Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

74results about How to "Reliable torque transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

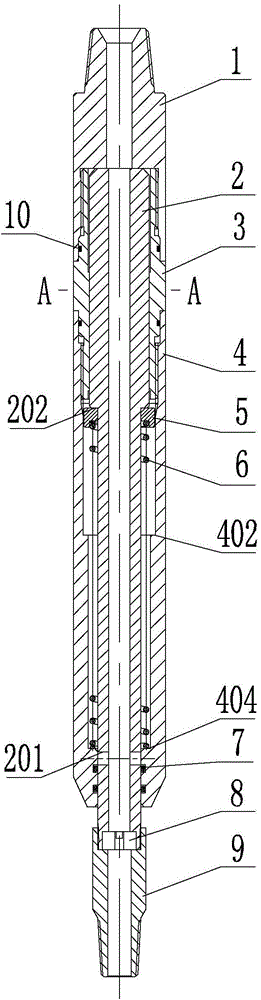

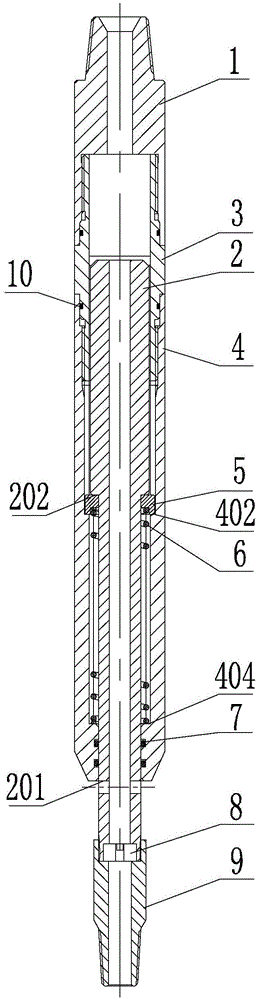

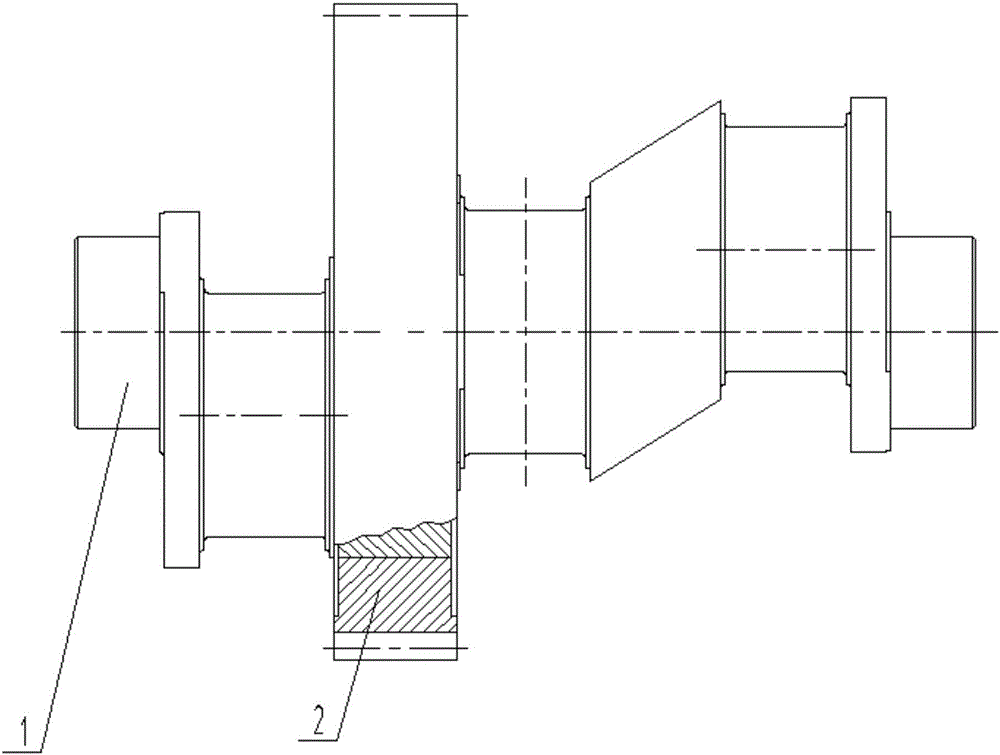

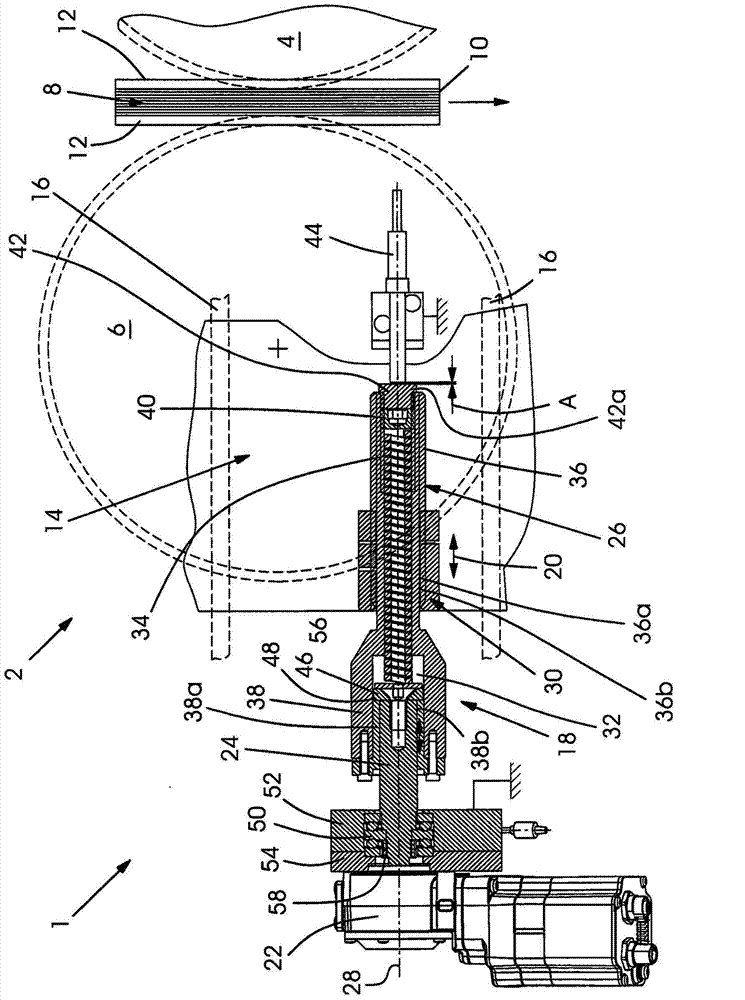

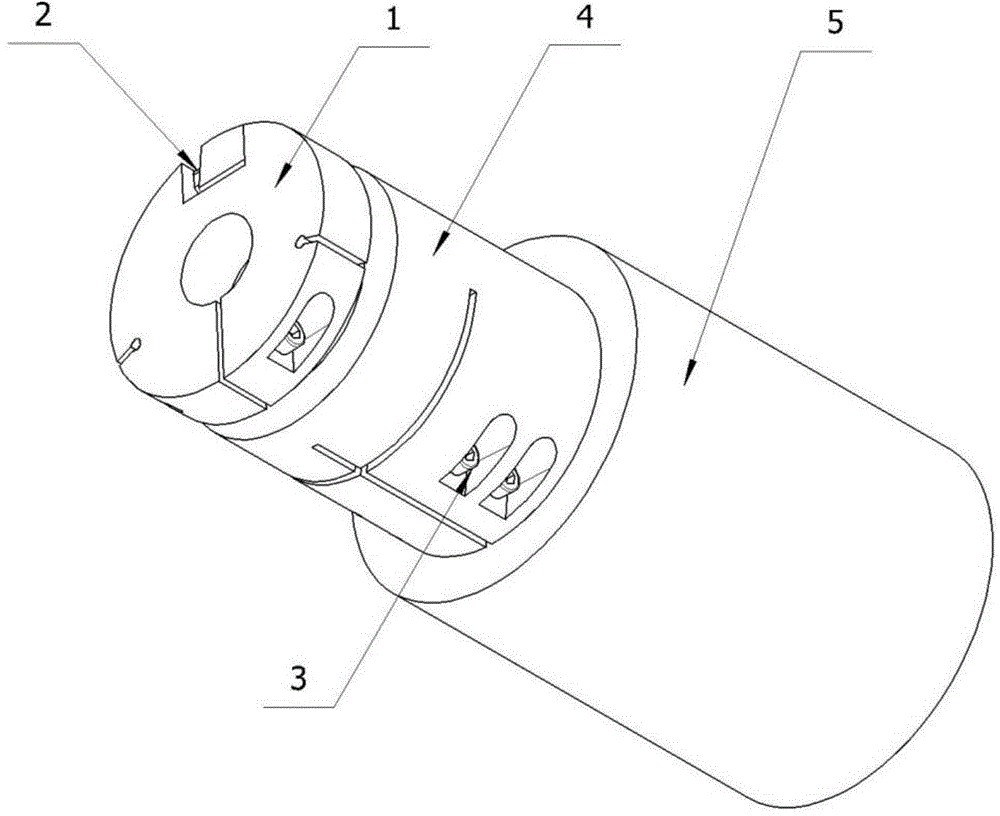

Drilling pressure pushing pressurizer

ActiveCN104405321ALower the pressure valueControl feedDrilling rodsDrilling casingsUpper jointEngineering

The invention a drilling pressure pushing pressurizer which comprises an upper joint, a lower joint, a shell, a piston and a throttling ring, wherein the shell is a hollow barrel; one end of the shell is connected with one end of the upper joint; the piston is arranged in the inner cavity of the shell in a manner of moving up and down; one end, which is far away from the upper joint, of the piston extends out of the shell; the extending end of the piston is in sliding sealed fit with the shell and is connected with one end of the lower joint; the throttling ring is connected with the extending end of the piston and is used for generating throttling pressure difference; through holes are respectively formed in the upper joint, the piston, the throttling ring and the lower joint and are connected with one another in sequence to form a liquid guide channel; at least one pressure release hole penetrating from the through hole in the piston to the outer wall of the piston is formed in the lower part of the piston and retracts into or extends out of the shell along with the up-and-down sliding of the piston. The drilling pressure pushing pressurizer realizes drilling pressure adjustment and can judge the completion of hole drilling on the ground.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Tool head

InactiveUS6925718B2Simple assembly and removalReliable torque transmissionGrinding wheel securing apparatusMowersMotor driveElectric motor

A tool head for a motor-driven, manually guided implement for receiving a rotatable cutter tool is provided. The tool head comprises a housing in which is provided a tool shaft that is rotatably mounted via bearings. Secured on the tool shaft so as to turn with it is a tool carrying mechanism for the cutter tool. This tool carrying mechanism includes an engagement plate having an engagement surface, which is oriented perpendicular to the axis of the shaft, and a centering shoulder. The engagement plate and a centering element having the centering shoulder are embodied as separate components. The engagement plate is of light weight construction and is positively connected with the tool shaft. The centering element is made of a material, the hardness of which is adapted to the cutter tool.

Owner:ANDREAS STIHL AG & CO KG

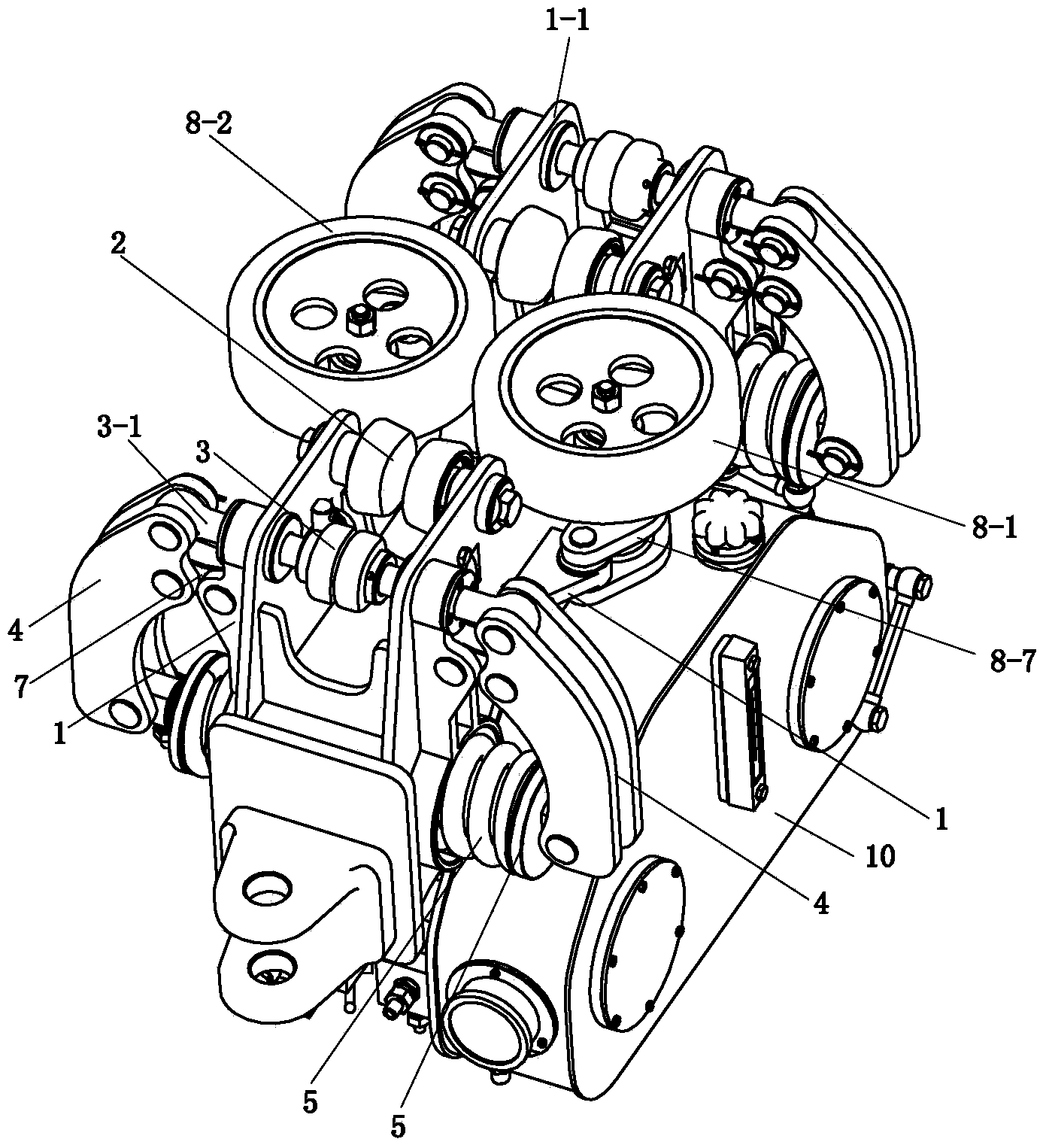

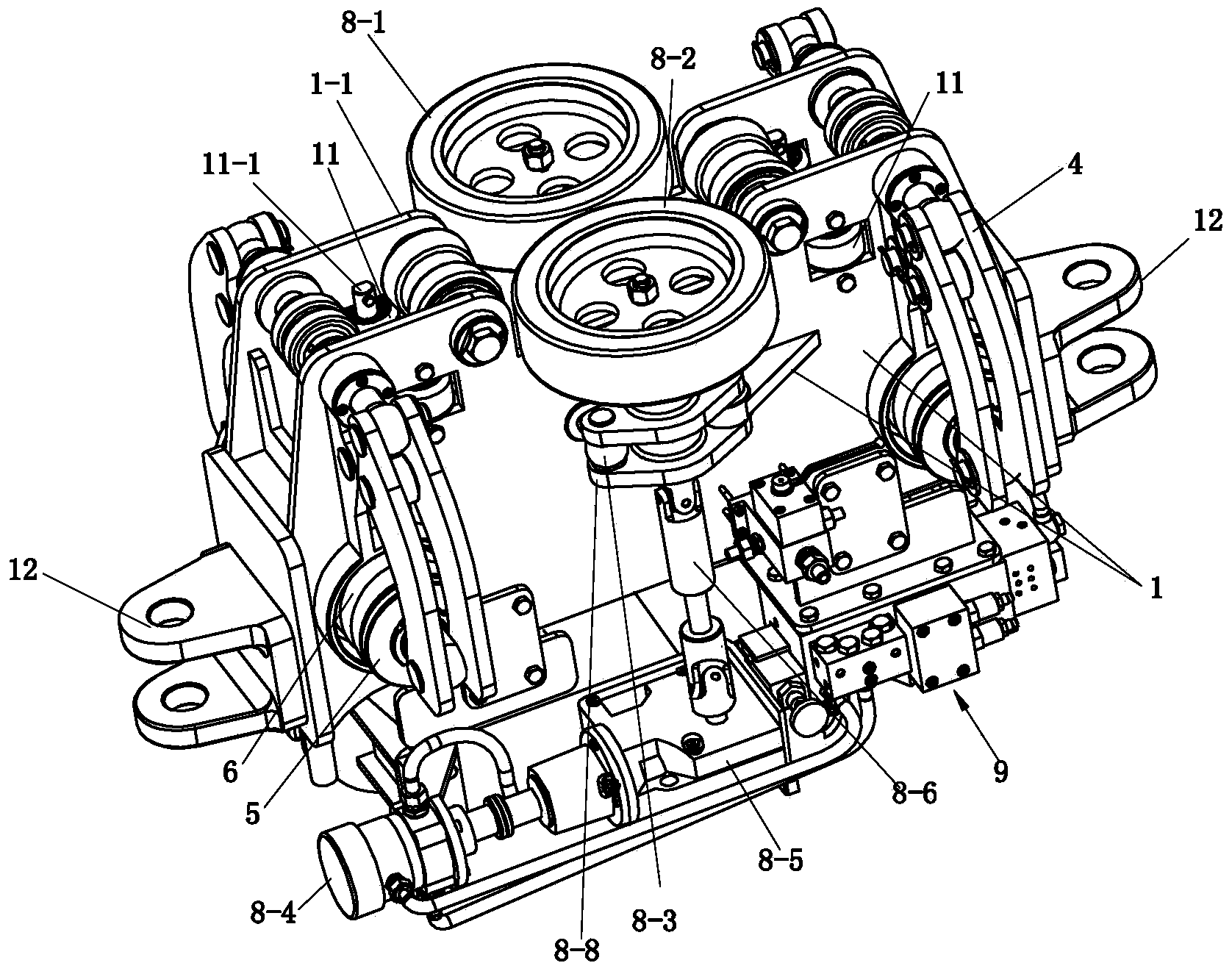

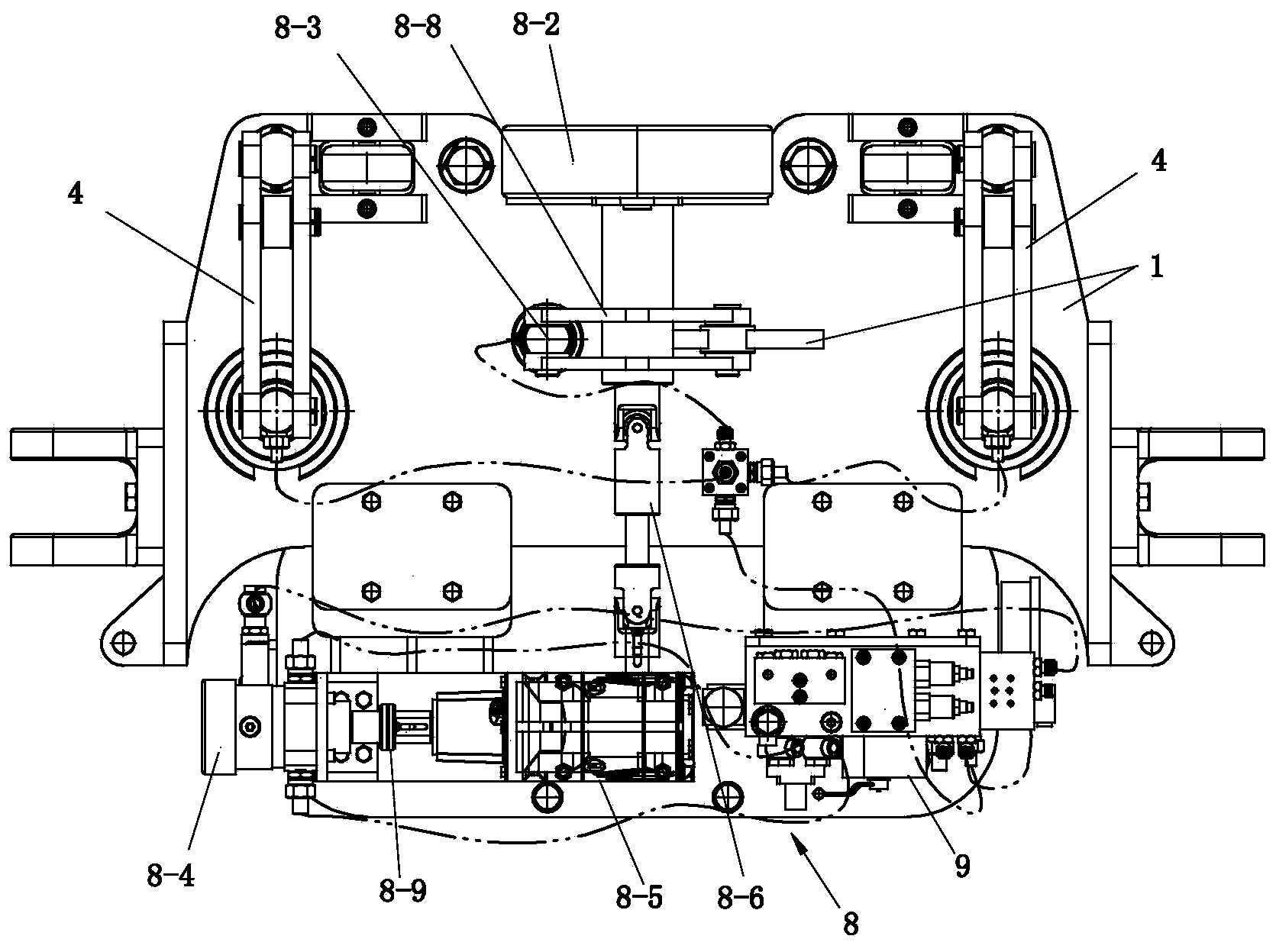

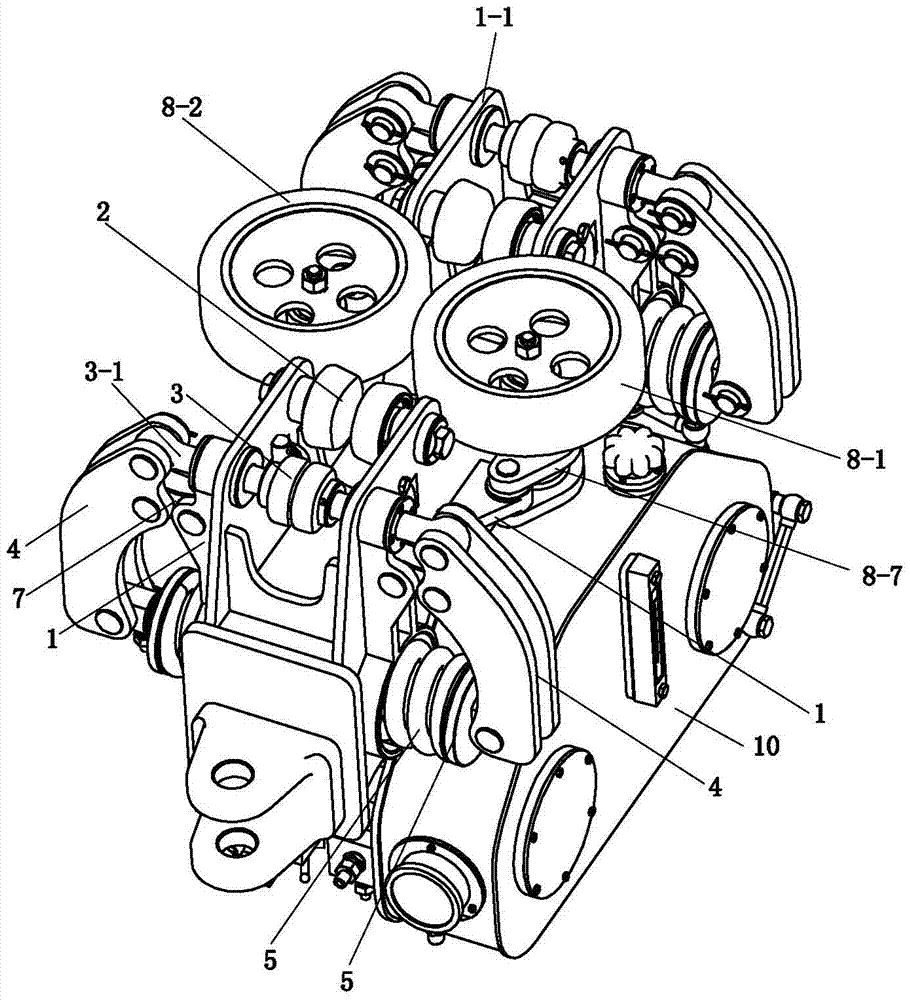

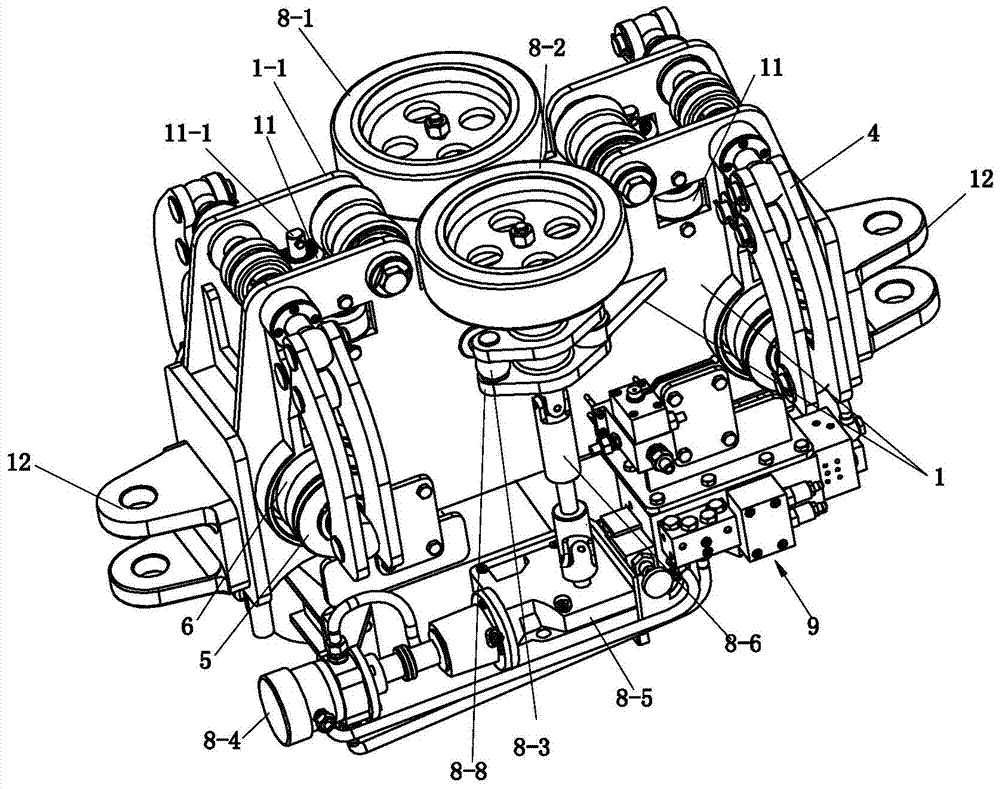

Rope traction monorail crane system braking vehicle

ActiveCN104260744ADriving safetyFully absorb liquidTrack-braking member co-operationHydraulic motorVehicle frame

The invention discloses a rope traction monorail crane system braking vehicle, and the rope traction monorail crane system braking vehicle comprises a frame, two pairs of walking wheels and two pairs of brake shoes are arranged between two sidewalls of the frame, two pairs of brake shoes are driven by a pair of brake arms, two pairs of brake arms are driven by brake oil cylinder, the frame is provided with a speed selecting and increasing device, the speed selecting and increasing device comprises a first speed selecting wheel, a second speed selecting wheel, a clamping oil cylinder, a dual-direction hydraulic motor and a gearbox, the first speed selecting wheel shaft and the second speed selecting wheel shaft are supported by the first wheel shelf and the second wheel shelf, the shaft of the second speed selecting wheel is connected to the low speed shaft of the gearbox through cross-shaped universal coupler, the high speed shaft of the gearbox is connected to the drive shaft of the dual-direction hydraulic motor through elastic coupler. The speed selecting and increasing device controls two pairs of brake shoes of the braking vehicle by selecting speed judgment, the brake shoes on the other vehicles can also be controlled for guaranteeing the safe drive for the rope traction monorail crane system.

