Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

101results about How to "Reduce transmission error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

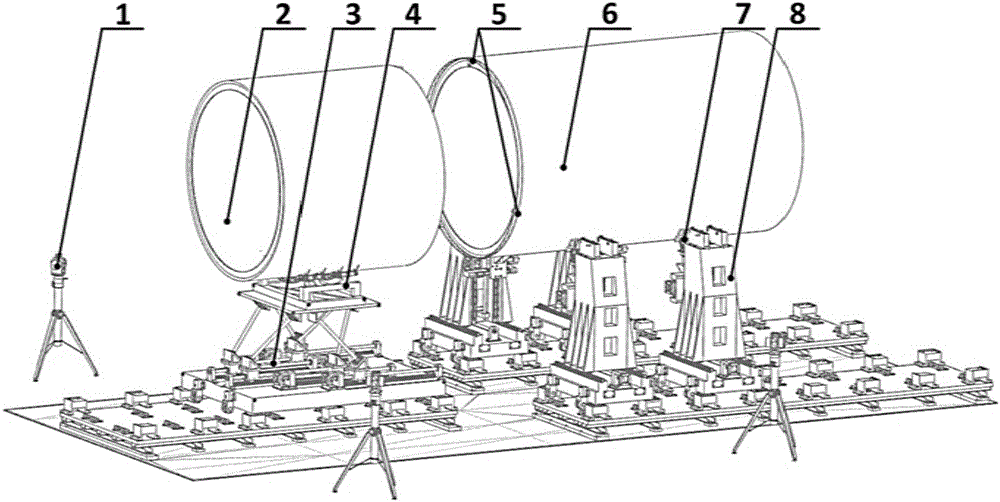

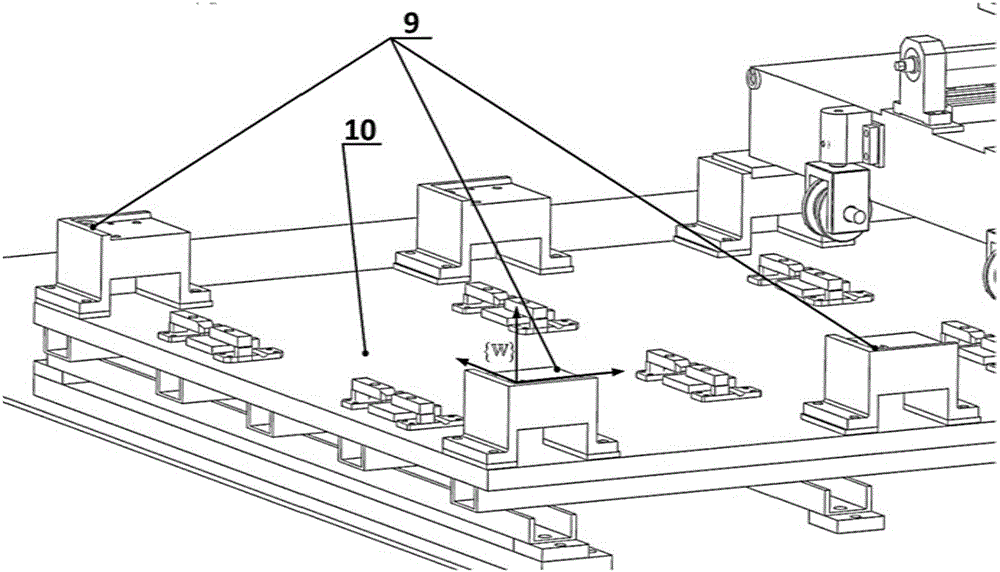

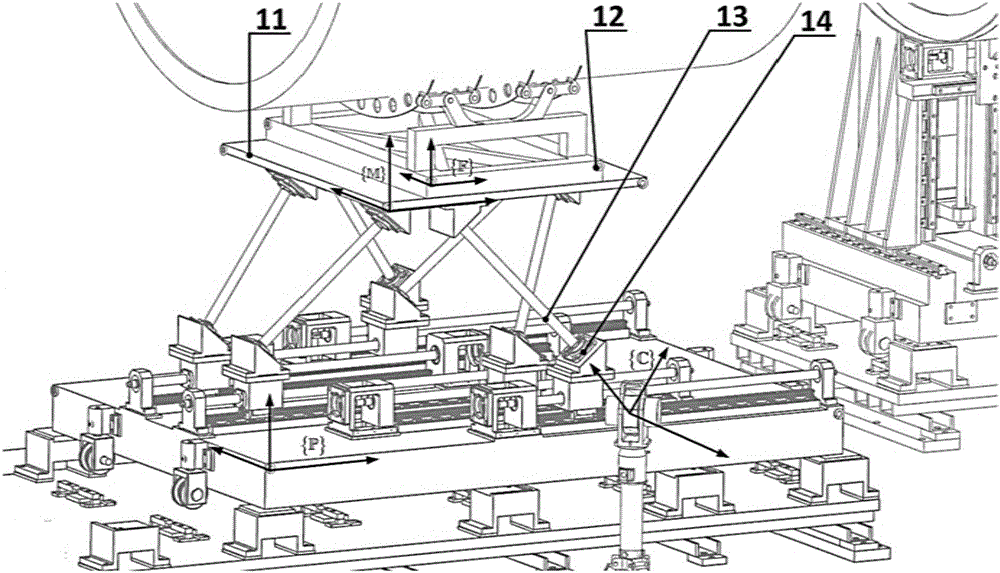

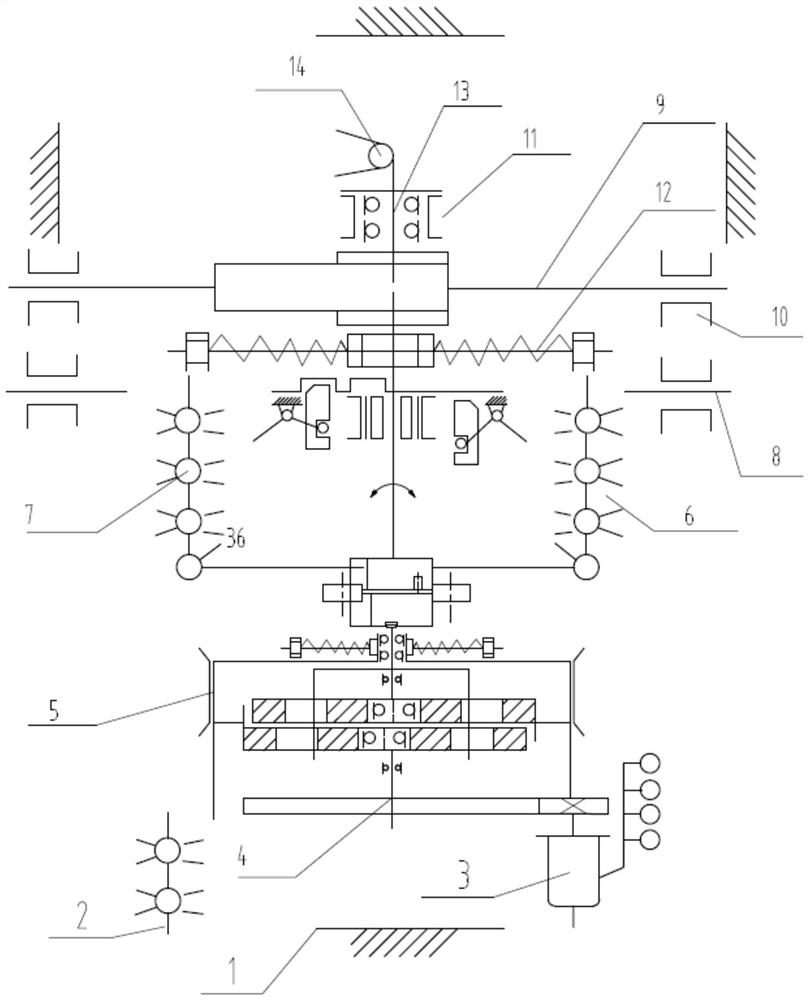

Automatic butt assembling method for large part as well as system

ActiveCN105787200AReduce the impactReduce transmission errorGeometric CADAssembly machinesKinematicsMathematical model

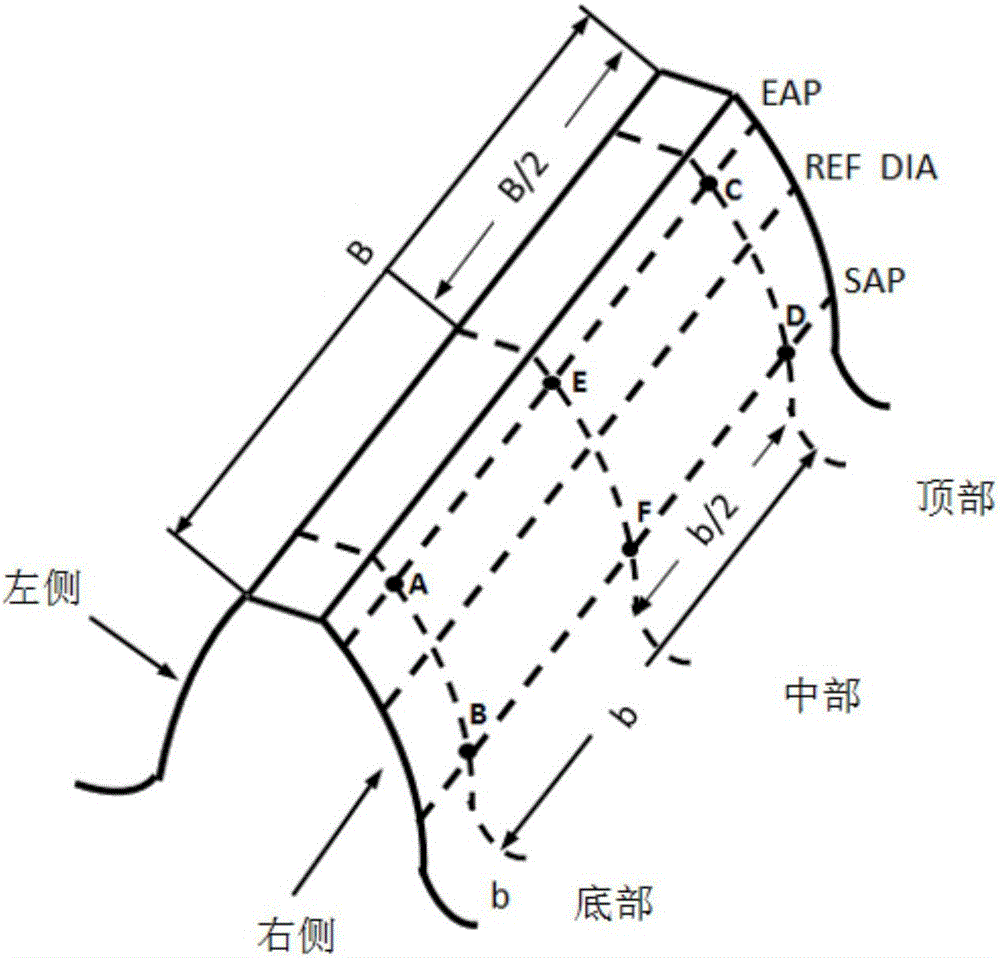

The invention discloses an automatic butt assembling method for a large part as well as a system. The method comprises steps as follows: kinematic parameters of a servo posture adjusting positioner under the loading condition are calibrated firstly, an actual mathematical model of a butt part is established according to measurement data of the butt part, the butt part is corrected or reworked through comparison of the actual mathematical model and an ideal mathematical model of the butt part, then the relative position between a butt feature point of the butt part and a support measurement point arranged on a support device is calibrated, the butt part is mounted on the servo posture adjusting positioner, the position of the butt part in an overall reference coordinate system is determined, then a path of the butt part is planned with the optimum matching algorithm, the driving amount of each shaft of the servo posture adjusting positioner is obtained through inverse solution, finally, the butt part is moved by the servo posture adjusting positioner, and butt assembly of the butt part is completed. According to the automatic butt assembling method for the large part as well as the system, transfer errors are reduced, and errors caused by utilization of the ideal mathematical model or non-measurable property of the butt feature point are avoided, so that the quality and the success rate of automatic assembly are guaranteed.

Owner:SHANGHAI JIAO TONG UNIV

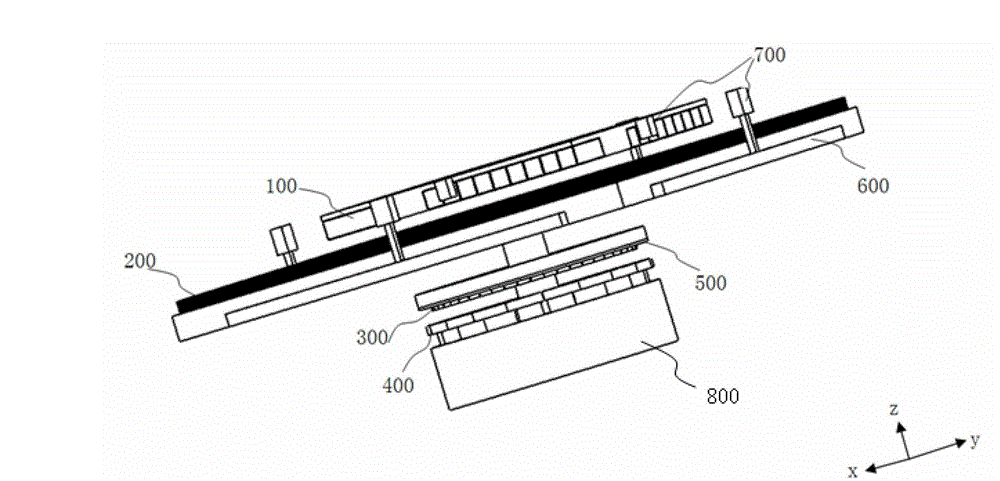

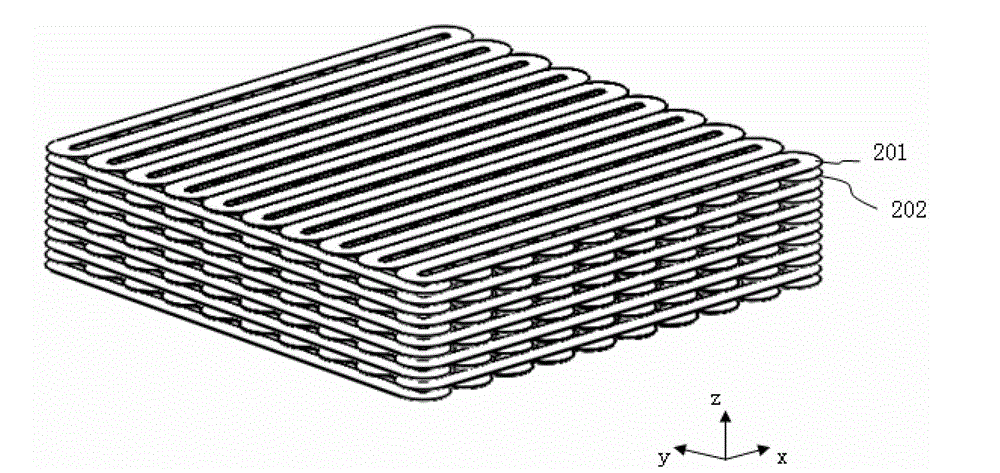

Six degrees of freedom magnetic levitation workpiece table

ActiveCN103066894ASimple structureSmall footprintMechanical energy handlingPositioning apparatusCoil arrayElectric machine

Provided is a six degrees of freedom magnetic levitation workpiece table. The six degrees of freedom magnetic levitation workpiece table comprises a base, a rotating drive device, a surface movement device, an angle measurement device and a displacement measurement device, wherein the displacement measurement comprises four linear motors and four Phrase Shift Driver (PSD) components. Under the action of the rotating drive device, a surface movement device permanent magnetic array stator which is connected with a rotating drive device annular permanent magnetic array rotor through a shaft rotates, a phrase difference is formed between the surface movement device permanent magnetic array rotor and a surface movement device coil array stator, and the magnetic levitation workpiece table, namely, the surface movement device permanent magnetic array rotor achieves rotation of 360 degrees. Meanwhile, the surface movement device permanent array rotor conducts a large-scale surface movement under the action of lorentz force, conducts narrow range rotation around an X shaft and a Y shaft and movement along a Z shaft and achieves the six degrees of freedom movement of the magnetic levitation workpiece table.

Owner:TSINGHUA UNIV +1

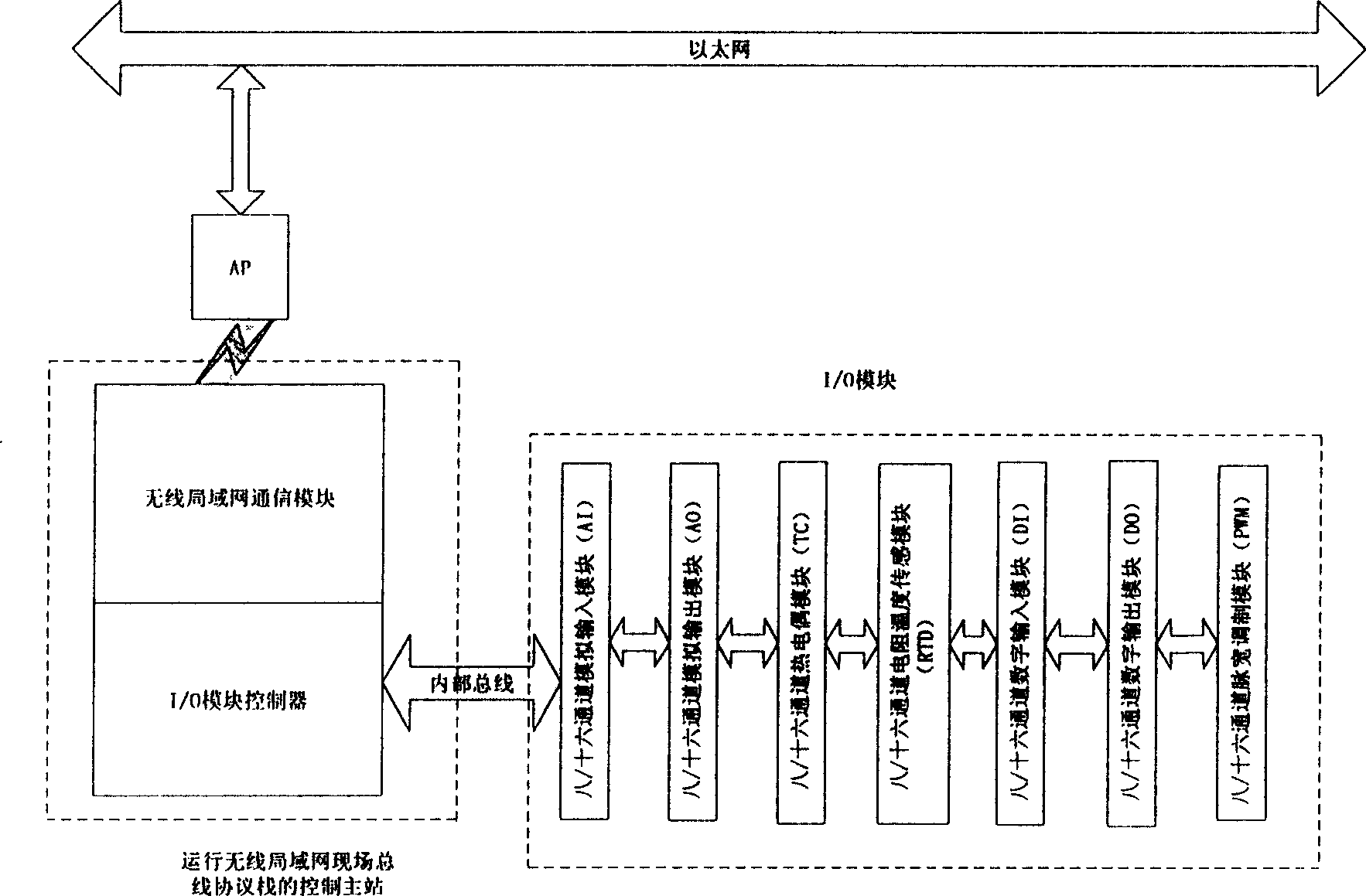

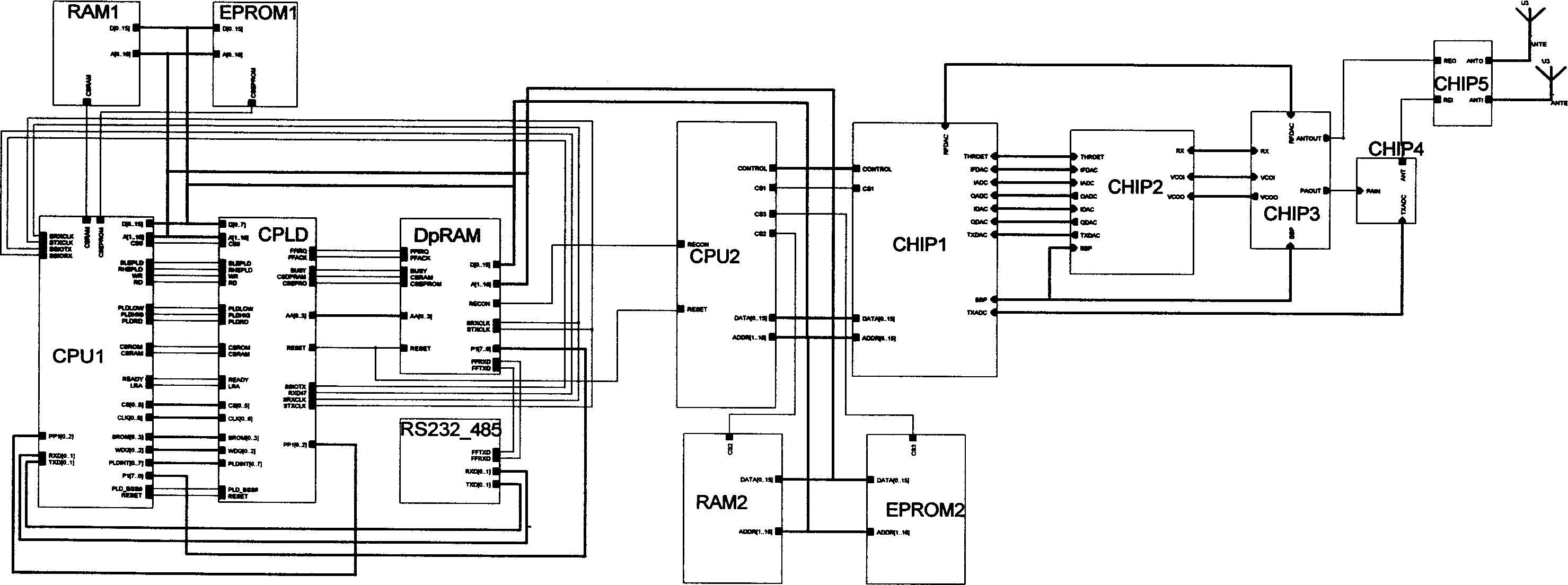

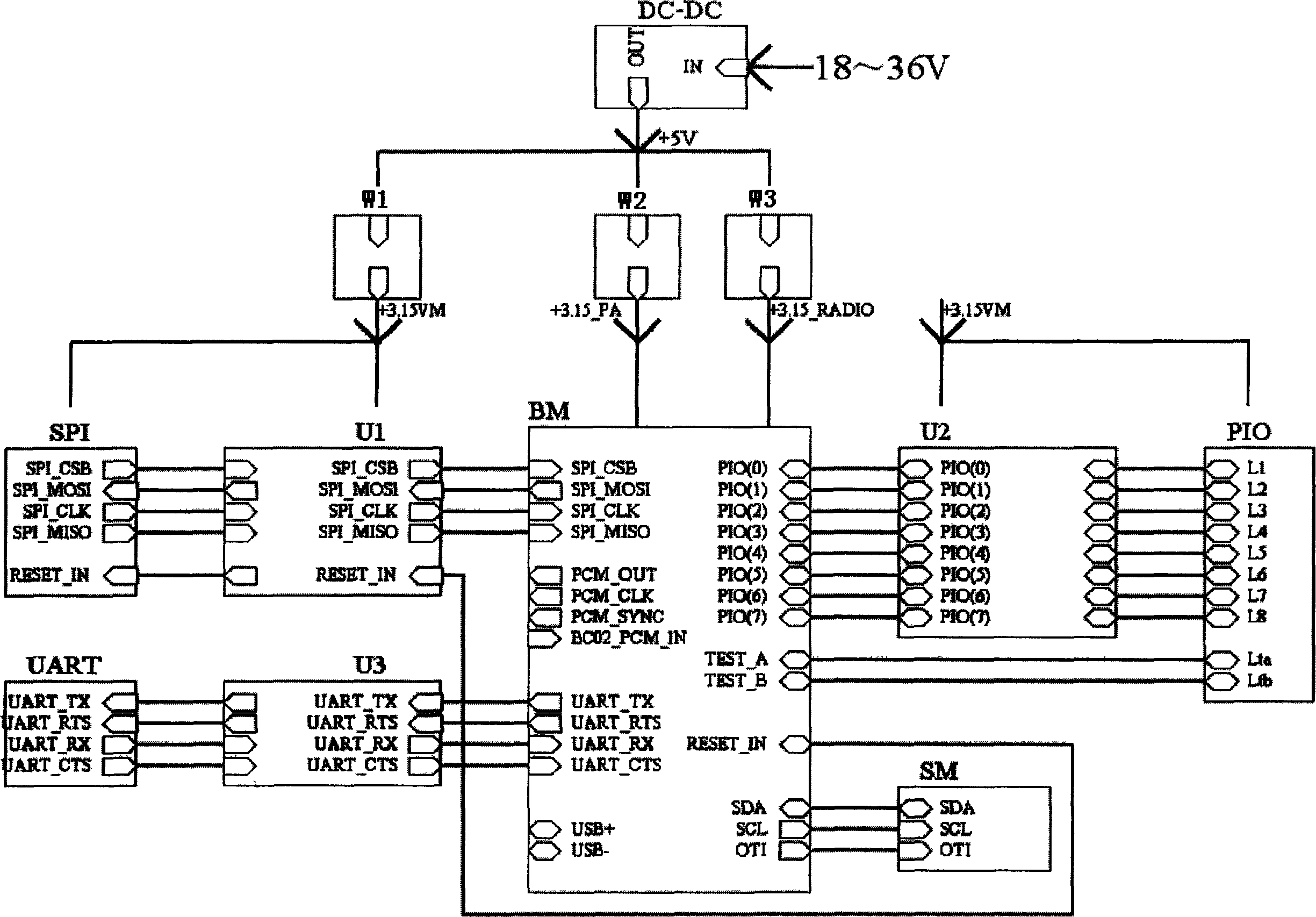

Wireless local area network on-site bus network control station

InactiveCN1567114ASupport hot swapSupport plug and play technologyTotal factory controlElectric digital data processingAutomatic controlDistributed structure

This invention relates to auto-control field, which in detail is used to a wireless LAN on-site bus net control station. It comprises main control station and I / O module, wherein, its main control station runs the wireless LAN on-site bus agreements and accomplishes the distribution I / O control through I / O module controller and receives and transmits data to Ethernet through wireless LAN transmission module. The I / O module is to accomplish the collection and conversion of the on-site signals. It is based on intelligence control device of the wireless Ethernet and turns the DCS total distributed system structure into new type of total distribution structure to completely distribute the control into the on site by network control station. This invention especially applies to old industry control system reconstruction to make it possible for old enterprises to enter the new time of on-site bus.

Owner:无锡中科泛在信息技术研发中心有限公司

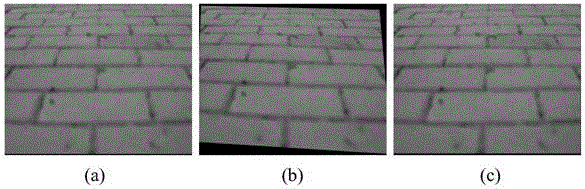

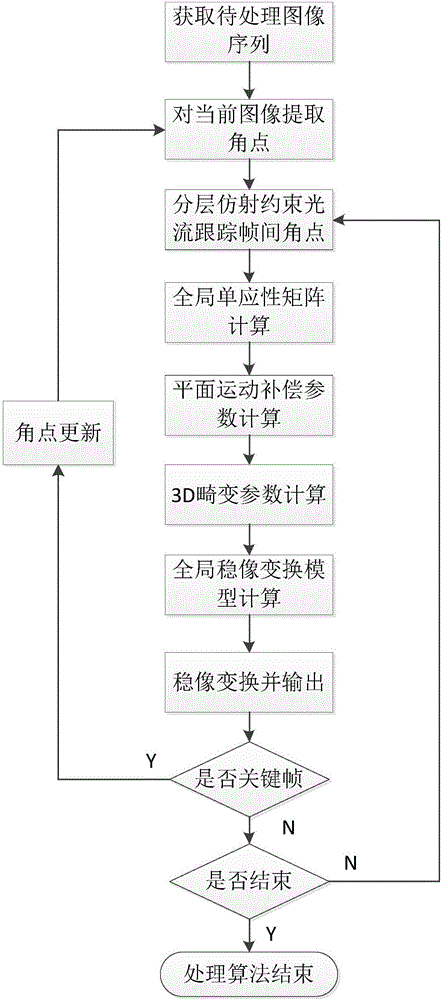

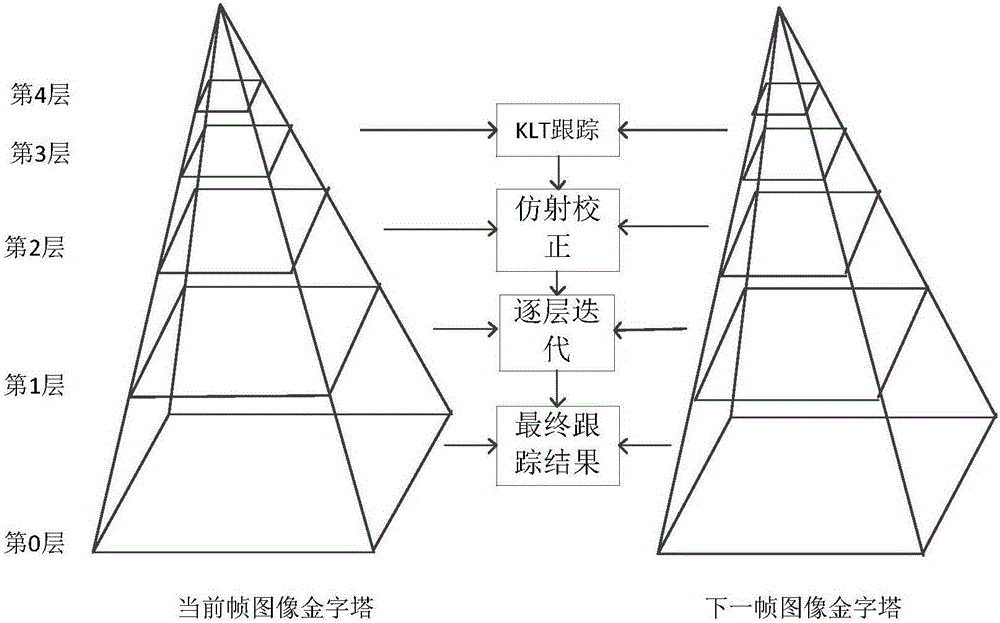

Real-time video stabilization method based on homography matrix

ActiveCN106550174AReduce transmission errorIncrease inlier ratioTelevision system detailsColor television detailsCorrection algorithmVideo sequence

The invention discloses a real-time video stabilization method based on a homography matrix and is used for stabilizing video sequences obtained by devices such as a handheld DV and an unmanned aerial vehicle. The method comprises the steps of A, extracting angular points uniformly distributed in images; B, calculating an interframe optical flow vector and tracking an interframe motion angular point through utilization of the interframe optical flow vector; C, calibrating the tracked angular point through utilization of a layered affine calibration algorithm; D, solving an interframe homography matrix through utilization of a random sampling unification algorithm; E, separating interframe active motion compensation quantity and distortion calibration quantity by employing a kalman filter; and F, carrying out stabilization conversion on one video image by employing the homography matrix, the motion compensation quantity and the distortion calibration quantity to obtain stabilized current frame output. According to the method, shake existing in the video sequences can be effectively removed, the algorithm complexity is relatively low, the operation speed is fast, and the high application value is provided for the real-time video processing system.

