Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Reduce structure cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

E-shaped fastener constrained type assembled buckling-restrained energy-consumed brace

InactiveCN101718123AImprove performanceGood lateral force resistanceShock proofingEngineeringHigh rise

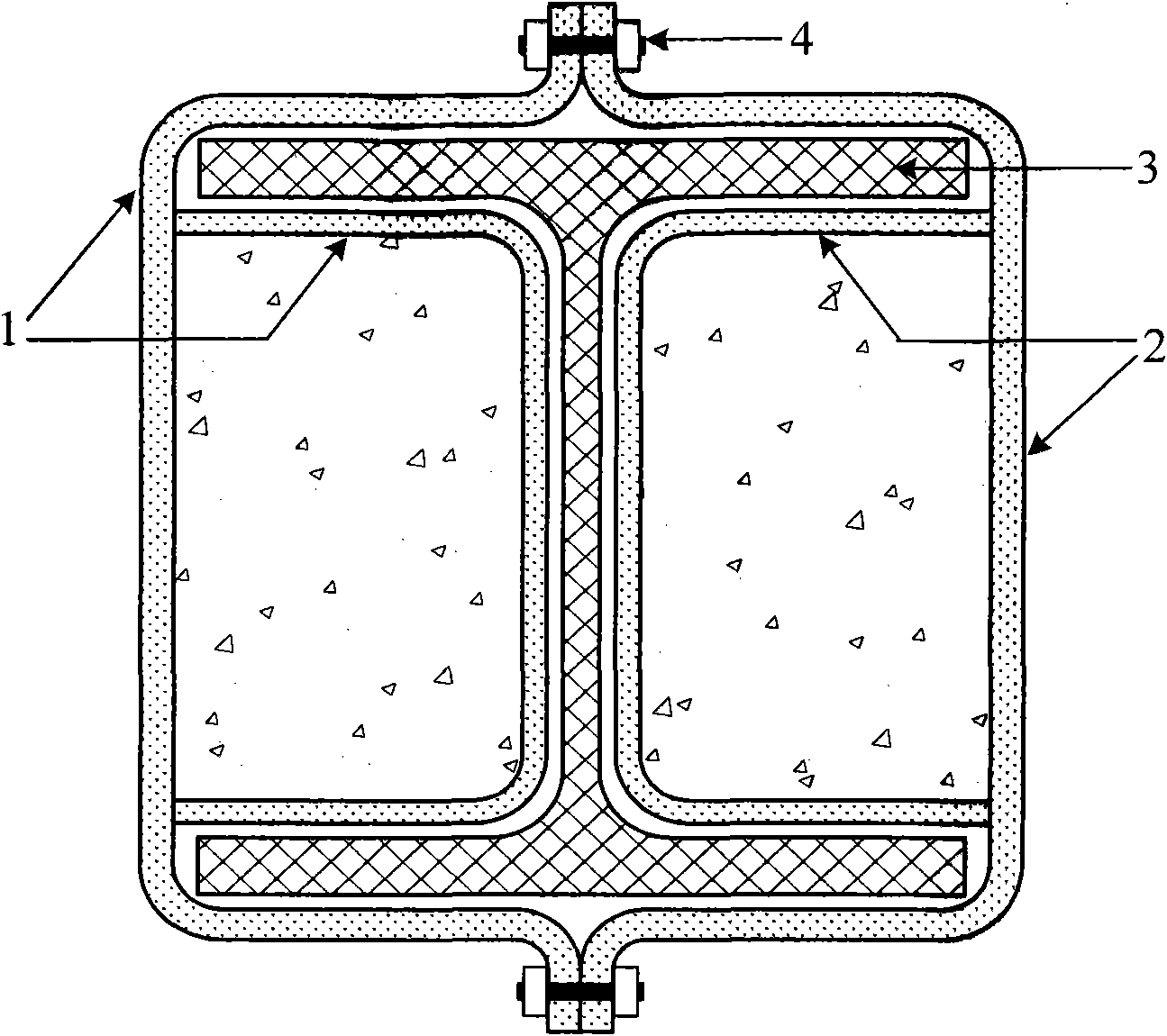

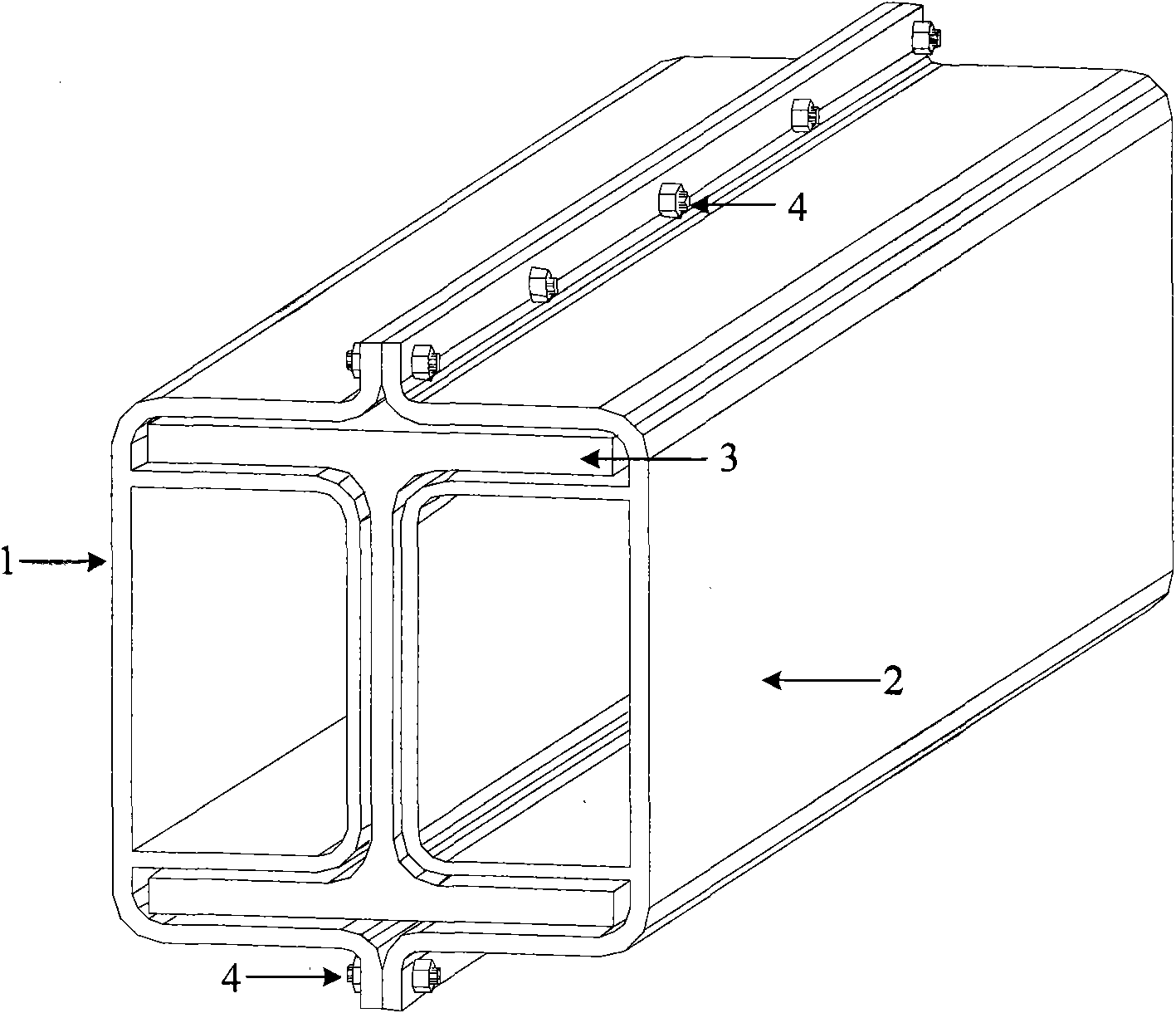

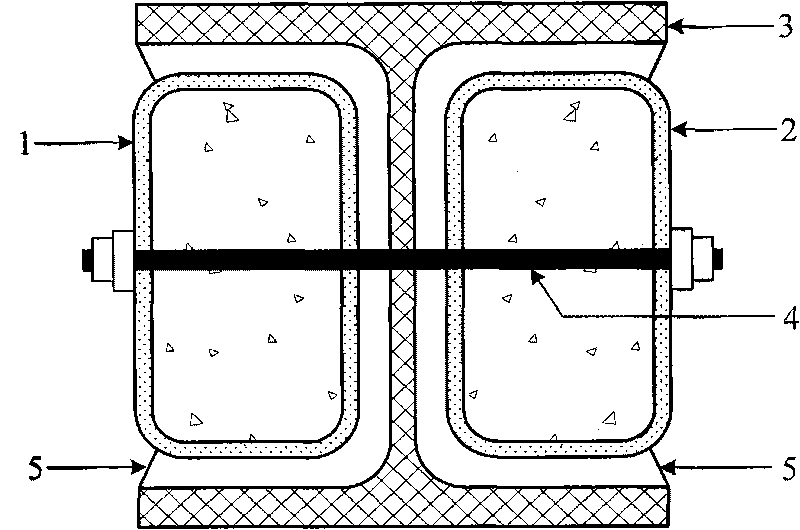

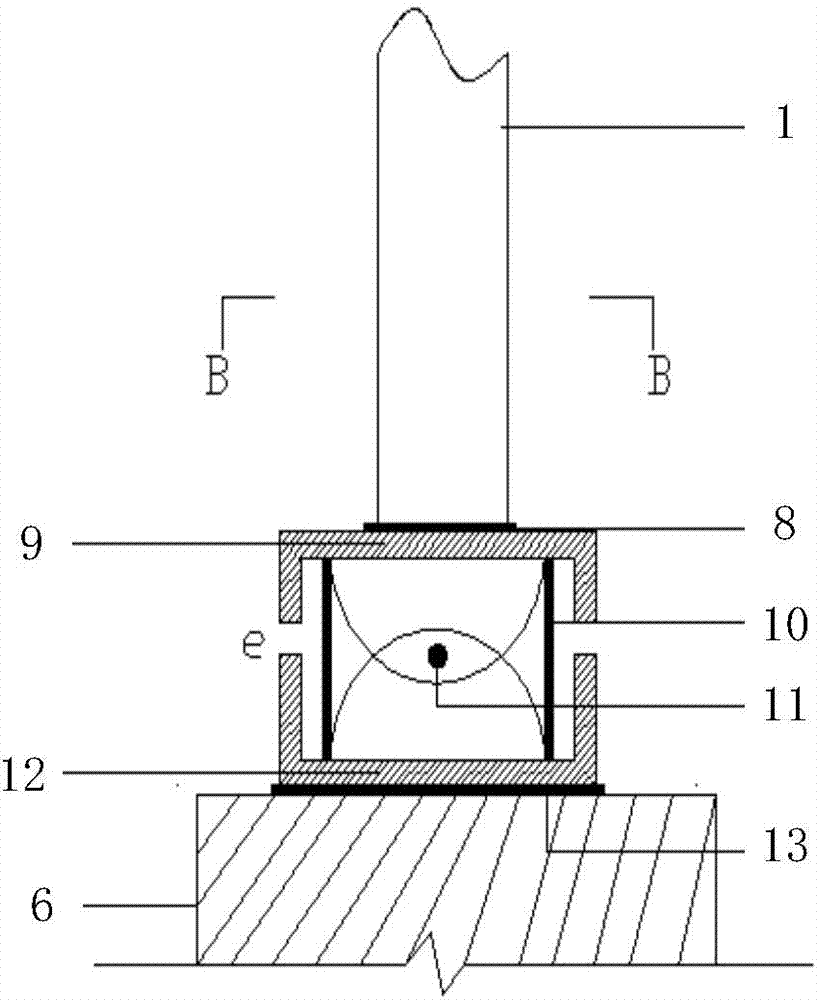

The invention discloses an E-shaped fastener constrained type assembled buckling-restrained energy-consumed brace, belonging to the technical field of structural engineering. The E-shaped fastener constrained type assembled buckling-restrained energy-consumed brace is characterized in that the brace comprises two E-shaped fasteners and a hot rolled H-shaped steel; the two E-shaped fasteners are connected together through bolts and form a periphery constrained component; enclosed rectangle tubes of the two E-shaped fasteners are internally injected with concretes; and appropriate gaps are left between the two E-shaped fasteners and the hot rolled H-shaped steel. The invention can provide lateral resistant effect to multiple-story and high-rise buildings and reach total cross-section buckling under the action of strong earthquake, thereby effectively consuming energy. By taking the hot rolled H-shaped steel as an inner core stressed component, cross sections have wide specification selection range, buckling loads with larger tonnage can be realized, and better ductility is achieved in comparison with the welding of I shaped steel. In addition, the invention has the advantages of easy material selecting, simple processing, convenient construction, low construction cost and convenience for industrial scale production.

Owner:TSINGHUA UNIV

Steel structure type point glass curtain wall construction method

InactiveCN102758530AEasy maintenanceLight weightWallsBuilding material handlingWork periodBuilding construction

The invention discloses a steel structure type point glass curtain wall construction method comprising the steps of: aligning and processing an embedded piece, mounting a steel support, mounting a connection system, mounting a glass panel, inspecting and accepting and the like. The steel structure type point glass curtain wall construction method disclosed by the invention has the advantages of convenient and rapid in construction, short in work period and light in self-gravity of a wall body, so that the construction cost of a main body structure and a foundation is reduced. A curtain wall component is convenient to maintain and is replaceable, and a building is bright and lively so as to bring a brand new concept to people; and a relatively good building artistic effect can be generated.

