Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Reduced sedimentation volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified calcium carbonate with good antistatic effect and preparation method thereof

InactiveCN104987723AImprove suspension stabilityImprove the lubrication effectSodium bicarbonateSodium Bentonite

The invention discloses modified calcium carbonate with good antistatic effect and a preparation method thereof. The modified calcium carbonate is characterized by being prepared from the following raw materials by weight: 100 to 150 parts of calcium carbonate, 30 to 50 parts of sodium oleate, 0.3 to 0.7 part of sodium dodecyl benzene sulfonate, 1 to 3 parts of sodium bicarbonate, 4 to 8 parts of styrene, 0.02 to 0.05 part of potassium persulphate, 3 to 5 parts of fused silica, 2 to 3 parts of organic bentonite, 1 to 1.5 parts of sodium ethylene diamine tetracetate, 1 to 2 parts of an antistatic agent SN, 2 to 4 parts of silicone powder and a proper amount of deionized water. According to the invention, cooperation among sodium ethylene diamine tetracetate, the antistatic agent SN and the silicone powder greatly improves the antistatic property and lubricity of calcium carbonate; the preparation method has the advantages of simple production process, reduced cost and suitability for production; and a prepared modified calcium carbonate filling modification material has obviously improved mechanical properties, is simple and convenient to prepare, uses easily available raw materials and has low cost.

Owner:安徽雪城超细碳酸钙有限公司

Modified calcium carbonate with excellent acid resistance and preparation method thereof

InactiveCN105111504AImprove the lubrication effectImprove water resistanceCoatingsPigment treatment with macromolecular organic compoundsPotassium persulfateSodium bicarbonate

The invention discloses modified calcium carbonate with the excellent acid resistance and a preparation method thereof. The modified calcium carbonate is characterized by comprising, by weight, 100 parts to 150 parts of calcium carbonate, 30 parts to 50 parts of sodium oleate, 0.3 part to 0.7 part of sodium dodecyl benzene sulfonate, 1 part to 3 parts of sodium bicarbonate, 4 parts to 8 parts of styrene, 0.02 part to 0.05 part of potassium persulfate, 3 parts to 5 parts of fumed silica, 2 parts to 3 parts of organobentonite, 2 parts to 3 parts of zirconium tetrafluoride, 1 part to 3 parts of epoxy castor oil, 2 parts to 3 parts of sodium tripolyphosphate, 3 parts to 5 parts of shell powder and a proper amount of deionized water. According to the modified calcium carbonate, as the added zirconium tetrafluoride, the added epoxy castor oil, the added sodium tripolyphosphate and the added shell powder are cooperatively used, the calcium carbonate is good in acid resistance and adsorbability, resistant to bacteria, capable of achieving bacteriostasis, resistant to ultraviolet rays and good in heat resistance and light resistance; the modified calcium carbonate can be crosslinked with film forming matter in rubber, plastics and coatings to generate the good surface decoration effect, the performance of a product can be improved, and the modified calcium carbonate is green, safe and worthy of popularization.

Owner:CHIZHOU CELT NANO TECH

Wear-resistant surface modified calcium carbonate filler and preparation method thereof

InactiveCN105153750AImprove the lubrication effectImprove water resistancePigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsSodium bicarbonatePotassium persulfate

The invention discloses a wear-resistant surface modified calcium carbonate filler and a preparation method thereof. The filler is characterized by being prepared from the following raw materials by weight part: 100-150 of calcium carbonate, 30-50 of sodium oleate, 0.3-0.7 of sodium dodecyl benzene sulfonate, 1-3 of sodium bicarbonate, 4-8 of styrene, 0.02-0.05 of potassium persulfate, 3-5 of fumed silica, 2-3 of organic bentonite, 0.5-2 of an aluminate coupling agent, 3-5 of silicon carbide, 2-3 of grapheme, and a proper amount of deionized water. The silicon carbide and graphene added in the invention bond closely with calcium carbonate under the action of the aluminate coupling agent, and enhances the wear resistance, oxidation resistance, high hardness, good tensile strength and other characteristics of calcium carbonate. The wear-resistant surface modified calcium carbonate filler provided by the invention has reasonable formula and simple process, the prepared calcium carbonate filler has excellent performance in all aspects, is suitable for use as an additive of paint and building materials, and endows the product with wear resistance, better durability and longer service life.

Owner:青阳县盈捷非金属材料有限公司

Electric flocculation membrane bioreactor

InactiveCN103539323AImprove efficiencyImprove nitrogen and phosphorus removal efficiencyMultistage water/sewage treatmentActivated sludgeCell activity

The invention discloses an electric flocculation membrane bioreactor comprising a reactor body, wherein a contact oxidation tank, a settling tank and a membrane biological reaction tank are arranged in the reactor body; a contact oxidation aerator and soft fillers are arranged in the contact oxidation tank, the membrane biological reaction tank is communicated with a filtration membrane group, the membrane extraction water outlet of the filtration membrane group is communicated to a pure water discharge pipe, a sewage input pipe is further arranged on the reactor body, at least one group of positive and negative flocculation electrodes is arranged in the reactor body, and the positive and negative flocculation electrodes are electrically connected with an electric flocculation power supply; the contact oxidation tank, the settling tank and the membrane biological reaction tank are mutually communicated in sequence, and a precipitate return pipe is arranged in the settling tank and / or the membrane biological reaction tank. The electric flocculation membrane bioreactor disclosed by the invention can not only effectively reinforce the aggregation state of activated sludge, but also improve the cell activity of the sludge bacteria, enhance the deoxidation and dephosphorization effects, alleviate the membrane pollution and improve the flux and prolong the service life of the membrane, thereby being capable of being widely applied in treatment of various of sanitary sewage.