Owner:DALIAN UNIV OF TECH

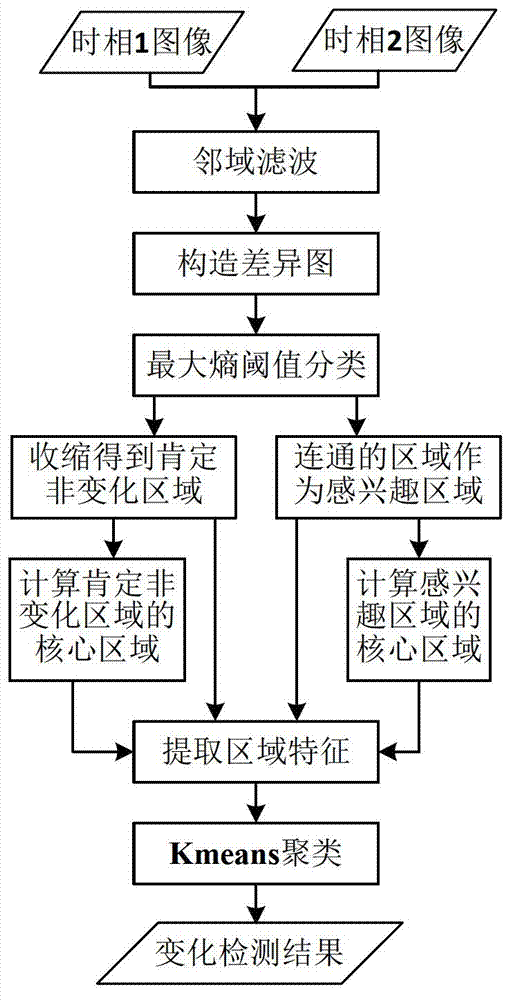

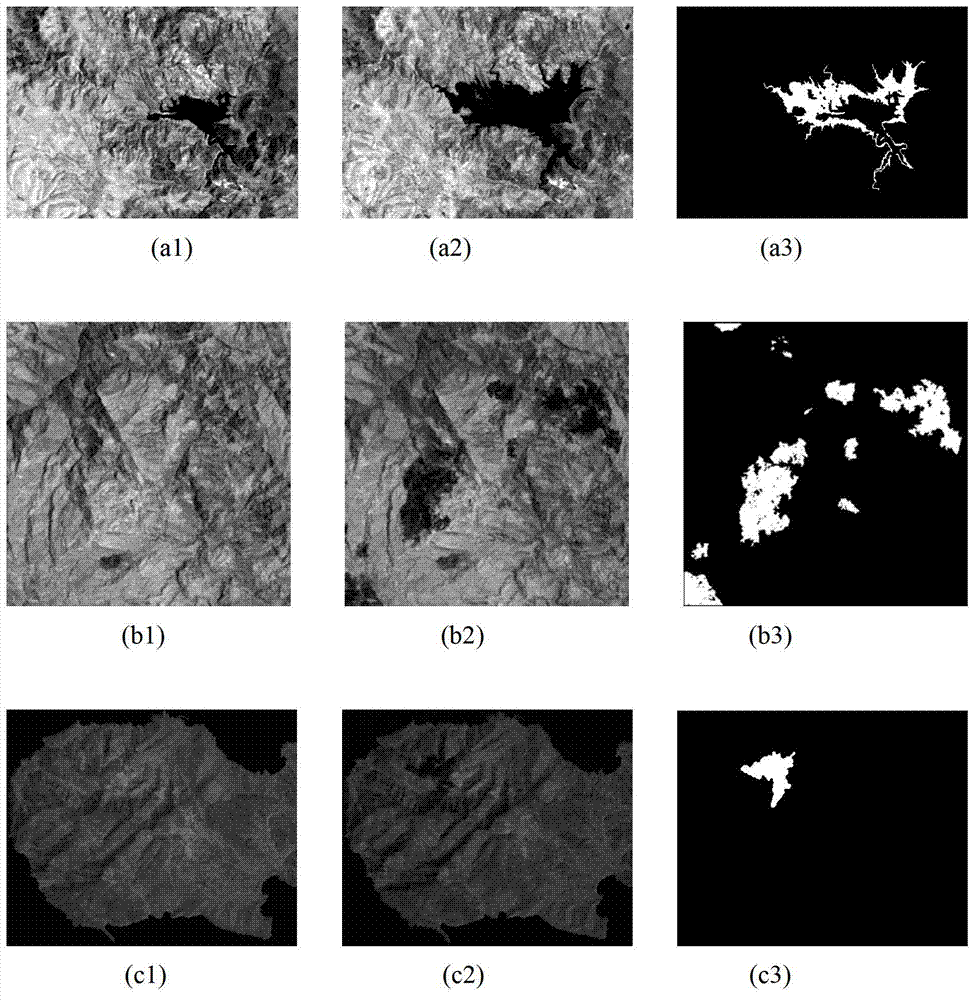

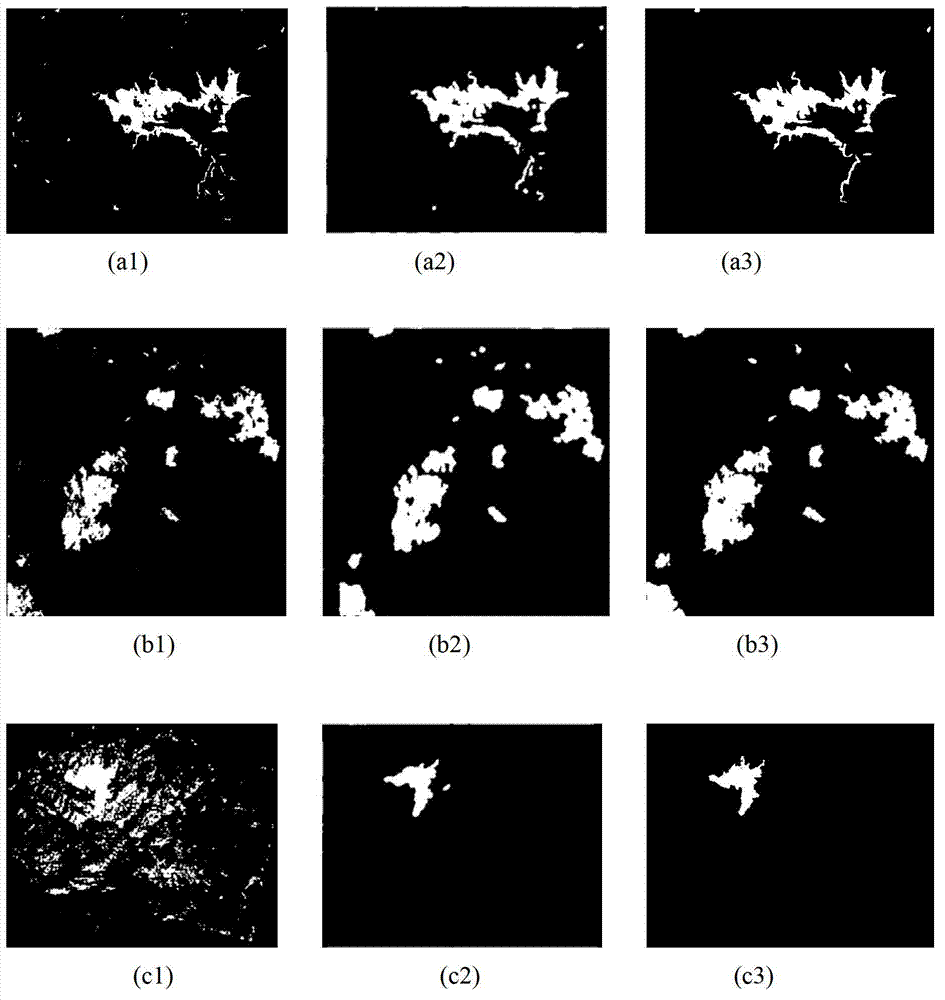

Remote sensing image change detection method based on area and Kmeans clustering

InactiveCN103198480AReduce transmission errorImprove Segmentation AccuracyImage analysisFeature vectorCluster algorithm

The invention discloses a remote sensing image change detection method based on an area and Kmeans clustering. The remote sensing image change detection method based on the area and the Kmeans clustering mainly solves the problems that an existing detection result has isolated pixel points and cavities exist in the area. The remote sensing image change detection method based on the area and the Kmeans clustering comprises the steps of reading-in two registered images X1 and X2, wherein the time phase of the image X1 is different from the time phase of the image X2; constructing a difference image after the image X1 and the image X2 are filtered; carrying out maximum entropy threshold segmentation on the difference image to extract interested areas and confirm non-variable areas; calculating feature vectors of the interested areas and the non-variable areas; dividing all areas into two classes according to the characteristics of the confirmed non-variable areas and all the interested areas by means of the Kmeans clustering algorithm; using an area corresponding to a difference image with a high graying value as a variable area and other areas of the difference image are used as non-variable areas according to a clustering result, and finally obtaining a change detection result. According to the remote sensing image change detection method based on the area and the Kmeans clustering, the detection result can maintain the consistency of the interior of the area, the isolated pixel points are removed, and detection precision is improved. The remote sensing image change detection method based on the area and the Kmeans clustering can be used for resource monitoring and disaster evaluation.

Owner:XIDIAN UNIV

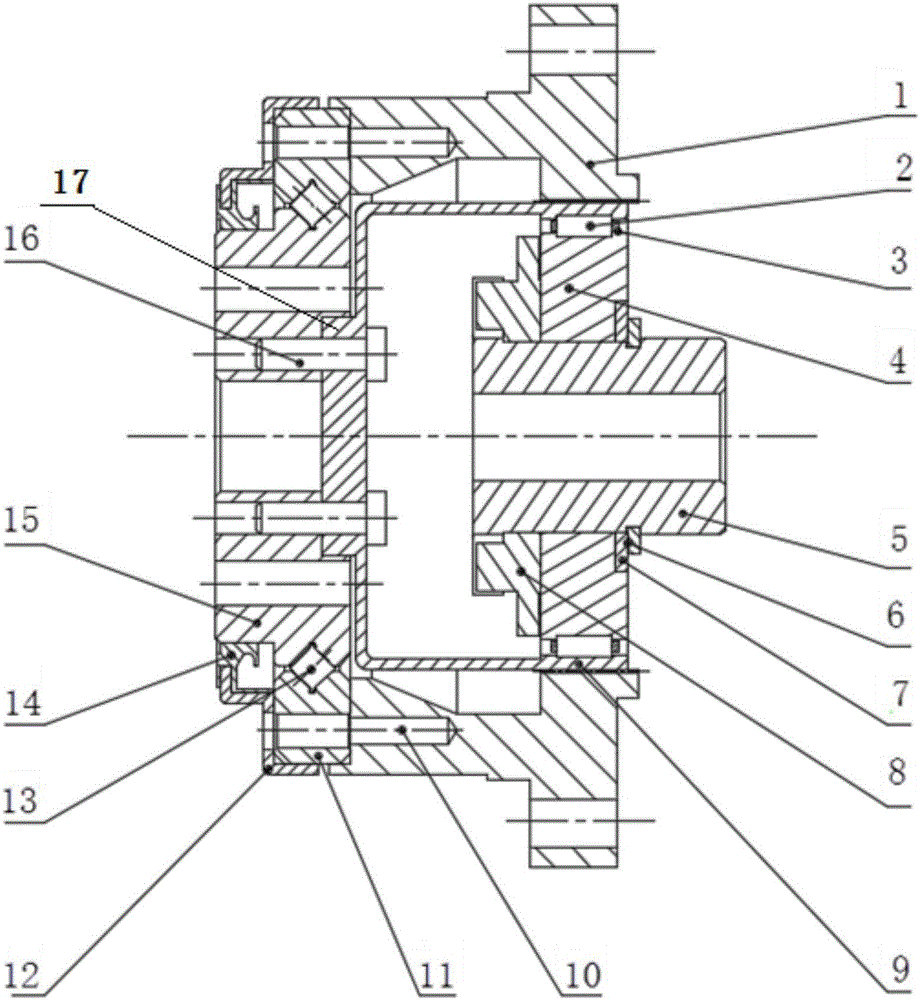

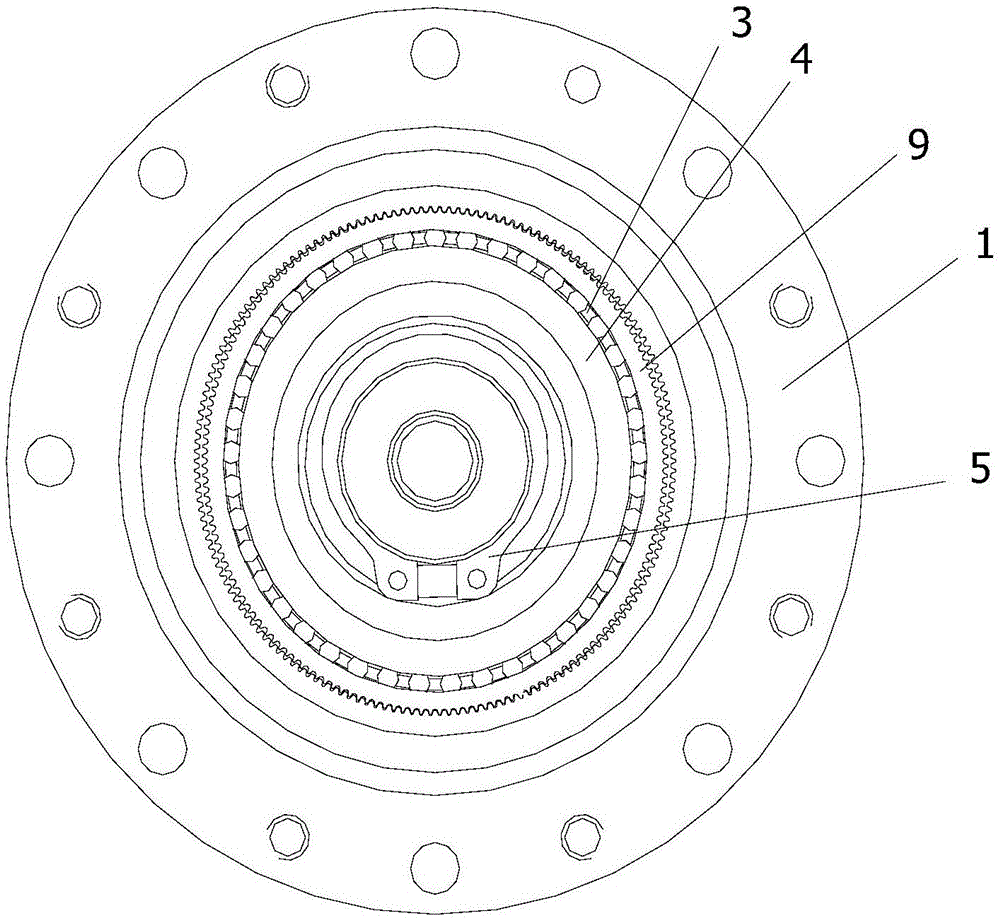

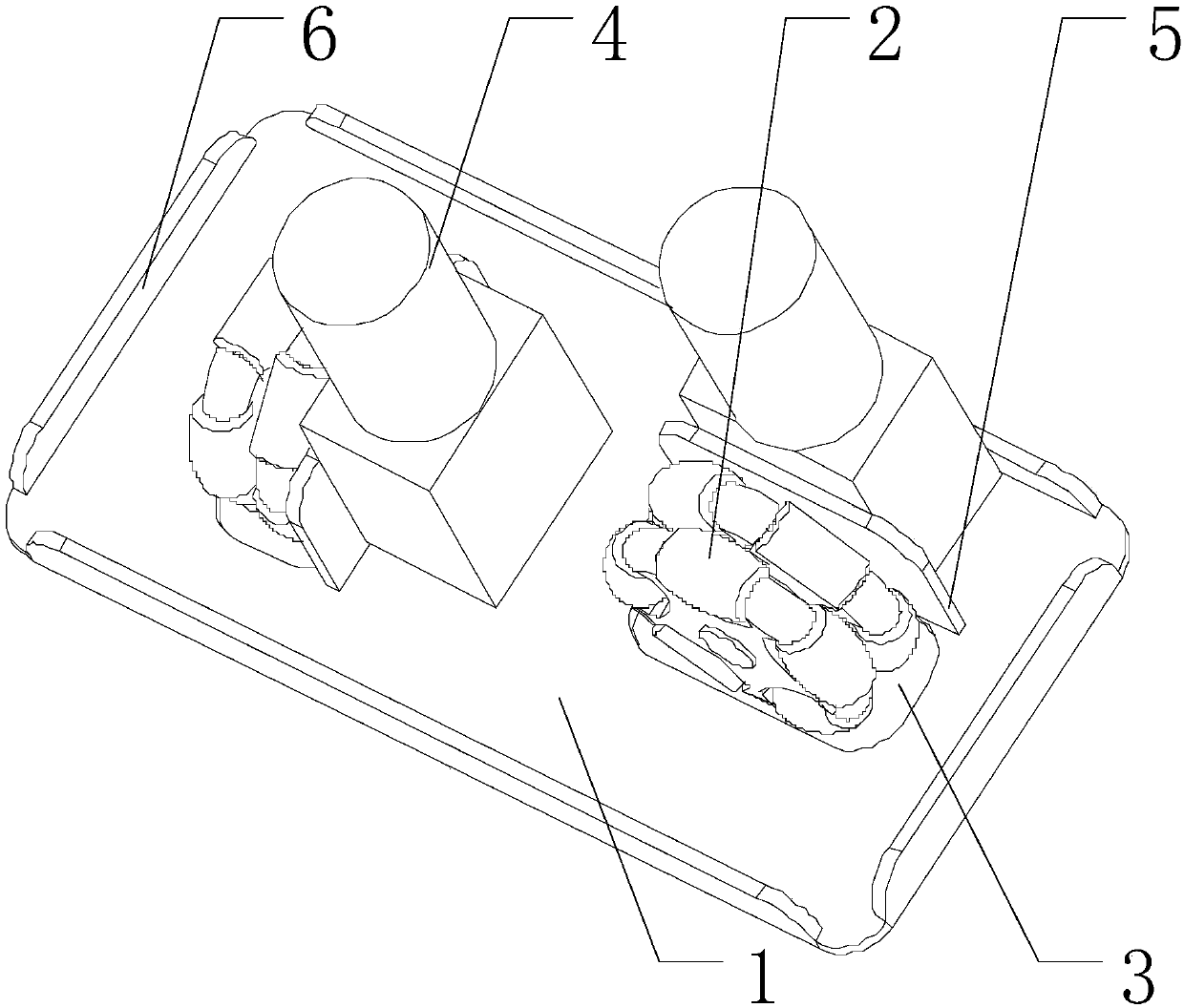

Novel harmonic reducer and input transmission structure thereof

The invention discloses a novel harmonic-reducer input transmission structure. The novel harmonic-reducer input transmission structure comprises a cam connected with an input shaft, and the cam is sleeved with a flexible gear; a steel gear is engaged with the flexible gear, outer teeth are arranged on the flexible gear, inner teeth are arranged on the steel gear, and the flexible gear is engaged with the steel gear through the outer teeth and the inner teeth; a keeping frame is arranged between the flexible gear and the cam, and a cylinder roller is installed in the keeping frame; annular flanges are formed inside the flexible gear and outside the cam in an outward-protruding mode, and C-shaped grooves matched with the cylinder roller are formed in the annular flanges; the annular flanges are located on the outer-tooth side of the flexible gear. By means of the novel harmonic-reducer input transmission structure, the assembly stress of a key part of a harmonic reducer is reduced or eliminated, the engaging stress of the steel gear and the flexible gear in the movement process is reduced, the input structure and the output structure of the harmonic reducer are newly designed, the movement of the harmonic reducer is more stable during working, and the service life is prolonged.

Owner:HUNAN UNIV

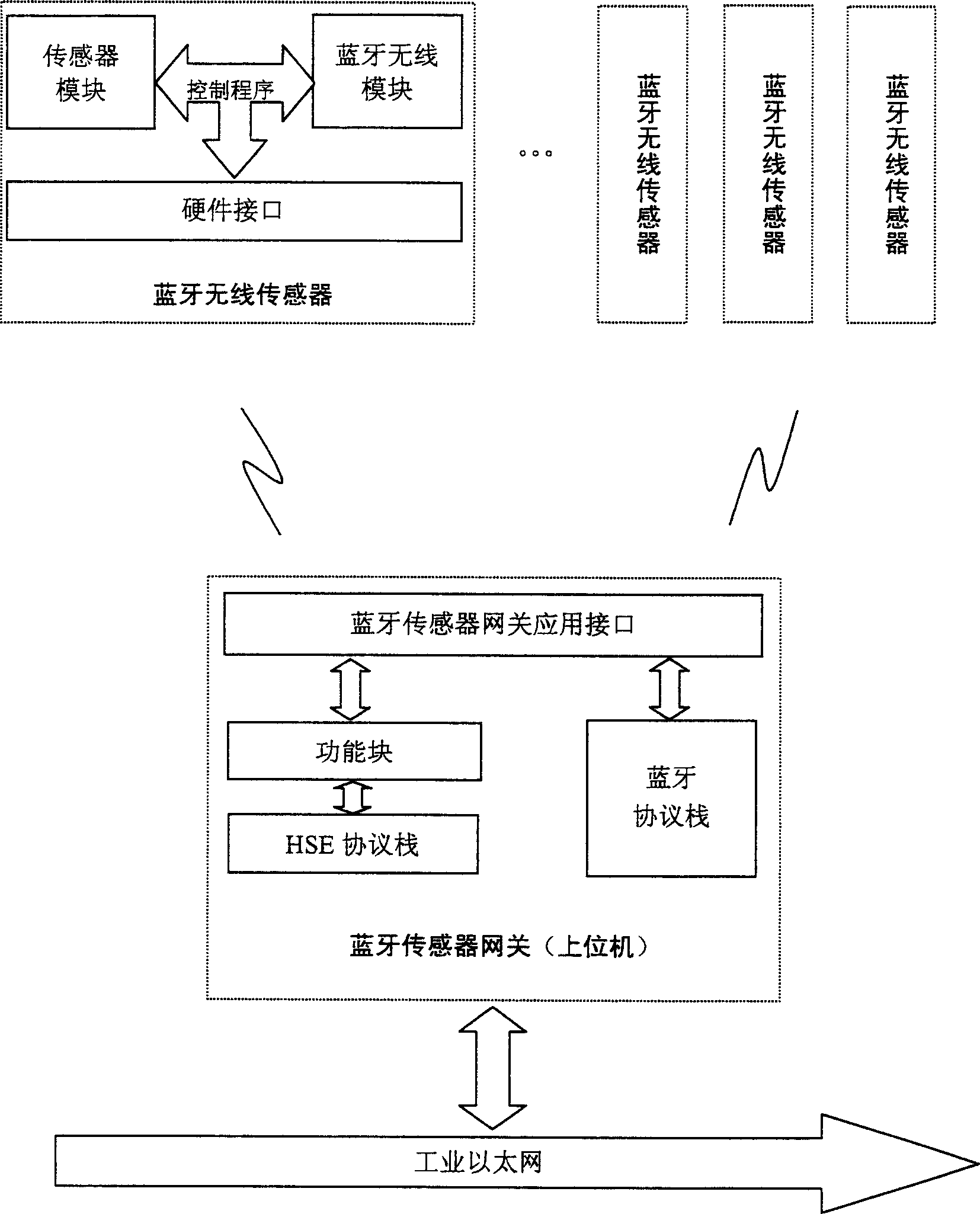

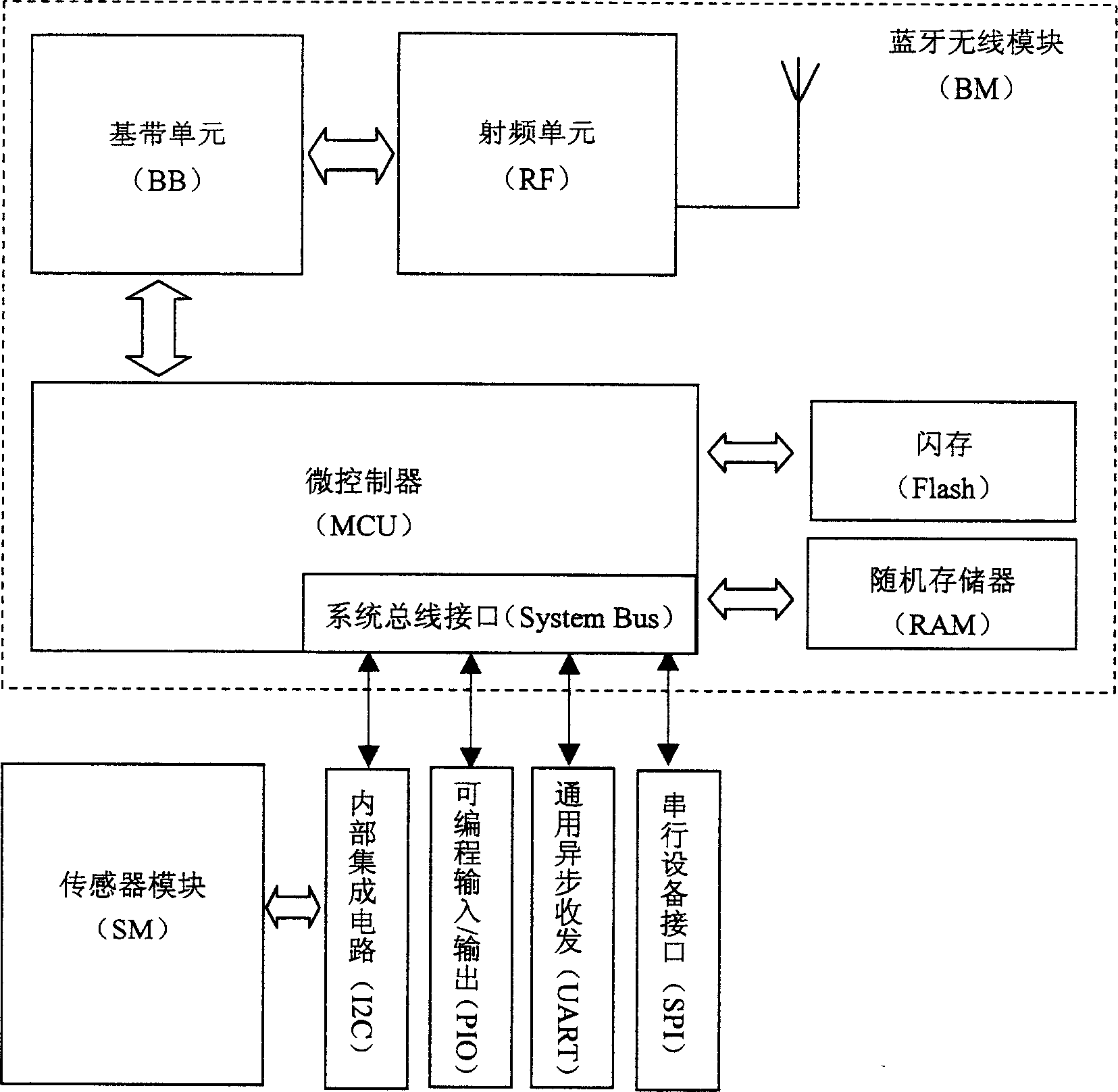

Blue tooth radio sensor

InactiveCN1617465AStrong opennessGuaranteed communication performanceNear-field systems using receiversLine sensorMultiple sensor

A blue-tooth wireless sensor includes a data collection module, a blue-tooth wireless moule further processing and transmitting data wirelessly, a program control module responsible for data collection, process and data communication with a level device. This device is mainly used in wireless data collection under industrial field control, it can set up connection and carry out data exchange with any device in conformity with blue-tooth wireless sensor stipulations and forms a wireless acess system with the level device by forming networks with multiple sensors to be used in many fields difficult of laying out cables.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