Owner:JIANGSU TONGZHOU FOURTH CONSTR GROUP

Nondestructive demounting method for prefabricated part of IMS system Dai nationality folk house major structure

InactiveCN101403257AReduce generationProtect environmentBuilding repairsPre stressAgricultural engineering

The invention discloses a method for demounting a prefabricated part without damage in an IMS system Dai nationality dwelling major structure, which selects and marks key points on the IMS system Dai nationality dwelling major structure, and carries out controllable slow release to the prestress of a steel stranded wire in each key point, without impact and damage on the prefabricated part in the prestress release process. After a prefabricated beam and a prefabricated slab of a floor are demounted and hanged back to the ground, open-channel post-cast concrete and the steel stranded wire contained in the concrete are separated out from the prefabricated beam and the prefabricated slab for leading the prefabricated beam and the prefabricated slab to be restored. The method can realize the undamaged recovery and reuse of the prefabricated beam, the prefabricated slab and a prefabricated column when demounting the IMS system Dai nationality dwelling, and is economical and environmentally friendly, thus being suitable to demounting not only the IMS system Dai nationality dwelling but also other IMS system buildings, and having reference function for demounting non-IMS system prestress structures.

Owner:KUNMING UNIV OF SCI & TECH

E-shaped fastener constrained type assembled buckling-restrained energy-consumed brace

InactiveCN101718123BImprove performanceGood lateral force resistanceShock proofingEngineeringHigh rise

The invention discloses an E-shaped fastener constrained type assembled buckling-restrained energy-consumed brace, belonging to the technical field of structural engineering. The E-shaped fastener constrained type assembled buckling-restrained energy-consumed brace is characterized in that the brace comprises two E-shaped fasteners and a hot rolled H-shaped steel; the two E-shaped fasteners are connected together through bolts and form a periphery constrained component; enclosed rectangle tubes of the two E-shaped fasteners are internally injected with concretes; and appropriate gaps are leftbetween the two E-shaped fasteners and the hot rolled H-shaped steel. The invention can provide lateral resistant effect to multiple-story and high-rise buildings and reach total cross-section buckling under the action of strong earthquake, thereby effectively consuming energy. By taking the hot rolled H-shaped steel as an inner core stressed component, cross sections have wide specification selection range, buckling loads with larger tonnage can be realized, and better ductility is achieved in comparison with the welding of I shaped steel. In addition, the invention has the advantages of easy material selecting, simple processing, convenient construction, low construction cost and convenience for industrial scale production.

Owner:TSINGHUA UNIV

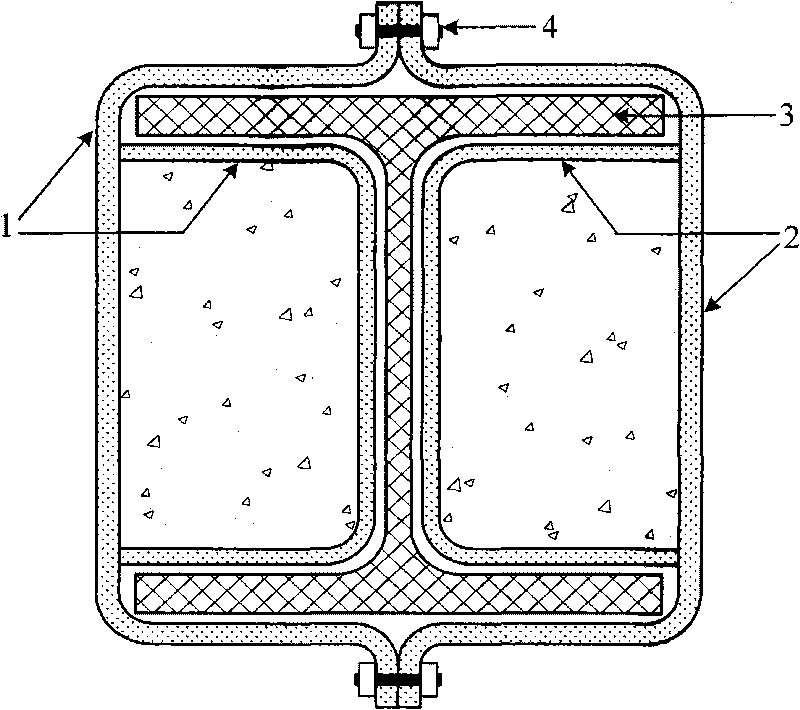

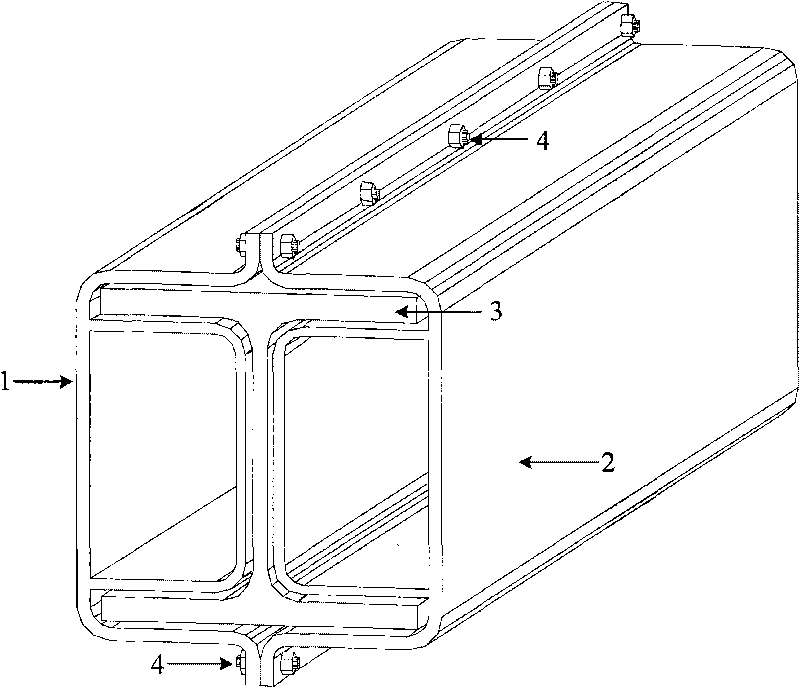

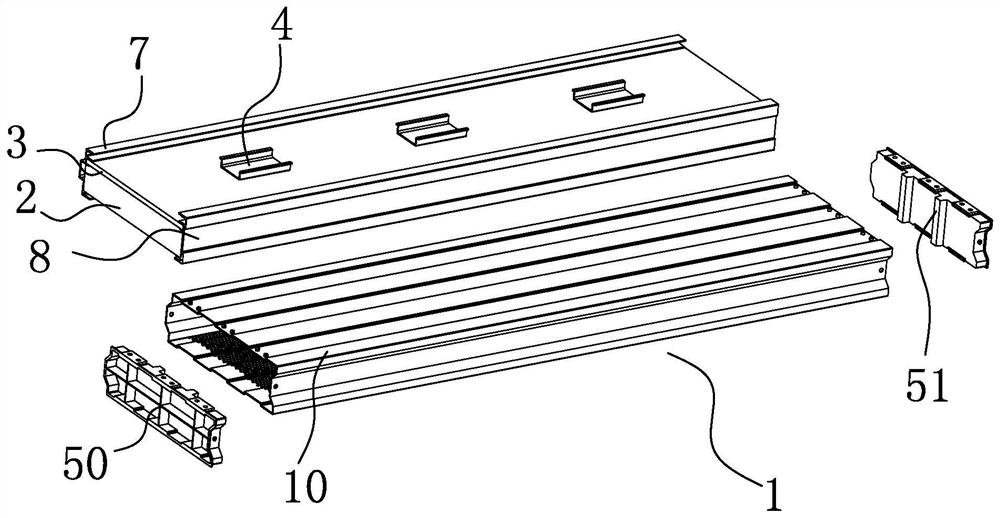

Double-rectangular pipe restraint H-shaped section assembling type bending prevention energy consuming support with ribs

InactiveCN101718125AImprove performanceGood lateral force resistanceShock proofingArchitectural engineeringHigh rise

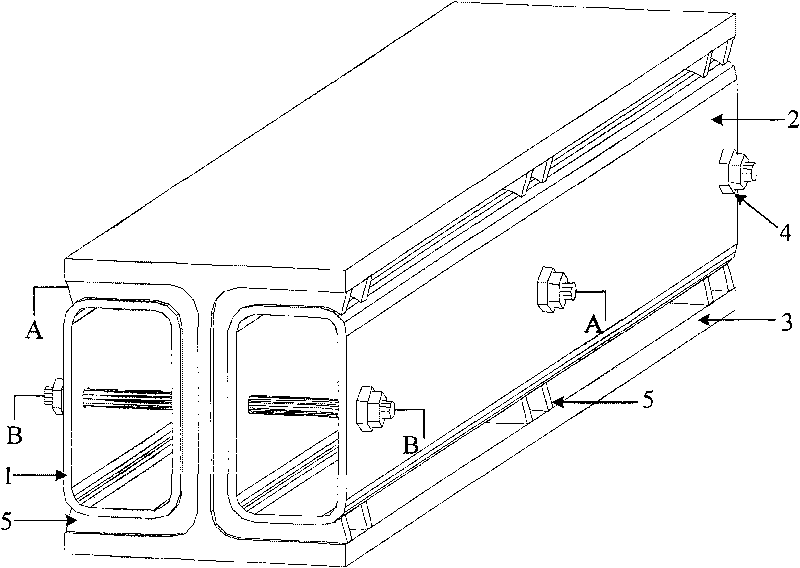

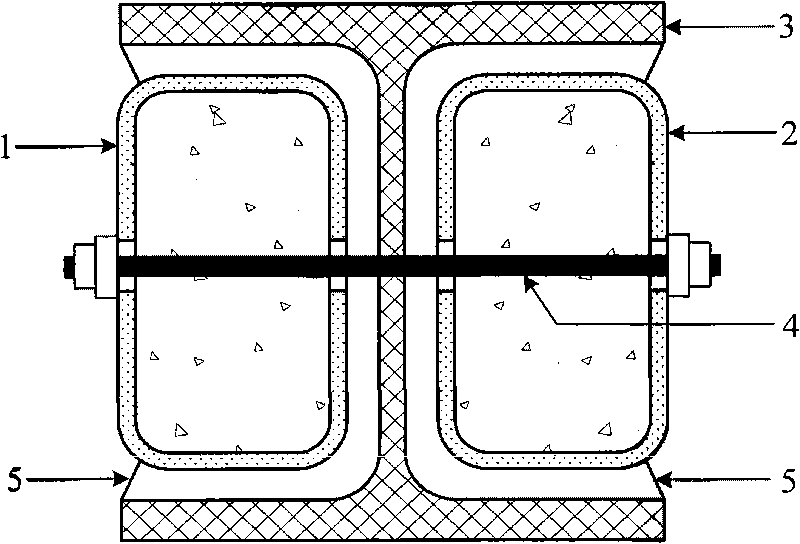

The invention relates to a double-rectangular pipe restraint H-shaped section assembling type bending prevention energy consuming support with ribs, which belongs to the technical field of structural engineering. The double-rectangular pipe restraint H-shaped section assembling type bending prevention energy consuming support with ribs is characterized by comprising two cold-bending thin-wall type steel rectangular pipes with ribs and hot-rolling H-shaped steel, wherein the two cold-bending thin-wall type steel rectangular pipes are pressed on a web plate of the hot-rolling H-shaped steel by a long screw rod connecting element to form an peripheral restraint component and form a restraint mechanism on the H-shaped steel of a kernel; the position of the hot-rolling H-shaped steel, which is penetrated by the long screw rod connecting element, is provided with a circular hole, and the non-midspan positions of the two cold-bending thin-wall type steel rectangular pipes, which are penetrated by the long screw rod connecting element, are provided with elliptical holes, and the midspan positions are provided with circular holes; and two groove-shaped stiffening ribs are symmetrically distributed on both opened sides of the two cold-bending thin wall type steel rectangular pipes . The invention can provide side force resistance for a multi-high-rise building structure and achieve the aim of total section yielding under the action of great vibration, thereby effectively consuming energy. The rectangular pipes with any section size are matched with the hot-rolling H-shaped steel by the groove-shaped stiffening ribs, and the material acquiring ranges of the rectangular pipes and the hot-rolling H-shaped steel are enlarged.

