Determining operating mode of electrical machine coupled to internal combustion engine

A state of operation, technology of internal combustion engines, applied in internal combustion engine testing, arrangement of multiple different prime movers of general power plants, machines/engines, etc., to achieve easily achievable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

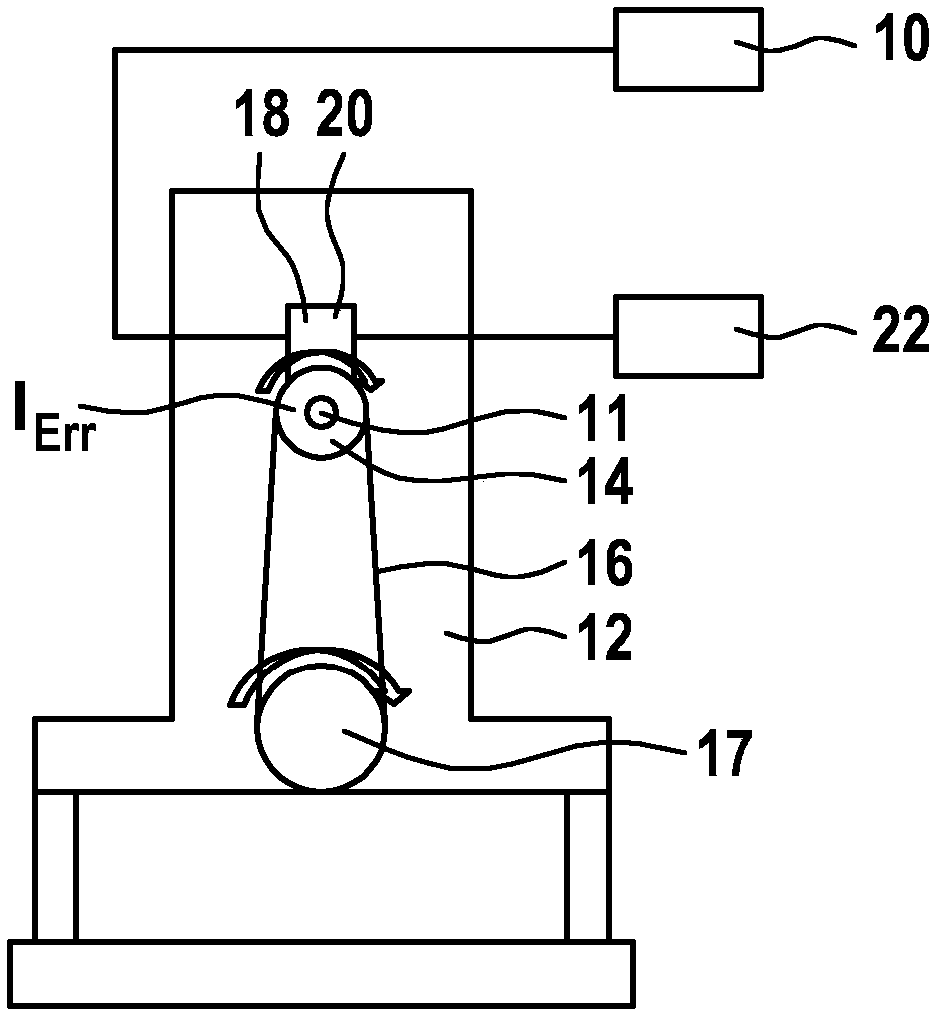

[0042] exist Figure 1a 2 shows a system known from the prior art consisting of a motor vehicle electrical system 10 and an electric machine 14 coupled to an internal combustion engine 12 by means of a flywheel element 11 , wherein the motor vehicle electrical system 10 supplies the electric machine 14 with energy. The electric machine 14 is driven by means of a coupling element 16 , usually a belt drive, wherein the coupling element 16 is arranged on the crankshaft 17 on the part of the internal combustion engine 12 and on a roller provided on the flywheel 11 on the part of the electric machine 14 . In order to regulate the voltage in the onboard electrical system 10 , a computing unit 18 is provided in the form of a regulator 20 , which adjusts the field current I of the electric machine 14 correspondingly depending on the voltage of the onboard electrical system 10 Err .

[0043] By changing the excitation current I Err , the load on the electric machine 14 and thus the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com