Owner:DONGTAI CITY DONGFANG MARINE FITTING

Modified calcium carbonate filler with favorable sound absorption and sound insulation effects and preparation method thereof

InactiveCN105038318AImprove suspension stabilityImprove the lubrication effectPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsPotassium persulfateSodium bicarbonate

The invention discloses a modified calcium carbonate filler with favorable sound absorption and sound insulation effects and a preparation method thereof. The invention is characterized in that the modified calcium carbonate filler is prepared from the following raw materials in parts by weight: 100-150 parts of calcium carbonate, 30-50 parts of sodium oleate, 0.3-0.7 part of sodium dodecyl benzene sulfonate, 1-3 parts of sodium bicarbonate, 4-8 parts of styrene, 0.02-0.05 part of potassium persulfate, 3-5 parts of vapor-phase silicon dioxide, 2-3 parts of organobentonite, 3-5 parts of nitrile-butadiene rubber powder, 3-4 parts of elacostearic acid, 2-3 parts of intumescent mica powder and a right amount of deionized water. The compounding of the nitrile-butadiene rubber powder, elacostearic acid and intumescent mica powder greatly enhances the functions of damping, shock absorption, sound absorption and sound insulation of the calcium carbonate. The modified calcium carbonate filler has the advantages of scientific and reasonable design, simple technique, high safety and reliability, low production cost and the like, and is easy to control, convenient to operate and suitable for large-scale production.

Owner:安徽雪城超细碳酸钙有限公司

Modified calcium carbonate with good heatproof property and preparation method thereof

InactiveCN105038321AImprove the lubrication effectImprove water resistancePigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsSodium bicarbonatePotassium persulfate

The invention discloses modified calcium carbonate with a good heatproof property and a preparation method thereof. The modified calcium carbonate is characterized by being prepared from the following raw materials in parts by weight: 100 to 150 parts of calcium carbonate, 30 to 50 parts of sodium oleate, 0.3 to 0.7 parts of sodium dodecyl benzene sulfonate, 1 to 3 parts of sodium bicarbonate, 4 to 8 parts of styrene, 0.02 to 0.05 part of potassium persulfate, 3 to 5 parts of gas-phase silicon dioxide, 2 to 3 parts of organic bentonite, 3 to 4 parts of quartz powder, 1 to 2 parts of alum, 1 to 2 parts of terpineol, and a proper amount of deionized water. The added quartz powder, alum, and terpineol cooperate with each other to improve the properties of calcium carbonate powder such as heatproof property, antibacterial property, fireproof performance, mechanical strength, and the like. The modified calcium carbonate can be used as filler and applied to the fields such as paints, construction, pigments, and the like. Moreover, the preparation technology is simple, the cost is low, and the modified calcium carbonate can be massively produced and is worthy to promote.

Owner:青阳县盈捷非金属材料有限公司

Modified calcium carbonate good in flame retardant effect and preparing method of modified calcium carbonate

InactiveCN105111503AImprove compatibilityEasy to disperseCoatingsPigment treatment with macromolecular organic compoundsAsbestineIon

The invention discloses modified calcium carbonate good in flame retardant effect and a preparing method of the modified calcium carbonate. The modified calcium carbonate is characterized by being prepared from, by weight, 100-150 parts of calcium carbonate, 30-50 parts of sodium oleate, 0.3-0.7 part of sodium dodecyl benzene sulfonate, 1-3 parts of sodium bicarbonate, 4-8 parts of styrene, 0.02-0.05 part of potassium persulfate, 3-5 parts of fumed silica, 2-3 parts of organic bentonite, 2-3 parts of magnesium stearate, 2-3 parts of asbestos fiber, 2-4 parts of antimonous oxide and a proper amount of deionized water. Due to the fact that zinc stearate, the asbestos fiber and the antimonous oxide are added, the effects that the calcium carbonate is not likely to stick to a mold and is good in self-lubrication property are enhanced when the calcium carbonate serves as packing, the calcium carbonate is not likely to burn, and the flame retardant performance of a product is improved. The prepared calcium carbonate powder is good in dispersity, not prone to aggregating or settling, good in comprehensive performance, good in applicability when serving as paint, plastic, pigments and other packing and worthy of popularization.

Owner:CHIZHOU CELT NANO TECH

Modified calcium carbonate filler for paint and preparation method thereof

InactiveCN105038369AImprove compatibilityEasy to disperseCoatingsPigment treatment with macromolecular organic compoundsIonSodium oleate

The invention discloses a modified calcium carbonate filler for paint and a preparation method thereof. The filler is characterized by being prepared from the following raw materials in parts by weight: 100 to 150 parts of calcium carbonate, 30 to 50 parts of sodium oleate, 0.3 to 0.7 part of sodium dodecyl benzene sulfonate, 1 to 3 parts of sodium bicarbonate, 4 to 8 parts of styrene, 0.02 to 0.05 part of potassium persulfate, 3 to 5 parts of gas-phase silicon dioxide, 2 to 3 parts of organic bentonite, 2 to 3 parts of hectorite powder, 1 to 3 parts of palm oil, 2 to 4 parts of calcium carbide slag powder, and a proper amount of deionized water. The added hectorite powder, palm oil, and calcium carbide slag powder can generate a synergetic effect, and can improve the lipophilicity of calcium carbonate, so the modified calcium carbonate can be well dispersed in paint, and the interface interaction is enhanced. Furthermore, the technology is simple and is easy to promote, the cost is low, no pollution is generated, and thus the application prospect is wide.