Owner:TSINGHUA UNIV

Self-reset swinging inner barrel shock absorption water tank

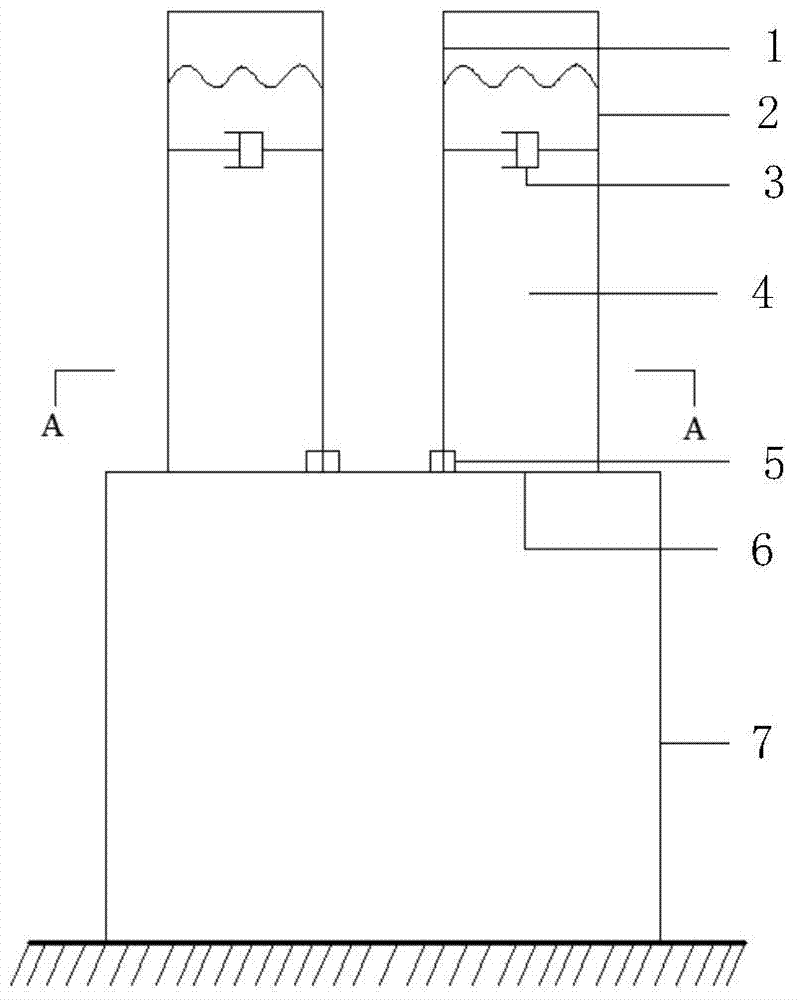

ActiveCN104847153AImprove seismic performanceSmall rotational stiffnessFoundation engineeringProtective buildings/sheltersAbsorption effectWall mount

The invention provides a self-reset swinging inner barrel shock absorption water tank which comprises a base mounted on a lower support structure, outer barrel walls mounted on the base and inner barrel walls mounted in the outer barrel walls, wherein storage water is mounted between the inner barrel walls and the outer barrel walls; six self-reset swinging bearings are uniformly arranged on the base along each inner barrel wall; each self-reset swinging bearing comprises a lower lug plate mounted on the base via a base embedded part, an upper lug plate connected with the lower lug plate via a bolt and four prestress rods symmetrically arranged between the lower lug plate and the upper lug plate; inner barrel wall embedded parts with the same quantity as that of the self-reset swinging bearings are uniformly arranged at the lower ends of the inner barrel walls; the inner barrel walls are fixedly connected with the corresponding upper lug plates via the inner barrel wall embedded parts; and dampers are further arranged at the upper ends between the inner barrel walls and the outer barrel walls. The water tank has the advantages of stable anti-seismic property, good shock absorption effect, reduced structure cost, factory module production and the like.

Owner:HARBIN ENG UNIV

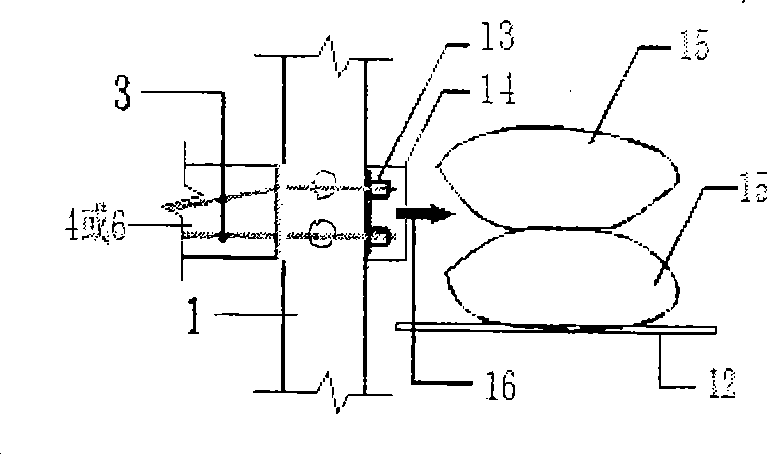

Recyclable oily sewage treatment device

InactiveCN107814431AImprove work efficiencyCompact structureWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesSewageOil water

The invention provides a recyclable oily sewage treatment device and relates to the field of sewage treatment. The recyclable oily sewage treatment device comprises a housing, an inlet and outlet pipe, a separating device and a circulation circuit. The housing comprises a cylindrical outer cylinder, an upper head and a lower head. The inlet and outlet pipe comprises an oil-containing sewage inletpipe, a first-stage overflow pipes, a second-stage overflow pipe and an outlet pipe. The separating device includes a cylindrical inner cylinder and a spirally-upward-inclined swirling flow guide plate disposed between the cylindrical outer cylinder and the cylinder inner cylinder, wherein the cylindrical inner cylinder is coaxial with the cylindrical outer cylinder, and the swirling flow guide plate is fixed on the upper part of the inner wall of the cylindrical outer cylinder. The circulation circuit is provided with a circulation pump for circulating part of treated sewage into the cylindrical outer cylinder. Organic combination of two oil-water separation unit technologies of swirling flow and air-floatation can be successfully realized by means of circulating injecting of part of theoily sewage into the treatment device, tiny oil droplets can be separated, the working efficiency is greatly improved, and the structure of the device is compact and simple.

Owner:刘曼华

Material-returning flow manufacturing process for heavy potassium pyrophosphate

ActiveCN110371942APrevent moisture absorptionReduce structure costDispersed particle filtrationPhosphorus compoundsGranularityEngineering

The invention discloses a material-returning flow manufacturing process for heavy potassium pyrophosphate. The material-returning flow manufacturing process comprises the following steps: step 1, erection of a material-returning flow-line device; step 2, drying treatment in the material-returning flow-line device; step 3, inputting of potassium pyrophosphate; step 4, dust suction and removal; step5, screening treatment; step 6, sorting, conveying and bagging; and step 7, boxing and storage. In the step 1, the material-returning flow-line device is erected at one side of a potassium pyrophosphate production flow line; and in the step 2, before the material-returning flow-line device is used in a material-returning flow, an induced draft fan is energized to work, so a conveyor belt is always in a dry environment. According to the invention, through technical modification, an overall transportation equipment structure is low in cost, so the cost of investment is reduced; through a screening plate, screening of the potassium pyrophosphate with different sizes can be realized, so a product has more regular appearance granularity, facilitates classification for sealed storage and collection, and is convenient for transportation in a later period; and the interior of the flow-line device is dried.

Owner:SHIFANG JINDIYAMEI CHEM ENG

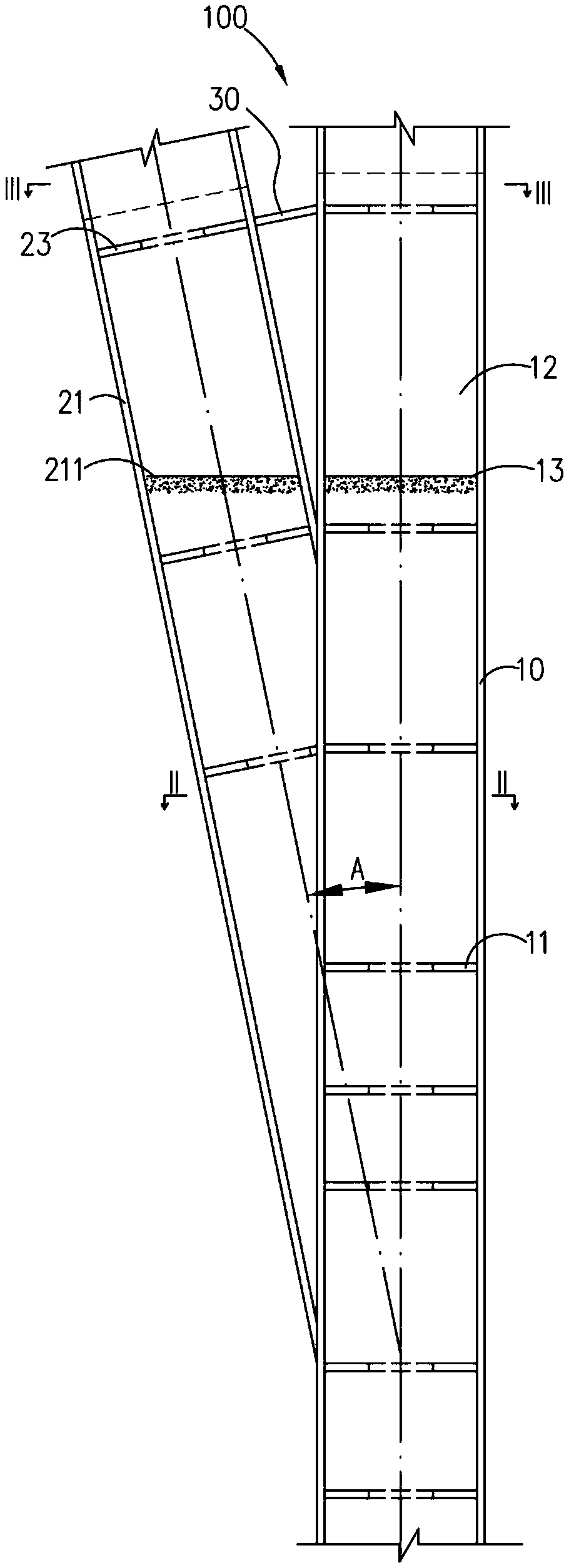

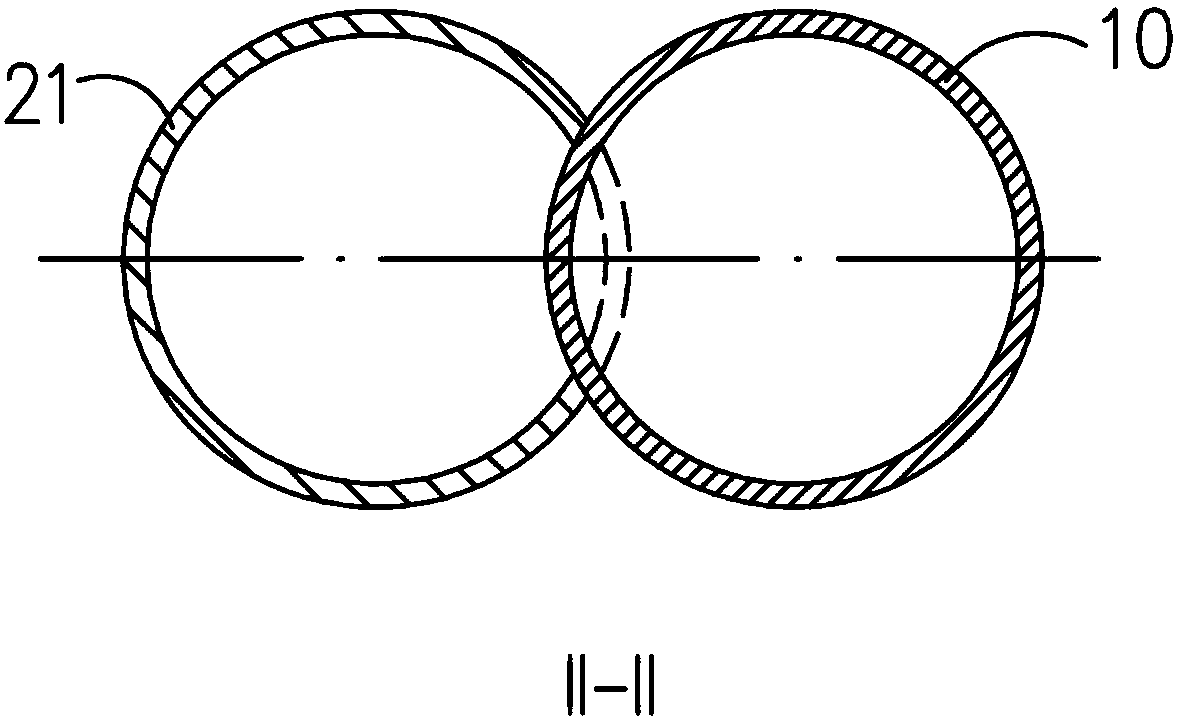

Integrated shell sound absorption unit for rail transit sound barrier

PendingCN111663462ABeautiful appearanceEasy to manufactureNoise reduction constructionSound barrierEngineering

The invention relates to an integrated shell sound absorption unit for a rail transit sound barrier. The unit comprises an integrated cylindrical shell, a sound absorption material and an end cover, the sound absorption material is arranged in an internal cavity formed by the integrated cylindrical shell, and the end cover is arranged on an end surface of the integrated cylindrical shell; and theintegrated cylindrical shell and / or the end cover are / is made of a fiber reinforced composite material. The unit is good in sound absorption and insulation performance, high in strength, simple in structure and the like by designing the structure. Because the selected fiber reinforced composite material can be pressed by a mold, the produced sound absorption unit is attractive in appearance, convenient to manufacture, high in production efficiency, suitable for batch production and particularly light, the sound absorption unit has a characteristic of light dead weight, a bearing load of an elevated light rail and an elevated road can be reduced, and structural cost can be decreased; and the fiber reinforced composite material has strong wind load resistance and is not easy to corrode.

