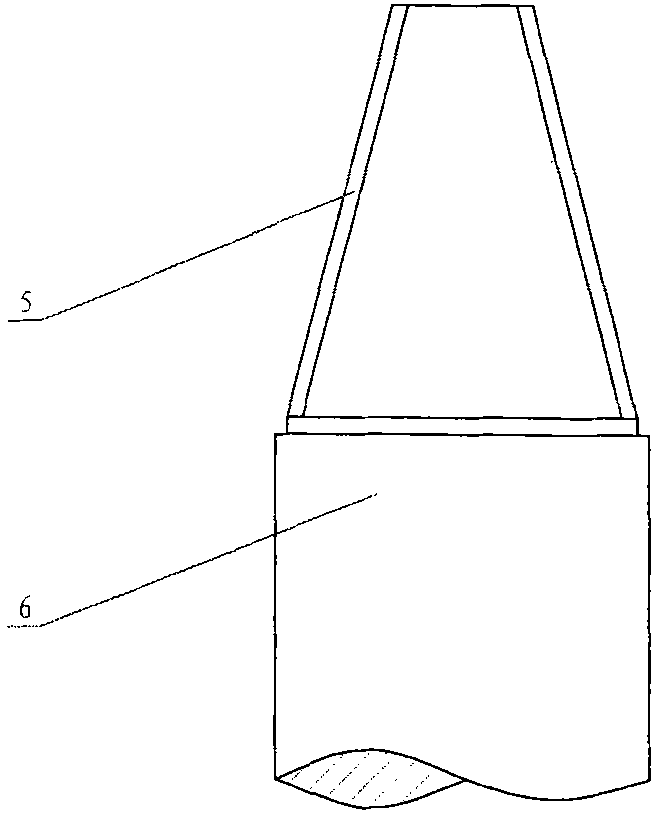

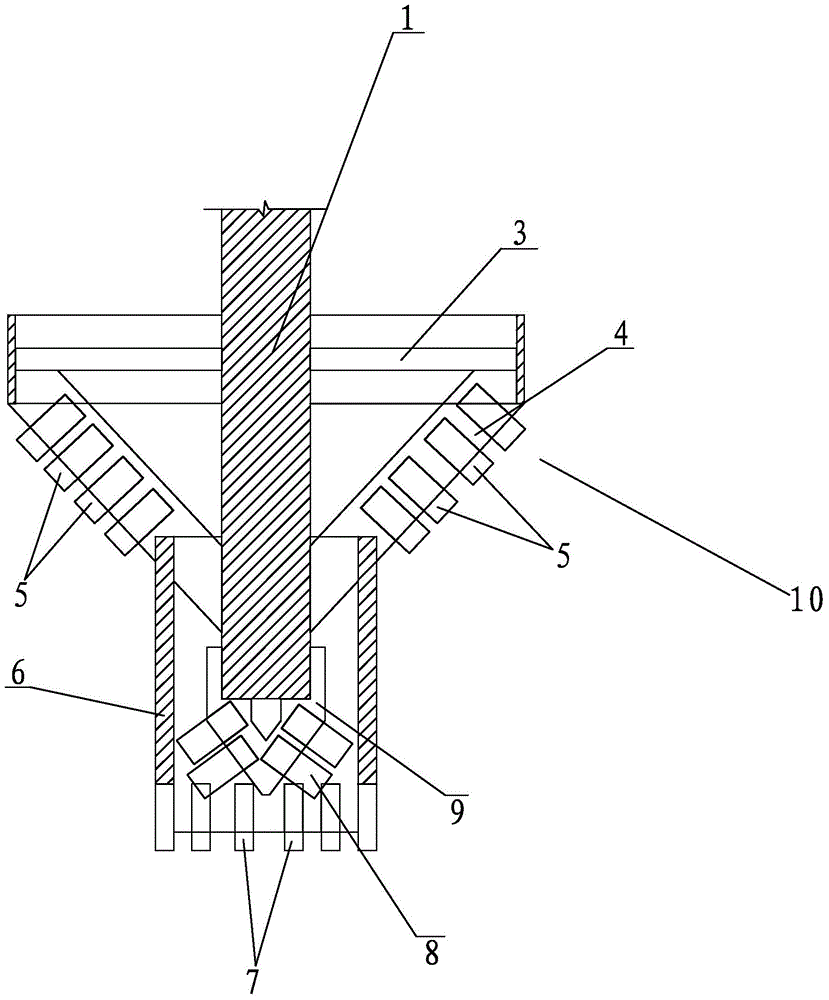

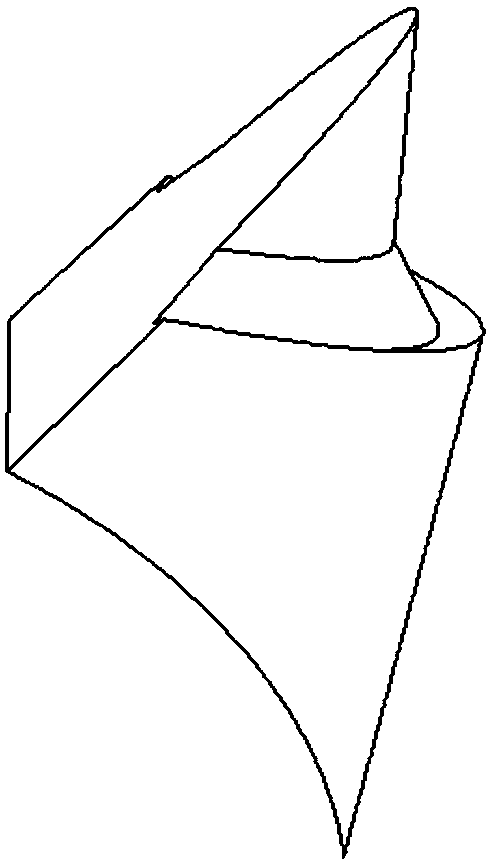

Single-waist multi-leaf hose bit for bored pile and drilling construction method thereof

ActiveCN104747088AGuaranteed verticalityOvercome direction uncertaintyDrill bitsBulkheads/pilesEngineeringDirectivity

The invention belongs to the field of building construction and particularly relates to a single-waist multi-leaf hose bit for a bored pile and a drilling construction method thereof. The technological process comprises the steps of positioning and sampling, centering in position, forming a hole, clearing the hole for the first time, descending a reinforcement cage, descending a guide pipe, clearing the hole for the second time and pouring concrete. The single-waist multi-leaf hose bit for the bored pile comprises a single-waist multi-leaf taper bit body. A positioning and guiding cylinder is fixedly welded to the end of the single-waist multi-leaf taper bit body. A plurality of positioning and guiding cylinder tungsten steel heads are distributed on a circumferential edge opening of one end of the positioning and guiding cylinder. The single-waist multi-leaf hose bit of the bored pile and the drilling construction method thereof have the advantages that the directivity is good, the hole forming perpendicularity is high, the wall protecting effect is good, deslagging is convenient, the hole forming speed is high, and the rock breaking speed is high.

Owner:ZHEJIANG YUJIAN CONSTR GRP CO LTD

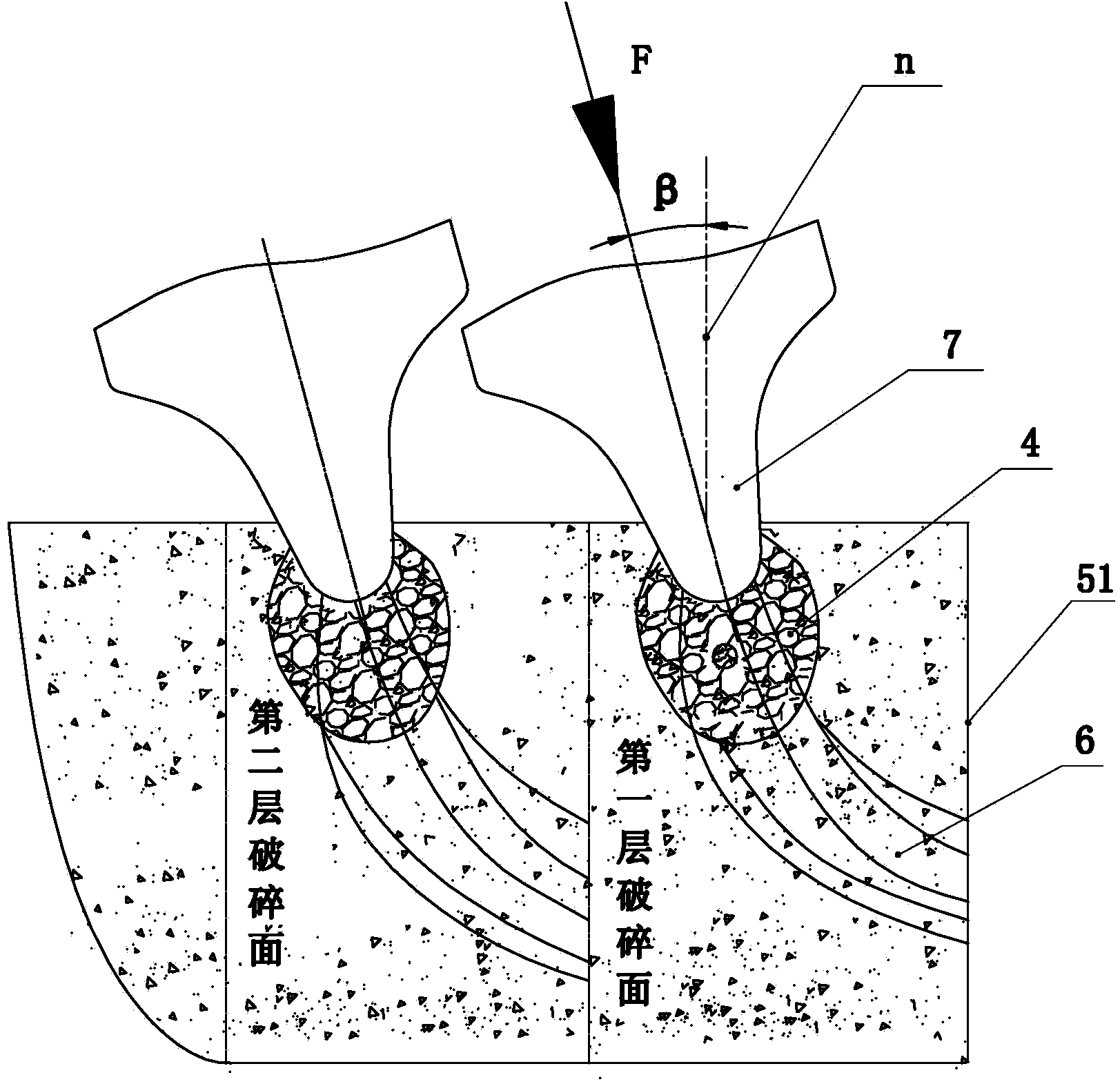

Novel rock breaking method and rock breaking hob

InactiveCN103953357AExtended service lifeShear strength to overcomeTunnelsCompressive strengthUltimate tensile strength

The invention discloses a novel rock breaking method and a rock breaking hob and relates to the technical field of tunnel boring. The novel rock breaking method and the rock breaking hob are applied to the rock breaking operation of tunnels; the problems that a hob is seriously worn and is short in service life in the existing rock breaking method are solved. According to the chipping rock breaking method, an included angle beta is formed between a hob blade and a normal of a tunnel face; after the pressure is applied to the disc-shaped hob, the blade penetrates into rock and a dense kernel is generated at the front end of the blade; the dense kernel continuously expands to tear off surrounding rock and forms a breaking area; rocks on a dangling face are chipped by expanding the breaking area; the blade of the disc-shaped hob is mainly used for bearing a shear force; the strength of the shear force is 6-9 percent of the compressive strength of the rock. The chipping rock breaking method has the advantages that firstly, the hob blade is mainly used for overcoming the shear resisting strength of the rocks, the compressive strength of a hob single spindle is greatly reduced, the blade of a hob ring is slow in wear and the hob is long in service life; secondly, the chipping rock breaking method is high in rock breaking and high in tunneling efficiency and is particularly suitable for excavating and tunneling of full-section hard-rock geology; thirdly, consumed power of tunneling equipment is lower.

Owner:邵祥顺

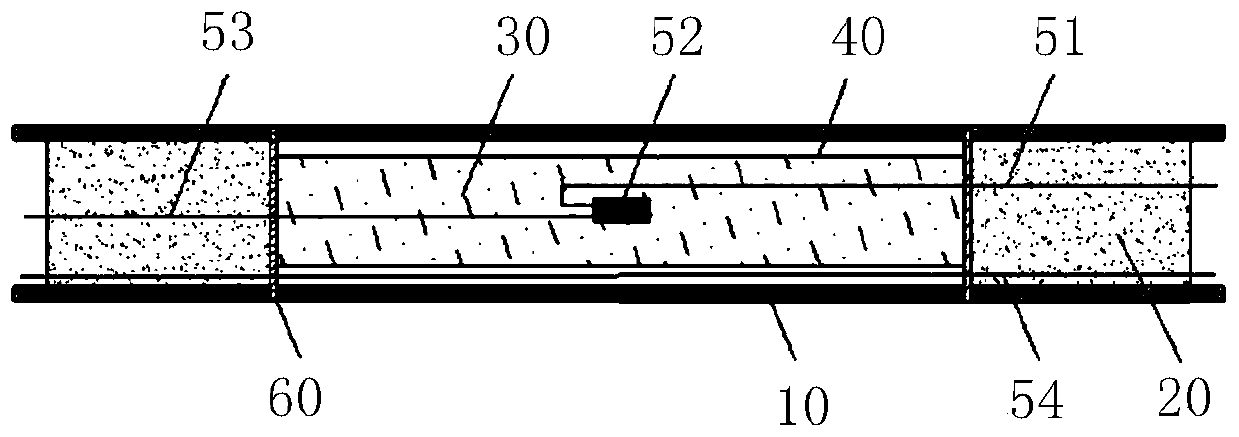

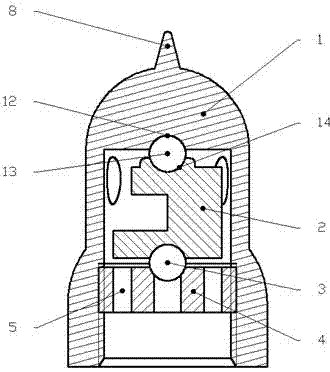

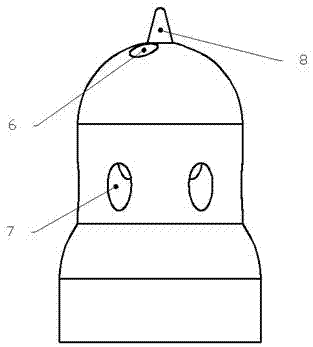

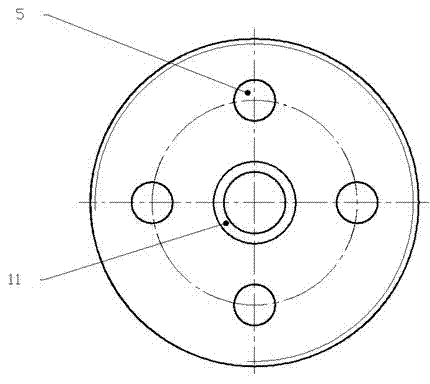

Single-cracked-surface instant spalling machine

ActiveCN110906798APrevent moistureImprove securityDisloding machinesUnderground miningStructural engineeringPipe

The invention discloses a single-cracked-surface instant spalling machine. The single-cracked-surface instant spalling machine comprises an energy gathering pipe, a filler pipe, a spalling agent, a coupling medium, a first lead, a second lead, a third lead and a trigger head; the energy gathering pipe is a hollow cylinder; multiple energy gathering holes are formed in two opposite radial sides ofthe energy gathering pipe; the multiple energy gathering holes extend in the axial direction of the energy gathering pipe; the filler pipe is positioned in the energy gathering pipe; the spalling agent is filled in the filler pipe; the coupling medium is arranged at the two ends of the filler pipe in the energy gathering pipe; the first lead and the second lead are connected with positive and negative poles of the trigger head, and are guided out from the two ends of a hollow pipe body; and the third lead penetrates through the energy gathering pipe, and is positioned between the outer wall ofthe filler pipe and the inner wall of the energy gathering pipe. The single-cracked-surface instant spalling machine is high in safety, low in rock breaking sound and high in rock breaking speed.

