Combination tool

A technology of combining tools and tool heads, which is used in the manufacture of tools, wrenches, screwdrivers, etc., which can solve the problems of impossible visual inspection of the rotational movement and fit of tools, hindering normal use, and unable to smoothly realize the combined use of machines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

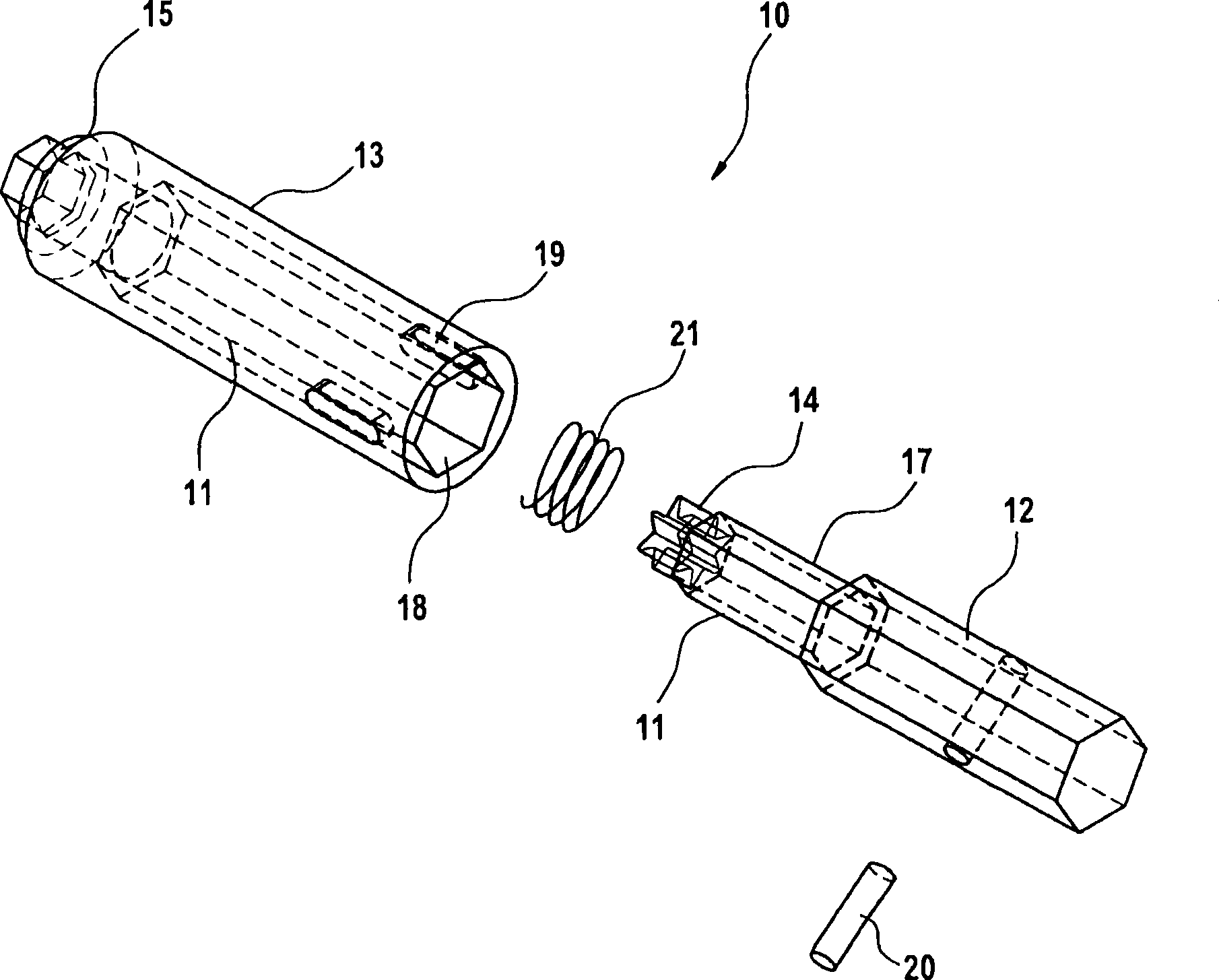

[0015] figure 1 An exploded perspective view of the combination tool 10 according to the invention is shown. The tool shaft 11 is formed from an outer part 13 and an inner part 12 . The inner part 12 has at its end a first tool bit 14 formed on it in the form of a screwdriver bit for Torx screws. The outer part 13 then has at its end a second tool bit 15 formed on it in the form of a hex key. In the area of the shank, the outer side 17 of the inner part 12 and the inner side 18 of the outer part 13 are designed such that a force-transmitting connection can be produced. In this way, a long service life and reliable torque transmission can be guaranteed. Here, this is achieved by a polygonal design in which the outer side 17 and inner side 18 are partly matched to one another. Furthermore, according to the illustrated embodiment of the invention, the combination tool 10 has a lockable fastening element 16 in the form of a pin mechanism 20 with a spring 21 . The pin can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com