Owner:CHINA RAILWAY ELECTRICAL IND CO LTD +3

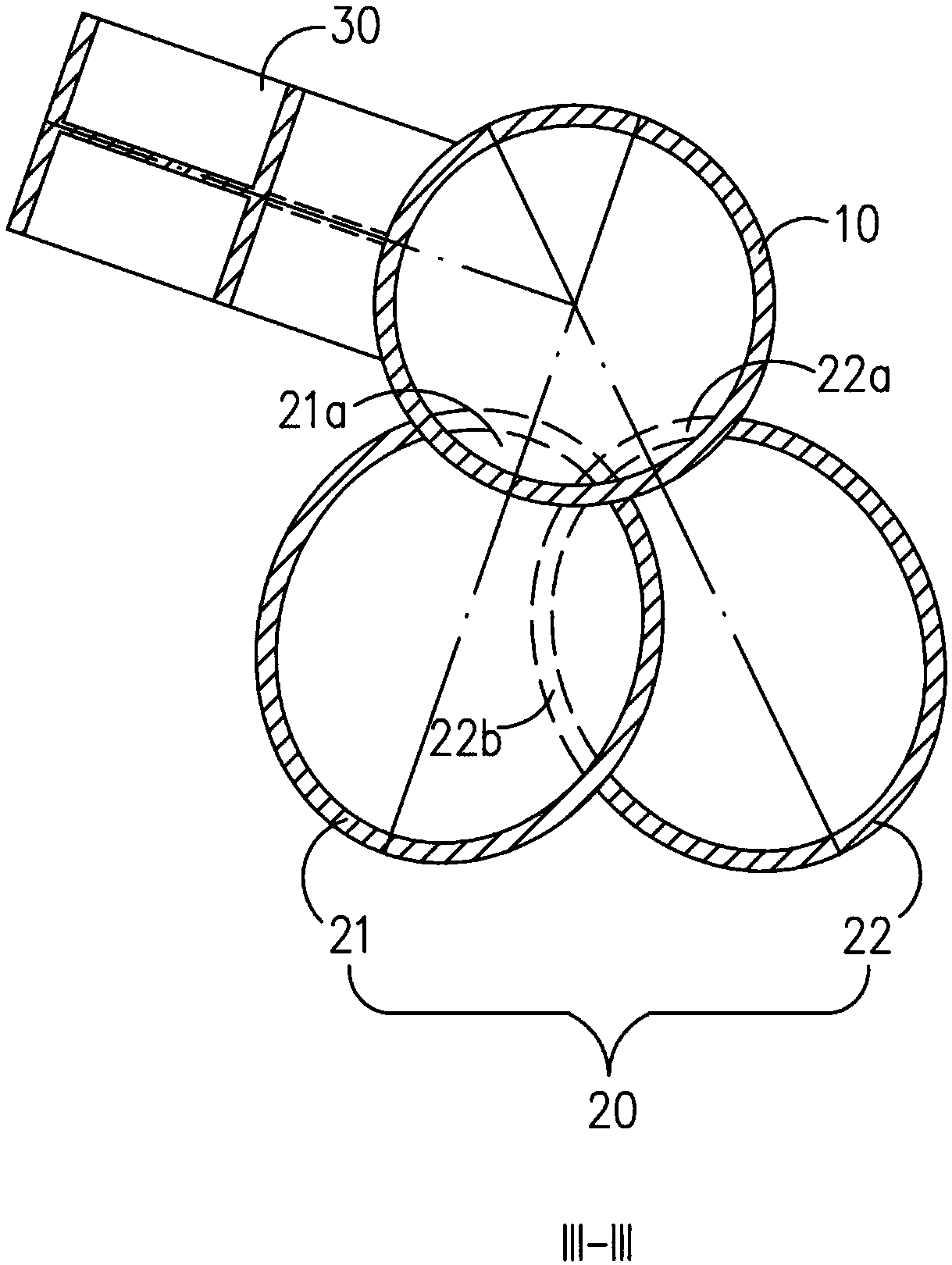

Joint structure of multi-coupled steel component

PendingCN107806178AImprove local stiffnessMeet structural strength requirementsBuilding constructionsStructural engineeringSteel casting

The invention discloses a joint structure of a multi-coupled steel component. The joint structure of the multi-coupled steel component comprises a main component and a plurality of connecting components, the main component is of a hollow tubular structure, the main component is provided with a connection joint area, a plurality of first inner strengthening ring plates are arranged in the position,corresponding to the connection joint area, in the main component, and all the first inner strengthening ring plates are arranged in the height direction of the main component at intervals in an arrayed mode; and the multiple connecting components are fixedly connected with the main component, and the ends, fixedly connected with the main component, of the multiple connecting components are located in the connecting joint area. The joint structure of the multi-coupled steel component can effectively optimize local force of the main component, an existing method by adopting cast steel joints or increasing the wall thickness of the main component is replaced, the wall thickness of the main component is effectively controlled, the machining period is shortened, and the weight of the multi-coupled steel component is reduced. Therefore, the whole structure cost of the joint structure of the multiple-limb steel component is lower than that of the method by adopting cast steel joint design and increasing the wall thickness of the main component.