Owner:何满潮

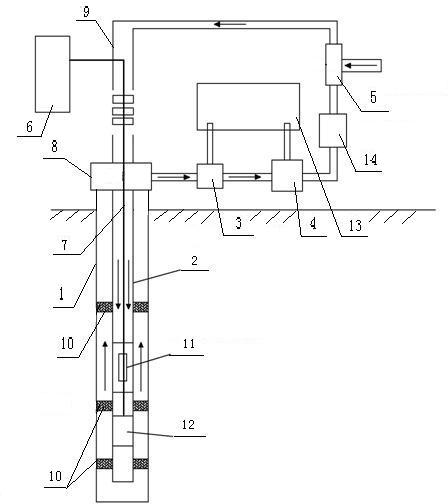

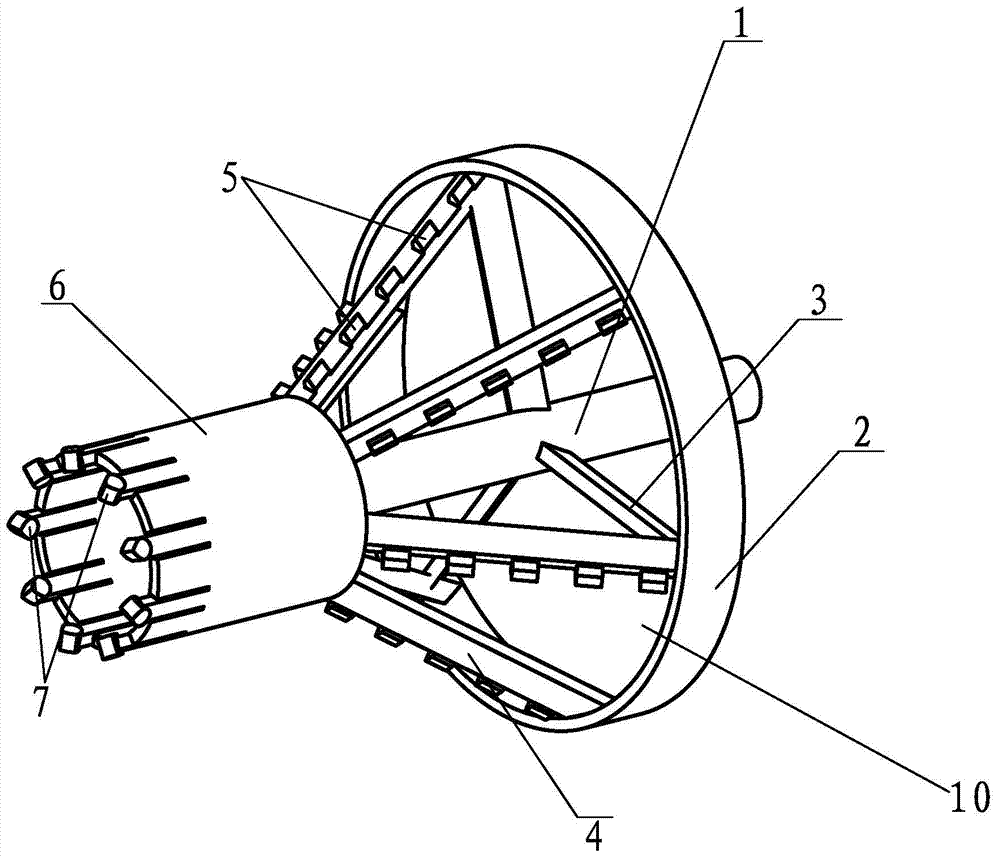

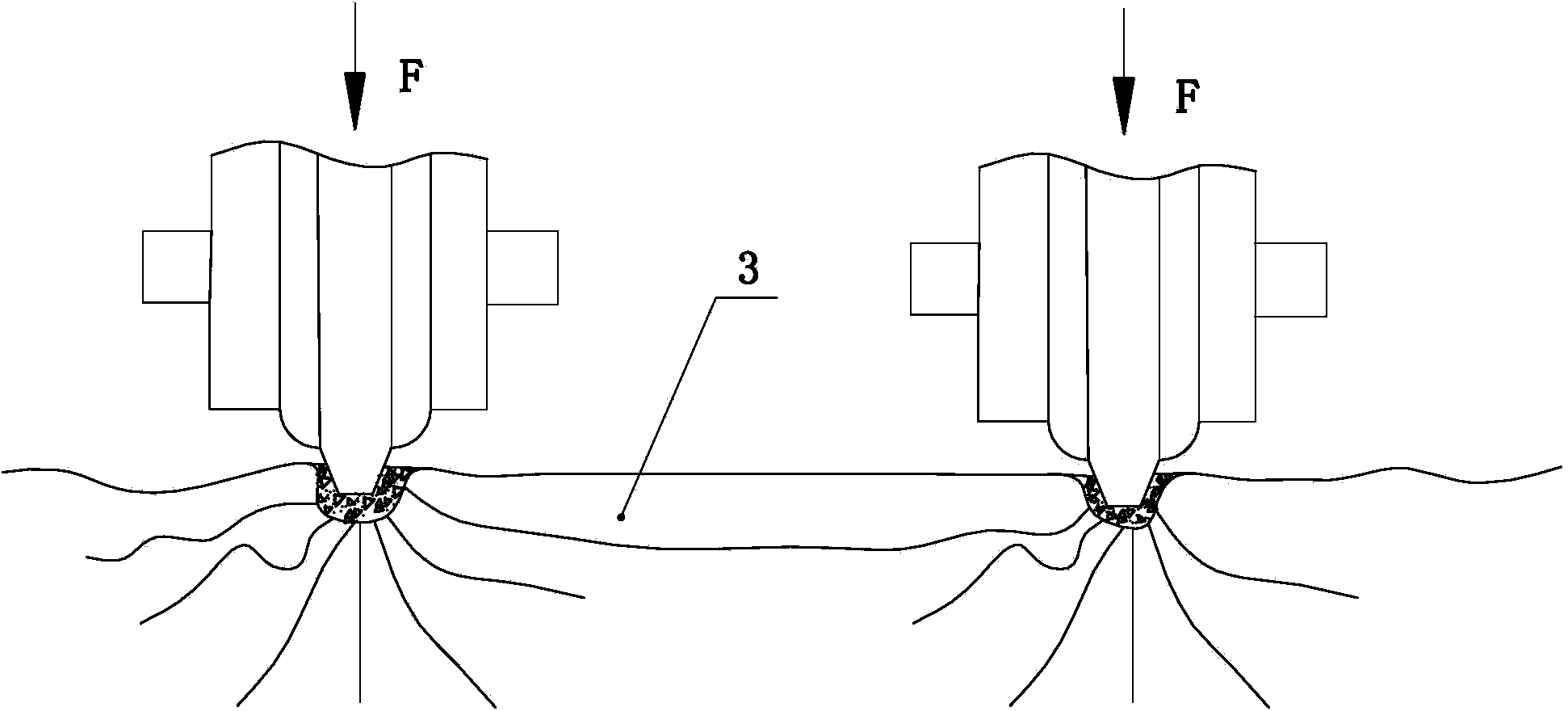

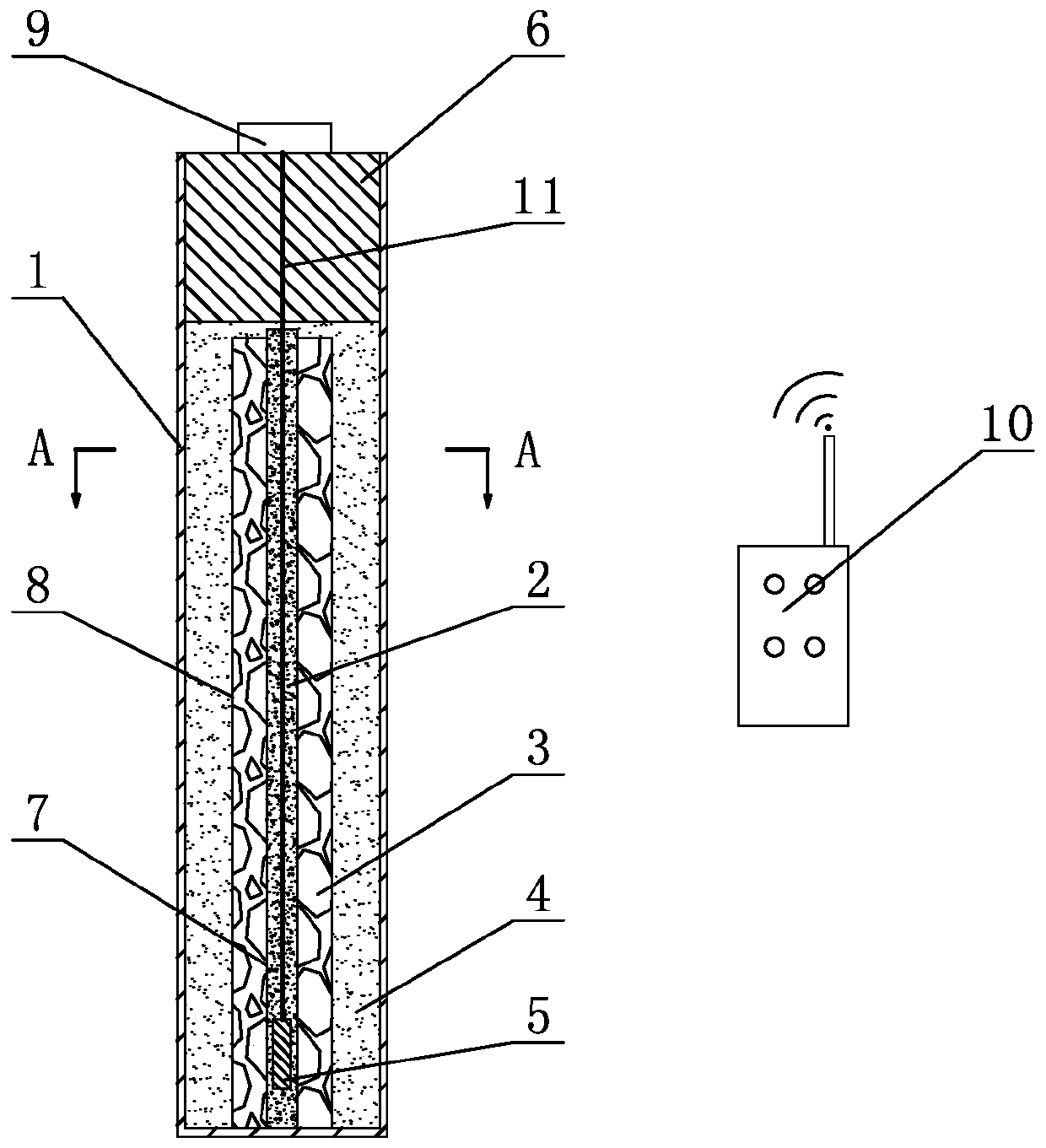

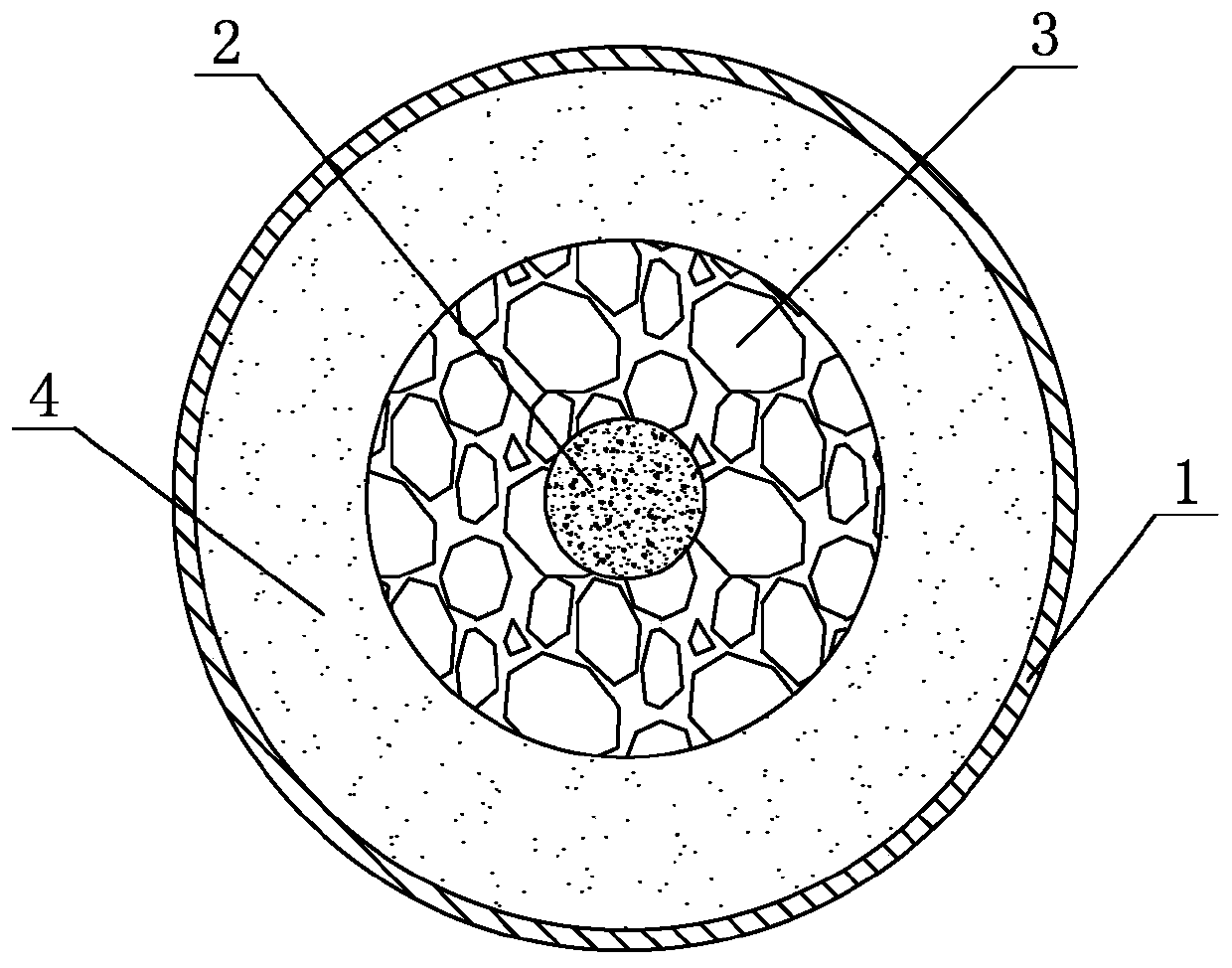

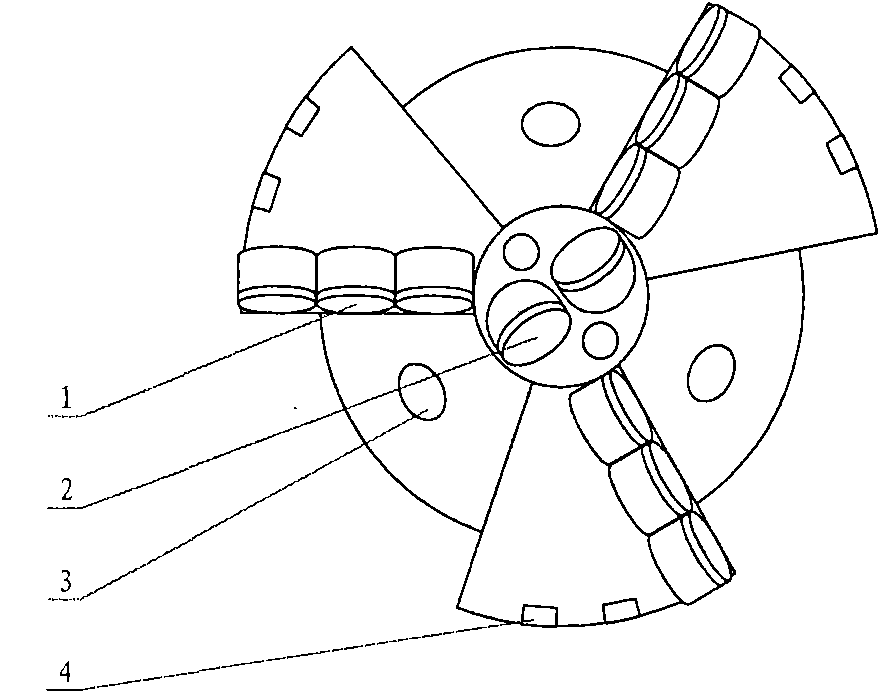

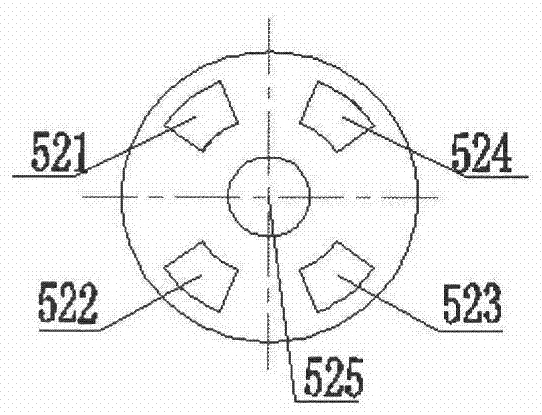