Owner:CHANGZHOU DEV & MFR CENT

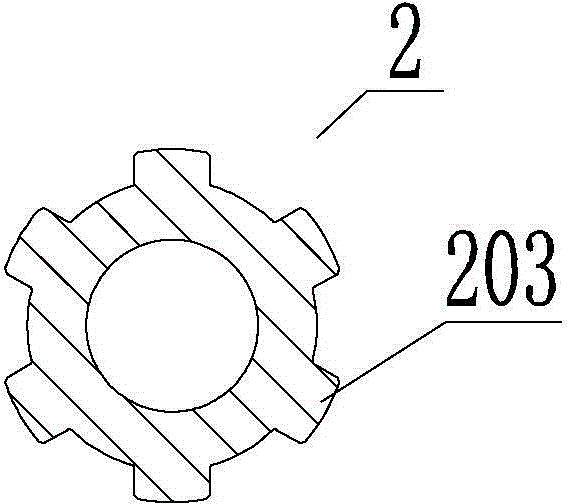

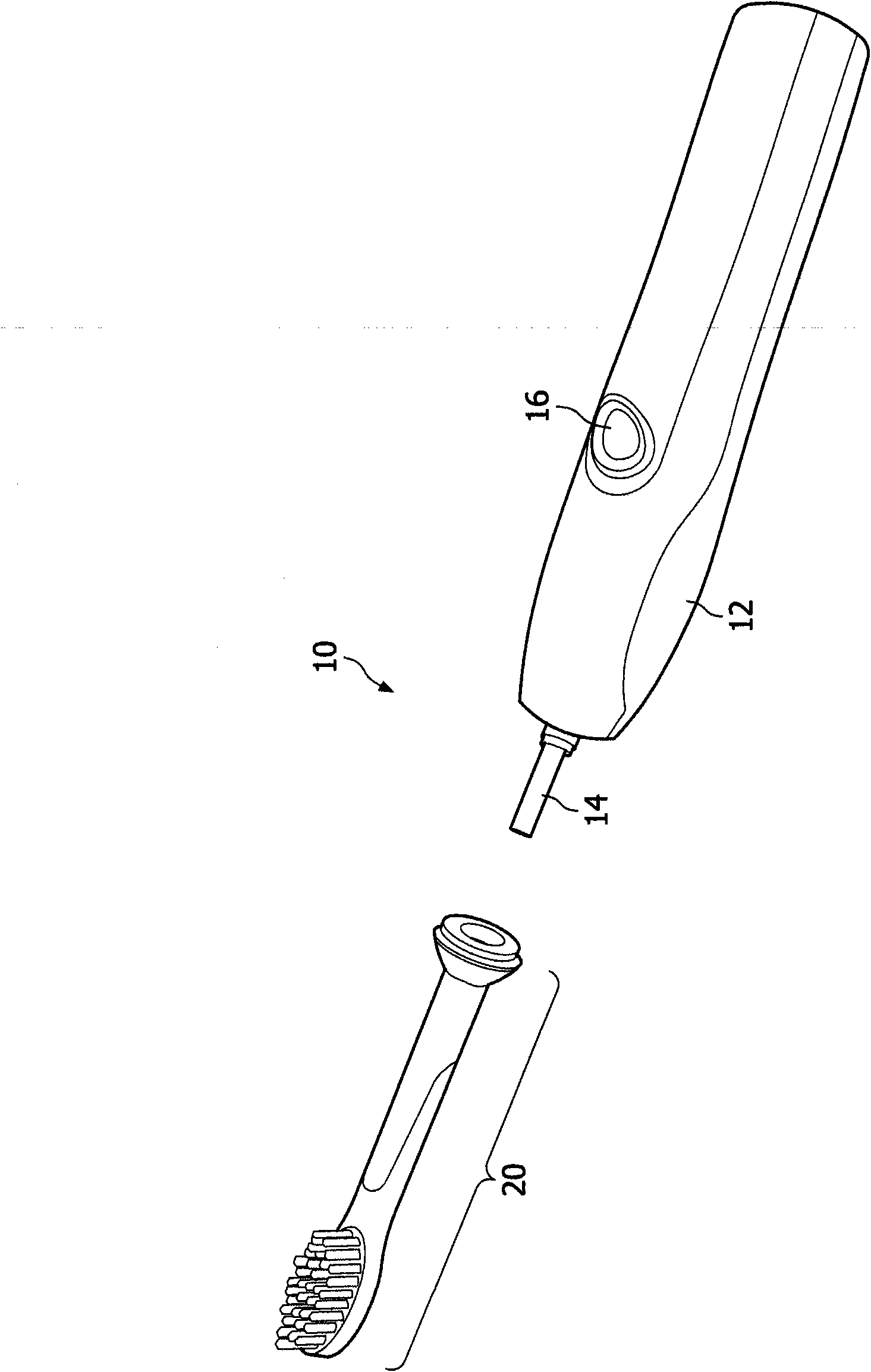

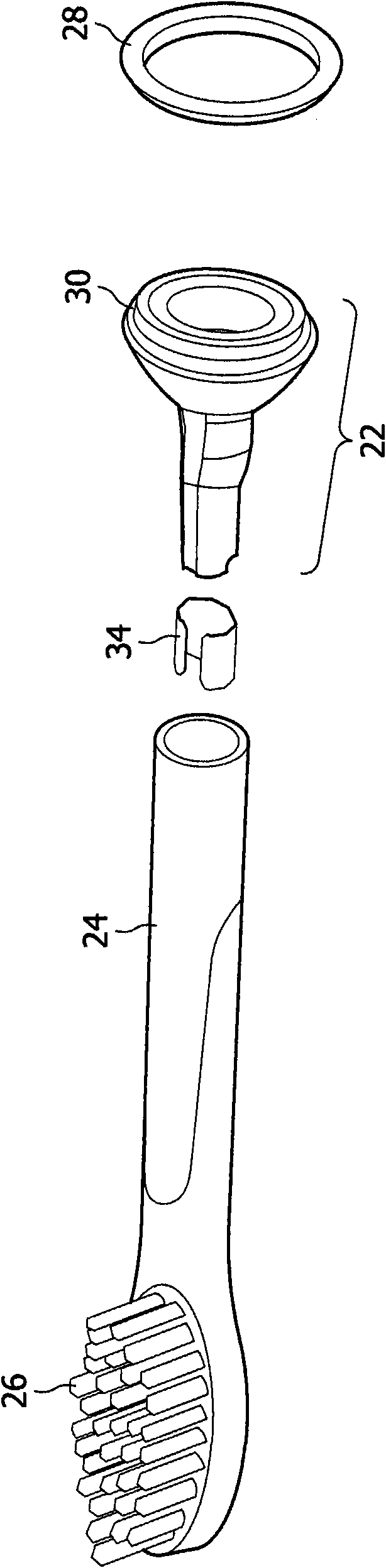

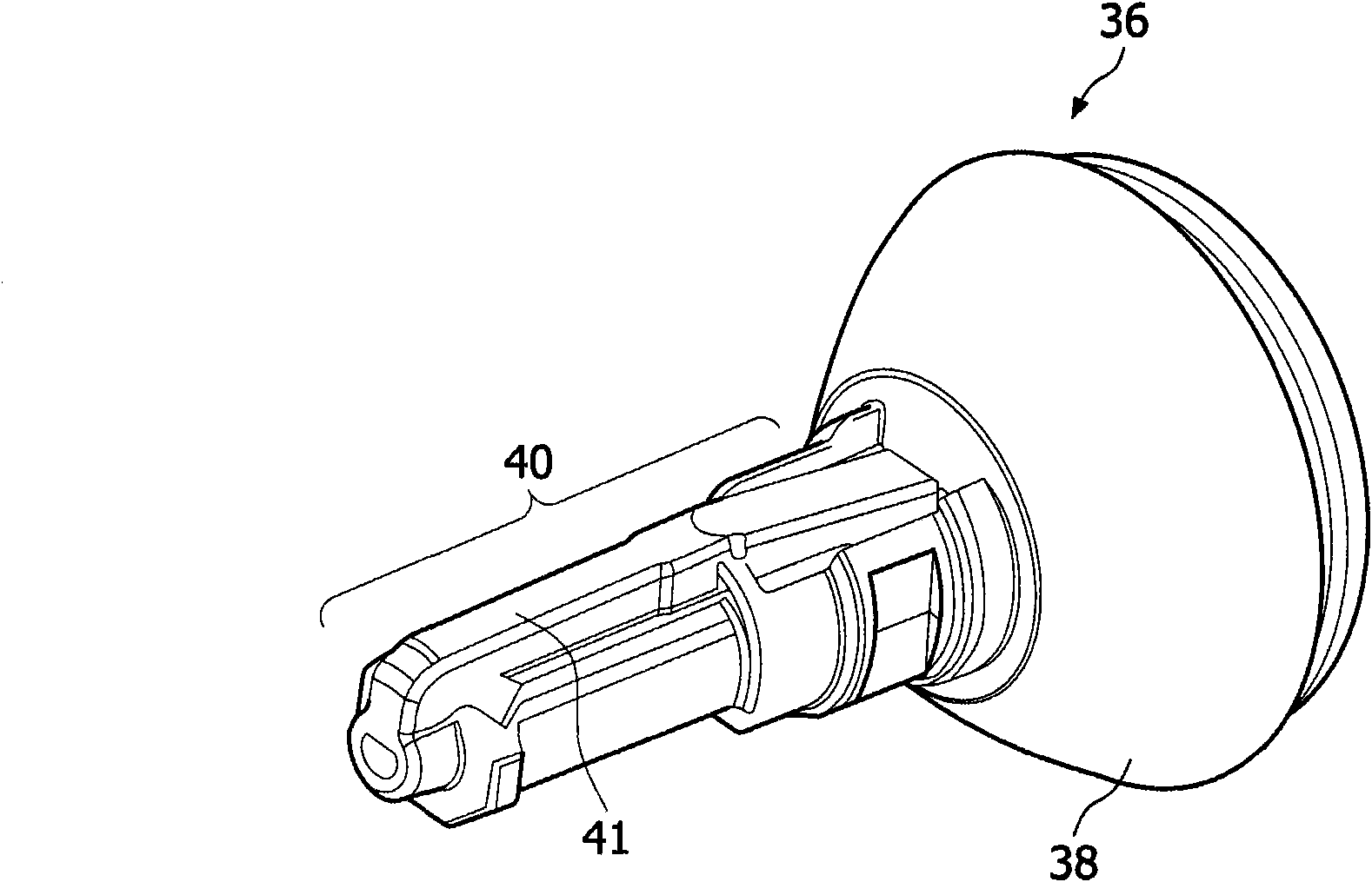

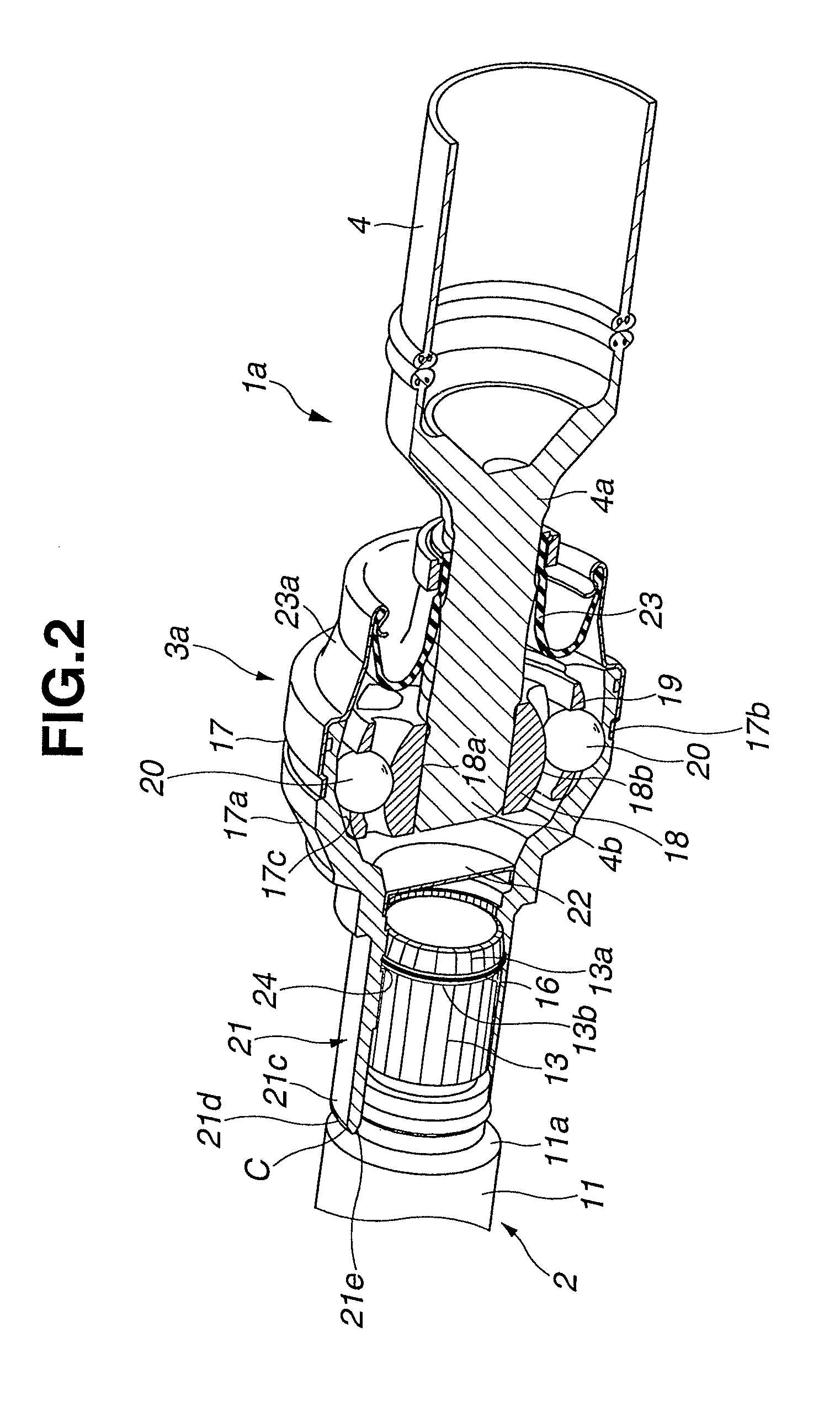

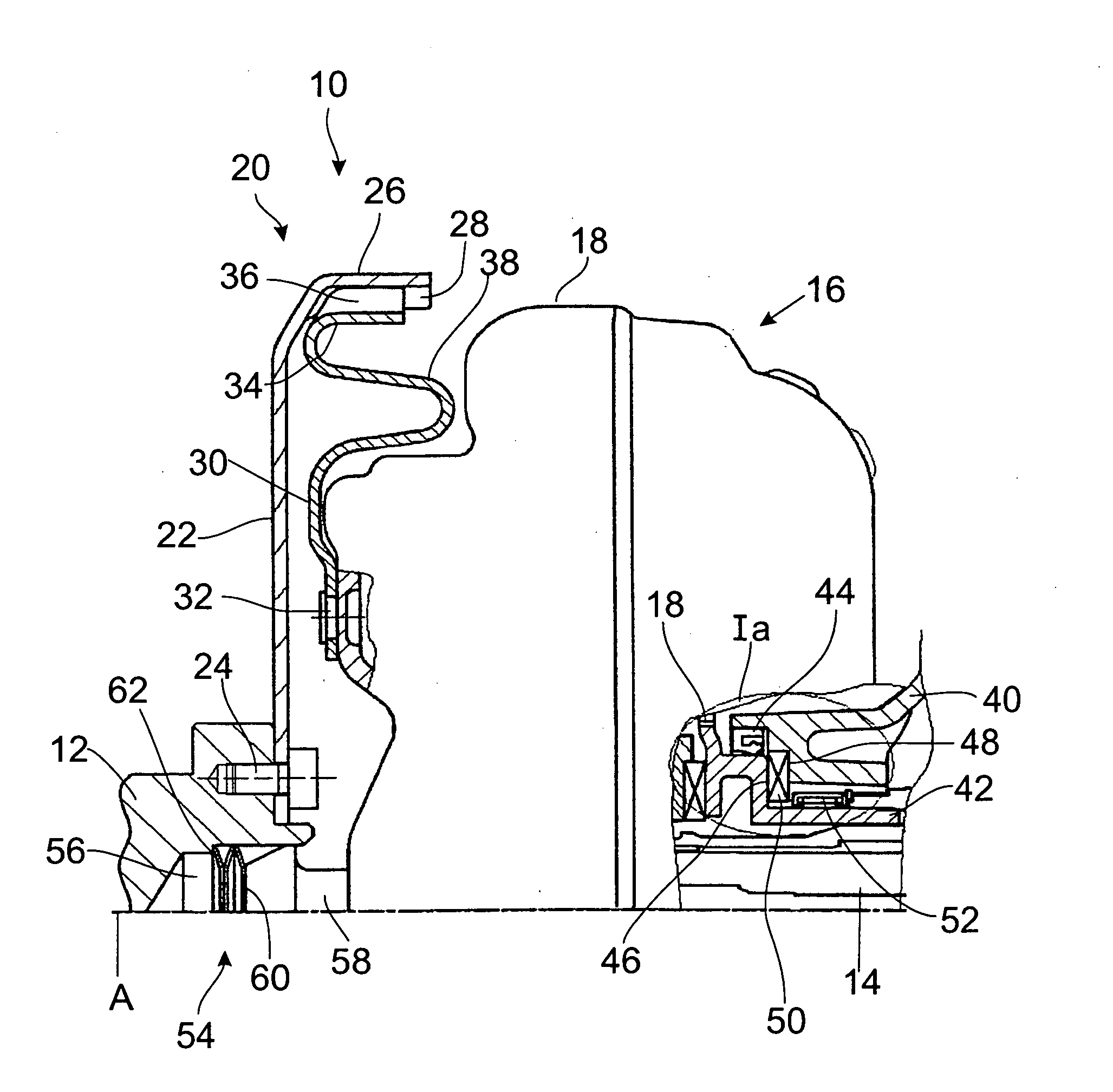

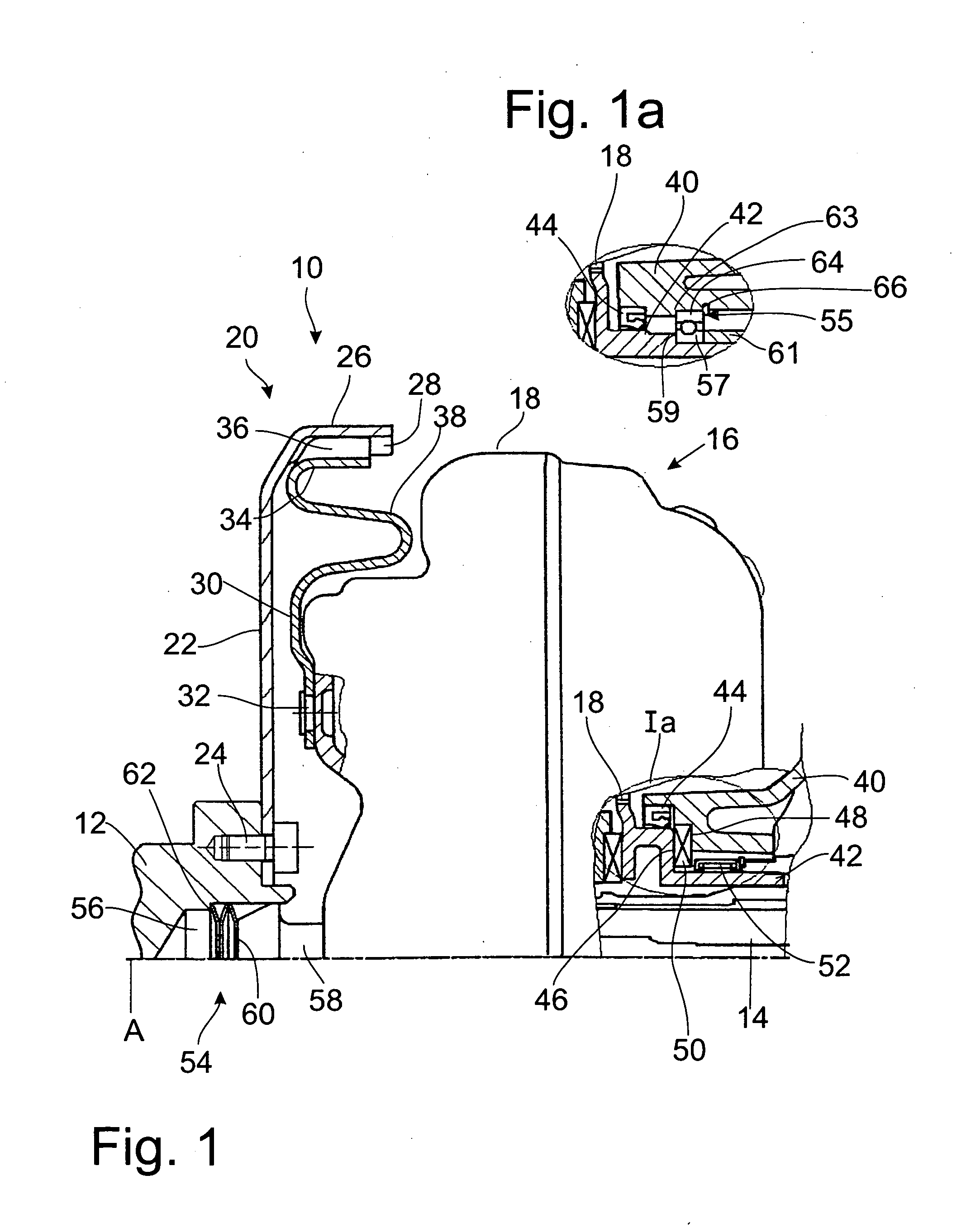

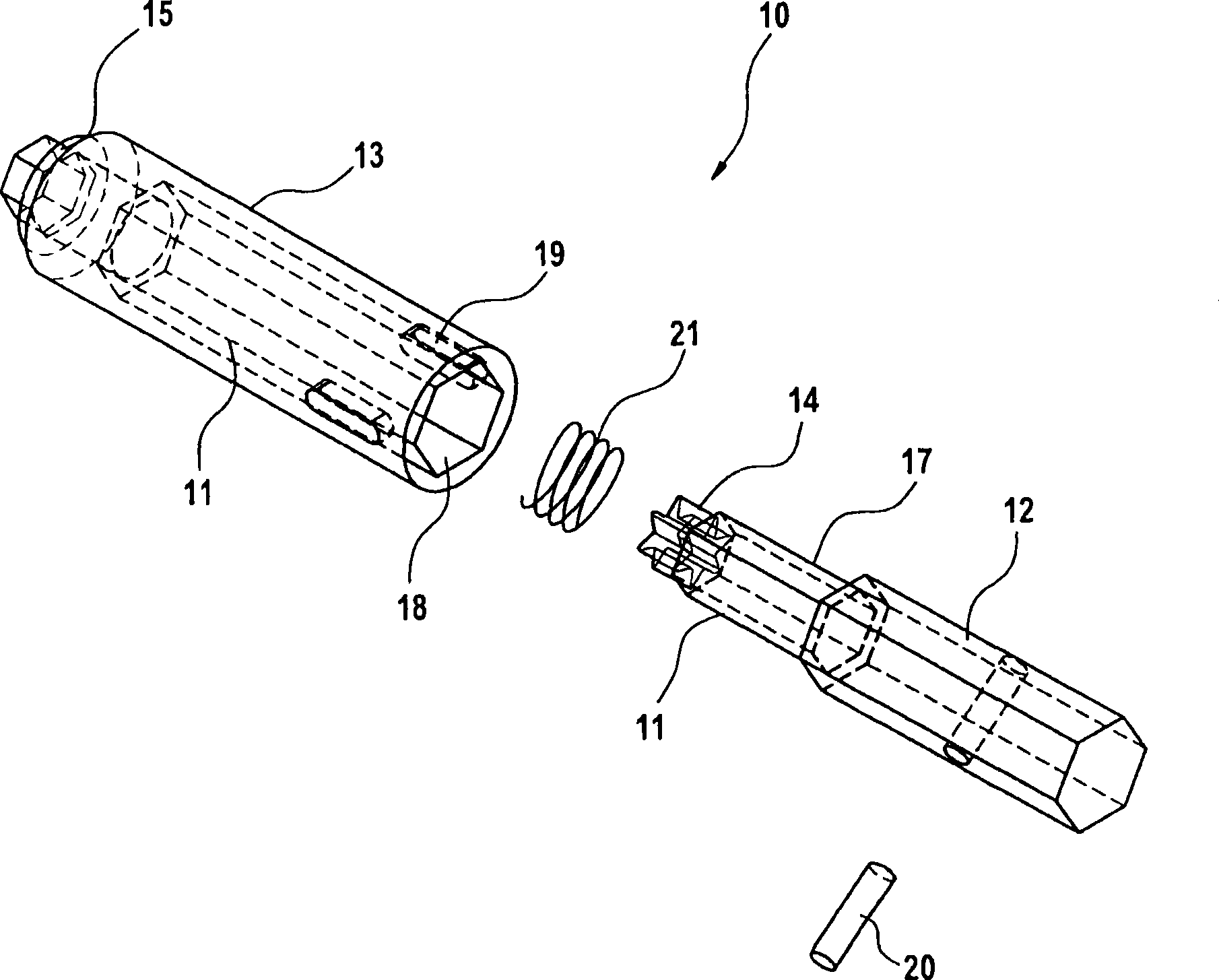

A brushhead/handle interface for a power toothbrush

ActiveCN101902986AReliable torque transmissionReliable functionTooth cleaningPower toothbrushEngineering

The brushhead / handle interface includes a brushhead assembly (20) which has a brush member (26) for cleaning teeth. A driveshaft (14) extends from a handle portion (12) of the toothbrush (10), which is driven in an oscillating manner through a selected rotational angle. The driveshaft includes one or more contact regions (49). The coupling member includes an interface portion or portions (46) which are forced against the contact regions of the driveshaft by a single spring member when the driveshaft is inserted into the coupling member. The single spring (34) exerts a sufficient force on the interface portions of the coupling member against the contact regions of the driveshaft to produce both a reliable torque transfer between the driveshaft and the brushhead assembly and to maintain axial retention of the brushhead assembly on the driveshaft during operation of the toothbrush.