Owner:深圳华森建筑与工程设计顾问有限公司

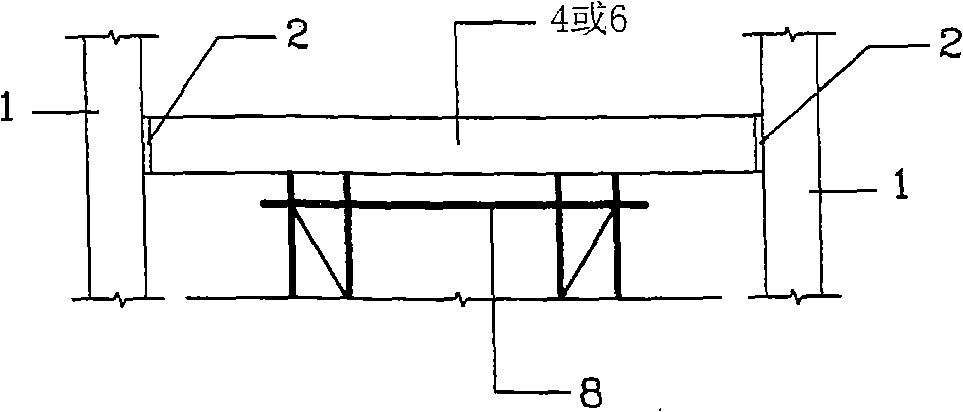

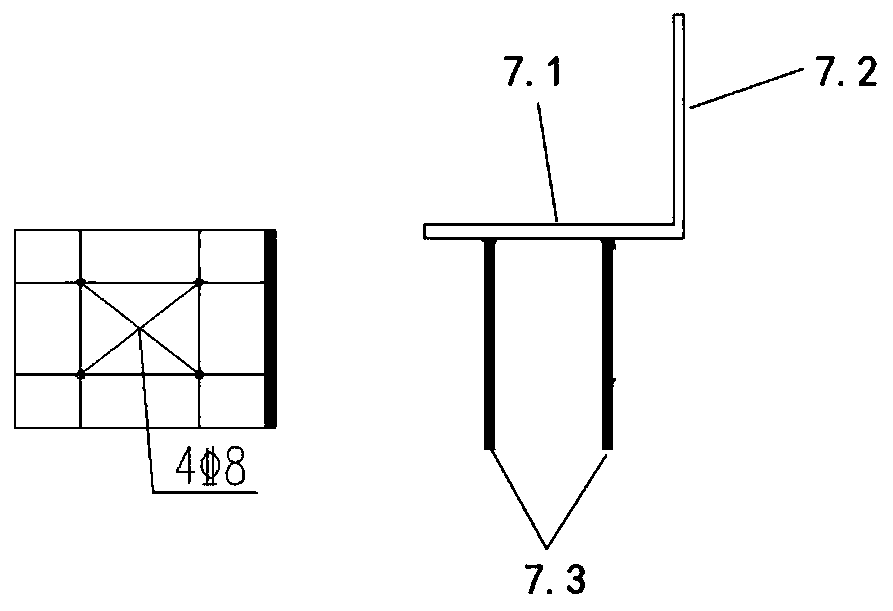

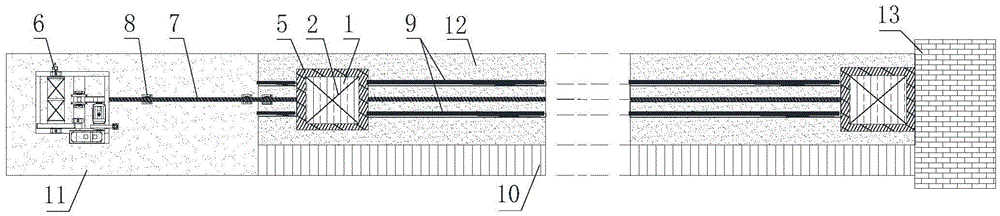

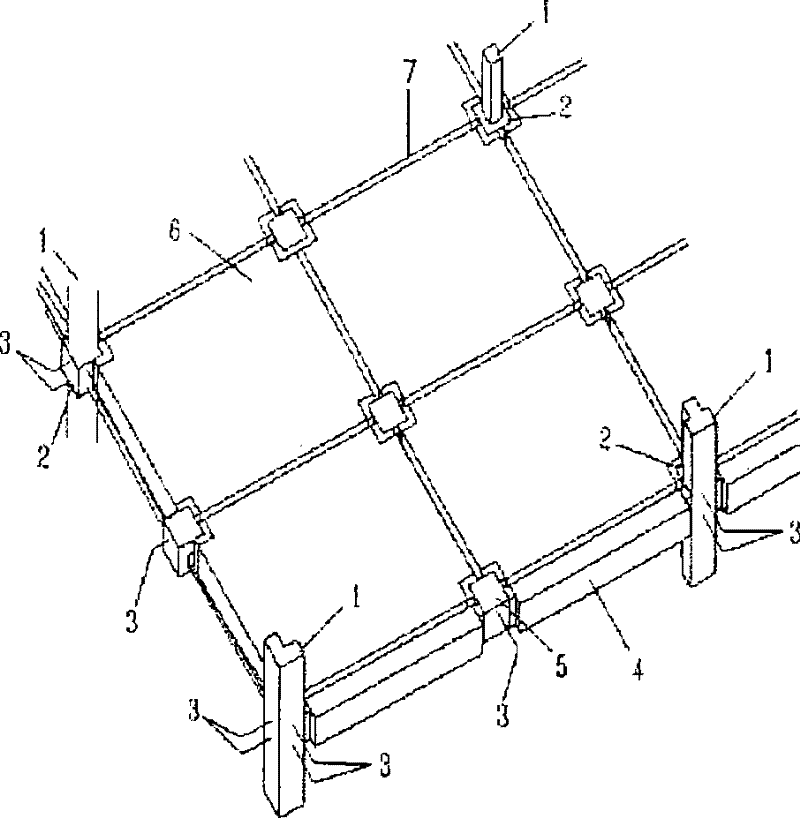

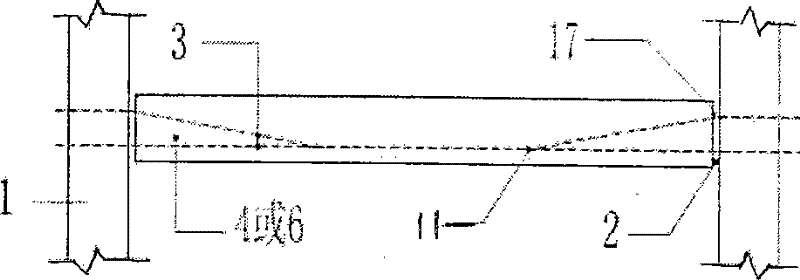

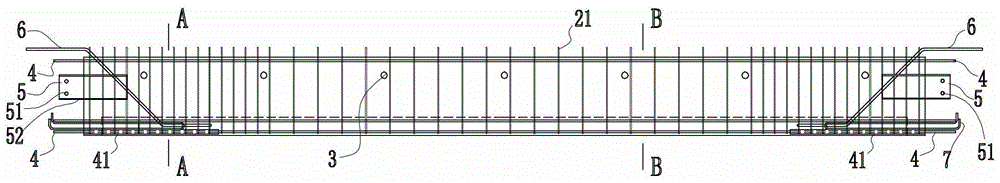

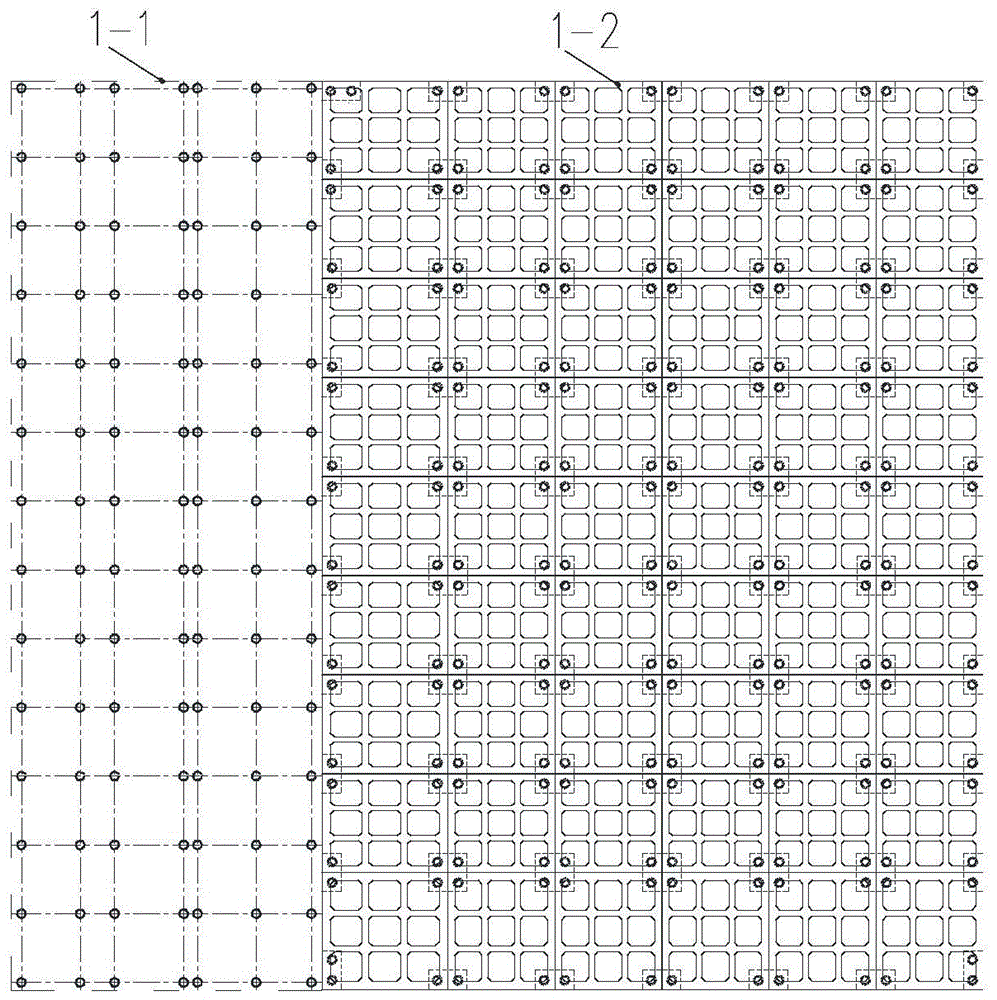

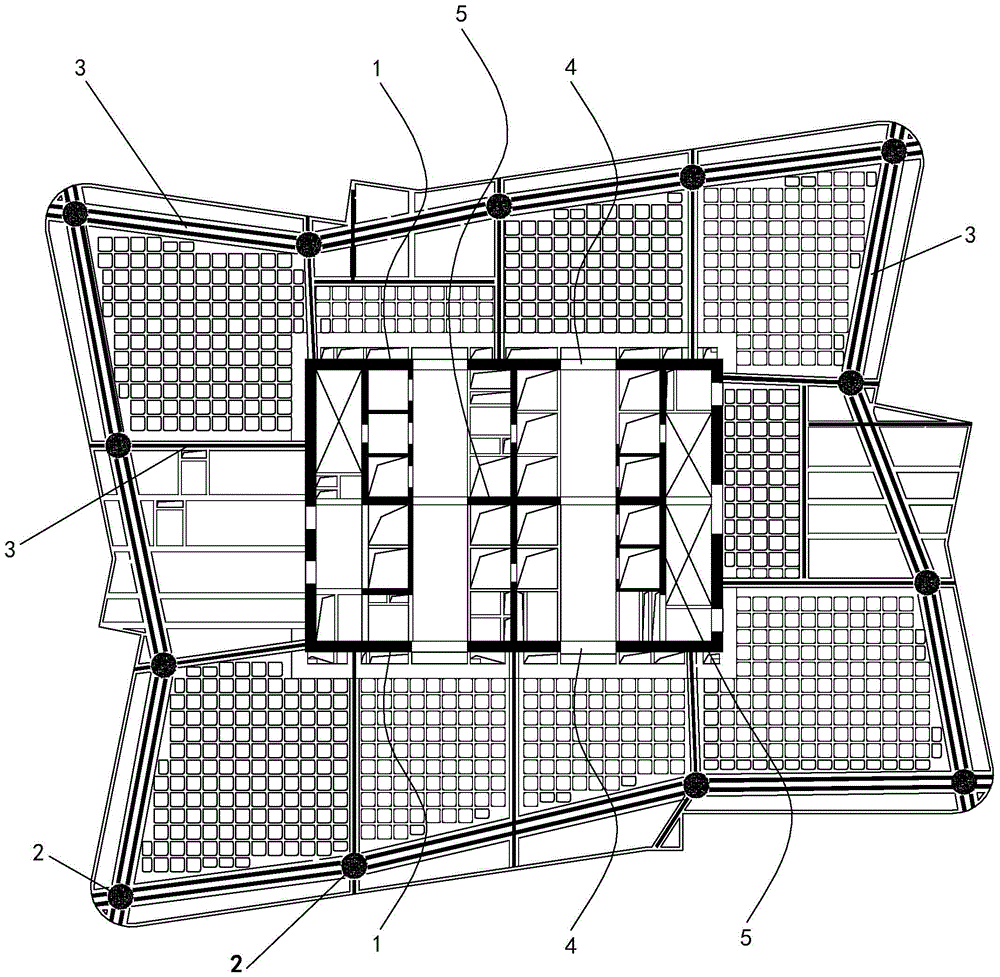

Prestressed hollow slab with variable rib widths

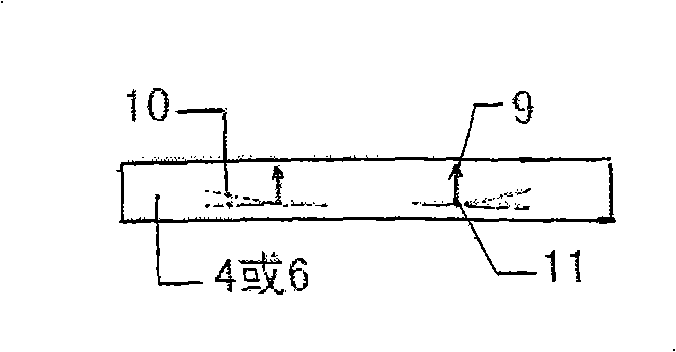

The invention relates to a reinforced concrete hollow floor system structure, particularly relates to a prestressed hollow slab with variable rib widths and a method for constructing the prestressed hollow slab, and belongs to the field of common building structures. The prestressed hollow slab comprises upper-layer slab reinforcing steel bars (1), lower-layer slab reinforcing steel bars (2), rib beams (3), prestressed bars (4), filling materials (5) and concrete (6). The filling materials (5) are positioned between the upper-layer slab reinforcing steel bars (1) and the lower-layer slab reinforcing steel bars (2) and are permanently buried in the concrete, the prestressed hollow slab is divided into a rib beam standard region (9) and two rib beam narrowing regions (10) by region boundaries (8), the total width of the rib beam standard region is larger than or equal to 1 / 3 of the span of the prestressed hollow slab in long-span directions, the widths of the rib beams in the rib beam narrowing regions are smaller than or equal to those of the rib beams in the rib beam standard region, and the quantities of the prestressed bars in the rib beams in the rib beam narrowing regions are smaller than the quantity of the rib beams in the rib beam standard region. The prestressed hollow slab and the method have the advantages that the prestressed hollow slab is wide in span, good in structural reliability and earthquake resistance and excellent in economical efficiency and applicability and is light.

Owner:徐焱

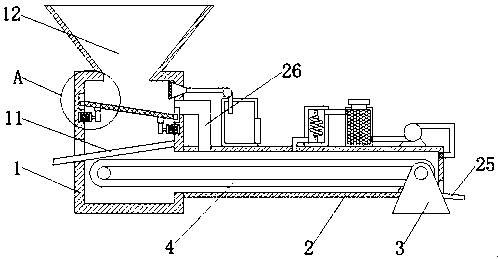

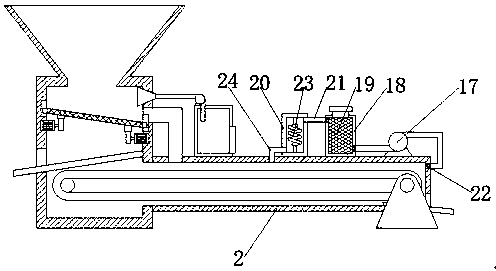

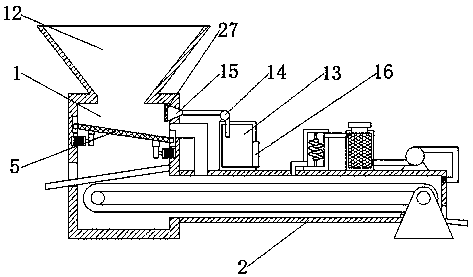

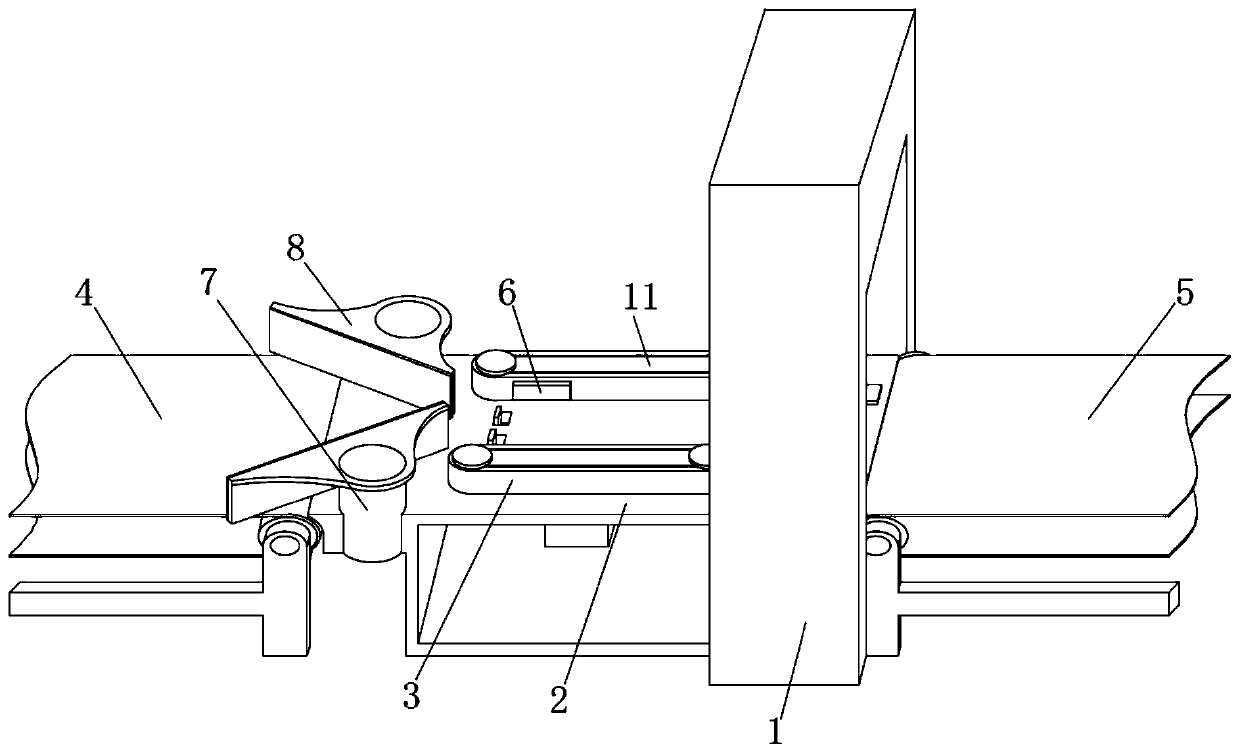

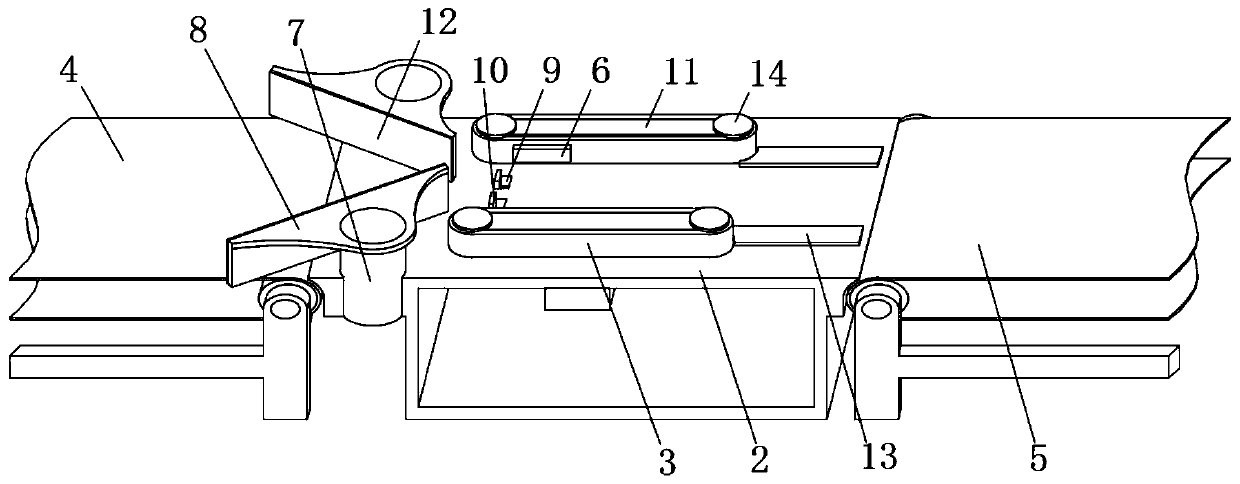

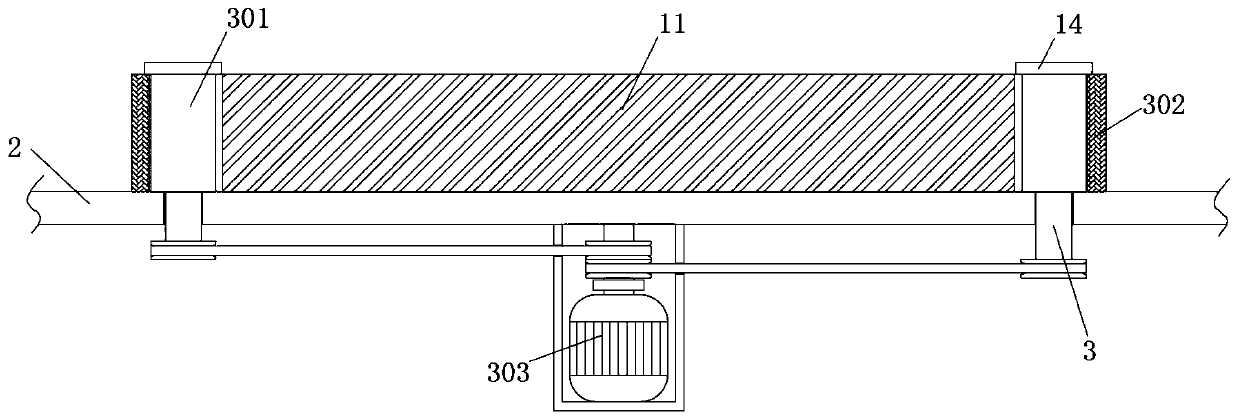

Full-automatic storage battery welding device

ActiveCN110480223AReduce structure costEasy to useWelding/cutting auxillary devicesAuxillary welding devicesAutomatic processingArchitectural engineering