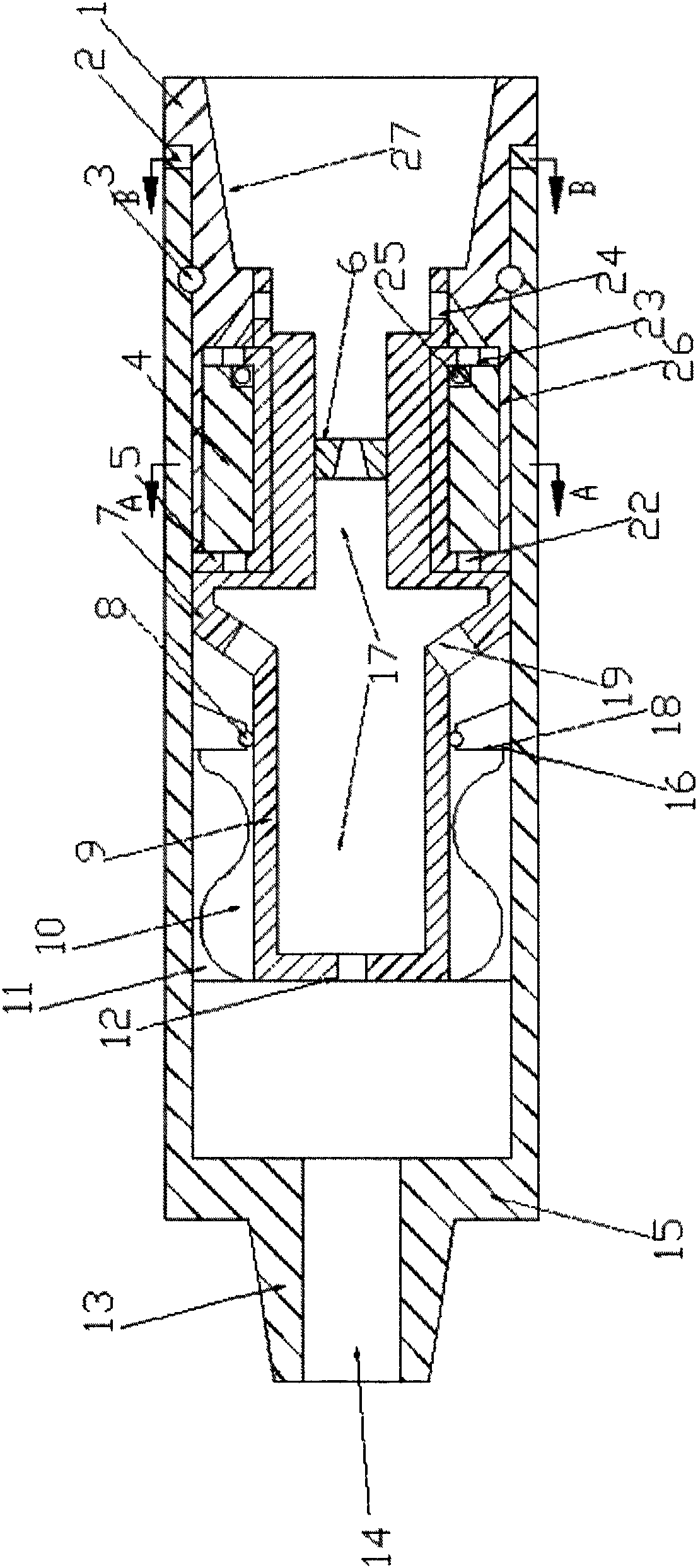

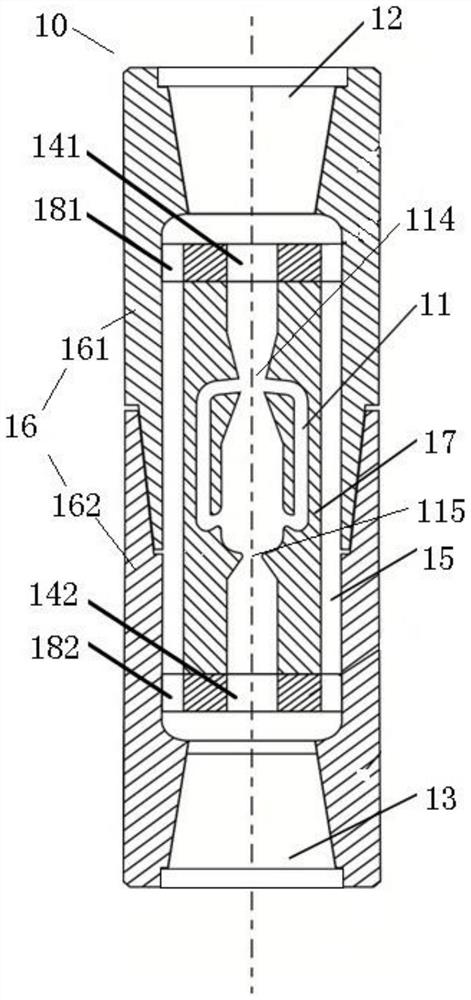

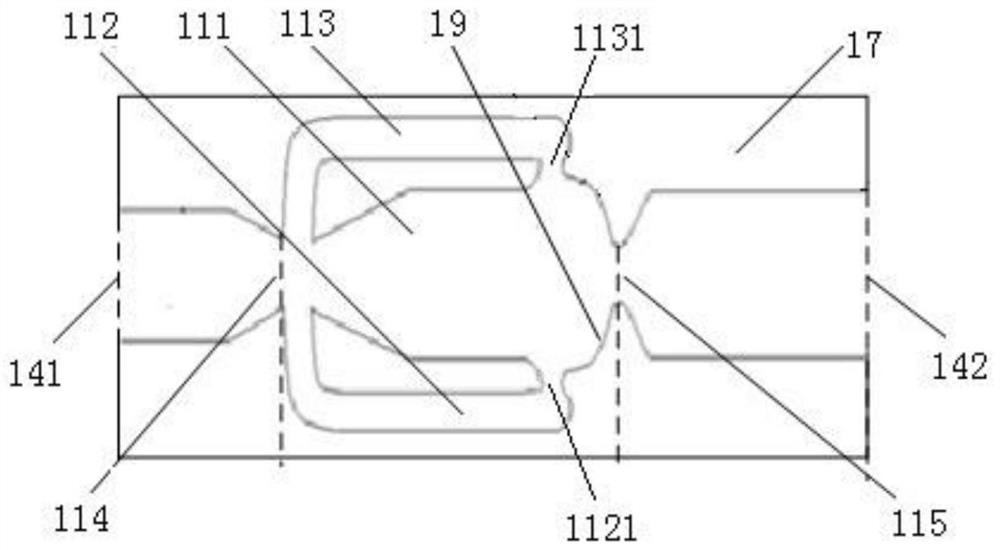

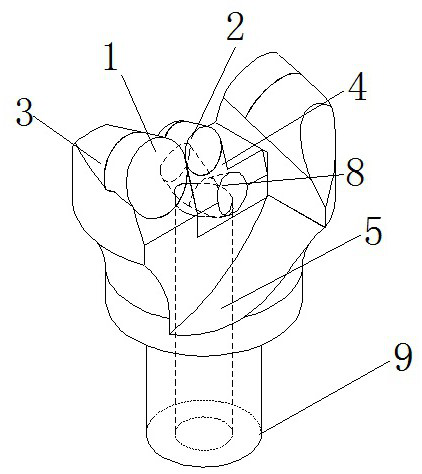

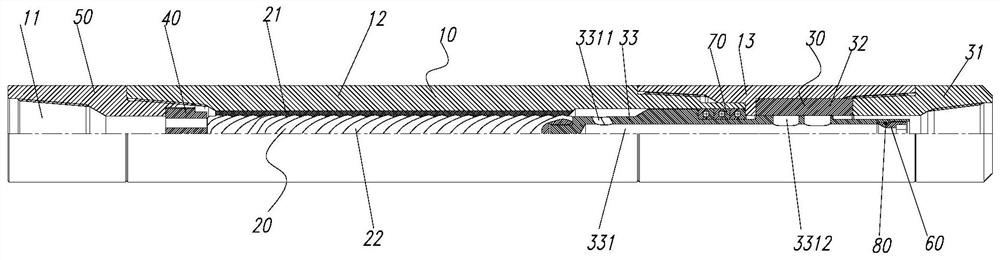

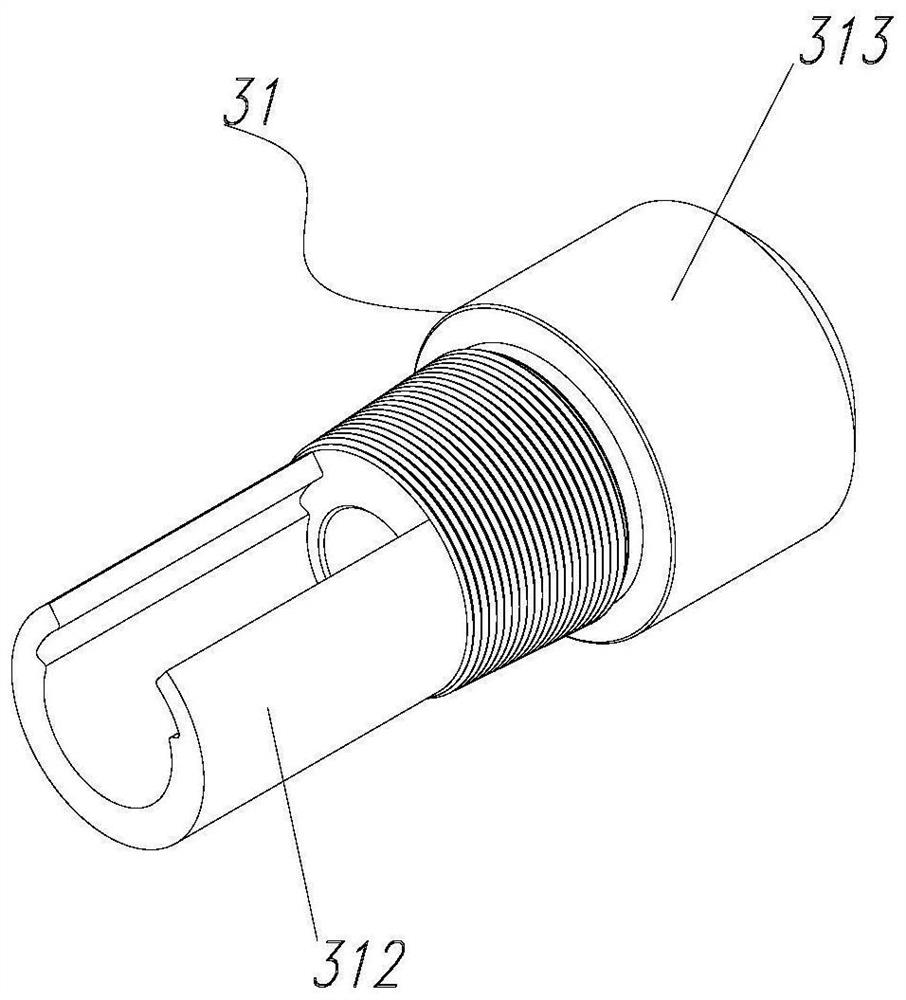

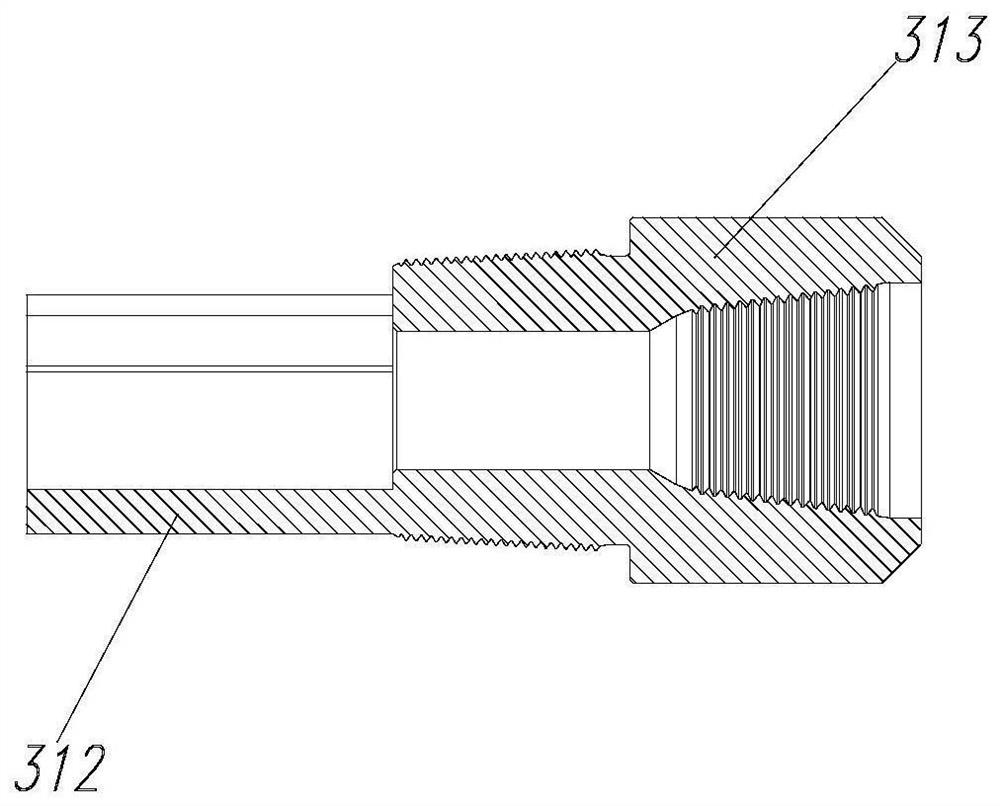

