Calamine lotion with bacteriostatic effect

A technology of calamine lotion and antibacterial effect, which is applied in the direction of local antibacterial agents, medical preparations with no active ingredients, medical preparations containing active ingredients, etc., and can solve the limitations of clinical application of calamine lotion, suspension Insufficient performance, no bactericidal effect, etc., to improve suspension performance, enhance water absorption and expansion performance, and improve anti-inflammatory effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

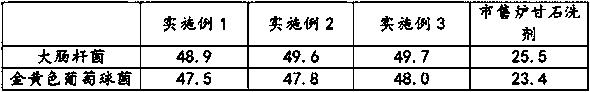

Examples

Embodiment 1

[0067] A calamine lotion with antibacterial effect, made of the following raw materials in parts by weight: 140 parts of modified calamine, 45 parts of zinc oxide, 5 parts of modified nano-zinc oxide, 8 parts of medicinal phenol, antibiotic 6 parts, 10 parts of menthol, 20 parts of Tween 20, 7 parts of glycerin, 2 parts of sodium carboxymethylcellulose, 800 parts of purified water;

[0068] Described calamine lotion is made by following steps:

[0069] Step S1, adding sodium carboxymethyl cellulose to purified water 10 times its mass, stirring and dissolving to make sodium carboxymethyl cellulose solution;

[0070] Step S2, mixing medicinal phenol and antibiotics, adding them into purified water according to the solid-to-liquid ratio of 1 g: 25 mL, heating to raise the temperature of the purified water to 68° C., and stirring to dissolve all the solids to obtain the first mixed solution;

[0071] Step S3, mixing Tween 20 and glycerin, stirring evenly to obtain a second mixed ...

Embodiment 2

[0077] A calamine lotion with antibacterial effect is made of the following raw materials in parts by weight: 150 parts of modified calamine, 50 parts of zinc oxide, 6 parts of modified nano-zinc oxide, 9 parts of medicinal phenol, antibiotic 7 parts, 11 parts of menthol, 23 parts of Tween 20, 8.5 parts of glycerin, 2.5 parts of sodium carboxymethylcellulose, 850 parts of purified water;

[0078] Described calamine lotion is made by following steps:

[0079] Step S1, adding sodium carboxymethyl cellulose to purified water whose mass is 13 times larger, stirring and dissolving to make a sodium carboxymethyl cellulose solution;

[0080] Step S2, mixing medicinal phenol and antibiotics, adding them into purified water according to the solid-to-liquid ratio of 1 g: 28 mL, heating to raise the temperature of the purified water to 70° C., and stirring to dissolve all the solids to obtain the first mixed solution;

[0081] Step S3, mixing Tween 20 and glycerin, stirring evenly to ob...

Embodiment 3

[0087] A calamine lotion with antibacterial effect is made of the following raw materials in parts by weight: 160 parts of modified calamine, 55 parts of zinc oxide, 7 parts of modified nano-zinc oxide, 10 parts of medicinal phenol, antibiotic 8 parts, 12 parts of menthol, 26 parts of Tween 20, 10 parts of glycerin, 3 parts of sodium carboxymethylcellulose, 900 parts of purified water;

[0088] Described calamine lotion is made by following steps:

[0089] Step S1, adding sodium carboxymethyl cellulose to purified water 15 times its mass, stirring and dissolving to make sodium carboxymethyl cellulose solution;

[0090] Step S2, mixing medicinal phenol and antibiotics, adding them into purified water according to the solid-to-liquid ratio of 1 g: 30 mL, heating to raise the temperature of the purified water to 72°C, and stirring to dissolve all the solids to obtain the first mixed solution;

[0091] Step S3, mixing Tween 20 and glycerin, stirring evenly to obtain a second mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com