Owner:KONINKLJIJKE PHILIPS NV

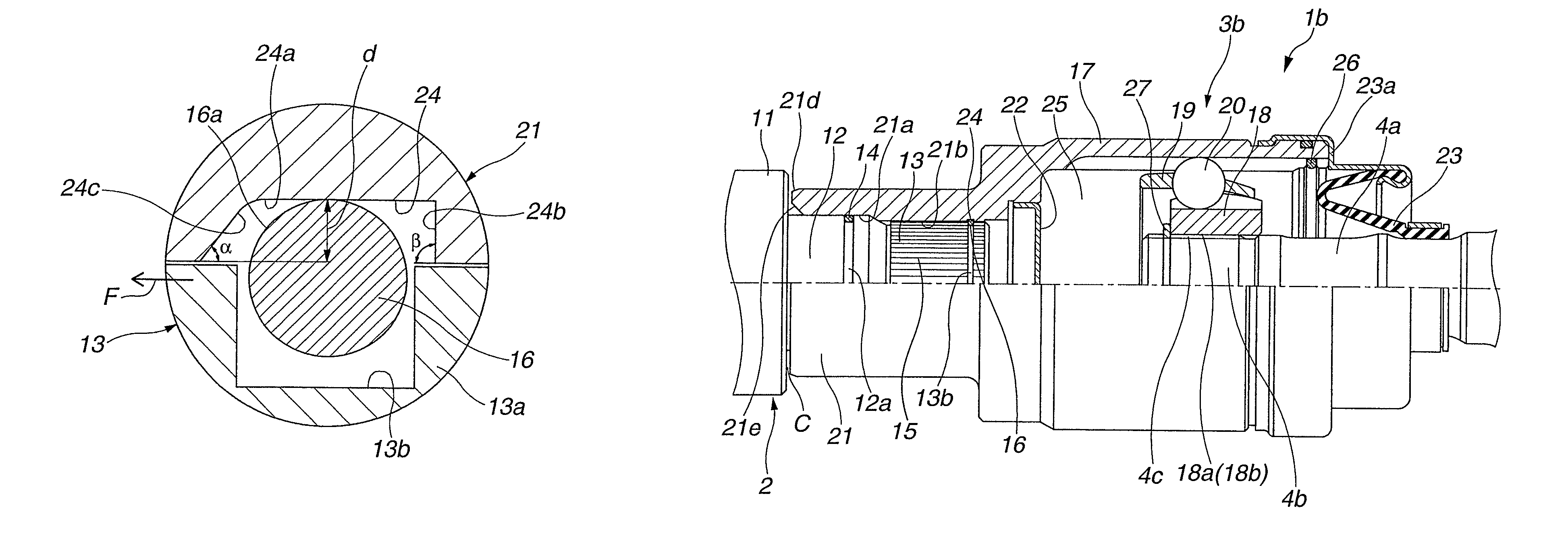

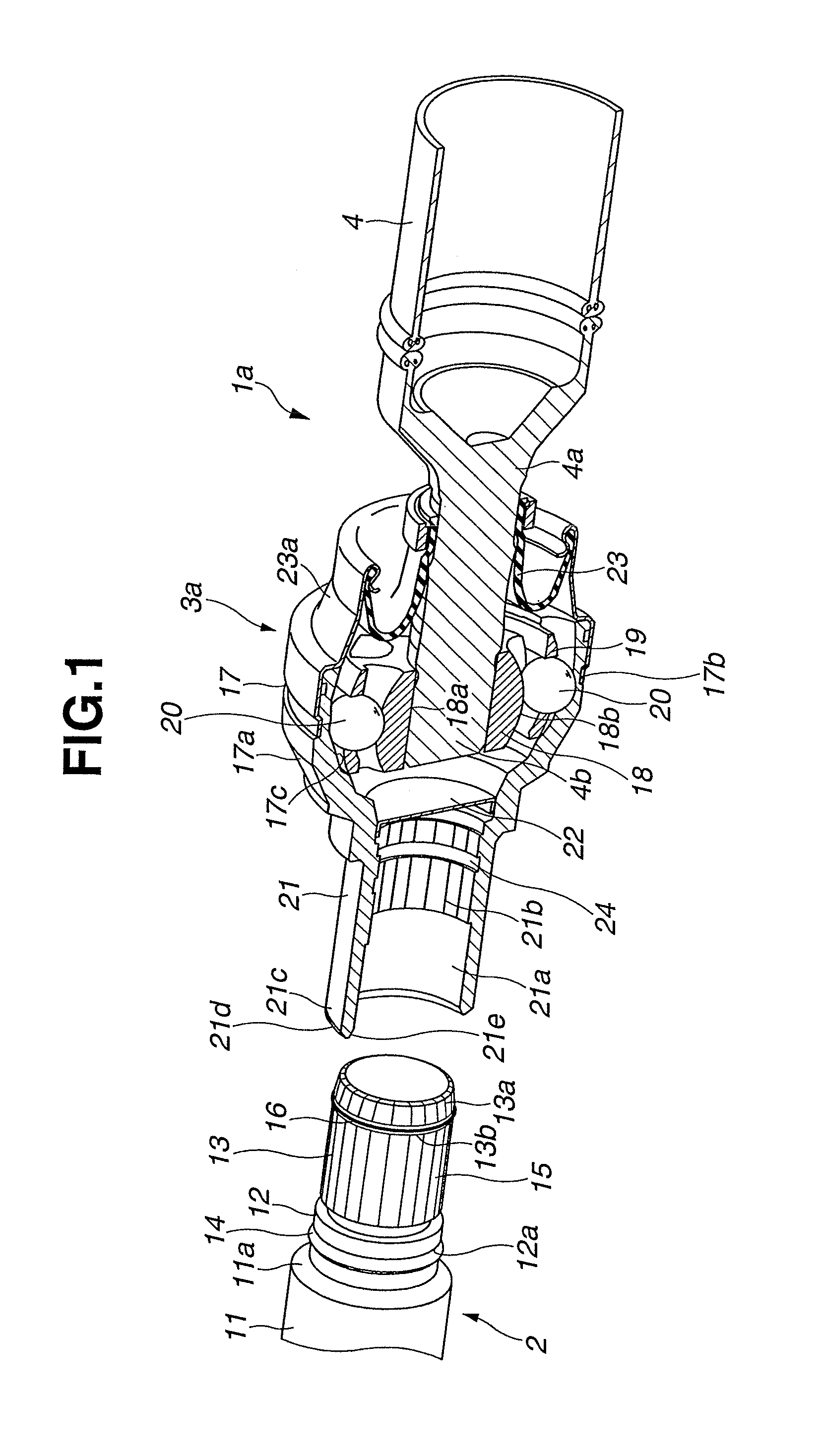

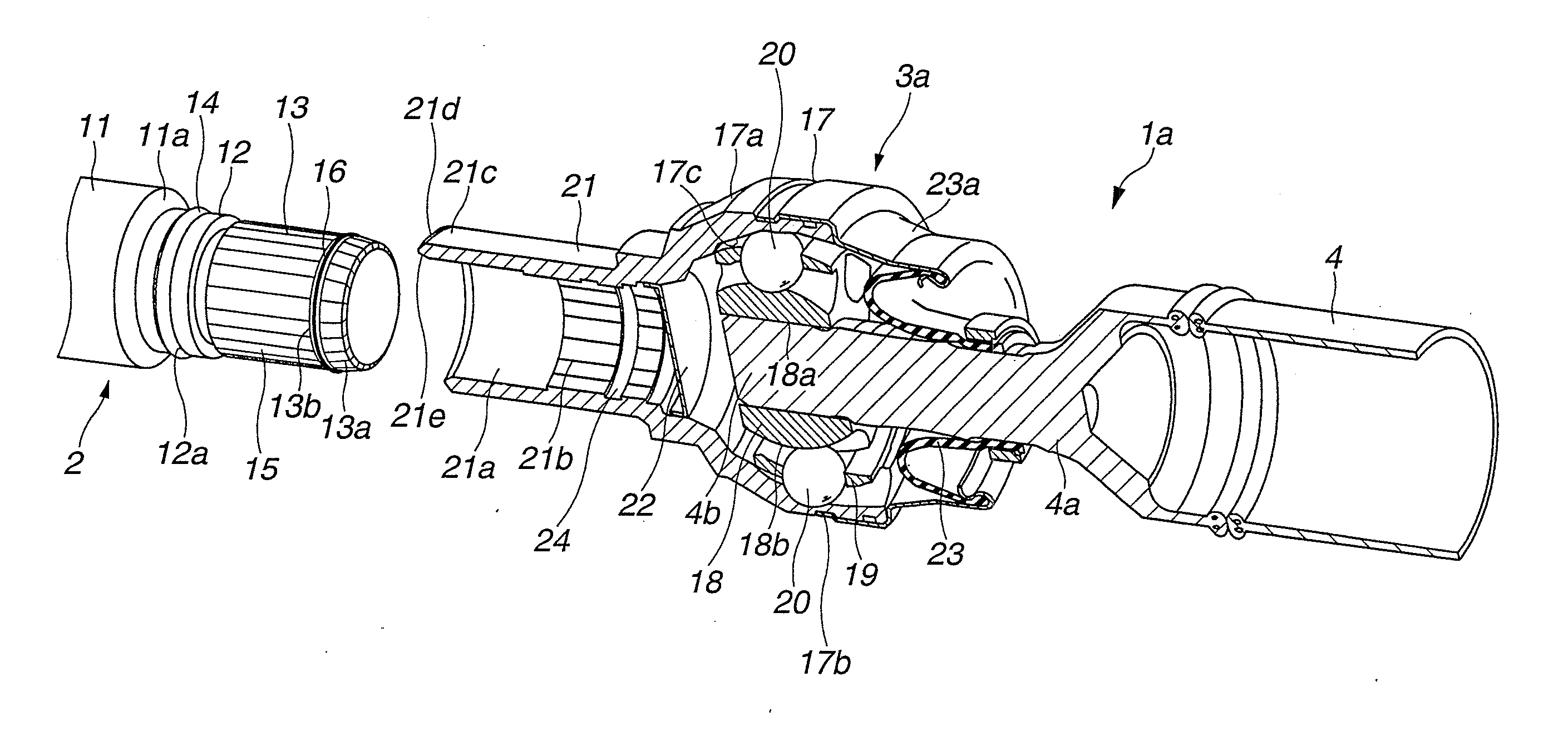

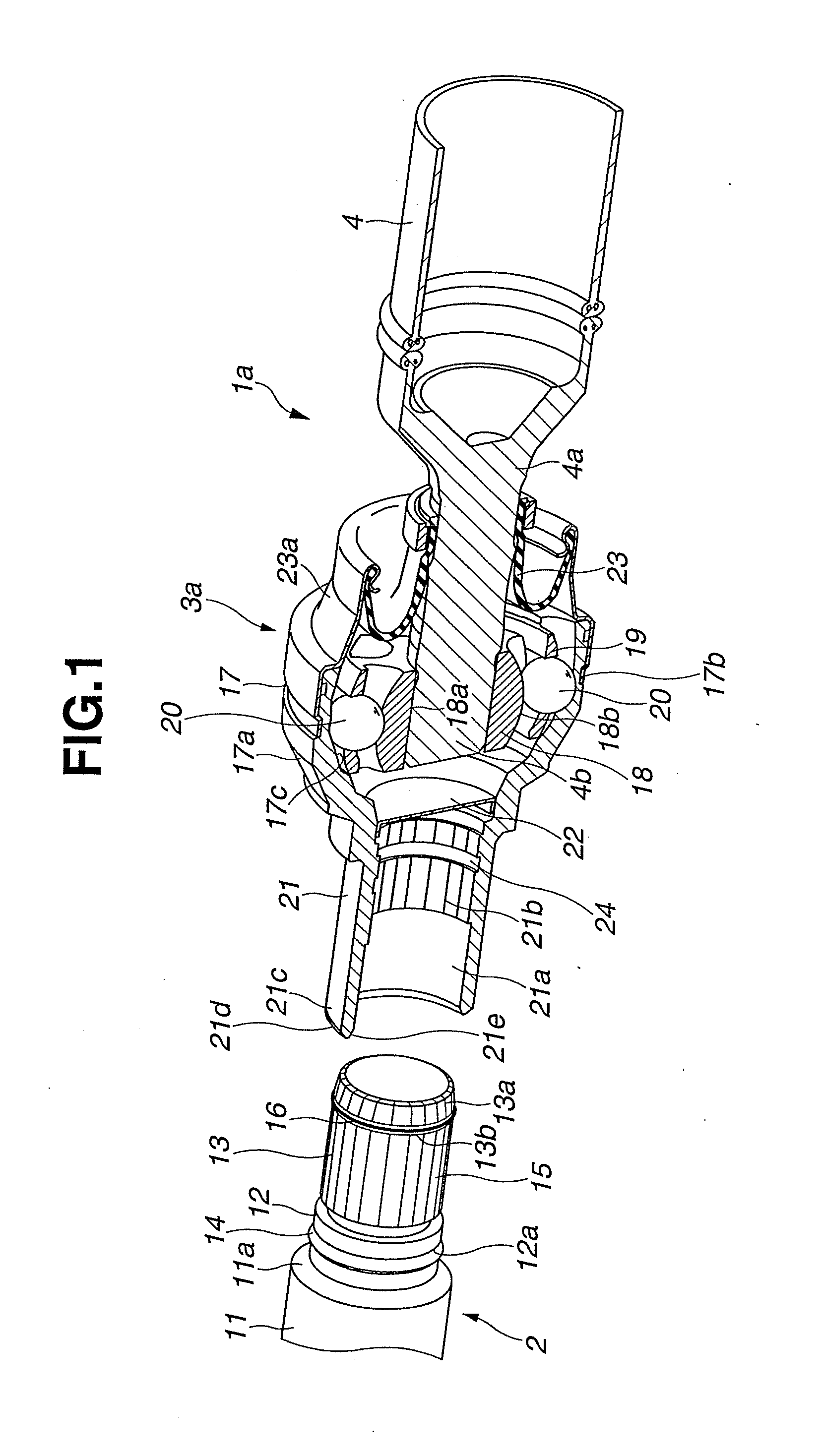

Propeller shaft and constant velocity universal joint used therein

A propeller shaft is proposed which comprises an outer cylindrical member formed with a sleeve portion that has a splined cylindrical inner wall with which a splined cylindrical outer wall of a shaft is engaged; an inner cylindrical member installed in the outer cylindrical member; a torque transmitting unit through which a torque is transmitted from the outer cylindrical member to the inner cylindrical member; and a connecting mechanism that, upon engagement of the splined cylindrical outer wall with the splined cylindrical inner wall, effects an axial and relative positioning between the shaft and the outer cylindrical member while establishing a detachable connection therebetween.

Owner:HITACHI ASTEMO LTD

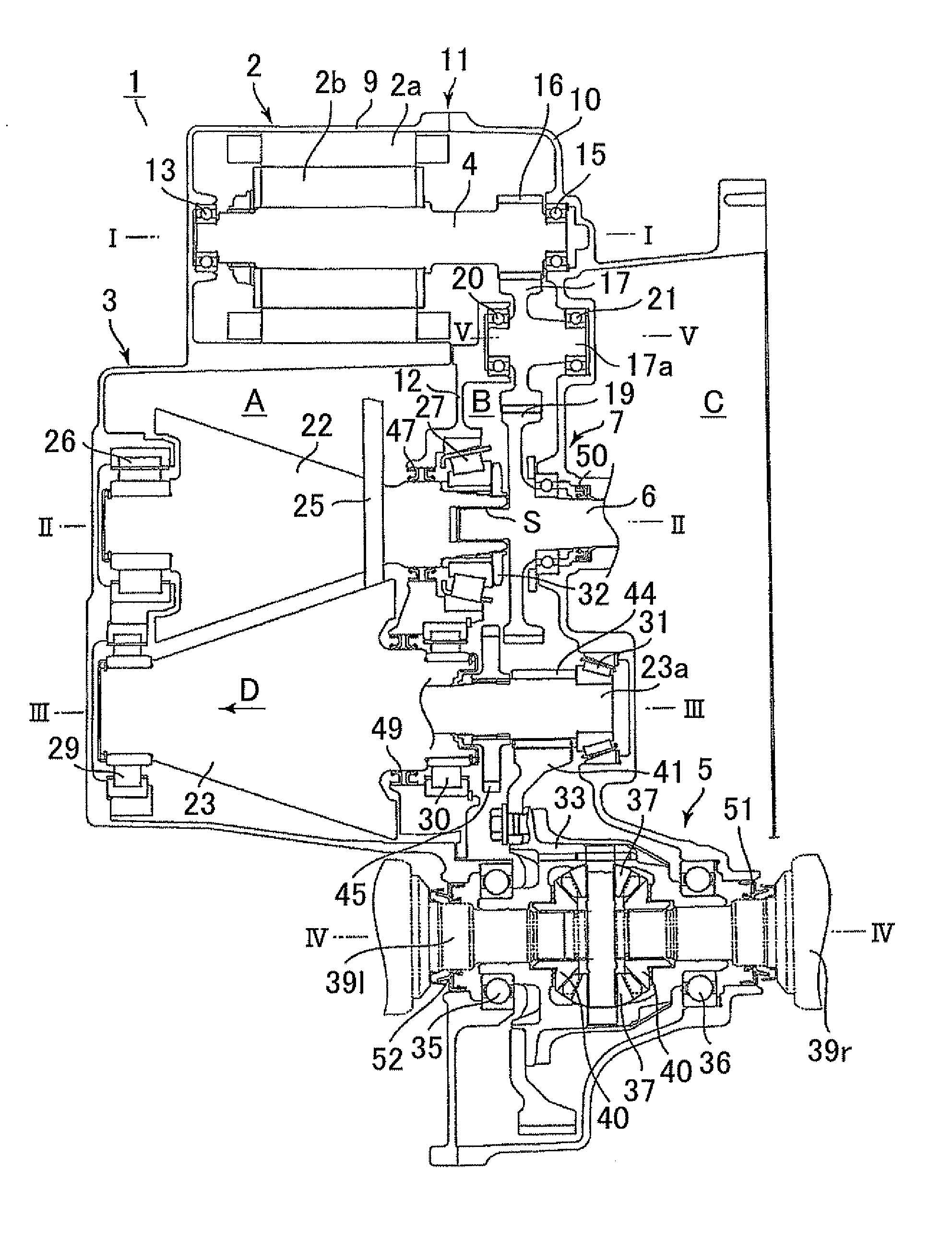

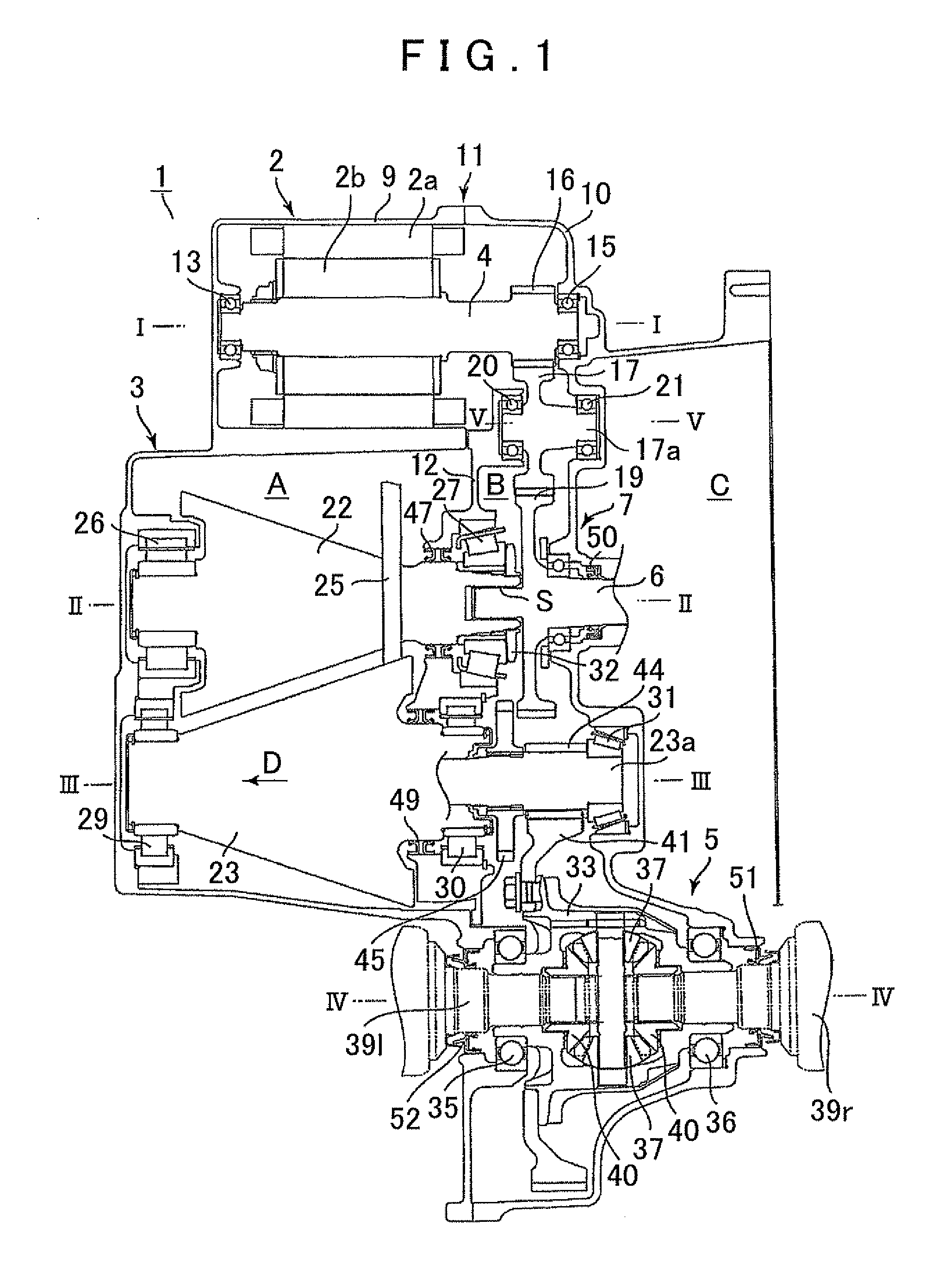

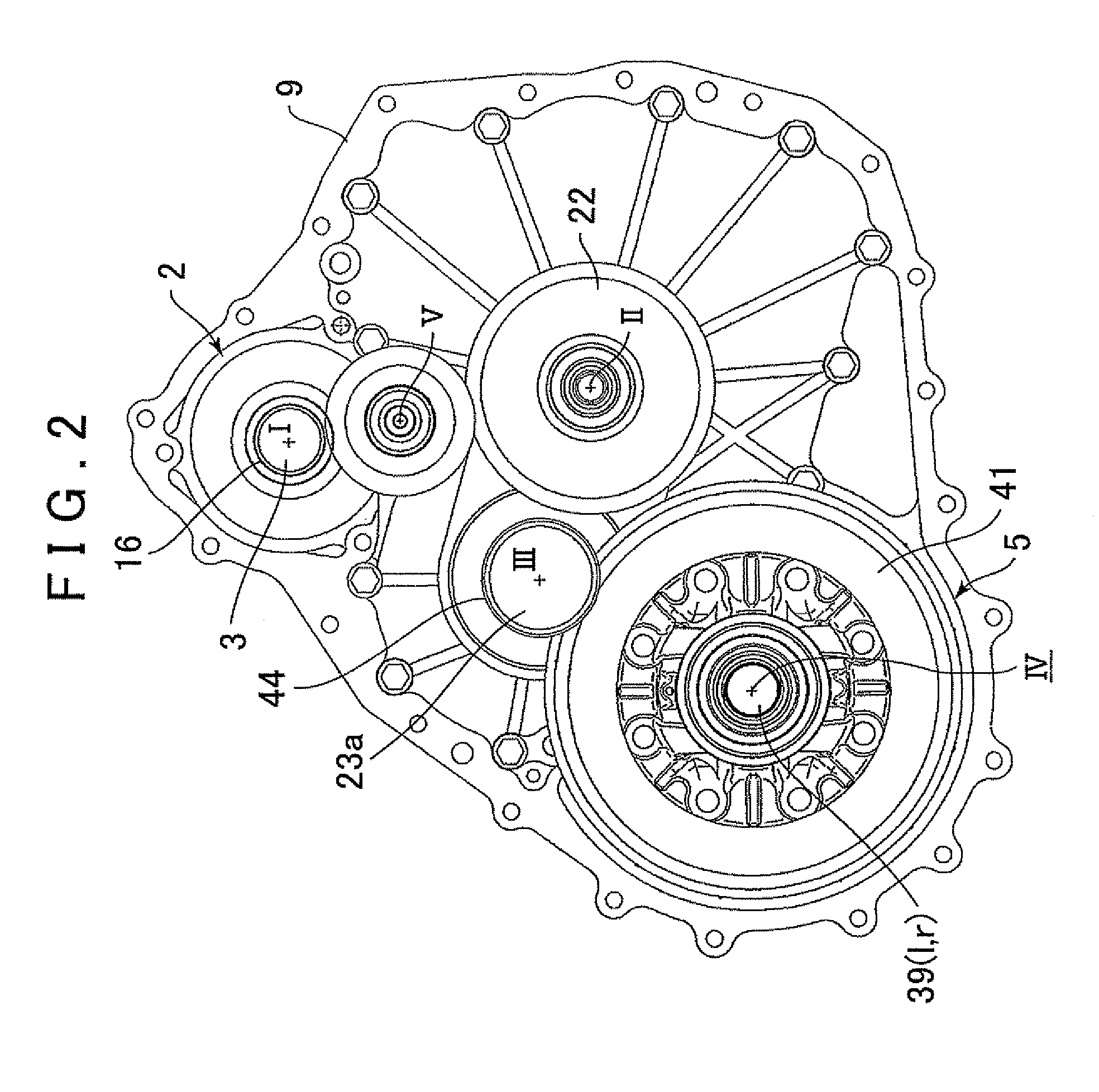

Hybrid drive system

InactiveUS20110070995A1Reliable torque transmissionImprove accuracyGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingContact positionControl theory

A hybrid drive system configured with an input shaft and a friction type continuously variable transmission (CVT) device. The CVT includes an input member drivingly connected to the input shaft, and an output member. Rotation of the input member is steplessly changed in speed and transmitted to the output member by a shear force of an oil film interposed at the contact position. The drive system includes an electric motor having a dedicated output shaft, a differential device, and a gear transmission device that is structured from a meshing rotary transmission mechanism. A case includes at least a first space filled with traction oil and accommodating the CVT device, and a second space filled with lubricant oil and accommodating the gear transmission device.