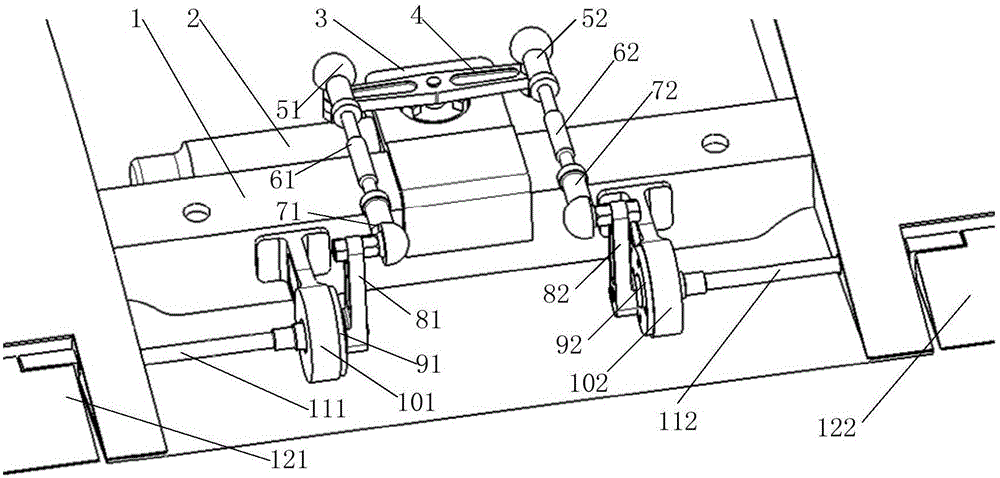

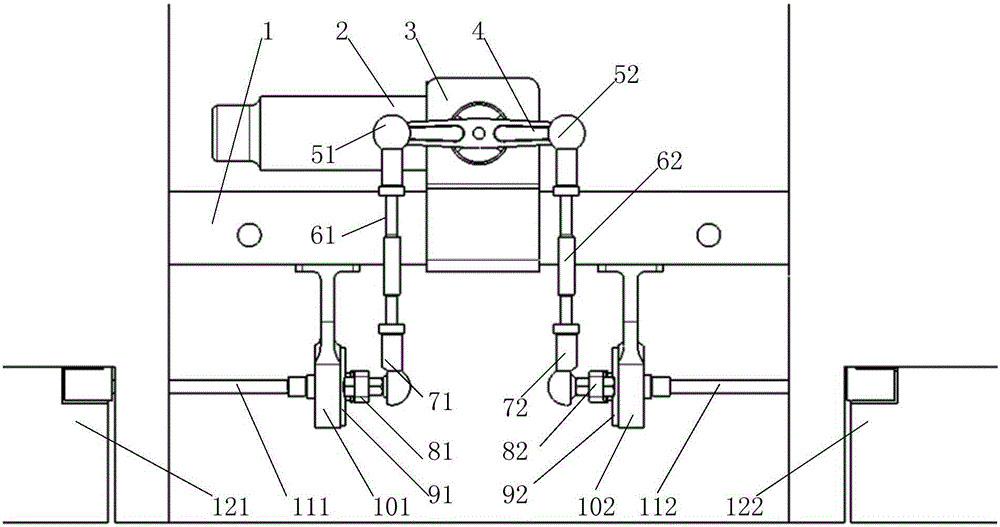

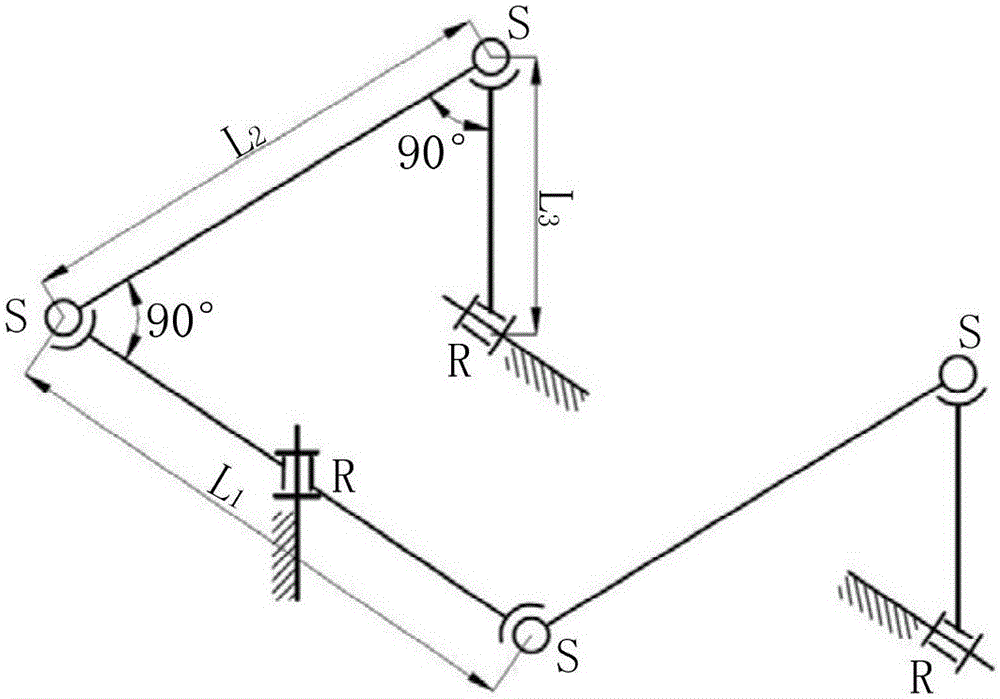

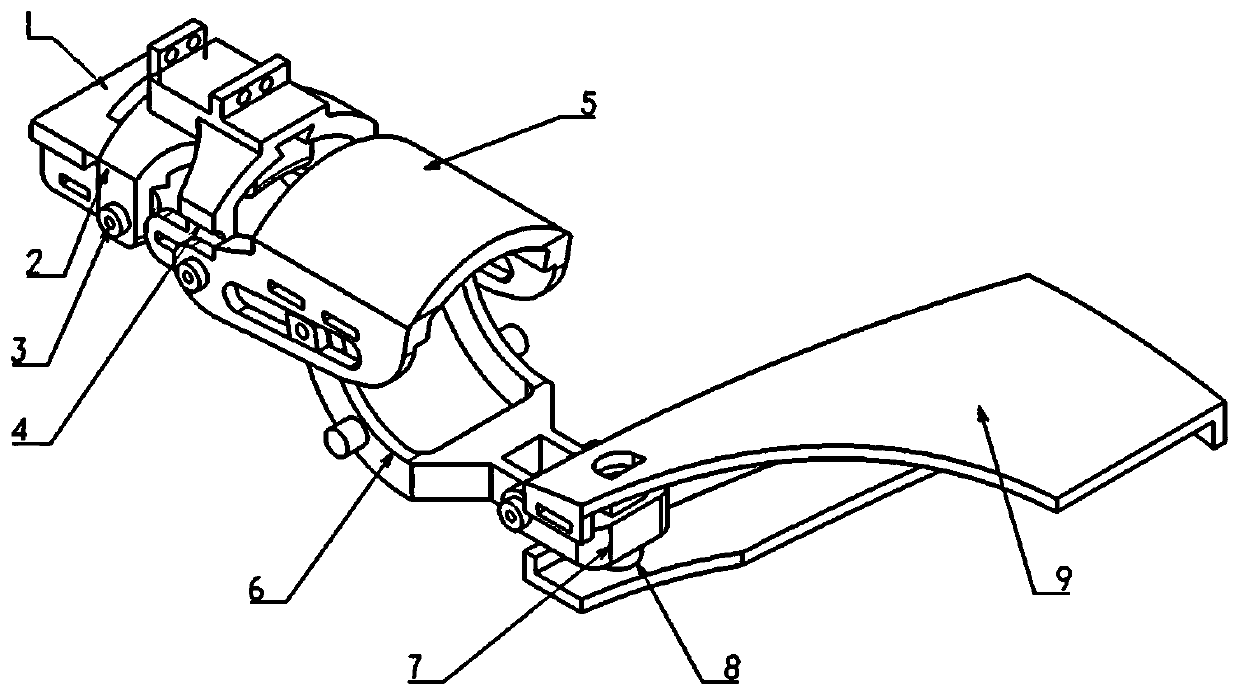

Control surface differential drive mechanism suitable for unmanned aerial vehicle

ActiveCN105151278ARealize differential rotationReduce control difficultyWithout power ampliicationWith power amplificationEngineeringUnmanned air vehicle

The invention relates to a control surface differential drive mechanism suitable for an unmanned aerial vehicle. The control surface differential drive mechanism comprises a common module, a left aileron drive mechanism module and a right aileron drive mechanism module. A dual-output steering engine connecting rod (2) is driven by an electric steering engine (2) to rotate, and a left aileron rudder shaft (111) and a right aileron rudder shaft (112) are driven to rotate oppositely through movement of a left connecting rod (61), a right connecting rod (62), a left rudder shaft connecting rod (81) and a right rudder shaft connecting rod (82), so that a left aileron (121) and a right aileron (122) deflect oppositely. Differential drive of the left aileron and the right aileron is achieved through a dual RSSR space four-connecting-rod combined mechanism, movement synchronization of the left aileron and the right aileron is achieved, constant-speed transmission of the left aileron and the right aileron is achieved, meanwhile, the requirements for machining precision and tools are lowered, and manufacturing cost is reduced.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

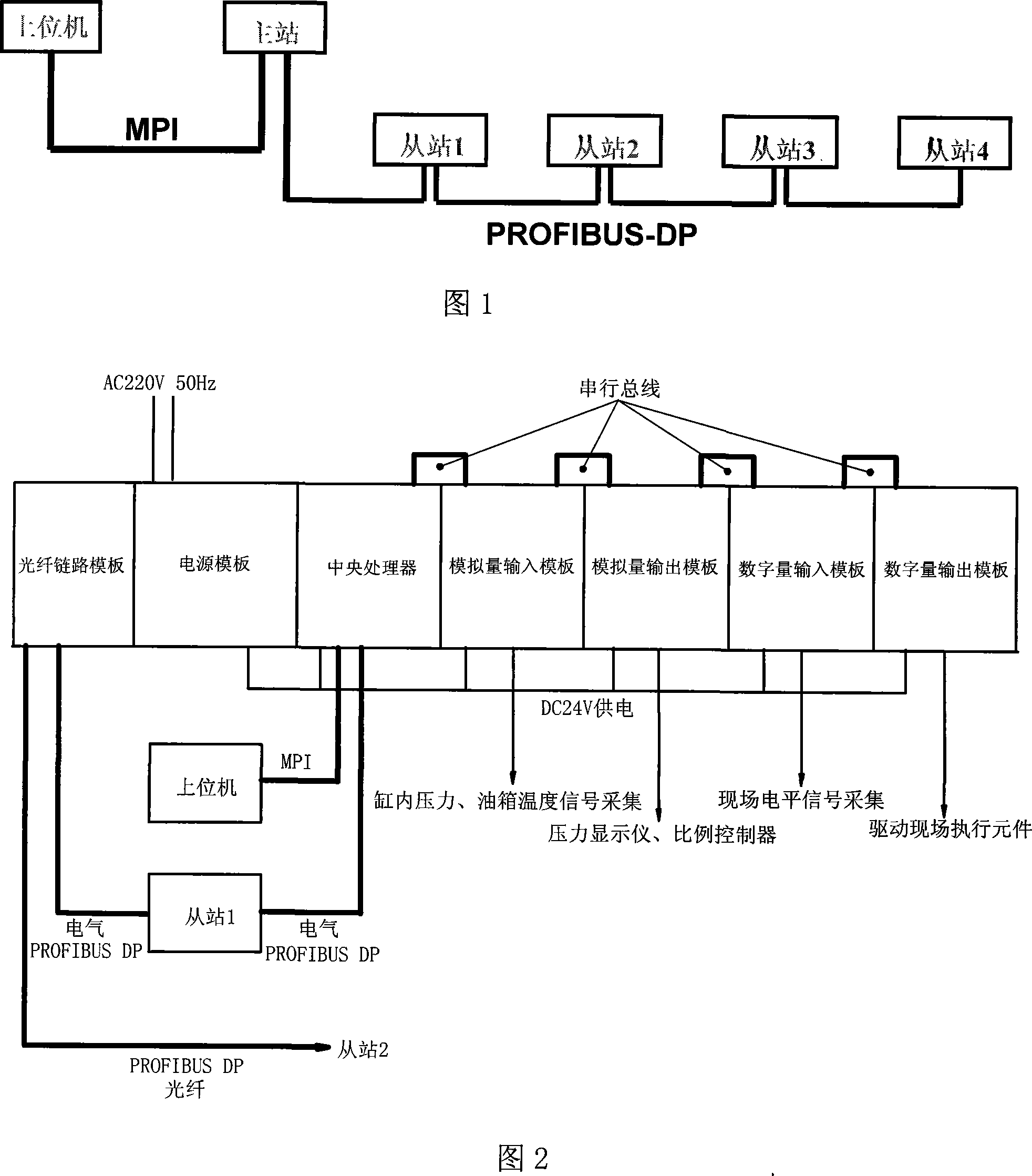

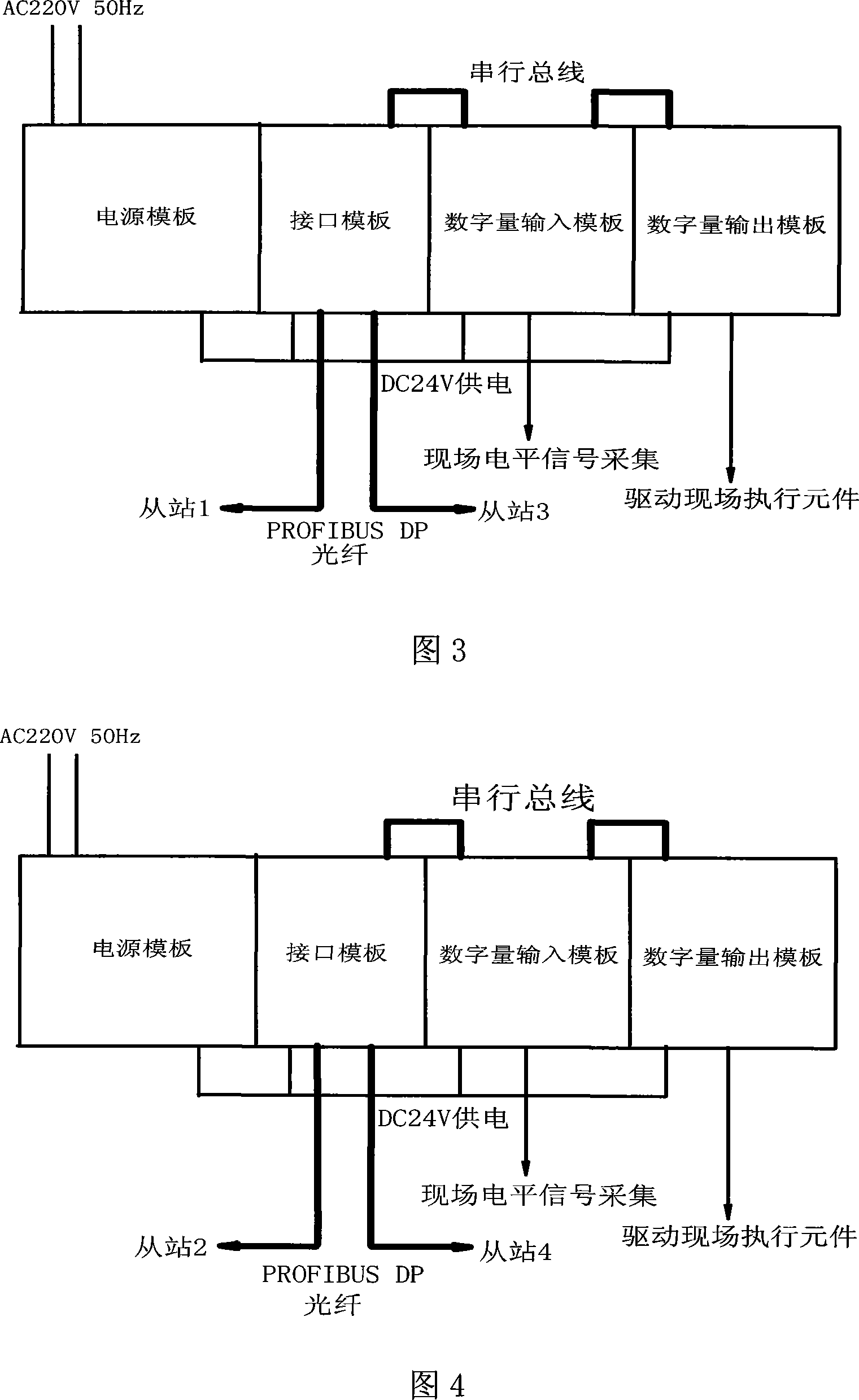

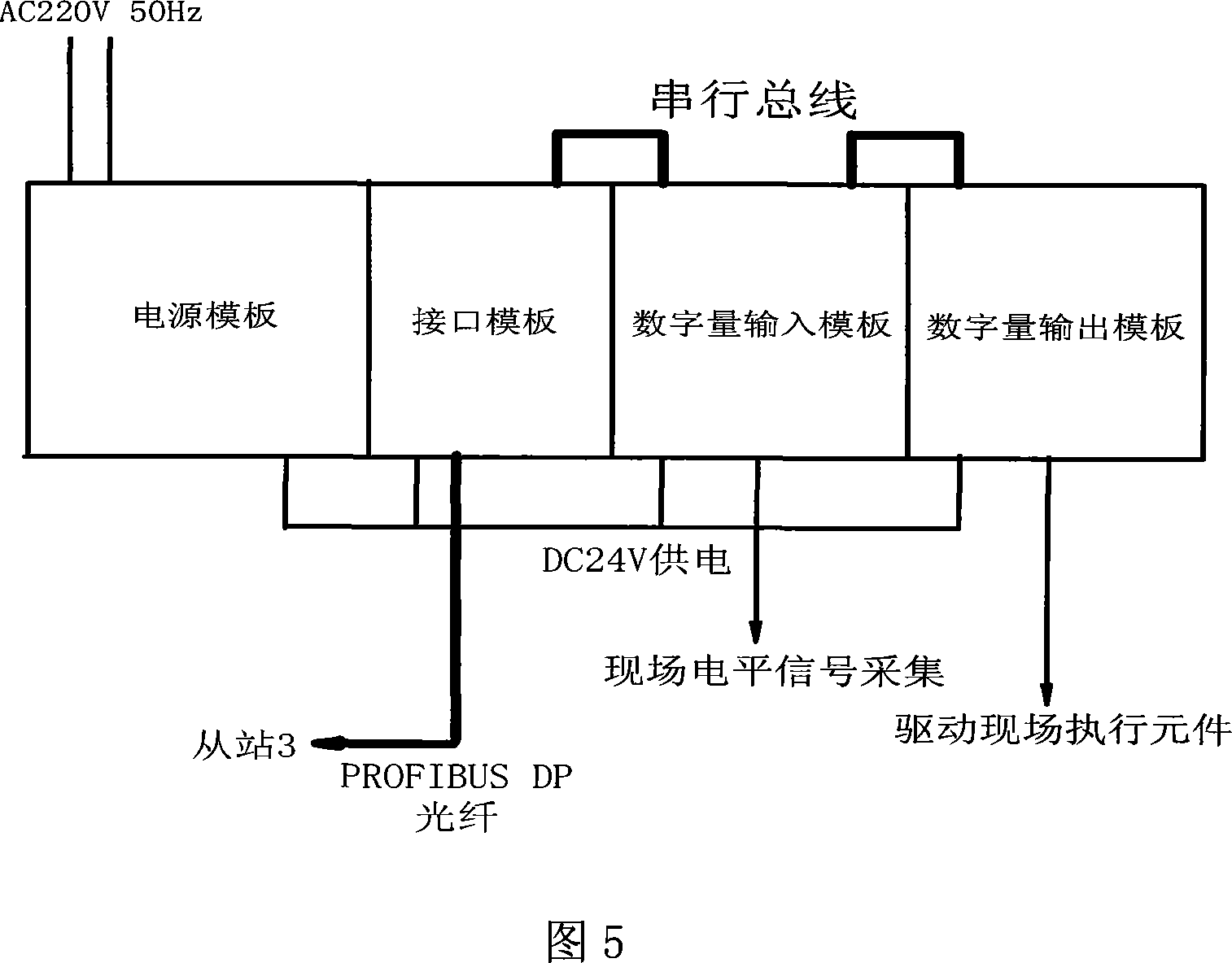

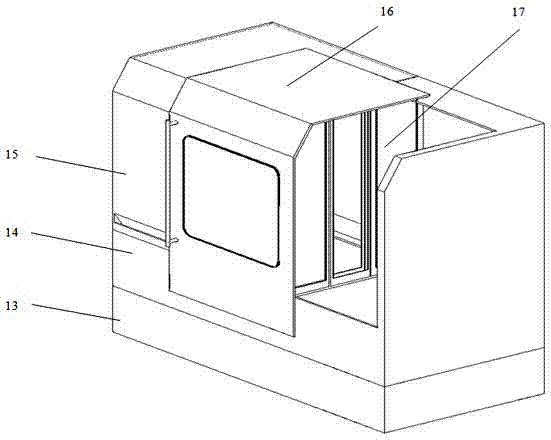

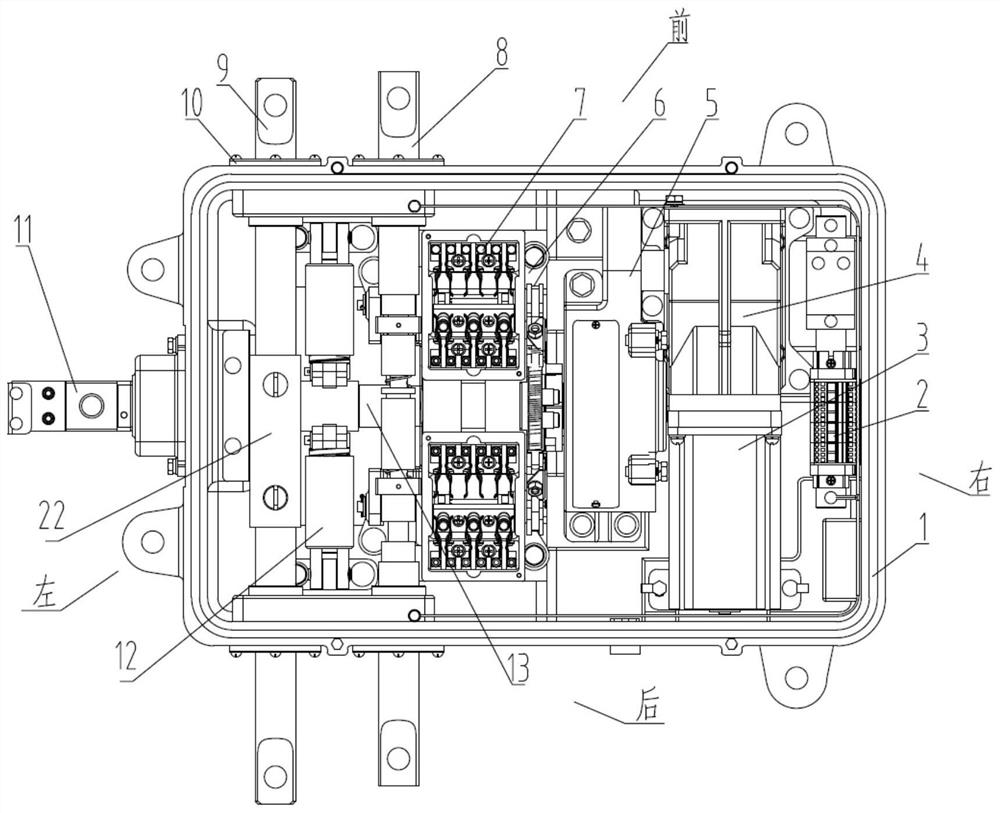

Electrical control workstation of macrotype isostatic pressing machine

InactiveCN101221438AReduce round tripsSimple designComputer controlSimulator controlData accessElectric control

The invention discloses an electric control work station of a large-scale isostatic press, comprising an upper computer provided with a programming software part and a monitoring software part, a master station with an on-the-spot and process communication PROFIBUS-DP interface and at least one slave station connected with a multi-branch communication network bus, wherein the master station through which a programmable controller (PLC) passes realizes bus communication control and management and completes periodic data access; a master station can control a plurality of slave stations on the bus; moreover, at least one logic link adopting round robin communication mode in information exchange is set up between the master station and each slave station. By means of the programmable controller, the invention sets up a high-performance industrial on-the-spot local area network through an on-the-spot and process communication field bus, thereby realizing network monitoring of process and reducing a great amount of wiring and cable investment; meanwhile, the communication network field bus with an all digital multi-branch structure improves system accuracy and reliability; moreover, the invention has low cost in installation, operation and maintenance, simpler operation and more visualized monitoring.

Owner:SICHUAN AVIATION IND CHUANXI MACHINE

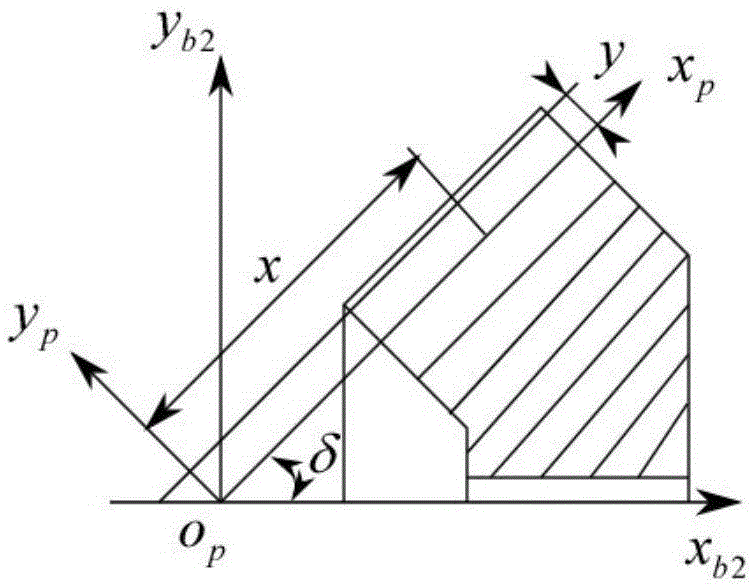

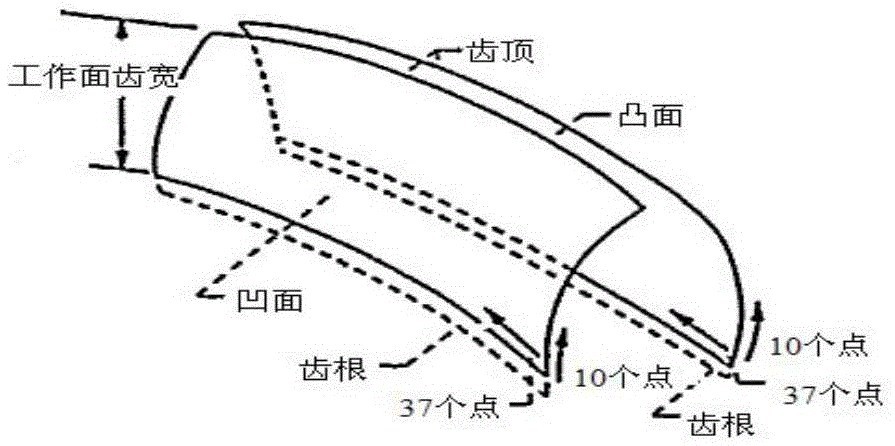

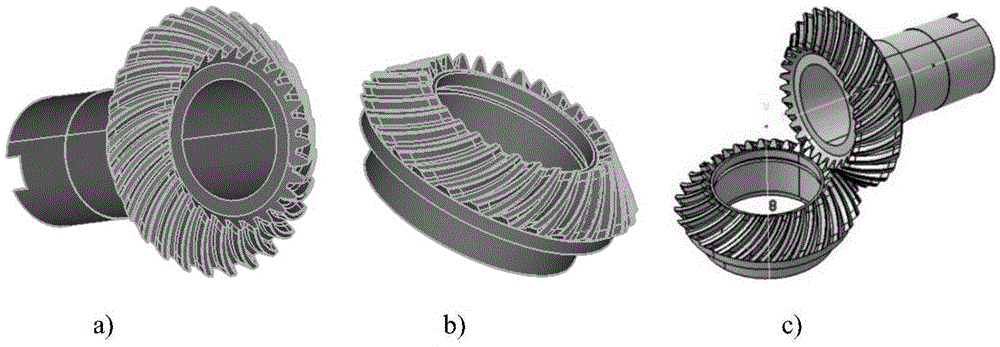

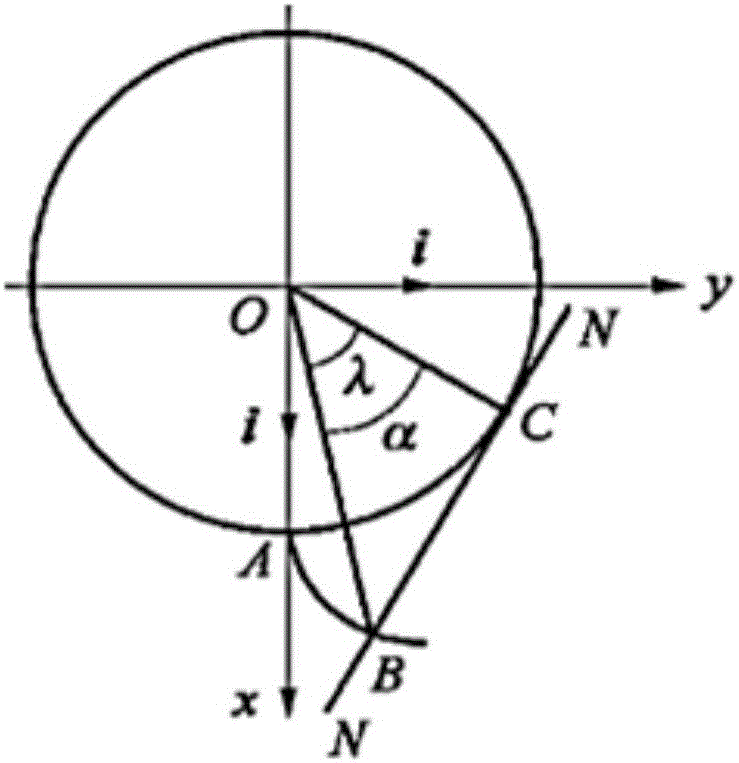

Profile shaping method for machining cutter tooth main cutting edge according to cycloid bevel gear

ActiveCN105522227AAvoid stress concentrationReduce noiseGear teeth manufacturing toolsGear teethStress concentrationGear wheel

The invention relates to a profile shaping method for machining a cutter tooth main cutting edge according to a cycloid bevel gear, and belongs to the field of machine designing and manufacturing. The method is based on a gear tooth surface machining principle, a gear meshing principle is used, the surface profile of the cutter tooth main cutting edge of a machined tooth surface is modified, and a tooth surface equation is obtained according to space coordinate system changes. A meshing track and a transmission error of a gear tooth machined through a new method is analyzed through a TCA analysis method, and are compared with those of a gear machined through a traditional method, and the gear constructed in the invention is obtained, so that the transmission error is substantially reduced, and meanwhile the better contact track is obtained; and through an experimental verification and analysis method, the constructed gear conducts a loading experiment and analyzes the position of a contact zone, and stress concentration can be avoided through the gear constructed in the invention. Stress concentration during gear meshing is completely avoided, the transmission error is reduced, noise of the gear is reduced accordingly, and the transmission stability is improved.