Owner:青阳县金峰石业有限公司

High fluidity modified calcium carbonate for plastics and preparation method thereof

InactiveCN105153751AImprove the lubrication effectImprove water resistancePigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsPotassium persulfateSodium bicarbonate

The invention discloses a high fluidity modified calcium carbonate for plastics and a preparation method thereof. The high fluidity modified calcium carbonate is characterized by being prepared from the following raw materials by weight part: 100-150 of calcium carbonate, 30-50 of sodium oleate, 0.3-0.7 of sodium dodecyl benzene sulfonate, 1-3 of sodium bicarbonate, 4-8 of styrene, 0.02-0.05 of potassium persulfate, 3-5 of fumed silica, 2-3 of organic bentonite, 0.4-1 of dioctyl phthalate, 1-2 of pregelatinized starch, 1-3 of zinc stearate, and a proper amount of deionized water. The dioctyl phthalate, pregelatinized starch and zinc stearate added in the invention can enhance the self-lubrication and fluidity of calcium carbonate, can reduce material loss during processing, also can enhance the toughness and hardness of plastics, and improve the quality of plastic parts. The high fluidity modified calcium carbonate for plastics provided by the invention has the advantages of simple preparation method, convenient raw material sources, and low cost, and has the effect of reinforcing all performance of products as an industrial filler, thus being worth popularizing.

Owner:池州青阳县龙酉钙业有限公司

Modified calcium carbonate and preparation method thereof

InactiveCN104927401AImprove compatibilityEasy to dispersePigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsSodium oleateSODIUM DODECYL BENZENE SULFONATE

The invention discloses modified calcium carbonate and a preparation method thereof. The modified calcium carbonate is characterized by being prepared from the following raw materials in parts by weight: 100-150 parts of calcium carbonate, 30-50 parts of sodium oleate, 0.3-0.7 part of sodium dodecyl benzene sulfonate, 1-3 parts of sodium bicarbonate, 4-8 parts of styrene, 0.02-0.05 part of potassium persulfate, 3-5 parts of fumed silica, 2-3 parts of organic bentonite, 2-3 parts of polyimide, 0.4-1 part of ammonium bicarbonate, 2-4 parts of high abrasion furnace black and a proper amount of deionized water. The added polyimide, ammonium bicarbonate and high abrasion furnace black are combined with calcium carbonate to enable calcium carbonate to be wear-resistant in surface, lipophilic and hydrophobic, and have the fire-extinguishing property and other properties, the modified calcium carbonate has relatively good compatibility with polymers, and the interface effect is enhanced. The modified calcium carbonate has the advantages of simple modification process, relatively low cost, zero pollution, easy popularization and wide application prospect.

Owner:安徽雪城超细碳酸钙有限公司

Multifunctional environment-friendly modified calcium carbonate and preparation method thereof

InactiveCN105037798AImprove the lubrication effectImprove water resistancePigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsEpoxyPotassium persulfate

The invention discloses multifunctional environment-friendly modified calcium carbonate and a preparation method thereof. The modified calcium carbonate is characterized by being prepared from the following raw materials in parts by weight: 100 to 150 parts of calcium carbonate, 30 to 50 parts of sodium oleate, 0.3 to 0.7 part of sodium dodecyl benzene sulfonate, 1 to 3 parts of sodium bicarbonate, 4 to 8 parts of styrene, 0.02 to 0.05 part of potassium persulfate, 3 to 5 parts of gas-phase silicon dioxide, 2 to 3 parts of organic bentonite, 3 to 4 parts of epoxy triglyceride, 1 to 3 parts of ammonium molybdate, 2 to 4 parts of polyethylene powder, and a proper amount of deionized water. The added epoxy triglyceride, ammonium molybdate, and polyethylene powder interact with each other to strengthen the oleophylic effect of calcium carbonate surface, thus the compatibility between the modified calcium carbonate and organic substances is good, the modified calcium carbonate can be more easily dispersed in high-molecular polymer; the modified calcium carbonate can be used to fill PVC materials, the reinforcing effect is better than that of common calcium carbonate, the modified calcium carbonate is environment-friendly and safe, and has a good application effect in various fields, and thus the modified calcium carbonate is worthy to promote.

Owner:青阳县盈捷非金属材料有限公司

Calamine lotion with bacteriostatic effect

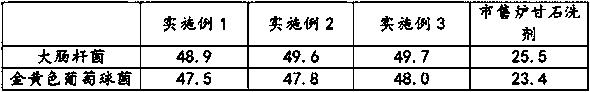

PendingCN109674750AGood dispersionGood suspensionHydroxy compound active ingredientsInorganic active ingredientsAdditive ingredientSuspending Agents

The invention discloses calamine lotion with a bacteriostatic effect. The calamine lotion is prepared from the following raw materials in parts by weight: 140-160 parts of modified calamine, 45-55 parts of zinc oxide, 5-7 parts of modified nano zinc oxide, 8-10 parts of officinal phenol, 6-8 parts of antibiotic, 10-12 parts of menthol, 20-26 parts of tween 20, 7-10 parts of glycerinum, 2-3 parts of sodium carboxymethylcellulose, and 800-900 parts of purified water. The calamine lotion disclosed by the invention takes the modified calamine and the zinc oxide as main effective ingredients of thelotion, wherein the anti-bacterial, convergent, antiseptic and antipruritic effects of the both ingredients are strong; through adding a proper amount of the modified nano zinc oxide, the lotion is endowed with good antibacterial performance; the officinal phenol is capable of prolonging a using expiration date of a preparation, increasing stability of the preparation, and enhancing the sterilizing, bacteriostatic and antipruritic effects of the preparation; in addition, in a preparation process of the calamine lotion, a sodium carboxymethylcellulose suspending agent is added to increase thestability of suspension; and the calamine lotion with the bacteriostatic effect, stable characters and a strong physiological property is prepared.