Owner:AISIN AW CO LTD

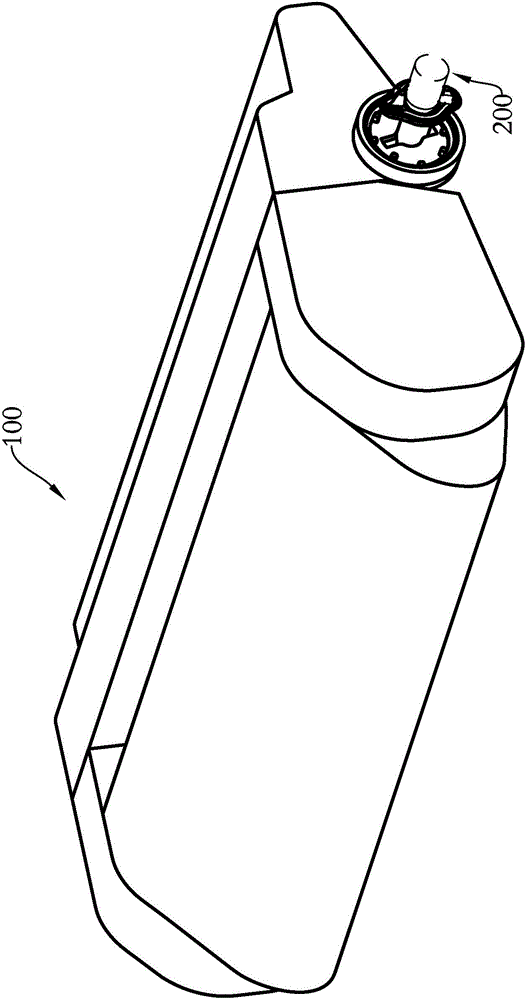

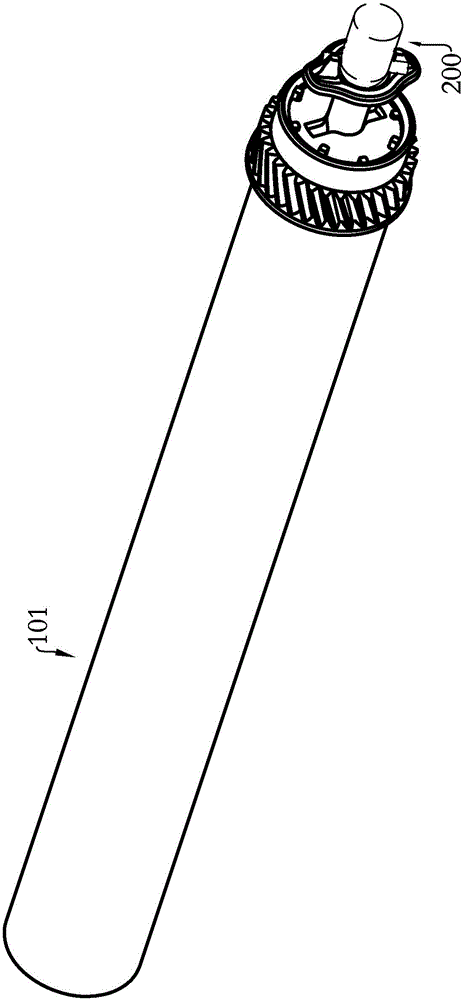

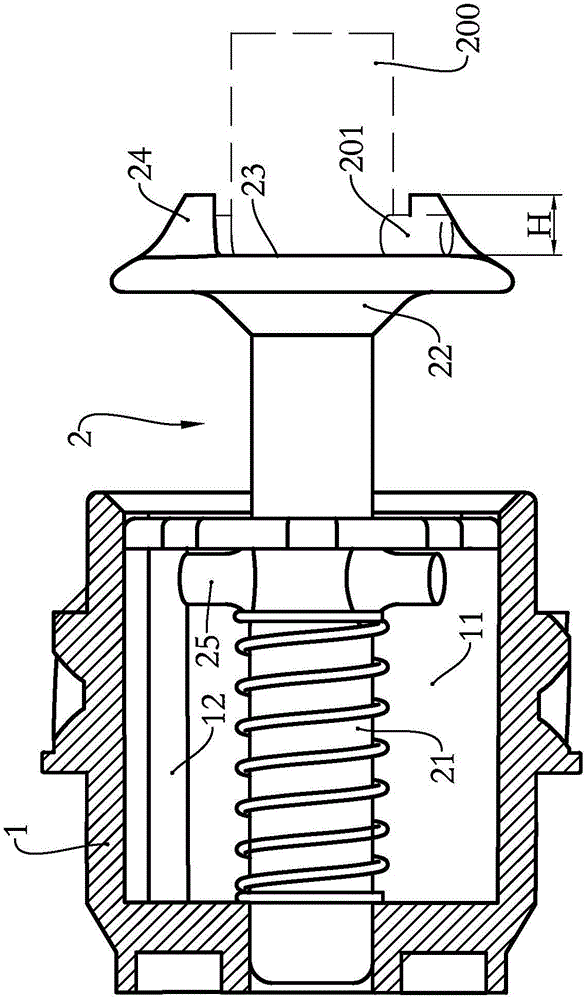

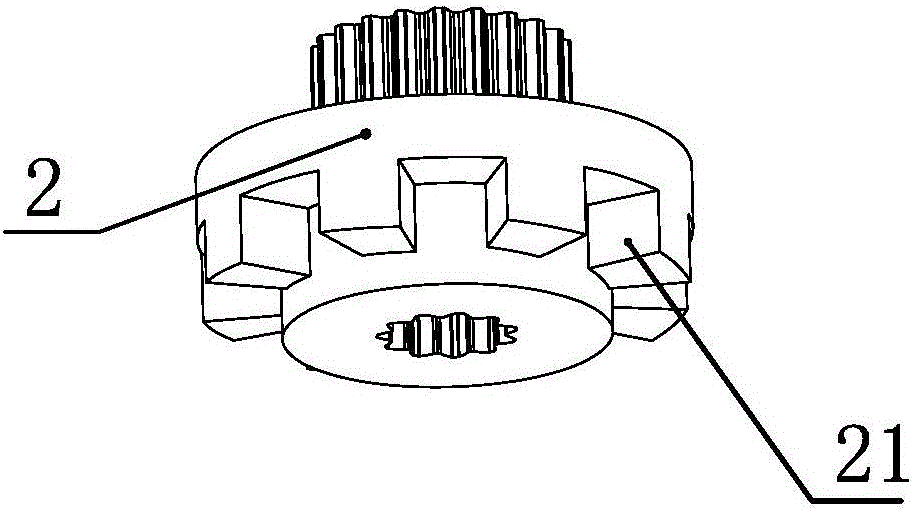

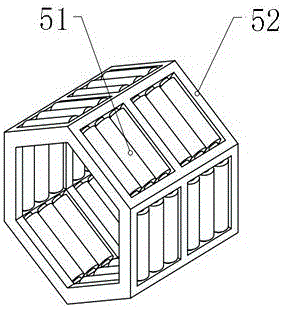

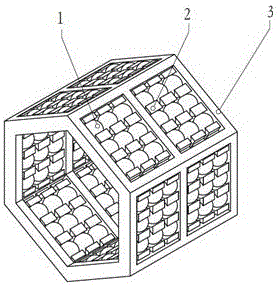

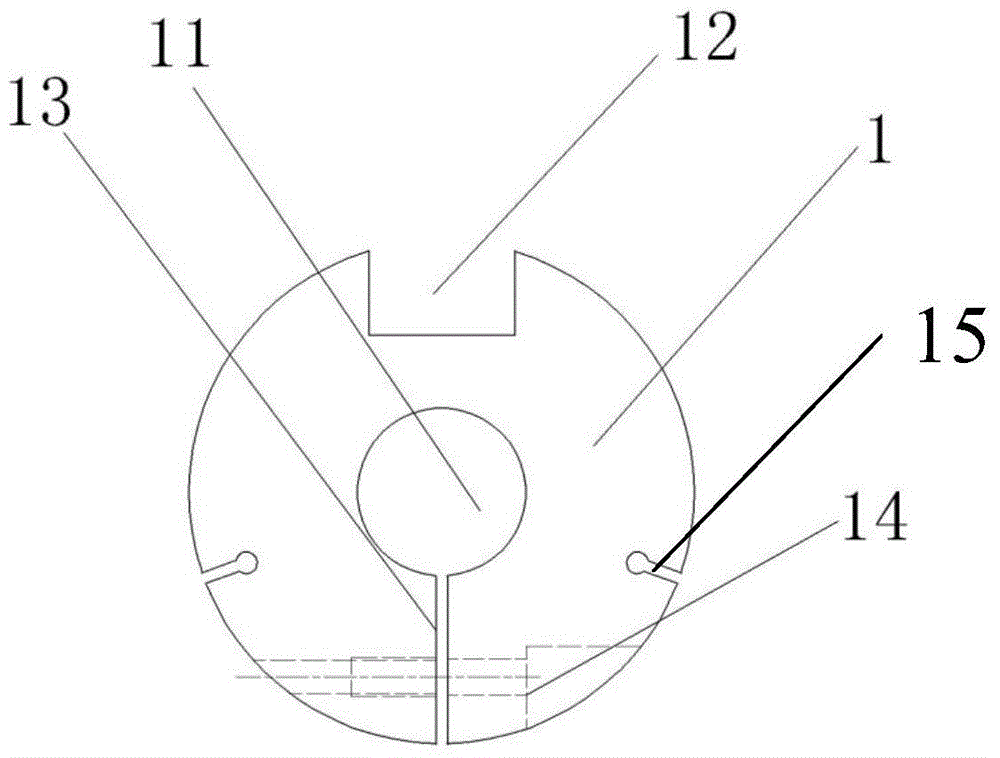

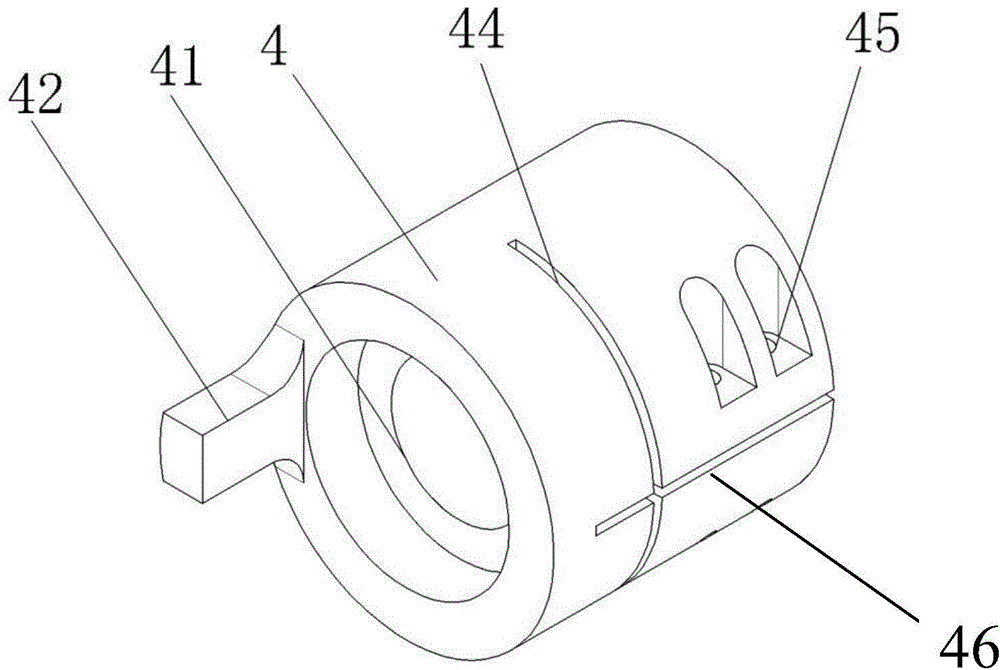

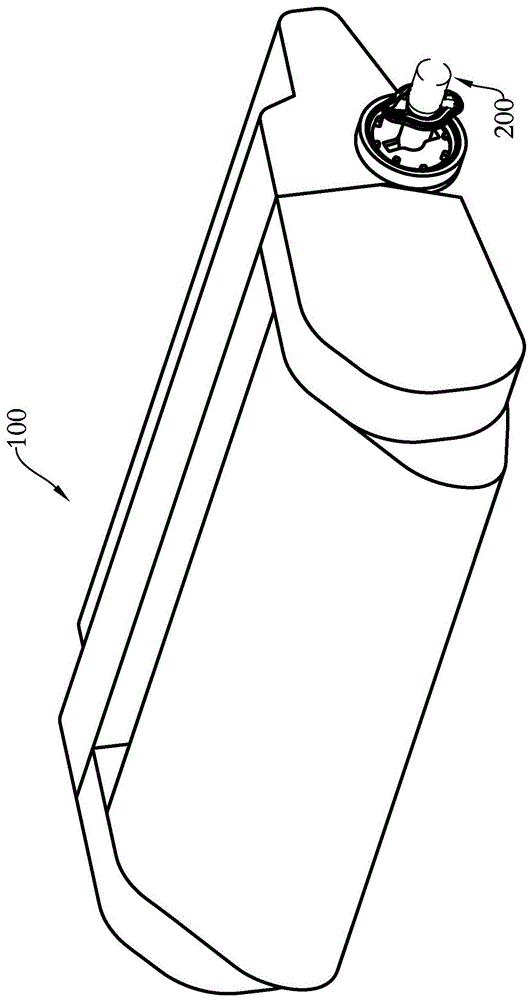

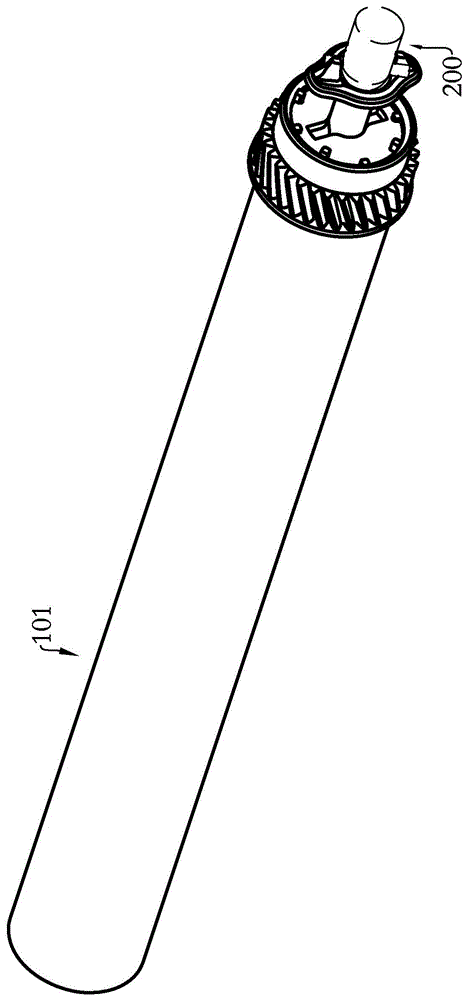

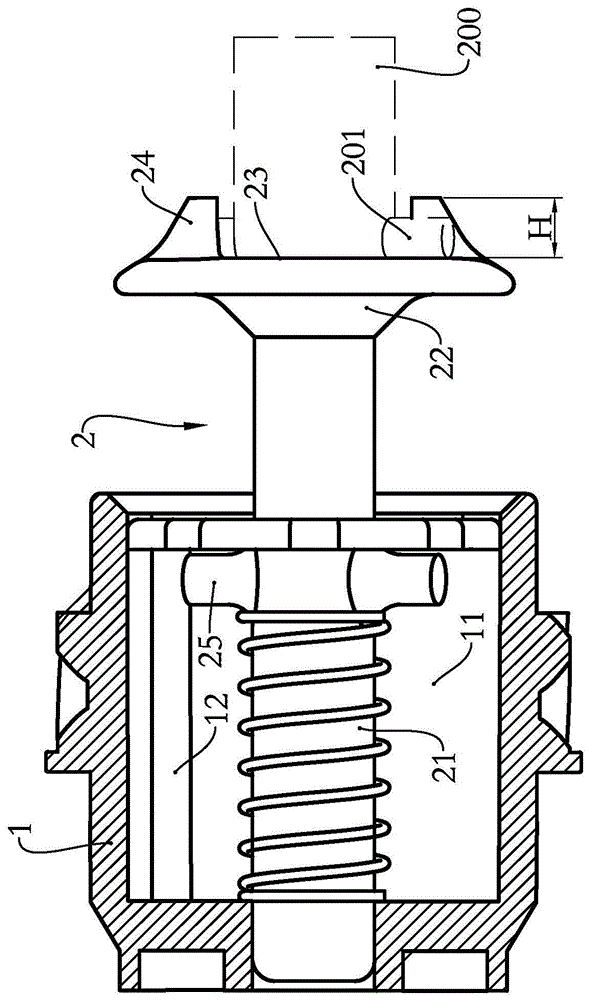

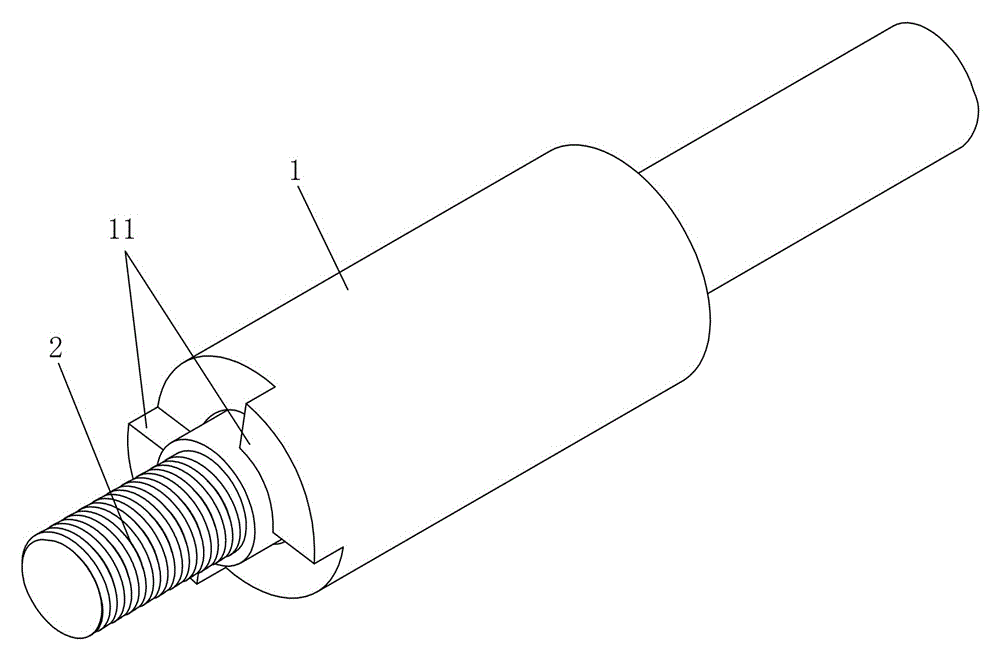

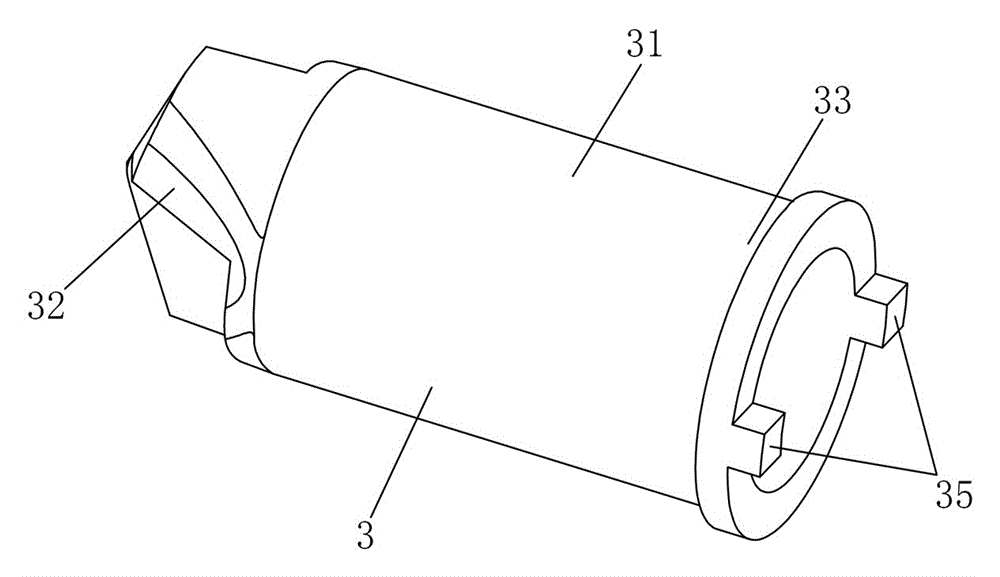

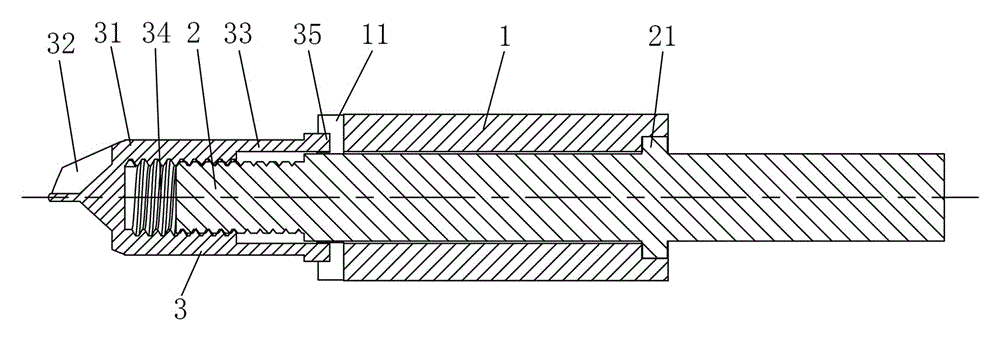

Torque receiving assembly, photosensitive drum, and process cartridge

ActiveCN104155864AReliable torque transmissionAvoid stickingElectrographic process apparatusTorque transmissionEngineering

The invention relates to a torque receiving assembly, a photosensitive drum taking the torque receiving assembly as a constituent part, and a process cartridge The torque receiving assembly comprises a body and a driven rod. The driven rod comprises a guiding column and an input head arranged on the length direction side of the guiding column. An embossment, which extends outwards along the length direction of the guiding column, is arranged on the outer end wall, whose back is opposite to the guiding column in the length direction of the guiding column, of the input head. The H value of the embossment satisfies a relationship formula as follows: h<H<=h+r; wherein H represents the distance between the outer end wall and the end point that extends outwards; h represents the distance from the outer end wall to the central line of a cylindrical output gear, when a driving rod and the driven rod are engaged to transfer torques; and r represents the radius of the cylindrical output gear. The torque receiving assembly has he advantages of stable torque transmission and smooth disengagement.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

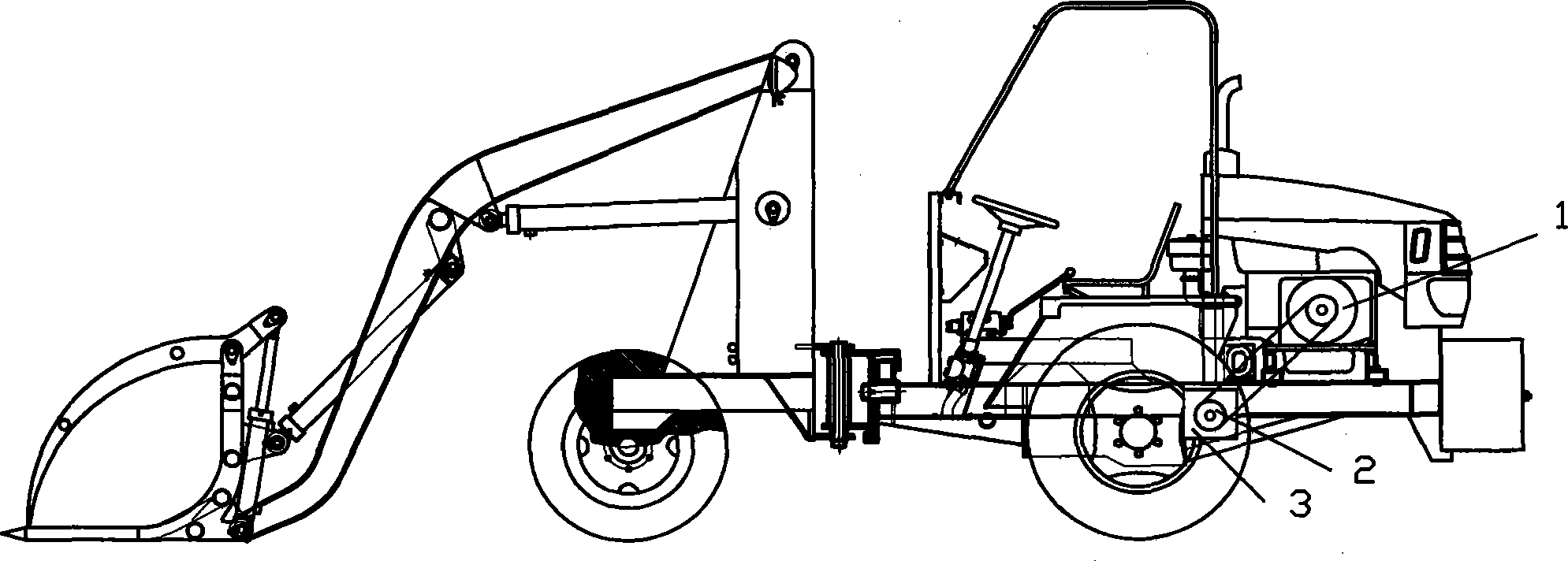

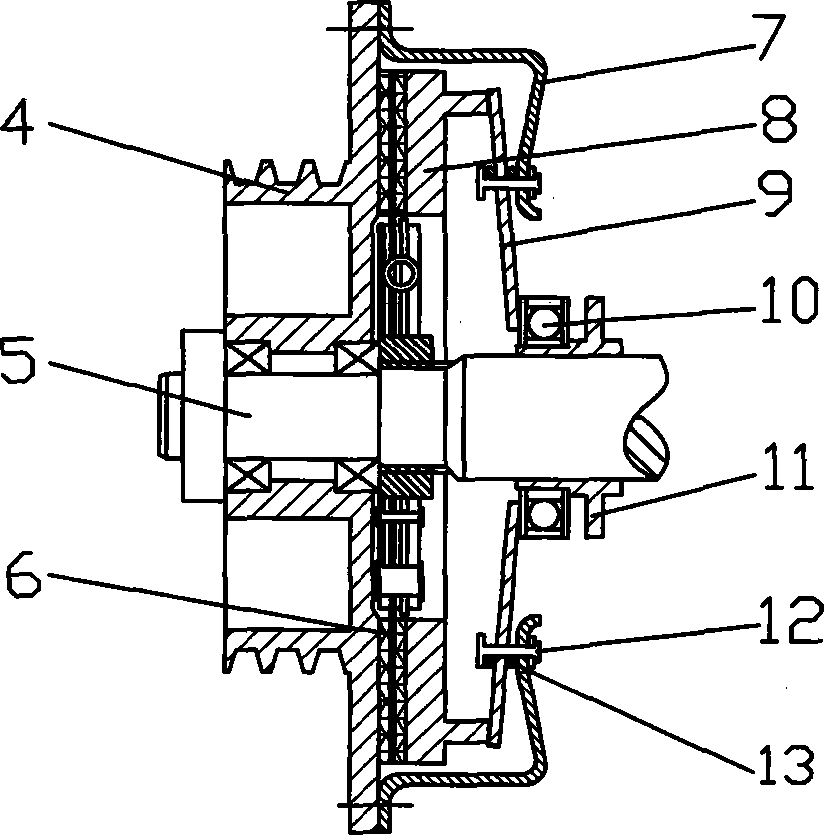

Grass grasping machine with diaphragm spring clutch

InactiveCN103362975AAutomatically adjust the pressing forceSeparation saves effortMechanical machines/dredgersFriction clutchesTorque transmissionRivet

The invention discloses a grass grasping machine with a diaphragm spring clutch. A clutch is the diaphragm spring clutch, and comprises a clutch cover, a friction plate, a pressure plate, support rings, a diaphragm spring and a driving spring, wherein a clutch belt pulley is fixedly connected with the outer edge of the clutch cover; the friction plate is clamped between the end face of the clutch belt pulley and the pressure plate; the driving spring is connected to the outer peripheral surface of the pressure plate; the other end of the driving spring is connected with the clutch cover; the inner edge of the clutch cover is connected with the diaphragm spring through rivets; two support rings which are same are arranged between the two lateral surfaces of the diaphragm spring and the rivets; the outer periphery of the diaphragm spring contacts with the raised part of the lateral surface of the pressure plate; and the inner periphery of the diaphragm spring contacts with a separation bearing. According to the grass grasping machine, a riveting structure is adopted for a diaphragm of the diaphragm spring clutch of the grass grasping machine, and separation gaps between every two of a plurality of separation claws are the same, and are not required to be regulated respectively; and the clutch of the grass grasping machine functions as a pressure element and a separation lever, so that the clutch is uniform in pressure, stable and reliable in torque transmission, smooth in jointing and convenient to operate.