Owner:BEIJING UNIV OF TECH

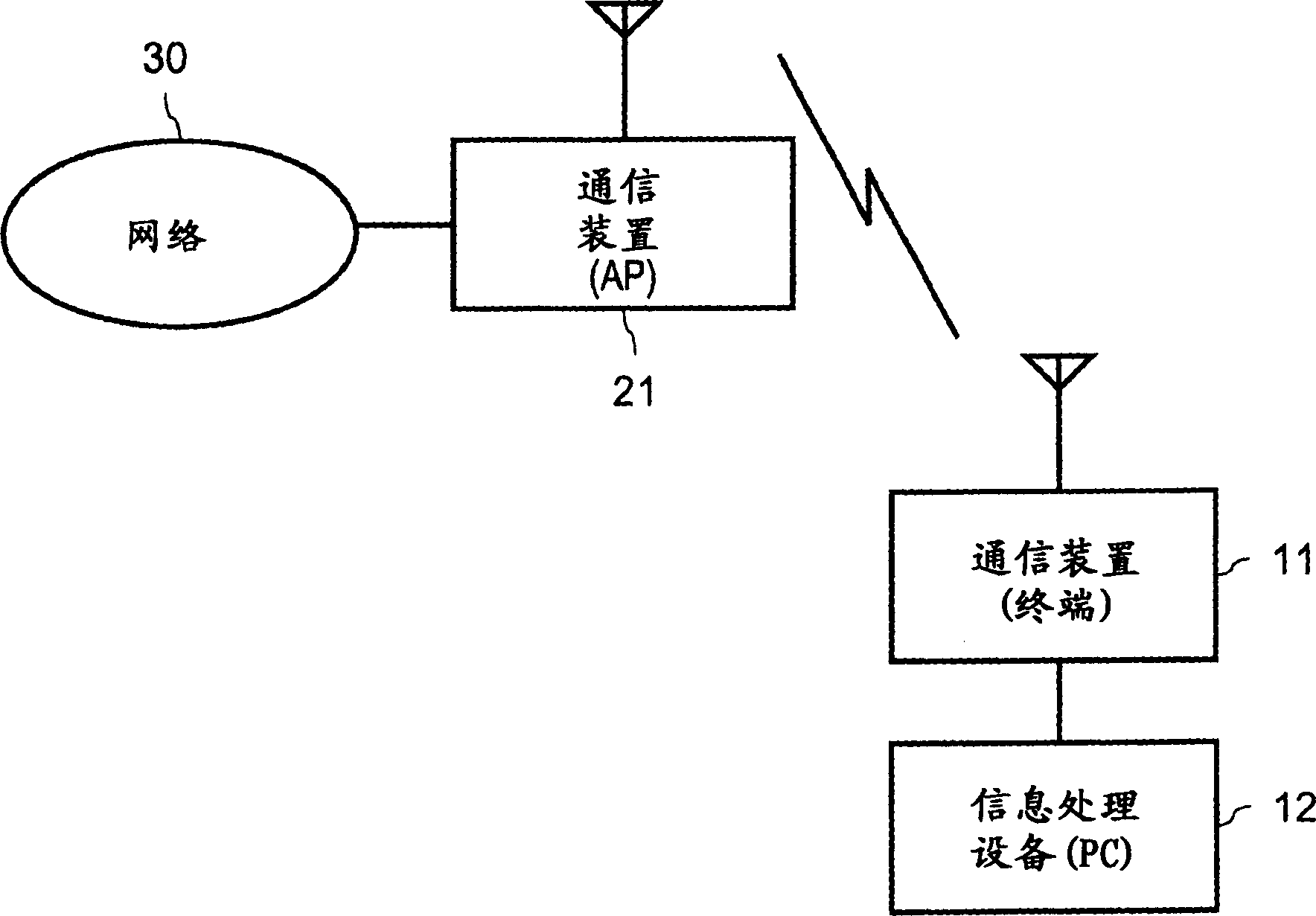

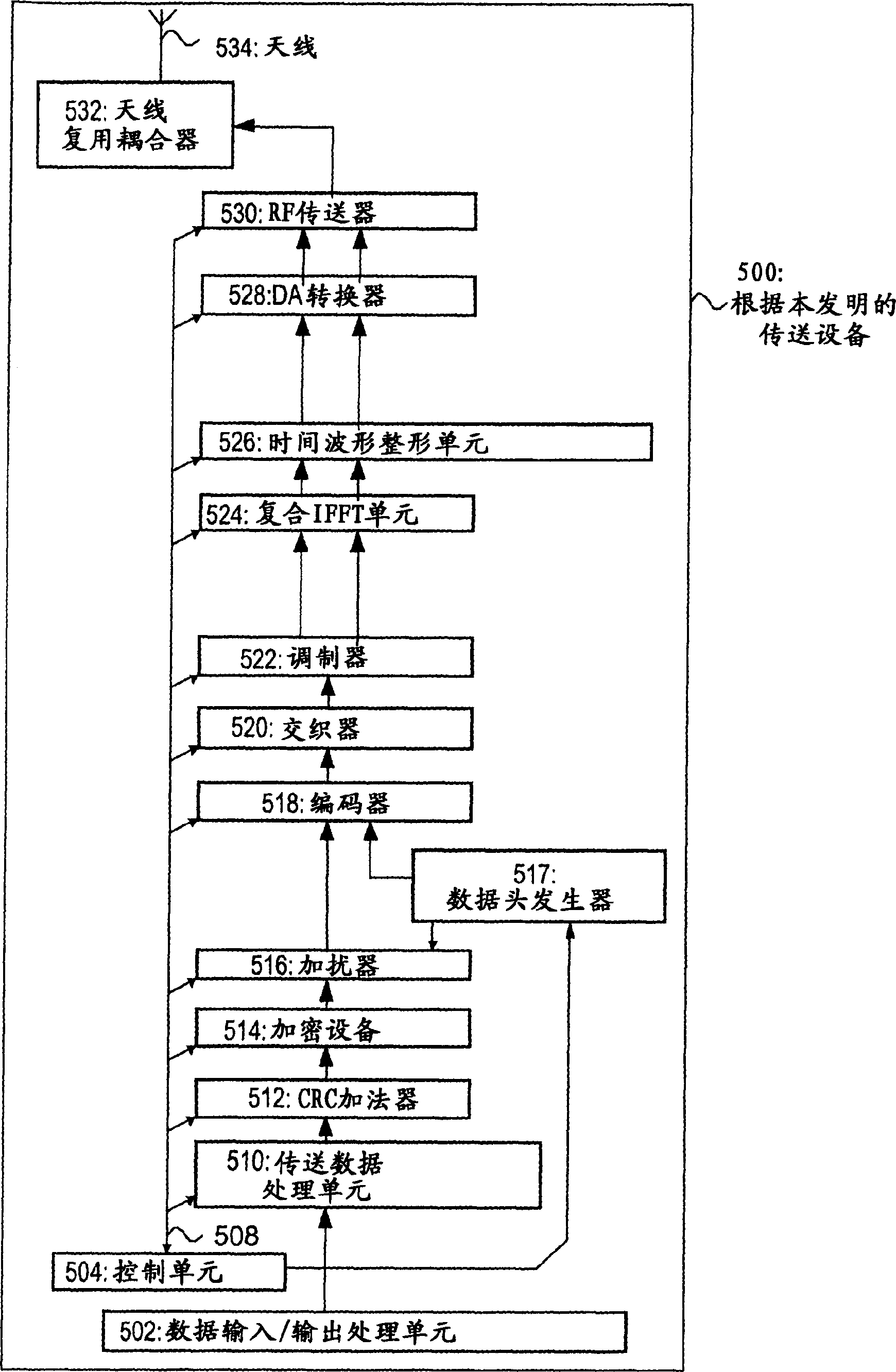

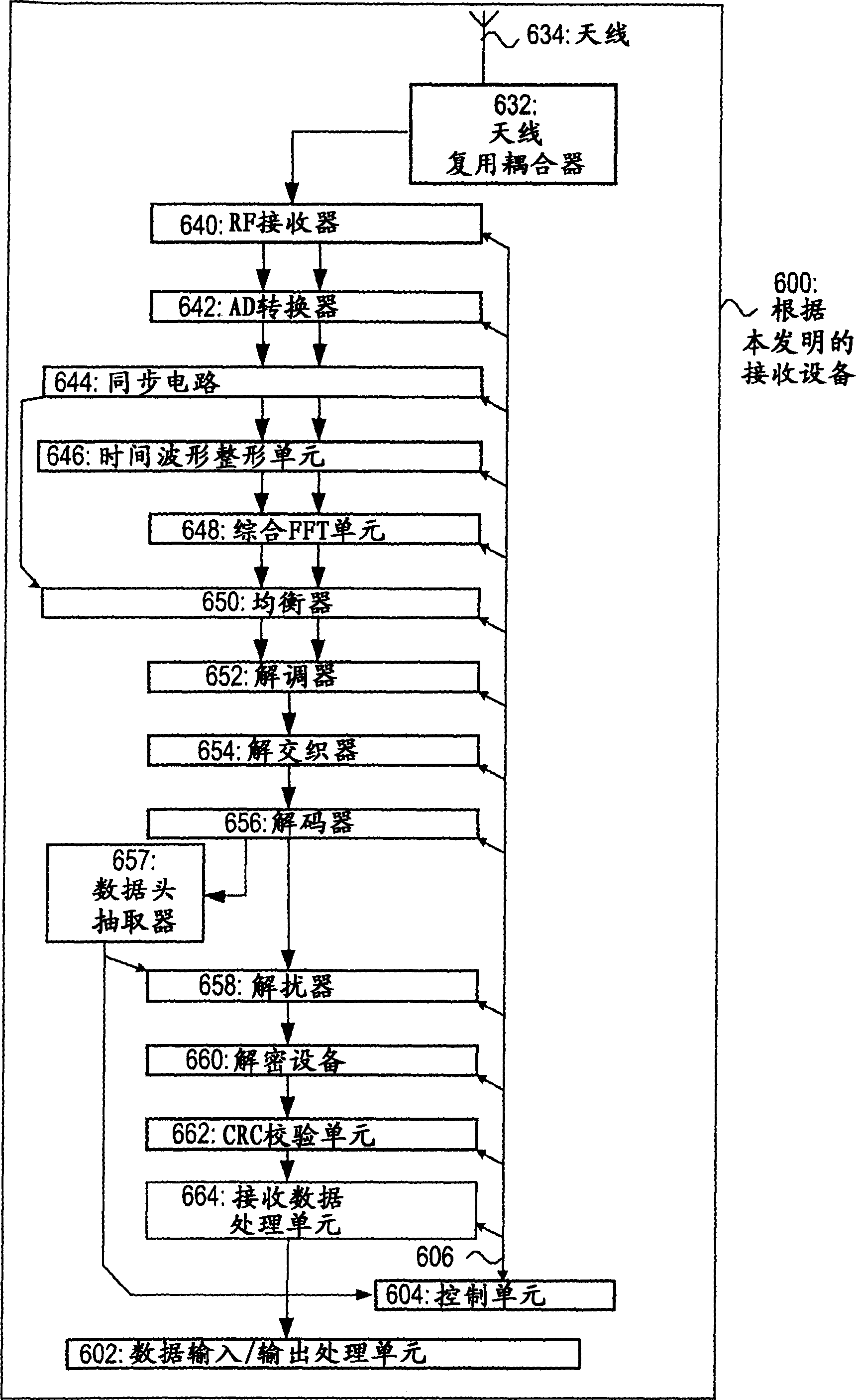

Radio communication system, radio communication device, radio communication method, and computer program

InactiveCN1823488AAchieve synchronizationNo deterioration in transmission efficiencyError preventionCoding/ciphering apparatusComputer hardwareCommunications system

A scrambling initial value is shared without deteriorating transmission efficiency. On the transmission side, a scrambling initial value is created based on a part of a physical layer header not scrambled, a transmission signal sequence scrambled is created by calculating an exclusive-OR operation between a scrambled sequence generated from the scrambling initial value and a transmission data sequence, and is transmitted. On the reception side, the same descrambling initial value as the scrambling initial value is created based on a part of a physical header of a reception frame, and a reception data sequence is descrambled by calculating an exclusive-OR operation between a descrambled sequence generated from this descrambling initial value and a reception signal sequence scrambled.

Owner:SONY CORP

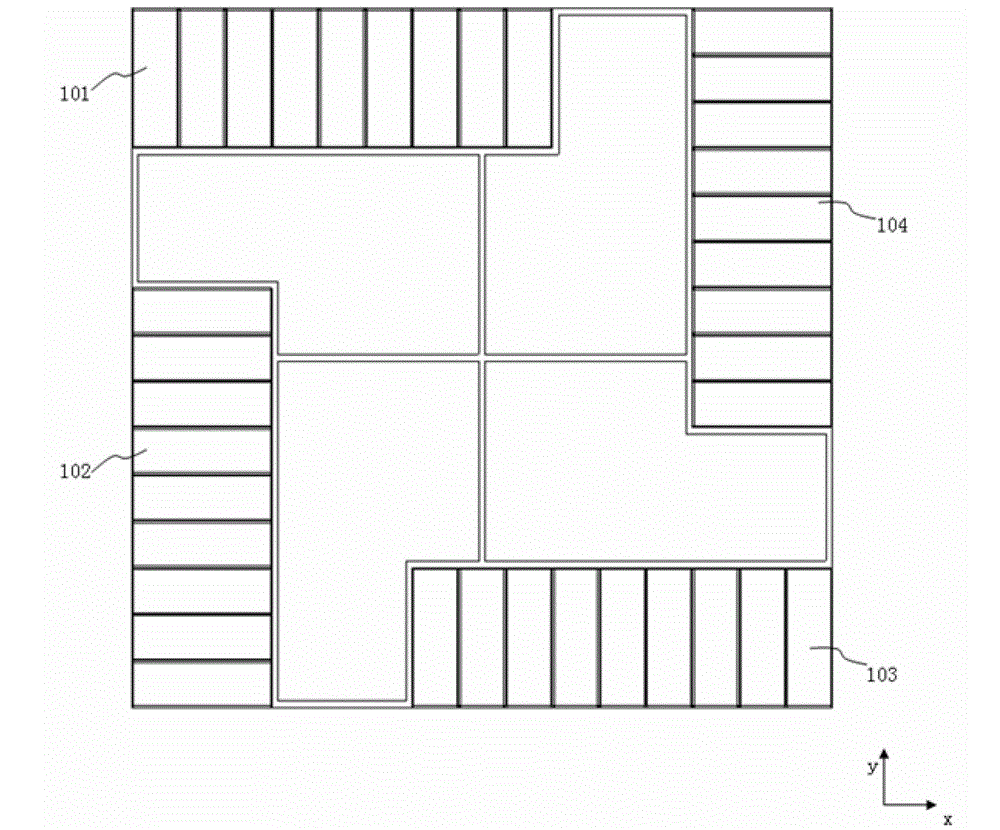

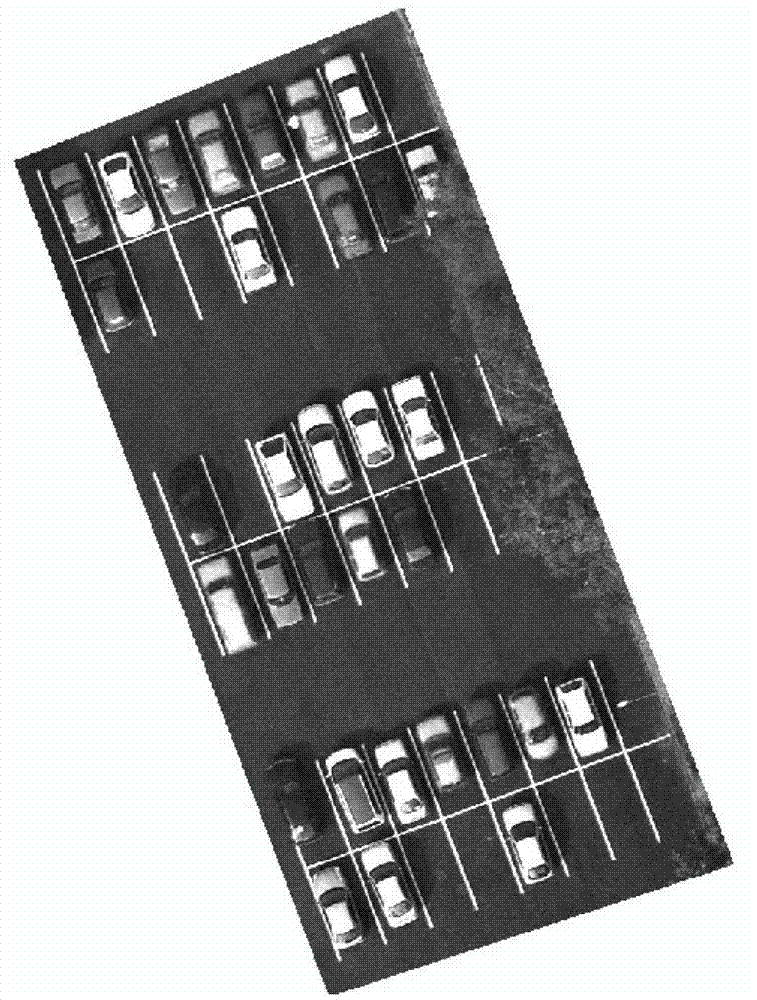

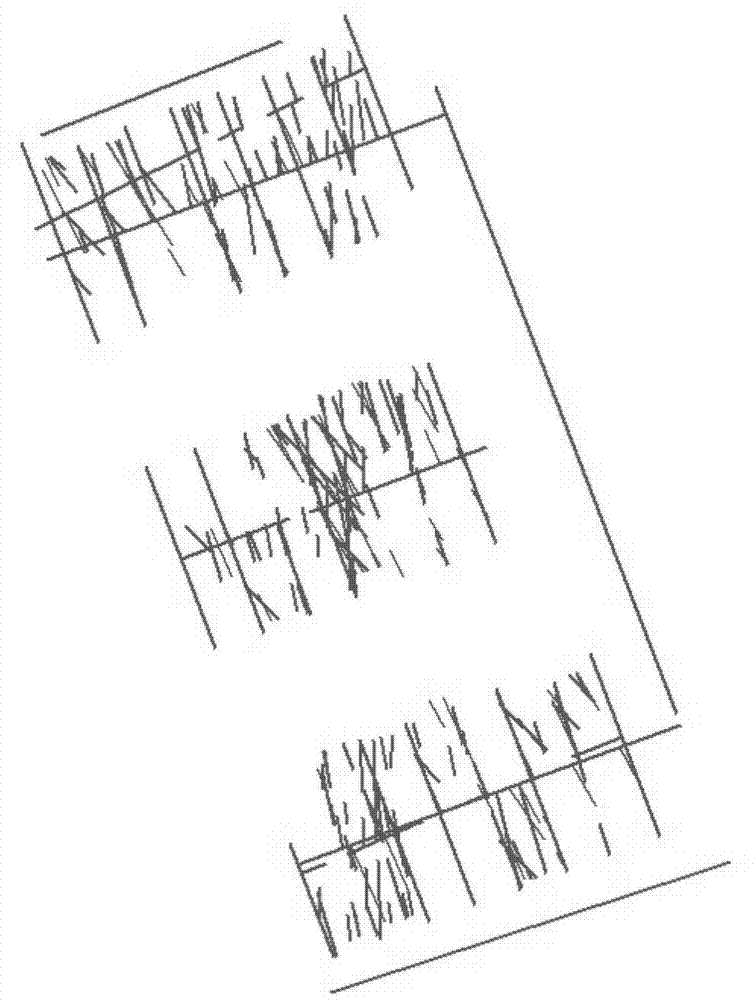

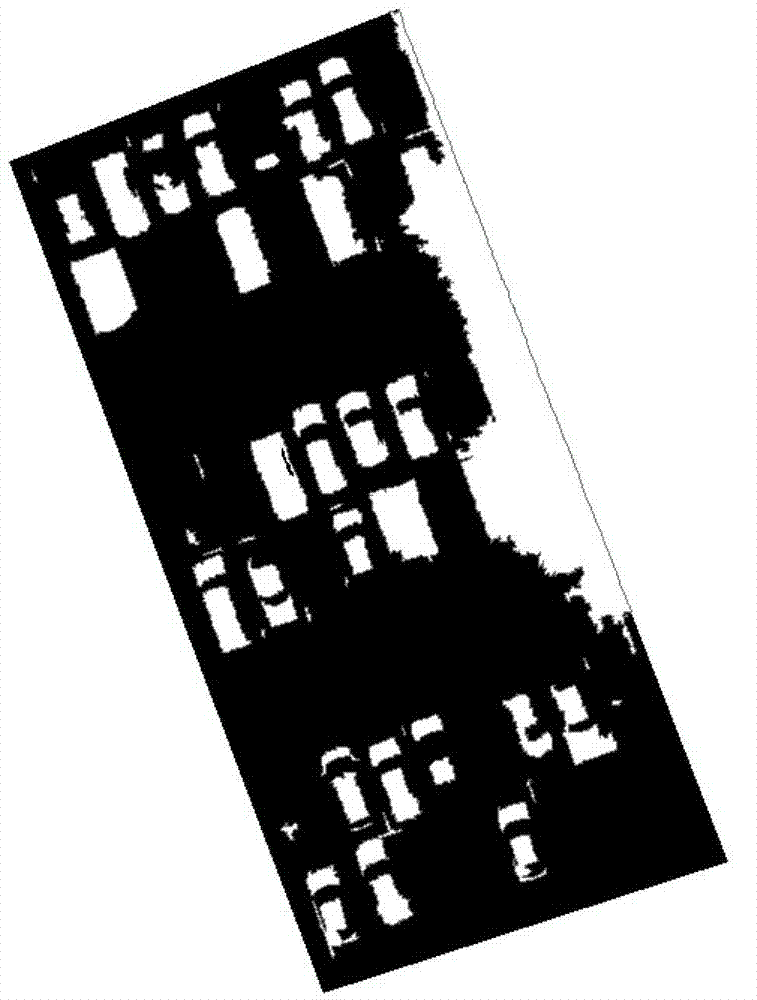

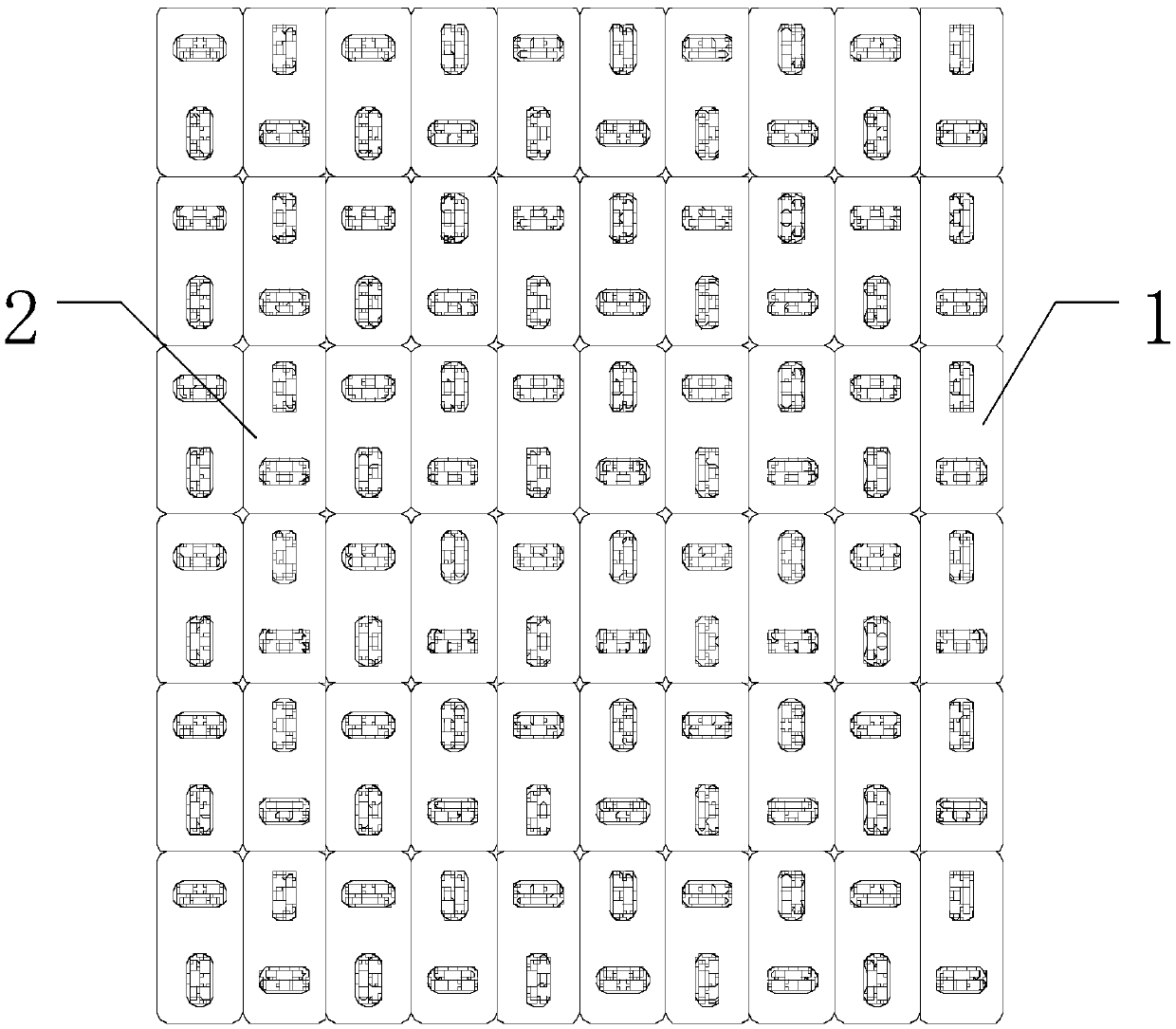

Method for extracting parking lot structure under main direction restriction

InactiveCN102968634AEasy to missImprove accuracyImage analysisCharacter and pattern recognitionAviationSplit lines

The invention discloses a method for extracting a parking lot structure under main direction restriction. The method comprises the following steps of: performing initial line segment detection on an aviation orthoimage by using an Edison algorithm and Hough transformation so as to acquire a main direction of a parking space line; detecting a correct parking lot line by using a line segment extraction method under the main direction restriction according to the acquired main direction; grouping and screening the parking lot line according to an angle of the parking lot line and dividing parking lanes by using a maximum intersecting direction method; calculating structural parameters of a parking lot by the extracted parking lot line and the divided parking lanes; and re-building a correct parking space line of the parking lot according to the structural parameters of the parking lot so as to generate a segment line of each parking lane to finish automatic extraction of the parking lot structure. According to the method, the main direction of the parking space line can be acquired by using the initial line segment detection, the parking space line is extracted by using the main direction as the restriction, so that the accuracy, the completeness and the positioning accuracy of the extracted parking space line are high, and an evidence is provided for extracting the parking lot structure; and moreover, the parking lot structure is extracted by using single-scene aviation orthoimages as data, so that the data are easily acquired, and the acquisition cost of the data is low.