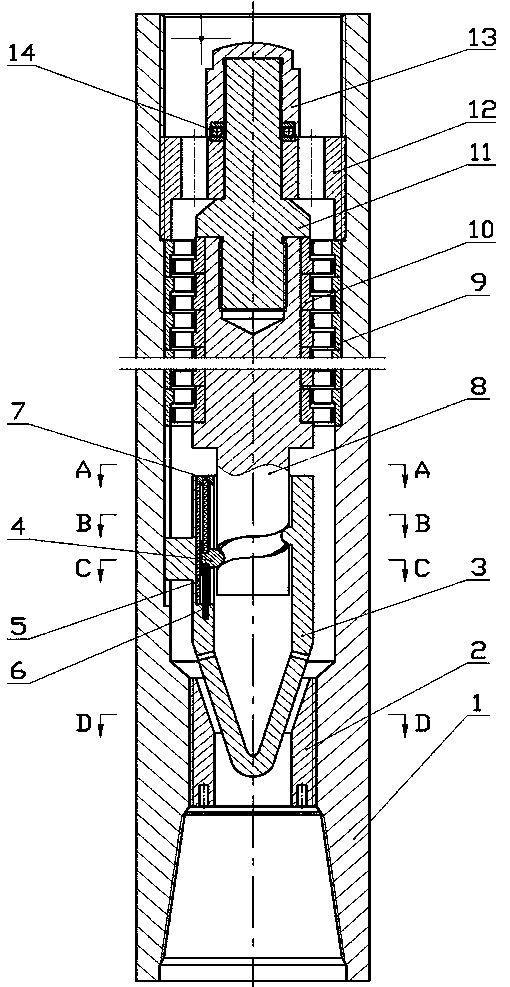

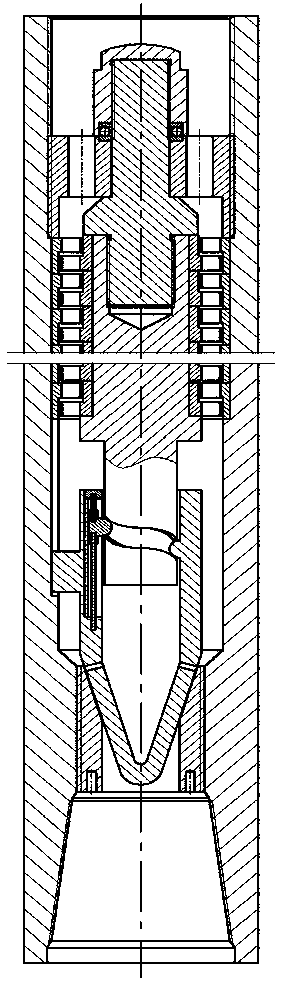

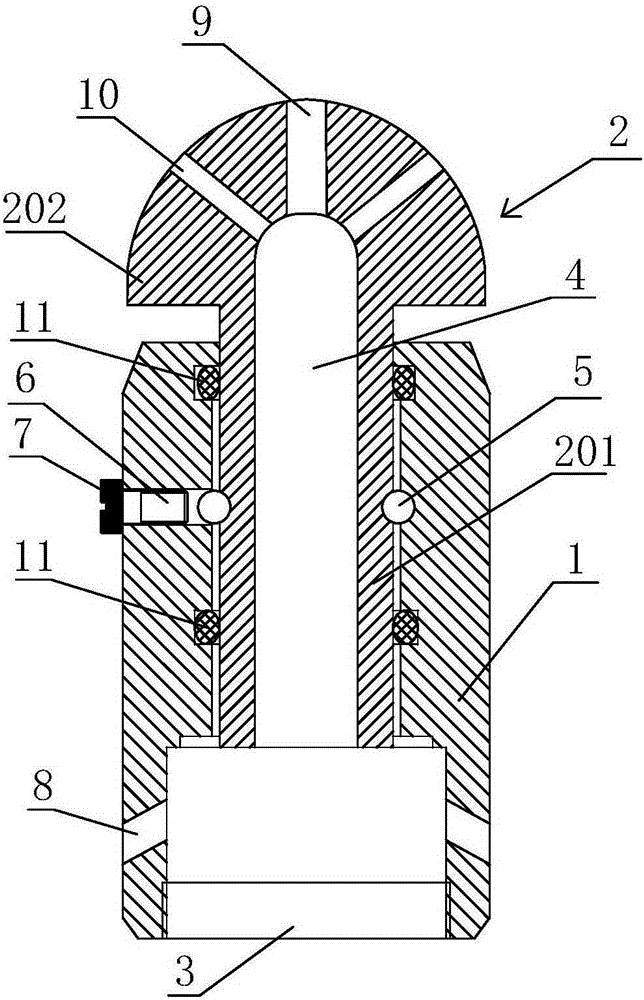

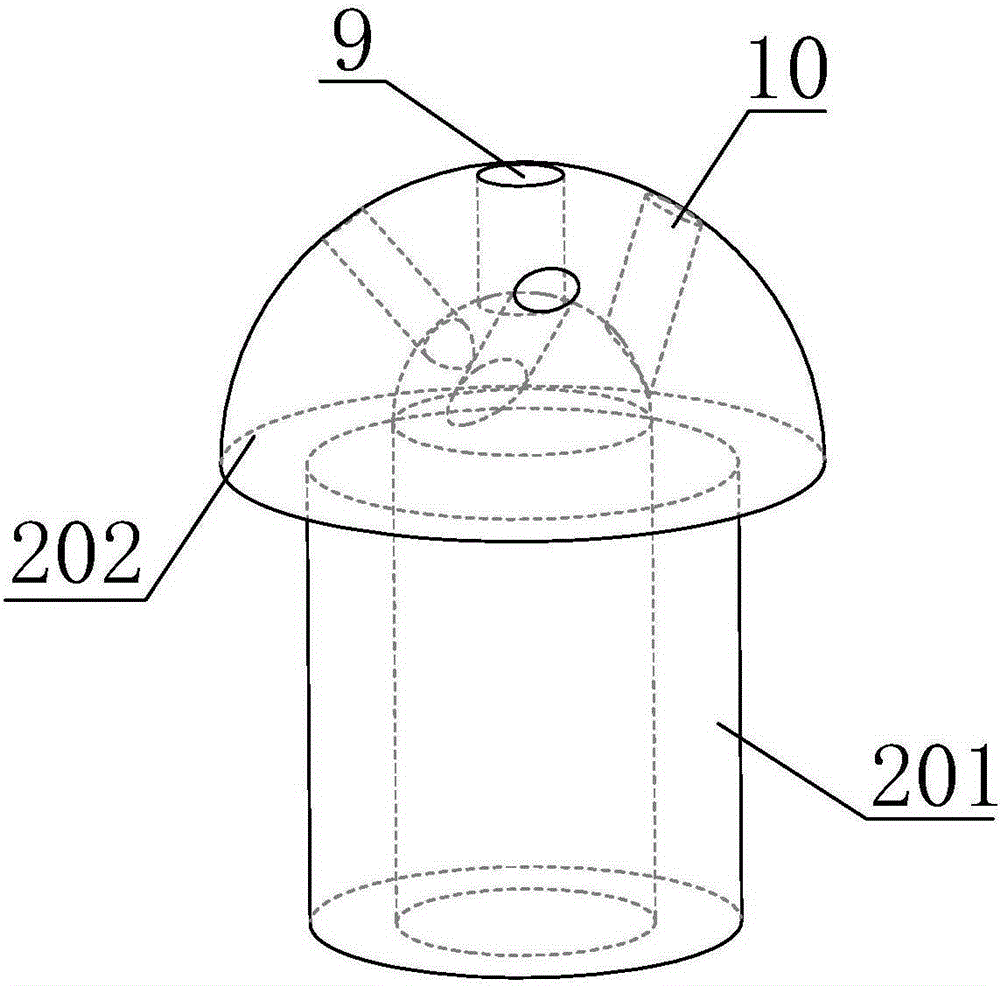

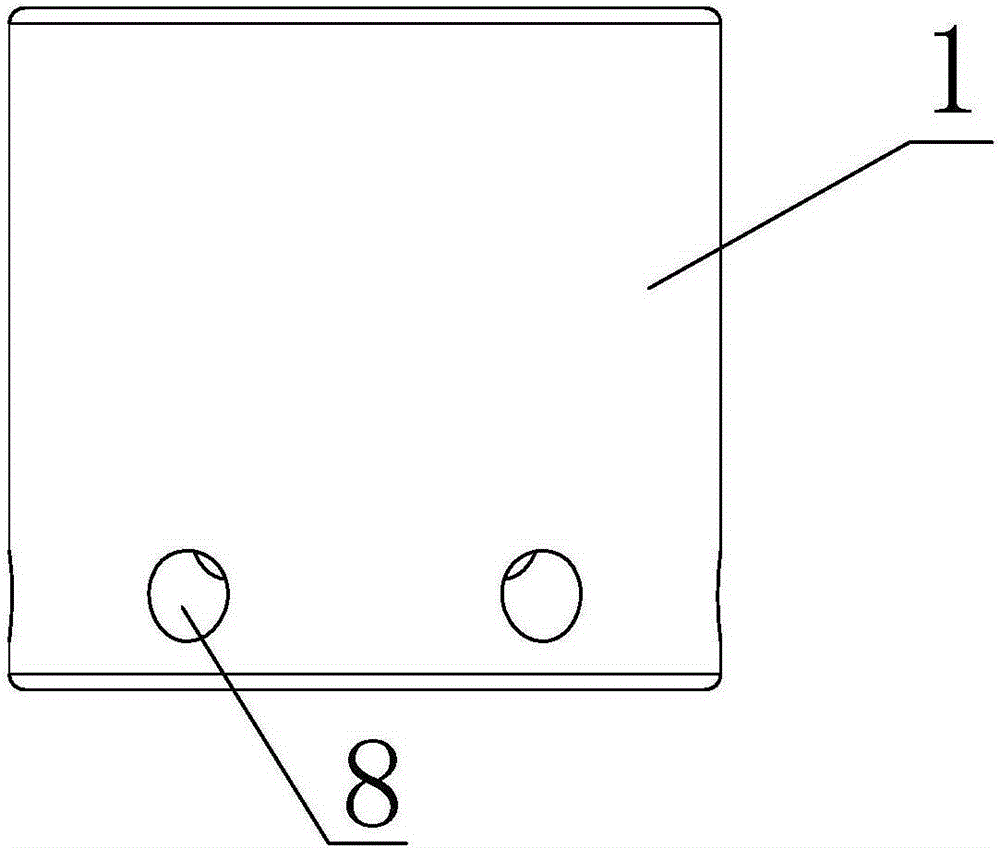

Self-advancing type high-pressure jet sprayer for radial horizontal well drilling

