Veneer longitudinal glue jointer

A glue splicing machine and vertical technology, which is applied in the jointing of wooden veneers, forming/shaping machines, special forming/shaping machines, etc., can solve scratches, affect production efficiency, hot melt glue stays in cooling rods, Problems such as clamping parts and transmission parts, etc., to achieve the effect of reducing transmission error, high quality of tooth connection, and good effect of tooth connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

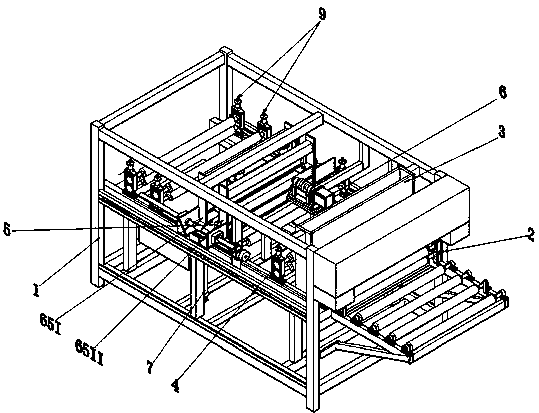

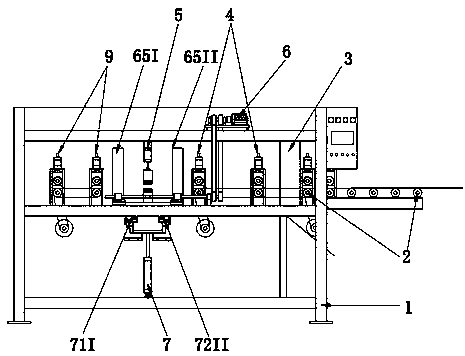

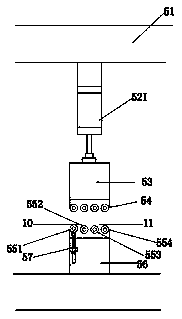

Embodiment 1

[0049] Embodiment 1: as Figure 1-2 , as shown in 3-7, the lifting parts of a kind of veneer longitudinal gluing machine in this embodiment include a bracket 51, a first cylinder 52I, a pressing connector 53, four pressing cooling pipes 54, and four supporting cooling pipes. The pipes are the first supporting cooling pipe 551, the second supporting cooling pipe 552, the third supporting cooling pipe 553, the fourth supporting cooling pipe 554, and the supporting connecting piece 56. The bottom of the bracket 51 is connected to the first cylinder 52I, and the Below the first cylinder 52I is provided with the press-down connector 53, the press-down cooling pipe 54 is connected to the press-down connector 53, and four support cooling pipes are arranged below the press-down cooling pipe 54. The support connector 56 is provided below the cooling pipe, the bracket 52I and the support connector 56 are connected to the main frame 1, the two ends of the support connector 56 are respect...

Embodiment 2

[0053] Embodiment 2: as Figure 1-2, As shown in 8-12, a kind of veneer longitudinal gluing machine of the present embodiment, the lifting part includes a bracket 51, a first cylinder 52I, a downward pressure connector 53, four downward pressure cooling pipes 54, four support The cooling pipes are the first supporting cooling pipe 551, the second supporting cooling pipe 552, the third supporting cooling pipe 553, the fourth supporting cooling pipe 554, and the supporting connecting piece 56. The bottom of the bracket 51 is connected to the first cylinder 52I. Below the first cylinder 52I, there is the press-down connector 53, the press-down cooling pipe 54 is connected to the press-down connector 53, and four supporting cooling pipes are arranged below the press-down cooling pipe 54, four The support connecting piece 56 is provided below the supporting cooling pipe, the support 52I and the supporting connecting piece are connected to the main frame 1, and the two ends of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com