Owner:JIANGSU PENGYAO PHARMA

Modified calcium carbonate with high whiteness and wide application range and preparation method thereof

InactiveCN105086516AStir wellImprove the lubrication effectPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsPotassium persulfateSodium bicarbonate

The invention discloses modified calcium carbonate with high whiteness and a wide application range and a preparation method thereof. Modified calcium carbonate is characterized by being prepared from the following raw materials in parts by weight: 100-150 parts of calcium carbonate, 30-50 parts of sodium oleate, 0.3-0.7 part of sodium dodecyl benzene sulfonate, 1-3 parts of sodium bicarbonate, 4-8 parts of styrene, 0.02-0.05 part of potassium persulfate, 3-5 parts of fumed silica, 2-3 parts of organic bentonite, 1-2 parts of shea butter, 2-3 parts of nano barium sulfate, 2-3 parts of activated zinc oxide and proper amount of deionized water. The whiteness of calcium carbonate powder is improved and the light, weather and chemical corrosion resistance, impact strength, and the like of the product can be improved through synergistic effects of the shea butter, nano barium sulfate and activated zinc oxide, so that the quality of the product is greatly improved and the product is worthy to be popularized.

Owner:CHIZHOU CELT NANO TECH

Corrosion resistant modified calcium carbonate with excellent overall performances and preparation method thereof

InactiveCN104927399AImprove the lubrication effectImprove water resistancePigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsCorrosion resistantPolytetrafluoroethylene

The invention discloses corrosion resistant modified calcium carbonate with excellent overall performances and a preparation method thereof. The corrosion resistant modified calcium carbonate is characterized by comprising the following raw materials in parts by weight: 100-150 parts of calcium carbonate, 30-50 parts of sodium oleate, 0.3-0.7 part of sodium dodecyl benzene sulfonate, 1-3 parts of sodium bicarbonate, 4-8 parts of styrene, 0.02-0.05 part of potassium persulfate, 3-5 parts of fumed silica, 2-3 parts of organobentonite, 1-2 parts of trioctyl trimellitate, 2-4 parts of glass dust, 2-5 parts of polytetrafluoroethylene powder and appropriate amount of deionized water. According to the invention, the added trioctyl trimellitate, glass dust and polytetrafluoroethylene powder have a synergistic effect to enhance the corrosion resistance, acid resistance and abrasion resistance of calcium carbonate and are added into a coating to improve the hardness, tenacity and weather fastness of a paint film; when the modified calcium carbonate prepared through the preparation method disclosed by the invention is added into a coating, the enhancement function is realized, the paint quality is improved, the cost is reduced, and the preparation technology is simple and deserves popularization.

Owner:安徽雪城超细碳酸钙有限公司

Easily dispersable and nonsettleable modified calcium carbonate and preparation method thereof

InactiveCN105153752AImprove the lubrication effectImprove water resistancePigment treatment with macromolecular organic compoundsPigment physical treatmentPotassium persulfateSodium bicarbonate

The invention discloses an easily dispersable and nonsettleable modified calcium carbonate and a preparation method thereof. The modified calcium carbonate is characterized by being prepared from the following raw materials by weight part: 100-150 of calcium carbonate, 30-50 of sodium oleate, 0.3-0.7 of sodium dodecyl benzene sulfonate, 1-3 of sodium bicarbonate, 4-8 of styrene, 0.02-0.05 of potassium persulfate, 3-5 of fumed silica, 2-3 of organic bentonite, 1-2 of disproportionated potassium rosinate, 3-5 of palm oil, 2-3 of talcum powder, and a proper amount of deionized water. The disproportionated potassium rosinate, palm oil and talcum powder added in the invention enhance the corrosion resistance and mechanical properties of calcium carbonate, the process is safe and environment friendly, energy-saving and cost-reducing. The preparation method is simple, and is worthy of promotion.

Owner:池州青阳县龙酉钙业有限公司

Modified calcium carbonate with good mildew-resistant and insect-preventing effects and preparation method thereof

InactiveCN104987755AImprove the lubrication effectImprove water resistancePigment treatment with non-polymer organic compoundsSodium bicarbonateSodium Bentonite

The invention discloses modified calcium carbonate with good mildew-resistant and insect-preventing effects and a preparation method thereof. The modified calcium carbonate is characterized by being prepared from the following raw materials by weight: 100 to 150 parts of calcium carbonate, 30 to 50 parts of sodium oleate, 0.3 to 0.7 part of sodium dodecyl benzene sulfonate, 1 to 3 parts of sodium bicarbonate, 4 to 8 parts of styrene, 0.02 to 0.05 part of potassium persulphate, 3 to 5 parts of fused silica, 2 to 3 parts of organic bentonite, 1 to 3 parts of eucalyptus oil, 0.4 to 1 part of geramine, 3 to 5 parts of diatomite and a proper amount of deionized water. According to the invention, the added eucalyptus oil, geramine and diatomite have natural bactericidal, mildew-resistant and insect-preventing effects, can greatly enhance bactericidal, mildew-resistant and insect-preventing effects of calcium carbonate when mixed with calcium carbonate and enable the modified calcium carbonate to be easy to store; and through mixing of surfactants with a plurality of functions, surface energy and interfacial tension of particles are greatly reduced, auto-agglutination of micronized particles can be effectively prevented, and the modified calcium carbonate has improved compatibility and dispersibility in plastic and rubber, good mildew-resistant, insect-preventing and bactericidal properties and wide application prospect and is worth popularization.