ActiveCN102518398AUniform mass distributionWith rotating jetLiquid/gas jet drillingHigh pressureAerospace engineering

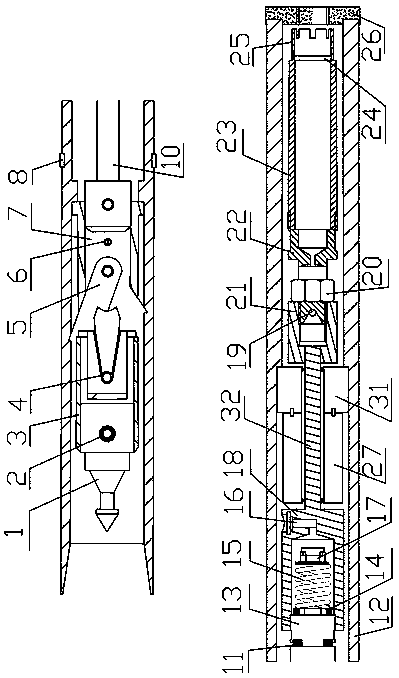

The invention relates to a self-advancing type high-pressure jet sprayer for radial horizontal well drilling, which mainly comprises a shell, a turbine rotor, wear-resistant steel balls, a baffle plate and the like. The self-advancing type high-pressure jet sprayer is technically characterized in that a tip, a forward spray nozzle and a backward spray nozzle are processed on the shell, hard alloy is welded on the outer surface of the shell, the turbine rotor is mounted in the shell, spherical grooves are processed at the upper end and the lower end of the turbine rotor, the turbine rotor is positioned via the upper wear-resistant steel ball and the lower wear-resistant steel ball, the upper wear-resistant steel ball is placed between the inside of the shell and the corresponding spherical groove of the turbine rotor, the lower wear-resistant steel ball is placed between the turbine rotor and a spherical groove on the baffle plate, the shell is connected with the baffle plate in a threaded manner, and four to six water injection holes are uniformly distributed on the baffle plate. The self-advancing type high-pressure jet sprayer is simple in structure and reliable in work, and can be widely applied to radial horizontal well drilling operation.

Owner:SOUTHWEST PETROLEUM UNIV

Generating device for static crushing agent

InactiveCN110375590AShorten the timeImprove rock breaking efficiencyBlasting cartridgesBlastingEngineeringElectrolyte

The invention relates to a generating device for a static crushing agent. The generating device comprises a barrel-shaped shell. The shell is sequentially filled with a combustible agent, an electrolyte solution and the static crushing agent from inside to outside in a layered manner. The combustible agent wraps an electronic igniter. A blocking block is arranged on an opening of the shell to sealthe shell. According to the technical scheme, the combustible agent, the electrolyte solution and the static crushing agent are contained in the shell in the layered manner, the shell is firstly placed in an expansion hole in rock during rock crushing, and the combustible agent is ignited through the electronic igniter; and the combusted combustible agent releases a large amount of heat, and thetemperature of the electrolyte solution and the static crushing agent in the shell rises. Due to the fact that the electrolyte solution is close to the combustible agent, the electrolyte solution canbe fast atomized. The atomized electrolyte solution is in contact with the heated static crushing agent, the static crushing agent can be fast cured and expanded in sealed space, and the rock crushingspeed is increased.

Owner:CHONGQING URBAN CONSTR HLDG GRP +3

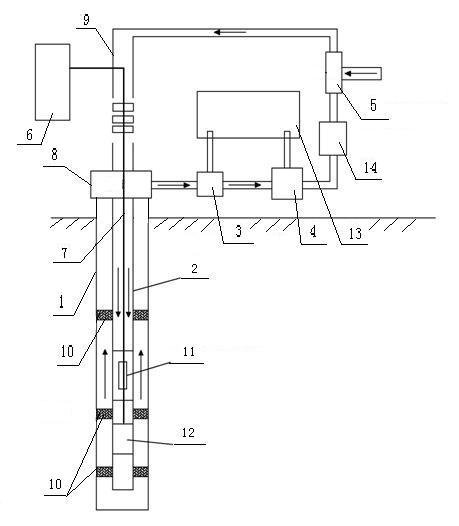

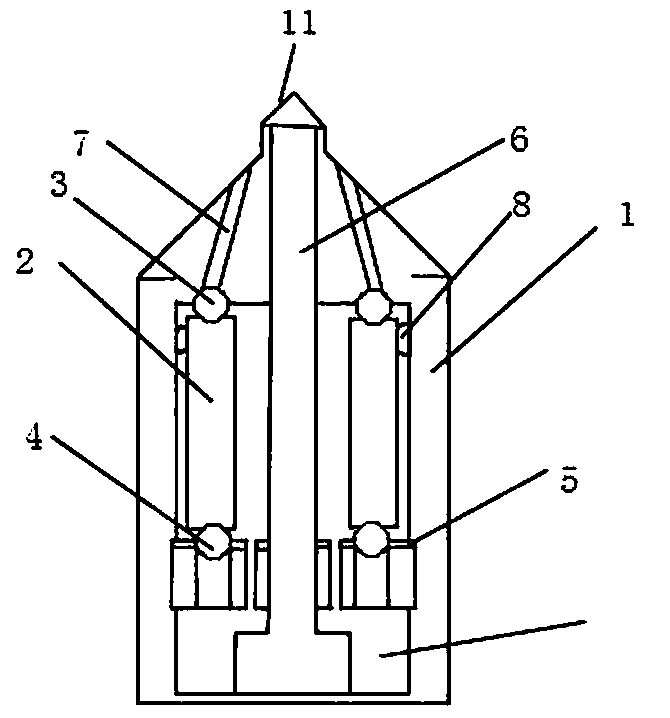

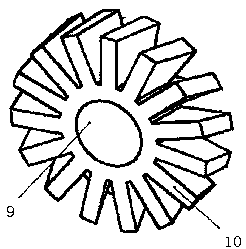

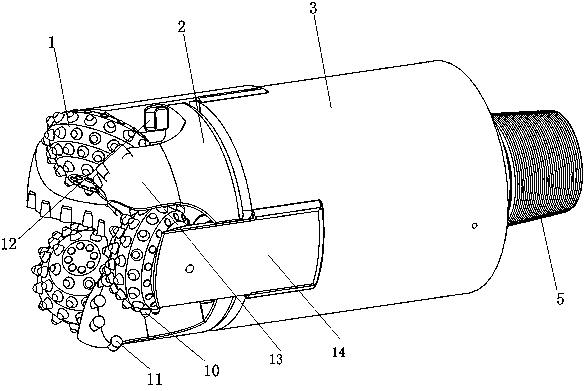

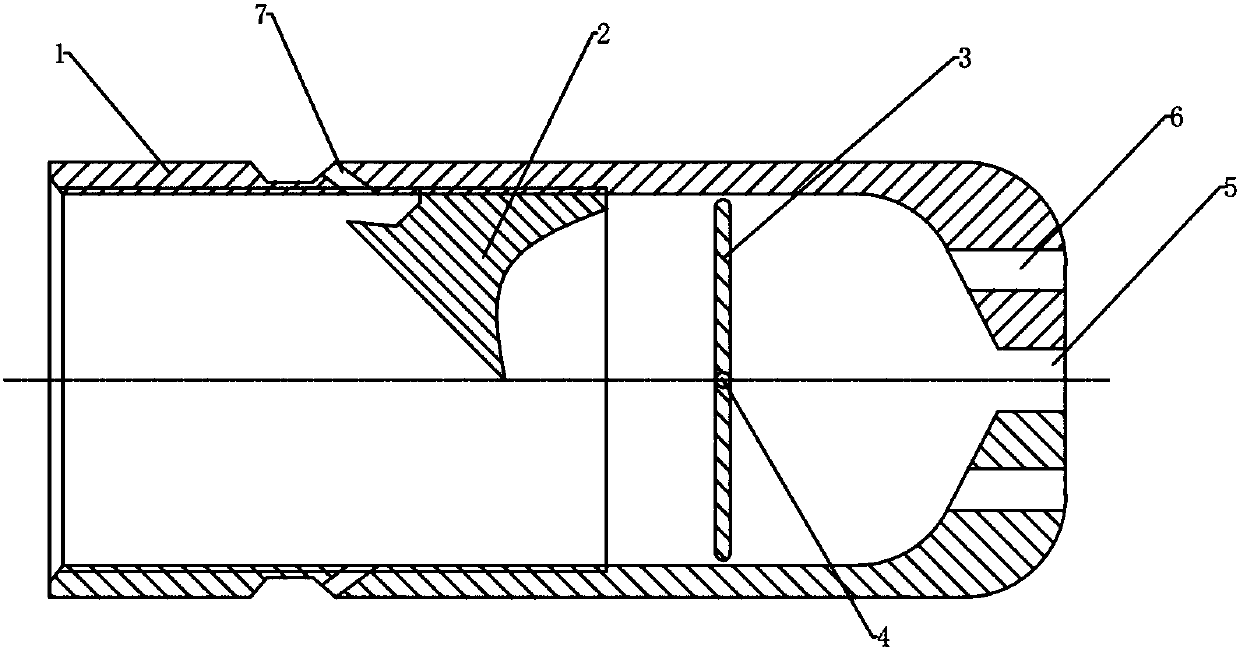

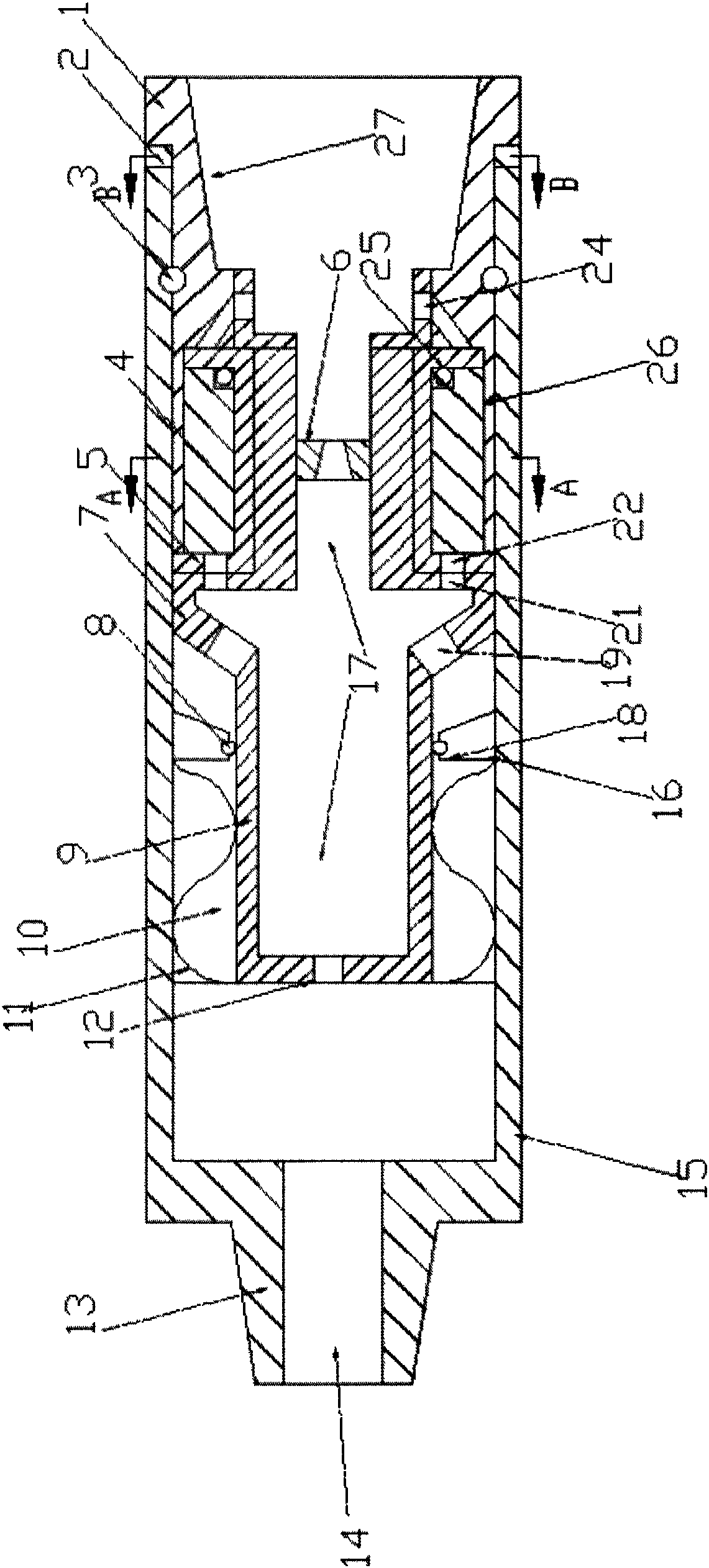

Self-propelled high pressure water jet drill

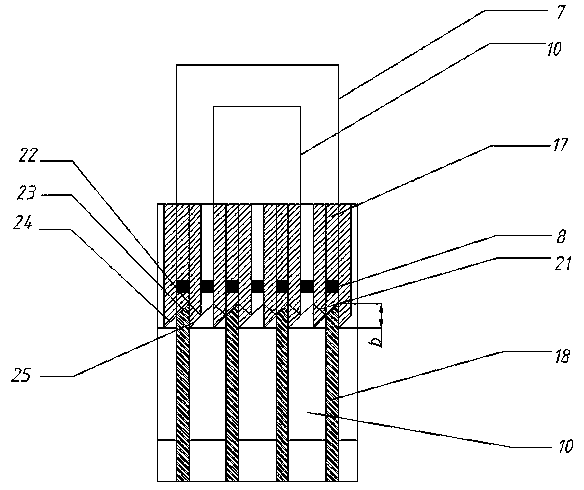

InactiveCN108086912ALarge diameterReduced forward resistanceConstructionsLiquid/gas jet drillingWear resistantSteel ball

The invention discloses a self-propelled high pressure water jet drill mainly comprising a bit body, turbine rotors, an upper wear-resistant steel ball, a lower wear-resistant steel ball and a baffle.The self-propelled high pressure water jet drill is characterized in that a blind hollow shaft is arranged in the center as a support; an annular outlet is disposed on the blind hollow shaft; the front end of the blind hollow shaft is connected to the front end of the bit body; a forward nozzle and a backward nozzle are arranged on the bit body; both sides of the left and right side of the blindhollow shaft are symmetrically installed with the turbine rotor; both ends of the upper and lower end of the turbine rotor are processed with a spherical groove; with the upper and lower wear-resistant steel balls used for positioning, the upper wear-resistant steel ball is placed between the bit body and the spherical groove of the turbine rotor, and the lower wear-resistant steel ball is placedbetween the turbine rotor and the spherical groove of the baffle; the bit body and the internal baffle thereof are connected through screw threads. The self-propelled high pressure water jet drill hasthe advantages of realizing rapid continuous drilling of long holes in various rock formations, and having simple structure, reliable work and wide application prospects.