The invention discloses a full-automatic storage battery welding device, and belongs to the field of storage battery production. The full-automatic storage battery welding device comprises a welding machine main body, wherein a welding platform is fixedly connected to the bottom of the welding machine main body; transmission devices are fixedly arranged on the front and back of the top of the welding platform; the opposite sides of the two transmission devices are fixedly connected to rubber fixture blocks; a first conveyor belt and a second conveyor belt are respectively arranged at the leftside and right side of the welding platform; support pillars are integrally formed on the front and back of the top of the welding platform; the two support pillars are respectively located at the left sides of the two transmission devices; the tops of the two support pillars are hinged with guide plates; and two locating slots are formed in the top of the welding platform. The full-automatic welding device has low structure construction cost, is economical and practical, is simple and convenient to use, can effectively achieve the purpose of full-automatic processing, improves the welding efficiency of the storage battery, and reduces the production cost.

Owner:SICHUAN SIMEI TECH

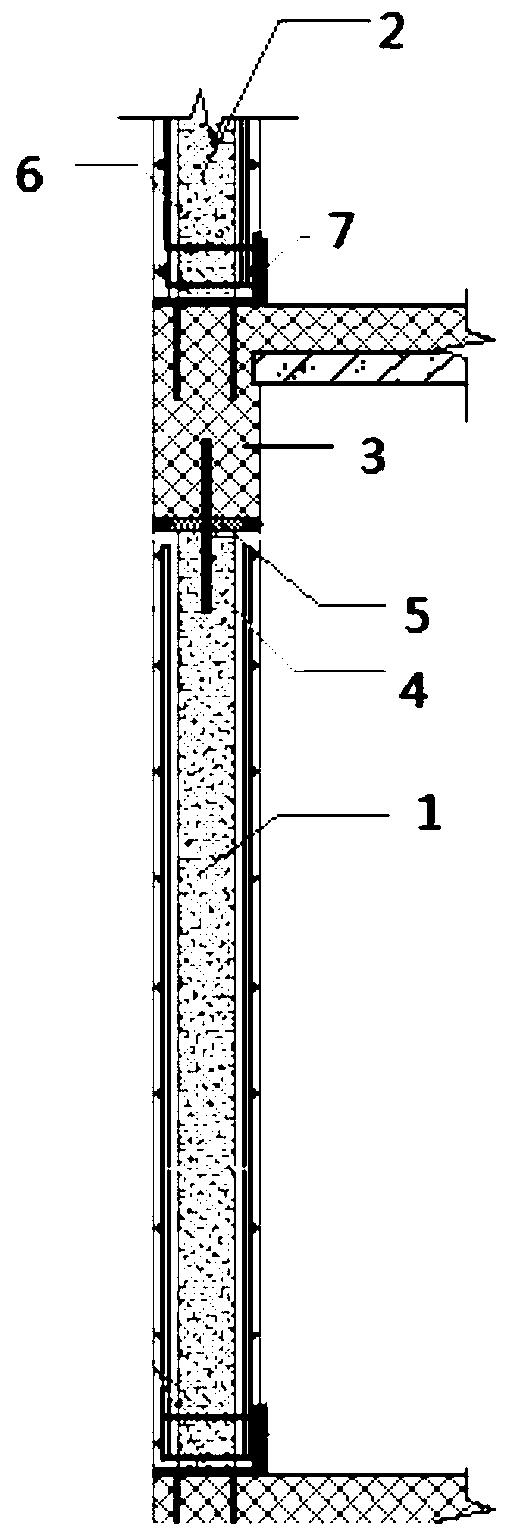

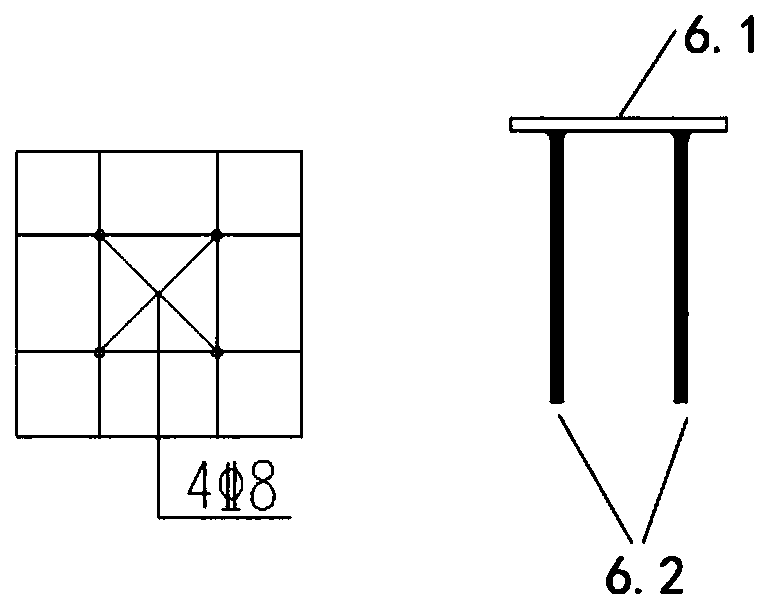

External enclosure weight-reduction pre-fabricated wall connecting joint and construction method thereof

PendingCN110397190AImprove the problem of complex construction of old nodesLose weightConstruction materialWallsBuilding construction

The invention provides an external enclosure weight-reduction pre-fabricated wall connecting joint and a construction method thereof. The external enclosure weight-reduction pre-fabricated wall connecting joint comprises a first pre-fabricated double-sided composite wall and a second pre-fabricated double-sided composite wall; the first pre-fabricated double-sided composite wall and the second pre-fabricated double-sided composite wall are spliced in the vertical direction and are connected and fixed through a cast-in-situ beam; inserting ribs and partition boards are disposed at the upper endof the first pre-fabricated double-sided composite wall; the inserting ribs are buried in the first pre-fabricated double-sided composite wall and are partially exposed out of the upper end of the first pre-fabricated double-sided composite wall; the portions, exposed out of the first pre-fabricated double-sided composite wall, of the inserting ribs penetrate through the partition boards to extend into the cast-in-situ beam; a first pre-buried part is buried in the lower end of the second pre-fabricated double-sided composite wall; a second pre-buried part is buried in the upper end of the cast-in-situ beam; the second pre-fabricated double-sided composite wall is fixed to the cast-in-situ beam in a matched mode through the first pre-buried part and the second pre-buried part; and accordingly construction and popularization of a pre-fabricated enclosure wall are facilitated.