Owner:安徽雪城超细碳酸钙有限公司

Modified calcium carbonate for automobile plastic and preparation method thereof

InactiveCN105038322AImprove the lubrication effectImprove water resistancePigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsSodium bicarbonatePotassium persulfate

The invention discloses modified calcium carbonate for automobile plastic and a preparation method thereof. The modified calcium carbonate is characterized by being composed of the following raw materials in parts by weight: 100 to 150 parts of calcium carbonate, 30 to 50 parts of sodium oleate, 0.3 to 0.7 part of sodium dodecyl benzene sulfonate, 1 to 3 parts of sodium bicarbonate, 4 to 8 parts of styrene, 0.02 to 0.05 part of potassium persulfate, 3 to 5 parts of gas-phase silicon dioxide, 2 to 3 parts of organic bentonite, 2 to 4 parts of zinc oxide, 1 to 2 parts of silane coupling agent kh550, 3 to 4 parts of meerschaum powder, and a proper amount of deionized water. The added zinc oxide and meerschaum powder can be bonded to calcium carbonate under the action of coupling agent, thus the sterilizing performance, thermal insulation property, and anticorrosion performance of calcium carbonate are further enhanced, the modified calcium carbonate can be applied to automobile plastic to prolong the service life of automobile shell, at the same time, anti-aging performance and decorative effect of the automobile plastic are also strengthened, the automobile quality is improved therefore, and the modified calcium carbonate is worthy to promote.

Owner:池州青阳县龙酉钙业有限公司

Modified calcium carbonate having sterilization and deodorization effects and preparation method thereof

InactiveCN105111793AImprove the lubrication effectImprove water resistancePigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsSodium bicarbonatePotassium persulfate

The invention discloses modified calcium carbonate having sterilization and deodorization effects and a preparation method thereof. The modified calcium carbonate is characterized by being prepared from, 100-150 parts of calcium carbonate, 30-50 parts of sodium oleate, 0.3-0.7 part of sodium dodecyl benzene sulfonate, 1-3 parts of sodium bicarbonate, 4-8 parts of styrene, 0.02-0.05 part of potassium persulfate, 3-5 parts of gas phase silica, 2-3 parts of organic bentonite, 3-4 parts of dried tea residue powder, 2-3 parts of zinc borate, 1-2 parts of emulsified paraffin and an appropriate amount of deionized water. The added emulsified paraffin, the added dried tea residue powder and the added zinc borate attach to the surface of calcium carbonate powder and are good in adhesive power, heat stability and dispersibility and have natural sterilization, purification and deodorization effects. The modified calcium carbonate is wide in usage range, has good using effect when serving as a functional paper assistant, a preservative film assistant, a pigment or other additives, is safe, is environmentally friendly and is worth of popularization.

Owner:CHIZHOU CELT NANO TECH

Modified calcium carbonate capable of reinforcing plastic strength and preparation method therefor

InactiveCN105111499AImprove the lubrication effectImprove water resistancePotassium persulfateSodium bicarbonate

The present invention discloses a modified calcium carbonate capable of reinforcing plastic strength and a preparation method therefor. The modified calcium carbonate is characterized of being prepared by the following raw materials in parts by weight: 100-150 parts of calcium carbonate, 30-50 parts of sodium oleate, 0.3-0.7 parts of sodium dodecyl benzene sulfonate, 1-3 parts of sodium bicarbonate, 4-8 parts of styrene, 0.02-0.05 parts of potassium persulfate, 3-5 parts of fumed silica, 2-3 parts of organobentonite, 2-4 parts of dimethyl silicone oil, 3-5 parts of brown corundum powder, 0.6-1.4 parts of boric acid ester coupling agent, and an appropriate amount of deionized water. According to the present invention, the added dimethyl silicone oil and brown corundum powder has a good cohesiveness with the calcium carbonate powder under an effect of the boric acid ester coupling agent, and therefore the strength, the hardness, the fire resistance and the fire-proof property of the calcium carbonate powder are reinforced, and when the modified calcium carbonate is used as a filler of a plastic material, the modified calcium carbonate has a reinforcing effect, which can greatly improve the property of the plastic, and has a wide application prospect.

Owner:陈传松

Modified calcium carbonate with heat insulation and heat preservation effects and preparation method thereof

InactiveCN104945956AImprove the lubrication effectImprove water resistancePigment treatment with macromolecular organic compoundsPigment physical treatmentSODIUM DODECYL BENZENE SULFONATEPolymer

The invention discloses modified calcium carbonate with heat insulation and heat preservation effects and a preparation method thereof. The modified calcium carbonate is prepared from 100-150 parts by weight of calcium carbonate, 30-50 parts by weight of sodium oleate, 0.3-0.7 parts by weight of sodium dodecyl benzene sulfonate, 1-3 parts by weight of sodium bicarbonate, 4-8 parts by weight of styrene, 0.02-0.05 parts by weight of potassium persulphate, 3-5 parts by weight of fumed silica, 2-3 parts by weight of organic bentonite, 1-2 parts by weight of aluminum sulfate, 2-4 parts by weight of polyoxyethylene, 1-1.5 parts by weight of cetanol and a proper amount of deionized water. Through interaction of aluminum sulfate, polyoxyethylene and cetanol, heat insulation, heat preservation and erosion resistance of calcium carbonate are greatly promoted. The modified calcium carbonate is superior to unmodified calcium carbonate, and obviously improves calcium carbonate use performances such as tensile property and rigidity in a polymer. The modification method is simple and environmentally friendly. Compared with the existing product, the product obtained by the preparation method has higher performances and a good application prospect and is suitable for large scale production.