Owner:NANJING UNIV

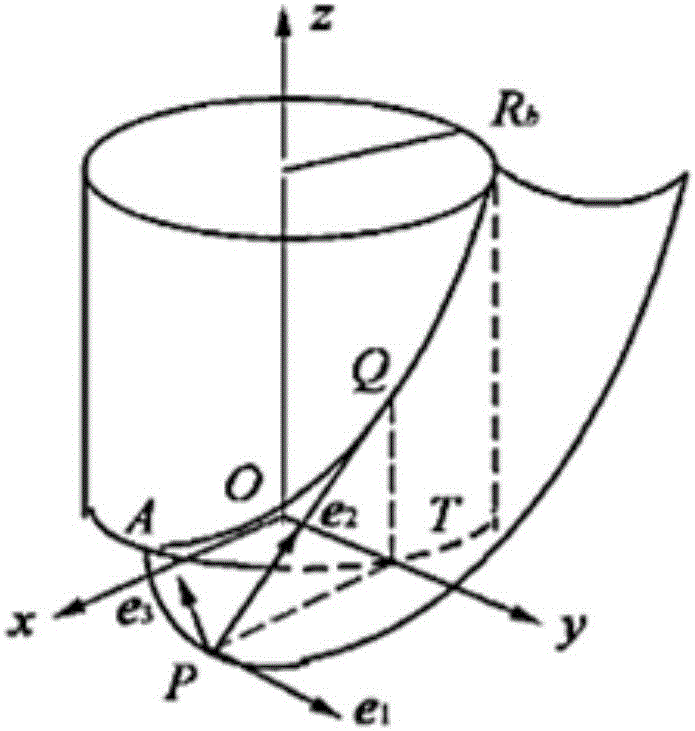

Natural twist microscopic profile correction optimization method of worm grinding wheel grinding helical gear

ActiveCN106383942AOptimizing Microscopic Modification ParametersImprove carrying capacityGeometric CADPortable liftingNoise, vibration, and harshnessEngineering

The invention discloses a natural twist microscopic profile correction optimization method of a worm grinding wheel grinding helical gear. A meshing model of the worm grinding wheel grinding helical gear is constructed to deduce a contact trace equation, a gear form and lead evaluation range is selected, a gear surface twisting model is established, and a gear form and lead angle deviation value is obtained under the natural twist of the worm grinding wheel grinding helical gear; the correlation detection data of an existing project is collected, a twist quantity under natural twist is calculated, whether calculation data and detection data are matched or not is verified, and a transferring error under existing natural twist is calculated; and therefore, gear microscopic profile correction parameters related to the natural twist are optimized, wherein optimization comprises the following steps of: reducing a lead drum-shaped size, regulating a mating gear drum-shaped size, regulating a mating gear twist quantity, and lowering and compensating influence brought by the natural twist of the worm grinding wheel grinding helical gear. By use of the method, gear bearing performance can be effectively improved, gear meshing impact is reduced, and transmission accuracy and a NVH (Noise Vibration and Harshness) level are improved.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

Complex surface numerical control efficient electrolytic machining tool

ActiveCN104259604AImprove machining accuracyReduce shadingElectrochemical machining apparatusNumerical controlElectrolysis

The invention relates to a complex surface numerical control efficient electrolytic machining tool which comprises a base, a standard platform, an X, Y and Z straight line moving platform, a Y direction numerical control rotating table (a tool B shaft), a Z direction rotating and X direction inclining swinging numerical control rotating table (a tool A shaft and a C shaft), an output end, a stand column, a balance weight, a tool outer cover and the like. According to the tool, feeding of an instrument along a Y and Z space track can be achieved, meanwhile, rotating in the B direction is matched, and blisk blade lattice channel electrolytic machining is completed in a space rotating feeding mode. Through the method, blade body margin difference can be lowered, and irregular hub face machining can be achieved. According to the tool, a workpiece can be obliquely placed according to a corresponding optimized angle, an optimized space angle is formed between the instrument feeding direction and the workpiece, and blisk blade lattice channel electrolytic machining is completed in a space angle feeding mode. According to the method, following blade surface machining accuracy can be improved. According to the tool, efficient electrolytic machining of an aero-engine diffuser, a cartridge receiver and other complex surface parts can be achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

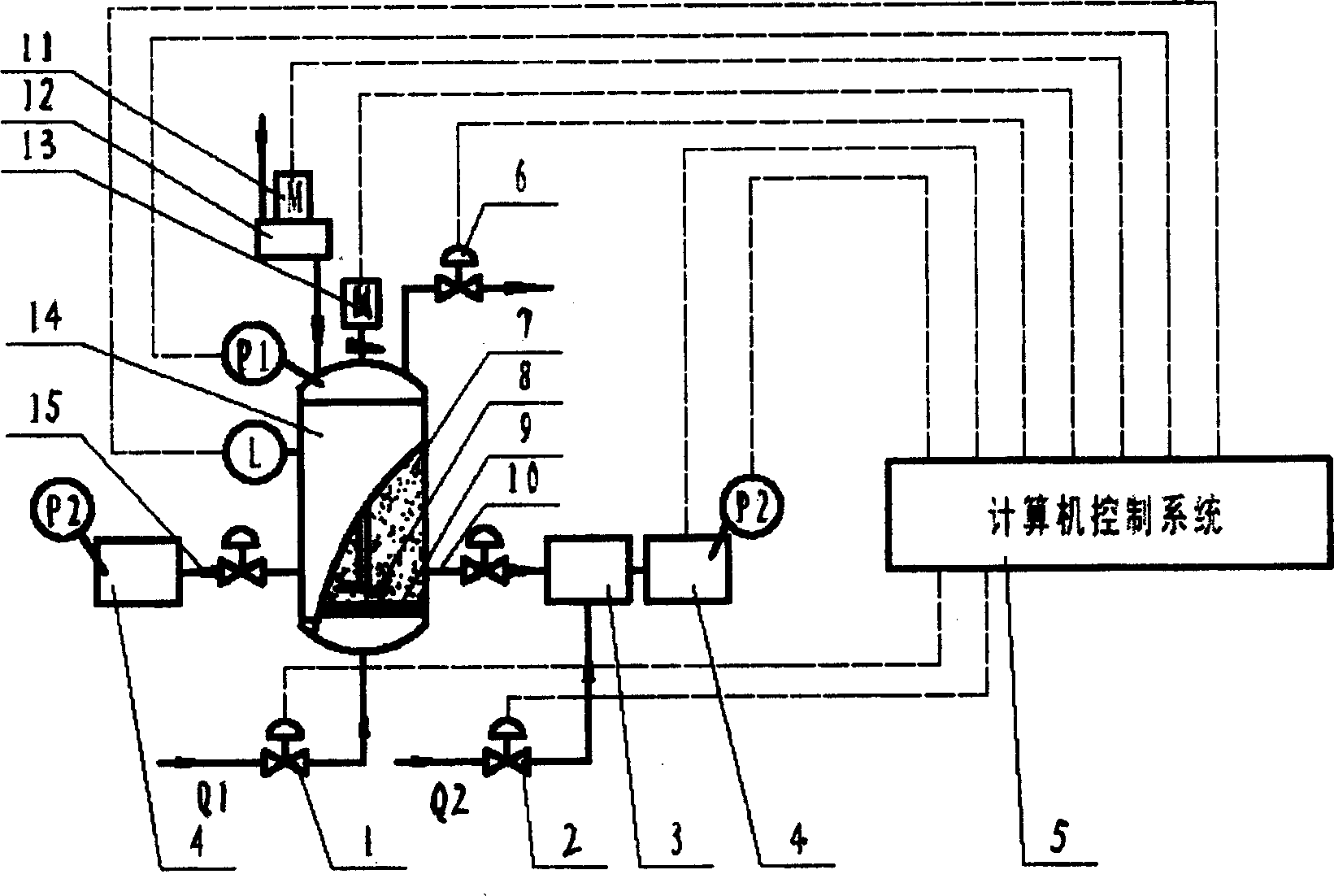

Fixed fluidized bed powder metering and distributing delivery device and methed of realizing high stability transferring and distributing powder

The present invention discloses a fixed fluidized bed powder body metering, distributing and conveying equipment and method for implementing high-stable conveyance and distribution of powder body. Said invention includes the following several components: fluidizing tank, powder body feeding pipe, gas feeding pipe, powder body level indicator, fluidized gas distributor, mechanical stirring paddle and power-conveying pipeline, etc. Besides, said invention also provides its extensive application fields.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI +1

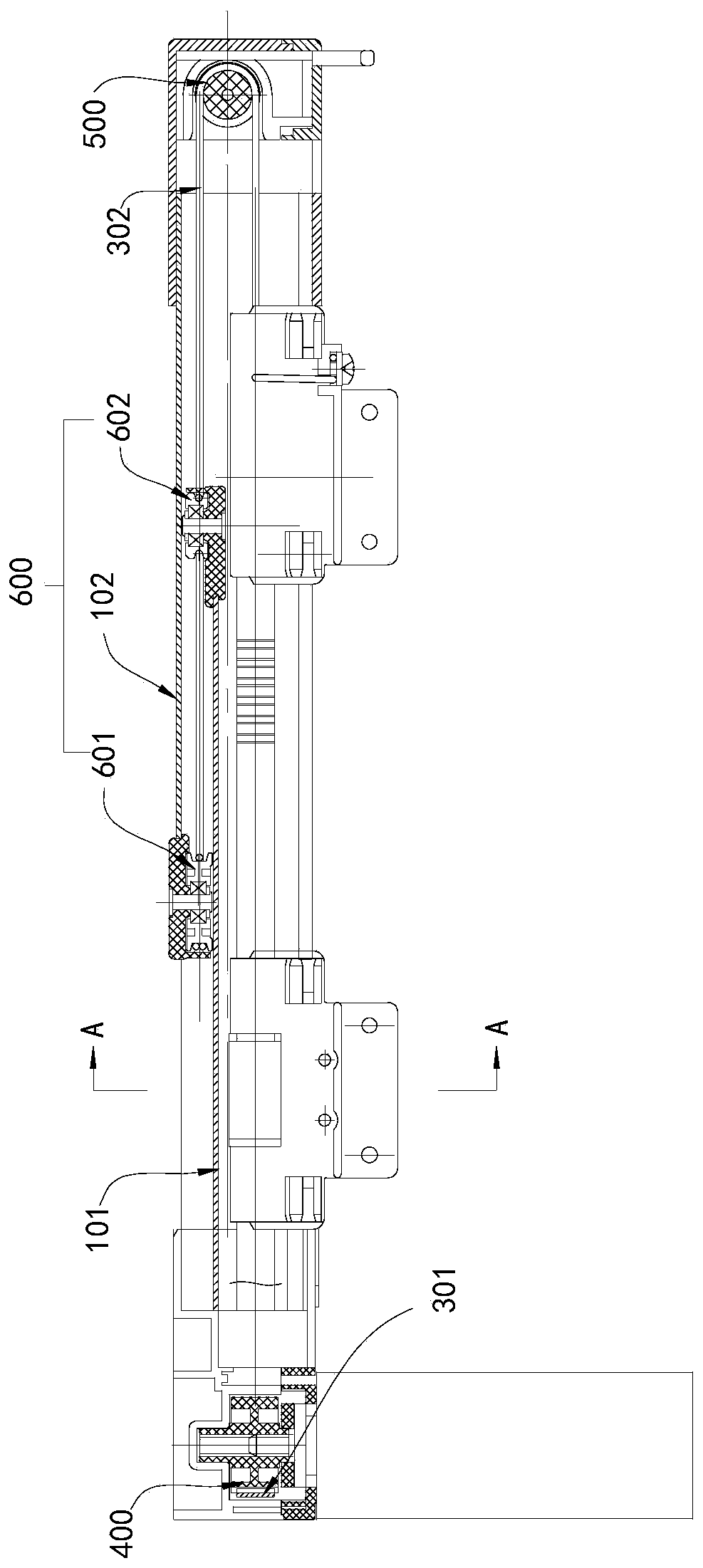

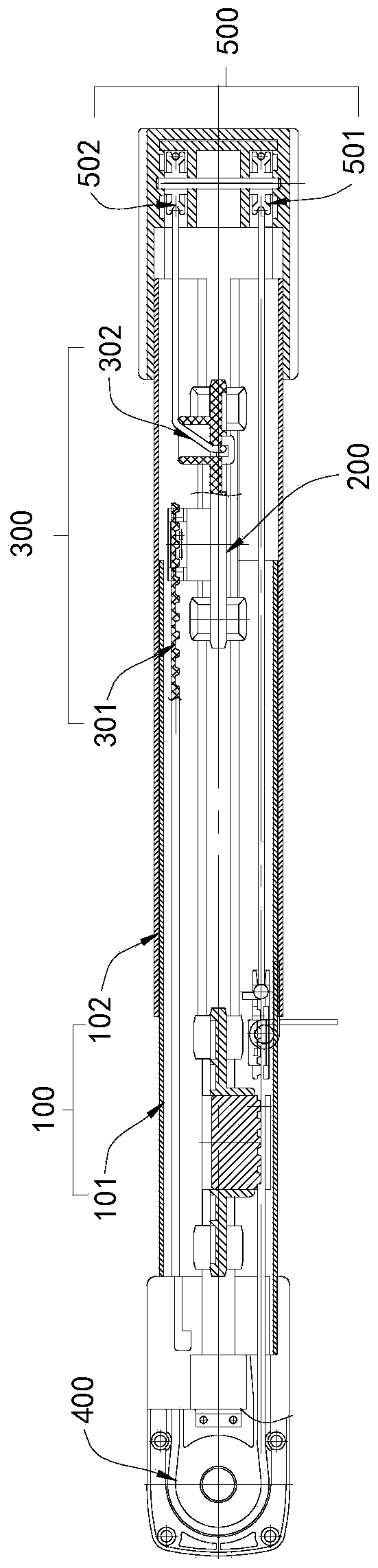

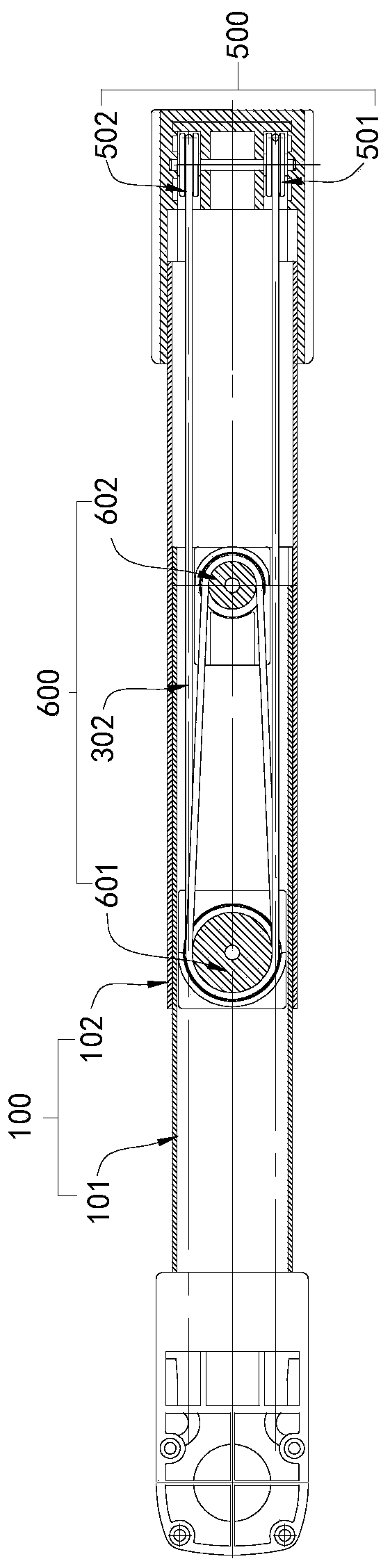

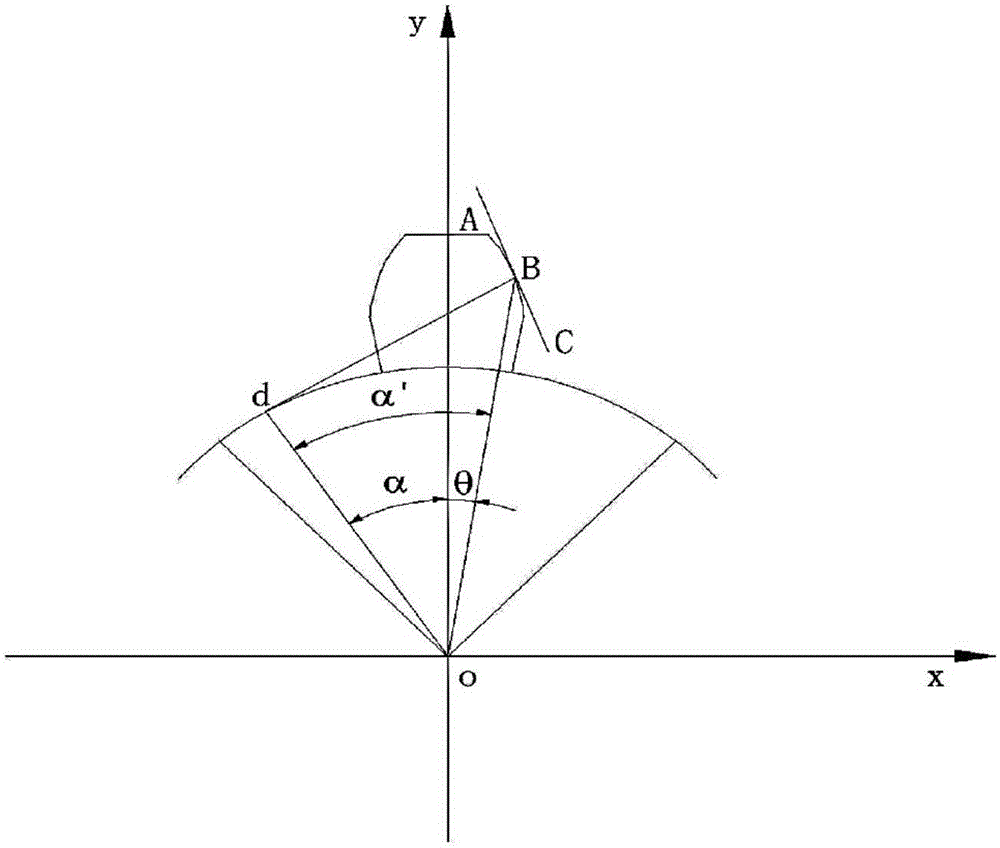

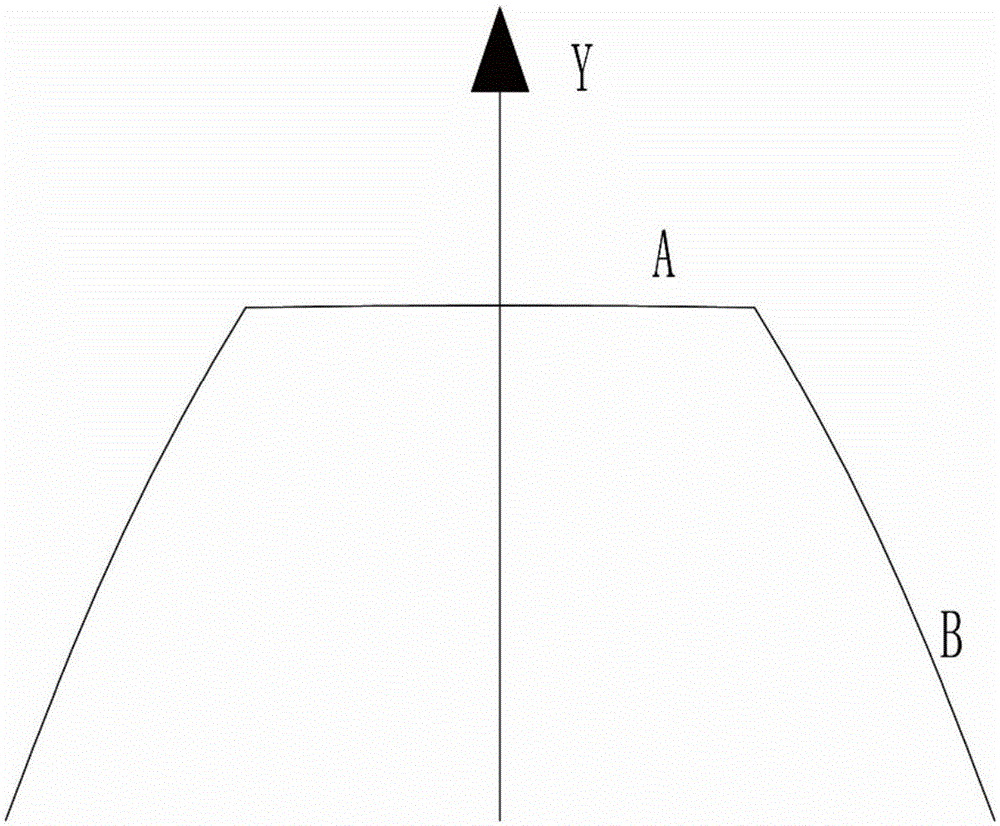

Curtain telescopic rail

The invention discloses a curtain telescopic rail. A customer can control expansion amount of a cyclo-conveyor belt between a driving wheel and a guide wheel and the expansion amount of the cyclo-conveyor belt between a first fixed pulley and a second fixed pulley as own required, so that an inner guide rail can perform expansion along an outer guide rail, the guide rail length is adjusted, and the adaptability and the usability are extremely high; by arranging the cyclo-conveyor belt as a belt segment and a cord segment the driving wheel is driven through the belt segment, the driving error and blocking are reduced, the problems of the easy slipping of the driving wheel and the cord and the expansion and the limited driving are solved, and the torque can be accurately transmitted. And thetelescopic rail can be used for the field of the curtain.

Owner:GUANGDONG RAEX INTELLIGENT TECH CO LTD

Involute straight tooth gear modification optimization method

InactiveCN105156634AImprove optimization accuracyImprove efficiencyPortable liftingGearing elementsNumerical controlProcess optimization

The invention provides an involute straight tooth gear modification optimization method; and the method comprises the steps of: building engaged three-dimensional gear pair models; primarily selecting modification optimization parameters; respectively performing the primary modification processing for the three-dimensional gear pair models; performing the primary modification optimization analysis to obtain optimal primary analysis optimization parameters; obtaining more precise optimization samples in finite element analysis software according to the optimization parameters; and screening the samples. After screening, the secondary modification processing is performed for a pair of standard three-dimensional involute gears to obtain multiple sets of secondarily processed optimization parameters, optimal modification optimization gear parameters, one set of parabola modification and one set of arc modification; the three-dimensional diagram drawing is performed for gears optimized by the secondarily processed optimization parameters; and optimally modified three-dimensional diagrams are leaded in a numerical control machine tool to machine blanks to finished products. The method is more precise in modification, is more obvious in optimization effect, can preferably reduce the engagement noise and vibration, and reduces such adverse effects as load concentration.

Owner:梅文杰

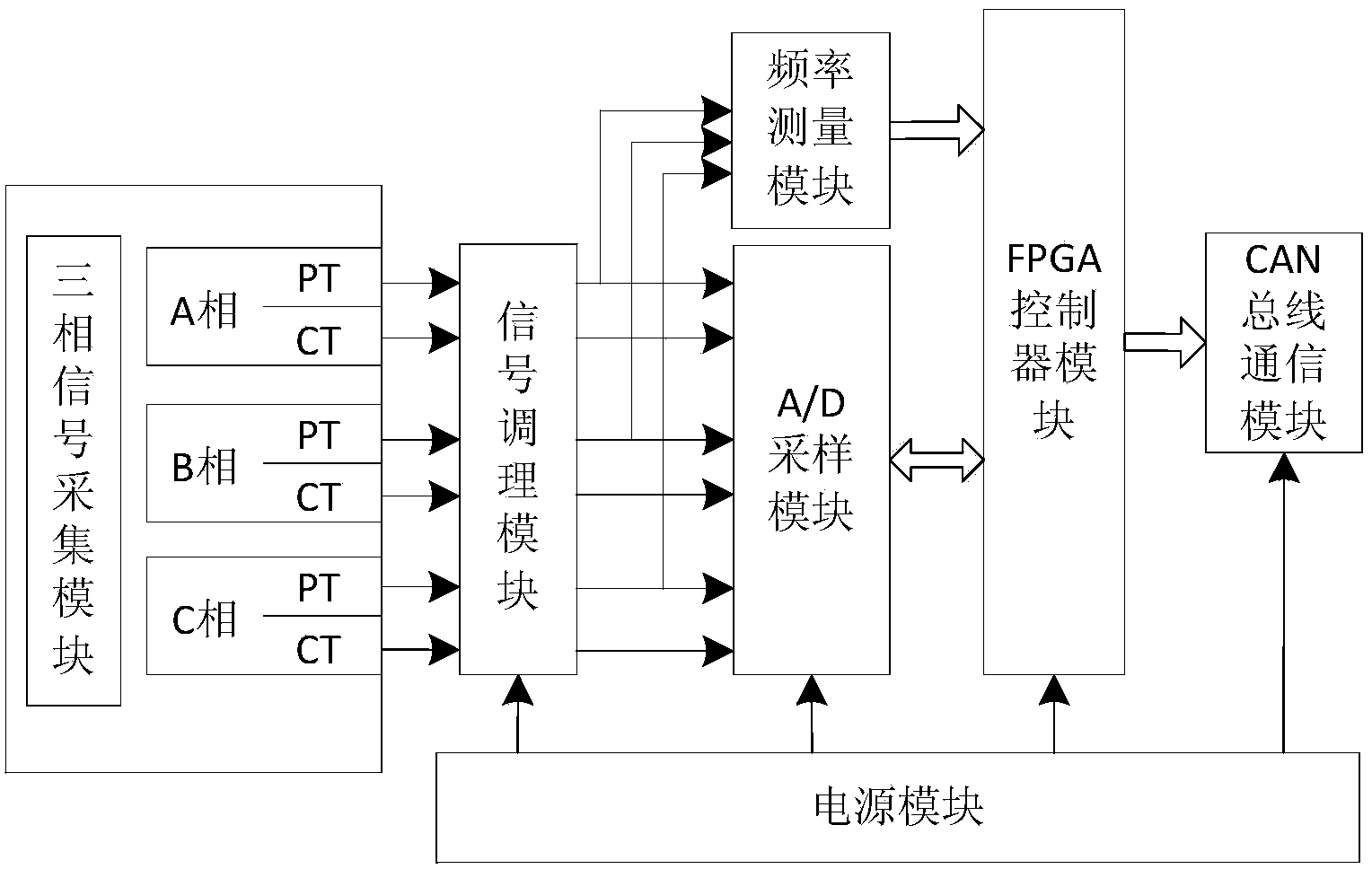

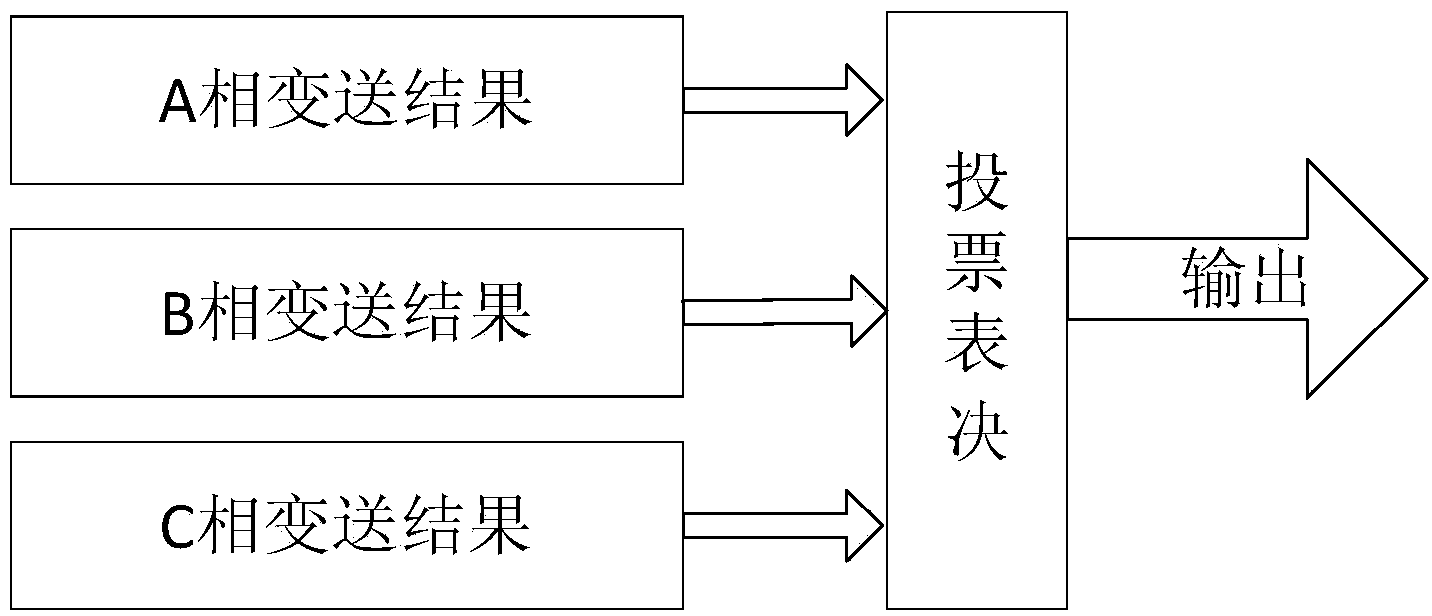

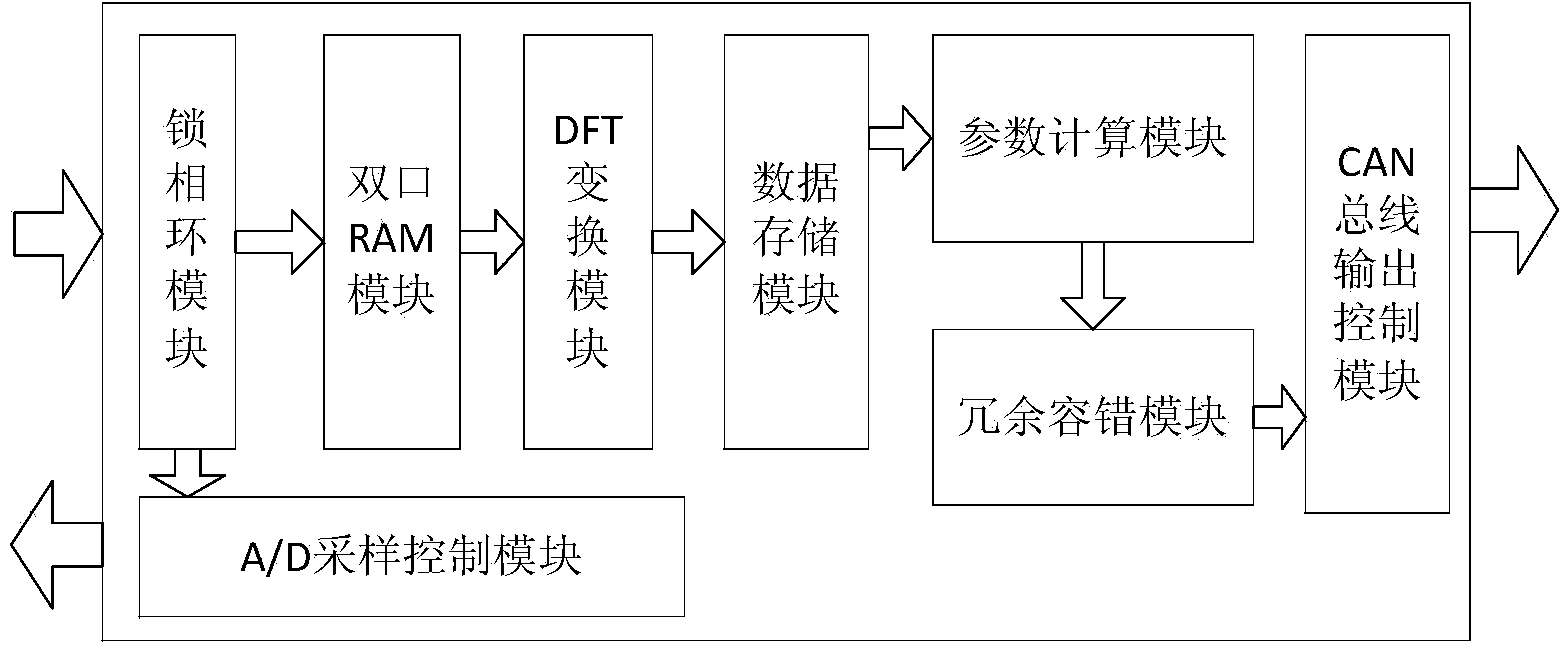

Electrical quantity transducer

ActiveCN103837738AHighlight substantive featuresAccurate outputElectrical measurementsFpga field programmable gate arrayFault tolerance

The invention discloses an electrical quantity transducer, and relates to a data processing device particularly suitable for achieving specific functions, in particular to an electrical quantity transducer with a fault tolerance function. The electrical quantity transducer is designed based on the FPGA according to the triple-module redundancy technology and comprises a three-phase signal acquisition module, a signal conditioning module, an A / D sampling module, a frequency measurement module, an FPGA controller module, a CAN bus communication module and a power module. The electrical quantity transducer overcomes the defect that an error in any single-phase transduction process of an existing electrical quantity transducer will directly result in inaccuracy of a final transduction result, open loops of a system or misoperation of equipment is caused and consequently breakdown of the whole system happens.

