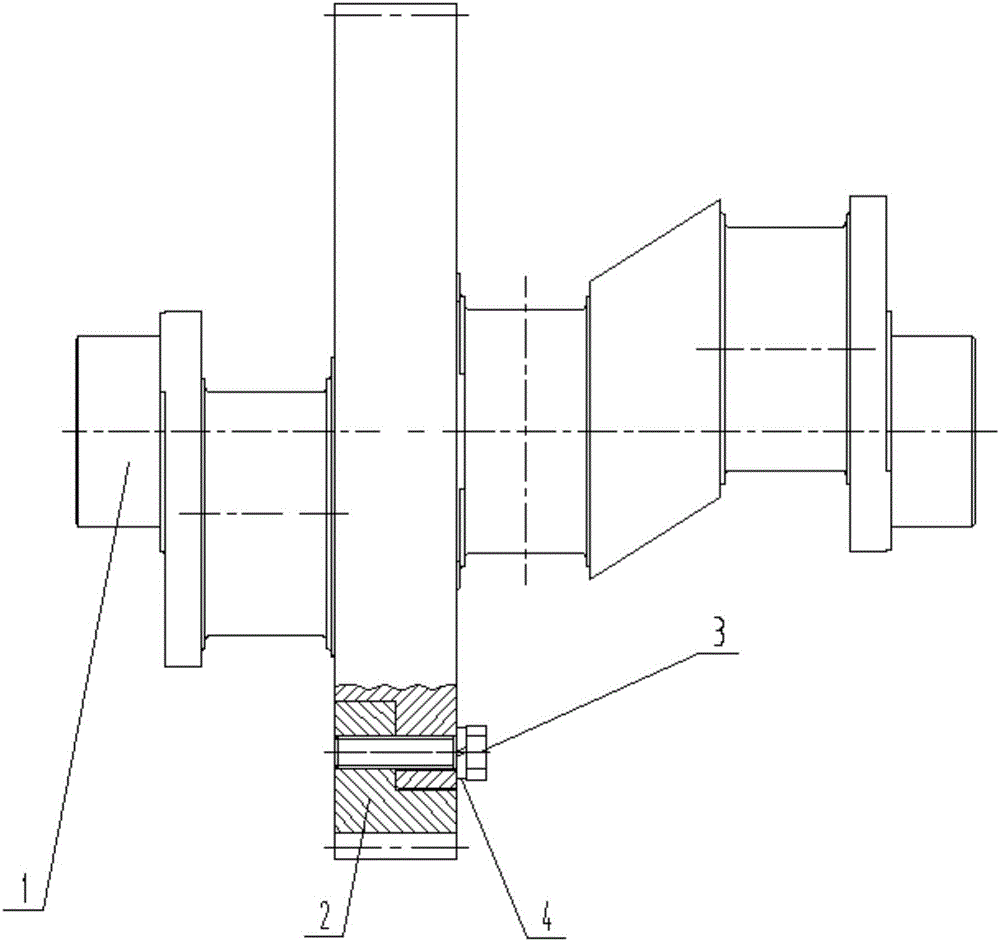

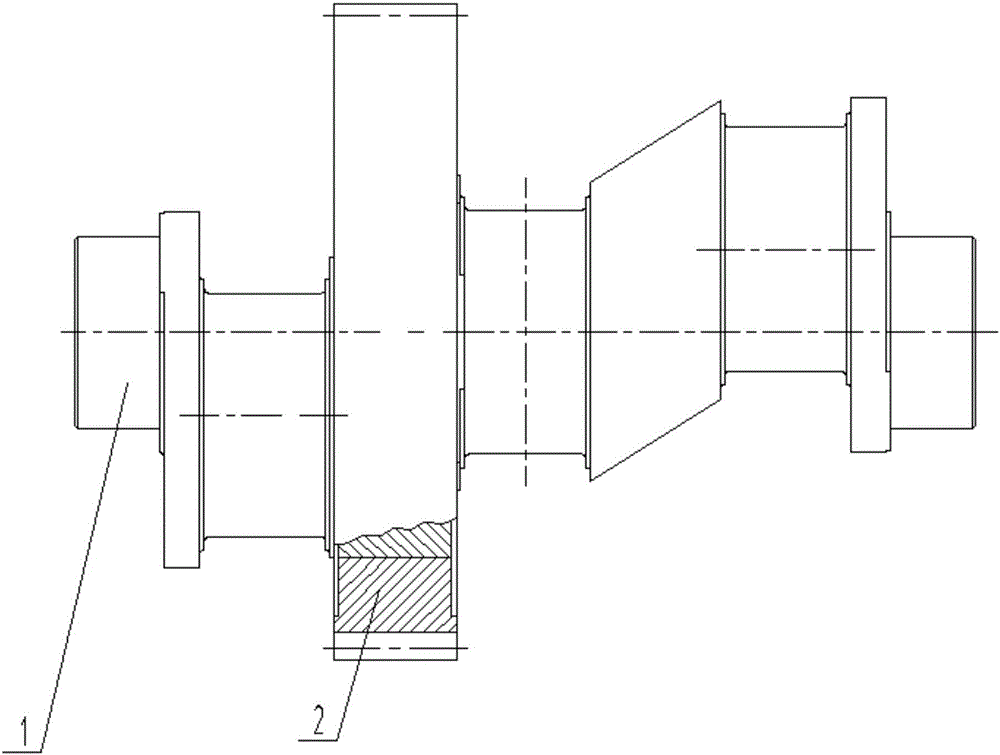

Crankshaft-gear connection structure and connection method thereof

A gear connection and crankshaft technology, applied in the direction of connecting components, shrinkage connections, couplings, etc., can solve the problems of large diameter, broken bolts, large power end volume, etc., to achieve uniform force, small footprint, and torque transmission reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0022] A crankshaft and gear connection method, the steps comprising:

[0023] Step 1: Heating: heat the gear to a temperature of 185-215°C;

[0024] Step 2: heat preservation: heat-preserve the heated gear in step 1, and the heat preservation time is 52-68 minutes;

[0025] Step 3: Installation: install the gear that has been heat-insulated in step 2 on the crankshaft;

[0026] Step 4: Cooling: Cool the assembled crankshaft and gears in air.

[0027] The tolerance fit between crankshaft and gear is H7 / u6.

Embodiment 3

[0029] A crankshaft and gear connection method, the steps comprising:

[0030] Step 1: Heating: heat the gear to a temperature of 190-210°C;

[0031] Step 2: heat preservation: heat-preserve the heated gear in step 1, and the heat preservation time is 55-65 minutes;

[0032] Step 3: Installation: install the gear that has been heat-insulated in step 2 on the crankshaft;

[0033] Step 4: Cooling: Cool the assembled crankshaft and gears in air.

[0034] The tolerance fit between crankshaft and gear is H7 / u6.

Embodiment 4

[0036] A crankshaft and gear connection method, the steps comprising:

[0037] Step 1: Heating: heat the gear to a temperature of 195-205°C;

[0038] Step 2: heat preservation: heat-preserve the heated gear in step 1, and the heat preservation time is 58-62 minutes;

[0039] Step 3: Installation: install the gear that has been heat-insulated in step 2 on the crankshaft;

[0040] Step 4: Cooling: Cool the assembled crankshaft and gears in air.

[0041] The tolerance fit between crankshaft and gear is H7 / u6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com