Owner:安徽雪城超细碳酸钙有限公司

Anti-aging effect enhanced modified calcium carbonate and preparation method therefor

InactiveCN105111790AGood compatibilityImprove the lubrication effectPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsSodium bicarbonatePotassium persulfate

The invention discloses anti-aging effect enhanced modified calcium carbonate and a preparation method therefor. The anti-aging effect enhanced modified calcium carbonate is characterized by being prepared from the following raw materials in parts by weight: 100-150 parts of calcium carbonate, 30-50 parts of sodium oleate, 0.3-0.7 part of sodium dodecylbenzene sulfonate, 1-3 parts of sodium bicarbonate, 4-8 parts of styrene, 0.02-0.05 part of potassium persulfate, 3-5 parts of aerosil, 2-3 parts of organobentonite, 1-3 parts of silane coupling agent kh560, 1-2 parts of straw ash, 2-4 parts of PVC (Polyvinyl Chloride) waste powder and a proper volume of deionized water. According to the anti-aging effect enhanced modified calcium carbonate and the preparation method therefor, the added silane coupling agent kh560, straw ash and PVC waste powder are subjected to waste recycling, so that the modified calcium carbonate is energy-saving and environment-friendly, and resources are saved; due to matched use, properties such as aging resistance, weather resistance, oil resistance, corrosion resistance and the like of the modified calcium carbonate are greatly enhanced; and the modified calcium carbonate disclosed by the invention has good organic substance compatibility, is good in performance of all aspects and is stable in quality. The modified calcium carbonate is low in production cost and is suitable for serving as various industrial fillers.

Owner:陈传松

Modified calcium carbonate for uvioresistant cable material and preparation method thereof

The invention discloses modified calcium carbonate for an uvioresistant cable material and a preparation method thereof. The modified calcium carbonate is characterized by being prepared from, by weight, 100-150 parts of calcium carbonate, 30-50 parts of sodium oleate, 0.3-0.7 part of sodium dodecyl benzene sulfonate, 1-3 parts of sodium bicarbonate, 4-8 parts of styrene, 0.02-0.05 part of potassium persulfate, 3-5 parts of gas phase silica, 2-3 parts of organic bentonite, 2-4 parts of emulsified paraffin, 2-4 parts of carbon nano powder, 2-3 parts of sodium lignosulphonate and an appropriate amount of deionized water. The added carbon nano powder, the added sodium lignosulphonate and the added emulsified paraffin improve the dispersibility of calcium carbonate powder, and the modified calcium carbonate is good in fluidity and excellent in uvioresistant performance and can prolong the service life of the cable material when serving as the packing of the cable material. The preparation method is simple, raw material sources are wide, the cost is low, and the modified calcium carbonate has very good strengthening effect when serving as the packing of the cable material, and is worthy of popularization.

Owner:CHIZHOU CELT NANO TECH

Coking wastewater treatment method and coking wastewater treatment device

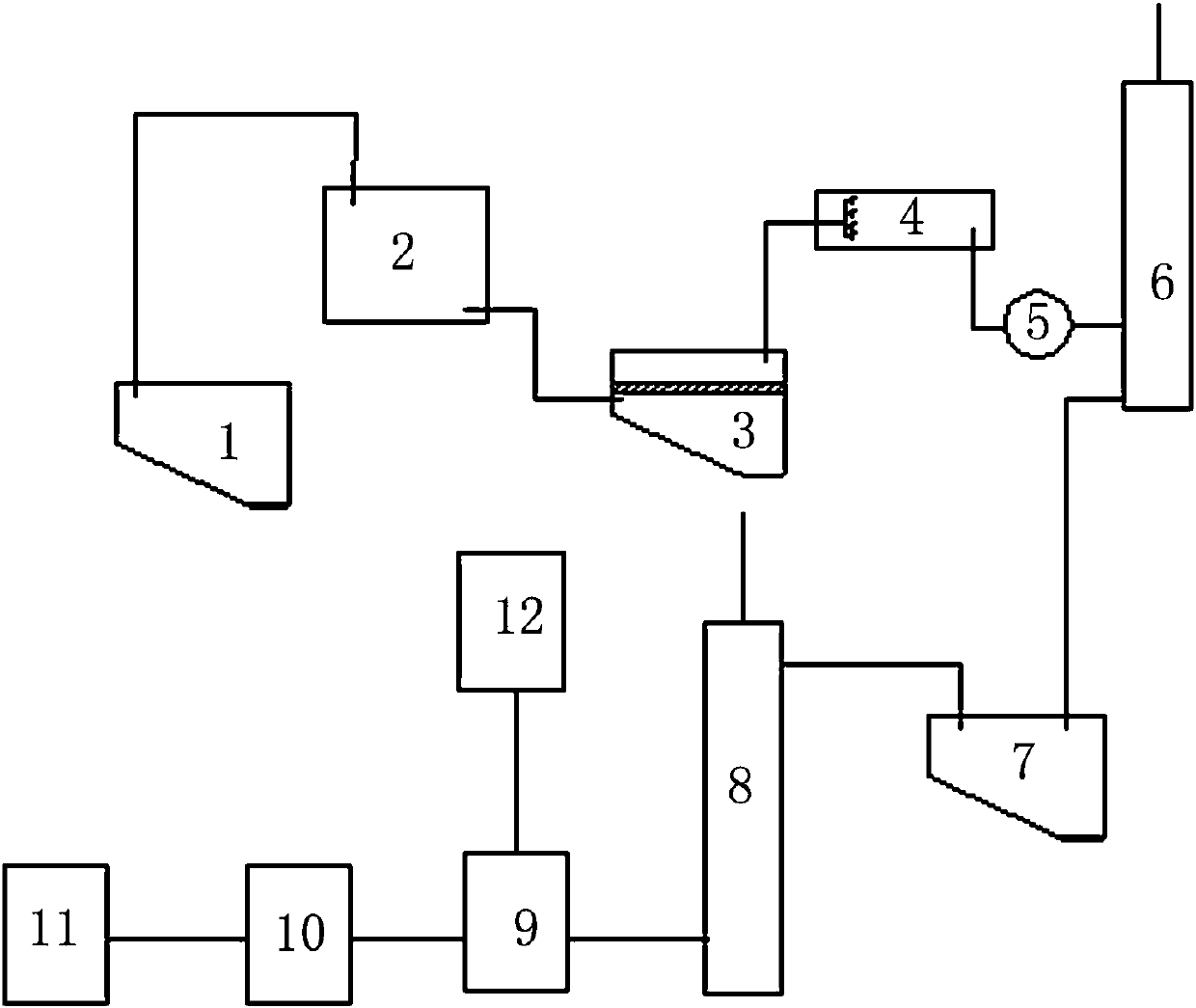

PendingCN107935299AImprove processing efficiencyMeet the requirements of circulating waterTreatment using aerobic processesTreatment involving filtrationVolatile phenolsActivated carbon filtration