Owner:HEBEI UNIV OF TECH

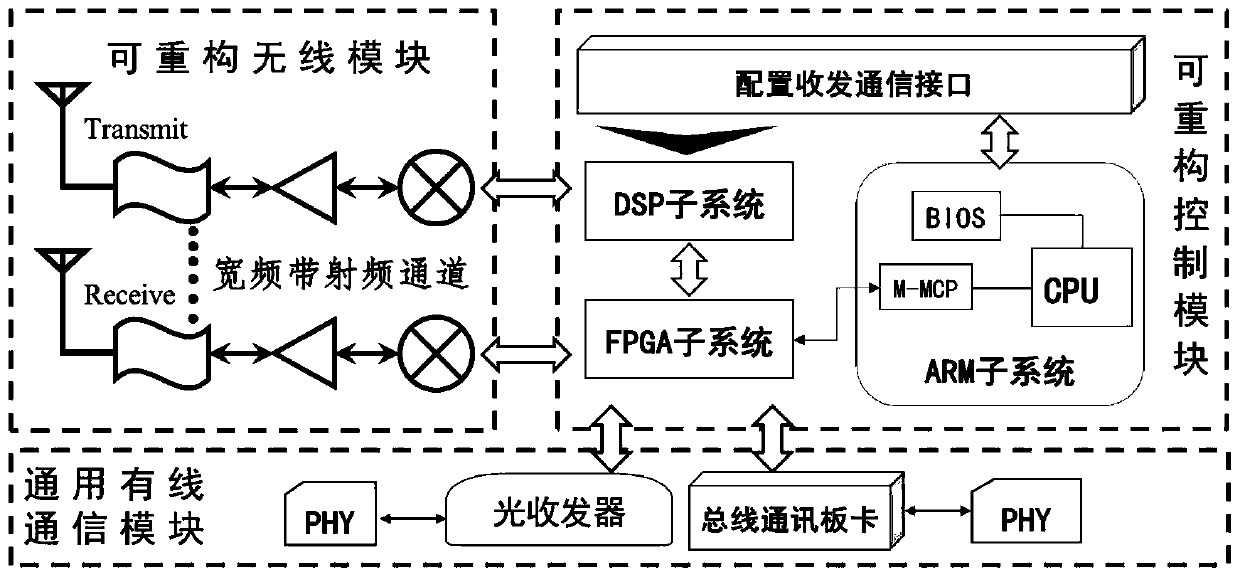

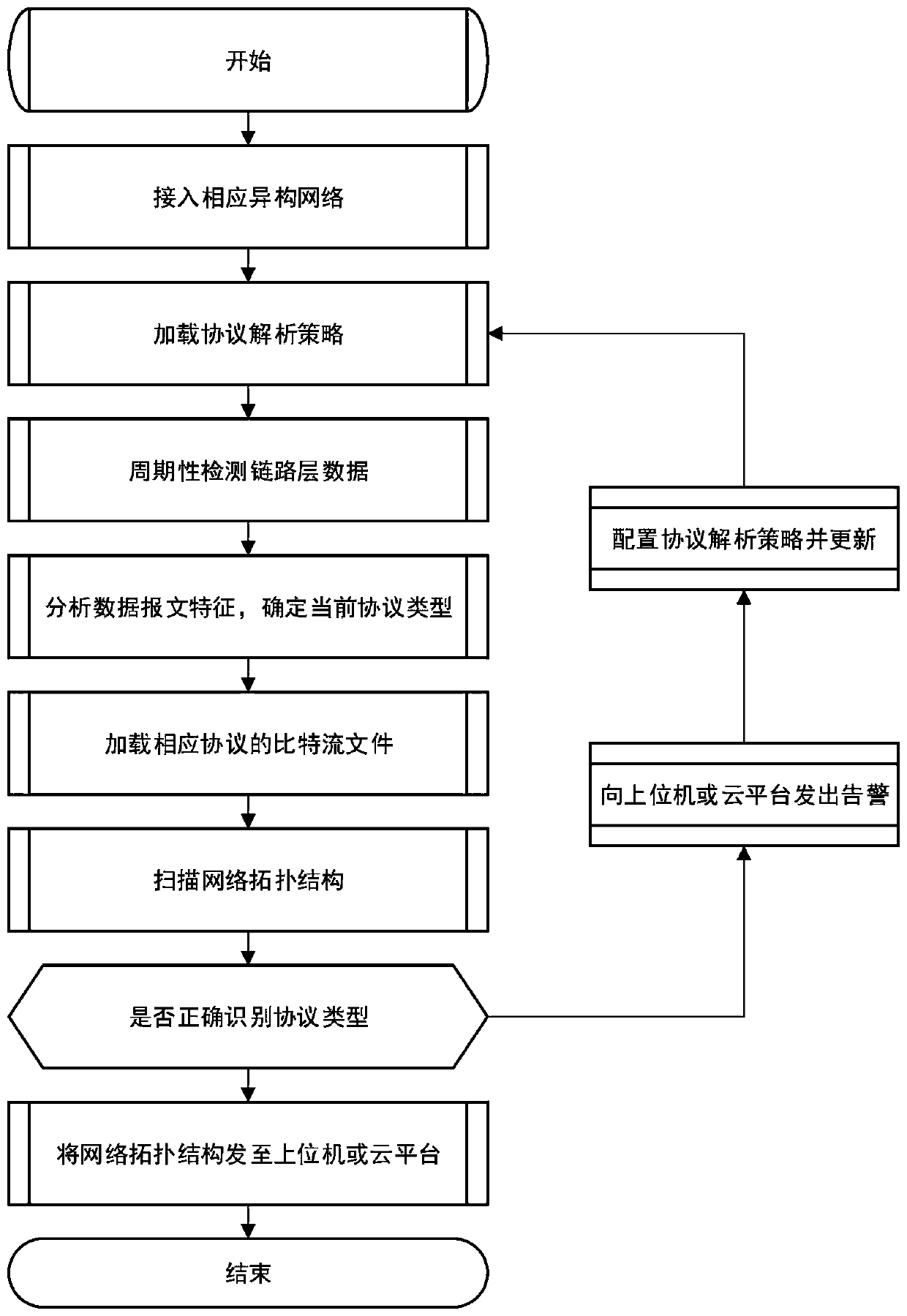

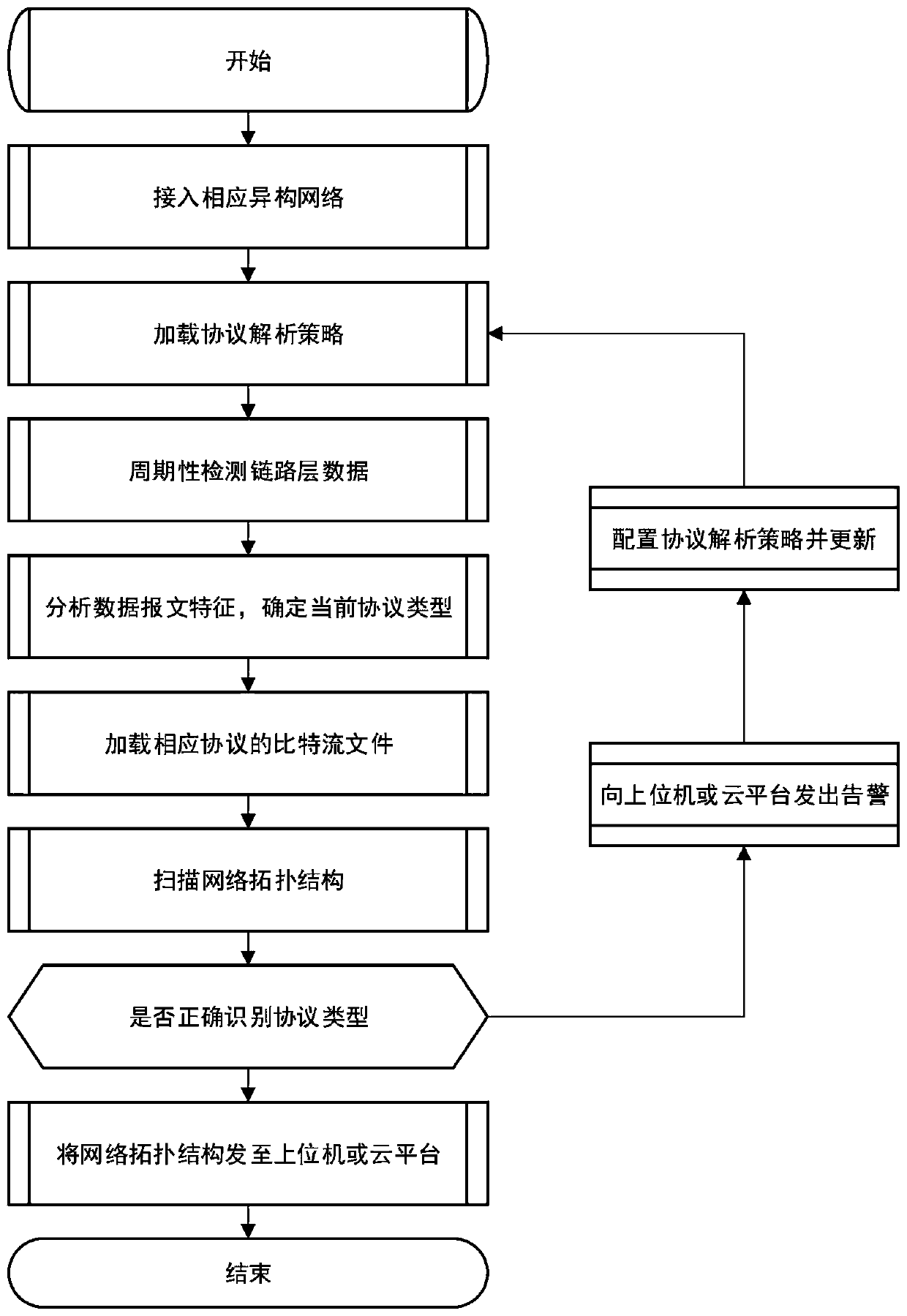

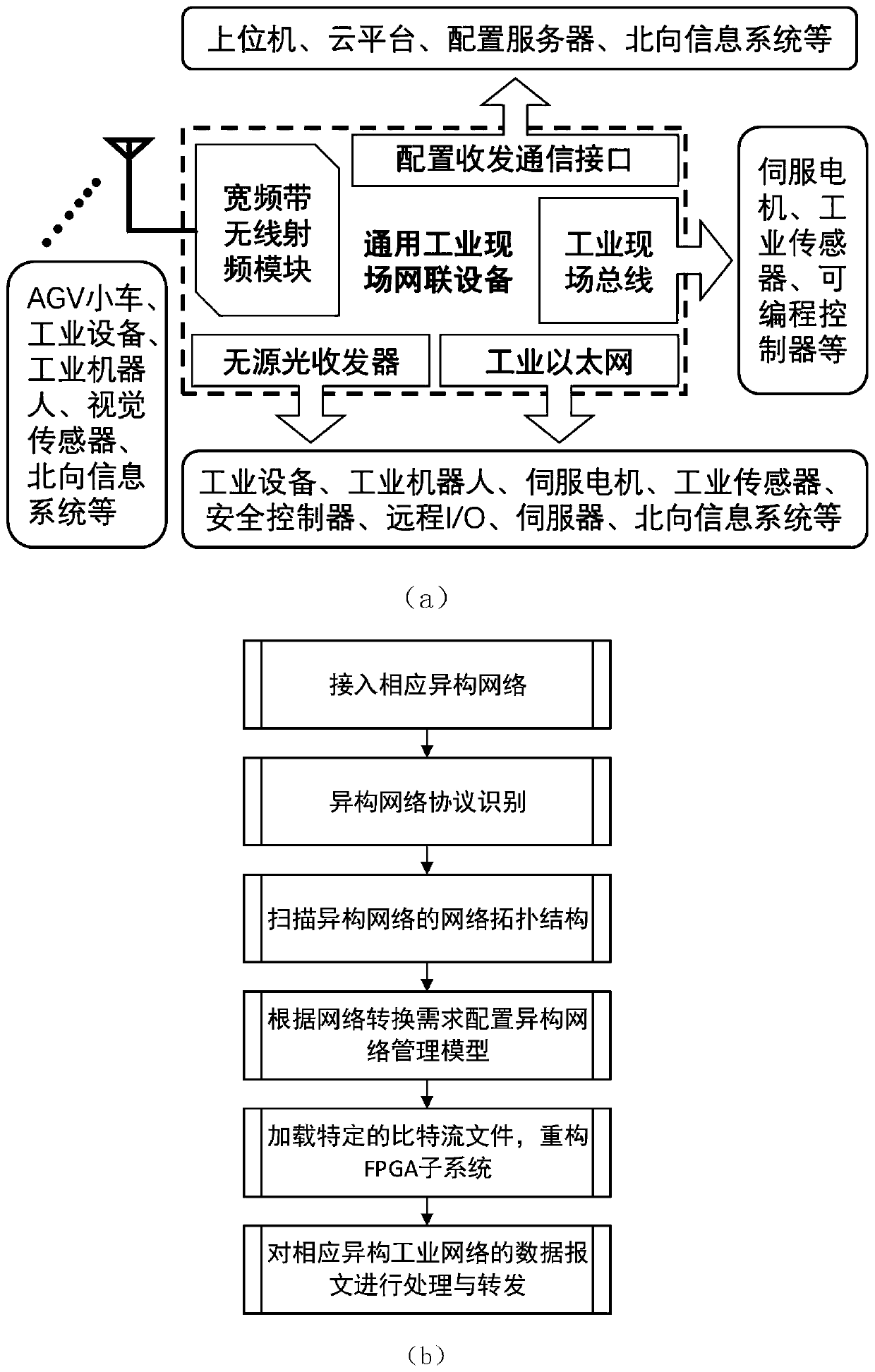

Heterogeneous industrial network interconnection method based on dynamic reconstruction and universal wired communication module

ActiveCN111464339AReal-time embedded computing controlLow costData switching networksTransceiverNetwork connection

The invention discloses a universal wired communication module based on dynamic reconstruction, which comprises a bus communication board card, an optical transceiver and a corresponding physical interface, and is connected and interactively communicates with a reconfigurable control module and a reconfigurable wireless module to form a universal industrial field network connection fusion system based on dynamic reconstruction. The invention also discloses a heterogeneous industrial network interconnection method adopting the module, and the method comprises the steps: setting a universal industrial field network connection fusion system, carrying out detection and analysis of link layer data in a heterogeneous network, and generating a network management strategy file; and loading the corresponding network management strategy file, and downloading the network management strategy file to the FPGA subsystem of the reconfigurable control module to complete network reconfiguration. According to the invention, interconnection and intercommunication between heterogeneous equipment and networking acquisition of industrial data can be realized, so that the equipment has interoperability and interoperability, flexible networking and reconstruction are easy, and the process of automatic and intelligent upgrading and reconstruction of the industrial equipment is promoted.

Owner:CHINA ELECTRONICS PROD RELIABILITY & ENVIRONMENTAL TESTING RES INST

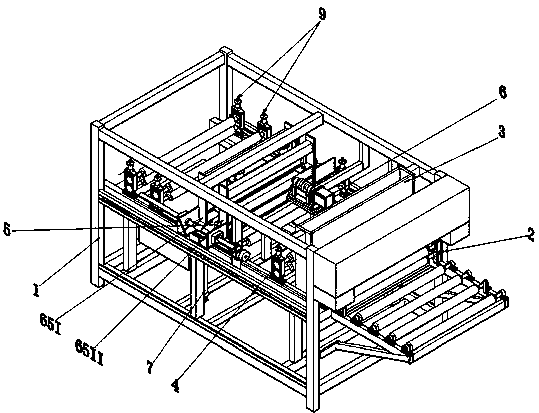

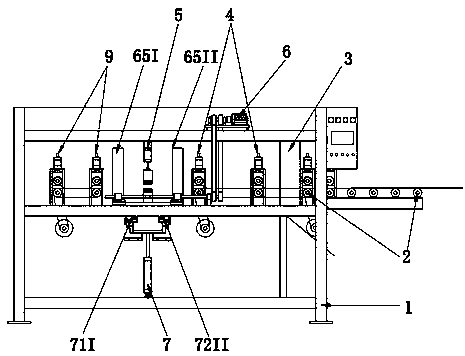

Veneer longitudinal glue jointer

InactiveCN110466011AAvoid strandedAvoid residueProfiling/shaping machinesWood veneer joiningHot meltEngineering

The invention discloses a veneer longitudinal glue jointer. The veneer longitudinal glue jointer comprises a main frame, a tooth cutting device, a tooth cutting conveying device, a tooth jointing conveying device, a veneer output conveying device, a clamp plate moving device, a gluing device and a tooth jointing device, wherein the tooth jointing device mainly comprises a support, a first air cylinder, a downward pressing connection piece, a downward pressing cooling pipe, a support cooling pipe and a support connection piece. By respectively arranging two lifting components at two ends of thesupport connection piece, lifting motion of the support cooling pipe is achieved, veneers after completing tooth jointing on the tooth jointing device is raised when the veneers are output, retentionof hot melt glue on the support cooling pipe, the clamping component and the veneer output conveying component is avoided, the hot melt glue on the veneers after being formed through the tooth jointing is cooled once again when the veneers are output, and good tooth jointing effect is achieved.

Owner:广州市俊金机械有限公司

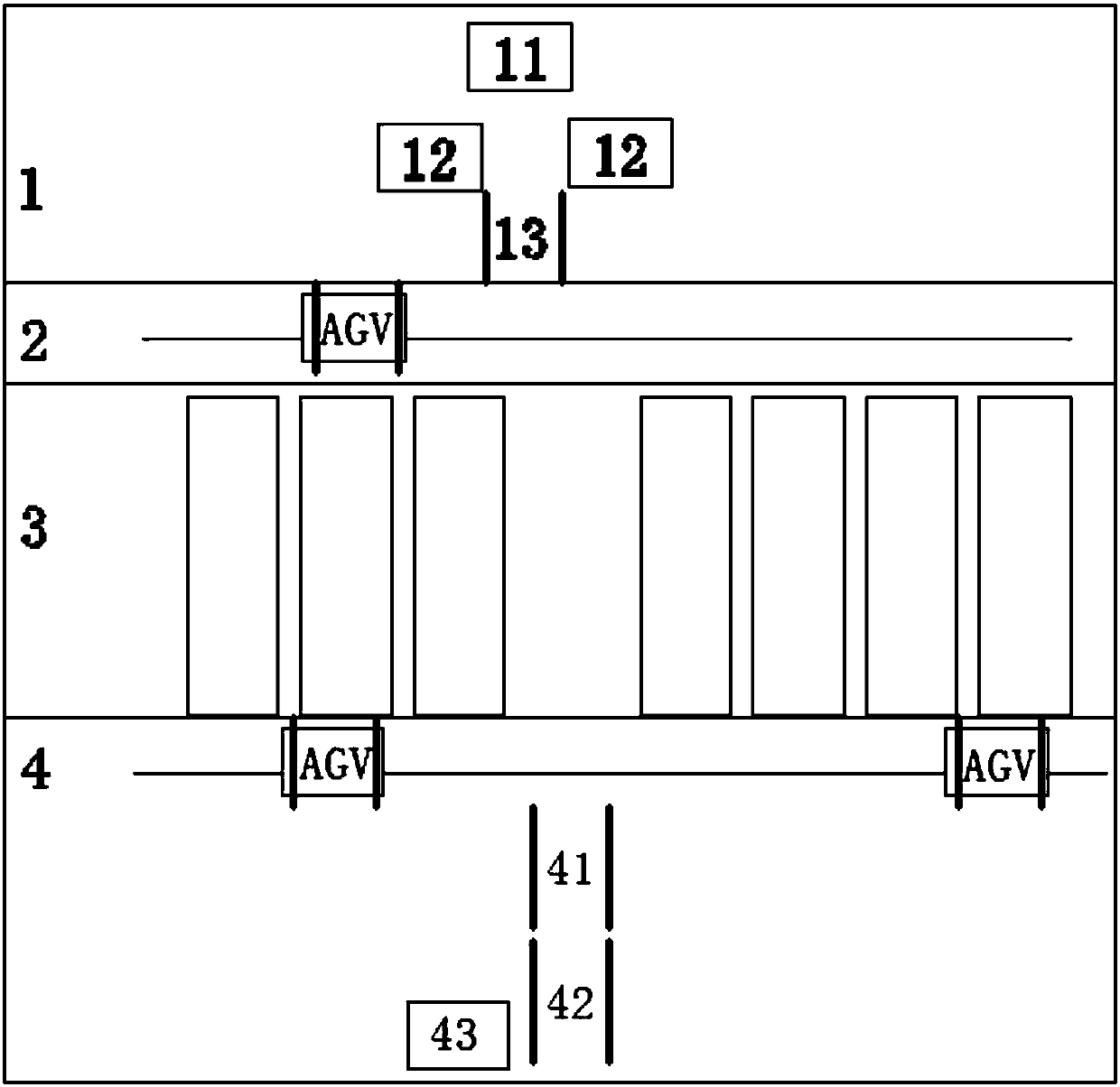

Vehicle bumper repairing, maintaining, carrying and storing system

ActiveCN107685792AIncrease the switching frequencyReduce labor intensityVehiclesProduction lineControl system

The invention discloses a vehicle bumper repairing, maintaining, carrying and storing system which is characterized by comprising a repairing and maintaining region, a conveying region, a storage location region, a guiding and fetching region and a control system. An inlet side of the repairing and maintaining region is connected with an injection molding machine at a previous station, and an outlet side of the repairing and maintaining region is connected with an inlet side of the conveying region; an inlet side of the storage location region is connected with an outlet side of the conveyingregion, and an outlet side of the storage location region is connected with an inlet side of the guiding and fetching region; an outlet side of the guiding and fetching region is connected with an inlet side of a coating production line at a next station. Each of the conveying region and the guiding and fetching region comprises at least one lift type AGV (automatic guide vehicle). The storage location region comprises a plurality of storage locations, and the storage locations are parallelly arrayed. The vehicle bumper repairing, maintaining, carrying and storing system has the advantages that flexible manufacturing production takt and requirements can be met by the multiple lift type AGV and the storage locations, the bumper type switching frequencies can be increased, labor environmentscan be improved, the labor intensity of workers can be relieved, the error rates of the workers can be lowered, labor loss in carrying procedures can be prevented, and bumpers can be efficiently intelligently managed.

Owner:HEBEI UNIV OF TECH

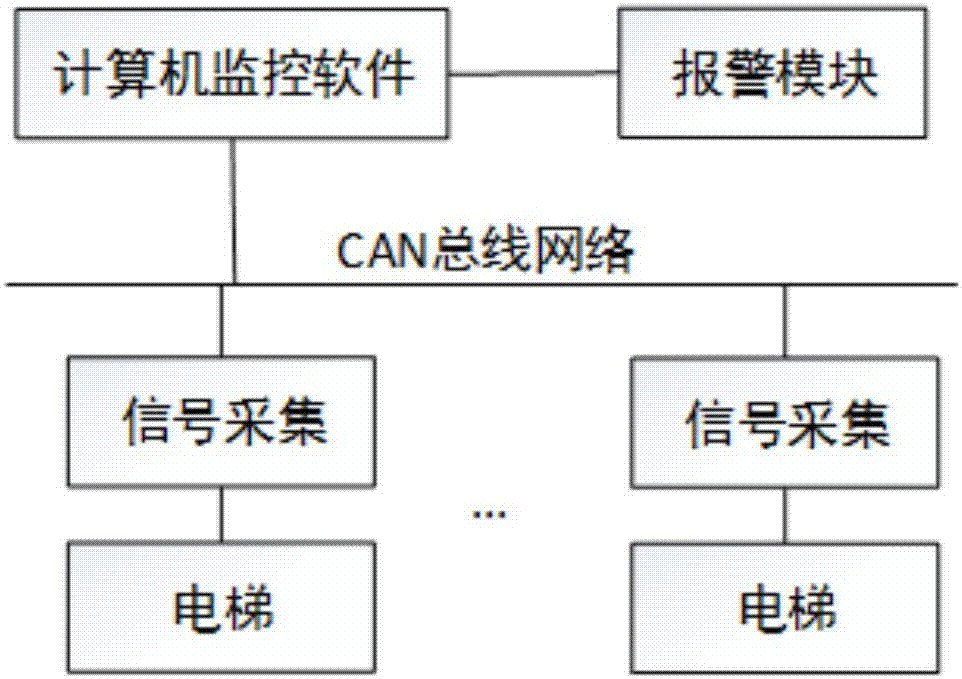

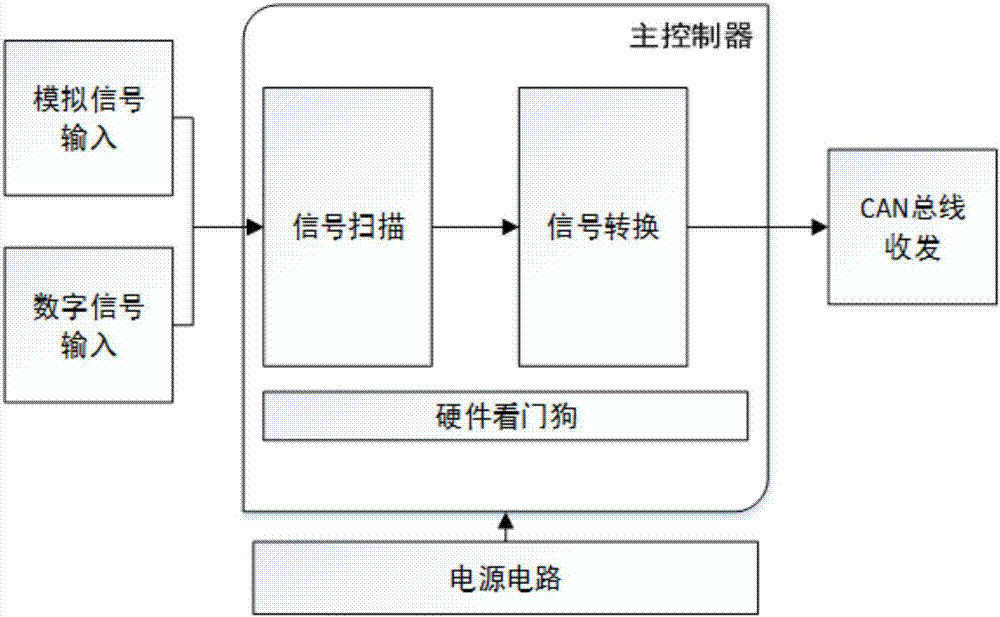

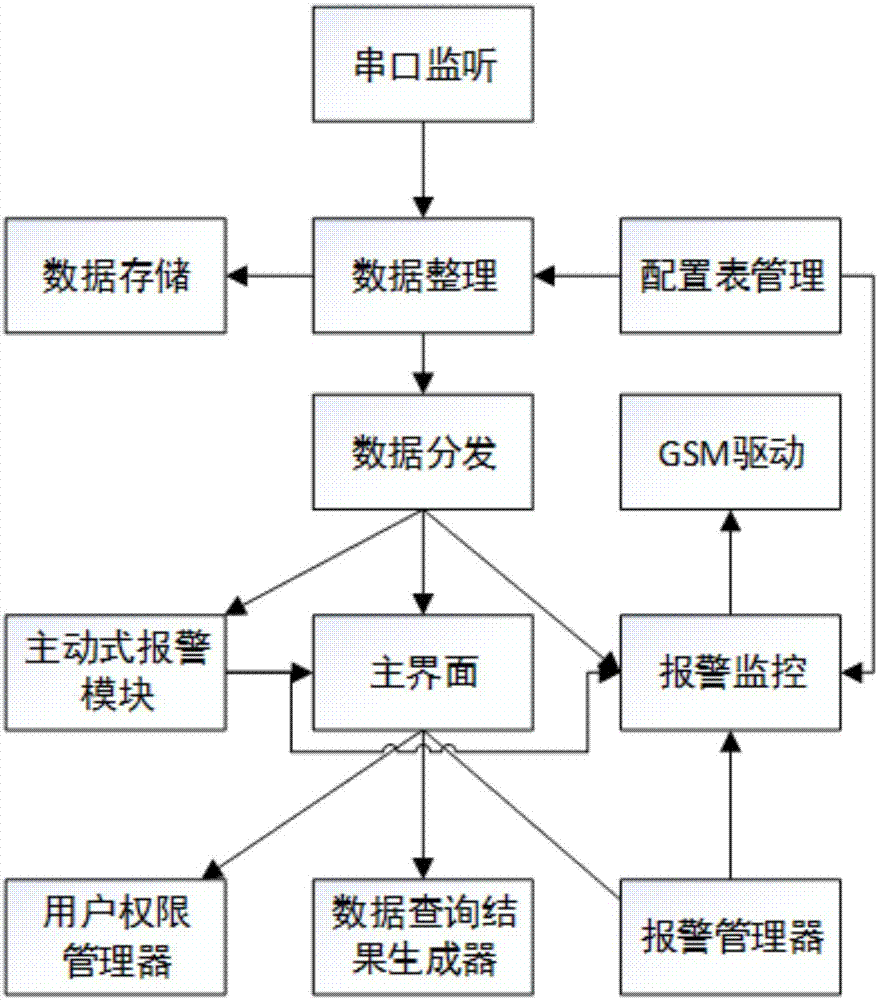

CAN (Controller Area Network) bus-based elevator monitoring method

InactiveCN107203201AReduce transmission errorEfficient fault alarm functionProgramme controlElectric testing/monitoringArea networkData acquisition

The invention discloses a CAN (Controller Area Network) bus-based elevator monitoring method. A CAN bus communication circuit, a main controller, a signal collection module and an alarm module are involved; the CAN bus communication circuit comprises at least one CAN controller and a CAN transceiver; the main controller is connected with the CAN bus communication circuit and can monitor a working state of an elevator; the signal collection module can collect data and realize a communication function between the signal collection module and the CAN bus communication circuit; the alarm module is connected with the main controller and can sound an alarm for an abnormal working state of the elevator.