Owner:LINYING COUNTY YING MACHINERY MFG

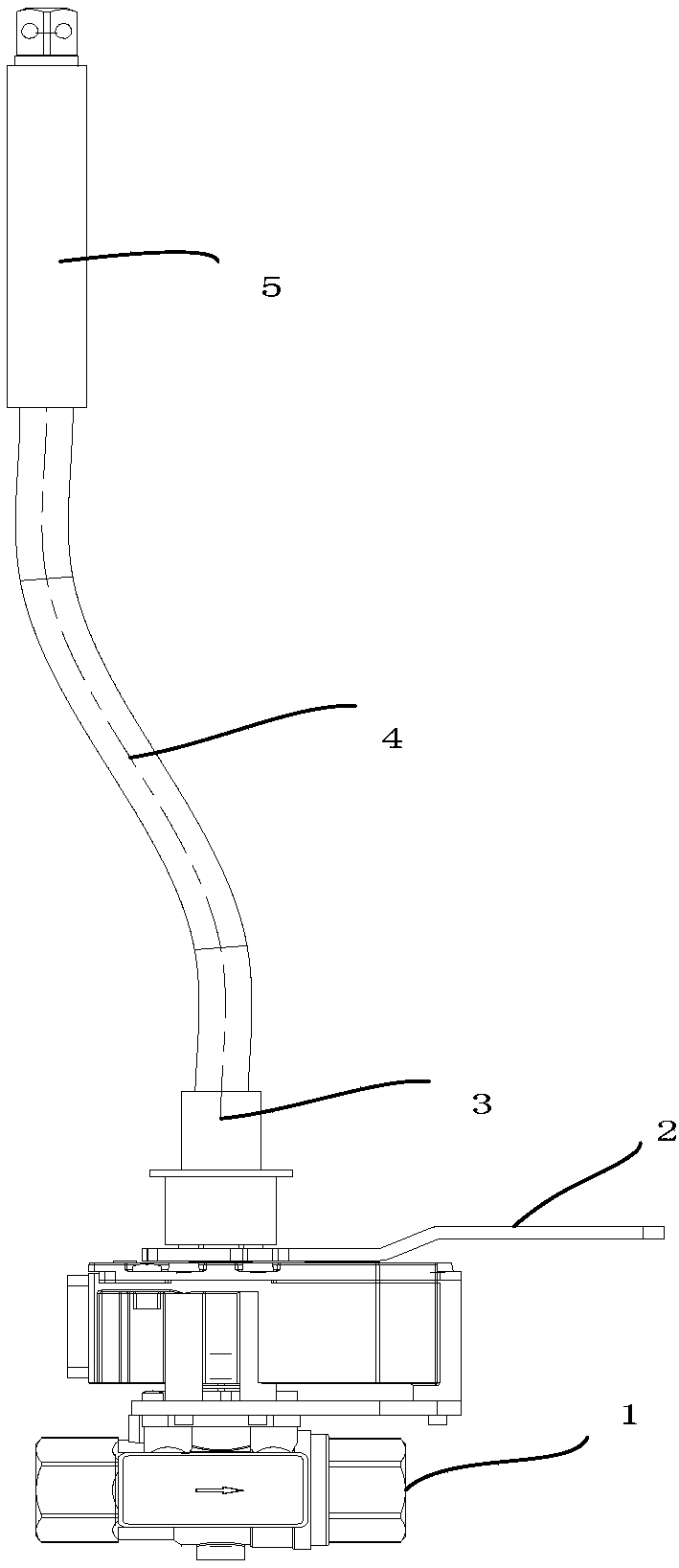

Manual release device for air brake

The embodiment of the invention provides a manual release device for an air brake. The manual release device comprises a cut-out cock, a first operation handle, a flexible shaft and two connection devices, wherein the cut-out cock is provided with a first rotating rod; the first end of the first rotating rod is connected with a valve core of the cur-out cock; the first rotating rod is provided with first grooves; one of the connection devices comprises steel balls, a clamping sleeve, springs and a connection body; the first end of the connection body is provided with a holding cavity and the second end thereof is connected with the flexible shaft; stopping parts are arranged at the circumference of the first end of the connection body; first through holes are arranged at the outer wall ofthe holding cavity; the clamping sleeve is sleeved on the connection body; the inner wall of one end, which is away from the flexible shaft, of the clamping sleeve is provided with second grooves; oneend of each spring is connected to the outer wall of the connection body and the other end thereof is connected to the inner wall of the clamping sleeve; the first end of the connection body of the one connection device is connected with the second end of the first rotating rod; and the other connection device is arranged in a vehicle body. The manual release device for the air brake can realizethe cutoff and recovery operation of air supply for braking in a vehicle or under the vehicle.

Owner:CRRC TANGSHAN CO LTD

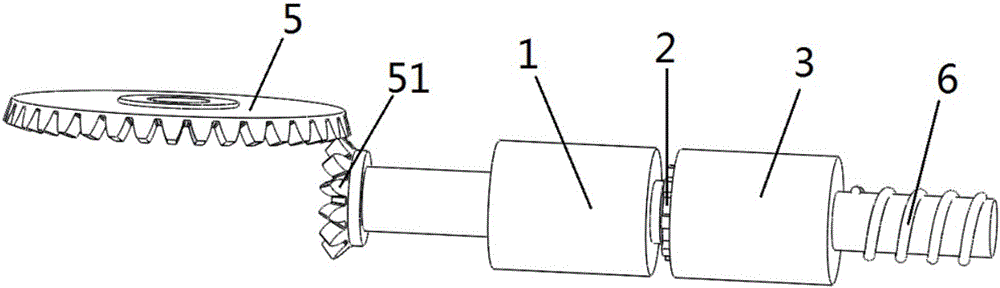

Power transmission mechanism of double-screw extrusion equipment

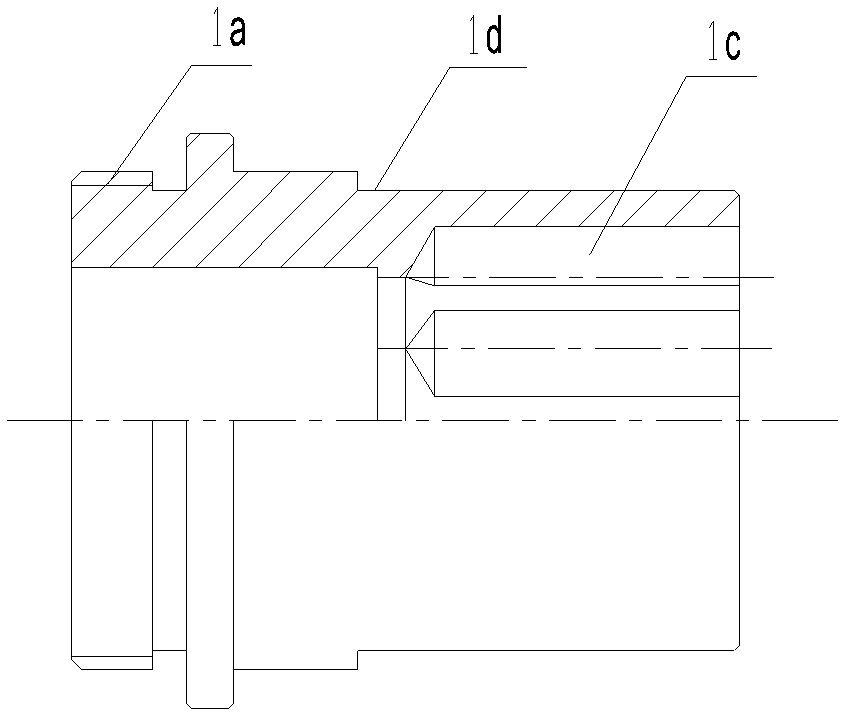

InactiveCN102318884ASimple structureImprove securityFeeding-stuffFood shapingCouplingElectric machine

The invention relates to an improved structure of double-screw extrusion equipment. The double-screw extrusion equipment is a particle-cutting power transmission mechanism in the high-heat condition. A motor (9) is installed on a fixed motor seat stand (10) and can rotate up and down or / and from side to side. Two cylindrical connectors (2) are respectively arranged in two cylindrical connecting housings (1) of a rotary fabricated coupler and are fixed through embedding of a plurality of rubber pins (3), and the two cylindrical connectors (2) are mutually inserted and connected. The cylindrical connecting housings (1), one end of each connecting housing is connected with a rotating shaft of a cutter (7) or an output shaft of the motor (9), and the inner wall of the other end of each connecting housing is uniformly provided with a plurality of semicircular outer holes (1c) in the circumferential direction. The the circumferential-direction outer wall of one end of each connector is provided with a circle of semicircular inner holes (2c), and the other end of each connector extends a convex plate (2b) or a corresponding groove (2a) to the opposite side. The rubber pins (3) are cylinders and are embedded into circular holes on the connecting housings (1) and the cylindrical connectors (2). According to the invention, the assembly space and distance are not reserved in the axial direction in order to connect the cutter with the motor of a double-screw extruder, so that the site is reduced, and the safety is improved.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

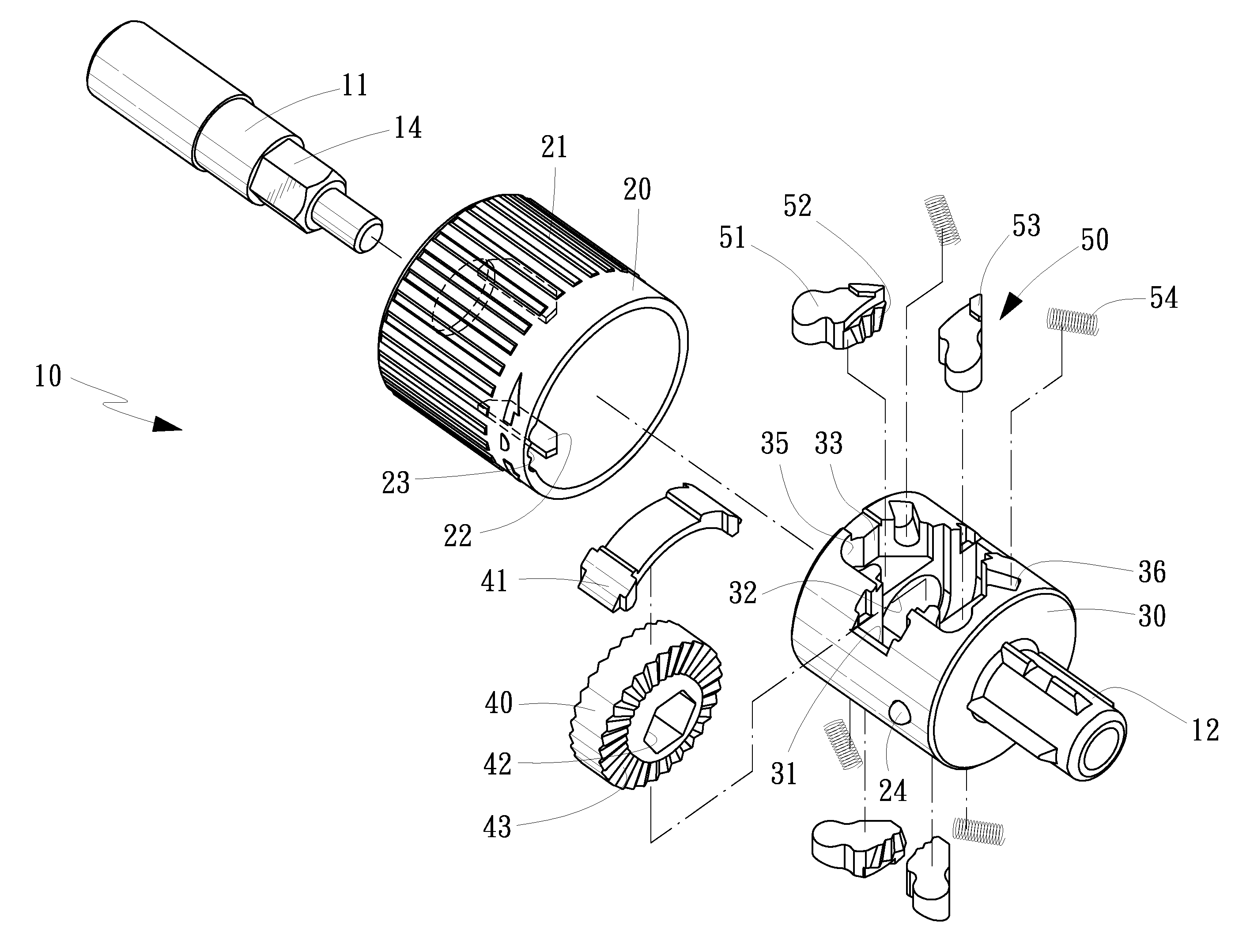

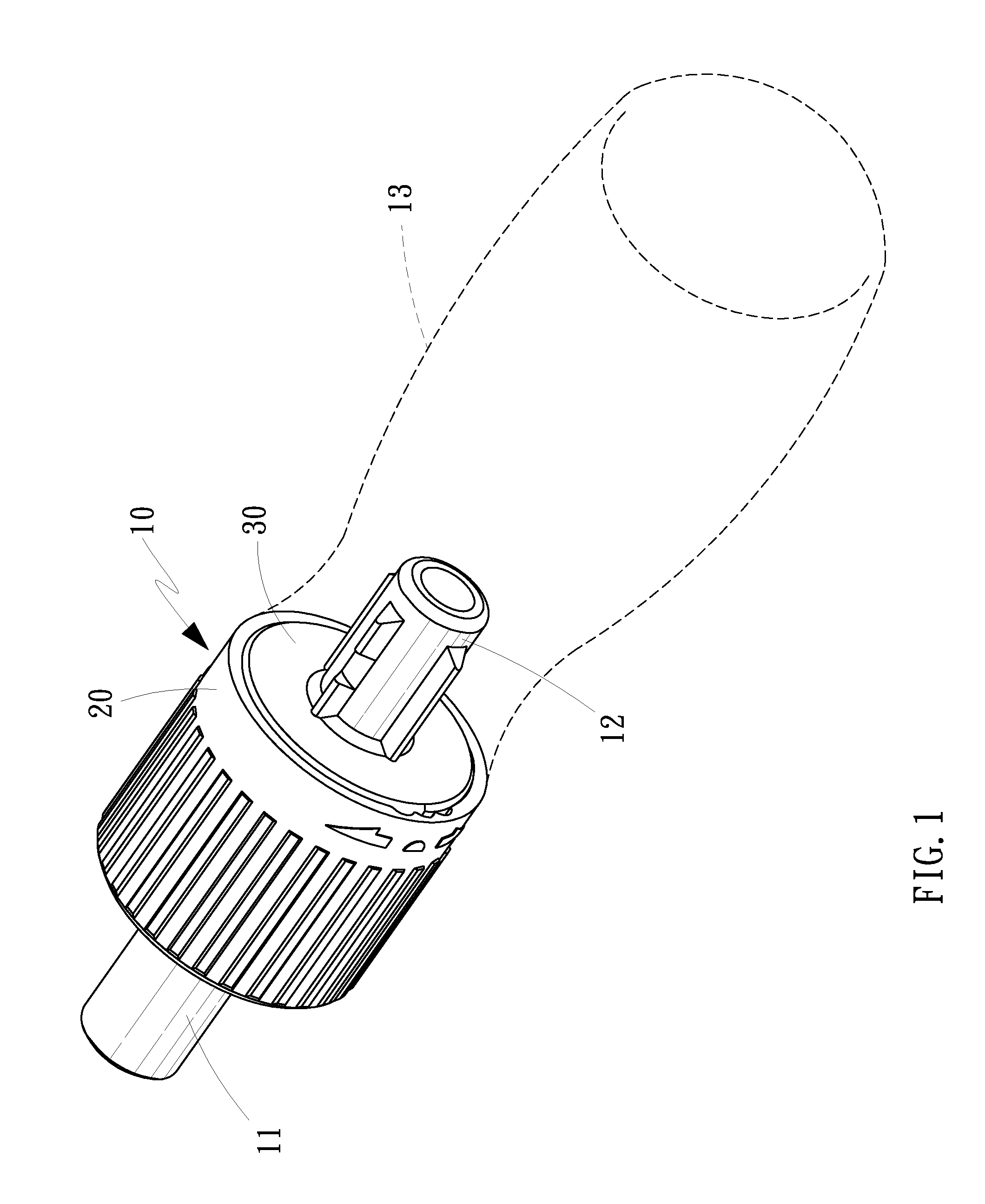

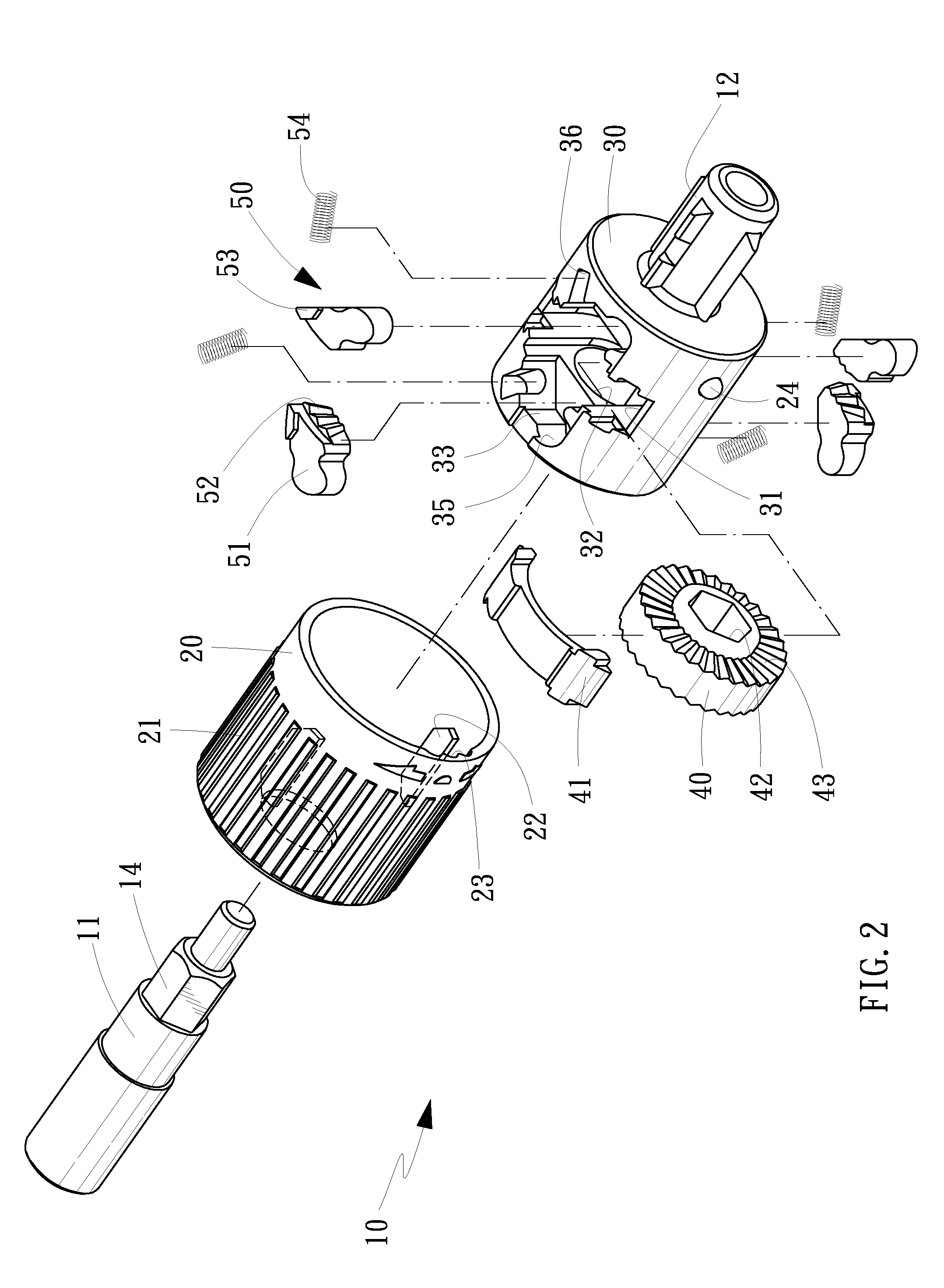

Screwdriver

InactiveUS20130112048A1Easy to assembleReliable torque transmissionSpannersWrenchesTorque transmissionEngineering

A screwdriver-used torque transmission apparatus includes a frame including a slot, an aperture and four cavities. The slot is in communication with the aperture and cavities. A gear includes a non-circular aperture axially defined therein, teeth formed on a side thereof, and teeth formed on an opposite end thereof. The gear is located in the slot. A pawl formed with at least one tooth and a block is located in each of the cavities. A shell includes two pushers formed on an internal side thereof. The shell is rotationally provided around the frame between two one-way modes in each of which a related one of the pushers pushes the blocks of two related ones of the pawls to disengage the teeth of the two pawls from the teeth of the gear.

Owner:YIH CHENG FACTORY

Drive system for a motor vehicle

InactiveUS20080179155A1Simple designEasy to installYielding couplingRotary clutchesMobile vehicleDrive shaft

A drive system for a motor vehicle comprises a drive unit with a drive shaft and a torque-transmitting assembly, which is to be connected on the drive side to the drive shaft for rotation in common around an axis of rotation (A) and which is to be connected on the takeoff side to a gearbox. The drive-side connection is accomplished by means of an axial plug-in connection arrangement, and the torque-transmitting assembly is supported in at least one axial direction on the gearbox.