Owner:SUZHOU TABINUO ELECTROMECHANICAL

Ultrastrong diamond compact bit

InactiveCN101892811AImprove wear resistanceGood cooling and chip removalDrill bitsWear resistanceScrew thread

The invention discloses an ultrastrong diamond compact bit belonging to rock-breaking tools, which is mainly applicable to coal-mine gas drainage holes, water detection holes, grouting holes and geological prospecting drilling holes. The ultrastrong diamond compact bit comprises a drill stem and a drill bit, wherein the drill stem and the drill bit are connected through screw threads. The bit is characterized in that the drill bit is composed of a diamond compact, a rock-breaking column, a water hole and a gauge-protection bar, wherein the drill bit is inlaid with the rock-breaking column and brazed with the diamond compact and the gauge-protection bar. The ultrastrong diamond compact bit can drill into medium hard rock stratum, and has the advantages of excellent wear resistance, strong torsion resistance, faster rock breaking speed, good cooling and scrap removal, inconspicuous gauge shrinkage phenomenon and high construction efficiency.

Owner:山西鑫博瑞科技有限公司

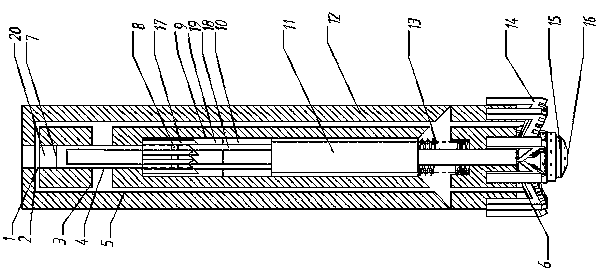

Self-propelled intermittent pulse high-pressure spray head for radial horizontal well

InactiveCN105888660AIncrease water powerImprove the efficiency of drilling and breaking rockSlitting machinesCutting machinesWear resistantSpray nozzle

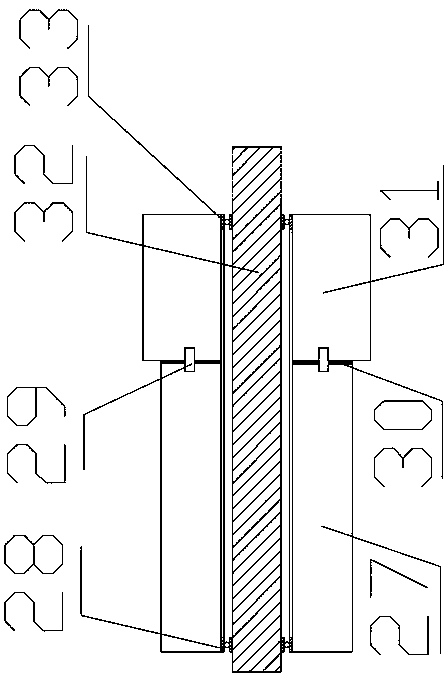

The invention discloses a self-propelled intermittent pulse high-pressure spray head for a radial horizontal well. The spray head is provided with a shell which is connected with a concave-type drainage plate through a thread, a spherical groove is formed in the inner wall of the shell, and the two ends of a horizontal shaft are provided with wear-resistant steel balls which are clamped in the spherical groove formed in the inner wall of the shell respectively; an overturning plate is arranged to be hollowed, and the horizontal shaft penetrates through the center. The concave-type drainage plate has a drainage effect and drives the overturning plate to conduct periodic rotation, and the drilling and rock breaking efficiency is improved; high-pressure drilling fluid forms an eddy current under the stirring action of the overturning plate, and the rock breaking speed is increased; along with rotation of the overturning plate, the drilling fluid below the drainage baffle produces an excited oscillation effect, and the energy of the fluid at the outlet of spray nozzles is increased; the groove is formed in the upper portion of the concave-type drainage plate, and the self-propelling capacity of the spray head is improved; the overturning plate adopts a mode that the mass is distributed nonuniformly, when the overturning plate rotates, the spray head is driven to jump continuously, and therefore the friction force between the spray head and a stratum is reduced, and the self-propelling capacity of the spray head is improved.

Owner:SOUTHWEST PETROLEUM UNIV

Spiral diamond drill bit

The invention discloses a spiral diamond drill bit. The drill bit includes a spiral rod, an extending block and a supporting block. A transition joint is installed at the upper end of the spiral rod,and stabilizing pieces are arranged at the upper end of the transition joint; a bracing piece is arranged at the upper ends of the stabilizing pieces, spiral connectors are fixed to the border of theupper end of the bracing piece, flank bases are fixed to the upper ends of the spiral connectors, and toothed addenda are fixed to the upper ends of the flank bases; the extending block is fixed to the portion among the flank bases, auxiliary pieces are fixed to the upper end of the extending block, a groove is formed in each stabilizing piece, a convex piece is fixed to one side of each groove, and the supporting block is arranged on the border of the interior of the bracing piece. According to the spiral diamond drill bit, toothed addenda are arranged on the surfaces of both the flank basesand the auxiliary pieces and can directly achieve an anti-wearing effect; through cooperation between the stabilizing pieces and the bracing piece, the impact toughness is enhanced; since the spiral connectors are fixed to the interior, the drill bit can have high impact toughness, great anti-wearing performance and high rock breaking speed, and the drilling efficiency is improved.

Owner:谷家菊

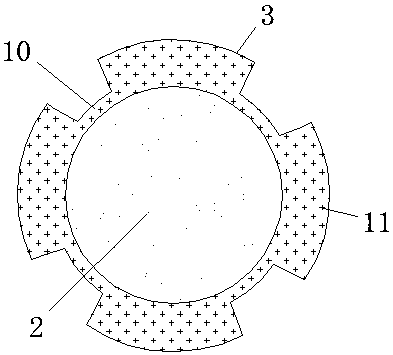

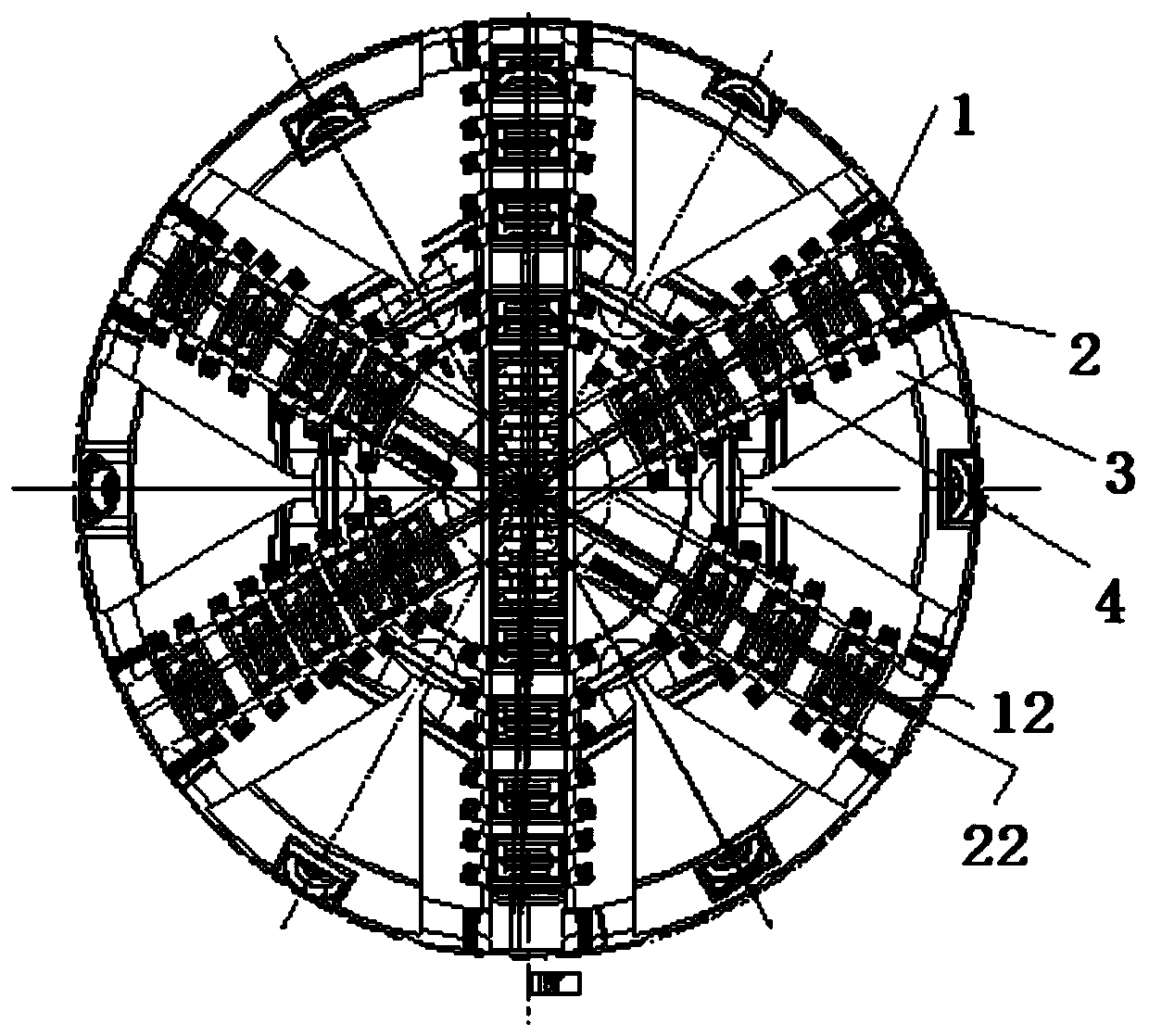

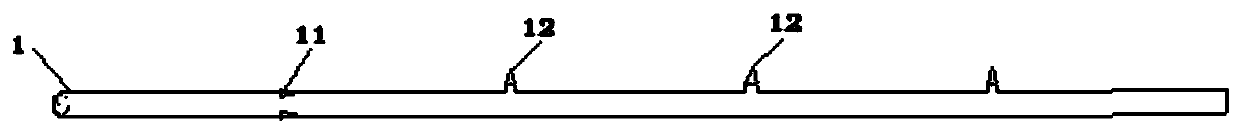

Thermal shock device and method for shield tunneling machine

InactiveCN111101959ADeterioration of mechanical propertiesImprove permeabilityTunnelsEngineeringShield tunneling

The invention relates to a thermal shock device and method for a shield tunneling machine, and belongs to the technical field of shield construction. The thermal shock device comprises a temperature measuring device arranged on a cutter head, heating pipelines and cooling pipelines, wherein the heating pipelines and the cooling pipelines are parallelly arranged on the end surface of the cutter head of the shield tunneling machine and uniformly distributed in the circumferential direction of the cutter head; the position, away from the end surface of the cutter head, of each heating pipeline isprovided a plurality of ignition devices which are sequentially distributed in the length direction of the heating pipeline, and heating switches used for controlling the ignition devices; the position away from the end surface of the cutter head, of each cooling pipeline is provided a plurality of cooling spray heads sequentially distributed in the length direction of the cooling pipeline, and cooling switches used for controlling the cooling spray heads; and the ignition devices and the cooling spray heads are lower than cutters on the cutter head. By utilizing a thermal shock principle, aspecial competent formation is rapidly heated and cooled, a lot of heat exchange is quickly generated, shock thermal stress is generated inside, and shock fracturing is caused, the mechanical propertyof the special competent formation is reduced, the rock breaking speed is increased, and cutter head abrasion is reduced.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

Mechanical rock-digging method

The invention discloses a mechanical rock-digging method. The mechanical rock-digging method comprises the following steps of: firstly punching a hole in rock, then inserting one end of a rigid rod piece into the punched hole, enabling the other end of the rod to expose out of the punched hole, then pushing and pulling the rod end exposing out of the punched hole along the smallest resistance line by using a machine, prying and breaking the rock and moving the rock by utilizing the rock, and enabling the rock to drop off. The mechanical rock-digging method adapted for breaking the rock is high in mechanical degree, high in rock breaking speed, high in working efficiency, few in site operators, convenient in management, only needs the common engineering machine and the rigid rod, is safe in operation and can be used for breaking and digging rocks, ore and concrete on and under the ground.

