Realization method and structure of a rotary valve reversing type hydrodynamic circumferential impactor

A technology of liquid power and realization method, which is applied in the direction of vibration drilling, etc., can solve the problems of low drilling efficiency and short service life of PDC bit, and achieve the effect of increasing drilling speed, improving drilling efficiency and reducing slipping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

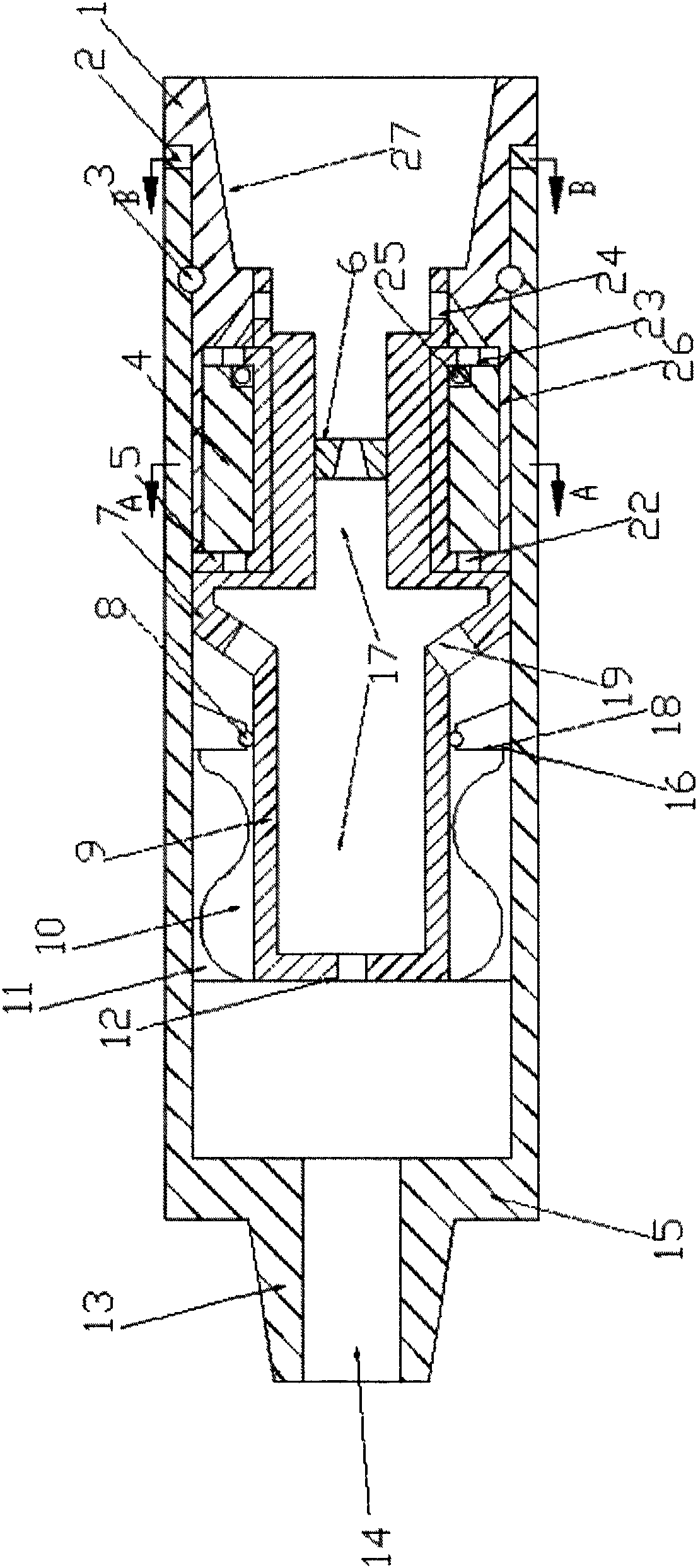

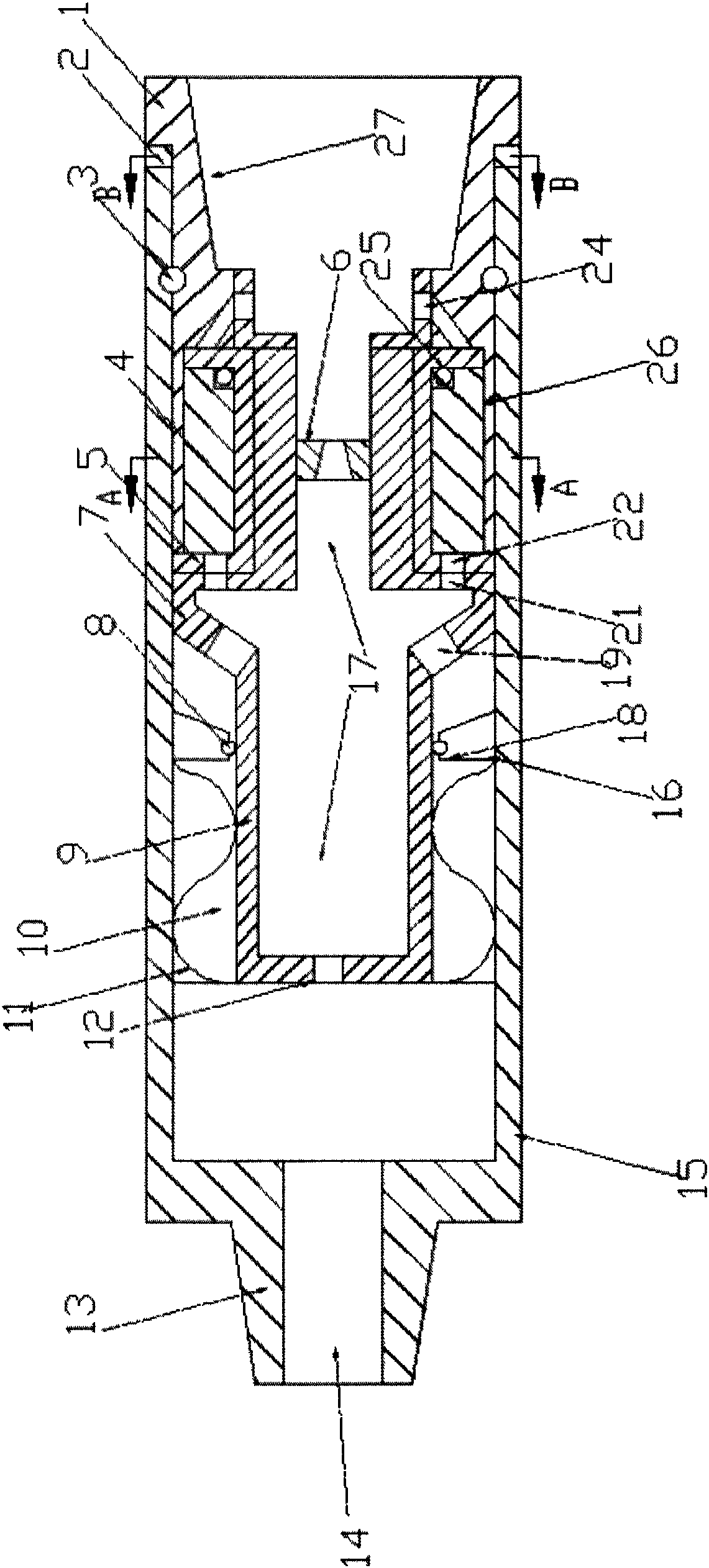