Owner:ZF FRIEDRICHSHAFEN AG

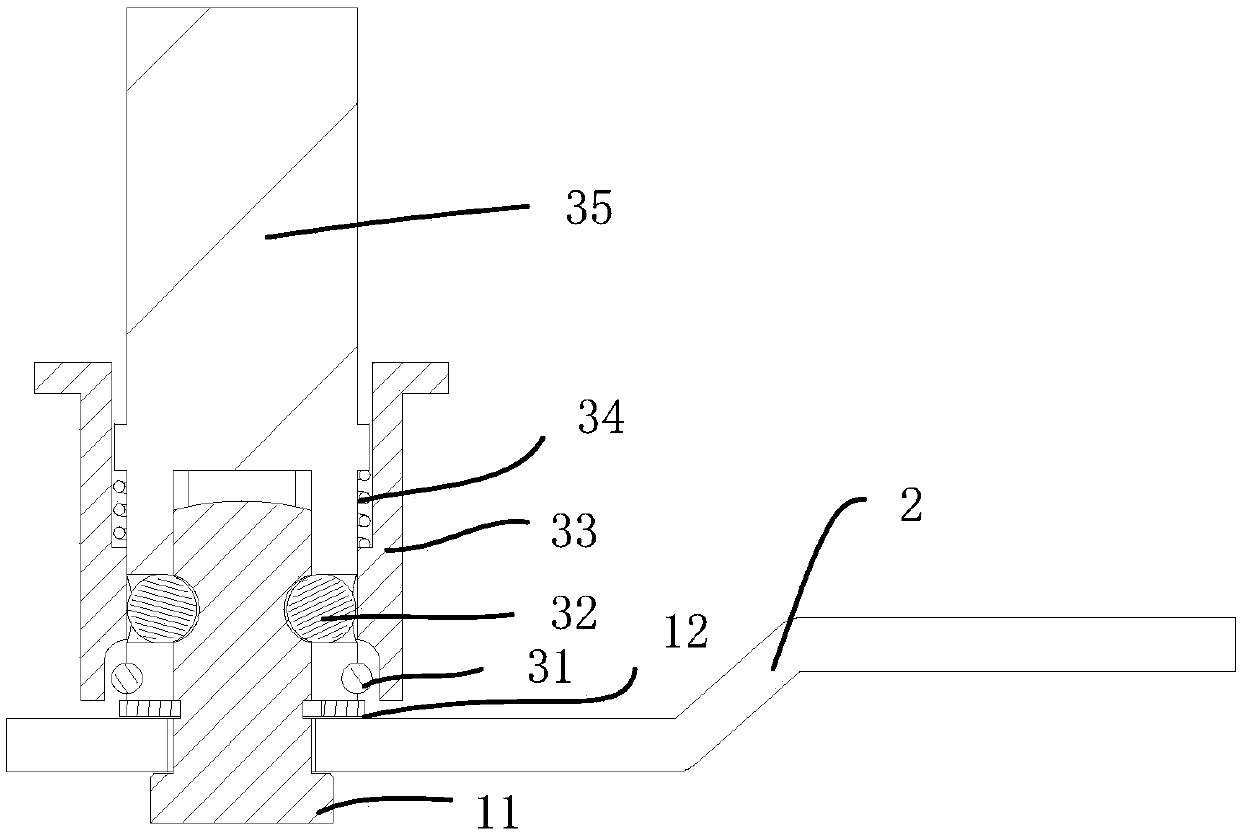

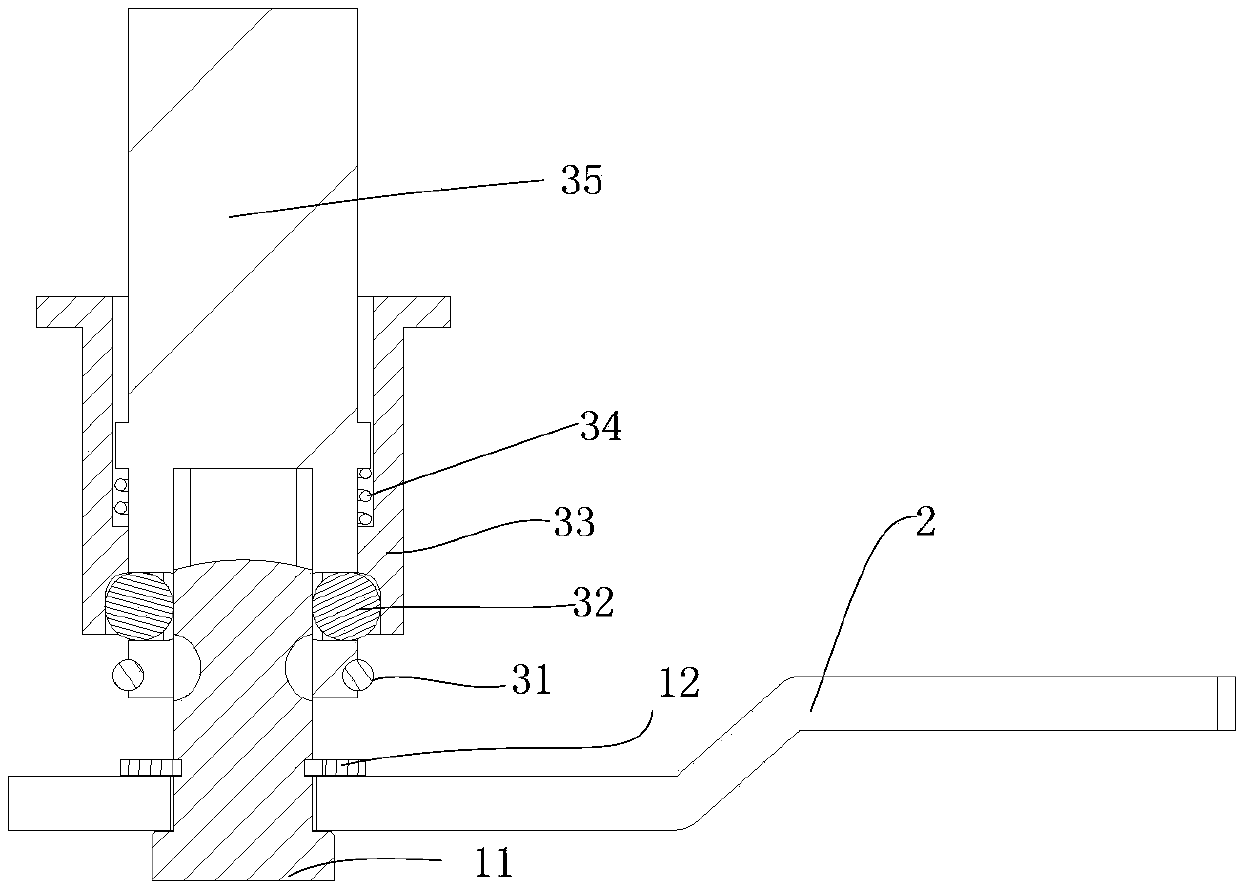

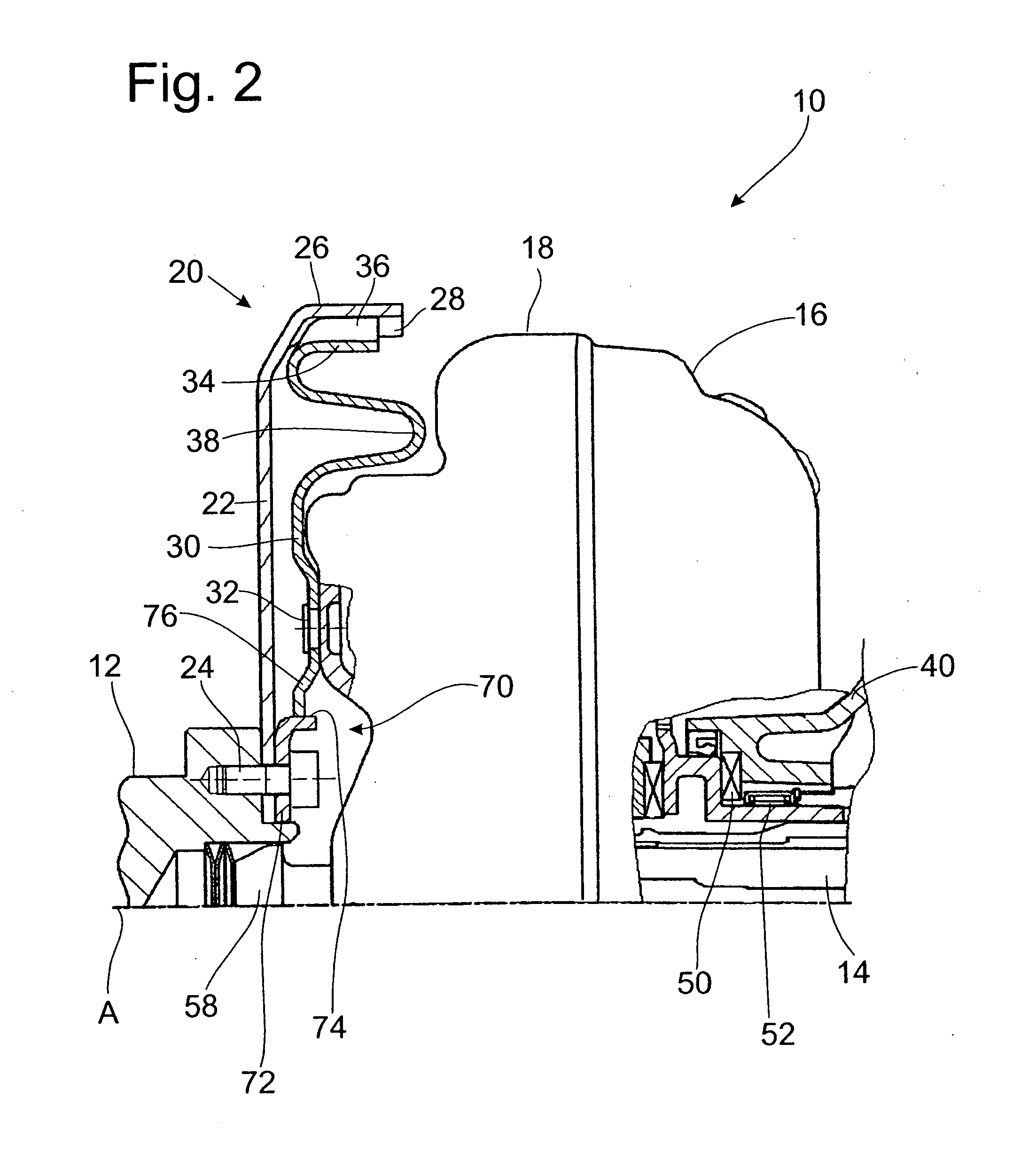

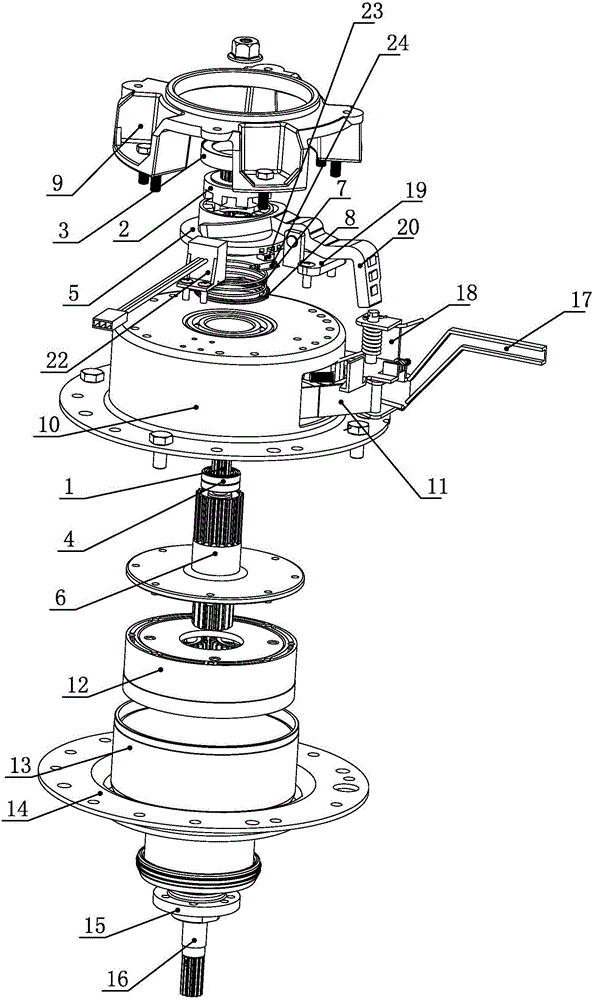

Decelerating clutch of intelligent washing machine

ActiveCN105019192AReliable clutchExtended service lifeOther washing machinesTextiles and paperTorque transmissionControl theory

The invention discloses a decelerating clutch of an intelligent washing machine. The decelerating clutch comprises an upper shell, a lower shell, a connection plate, a torque transmission shaft sleeve and a brake wheel axle. The connection plate is arranged on the brake wheel axle in a sleeving mode. The connection plate is provided with a magnet, a Hall sensor is arranged on the lower end face of the lower shell, the position of the Hall sensor is matched with the position of the magnet, and a gap is reserved between the Hall sensor and the magnet. First splines are arranged on the outer surface of the brake wheel axle, second splines matched with the first splines are arranged on the inner surface of an inner hole of the connection plate, third splines are arranged on the lower end portion of the connection plate, and fourth splines matched with the third splines are arranged on the upper end portion of the torque transmission shaft sleeve. A connection plate spring and a spring gland are arranged at the upper end of the connection plate. The spring gland is located at the upper end of the connection plate spring, and the spring gland abuts against the lower shell. According to the technical scheme, the decelerating clutch of the intelligent washing machine is reasonable in structural design, simple in structure, convenient to assemble, reliable in clutch action, stable in torque transmission and high in safety.

Owner:ZHEJIANG SANXING MECHANICAL & ELECTRONICSAL STOCK

Propeller Shaft and Constant Velocity Universal Joint Used Therein

ActiveUS20130252746A1Reliable torque transmissionAxial stabilityClutchesYielding couplingUniversal jointDrive shaft

A propeller shaft is proposed which comprises an outer cylindrical member formed with a sleeve portion that has a splined cylindrical inner wall with which a splined cylindrical outer wall of a shaft is engaged; an inner cylindrical member installed in the outer cylindrical member; a torque transmitting unit through which a torque is transmitted from the outer cylindrical member to the inner cylindrical member; and a connecting mechanism that, upon engagement of the splined cylindrical outer wall with the splined cylindrical inner wall, effects an axial and relative positioning between the shaft and the outer cylindrical member while establishing a detachable connection therebetween.

Owner:HITACHI ASTEMO LTD

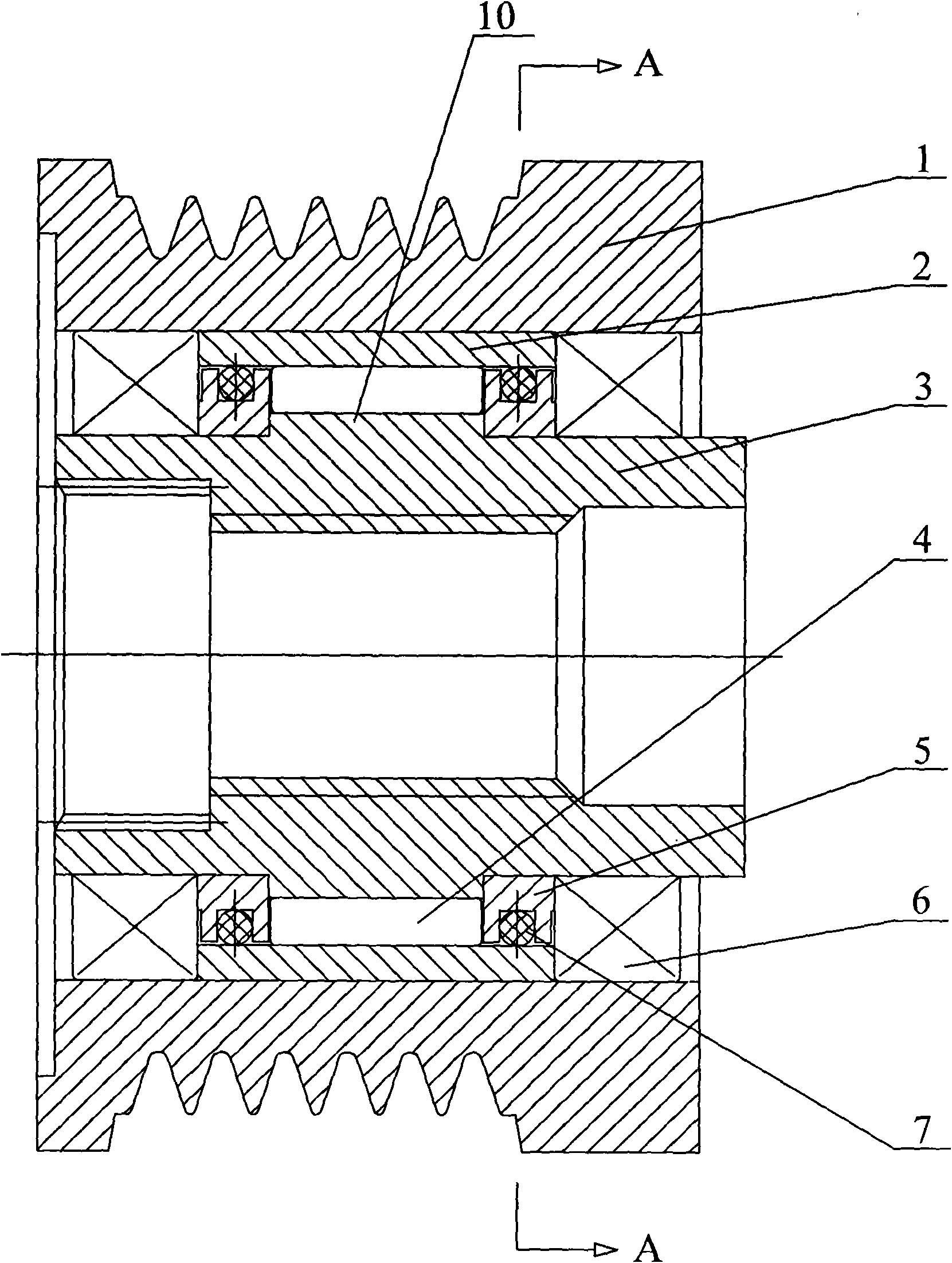

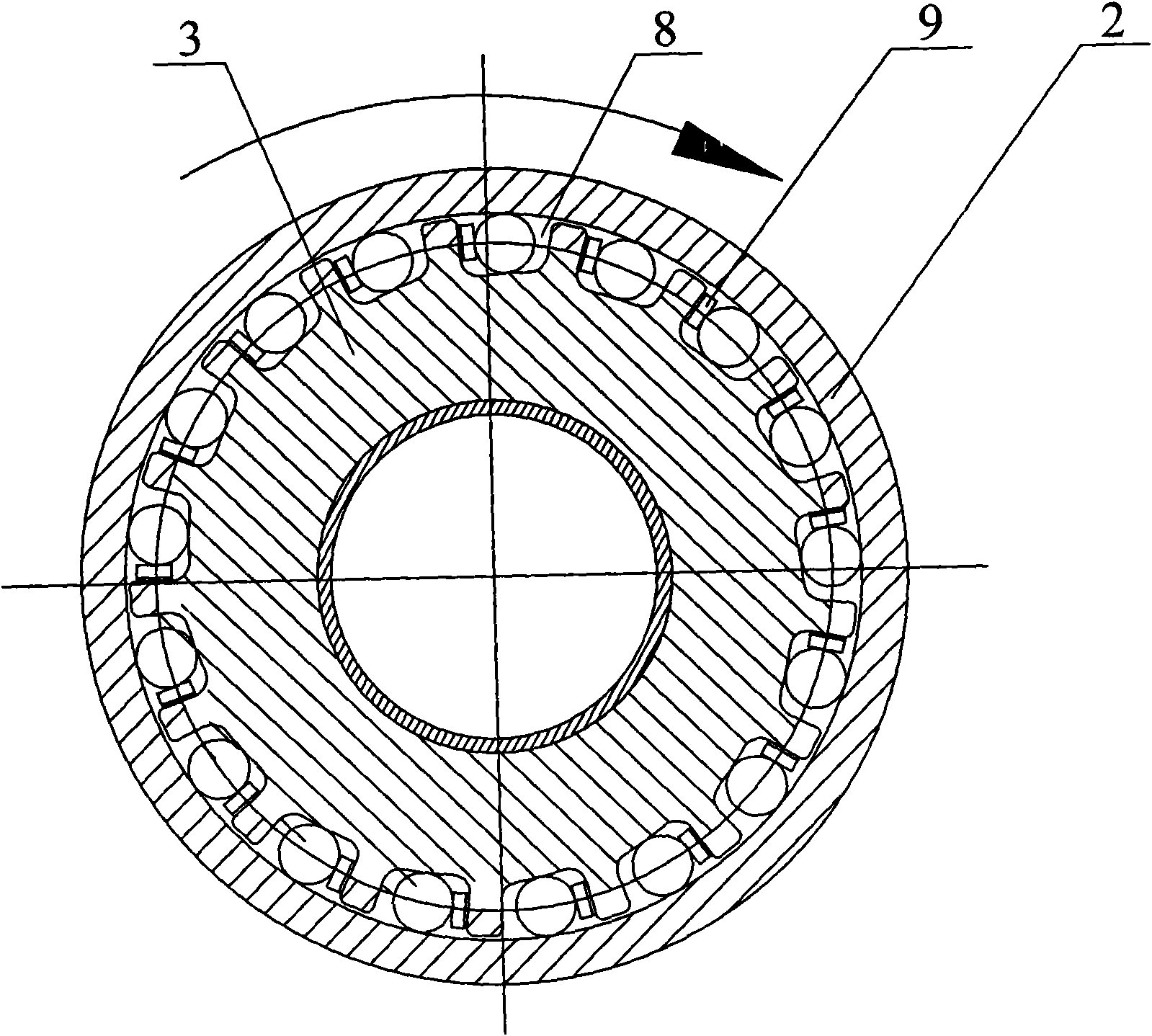

Unidirectional pulley

ActiveCN101644320ANon-slip friction phenomenonReduce generationPortable liftingGearing elementsEngineeringElectric generator

The invention relates to a unidirectional pulley. An inner ring body is sleeved outside a mandrel connecting sleeve, a pulley is sleeved outside the inner ring body, the left end and the right end ofthe mandrel connecting sleeve are sleeved with bearings, the inner surfaces of inner rings of the bearings are in contact with the outer surface of the mandrel connecting sleeve, the outer surfaces ofouter rings of the bearings are in contact with the inner-hole wall surface of the pulley, the inner ring body sleeve is sleeved outside the mandrel connecting sleeve arranged between the opposite end surfaces of the two bearings, the outer surface of the mandrel connecting sleeve arranged between the opposite end surfaces of the two bearings is provided with a curved surface die cavity, a rollerpin is arranged in the curved surface die cavity, the cross section of the curved surface die cavity is in a wedge shape, the small end of the curved surface die cavity is consistent with a rotatingdirection of an electric generator in a working process, the large end of the curved surface die cavity is provided with a restoring spring, the restoring spring is supported to the roller pin and pushes the roller pin to the small end of the curved surface die cavity, and a sealing device is sleeved on the mandrel connecting sleeve. The unidirectional pulley eliminates the phenomenon that the pulley skids when running at high speed and solves the conflict between spring thrust and frictional resistance.

Owner:无锡市神力齿轮冷挤有限公司

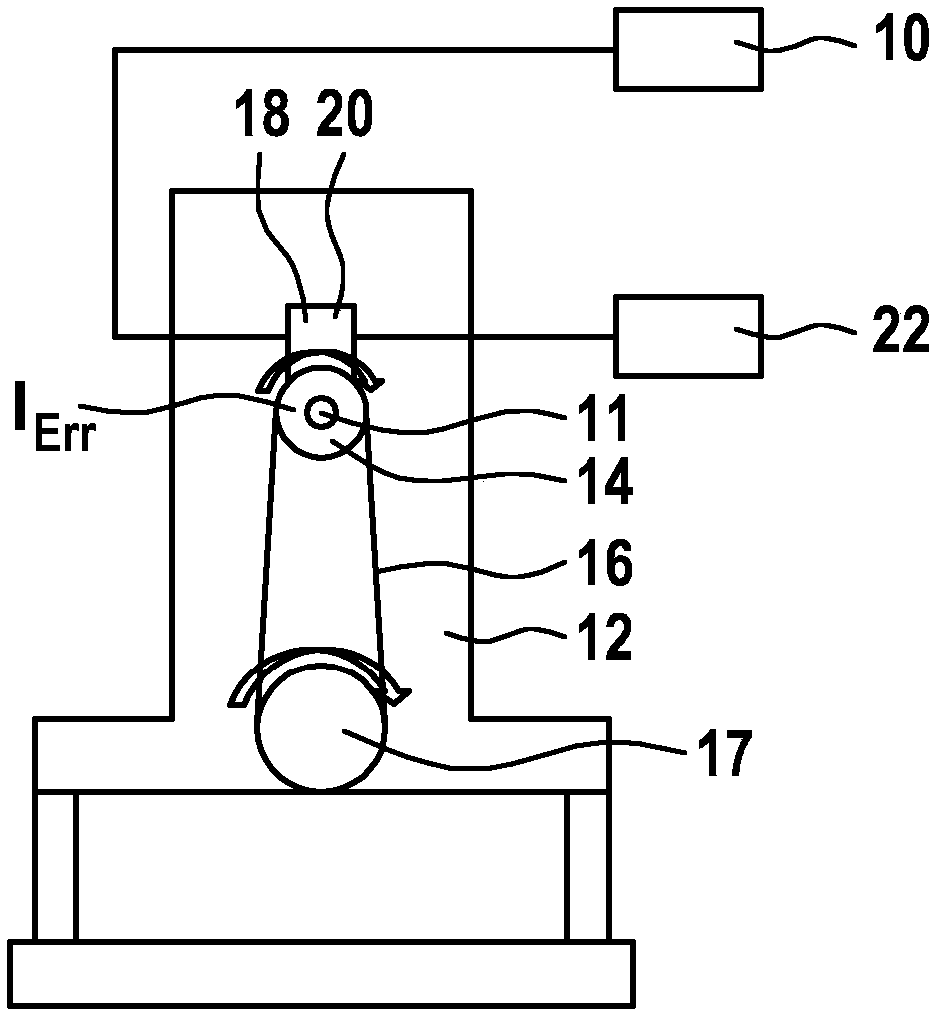

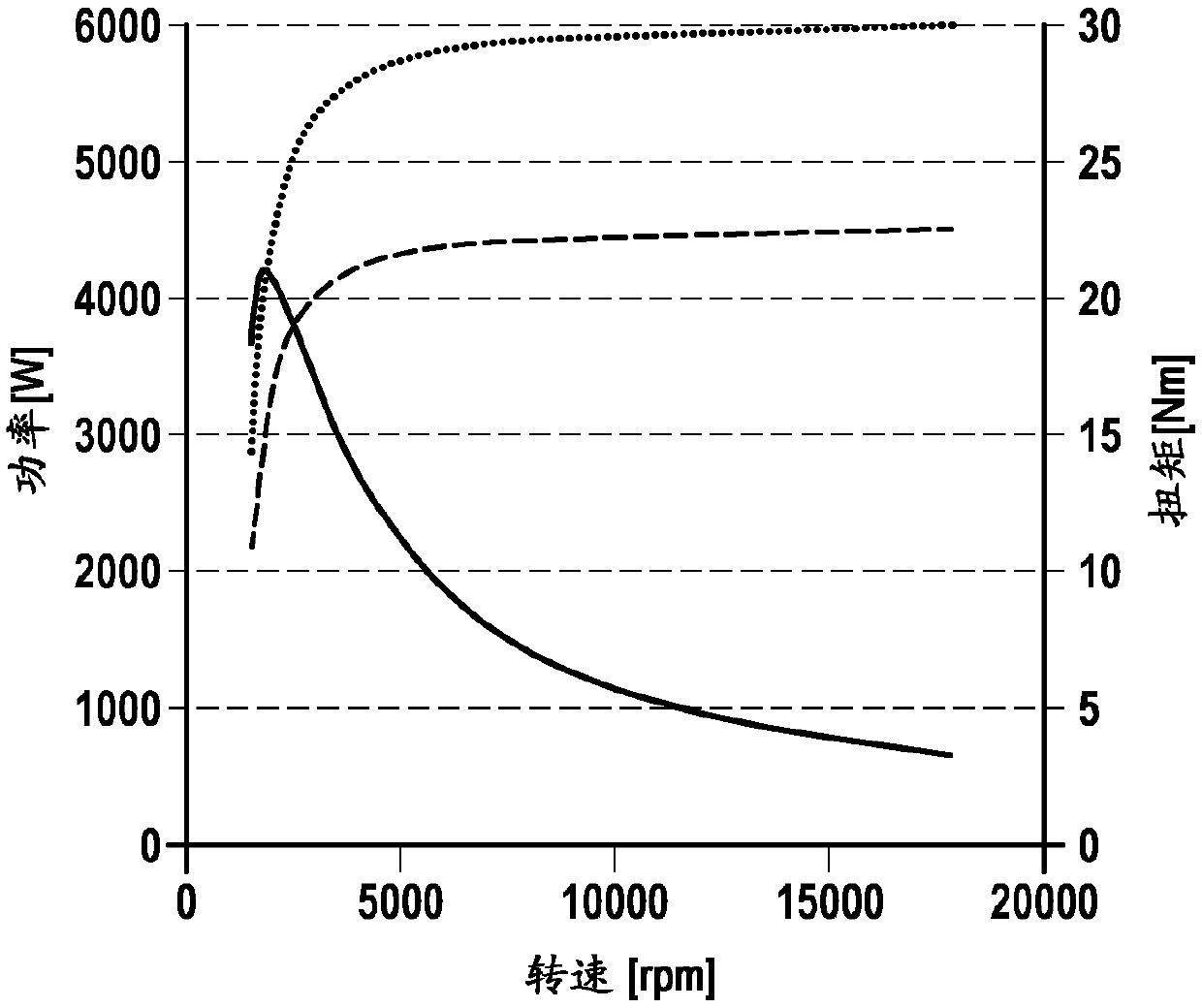

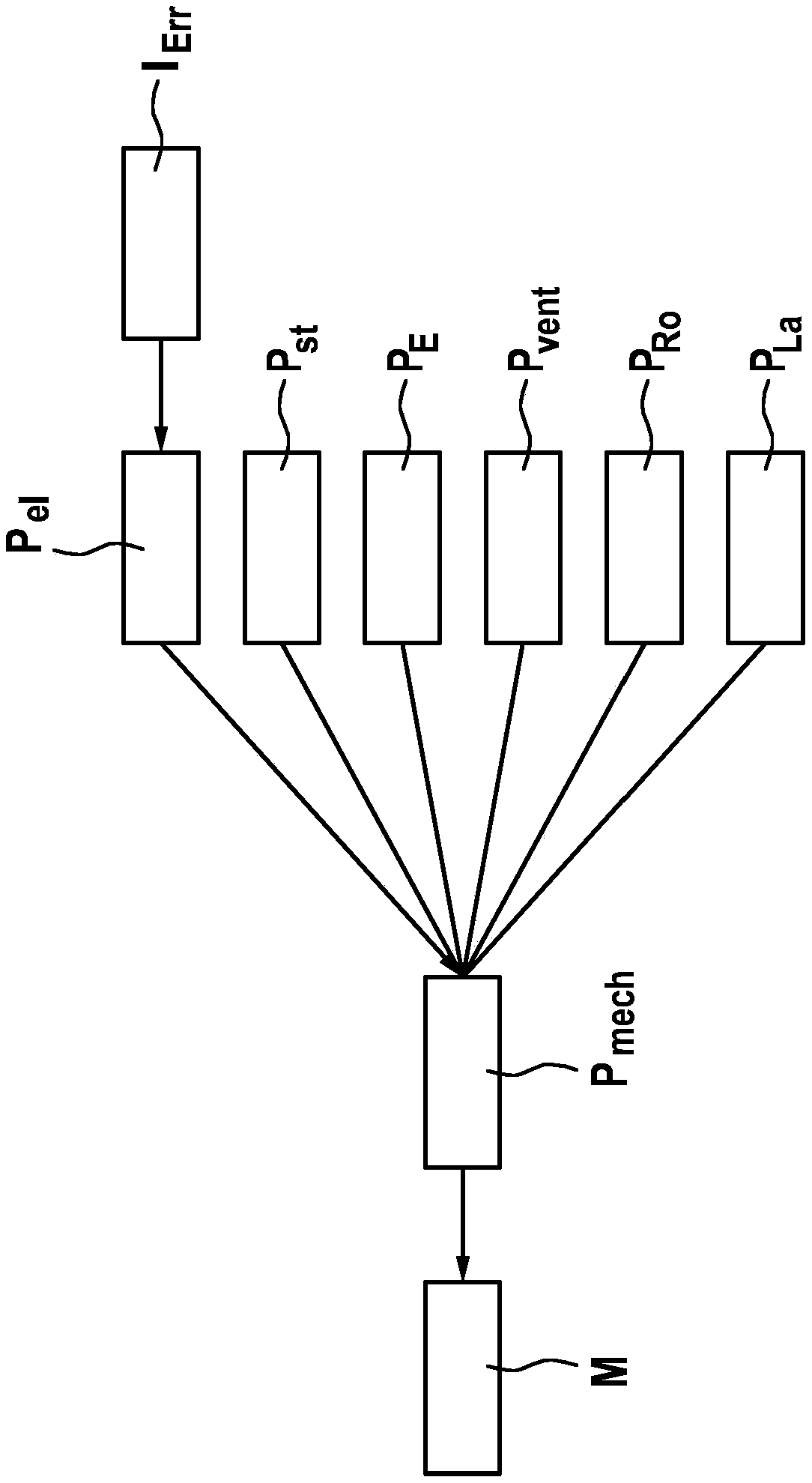

Determining operating mode of electrical machine coupled to internal combustion engine

InactiveCN108603804ARun without damageDeceleration torque to overcomeInternal-combustion engine testingMachine gearing/transmission testingExternal combustion engineInternal combustion engine

The invention relates to a method for determining an operating mode of an electrical machine (114) coupled to an internal combustion engine (112), the method comprising the steps: detecting a plot against time of a phase signal (121) of the electrical machine (114); determining a plot against time of a speed (122) of the electrical machine (114), the speed having oscillating speed oscillations; and determining the operating mode of the electrical machine (114) by comparing the plot against time of the phase signal (121) of the electrical machine (114) and the plot against time of the speed (n). The invention also relates to a corresponding arithmetic unit (118), configured for carrying out the method, and to a corresponding computer programme.