The invention discloses a coking wastewater treatment method and a coking wastewater treatment device, and relates to the technical field of coking wastewater treatment. The coking wastewater treatment method comprises the following steps: (1) standing wastewater to be treated, and filtering the wastewater to be treated to remove large-particle impurity deposits; (2) adding phosphoric acid to thewastewater, and filtering obtained precipitate; (3) carrying out high pressure atomization on the wastewater, spraying the atomized wastewater into a high-temperature smoke section, carrying out flashevaporation, generating salt crystals through a desulfurization tower, and cooling the wastewater; (4) carrying out multistage countercurrent extraction on the cooled wastewater with an extractant toobtain non-volatile phenols and monohydric phenols; (5) carrying out oxidation treatment on the wastewater through an aeration bio-filter; (6) filtering the wastewater by active carbon with the particle size being 90-130 [mu]m; (7) treating the wastewater by a membrane bioreactor; and (8) carrying out reverse osmosis filtration treatment on the wastewater through a reverse osmosis filtration device. The method and the device have the advantages of significant improvement the treatment efficiency of the coking wastewater, meeting the requirements of circulating water, stability in system running, and low cost.

Owner:山西振钢生物科技股份有限公司

Modified calcium carbonate for papermaking and preparation method thereof

InactiveCN105038319AImprove the lubrication effectImprove water resistanceInorganic compound additionPigment treatment with macromolecular organic compoundsSodium bicarbonatePotassium persulfate

The invention discloses modified calcium carbonate for papermaking and a preparation method thereof. The modified calcium carbonate is characterized by being prepared from the following raw materials in parts by weight: 100 to 150 parts of calcium carbonate, 30 to 50 parts of sodium oleate, 0.3 to 0.7 part of sodium dodecyl benzene sulfonate, 1 to 3 parts of sodium bicarbonate, 4 to 8 pats of styrene, 0.02 to 0.05 part of potassium persulfate, 3 to 5 parts of gas-phase silicon dioxide, 2 to 3 parts of organic bentonite, 1 to 2 parts of zinc stearate, 3 to 5 parts of linen-cotton fiber slurry, 1 to 2 parts of dimethyl diallyl ammonium chloride, and a proper amount of deionized water. The added zinc stearate, linen-cotton fiber slurry and dimethyl diallyl ammonium chloride can generate a synergetic effect, can be well dispersed, and can be tightly adhered to calcium carbonate to strengthen the alkali-resistant and salt-resistant performance of calcium carbonate. Moreover, the modified calcium carbonate is high efficient and nontoxic, is easy to control, can increase the paper whiteness and enhance the paper strength, and has a wide application prospect.

Owner:青阳县金峰石业有限公司

Modified calcium carbonate having good water-repellent oleophilic moisture-proof effects and preparation method thereof

InactiveCN105111792AImprove the lubrication effectImprove water resistancePigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsSodium bicarbonatePotassium persulfate

The invention discloses modified calcium carbonate having good water-repellent oleophilic moisture-proof effects and a preparation method thereof. The modified calcium carbonate is characterized by being prepared from, by weight, 100-150 parts of calcium carbonate, 30-50 parts of sodium oleate, 0.3-0.7 part of sodium dodecyl benzene sulfonate, 1-3 parts of sodium bicarbonate, 4-8 parts of styrene, 0.02-0.05 part of potassium persulfate, 3-5 parts of gas phase silica, 2-3 parts of organic bentonite, 1-2 parts of homo-polypropylene, 2-4 parts of nano iron slag, 1-2 parts of palmitic acid isopropyl ester and an appropriate amount of deionized water. The added nano iron slag, the added homo-polypropylene and the added palmitic acid isopropyl ester produce mutual effects to enable calcium carbonate powder to have good water-repellent, oleophilic, moisture-proof, mechanical and impact-resisting characteristics, and the modified calcium carbonate has very good strengthening effect when serving as a packing, improves the quality of a product and is wide in application field and worthy of popularization.

Owner:CHIZHOU CELT NANO TECH

Modified calcium carbonate padding for architectural decoration and preparation method thereof

InactiveCN104927402AImprove the lubrication effectImprove water resistancePigment treatment with macromolecular organic compoundsPigment physical treatmentSodium bicarbonatePhosphoric acid

The invention discloses a modified calcium carbonate padding for architectural decoration and a preparation method thereof. The padding is characterized by being prepared from the following raw materials in parts by weight: 100-150 parts of calcium carbonate, 30-50 parts of sodium oleate, 0.3-0.7 part of sodium dodecyl benzene sulfonate, 1-3 parts of sodium bicarbonate, 4-8 parts of styrene, 0.02-0.05 part of potassium peroxodisulfate, 3-5 parts of fumed silica, 2-3 parts of organic bentonite, 3-5 parts of shale ash, 2-4 parts of ardealite powder, 1-2 parts of aluminum dihydrogen tripolyphosphate and a moderate amount of deionized water. According to the preparation method, the added shale ash, ardealite powder and aluminum dihydrogen tripolyphosphate can significantly improve the rigidity, whiteness and stability of calcium carbonate, and have the characteristics of being anticorrosive and weather-proof, and capable of keeping relatively high strength; moreover, the cost is reduced; the preparation method provided by the invention is simple and convenient to operate; industrialization is easy to achieve; the produced padding has a good decorative function if used in architectural decoration industry.