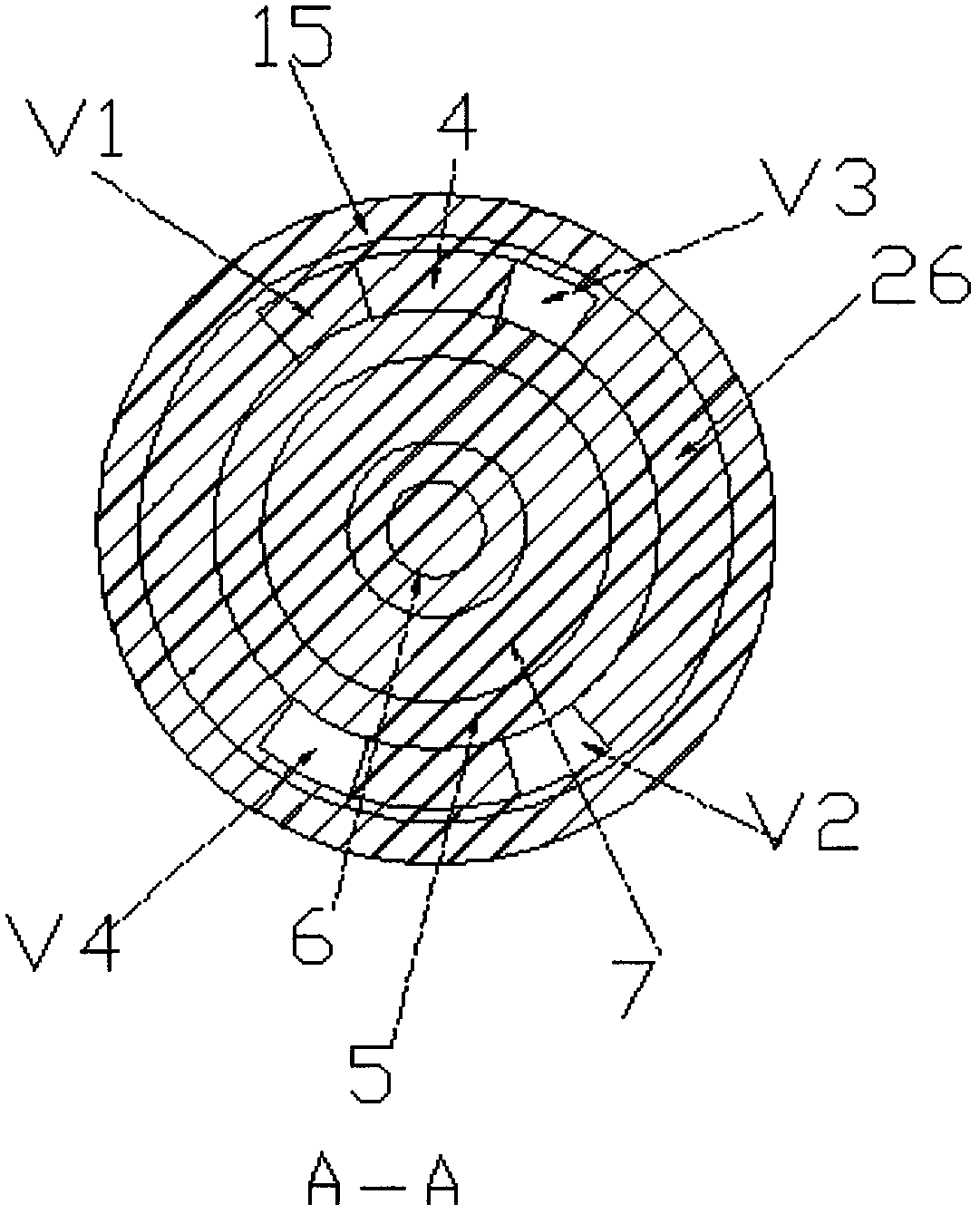

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings. It is specifically stated here that the accompanying drawings are provided only for better understanding of the present invention, and they should not be construed as limiting the present invention.

[0020] The invention provides a method and structure for realizing a rotary valve reversing type hydrodynamic circumferential impactor. When the fluid flows through the rotating blade, the blade is driven to rotate, and the torque is transmitted to the rotary valve spindle with a window on the side through the blade spindle. The windows on the wall of the rotary valve mandrel and the windows on the relatively stationary rotary valve housing are interlaced, and the windows are divided into low-pressure outflow windows and high-pressure inflow windows by setting nozzles, so that the liquid flows into the rotary valve alternately. The high-pressure window on the casing flows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com