A tool for drilling riveted fasteners

A fastener, drilling and riveting technology, applied in the field of fastener installation tools, can solve the problems of low safety factor of self-tapping screws, low installation efficiency, and many installation procedures, and achieves low cost, simple structure, and reliable torque transmission. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

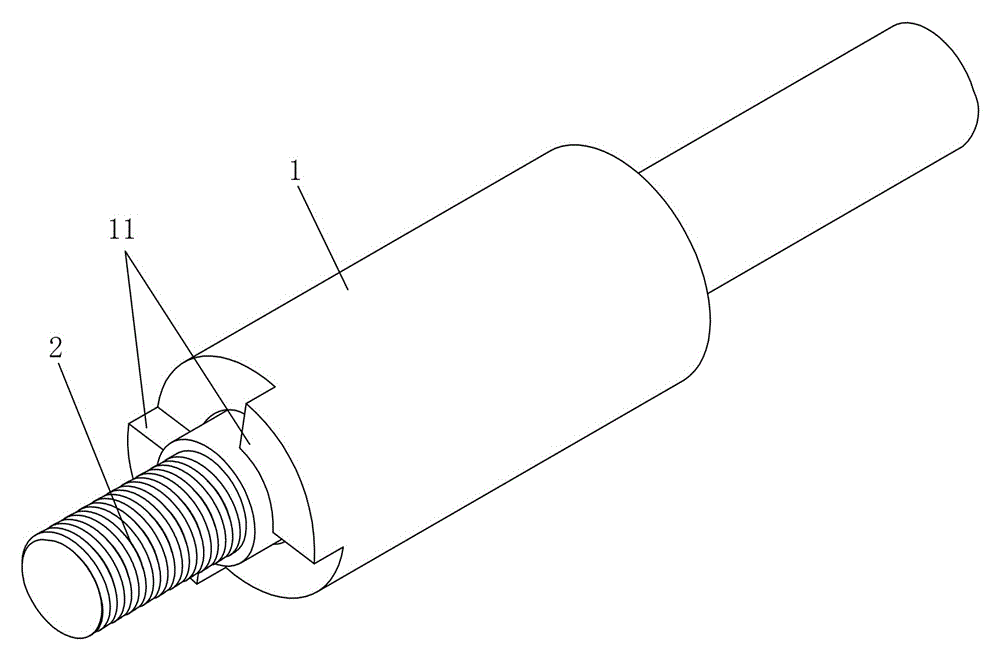

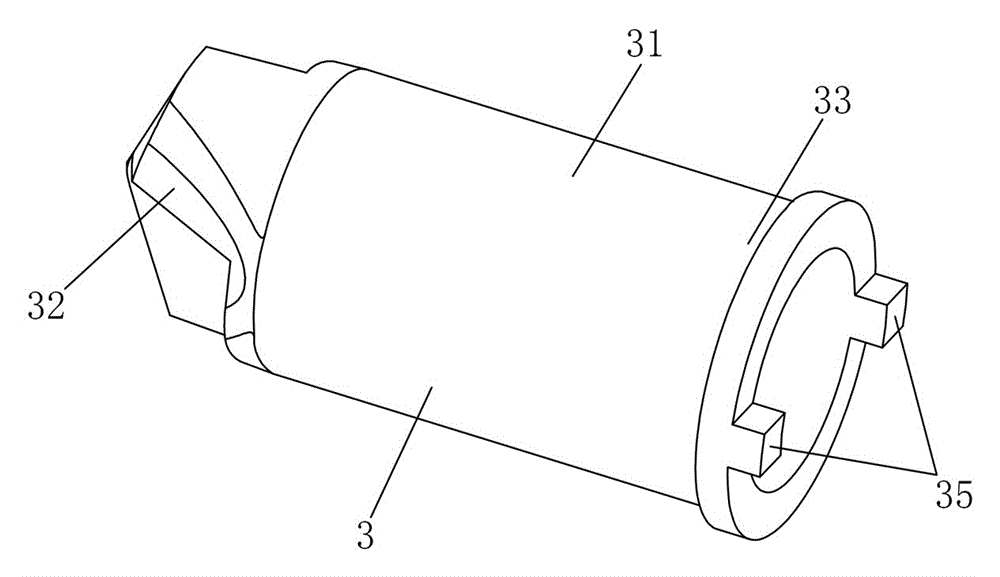

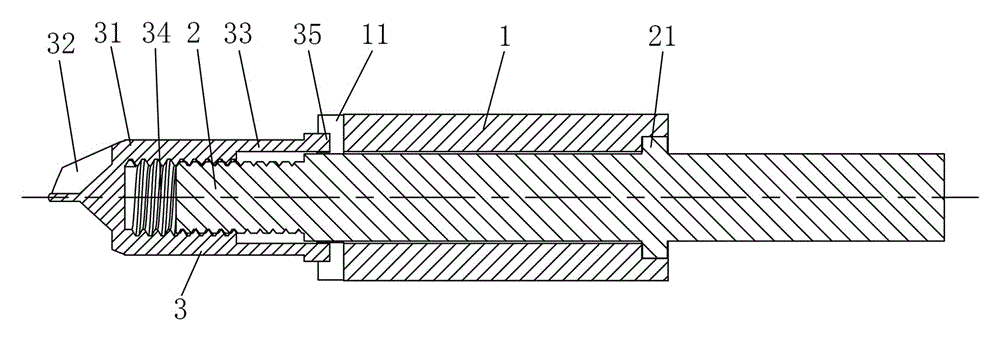

[0021] Figure 1 to Figure 6 An embodiment of the tool for drilling and riveting fasteners according to the present invention is shown, the tool includes a rotary driving part 1 and a blind riveting part 2, and the rotating driving part 1 can be realized by cooperating with the drilling and riveting fasteners 3 The transmission of torque, and then the rotation of the rotary drive member 1 can drive the drill rivet fastener 3 to rotate and drill the hole. The rivet 2 can cooperate with the drill rivet fastener 3 and apply axial tension, and then the rivet can be controlled by controlling the rivet. Part 2 extrusion drilling riveting fastener 3 deformation riveting. The tool has a simple structure and is easy to manufacture. It can not only make the drilling and riveting fastener 3 rotate and drill, but also squeeze the drilling and rive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com