Owner:ROBERT BOSCH GMBH

Tapping chuck

The invention discloses a tapping chuck comprising a handle, a torque adjusting mechanism, an engaging and disengaging mechanism and a screw tap clamping mechanism. The torque adjusting mechanism is rotatablely folded in the middle part of the handle of the tapping chuck; the engaging and disengaging mechanism is arranged on one side of the torque adjusting mechanism; the screw tap clamping mechanism comprises a chuck, a joint, two steel balls and a locking ring; the steel balls are respectively arranged in a pair of symmetrical holes which are disposed on the outer circumferential surface of the chuck body; the inner sides of the steel balls are leaned against the joint; the locking ring is sleeved on the outer circumferential surface of the chuck body and compresses tightly the outer sides of the steel balls; one end surface of the chuck body, which is far from one side of the edge of a flange, is provided with symmetrical bosses; and the bosses are clamped in the flange clamp slot of the joint. The tapping chuck can transmit the torque reliably without sliding, ensure the processing precision of the processed threaded hole and lock reliably, and the joint of the tapping chuck can be replaced conveniently and easily.

Owner:CSSC MARINE POWER

Combination tool

The present invention provides a combination tool, including a tool shaft (11) with an inner part (12) and an outer part (13), a first tool head (14) that is integrally formed on the inner part (12) and a differently designed second tool head (15) that is integrally formed on the outer part (13). The tool shaft (11) is realized in such a way that it can be inserted into a machine and features at least one holding element (16) for mounting a tool head (14, 15) thereon in a locking fashion.

Owner:GM GLOBAL TECH OPERATIONS LLC

Novel rolling friction combined multilevel screw rod

InactiveCN106224478AImprove reliabilityImprove transfer efficiencyGearingRolling resistanceEngineering

Owner:王建波

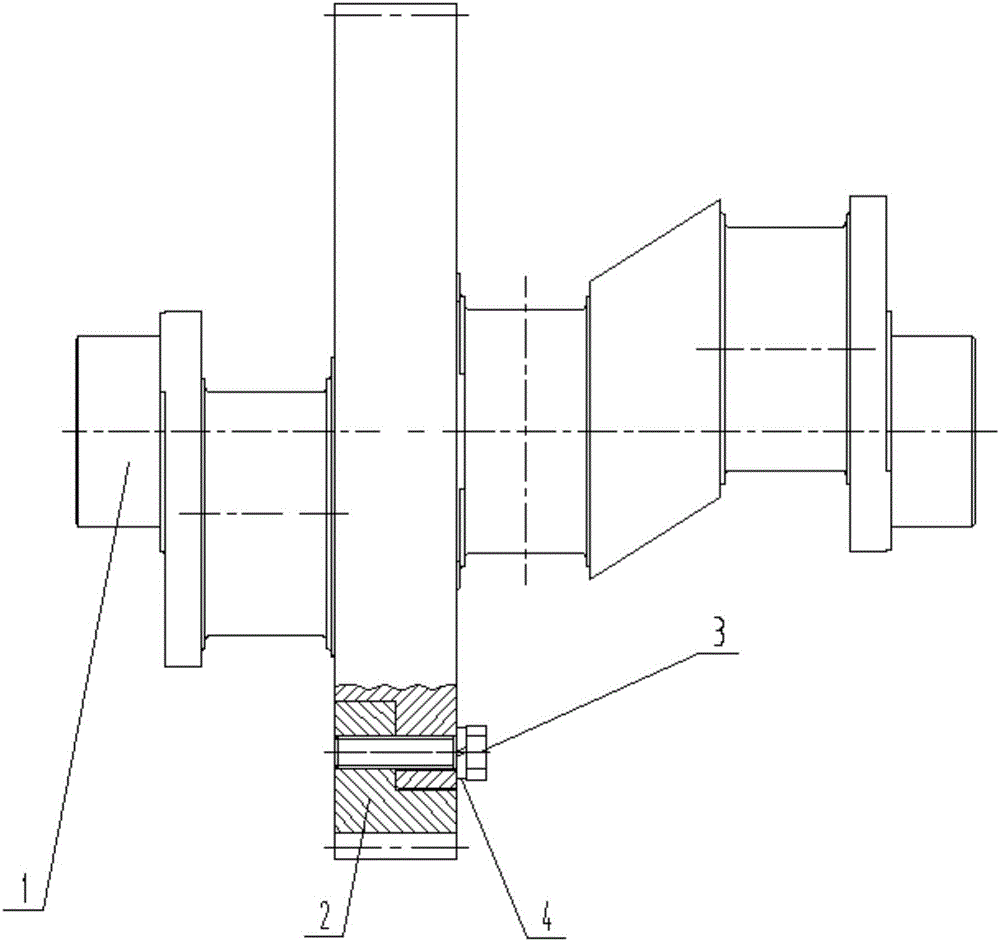

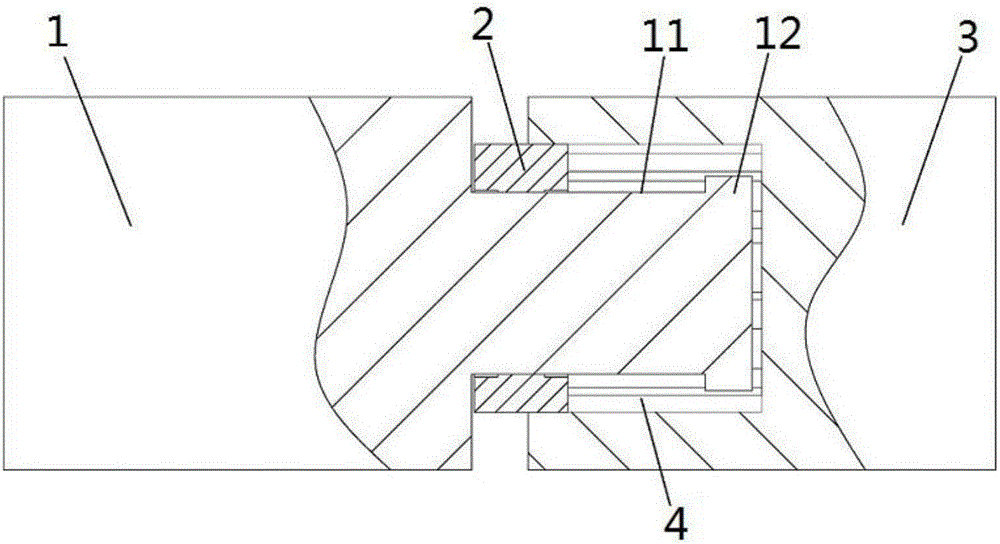

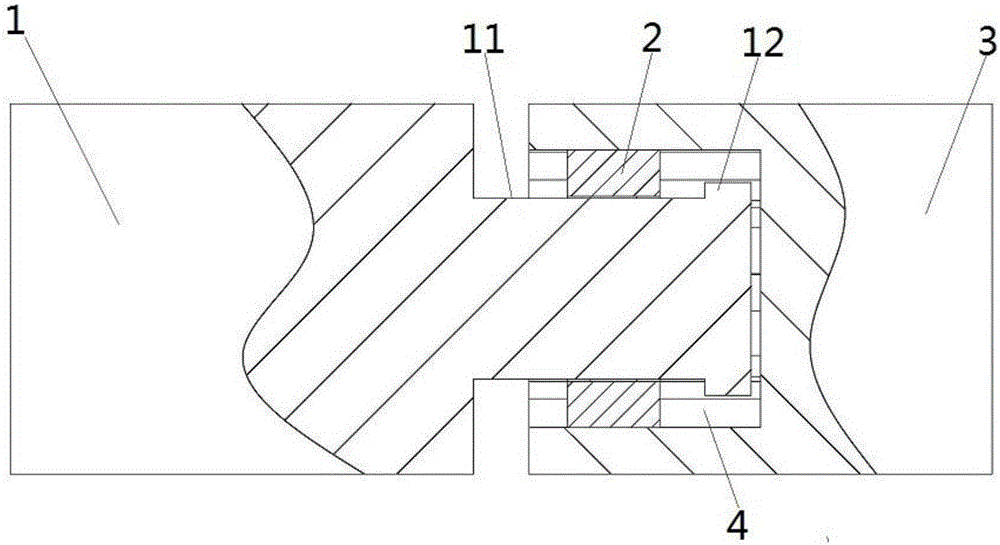

Crankshaft-gear connection structure and connection method thereof

PendingCN106090041ASmall footprintReliable torque transmissionShrinkage connectionsCouplings for rigid shaftsHolding timeEngineering

A crankshaft-gear connection structure and a mounting method thereof are provided. The structure includes a crankshaft and a gear. The gear, which is subjected to heating and heat preservation previously, is mounted on the crankshaft in an interference fitting manner. A heating temperature for the gear ranges from 180 to 220 DEG C, and the time of heat preservation ranges from 50 to 70 minutes. The tolerance fit of the crankshaft with the gear is H7 / u6. Due to the use of the above technical solution, the crankshaft-gear connection structure is small in size, reliable in transmitted torque, and stressed uniformly, as compared to the prior art.

Owner:HENGYANG ZHONGDI EQUIP PROSPECTING ENG MACHINERY

Automatic clutch device with free stroke and rotating door mechanism

ActiveCN105840691ASimple structureReasonable designPower-operated mechanismFreewheel clutchesDrive shaftTorque transmission

The invention provides an automatic clutch device with the free stroke. The automatic clutch device comprises a first drive shaft, a clutch drive part and a second drive shaft; the first drive shaft is in drive connection with the second drive shaft through a clutch drive component, the first drive shaft is a ladder shaft, threads are arranged on the surface of a small end shaft of the first drive shaft, and the clutch drive component is rotatably arranged on the threads; a baffle used for blocking the clutch drive component is arranged on the end face of the small end of the first drive shaft, a counter bore is formed in the end face of one end of the second drive shaft, and the small end of the first drive shaft, the clutch drive component and the baffle are all embedded in the counter bore; the clutch drive component and the second drive shaft are connected in a torque transmission manner and can slide axially relative to the inner wall of the counter bore; and compared with the prior art, the automatic clutch device is simple in structure, reasonable in design, convenient to manufacture, reliable in torque transmission, wide in application range and high in practicability, and the cost is reduced.

Owner:SHANGHAI HUAMING INTELLIGENT TERMINAL EQUIP

Device for receiving an overload in a spine processing station of a book binding machine

InactiveCN103802524AReliable torque transmissionCosmetic preparationsToilet preparationsElastic componentDrive shaft

The invention provides a device for receiving an overload in a spine processing station of a book binding machine. In order that the back of the body which inserts into a clamp and is conveyed at the back processing station may process it, show around through between a support roller of position fixing, and press rollers in the state where it was inserted, and the press roller, linear movement is possible and so that thickness of the back which should be processed may be adjusted via a linear guide and a spindle driving device the spindle driving device, with an adjusting driving device, a spindle with a screw thread pivotable at a motor ceremony, It has a slidable internal thread mountain element to a spindle with the screw thread accommodated in rotation impossible, a spring elastic component connected with the spindle driving device is provided, and this spring elastic component, it is set up by an interval between the press roller and the support roller, which can be grasped by a sensor in order that displacement of a spindle with the screw thread may be enabled and the displacement may specify page number of the body, when target thickness of the back guided in between the press roller and the support rollers is exceeded in equipment which absorbs an overload. A driving shaft of the adjusting driving device, and an end by the side of an adjusting driving device of a spindle with the screw thread, it is slidably connected mutually impossible along a rotating shaft line of a spindle with the screw thread via a length compensation element, the spring elastic component is the inside of a hollow chamber provided in a housing of a spindle with the screw thread, equipment which having extended in same axis to a rotating shaft line of a spindle with the screw thread, and being supported by the driving shaft at the first end, and supporting inside a housing of a spindle with the screw thread at the second end and which absorbs an overload.

Owner:MULLER MARTINI HLDG

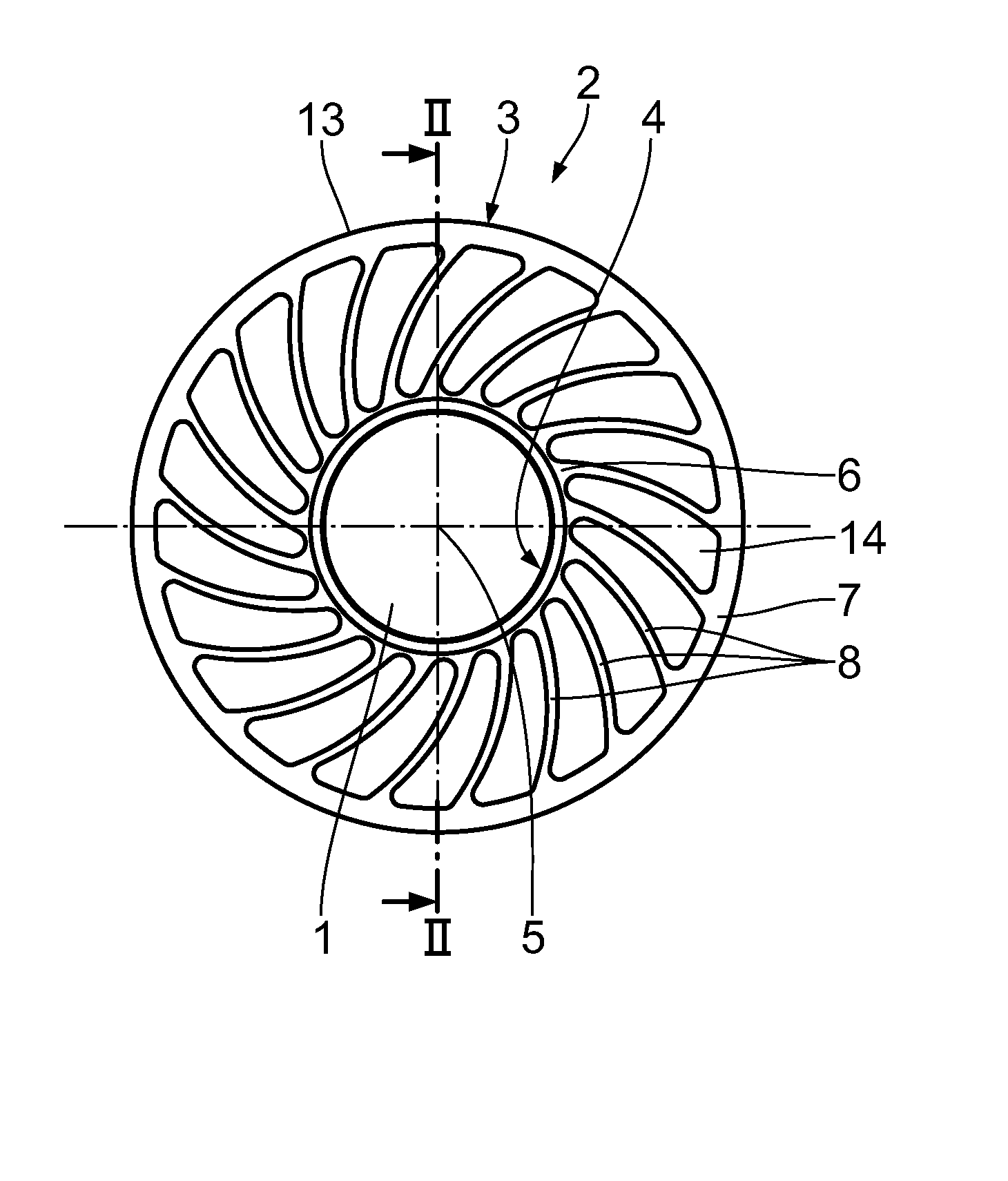

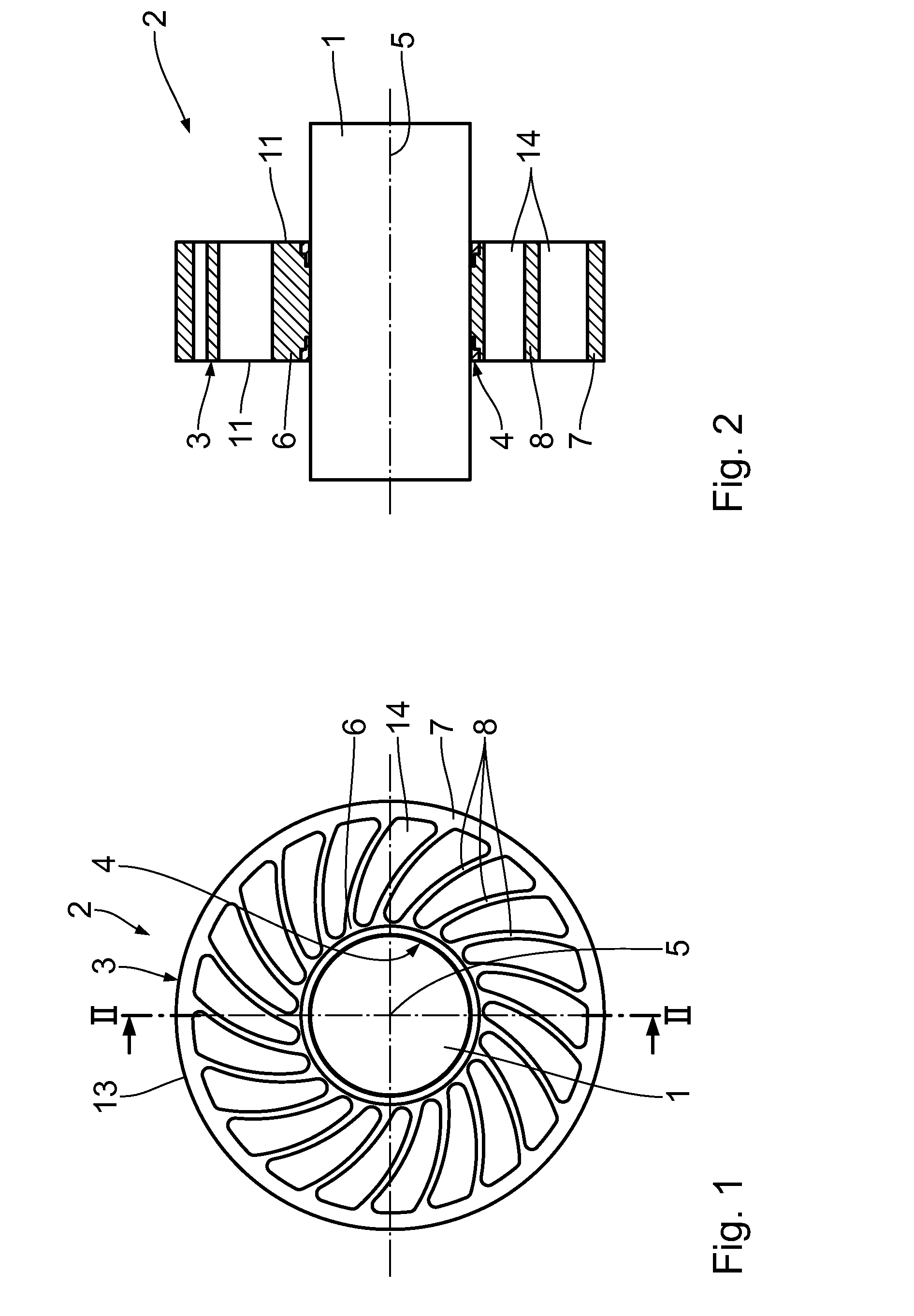

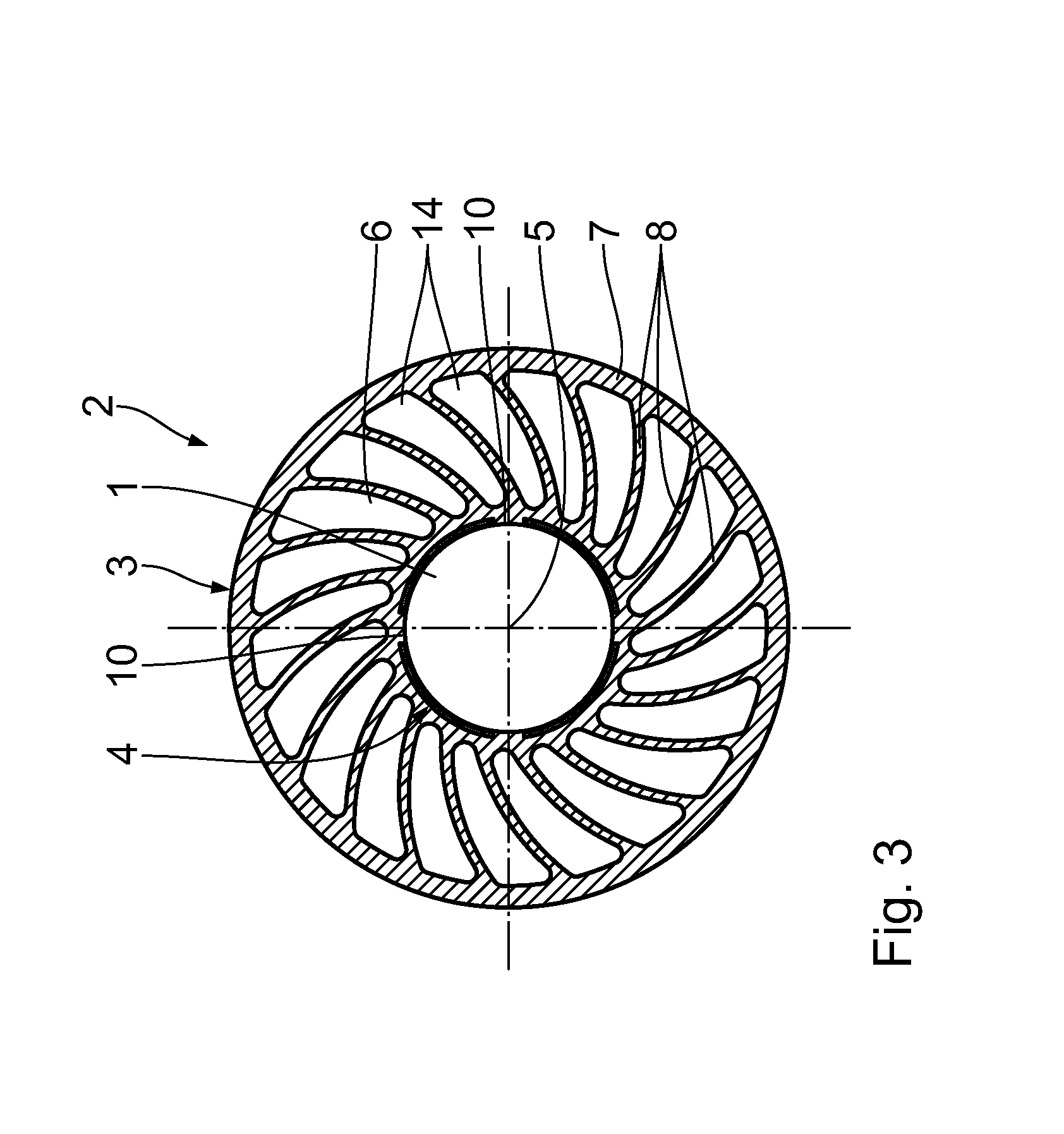

Guide wheel arrangement

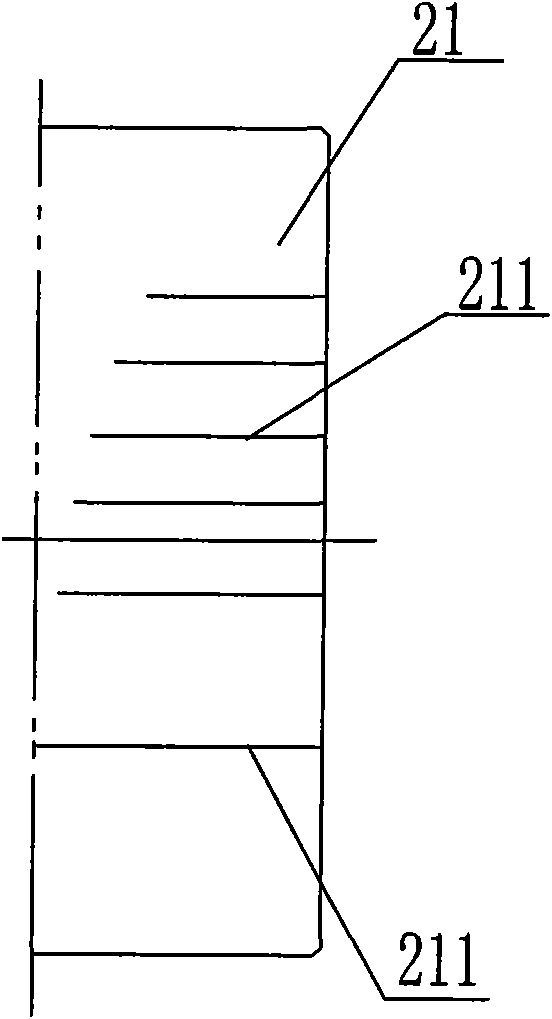

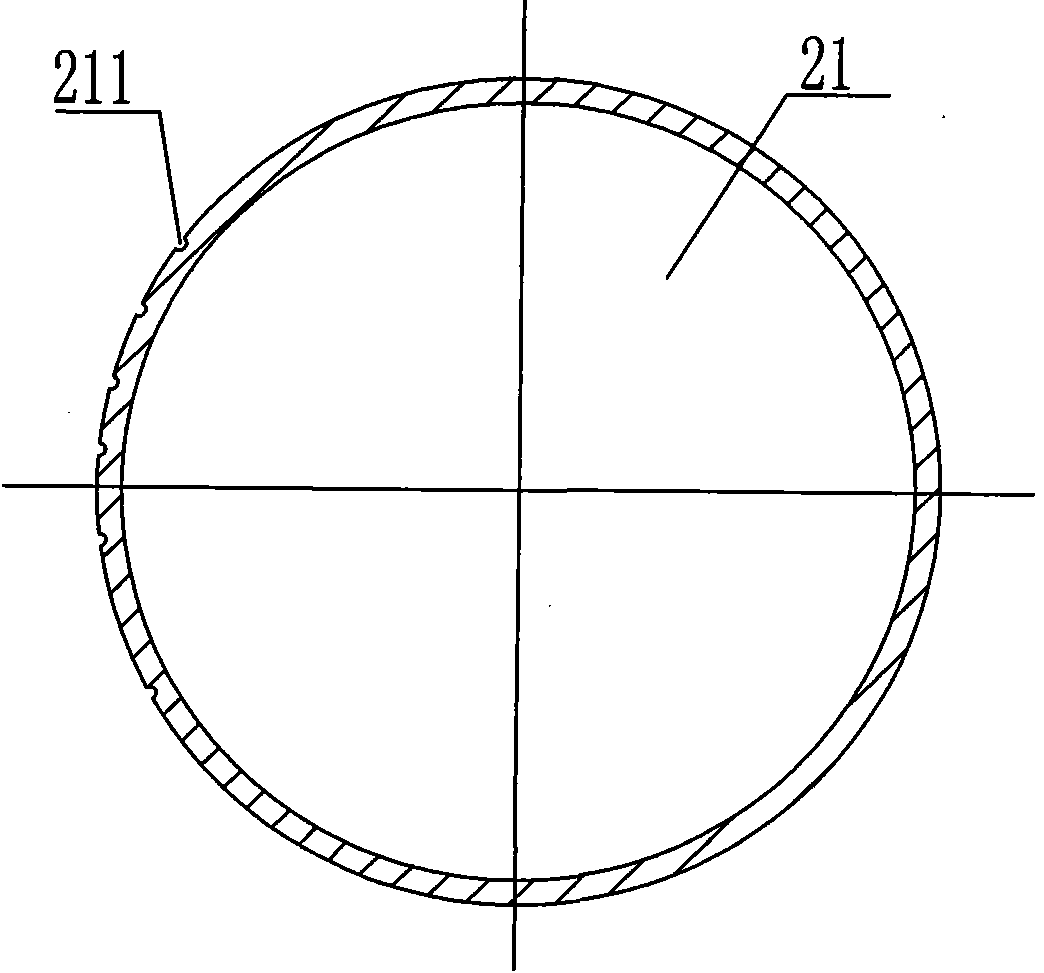

ActiveUS20140338511A1Easy to replaceReliable torque transmissionSlip couplingShaft and bearingsEngineeringMechanical engineering