Owner:JIANGSU LONG LEAPING ENG DESIGN

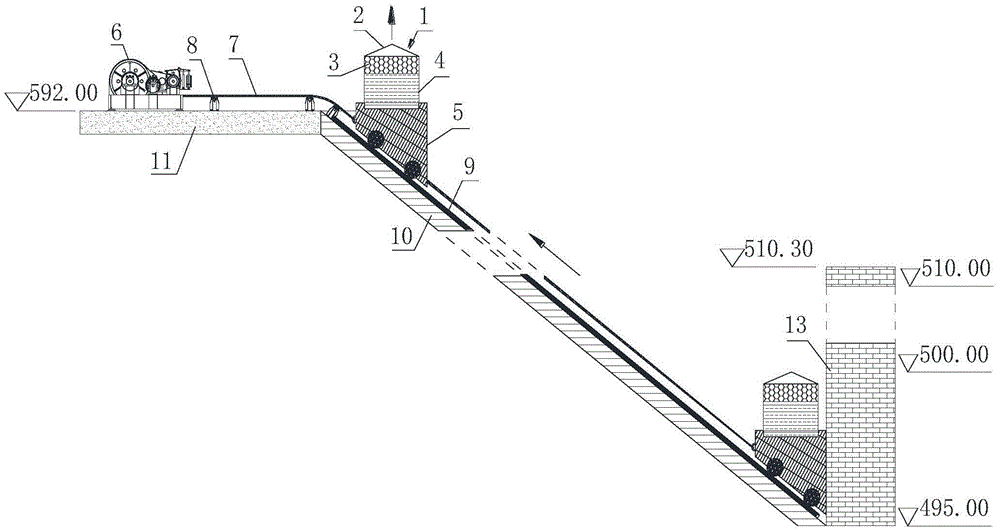

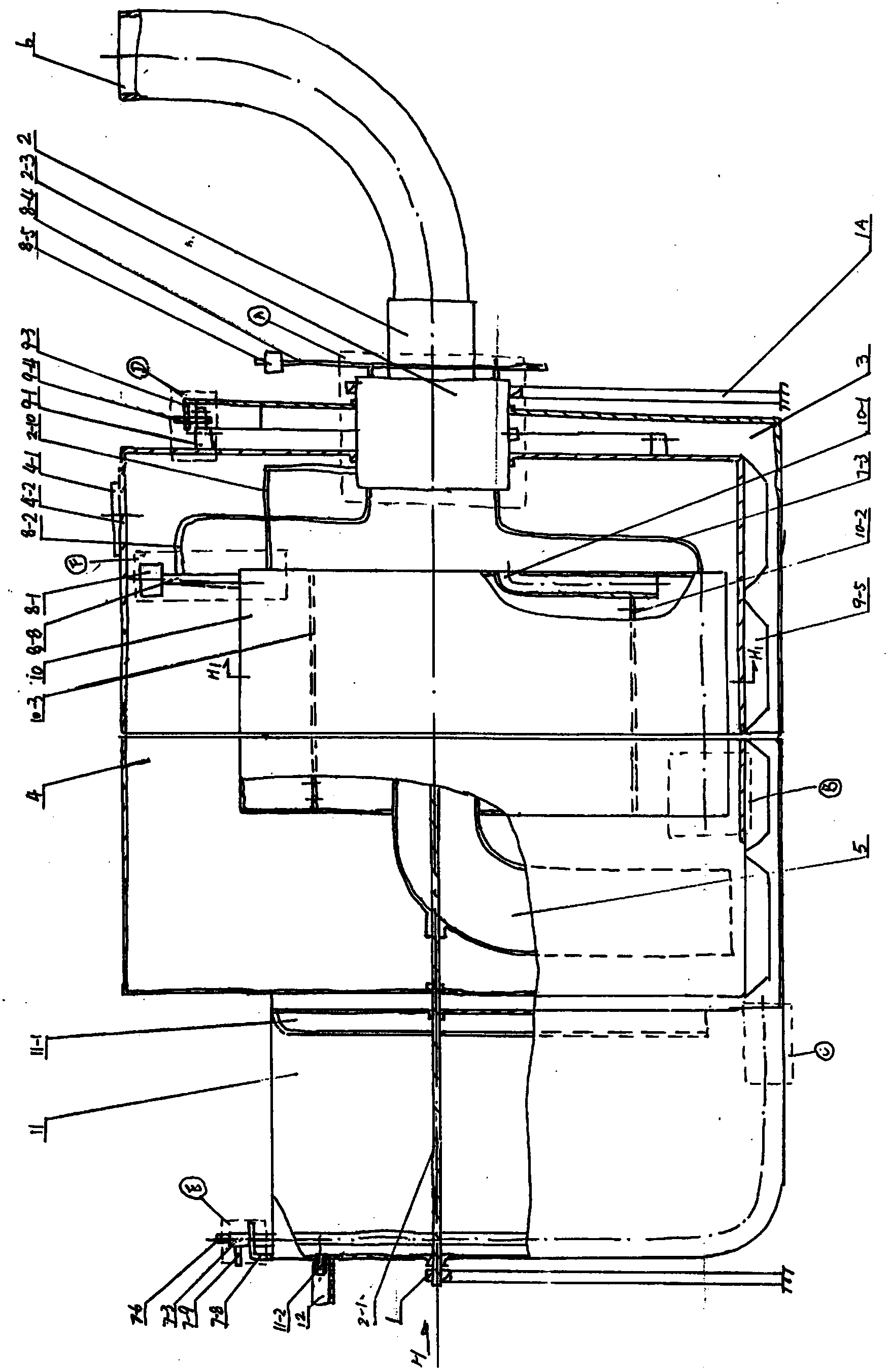

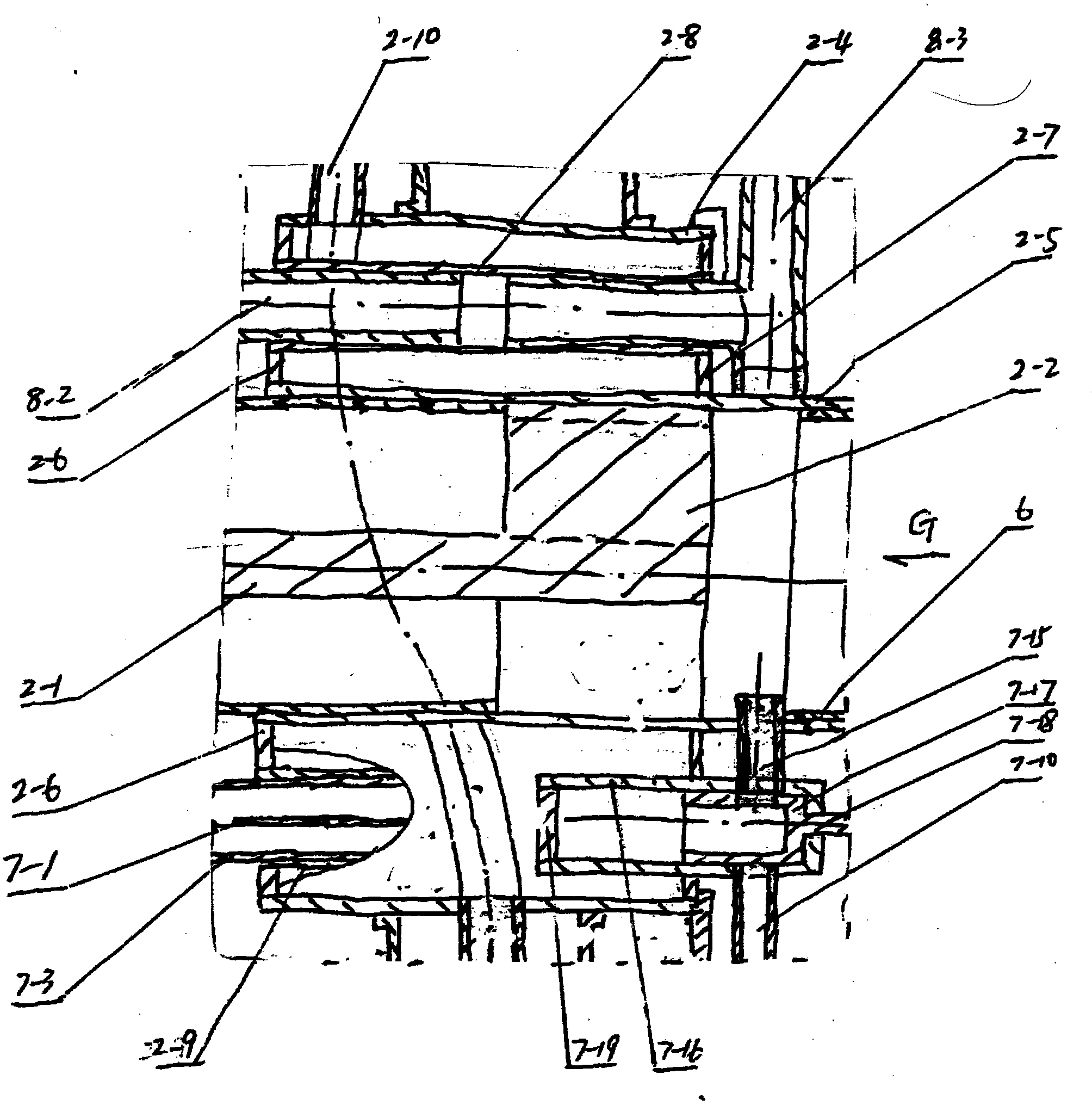

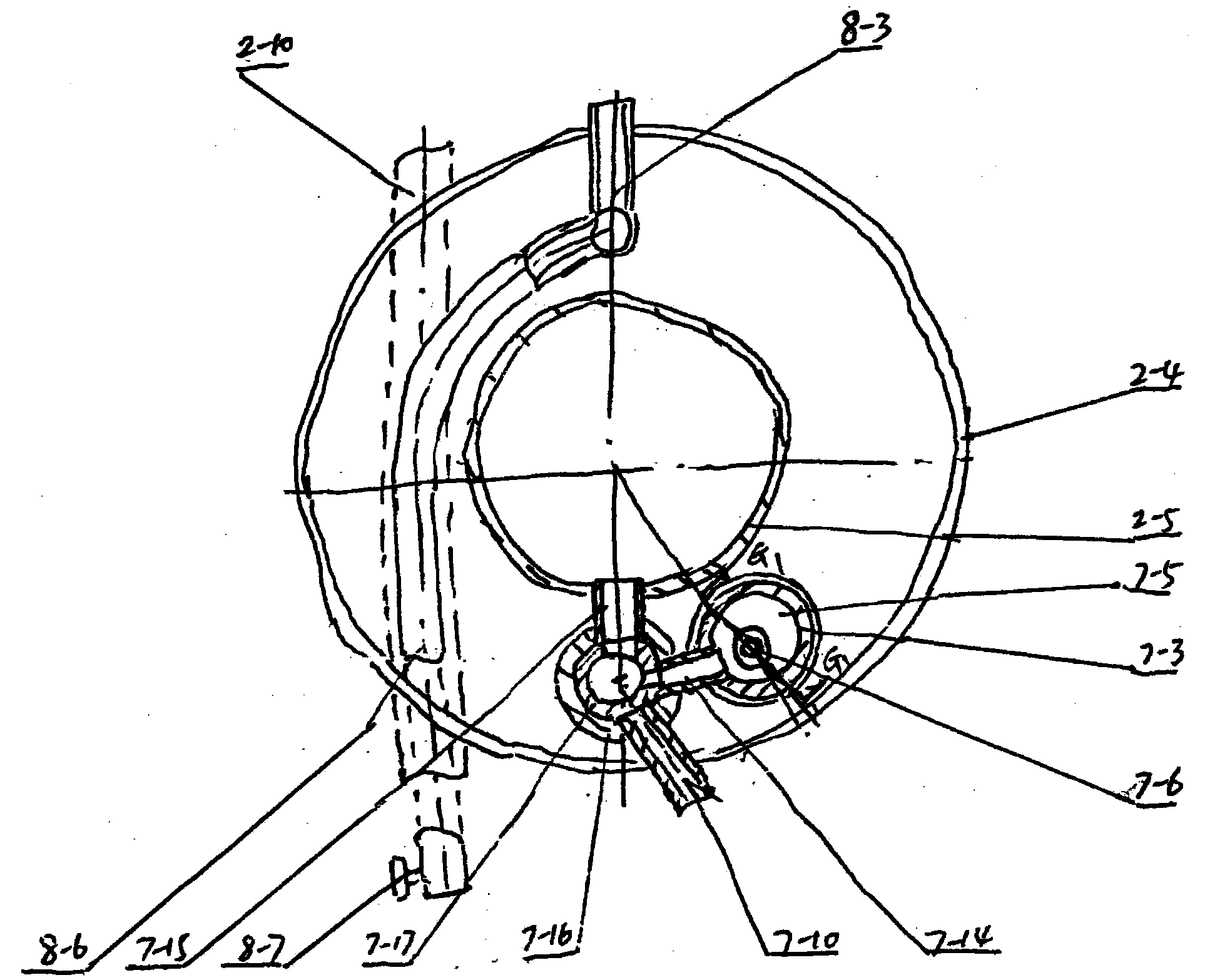

Rail type fish collection tank dam feeding system

InactiveCN105621324ATo achieve the purpose of gene exchangeReduce adverse effectsLifting devicesGreen environmentEngineering