Owner:安徽雪城超细碳酸钙有限公司

Styrene-coated modified calcium carbonate and preparation method thereof

InactiveCN104987753AImprove the lubrication effectImprove water resistancePigment treatment with macromolecular organic compoundsPigment physical treatmentFiberSodium bicarbonate

The invention discloses styrene-coated modified calcium carbonate and a preparation method thereof. The styrene-coated modified calcium carbonate is characterized by being prepared from the following raw materials by weight: 100 to 150 parts of calcium carbonate, 30 to 50 parts of sodium oleate, 0.3 to 0.7 part of sodium dodecyl benzene sulfonate, 1 to 3 parts of sodium bicarbonate, 4 to 8 parts of styrene, 0.02 to 0.05 part of potassium persulphate, 3 to 5 parts of fused silica, 2 to 3 parts of organic bentonite, 1 to 2 parts of magnesium laurate, 3 to 4 parts of meerschaum fiber, 3 to 5 parts of coconut shell charcoal and a proper amount of deionized water. According to the invention, the added magnesium laurate, meerschaum fiber and coconut shell charcoal interact to promote adsorptivity, resistance to acidic and alkaline corrosion, heat insulation and radiation resistance of calcium carbonate; and the prepared modified calcium carbonate has good dispersibility, heat insulation performance and corrosion resistance and is capable of reducing cost and improving various processing performances and service life of products when applied to a variety of materials.

Owner:安徽雪城超细碳酸钙有限公司

Enhanced modified calcium carbonate used as cable filler and preparation method thereof

InactiveCN105001676AImprove the lubrication effectImprove water resistancePigment treatment with macromolecular organic compoundsPigment physical treatmentSodium bicarbonateSilicon dioxide

The invention discloses an enhanced modified calcium carbonate used as cable filler and a preparation method thereof. The enhanced modified calcium carbonate is characterized by being prepared from the following raw materials in part by weight: 100-150 parts of calcium carbonate, 30-50 parts of sodium oleate, 0.3-0.7 parts of sodium dodecyl benzene sulfonate, 1-3 parts of sodium bicarbonate, 4-8 parts of styrene, 0.02-0.05 parts of potassium persulphate, 3-5 parts of gas phase silica, 2-3 parts of organic bentonite, 2-3 parts of polyisobutylene, 0.4-0.9 parts of 1,6-hexanediol diacrylate, 3-5 parts of vermiculite powder and a proper amount of deionized water. Polyisobutylene, 1,6-hexanediol diacrylate and vermiculite powder which are added according to the invention are matched for usage, so that acid and alkali resistance, acid corrosion and alkaline corrosion resistance, shrinkage resistance, fire resistance, insulation performance and other characteristics of the calcium carbonate powder are enhanced. When the product provided by the invention is used as a filling material of a cable, wear resistance, corrosion resistance, fire resistance, shrinkage resistance and performance in other aspects of the cable are improved. Material production cost is reduced and market competitiveness is improved.

Owner:青阳县金峰石业有限公司

Modified calcium carbonate with good electrical conductivity and preparation method therefor

InactiveCN105111789AImprove compatibilityEasy to dispersePigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsIonChemistry

The present invention discloses a modified calcium carbonate with a good electrical conductivity and preparation method therefor. The modified calcium carbonate is characterized of being prepared by the following raw materials in parts by weight: 100-150 parts of calcium carbonate, 30-50 parts of sodium oleate, 0.3-0.7 parts of sodium dodecyl benzene sulfonate, 1-3 parts of sodium bicarbonate, 4-8 parts of styrene, 0.02-0.05 parts of potassium persulfate, 3-5 parts of fumed silica, 2-3 parts of organobentonite, 3-5 parts of artificial graphites, 2-3 parts of polydimethylsiloxane, 2-4 parts of conductive carbon black, and an appropriate amount of deionized water. According to the calcium carbonate provided by the present invention, the added artificial graphites, polydimethylsiloxane and conductive carbon black promote an excellent and durable electrical conductivity of the calcium carbonate, so that a plastic material uses the calcium carbonate is provided with a high cracking resistance, pressure resistance and stablility, and the material has an improved corrosion resistance, a prolonged service life, a simple preparation process, can be mass produced, and has a wide application prospect.

Owner:陈传松

Modified calcium carbonate having good processability and preparation method thereof

InactiveCN105111791AImprove the lubrication effectImprove water resistancePigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsSodium bicarbonatePotassium persulfate

The invention discloses modified calcium carbonate having good processability and a preparation method thereof. The modified calcium carbonate is characterized by being prepared from, by weight, 100-150 parts of calcium carbonate, 30-50 parts of sodium oleate, 0.3-0.7 part of sodium dodecyl benzene sulfonate, 1-3 parts of sodium bicarbonate, 4-8 parts of styrene, 0.02-0.05 part of potassium persulfate, 3-5 parts of gas-phase silica, 2-3 parts of organic bentonite, 2-3 parts of quartz powder, 1-3 parts of glycerol monostearate, 2-3 parts of straw fiber powder and anappropriate amount of deionized water. The added quartz powder, the added glycerol monostearate and the added straw fiber powder improve the advantages of dispersibility, antistatic property, abrasion resistance, fire resistance, high mechanical strength, good adsorbability and the like of the calcium carbonate, the calcium carbonate can have good compatibility with lots of substances, produces stronger bonding power, serves as a packing to be added and does not reduce the performance of a product, the cost can be reduced, and the modified calcium carbonate is high in large-scale production feasibility and worthy of popularization.

Owner:CHIZHOU CELT NANO TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com