Device for receiving an overload in a spine processing station of a book binding machine

A technology of a binding machine and a processing station, which can be used in the composite continuous process of book processing, book binding, and dressing preparations, etc., and can solve problems such as accuracy limitations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

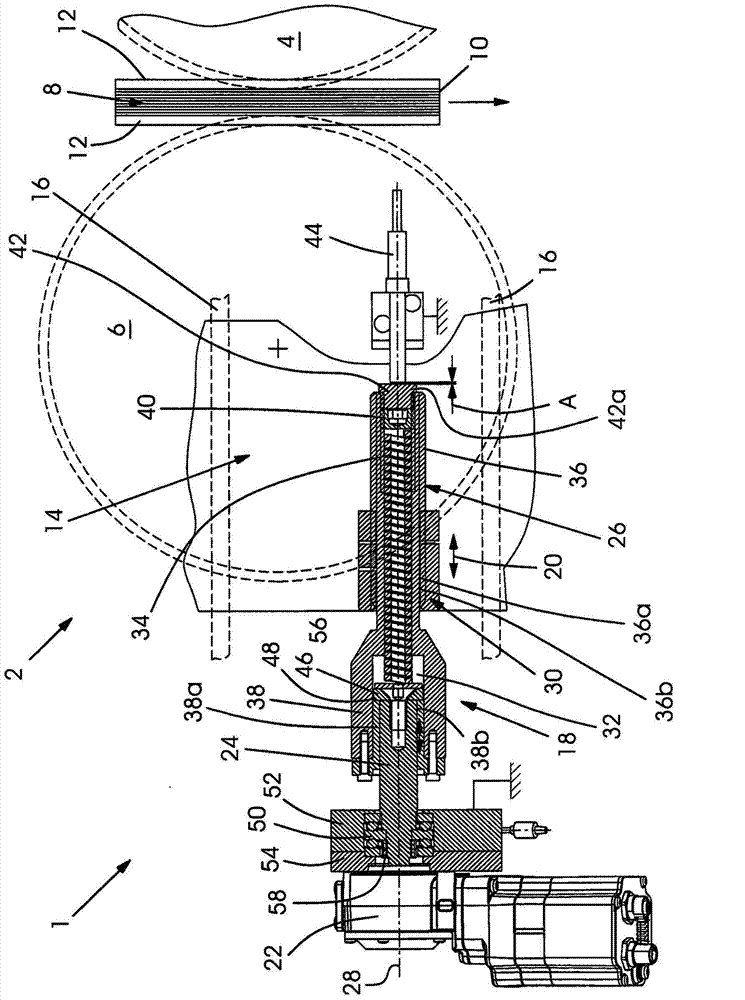

[0021] like figure 1 As shown, in order to receive an overload in the spine processing station 2 of the bookbinding machine, not shown in detail, the device 1 according to the invention comprises a support roller 4 and a pressing roller 6, while the spine 8 is conveyed preferably suspended in a gripper 12 And the support roller and the pressing roller act on the spine 8 of the book block 10 during processing by a milling machine not shown in detail. The pressure roller 6 is rotatably received on a bridge 14 , via a linear guide 16 , which is only shown schematically, via a screw drive 18 in the direction of the double arrow 20 relative to a support fixed to the machine frame Roller 4 can be moved. The movement of the pressure roller 6 is carried out by means of a servo drive 22 which has a drive shaft 24 which is non-rotatable relative to the threaded spindle 26 of the spindle drive 18 via a length compensation element 38 and at the same time can be moved along the threaded s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com