Owner:汪传松

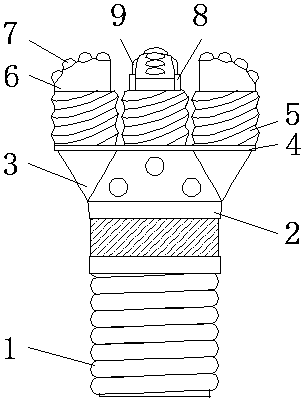

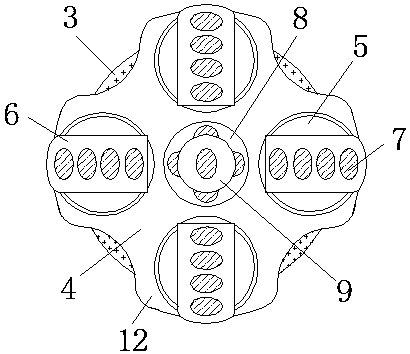

Hydraulically-driven multi-dimensional plasma combined drill bit and well drilling method thereof

PendingCN113187405AOvercome limitationsLow costBatteries circuit arrangementsDrill bitsGear wheelTurbine blade

The invention relates to a hydraulically-driven multi-dimensional plasma combined drill bit and a well drilling method thereof. The hydraulically-driven multi-dimensional plasma combined drill bit comprises a drill rod, a drill bit body, a plasma turntable gear, a plurality of plasma devices, a mechanical cutting gear and a power generator, a slurry turbine is arranged in the drill rod, and the bottom of the slurry turbine is connected with the power generator; the bottom of a cylinder on the outer edge of the turbine blade is fixedly connected with a turntable switch, the turntable switch is provided with a plurality of discharge switches in the circumferential direction, each discharge switch extends into an annular slide rail, a pair of cables also extends into the annular slide rail, and the end parts of the pair of cables are provided with switch electric brushes; and an upper gear is welded to the lower end of the turntable switch, the lower portion of the upper gear is engaged with two connecting gears, the two connecting gears are coaxially fixed to the plasma turntable gear and the mechanical cutting gear respectively, and the plasma turntable gear and the mechanical cutting gear are exposed out of the bottom of the drill bit body. Mechanical cutting and plasma impact are combined for rock breaking, and the rock breaking speed is increased.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Laser drilling device

InactiveCN111379523AIncrease drilling speedShorten the drilling cycleDrilling rodsThermal drillingThermodynamicsWell drilling

The invention relates to a laser drilling device. The laser drilling device comprises a ground part and an underground part, in a wellbore below the ground, a communicating guide pipe downwards extends from the ground into the wellbore and reaches the bottom of the wellbore, a measurement-while-drilling guiding instrument and a laser are mounted in the guide pipe, a cable downwards extends into the wellbore and is connected with the measurement-while-drilling guiding instrument and the laser, and stabilizers are mounted in an annular cavity between the guide pipe and the wellbore; a casing head is mounted at a ground wellhead, and the guide pipe penetrates through the casing head to be connected to a gas outlet hole of a gas compression booster station to form a gas inlet channel; and thewellbore is connected with the casing head through a surface layer casing, the casing head is connected with the other guide pipe, and the guide pipe passes through a grit catcher, a dust remover anda liquid-gas separator and then is connected to a gas inlet hole of the gas compression booster station to form a circulating channel for dust discharge, purification and pressurization. The drillingspeed is high, the drilling cycle is saved, and drilling benefits are increased.

Owner:广州探霸仪器有限公司

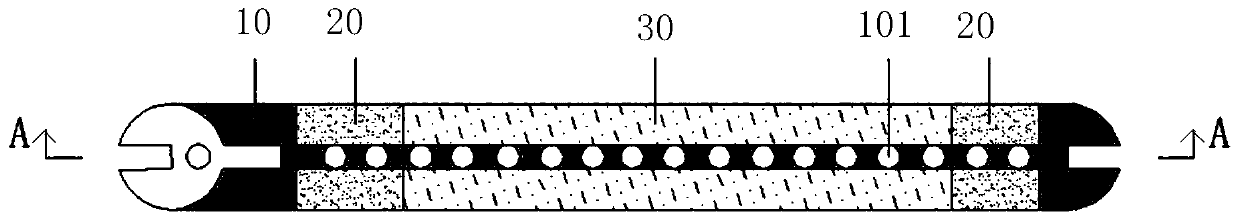

An Ultrasonic Vibration Wireline Coring Tool

InactiveCN105507804BIncrease drilling speedImprove drilling efficiencyReciprocating drilling machinesConstructionsRock coreResonance

The invention discloses an ultrasonic vibration cord coring drill tool. The ultrasonic vibration cord coring drill tool is characterized in that power can be supplied to a piezoelectric ceramic vibrator by a battery of the ultrasonic vibration cord coring drill tool, high-frequency voltages with different frequencies can be provided, and accordingly the piezoelectric ceramic vibrator can be excited to ultrasonically vibrate; generated ultrasonic vibration is transmitted to rock via an outer tube and a drill bit, and resonance breaking can be carried out on the rock; single-action characteristics of rock core tubes are kept among the battery, the piezoelectric ceramic vibrator and a solid shaft by the aid of bearings. The ultrasonic vibration cord coring drill tool has the advantages that the ultrasonic vibration cord coring drill tool is convenient to replace, the application range of ultrasonic drilling can be greatly expanded, the drilling periods can be shortened, and the cord coring drilling speeds can be increased.

Owner:JILIN UNIV

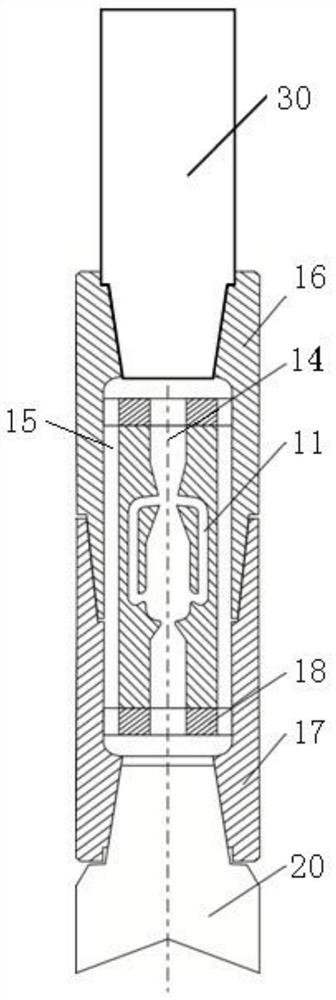

Downhole self-priming particle jet drilling device based on Venturi effect

ActiveCN109025825BSpeed up the boot processImprove purification effectDrill bitsConstructionsUpper jointWell drilling

The invention relates to a downhole self-priming particle jet drilling device based on the Venturi effect. The lower joint, the upper end of the liquid inlet chamber is threadedly connected with the upper joint, the inner cavity of the upper joint is composed of a horn section and a nozzle section, the outer part of the upper joint corresponding to the nozzle section is a reduced diameter section, the nozzle section is an equal diameter section, and the nozzle and the nozzle section are threadedly connected , the nozzle and the nozzle section extend into the liquid inlet chamber, the upper channel of the nozzle is a horn channel, the lower channel is a cylindrical channel, and the liquid inlet chamber has a liquid inlet hole; The throat pipe is arranged on a coaxial line, and the lower end of the diffusion pipe is connected with the lower joint. The invention can take the cuttings sucked from the annular space as impact particles, greatly improve the mechanical drilling speed, is suitable for the deep hard formation, and can effectively improve the rock breaking speed.

Owner:NORTHEAST GASOLINEEUM UNIV

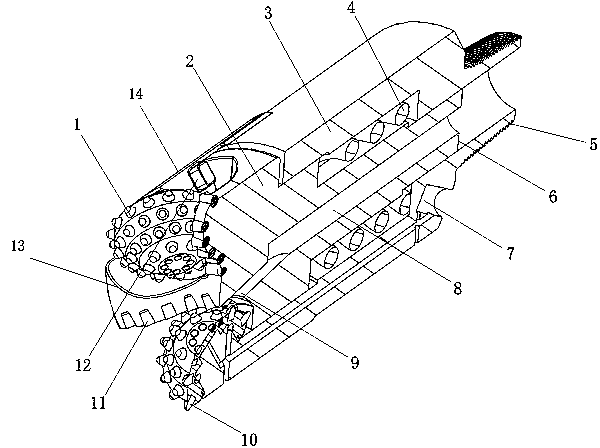

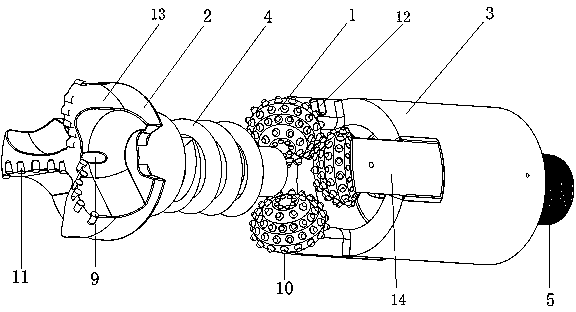

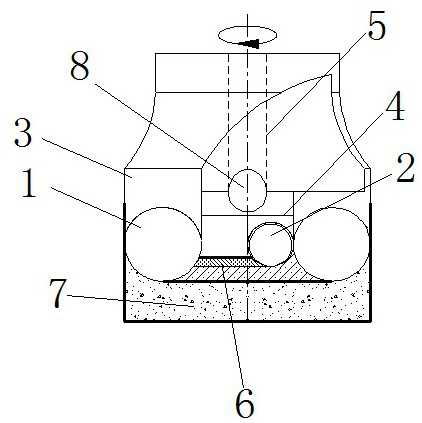

Self-adapting hybrid bit

InactiveCN102561953BOptimize the distribution of rock breaking volumeOptimize allocationDrill bitsAxial forcePetroleum oil

The invention discloses a hybrid bit for petroleum gas exploitation and other exploration drilling applications, wherein cones and blades are simultaneously arranged on a bit main body and are uniformly distributed in a staggering manner, and the cones are arranged on a tooth palm of the bit main body; the hybrid bit further comprises a movable blade body movably arranged in the bit main body and only capable of telescopically moving within a limited range along an axial direction, an elastic element for providing axial force for the movable blade body is also arranged between the movable blade body and the bit main body, the blades are arranged at the front end of the movable blade body, and a compression face for bearing mud pressure is arranged at the tail end of the movable blade body. The self-adapting hybrid bit disclosed by the invention is capable of controlling the relative positions of the cones and the blades in a self-adapting manner according to stress, thereby optimizing the rock breaking quantity distribution of the cones and the blades and guaranteeing a faster rock breaking speed, and the applicability is more extensive. Besides, by the self-adapting design, the rigid impact of common bits and rock stratum is optimized to flexible impact, so that the bit is greatly protected.

Owner:SOUTHWEST PETROLEUM UNIV

A single-waisted multi-leaf cylinder drill bit and a hole-forming construction method for bored piles

ActiveCN104747088BGuaranteed verticalityOvercome direction uncertaintyDrill bitsBulkheads/pilesDirectivityDrill bit

Owner:ZHEJIANG YUJIAN CONSTR GRP CO LTD

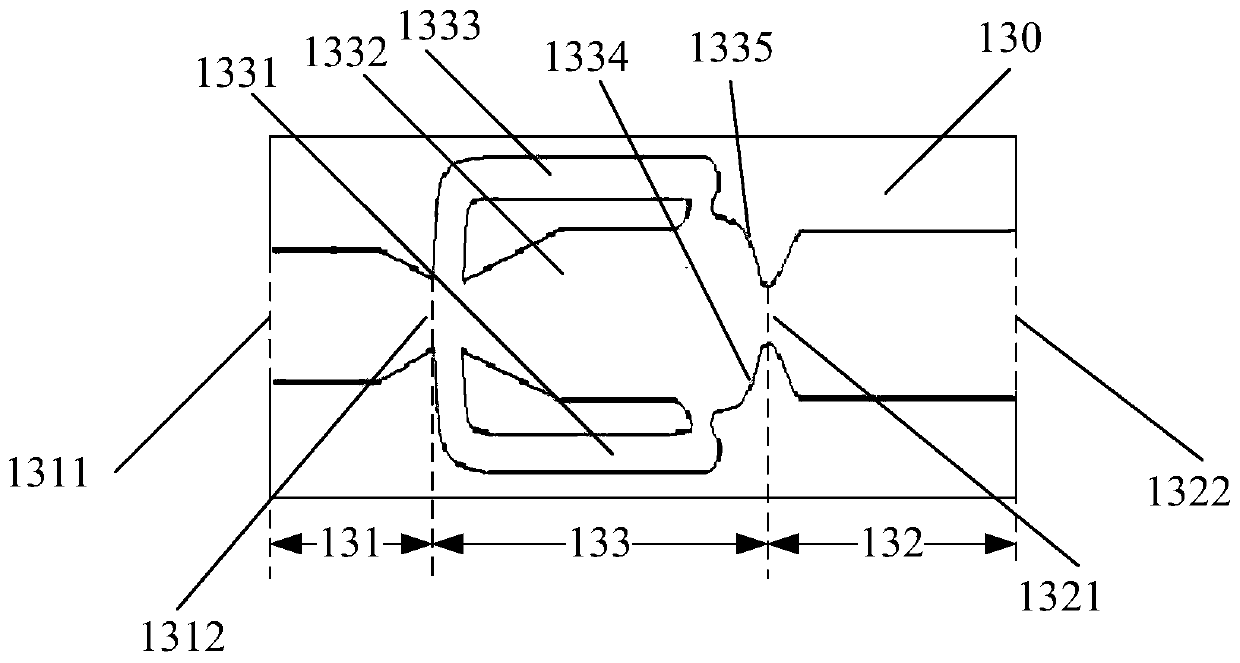

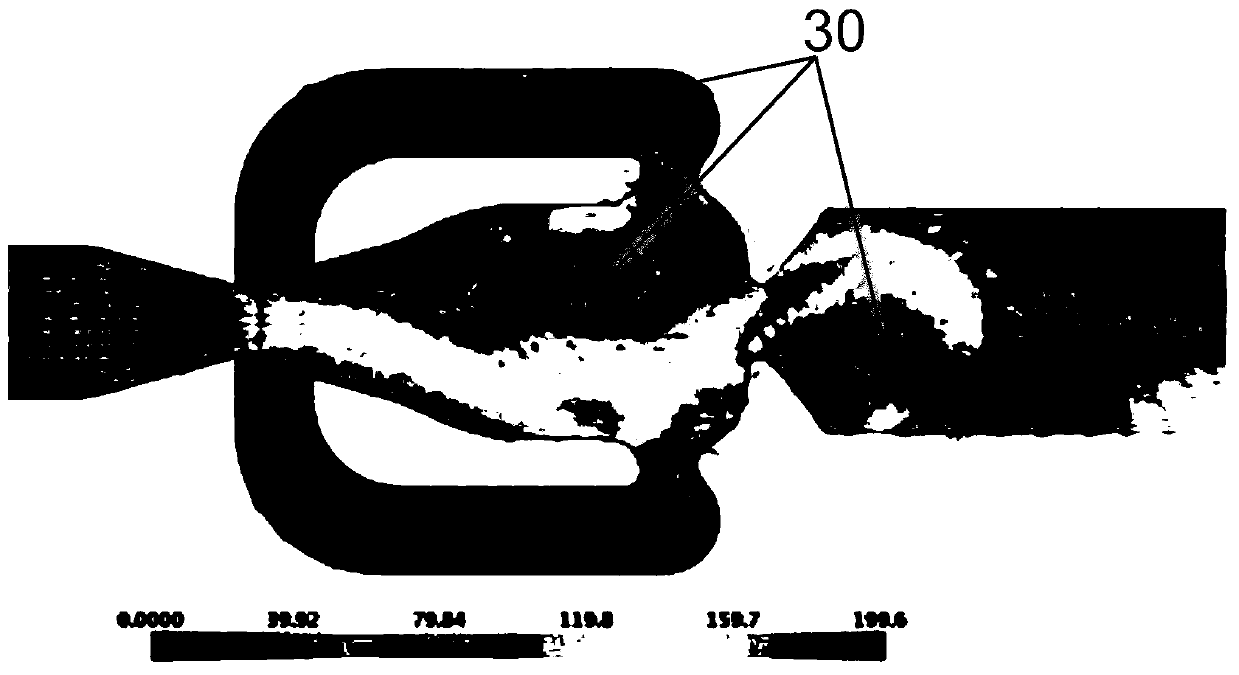

A Jet Type Torsional Drag Reducing Oscillator

InactiveCN104727748BExtended service lifeRock breaking speedVibration drillingTorsional oscillatorEngineering

The invention discloses a jet type twisting resistance reduction oscillator and relates to the technical field of drilling technologies. An impactor comprises an upper connector, an outer cylinder, an upper end cover, a bi-stable jet element, an alternating pressure passageway, a torque cylinder, a torque piston, bearings, clamping blocks and a drill sleeve. The upper end cover, the bi-stable jet element, the alternating pressure passageway, the torque cylinder, the torque piston and the bearings are sequentially arranged inside the outer cylinder. The upper end of the outer cylinder is in threaded connection with the upper connector, and the lower end of the outer cylinder is connected with the drill sleeve through the clamping blocks. Through the corresponding structural design, the service life of a drill bit can be prolonged, and the rock breaking efficiency of the PDC drill bit can be improved.