Owner:JILIN JIANZHU UNIVERSITY

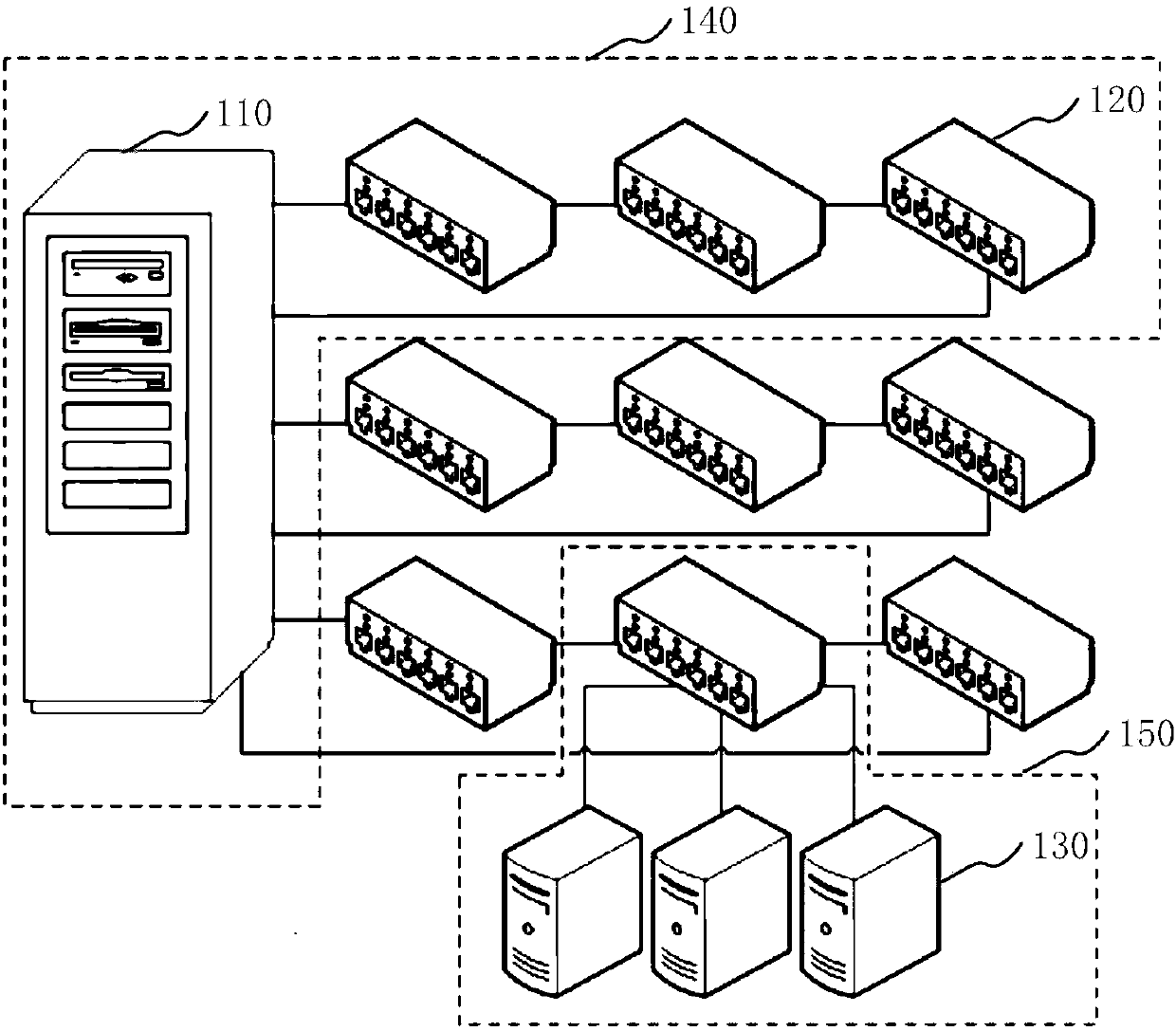

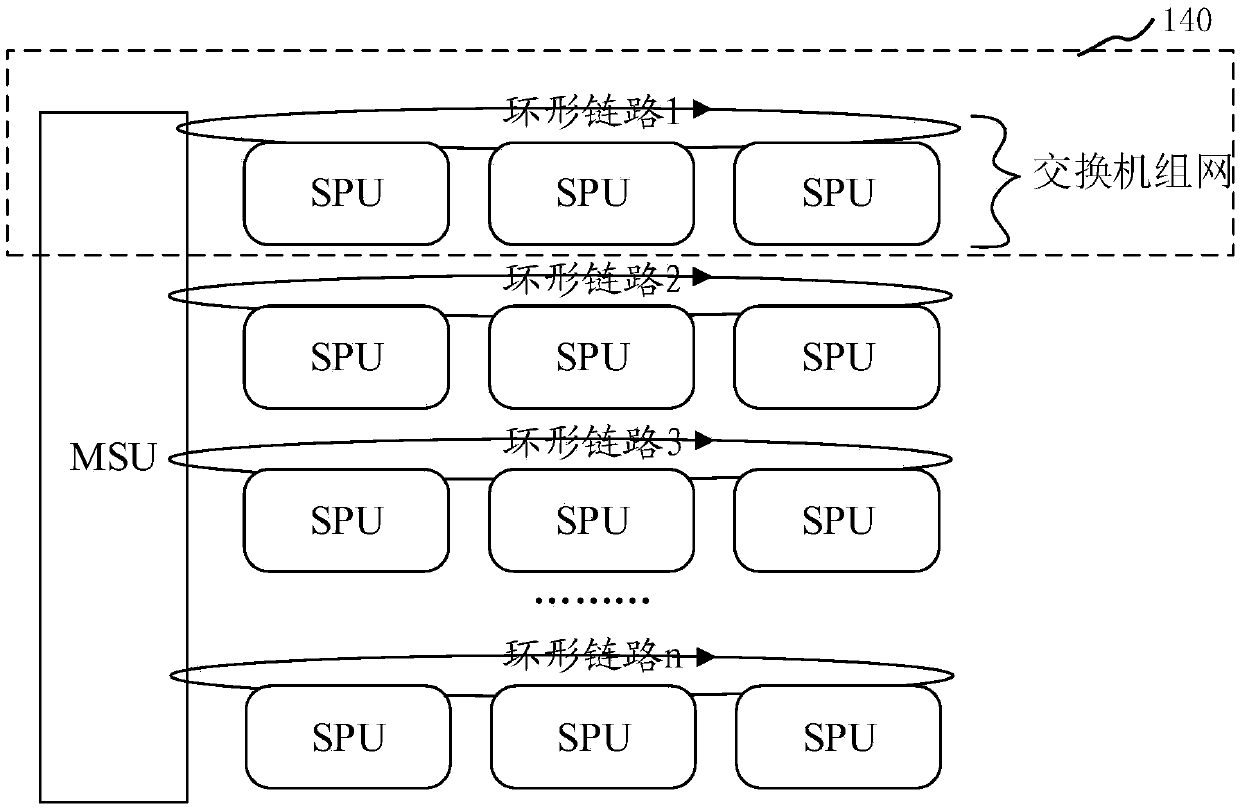

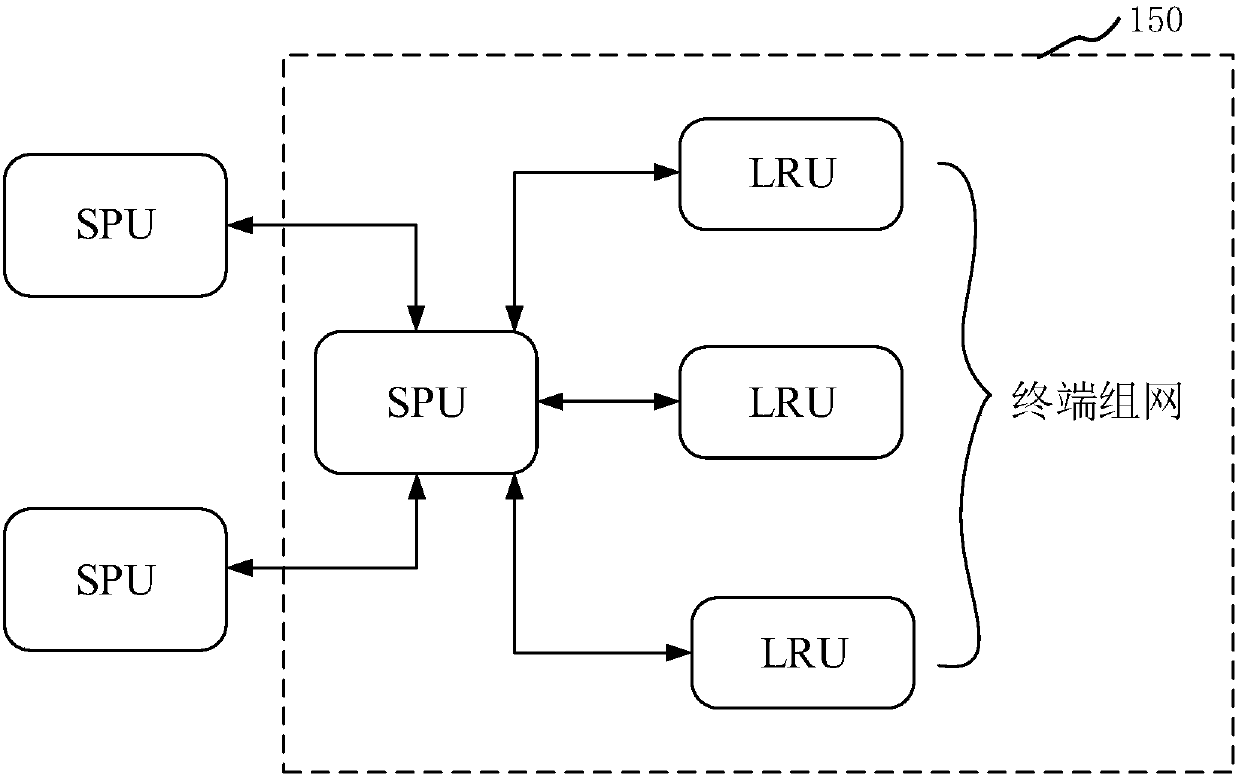

Airborne entertainment system

ActiveCN110166495AAvoid slowGuaranteed uptimeData switching current supplyStar/tree networksNetwork connectionPower exchange

The invention relates to an airborne entertainment system. The system comprises a server module, at least one power exchange module and at least one terminal device. The server module is in serial connection with the at least one power supply exchange module through a communication cable to form at least one annular switch network; and each power switching module in the annular switch network is respectively connected with at least one terminal device in parallel through a communication cable to form at least one star-shaped terminal network. According to the airborne entertainment system, thenetwork topology structure combining the ring topology and the star topology is adopted, and the network of the whole airborne entertainment system is divided into two levels. The annular switch network ensures the reliability of connection between power switching modules, effectively improves the efficiency of network transmission, and inhibits single-point faults. The star-shaped terminal network improves the load capacity of the airborne entertainment system, so that the network connection is clear and ordered, and the management and maintenance are easy.

Owner:苏州科可瑞尔航空技术有限公司

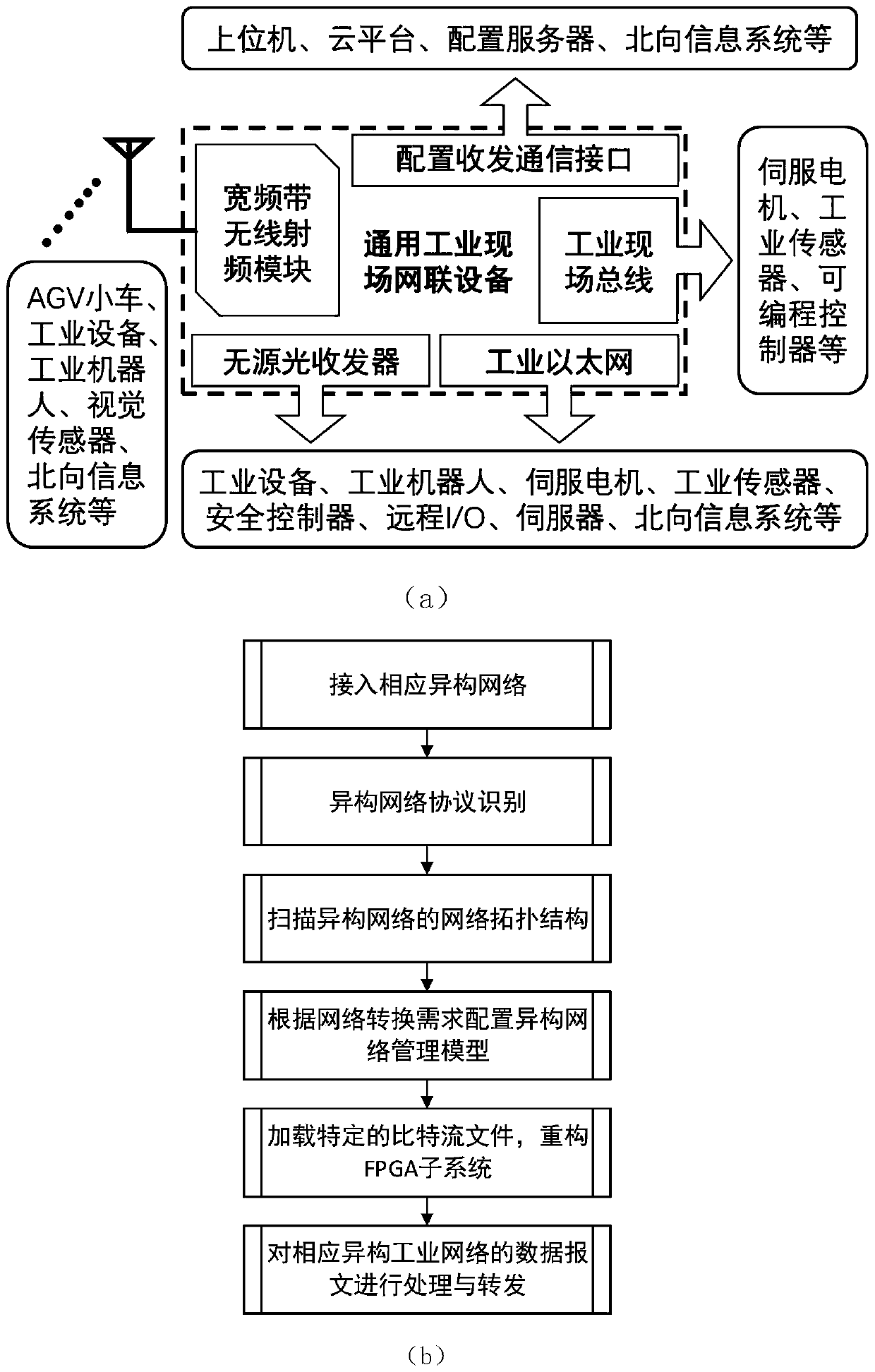

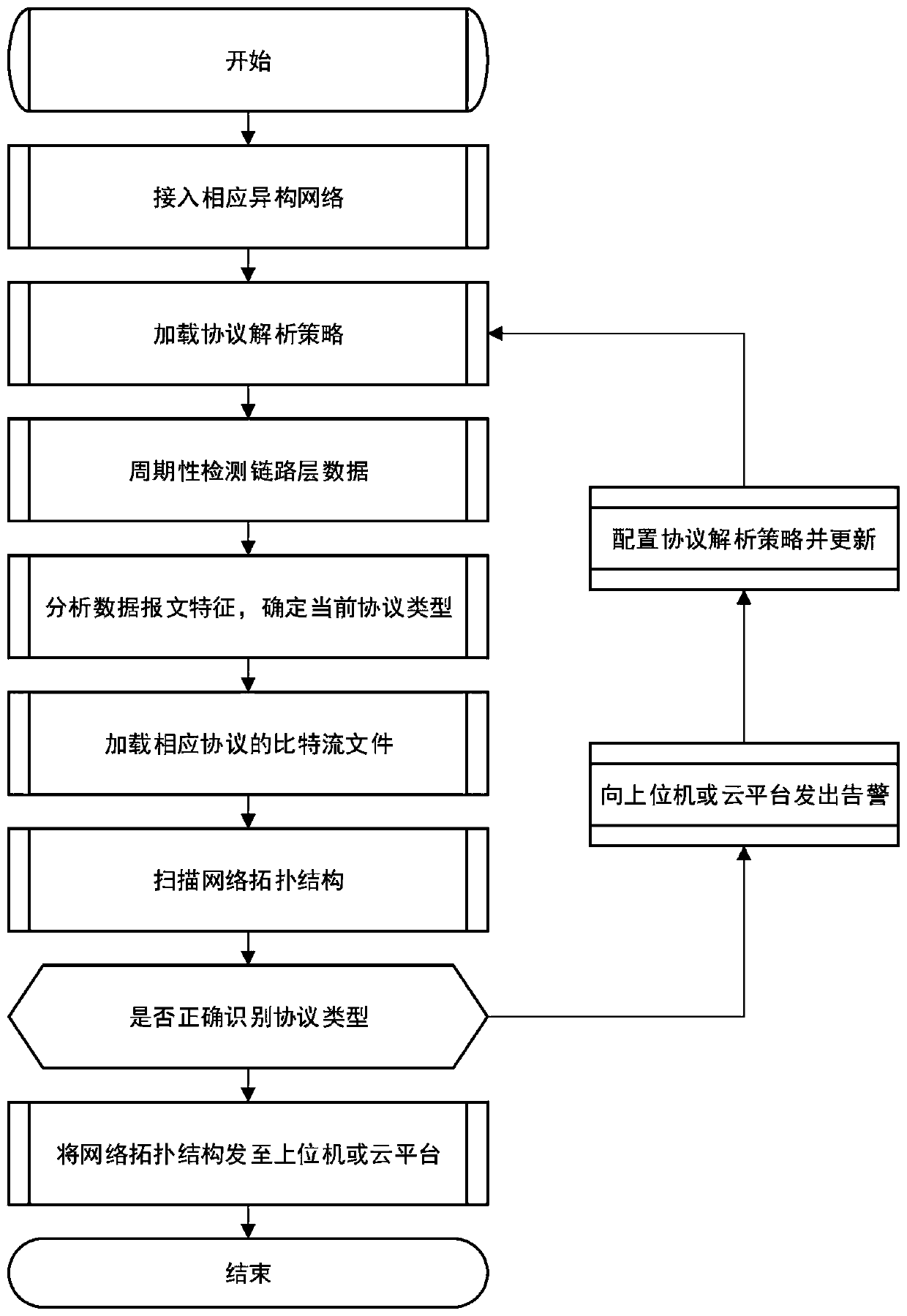

Interconnection fusion method and system for heterogeneous industrial network

ActiveCN111447084ALow costImprove accuracyProgramme controlComputer controlNetwork connectionIndustrial equipment

The invention discloses an interconnection fusion method for a heterogeneous industrial network. The method comprises the following steps of: setting a general industrial field network connection fusion system, and periodically detecting and analyzing link layer data in the heterogeneous network by the general industrial field network connection fusion system; generating a network management strategy file and storing the network management strategy file in a memory of a reconfigurable control module; and loading a corresponding network management strategy file, and downloading a compiled specific configuration bit stream file to an FPGA subsystem of the reconfigurable control module to complete network reconfiguration. The invention further discloses a system for implementing the method. The system comprises the reconfigurable control module, a reconfigurable wireless module and a universal wired communication module which are connected with one another and communicated with one another. According to the invention, interconnection and intercommunication between heterogeneous devices and networking acquisition of industrial data can be realized, so that the devices have interoperability and interoperability, and flexible networking and reconstruction are easy to realize, thereby promoting the process of automatic and intelligent upgrading and reconstruction of the industrial devices.

Owner:CHINA ELECTRONICS PROD RELIABILITY & ENVIRONMENTAL TESTING RES INST

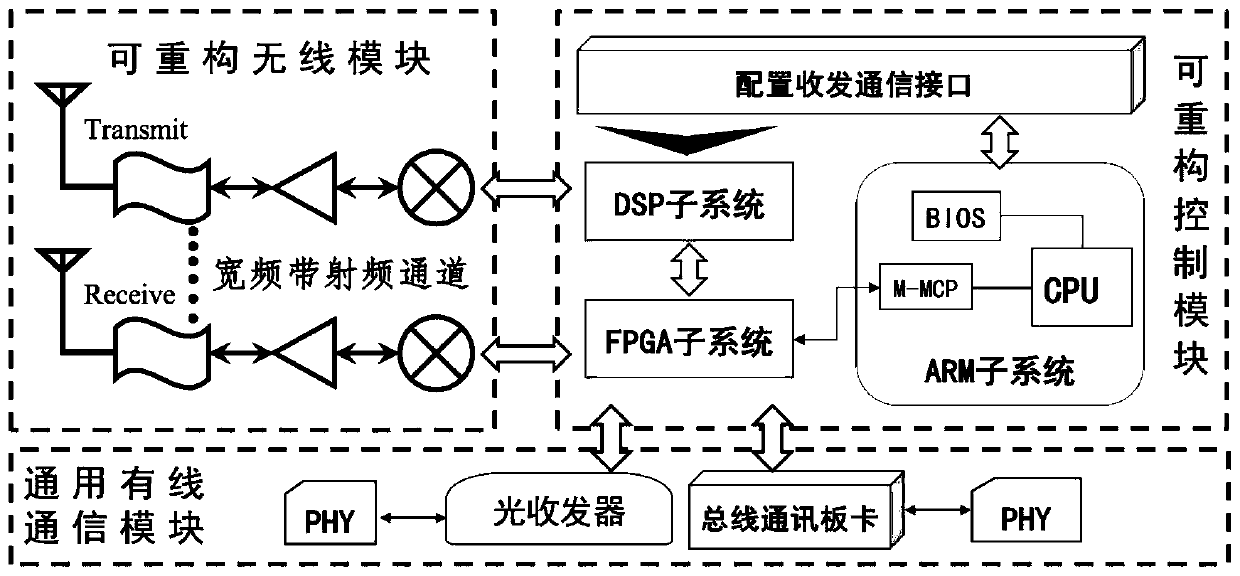

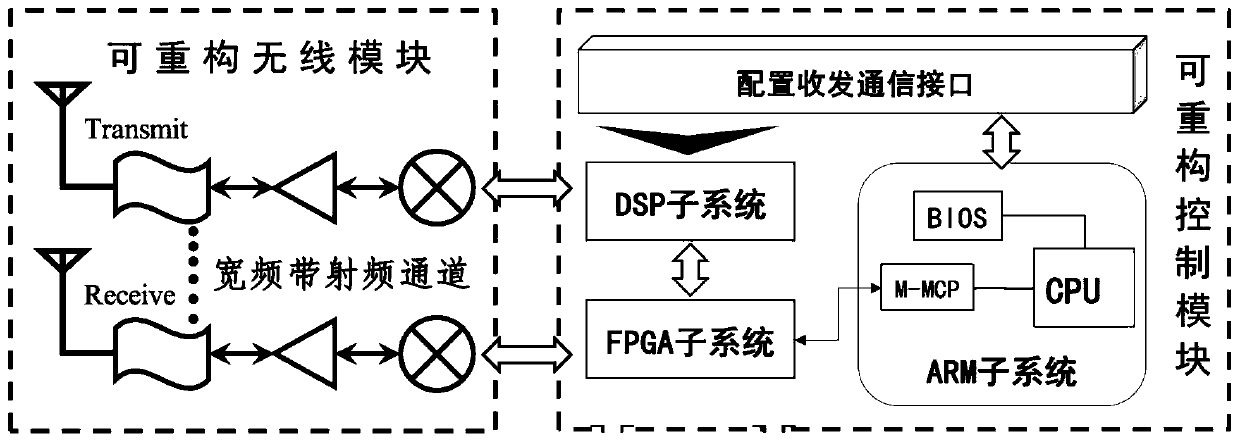

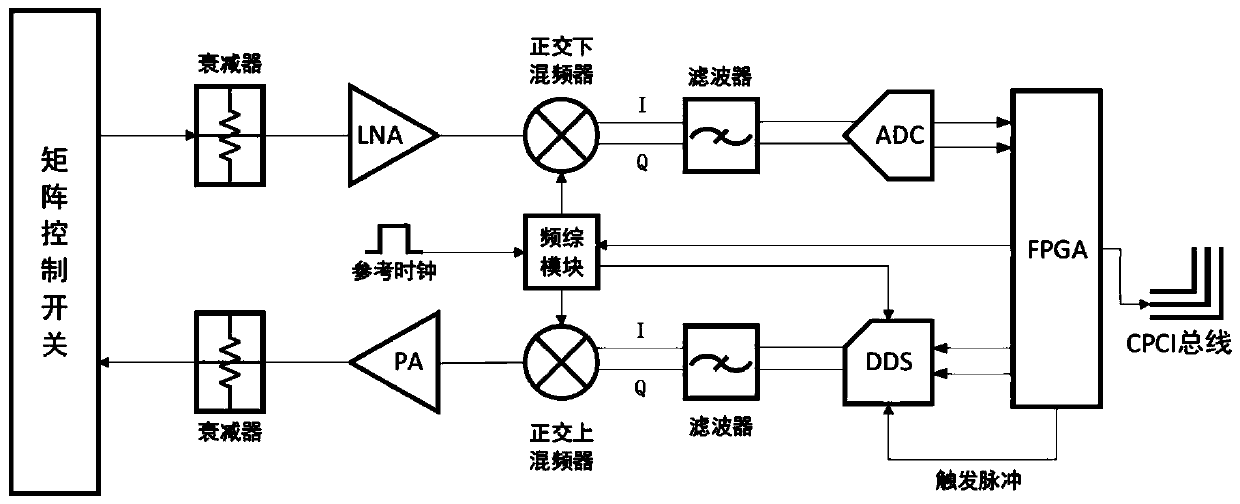

Heterogeneous industrial network interconnection method based on dynamic reconstruction and wireless module

ActiveCN111478799ALow costImprove accuracyData switching networksTotal factory controlNetwork connectionIndustrial equipment

The invention discloses a reconfigurable wireless module based on dynamic reconfiguration, which is characterized by consisting of a reconfigurable main control circuit, a broadband transmitting channel and a receiving channel, and the reconfigurable wireless module is connected and interactively communicated with the reconfigurable main control module and reconfigurable wireless module general wired module to form a general industrial field network integration system based on dynamic reconfiguration. The invention also discloses a heterogeneous industrial network interconnection method adopting the module, and the method comprises the steps: setting a universal industrial field network connection fusion system, carrying out the detection and analysis of link layer data in a heterogeneousnetwork, and generating a network management strategy file; and loading the corresponding network management strategy file, and downloading the compiled specific configuration bit stream file to a FPGA subsystem of the reconfigurable control module to complete network reconfiguration. According to the invention, interconnection and intercommunication between heterogeneous equipment and networkingacquisition of industrial data can be realized, so that the equipment has interoperability and interoperability, flexible networking and reconstruction are easy, and the process of automatic and intelligent upgrading and reconstruction of the industrial equipment is promoted.

