Decelerating clutch of intelligent washing machine

A deceleration clutch and washing machine technology, applied in the field of clutches, can solve the problems that affect the service life, stability and safety of the deceleration clutch, cannot be applied to large-capacity washing machines with pulsators, high torque, and clutch device failure, etc., to achieve simple structure and clutch action Reliable, well-structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

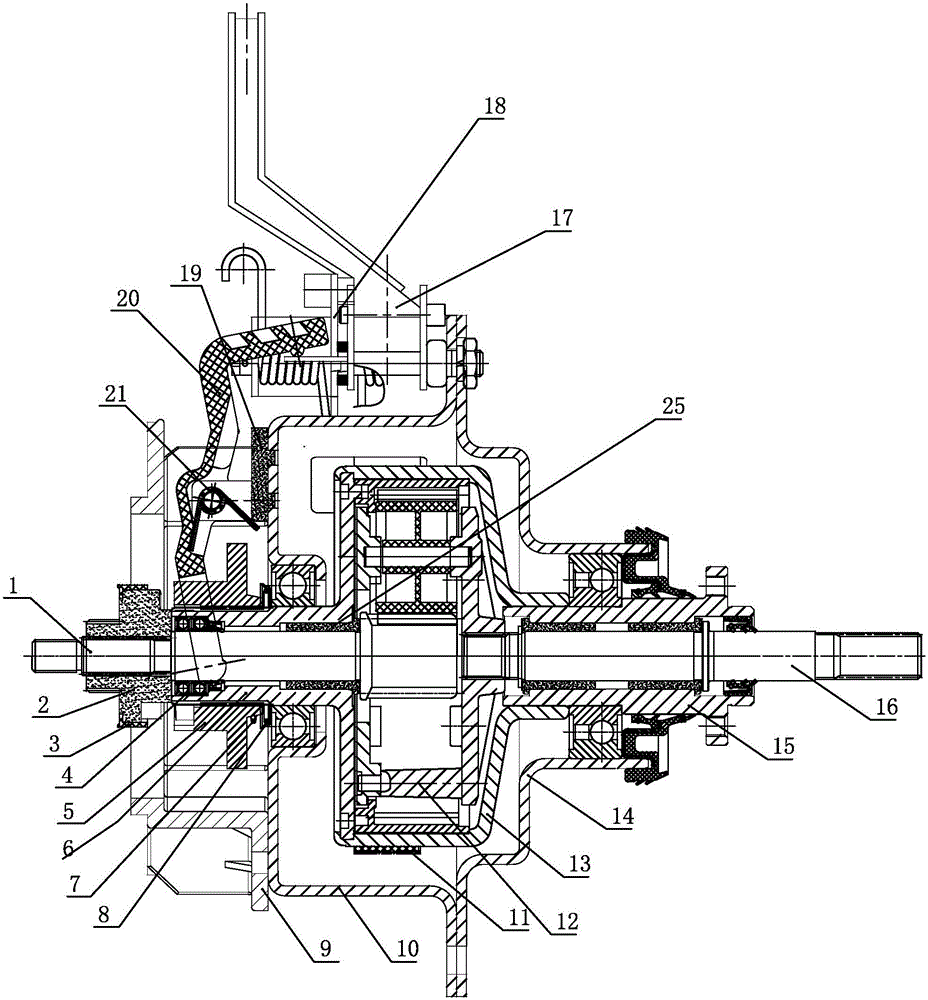

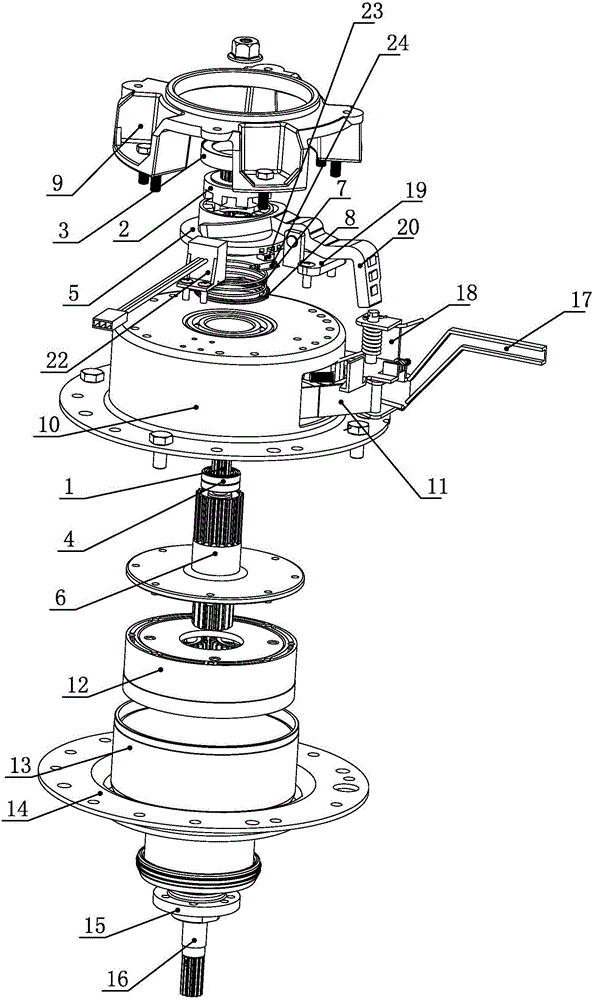

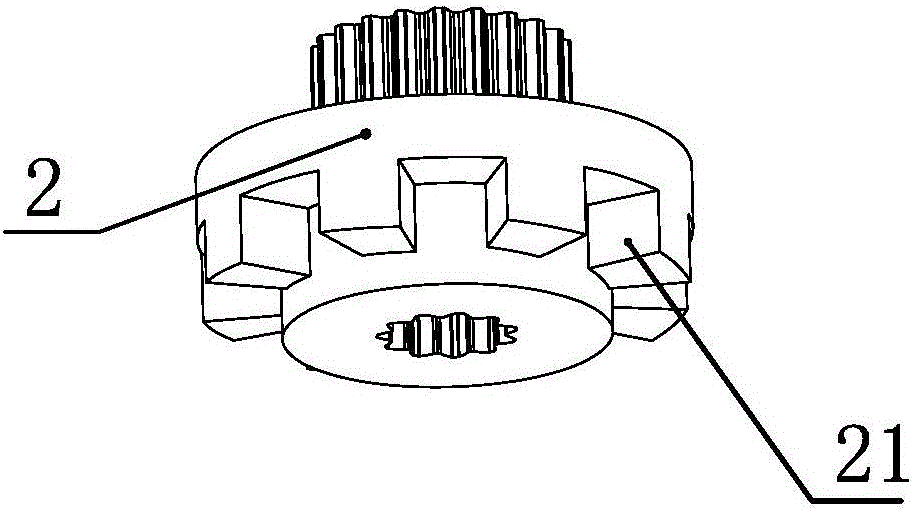

[0020] see Figure 1 to Figure 5 , a deceleration clutch for an intelligent washing machine disclosed in the present invention includes an upper housing 14, a lower housing 10, a connecting disc 5, a torque transmission sleeve 2 and a brake wheel shaft 6, and the coupling disc 5 is set on the brake wheel shaft 6 Above, a magnet 23 is set on the coupling plate 5, a Hall sensor 22 is set on the lower end surface of the lower casing 10, the position of the Hall sensor 22 matches the magnet 23, and the Hall sensor 22 There is a gap between the magnet 23; the outer surface of the brake wheel shaft 6 is provided with a first spline 61, and the inner surface of the inner hole of the coupling disc 5 is provided with a first spline 61 matching the first spline. Two splines 51, the third spline 52 is provided on the lower end of the coupling disc 5, the fourth spline 21 matching the third spline 52 is provided on the upper end of the torque transmission bushing 2, the coupling disc 5 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com