Novel rock breaking method and rock breaking hob

A hob and rock-breaking technology, which is applied in the field of flaking and rock-breaking methods and rock-breaking hobs suitable for flaking and breaking rocks, can solve the problems of short tool life and hob wear, and achieve slow blade wear and low consumption , The effect of high excavation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

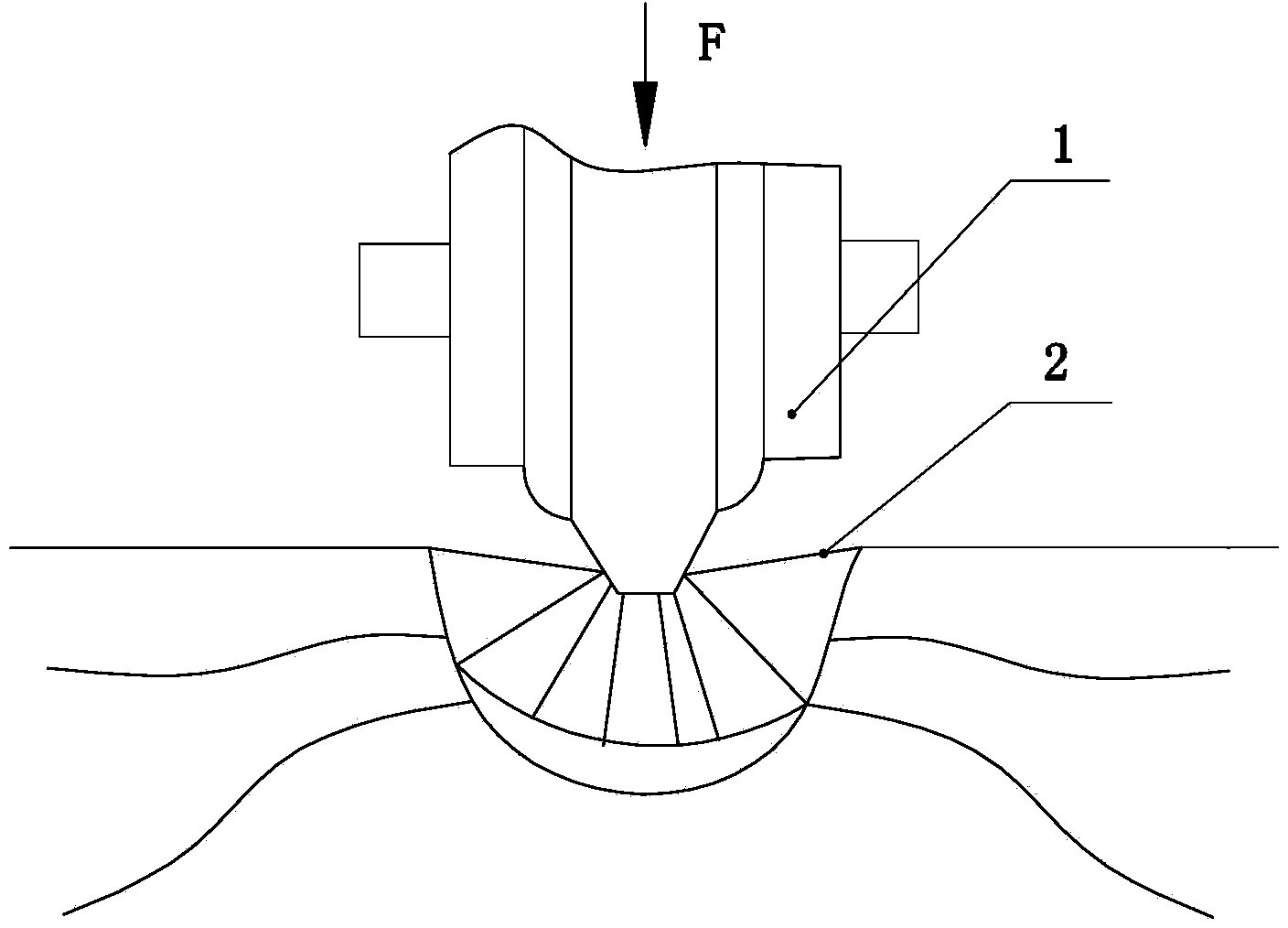

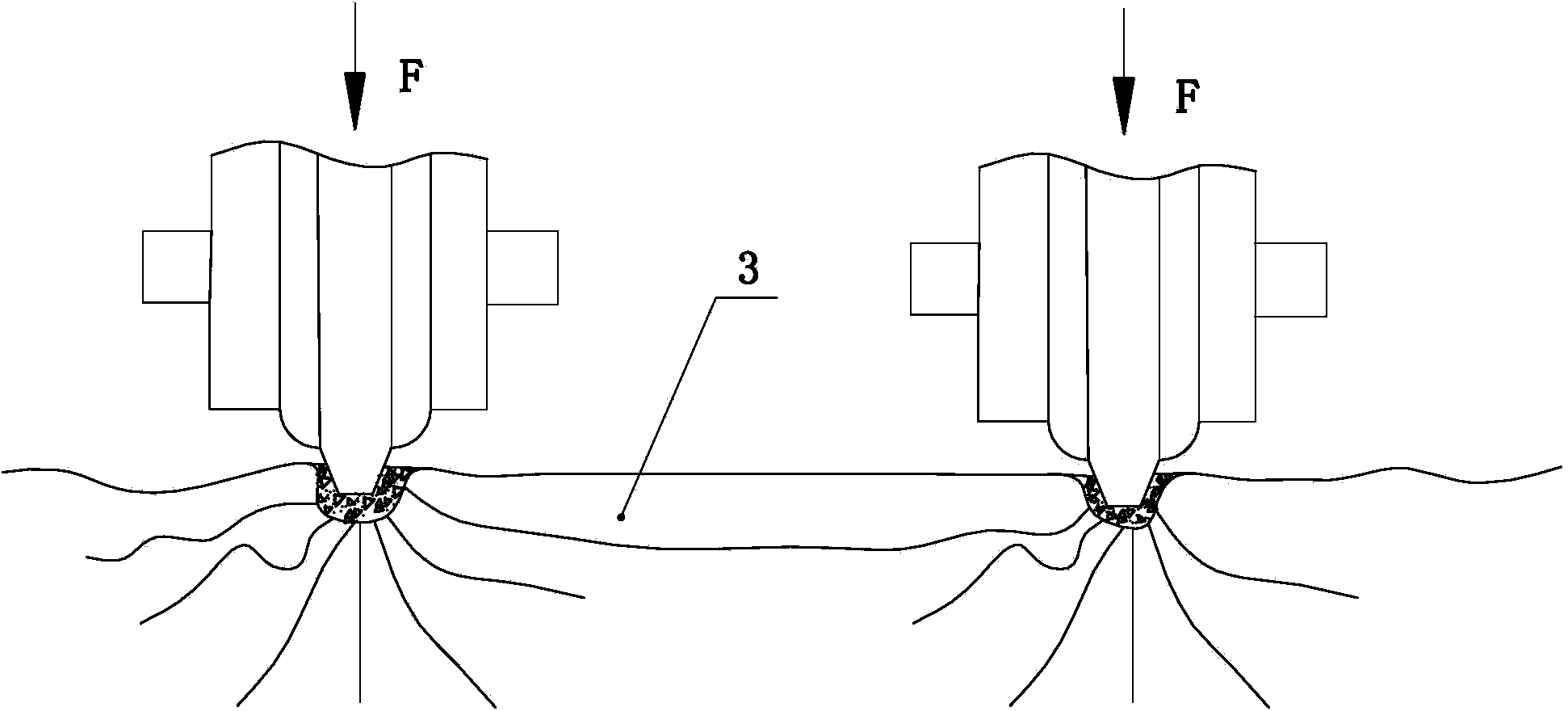

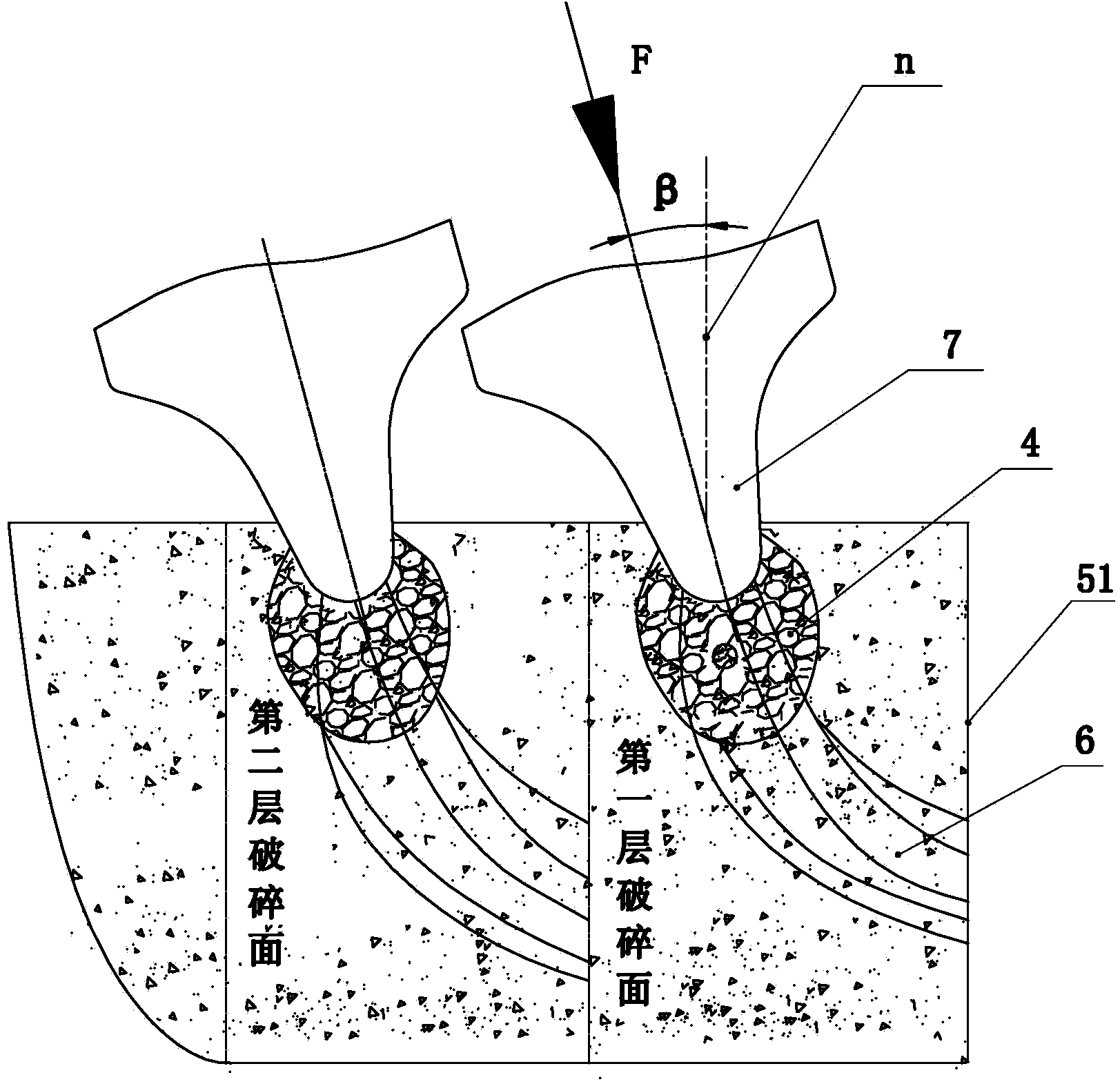

[0031] Such as figure 1 , figure 2 As shown, it is a schematic diagram of the existing rock-breaking method of "positive pressure straight cutting rock-breaking method". The central axis revolves, and on the other hand, it rotates around its own axis. Under the action of pressure F and torque, the disc hob cuts a series of concentric circles on the palm face. When the pressure exceeds the strength of the rock, the rock under the tip of the disc-shaped hob is directly broken, and the tip penetrates into the rock, and the rock on the face of the face is crushed by the disc-shaped hob to form multiple concentric circular grooves. As the depth of the groove increases, the cracks on the surface of the rock mass deepen and expand. When the pressure of the hob exceeds the shear and tensile strength of the rock, the rock between adjacent concentric grooves collapses in pieces, completing the breaking of the disc hob. rock process. In this rock-breaking method, the stress form of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com