Owner:CHINA ELECTRONICS PROD RELIABILITY & ENVIRONMENTAL TESTING RES INST

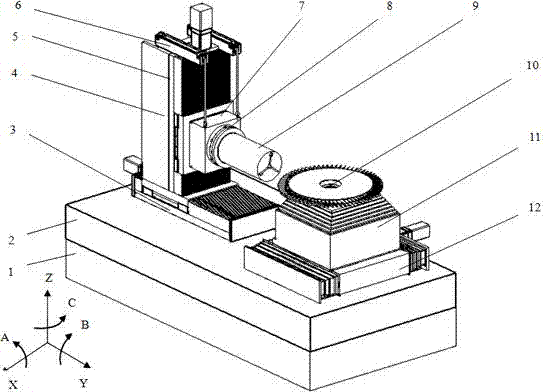

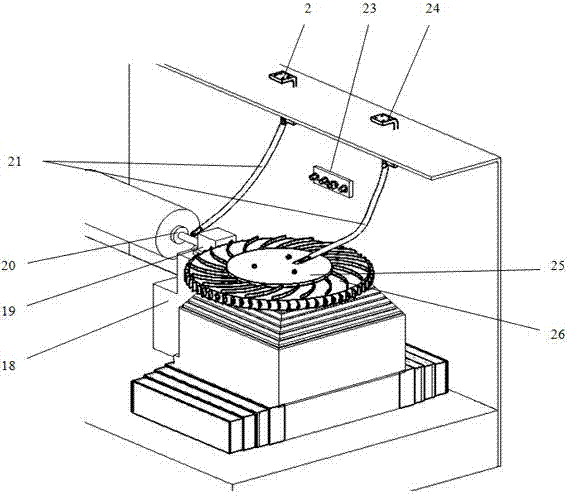

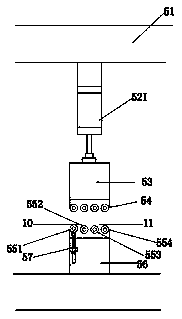

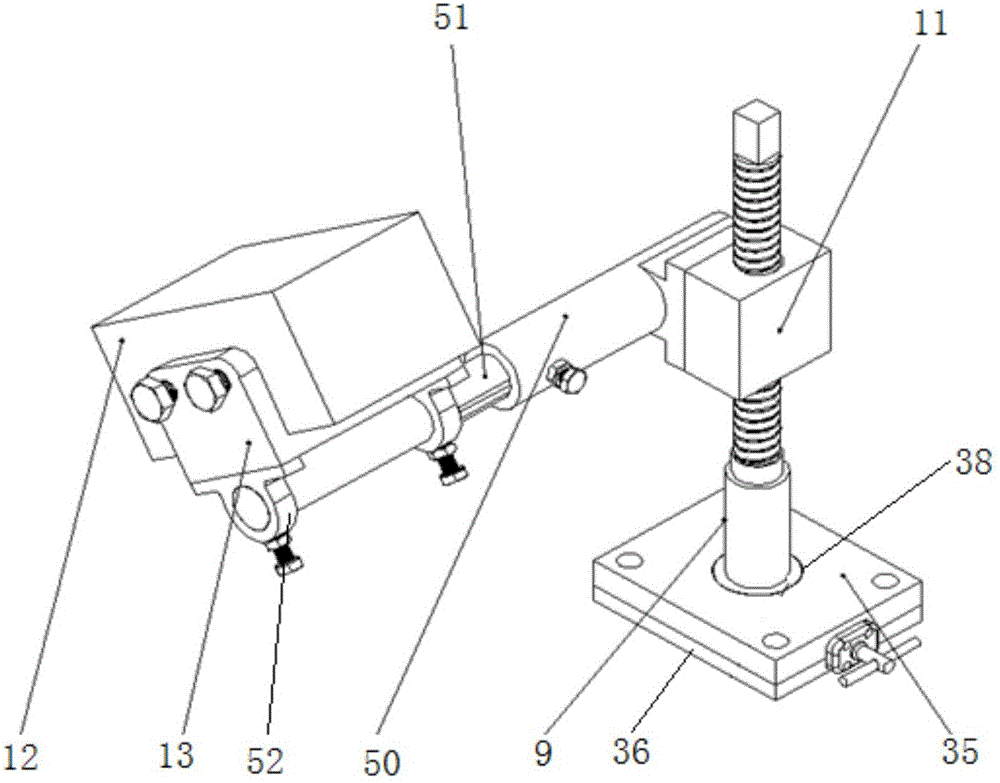

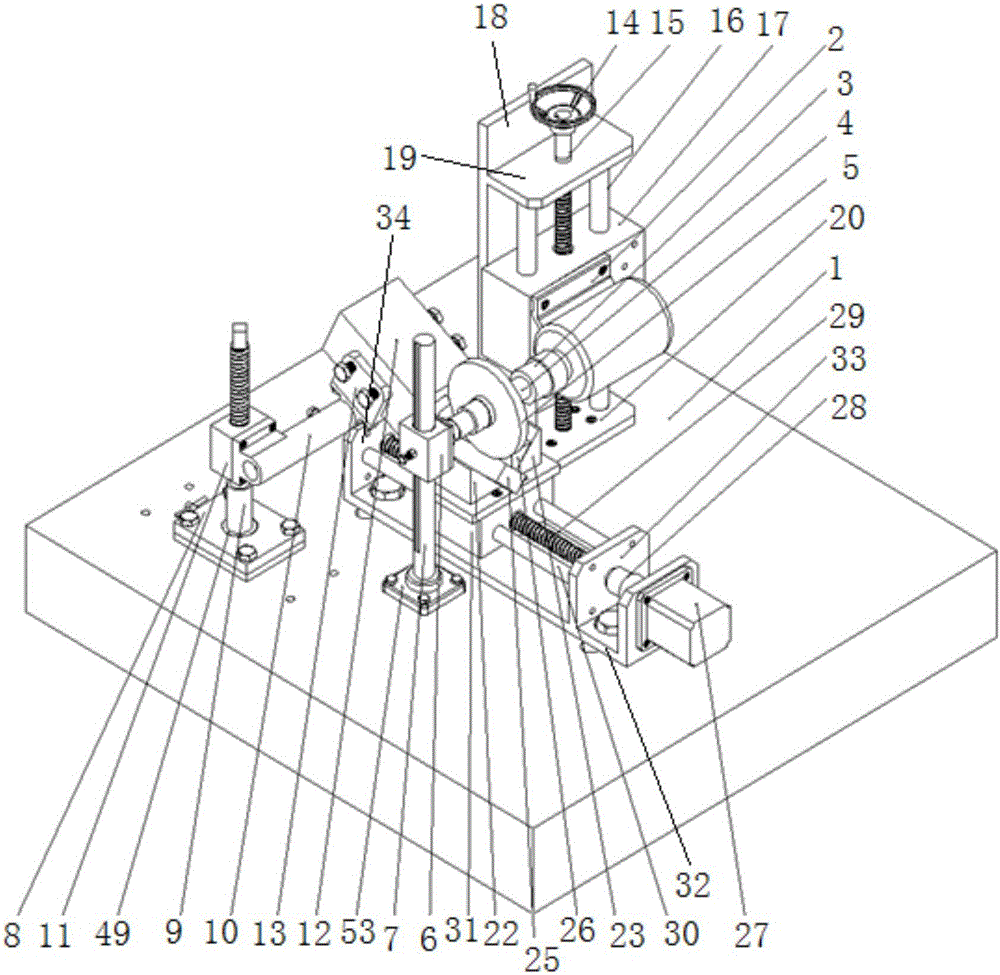

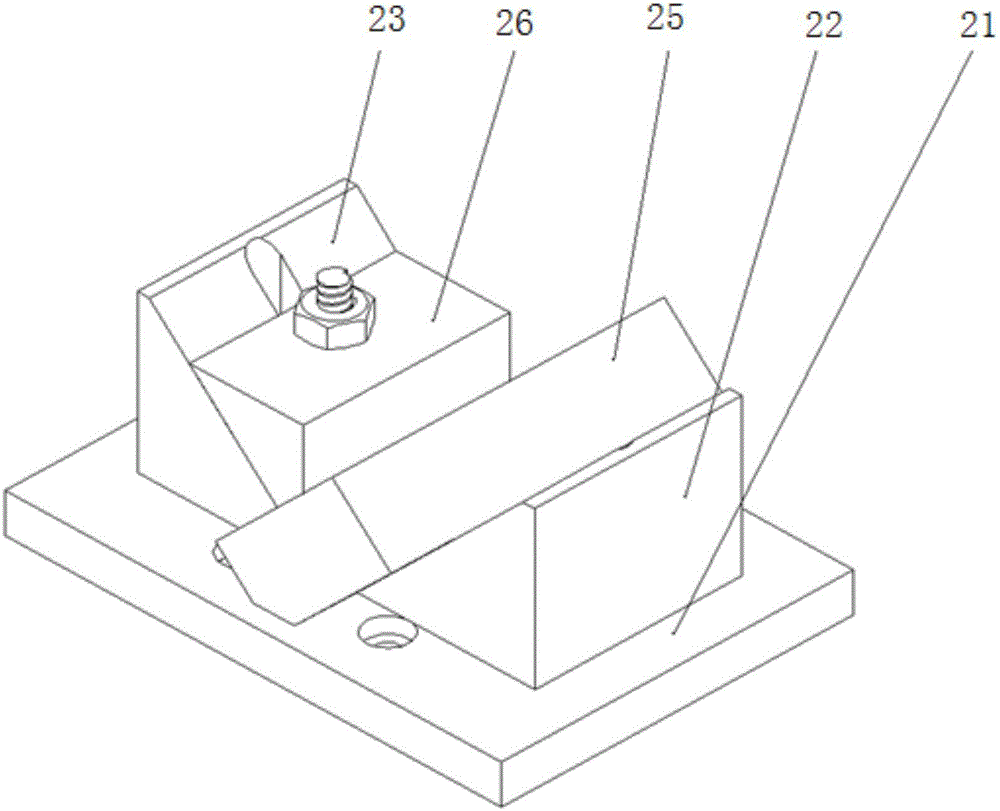

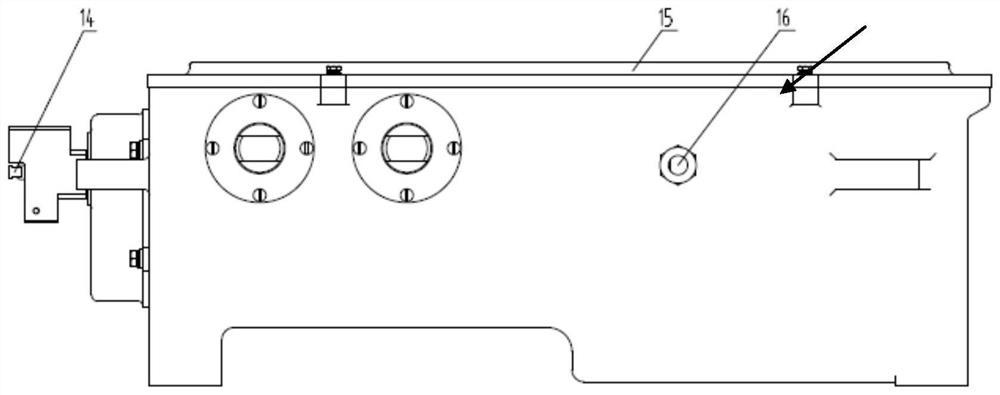

Laser-heating-assisted efficient grinding experiment table for hard and brittle material

ActiveCN106737070AGrinding quality is not easy to guaranteeLow grinding efficiencyGrinding carriagesGrinding drivesCouplingEngineering

The invention discloses a laser-heating-assisted efficient grinding experiment table for a hard and brittle material. The laser-heating-assisted efficient grinding experiment table comprises a base body, a grinding wheel support device, a clamping tool support device and a laser heating device. The grinding wheel support device comprises a motor and a vertical feeding device. The output end of the motor is connected with a horizontal shaft through a coupling I. The horizontal shaft is sleeved with a grinding wheel. The other end of the horizontal shaft is connected with a vertical rod fixed to the base body through a shaft seat. The shaft seat can slide in the axial direction of the vertical rod. The vertical feeding device is fixedly connected with the base body. According to the laser-heating-assisted efficient grinding experiment table, laser heating assistance is applied to grinding, and grinding efficiency and grinding quality are improved; the motor coupling is adopted for directly driving the grinding wheel, the grinding wheel is driven to grind a workpiece, transmission errors and accumulative transmission errors generated in the transmission link are reduced, the utilization rate of motor power is increased, and the rotating speed of the grinding wheel is guaranteed; and a gantry type mechanism is adopted for supporting the horizontal shaft, namely a grinding wheel shaft, rigidity of the horizontal shaft can be guaranteed, vibration of the shaft ends is effectively reduced, and furthermore, grinding precision can be correspondingly improved.

Owner:NORTHEASTERN UNIV

Turnout switching equipment and method suitable for tramcar

PendingCN111791917AReduce transmission errorPlay the function of breakout protectionElectric devices for scotch-blocksMachineElectric control

The invention relates to turnout switching equipment and method suitable for a tramcar. An action rod and a detection rod are located on the upper portion of a bottom shell and located on the same horizontal plane with a turnout connecting rod piece, when a turnout is pushed and pulled, force output by a switch machine and displacement transmitted to the detection rod by the turnout are located onthe same axis, and the transmission error is small; and the switch machine locks the turnout in an elastic locking mode, and the turnout and equipment are protected in a turnout squeezing mode underthe turnout squeezing condition. Under the condition of non-electric control equipment, the switching equipment can be manually moved by a tool to switch the turnout, and the operation is simple. Thesealing requirement of the IP67 protection level is adopted for sealing of a box body of the switch machine, the functions of the equipment are not affected after short-time soaking, and the dustproofand waterproof performance is good.

Owner:XIAN RAILWAY SIGNAL

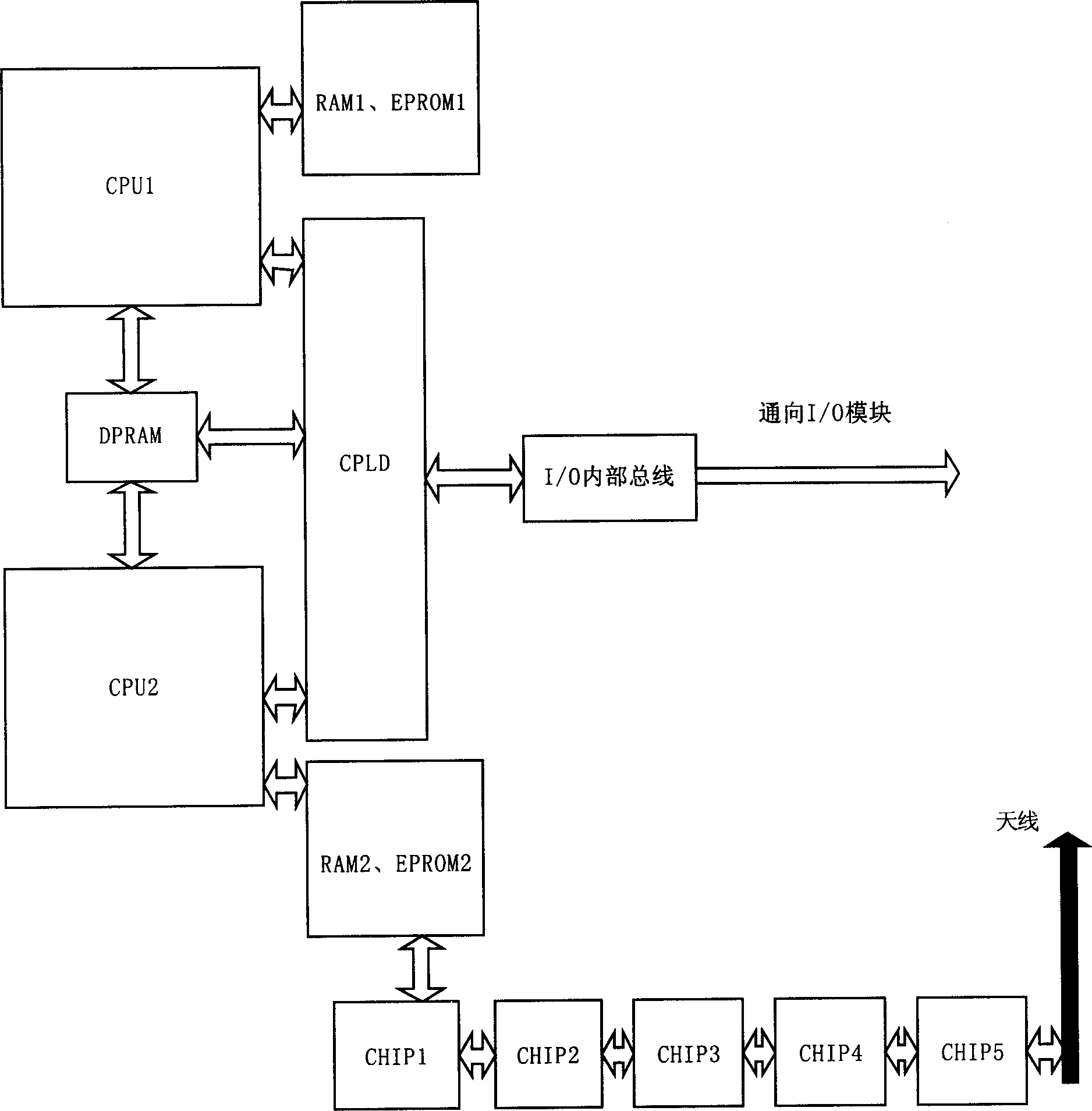

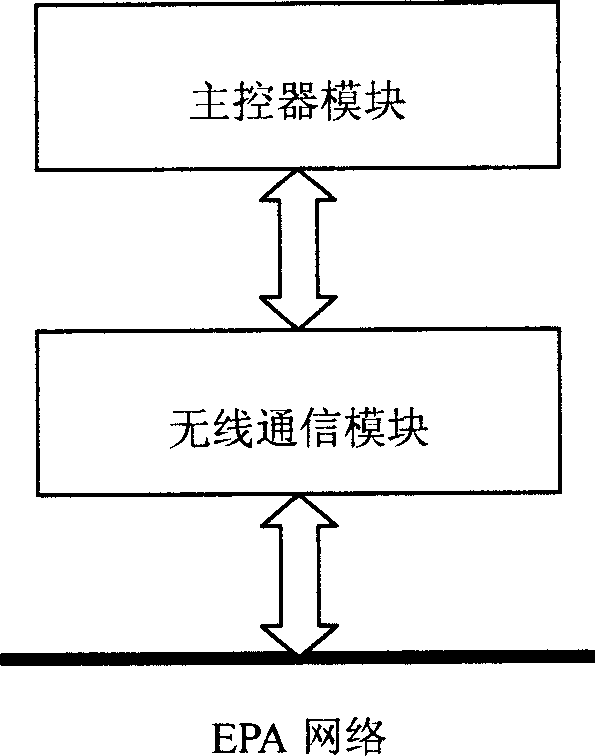

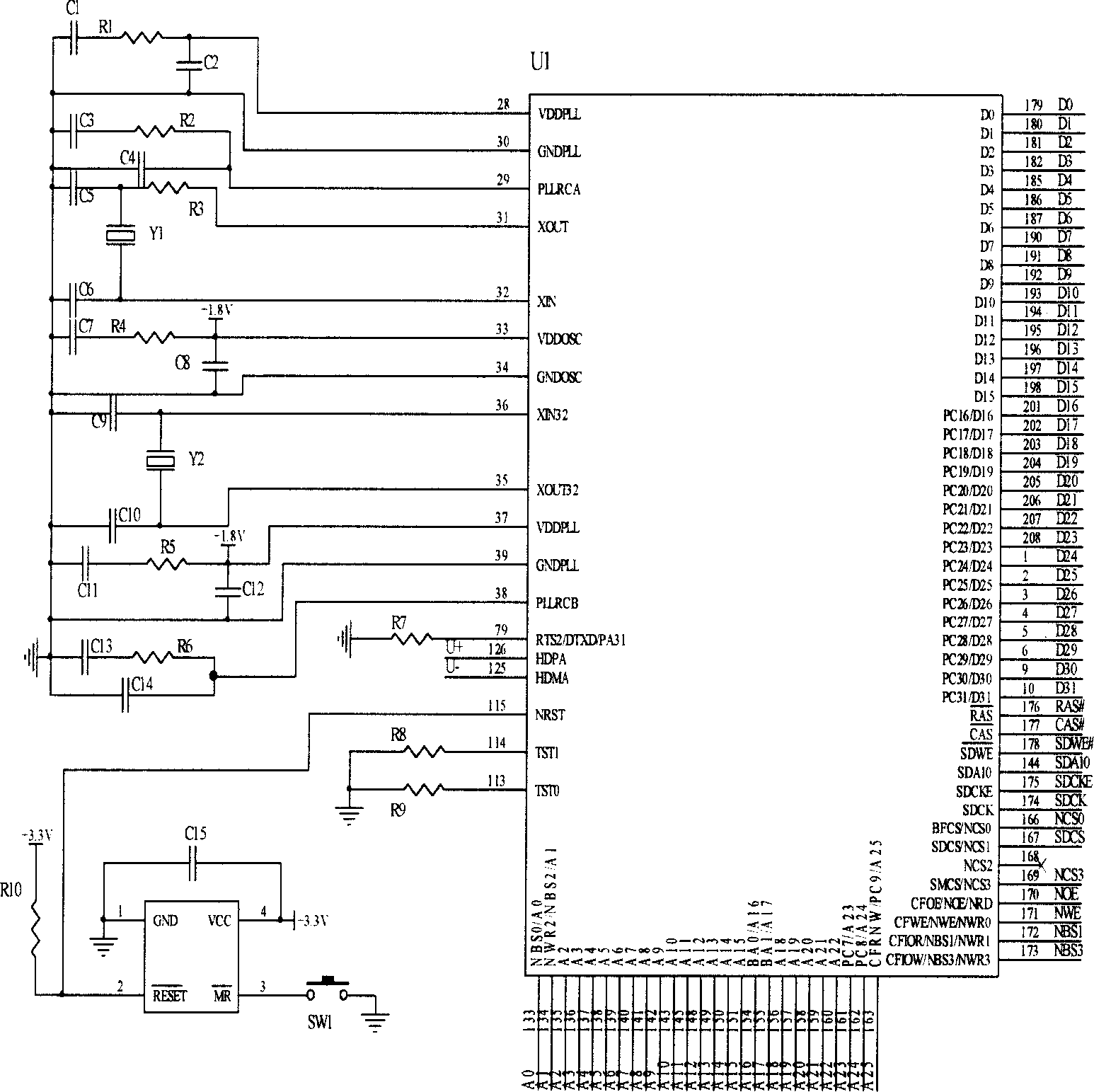

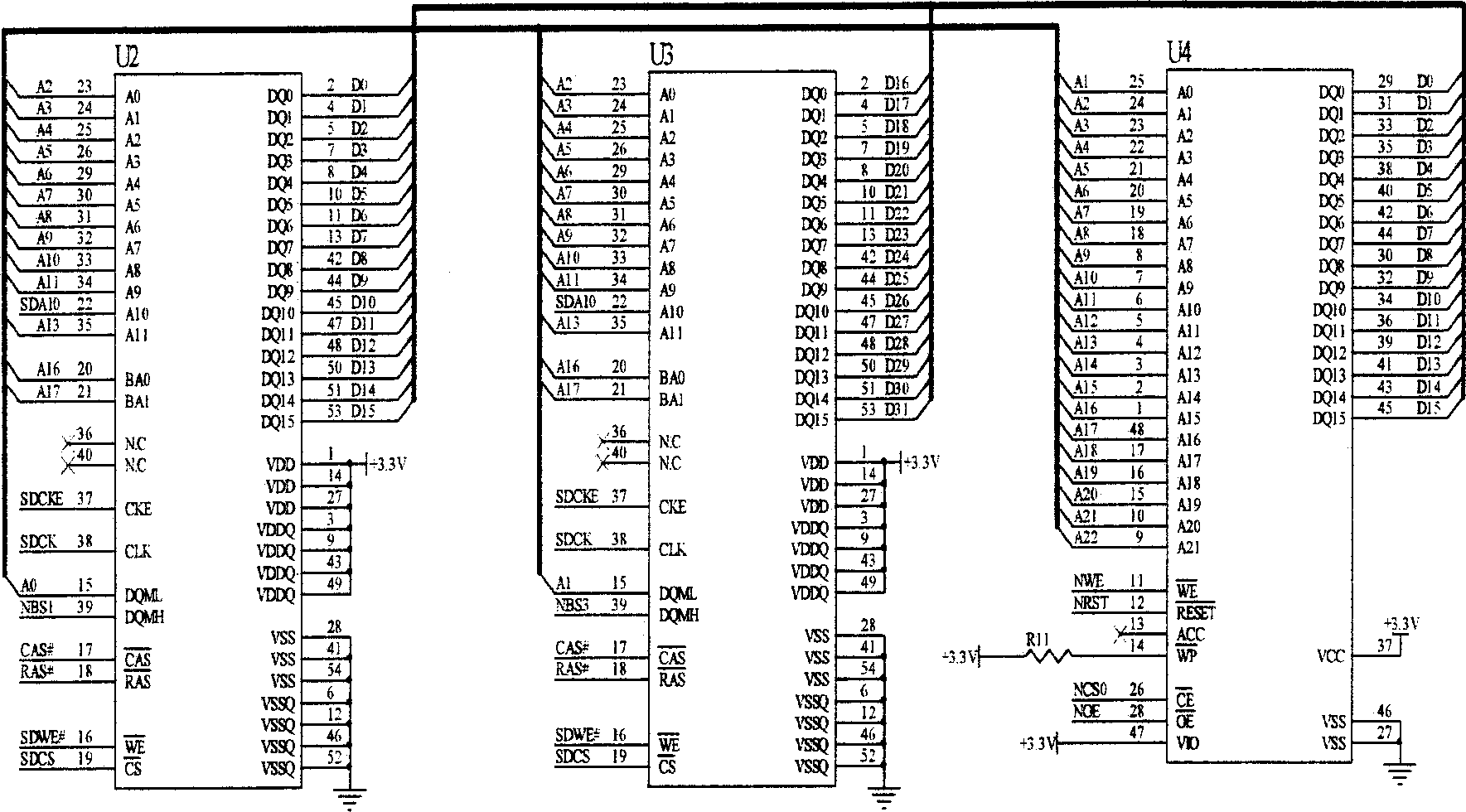

Wireless built-in controller based on automatic industrial Ethernet field bus

InactiveCN1897557AWith fully distributed controlIncrease opennessNetworks interconnectionNetwork connectionsAutomatic controlUSB

The invention comprises a main control module and a radio communication module. Wherein the main control module runs the EPA industrial Ethernet field bus communication protocol stack, and the radio communication module takes charge of the communication to the other radio field devices, provides seamless connection to Ethernet and through USB interface circuit connects to the main control module to commonly build the EPA control network.

Owner:无锡中科泛在信息技术研发中心有限公司

Manipulator underactuated driving structure applied to piano teaching and design method

ActiveCN110394784AFulfil requirementsThe need for increased precisionProgramme-controlled manipulatorGripping headsPianoEngineering

The invention discloses a manipulator underactuated driving structure applied to piano teaching and a design method. The manipulator underactuated driving structure comprises a far knuckle DIP structure, a near knuckle PIP structure, a palm knuckle MCP structure, a connecting rod, a finger swing mechanism, a circulation swing mechanism rotating shaft and a palm fixing plate, wherein the far knuckle DIP structure, the near knuckle PIP structure and the palm knuckle MCP structure are sequentially connected, the near knuckle PIP structure is formed by movably connecting a lower PIP structure andan upper PIP structure, an inverted triangular sliding rail is integrally arranged on the lower PIP structure, a sliding groove matched with the inverted triangular sliding rail is formed in the upperPIP structure, linear slideways are arranged on the two sides of the palm knuckle MCP structure, the finger swing mechanism is movably connected with one end of the connecting rod, the other end of the connecting rod is movably connected with the linear slideways, rotation of the palm knuckle MCP structure is controlled through the linear slideways, the connecting rod and the rotation of the finger swing mechanism, and the finger swing mechanism is movably connected with the palm fixing plate through the circulation swing mechanism rotating shaft.

Owner:TIANJIN UNIV

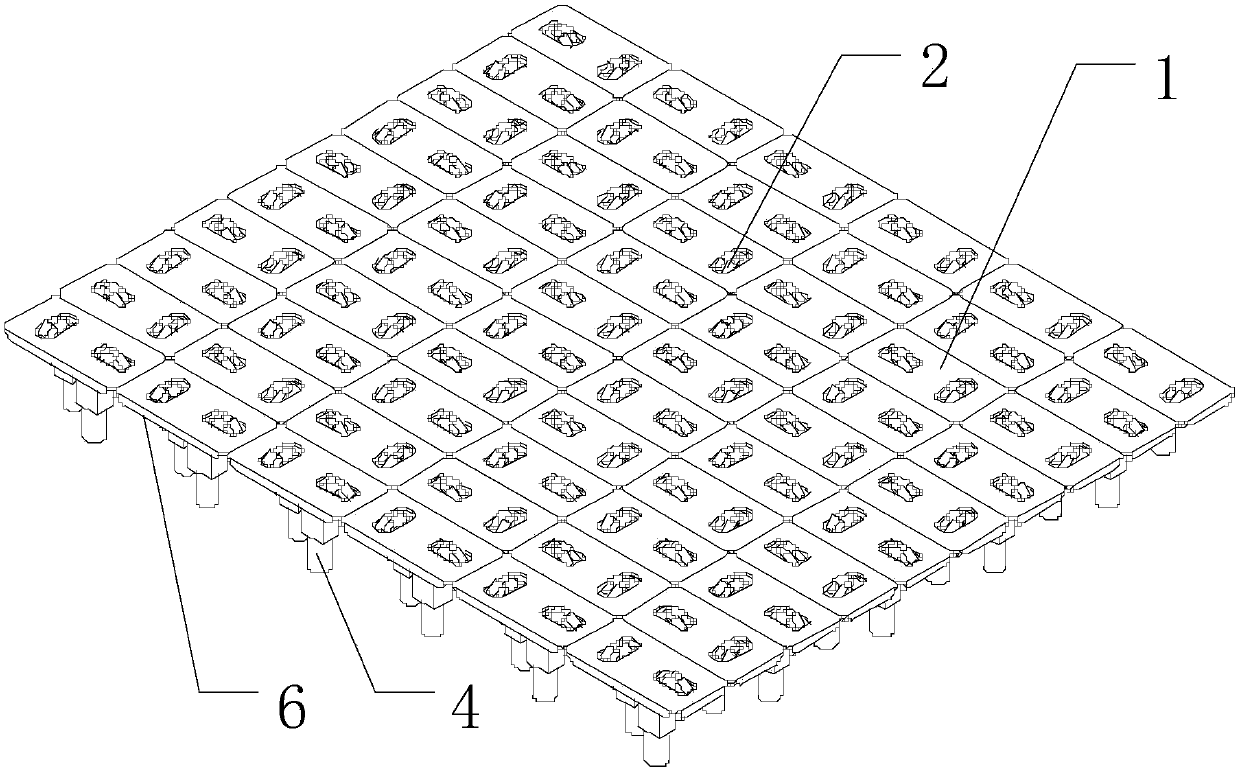

Omnidirectional conveying, sorting and transferring platform and transferring method thereof

PendingCN109552800ADoes not affect normal useEasy to replaceStacking articlesSortingCouplingModular design

The invention discloses an omnidirectional conveying, sorting and transferring platform which comprises a support frame and multiple mutually connected transferring mechanisms arranged on the supportframe. Each transferring mechanism comprises a transferring plate and two omnidirectional wheels; an included angle between central axes of the two omnidirectional wheels is not equal to 0 degree or 180 degrees; through holes are formed in each transferring plate; the omnidirectional wheels are arranged in the through holes in a penetrating way; rotary shafts in the centers of the omnidirectionalwheels are connected with output shafts of gear motors through a couplers; the rotary shafts, the couplers and the gear motors are arranged under the transferring plates; and the gear motors are connected with the transferring plates. According to the omnidirectional conveying, sorting and transferring platform with the structure and a transferring method thereof provided by the invention, the modular design is adopted, so that a damaged transferring mechanism can be conveniently replaced, and the use of the whole transferring platform cannot be influenced when a single transferring mechanismis damaged; and through controlling the turning directions and the speeds of the omnidirectional wheels so as to adjust a cargo conveying path, the omnidirectional conveying, sorting and transferringplatform is easy to operate, less in transferring error, and capable of transferring cargos in small volume.

Owner:张赛夫 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com