Owner:北京沃客石油工程技术研究院

A self-propelled intermittent pulse high-pressure nozzle for radial and horizontal wells

InactiveCN105888660BIncrease water powerImprove the efficiency of drilling and breaking rockSlitting machinesCutting machinesWear resistantSpray nozzle

The invention discloses a self-propelled intermittent pulse high-pressure spray head for a radial horizontal well. The spray head is provided with a shell which is connected with a concave-type drainage plate through a thread, a spherical groove is formed in the inner wall of the shell, and the two ends of a horizontal shaft are provided with wear-resistant steel balls which are clamped in the spherical groove formed in the inner wall of the shell respectively; an overturning plate is arranged to be hollowed, and the horizontal shaft penetrates through the center. The concave-type drainage plate has a drainage effect and drives the overturning plate to conduct periodic rotation, and the drilling and rock breaking efficiency is improved; high-pressure drilling fluid forms an eddy current under the stirring action of the overturning plate, and the rock breaking speed is increased; along with rotation of the overturning plate, the drilling fluid below the drainage baffle produces an excited oscillation effect, and the energy of the fluid at the outlet of spray nozzles is increased; the groove is formed in the upper portion of the concave-type drainage plate, and the self-propelling capacity of the spray head is improved; the overturning plate adopts a mode that the mass is distributed nonuniformly, when the overturning plate rotates, the spray head is driven to jump continuously, and therefore the friction force between the spray head and a stratum is reduced, and the self-propelling capacity of the spray head is improved.

Owner:SOUTHWEST PETROLEUM UNIV

Realization method and structure of a rotary valve reversing type hydrodynamic circumferential impactor

ActiveCN105804655BExtended service lifeRock breaking speedVibration drillingReciprocating motionLiquid dynamics

The invention discloses a rotary valve reversing type liquid power peripheral impacting device realization method and structure. Fluid flows through a rotary blade to drive a blade mandrel and a rotary valve mandrel to rotate relative to a static valve shell of a rotary valve; the rotary valve mandrel and the valve shell of the rotary valve are provided with windows which are communicated in a staggered manner, so that the fluid alternatively enters a working cavity formed by an impacting head and a piston cylinder and pushes the impacting head to do reciprocating motion so as to impact the piston cylinder. A main body structure is composed of an outer cylinder and an impacted drill bit sleeve from left to right; the outer cylinder and the impacted drill bit sleeve transfer torsion by adopting interlocking teeth; a power module and an impacting module are arranged in the outer cylinder from left to right; the power module is provided with the blade mandrel, the rotary blade and an alignment bearing; the impacting module is arranged at the lower end of the power module; the impacting module is provided with the rotary valve mandrel, the valve shell of the rotary valve, the impacting head, a thrust bearing, the piston cylinder and the impacted drill bit sleeve from inside to outside. The rotary valve reversing type liquid power peripheral impacting device realization method and structure have the effect of prolonging the service life of a drill bit.

Owner:万晓跃

Pup joint and well drilling device

PendingCN113863872AExtend your lifeReduce intensityDrilling rodsVibration devicesWell drillingHelmholtz resonator

The invention provides a pup joint and a well drilling device. The pup joint is used for being connected with a drill bit, the pup joint comprises a pup joint body, an oscillation cavity is formed in the pup joint body, so that drilling fluid flowing into the oscillation cavity forms Helmholtz resonance in the oscillation cavity to drive the pup joint body and the drill bit connected with the pup joint body to generate ultrahigh-frequency vibration with preset frequency, and when the vibration frequency is close to the rock resonance frequency, rock resonance crushing is induced. The pup joint solves the problems that in the prior art, a drilling speed increasing device is low in drilling and rock breaking efficiency, low in drilling speed and long in drilling period in deep hard formation drilling.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

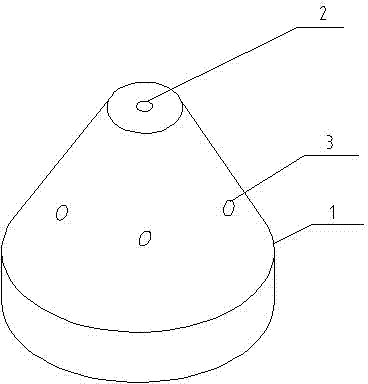

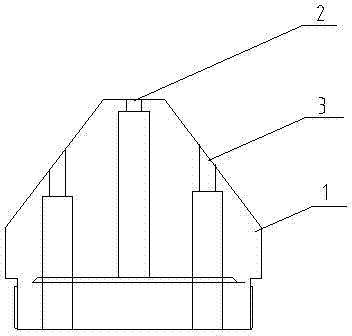

Hydraulic jetting drilling-well shower nozzle

ActiveCN102287136BAvoid undercutImprove wear resistanceLiquid/gas jet drillingWell drillingEngineering

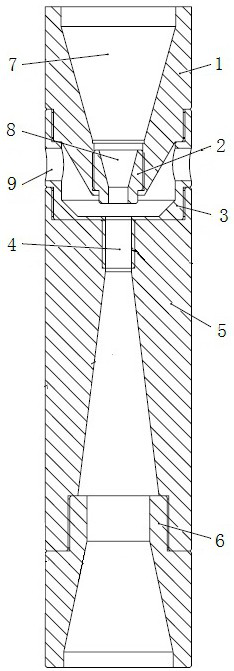

The invention discloses a hydraulic jetting drilling-well shower nozzle, which comprises a shower nozzle body (1), wherein the shower nozzle body (1) is provided with water outlets; water delivery paths are longitudinally arranged in the shower nozzle body (1) and are communicated with the water outlets; nozzles are built in the water delivery paths; the shower nozzle body (1) is in taper shape of which the front end is a flat end; the water outlets comprise a middle hole (2) and side holes (3), wherein the middle hole (2) is positioned at the flat end of the front end of the shower nozzle body (1); the side holes (3) are positioned on the taper-shaped inclined surface of the shower nozzle body (1) and are radially arranged by taking the middle hole (2) as the center; the water delivery path of the middle hole (2) is same with the axis direction of the shower nozzle; and the water delivery paths of the side holes (3) respectively incline for 5-15 degrees along the tangent direction and have the same inclination direction. When being used, the hydraulic jetting drilling-well shower nozzle is slowly fed in while spraying, a pore-forming of which the diameter is 120-130mm can be formed, and the joint of the shower nozzle and a steel pipe can be effectively prevented from backing off in the hydraulic jetting process.

Owner:DAQING JINGTAI PETROLEUM ENG TECH +1

Small-aperture rock breaking drill bit

ActiveCN112431554AGuaranteed damageSmall sizeConstructionsClimate change adaptationRock cuttingStructural engineering

The invention relates to a small-aperture rock breaking drill bit which comprises a drill bit connecting part; an external blade and a central blade are arranged at the top of the drill bit connectingpart; the external blade is arranged at the outer side of the central blade; external rock cutting blades are arranged on the external blade; the external rock cutting blades are arranged on the outer edge of the drill bit connecting part; central rock cutting blades are arranged on the central blades and arranged between the external rock cutting blades; a drill bit central hole is formed in thecenter of the drill bit connecting part; bilateral inclined holes are formed in the top of the drill bit central hole; and the two ends of the bilateral inclined holes are arranged on the outer sideof the drill bit center hole and the outer side of the drill bit connecting part respectively. The small-aperture rock breaking drill bit has the advantages that the rock breaking speed is increased,and the drilling slag production size is reduced.

Owner:HENAN POLYTECHNIC UNIV

Drilling Speed Up Tool

The invention provides a drilling speed-increasing tool. The drilling speed-increasing tool includes a casing, a driving assembly and an impact assembly. The casing has a flow passage, and the impact assembly includes: a first joint connected to the casing, and the first joint has an impact chamber; The swinging member has a first swinging position and a second swinging position relative to the first joint, the swinging member is located in the impact chamber and divides the impacting chamber into a first cavity and a second cavity; the flow guide has a communication channel The guide channel, the guide channel is selectively communicated with the first cavity or the second cavity, the driving assembly is drivingly connected with the guide member, so as to drive the guide member to rotate in the same direction relative to the housing, and the guide member is rotating During the process, the communication state of the guide channel and the first cavity and the second cavity is switched, so as to drive the swing member to swing between the first swing position and the second swing position and collide with the first joint. Through the technical solution provided by the application, the problem of low drilling speed in the prior art can be solved.

Owner:PETROCHINA CO LTD

Drill bit and drilling device

PendingCN111485827AExtend your lifeReduce intensityDrill bitsConstructionsWell drillingClassical mechanics

The invention discloses a drill bit and a drilling device. The drill bit comprises a joint and a drill bit body; a hydraulic oscillation cavity is formed in the joint, and used for making drilling fluid flowing into the hydraulic oscillation cavity form a self-excited oscillation effect in the hydraulic oscillation cavity, pressure fluctuation is generated, the longitudinal vibration of the drillbit is driven, the drill bit transmits high-frequency vibration to rocks in contact, and thus inducing the rocks to undergo resonance failure and assisting the drill bit to break the rocks; and a nozzle is arranged in a drill bit body, an outlet of the hydraulic oscillation cavity communicates with the nozzle, and the nozzle is used for ejecting the drilling fluid flowing out of the hydraulic oscillation cavity out the drill bit. According to the technical scheme, the rock breaking speed can be increased, the service life of drilling tools is prolonged, a smooth and stable borehole is advantageously formed, and the drilling efficiency is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

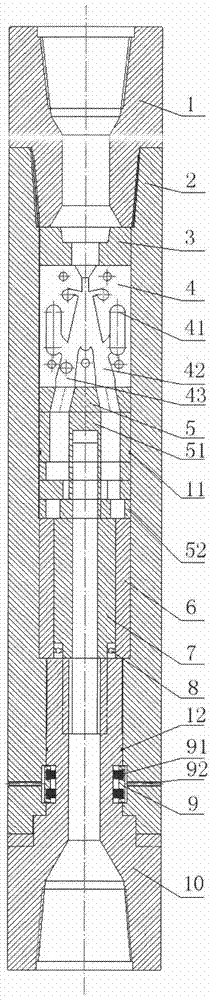

A hydraulic pulse generating device and its operating method

The invention discloses a hydraulic pulse generating device. The hydraulic pulse generating device mainly comprises a shell, a throttling nipple, a bullet-shaped nipple, a straightening block, a spacer, springs, a spring cover, a transmission shaft, a turbine stator, a turbine rotor, a pull rod, a supporting disc, a supporting cap and a thrust bearing, and is characterized in that the throttling nipple is connected to the lower end of the shell through threads; the throttling nipple and the bullet-shaped nipple form a hydraulic pulse generating unit; the straightening block is mounted inside a T-shaped groove in the bullet-shaped nipple; the spacer is arranged inside the T-shaped groove in the bullet-shaped nipple; the springs are mounted at both the upper end and the lower end of the straightening block; the spring cover is used for preventing the spring at the upper end of the straightening block from breaking away; a closed chute is formed in the cylindrical surface of the lower end of the transmission shaft; the turbine stator and the turbine rotor form a power unit; the turbine stator and the turbine rotor are fixed to the shell and the transmission shaft in a tightly pressing manner respectively; the pull rod, the supporting disc, the supporting cap and the thrust bearing form a supporting unit together. The hydraulic pulse generating device is simple in structure and convenient to operate and has easily adjustable shock frequency.

Owner:SOUTHWEST PETROLEUM UNIV

Radial sidetracking rotary self-propelled multi-hole jet drill bit

The invention relates to a radial sidetrack drilling rotating self-propelled porous jet flow drill bit, which mainly comprises a casing, a rotating drill bit body, a gear type slide ring type combined seal, an opening sealing screw, steel balls and the like, wherein a water inlet is processed at the tail end of the casing; a backward spray nozzle is processed on the casing; a forward spray nozzle and a center spray nozzle are processed on the rotating drill bit body; semicircular grooves are respectively processed in the casing and the rotating drill bit body; the steel balls are placed in the grooves formed between the casing and the rotating drill bit body; the rotating drill bit body is positioned through the steel balls and can rotate around the self axial line; the gear type slide ring type combined seal is adopted between the rotating drill bit body and the casing; through holes are formed at the lateral side of the casing; the steel balls are placed into the grooves through the through holes; and after the steel balls are placed into the grooves, the through holes are sealed through the opening sealing screws. The radial sidetrack drilling rotating self-propelled porous jet flow drill bit can effectively solve the problems of poor jet flow drill bit reaming capability, poor rock breaking hole smooth roundness, bent tracks of hydraulic jet hoses and the like of the hydraulic jet radial sidetrack drilling tiny drill hole technology, and can be widely applied to the hydraulic jet radial horizontal well technology.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com