The invention relates to a guide wheel arrangement for guiding two-dimensional material webs, in particular for guiding material webs or material sheets. The guide wheel arrangement comprises a guide wheel comprising an inner central hub section and an outer guide ring, which is connected to the inner hub section in a rotationally fixed manner for guiding the two-dimensional material elements, as well as an insert bushing which is to be arranged on a shaft and is concentrically inserted into the inner hub section, wherein the insert bushing is connected to the guide wheel in a rotationally fixed manner.

Owner:BHS CORRUGATED MASCHEN & ANLAGENBAU

Brake trolley with rope traction monorail system

ActiveCN104260744BDriving safetyFully absorb liquidTrack-braking member co-operationHydraulic motorLow speed

The invention discloses a rope traction monorail crane system braking vehicle, and the rope traction monorail crane system braking vehicle comprises a frame, two pairs of walking wheels and two pairs of brake shoes are arranged between two sidewalls of the frame, two pairs of brake shoes are driven by a pair of brake arms, two pairs of brake arms are driven by brake oil cylinder, the frame is provided with a speed selecting and increasing device, the speed selecting and increasing device comprises a first speed selecting wheel, a second speed selecting wheel, a clamping oil cylinder, a dual-direction hydraulic motor and a gearbox, the first speed selecting wheel shaft and the second speed selecting wheel shaft are supported by the first wheel shelf and the second wheel shelf, the shaft of the second speed selecting wheel is connected to the low speed shaft of the gearbox through cross-shaped universal coupler, the high speed shaft of the gearbox is connected to the drive shaft of the dual-direction hydraulic motor through elastic coupler. The speed selecting and increasing device controls two pairs of brake shoes of the braking vehicle by selecting speed judgment, the brake shoes on the other vehicles can also be controlled for guaranteeing the safe drive for the rope traction monorail crane system.

Owner:CHANGZHOU DEV & MFR CENT

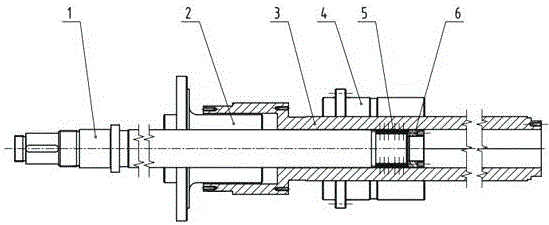

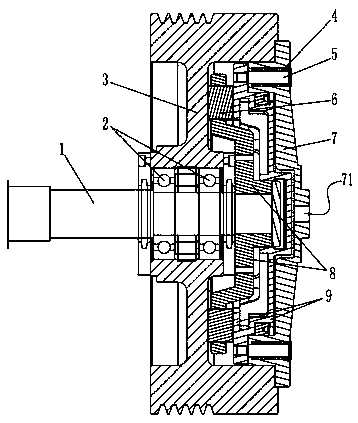

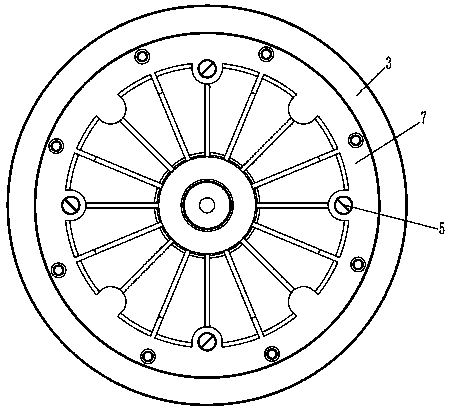

Synchronous rotation drive device for shaft part

ActiveCN104942714AReliable torque transmissionGuaranteed machining accuracyGrinding drivesEngineeringMachine tool

The invention belongs to the technical field of machining and manufacturing, and particularly relates to a synchronous rotation drive device for a shaft part. The synchronous rotation drive device for the shaft part comprises a locking flange, a clearance nut, multiple pressing screws and a drive sleeve. A groove is formed in the locking flange. A protrusion matched with the groove is arranged on the end face of the drive sleeve, and a threaded hole is formed in the protrusion. A nut head of the clearance nut abuts against the side wall of the groove. A threaded rod of the clearance nut is installed in the threaded hole of the protrusion. The pressing screws are used for installing a part to be machined on the locking flange and a machine tool cone vertex. The drive device is easy to machine, convenient to operate, and capable of guaranteeing the shaft part machining accuracy.

Owner:BAOJI FAST GEAR

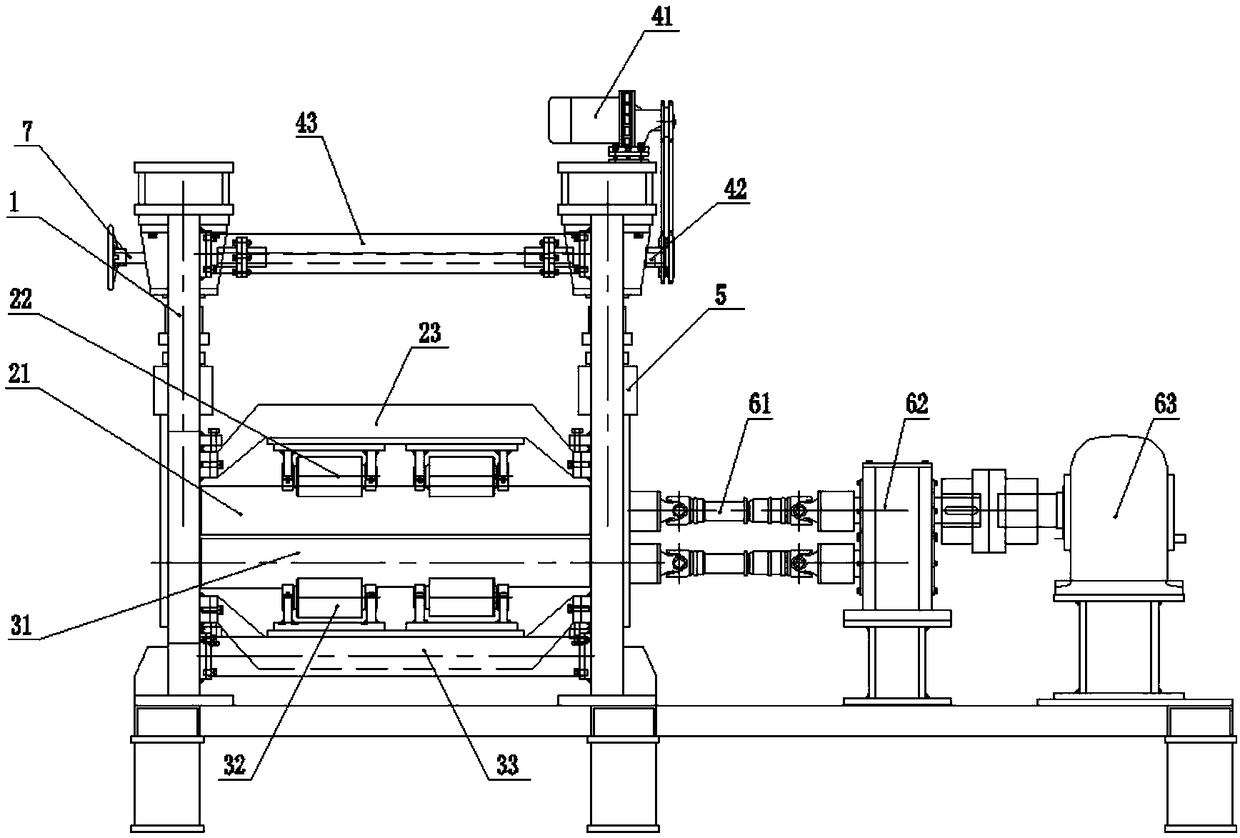

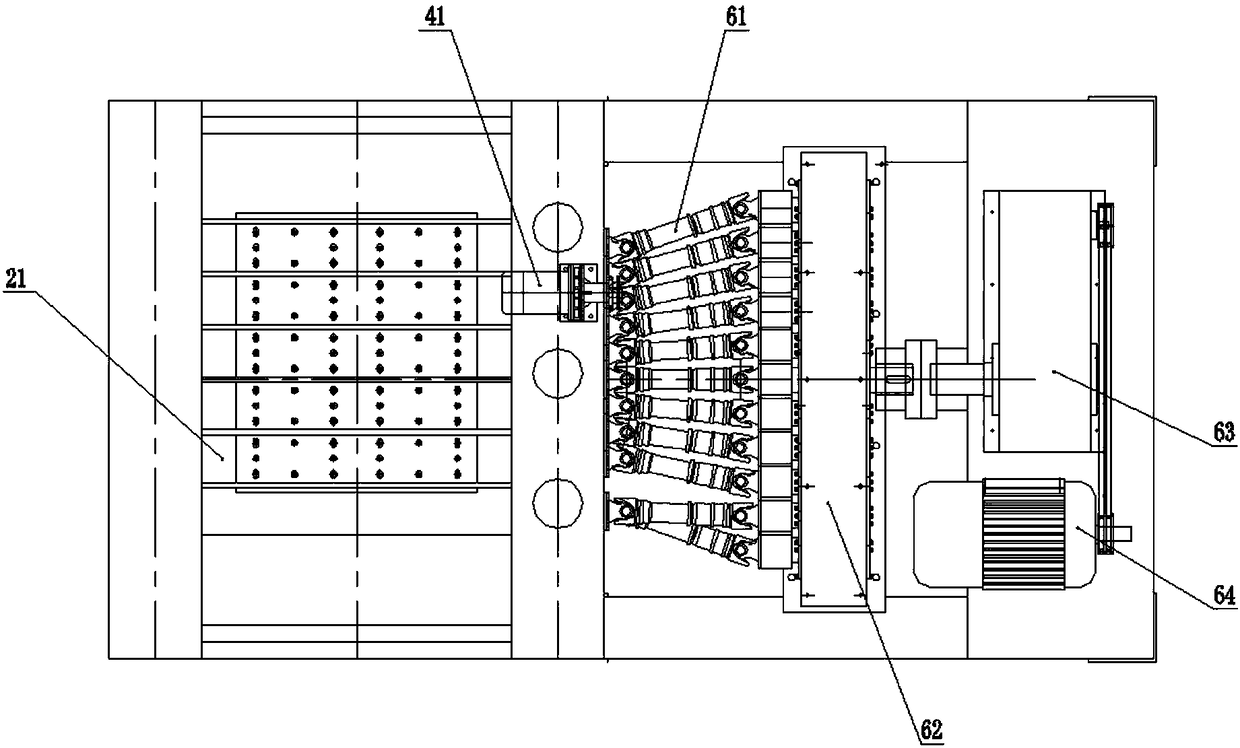

Plate rolling and leveling device

The invention provides a plate rolling and leveling device. The plate rolling and leveling device comprises a frame, an upper roller set, upper auxiliary carrying wheel sets, a lower roller set, lowerauxiliary carrying wheel sets, a lifting device and a rotating device. The upper roller set is mounted on the frame through the lifting device. Each of the upper roller set and the lower roller set comprises a plurality of rollers. The lifting device comprises clamping roller lifting devices and a leveling roller set lifting device. Two ends of a clamping roller are connected with the clamping roller lifting devices arranged on two sides of the frame respectively. The upper auxiliary carrying wheel sets on two sides are fixed to the upper side of the upper roller set through upper auxiliary carrying wheel set supports. The lower roller set is arranged below the upper roller set. The rotating device comprises universal couplers, a gear transmission case, a speed reduction box and a rotating motor. The plate rolling and leveling device has the advantages that a roller rolling and leveling mode is adopted, the rotating device drives rollers to drive the plates to move, the plates are bent repeatedly, stress is eliminated, and accordingly, leveling of the plates is achieved.

Owner:南京大吉铁塔制造有限公司

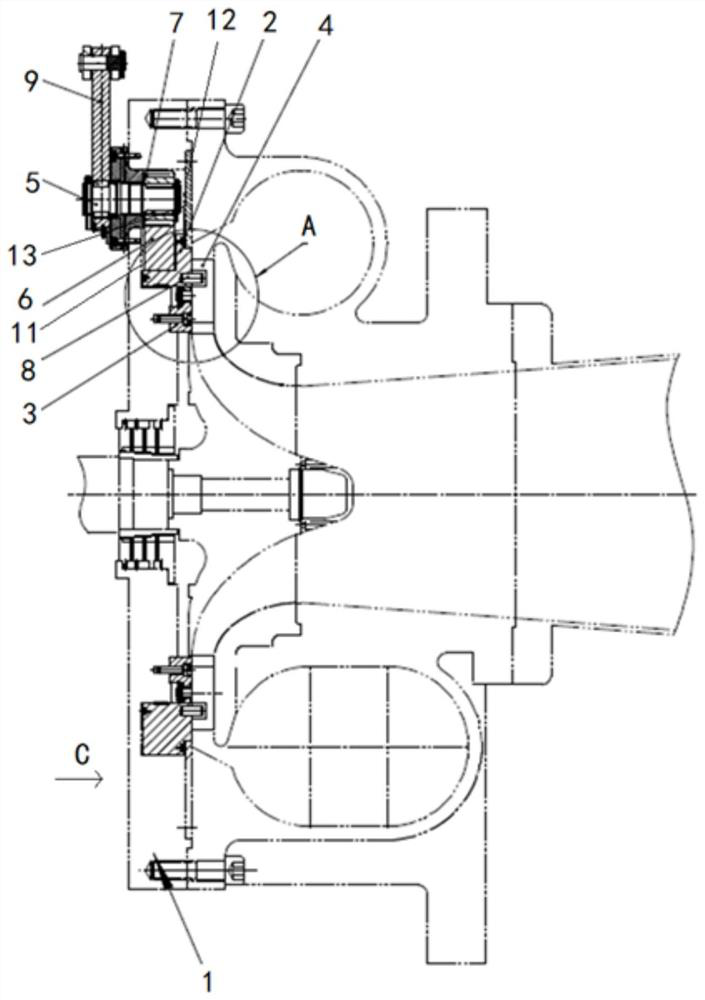

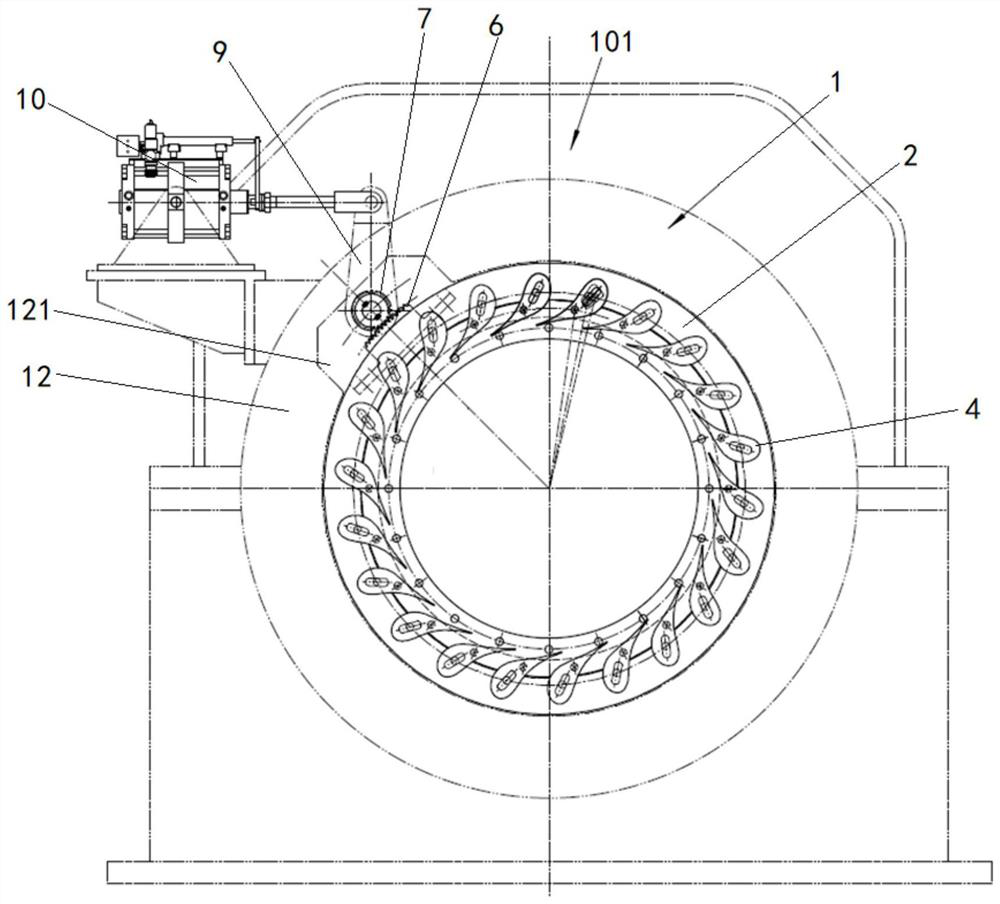

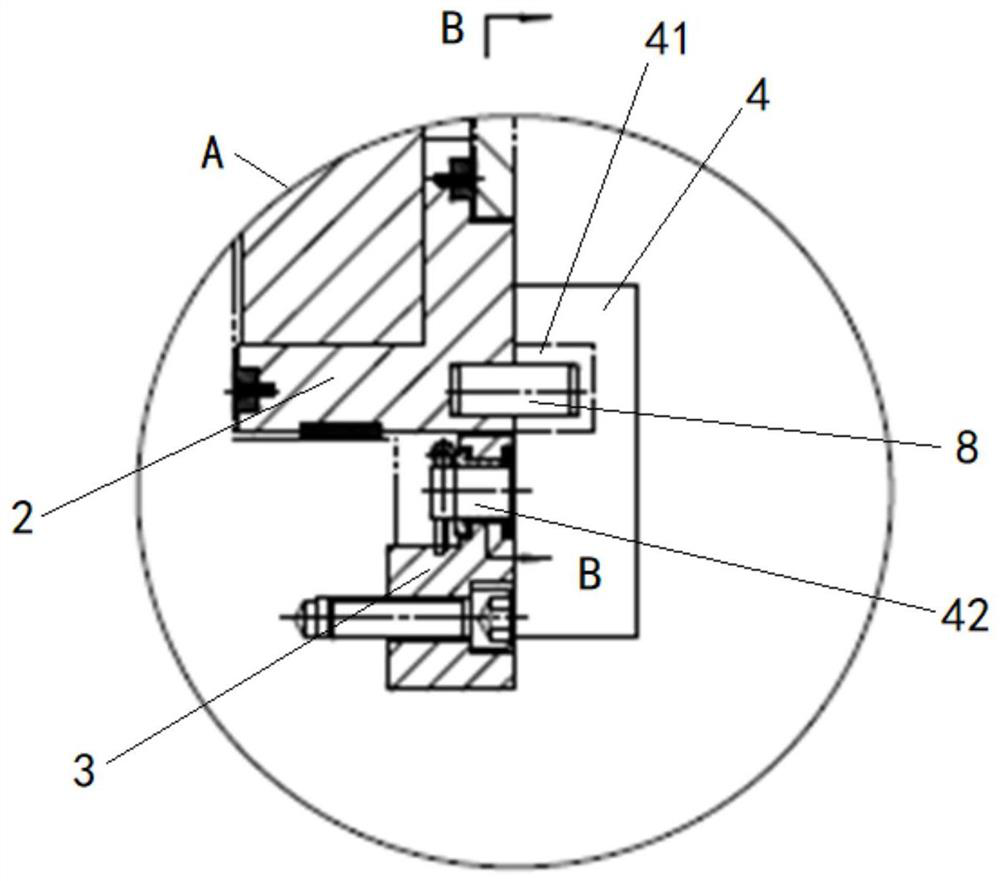

Expansion machine nozzle regulating device and expansion machine

PendingCN112761739AReduce the center distanceChange aerodynamic performanceMachines/enginesEngine componentsGear driveDrive shaft

The invention discloses an expansion machine nozzle regulating device and an expansion machine, relates to the technical field of expansion machines, and mainly aims to provide a rear-mounted nozzle regulating device so that the expansion machine can adopt an inner volute form. According to the main technical scheme, the expansion machine nozzle regulating device comprises an end flange, a ring body, a plurality of nozzle blades and a transmission mechanism, wherein the end flange is provided with a gear box side used for being connected with a gear box of the expansion machine; the ring body comprises a rotating ring rotationally arranged on the end flange and a fixed ring fixedly arranged on the end flange and located in the rotating ring; the nozzle blades are arranged in the circumferential direction of the rotating ring, and the two ends of the nozzle blades are rotationally connected to the fixed ring and the rotating ring correspondingly; the transmission mechanism comprises a driving shaft, a transmission part and a gear; the transmission part is connected to the rotating ring, and meshing teeth are arranged on the transmission part; the gear is rotatably arranged on the end flange and is in meshed connection with the transmission part; and the driving shaft is rotatably arranged on the end flange, one end of the driving shaft penetrates to the gear side, and the other end of the driving shaft is connected with the gear.

Owner:SHENYANG BLOWER WORKS GROUP CORP

Forging press

InactiveCN111255819ASimple structureReduce volumeFluid actuated clutchesFlywheelsDrive shaftFlywheel

The invention discloses a forging press. The forging press comprises a crankshaft, one end of the crankshaft is provided with a brake, and the other end of the crankshaft is provided with a clutch; the clutch comprises a flywheel, a driven shaft sleeve and a driving disc which sleeve the crankshaft sequentially; the flywheel is installed on the crankshaft through bearings, the driven shaft sleeveand the driving disc are arranged in a concave cavity of the flywheel, and the exterior of the concave cavity of the flywheel is fixedly connected with a casing; the driven shaft sleeve is fixedly connected with the crankshaft, and the outer ring of the driven shaft sleeve is inlaid with a plurality of movable friction blocks; the driving disc sleeves the crankshaft in an idling manner and is connected with the casing through a plurality of drive pins in a circumferentially fixed and axially moving manner, the drive pins are sleeved with a plurality of springs, and the driving disc and the casing are slidably connected in a nested manner to form a cylindrical air cylinder cavity; and the cylindrical air cylinder cavity communicates with a vent hole formed in the center of the casing and issealed through a sealing ring arranged between the driving disc and the casing. According to the technical scheme, the separate structural design of the clutch and the brake is adopted, the structureis simple, and operation is reliable.

Owner:湖北鑫锤锻造科技有限公司

Torque receiving unit, photosensitive drum and process cartridge

ActiveCN104155864BReliable torque transmissionAvoid stickingElectrographic process apparatusDrive shaftTorque transmission

The present invention relates to a torque receiving assembly and a photosensitive drum and a process cartridge having the torque receiving assembly as its constituent parts. The torque receiving assembly includes a body and a driven rod. The driven rod includes a guide column and an input head located on one side of the length direction of the guide column. On the outer end wall of the input head facing away from the guide column along the length direction of the guide column, a protrusion extending outward along the length direction of the guide column is provided. The H value of the protrusion satisfies the following relationship: h<H≤h+r; where: H is the distance between the protrusion from the outer end wall to the end point extending outward; h is the torque transmitted by the engagement of the driving rod and the driven rod , the distance from the outer end wall to the centerline of the cylindrical output tooth; r is the radius of the cylindrical output tooth. It has the advantages of stable torque transmission and smooth disengagement.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

A tool for drilling riveted fasteners

The invention discloses a tool for a drilling and riveting fastener. The tool comprises a rotation driving member for driving the drilling and riveting fastener to rotate so as to drill and a pulling and riveting member for extruding the drilling and riveting fastener to be deformed and riveted. The tool for the drilling and riveting fastener has the advantages of being simple in structure and capable of being used for drilling and riveting at the same time and improving working efficiency greatly and the like.

Owner:HUNAN GOLDWELL NEW MATERIALS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com