Power transmission mechanism of double-screw extrusion equipment

A technology of power transmission mechanism and twin-screw extruder, which is applied in the fields of food forming, feed, food science, etc., can solve the problems of increasing the volume and weight, and achieve the effect of simplifying the structure, eliminating the position error and simplifying the assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0047] A power transmission mechanism of twin-screw extrusion equipment, including a cutter 7 and a motor 9 of the twin-screw extruder, the motor 9 is installed on a fixed motor base 10, and the output shaft of the motor 9 can be used for up and down or / or and turn left and right;

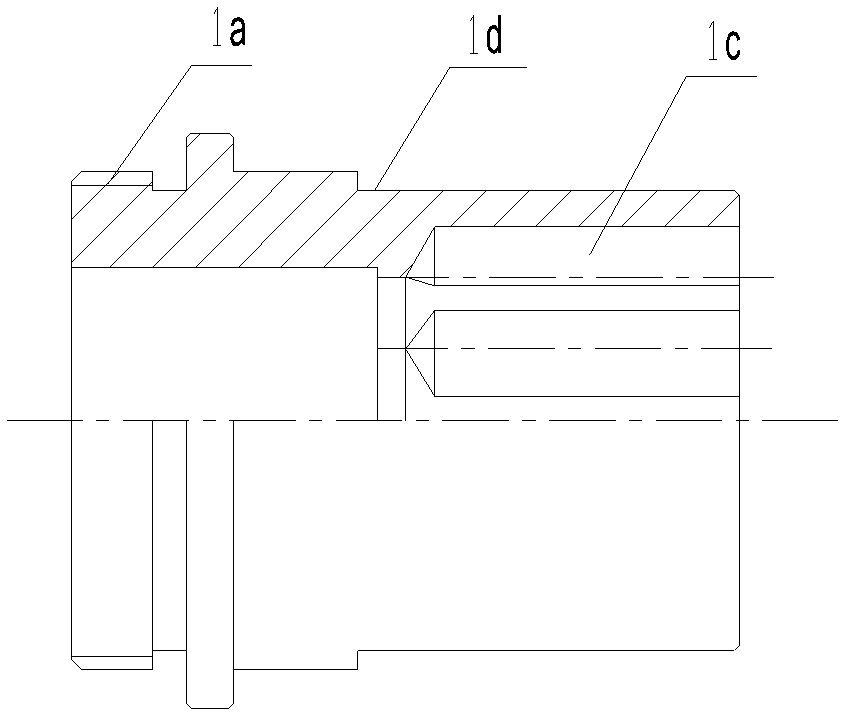

[0048] The rotating shaft of the cutter 7 and the output shaft of the motor 9 are respectively fixedly connected with the connecting sleeve 1 of the rotating assembled shaft coupling;

[0049] Two connecting heads 2 are respectively placed in the two connecting sleeves 1 of the rotary assembly type coupling, and are embedded and fixed by a plurality of rubber pins 3, and the two connecting heads 2 are inserted and connected with each other;

[0050] The connecting jacket 1 is cylindrical, one end is connected to the rotating shaft of the cutter 7 or the output shaft of the motor 9, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com