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

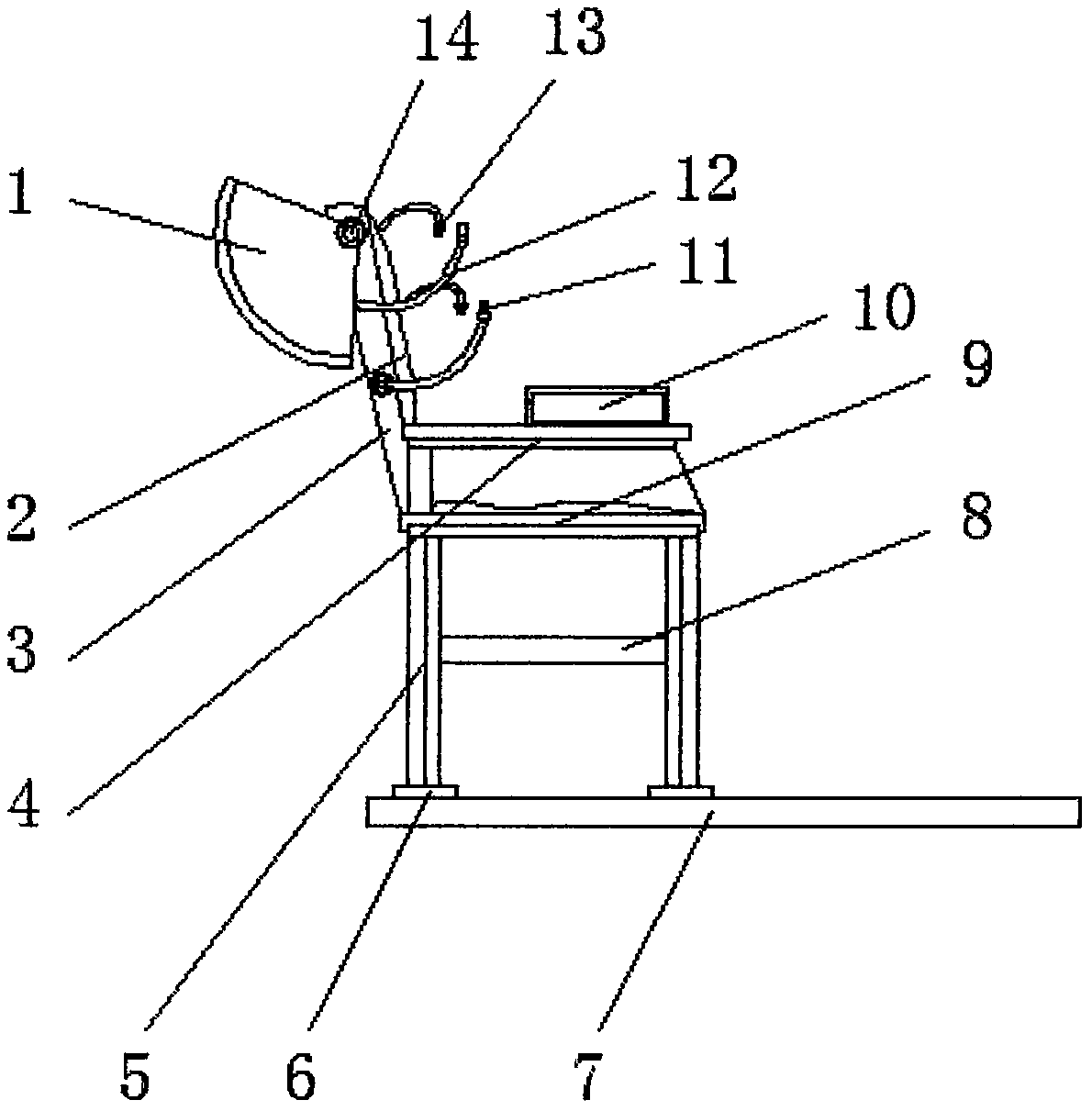

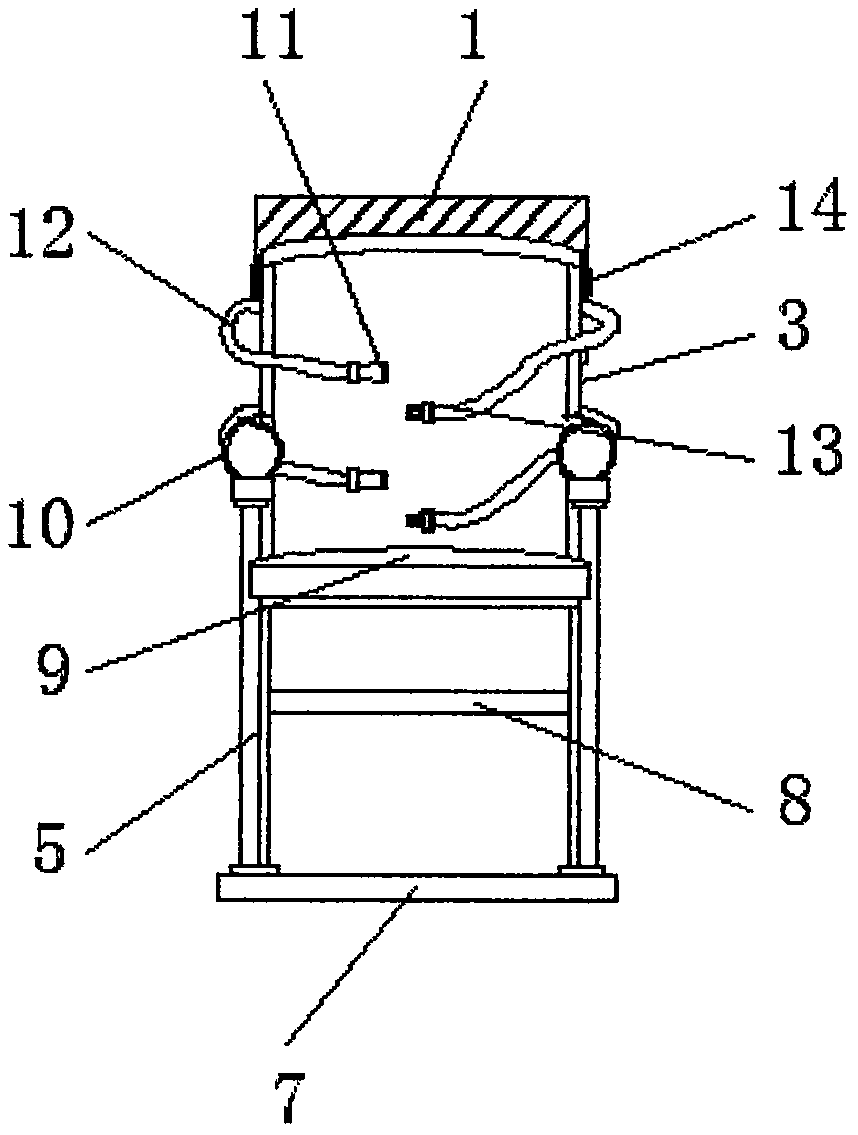

Mental disease detection auxiliary device

The invention discloses a mental disease detection auxiliary device. The metal disease detection auxiliary device comprises a weighted bottom plate; vertical rod fixing grooves are formed in the top of the weighted bottom plate; seat vertical rods are arranged above the vertical rod fixing grooves; a seat plate is arranged on the tops of the seat vertical rods, and seat cross rods are arranged onone sides of the seat vertical rods; seat armrests are arranged above the seat plate; backrest vertical columns are arranged on one side above the seat plate, near the seat armrests; the backrest vertical columns have upper body fixing ropes; one ends of the upper body fixing ropes have fixing rope pins, and the other ends of the upper body fixing ropes have fixing rope sockets; the tops of the backrest vertical columns have shielding cover rotating shafts; and a backrest cushion is arranged on one sides of the backrest vertical columns. In the present invention, after the weighted bottom plate is provided, the fixed connection of the vertical rod fixing groove does not cause the patient to easily lift the seat vertical rods by standing, and a good fixation effect can be achieved.

Owner:刘小翠

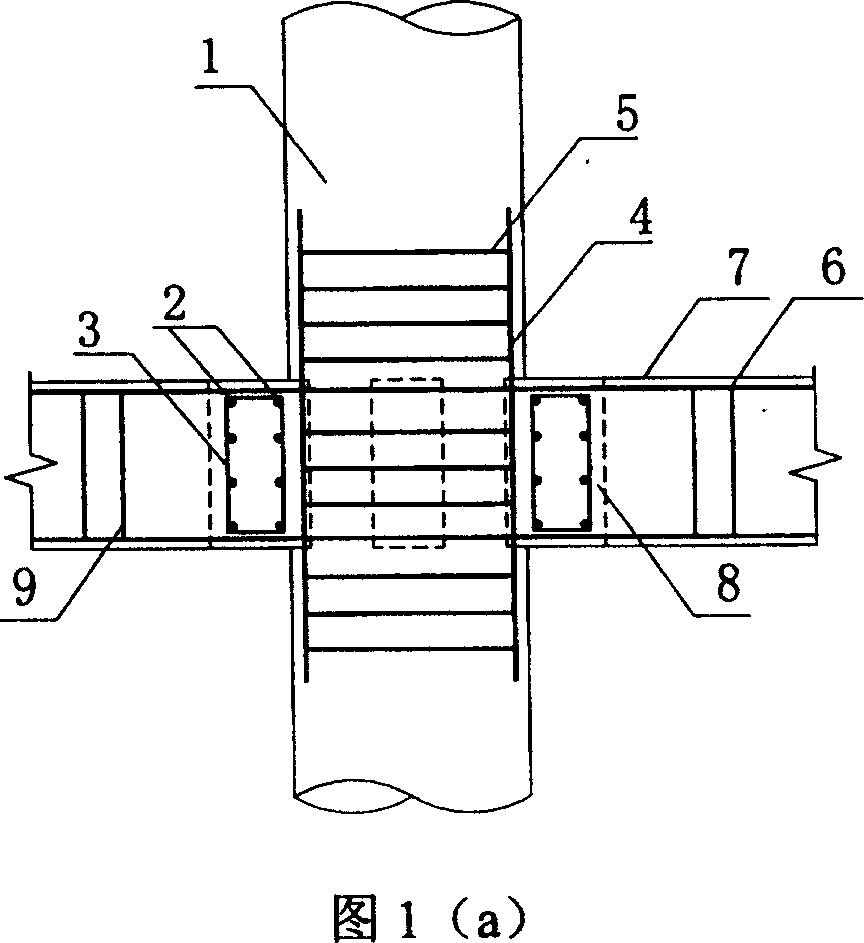

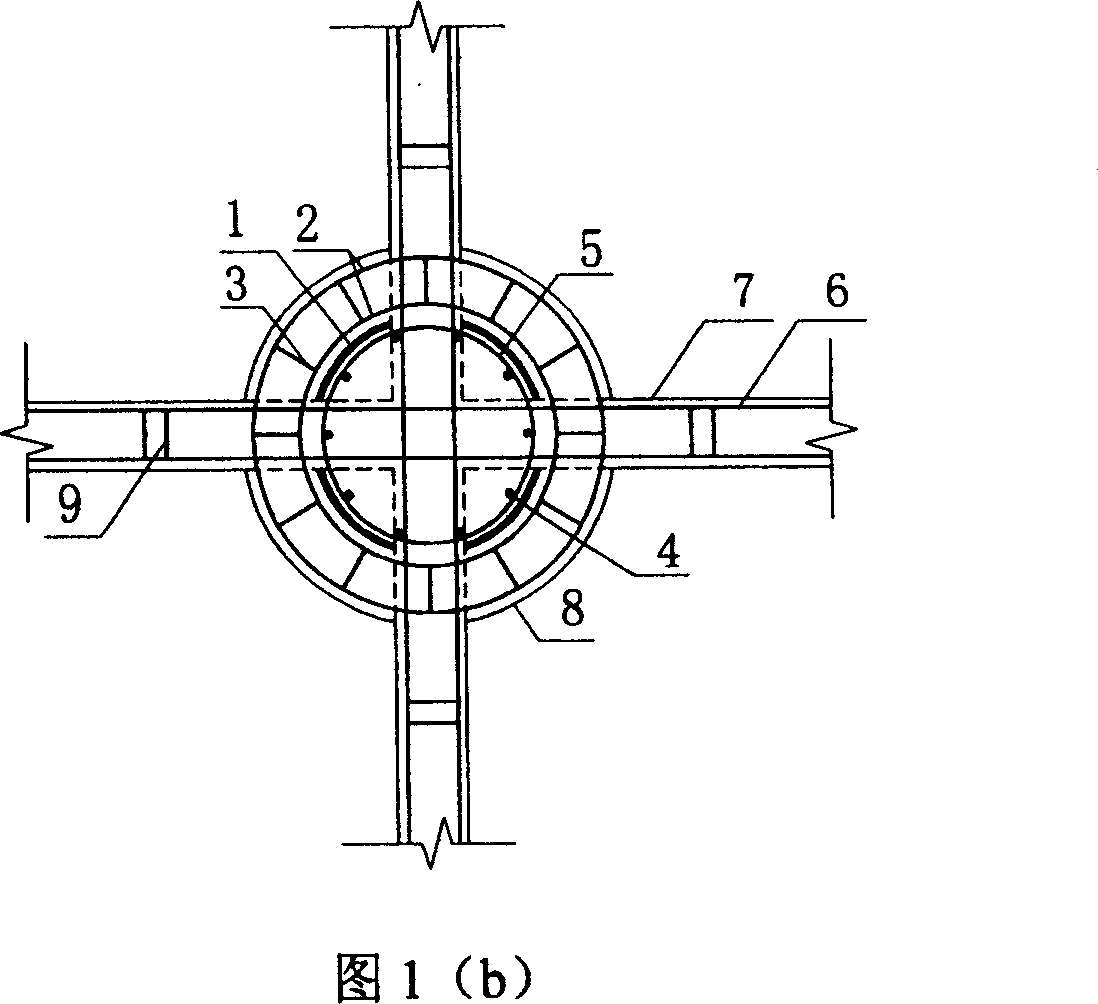

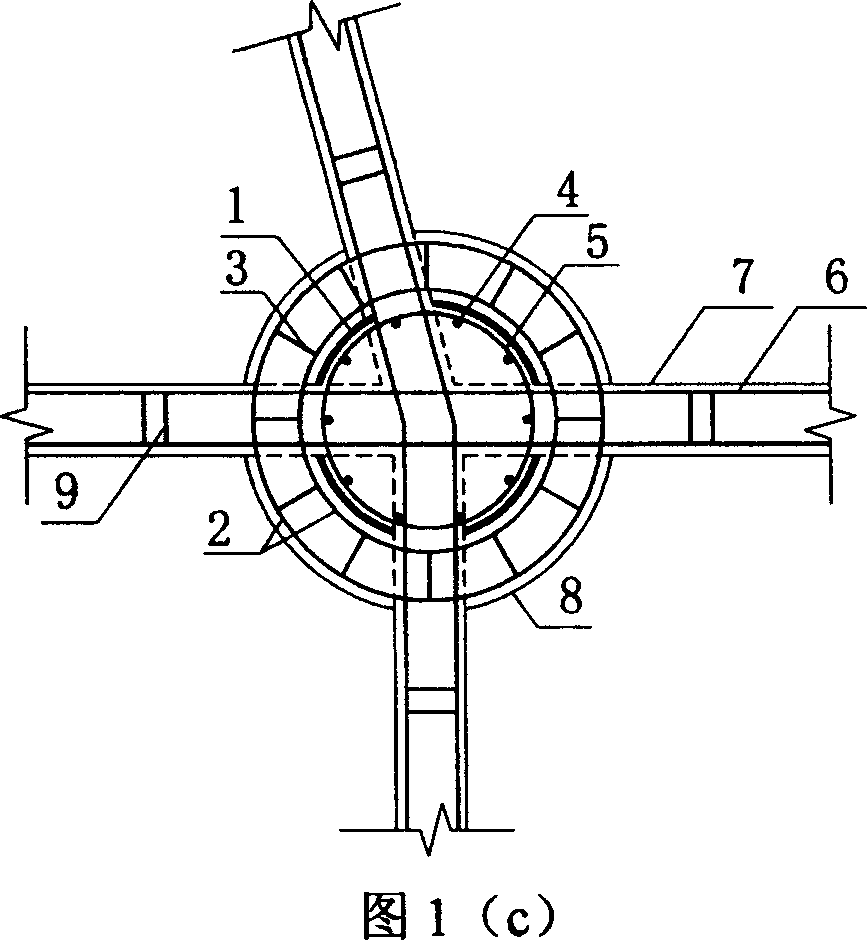

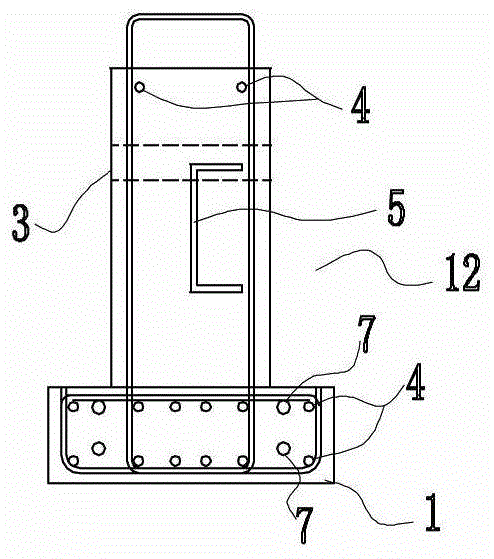

Connection structure of connection of floor beam and steel pipe concrece pole and construction method thereof

InactiveCN1314869CRigid Performance GuaranteeFirmly connectedBuilding reinforcementsHoopingConcrete beams

The invention discloses a joint structure at the connection part of steel pipe concrete pile and floor beam and the constructing method. The joint structure includes steel pipe concrete pile, floor beam and ring type concrete beam. The vertical component steel pile and the parallel component floor beam are connected at the joint, the steel pipe is drilled with a aperture at position correspondent to the joint on the floor, thus the beam lengthwise rib of the beam can pass through the steel pile directly; ring type concrete beams are arranged around the steel pipe in the joint area, the steel bar in the ring concrete beam includes ring type beam lengthwise rib which is concentric with the steel pipe concrete pile and radiate ring beam hooping in radius direction; a steel bar cage concentric with the steel pipe is arranged in the pile, which includes vertical pile connection lengthwise rib and parallel pile connection hooping, the anchor in the steel bar cage extension length is decided by the diameter of the steel bar.

Owner:SOUTH CHINA UNIV OF TECH

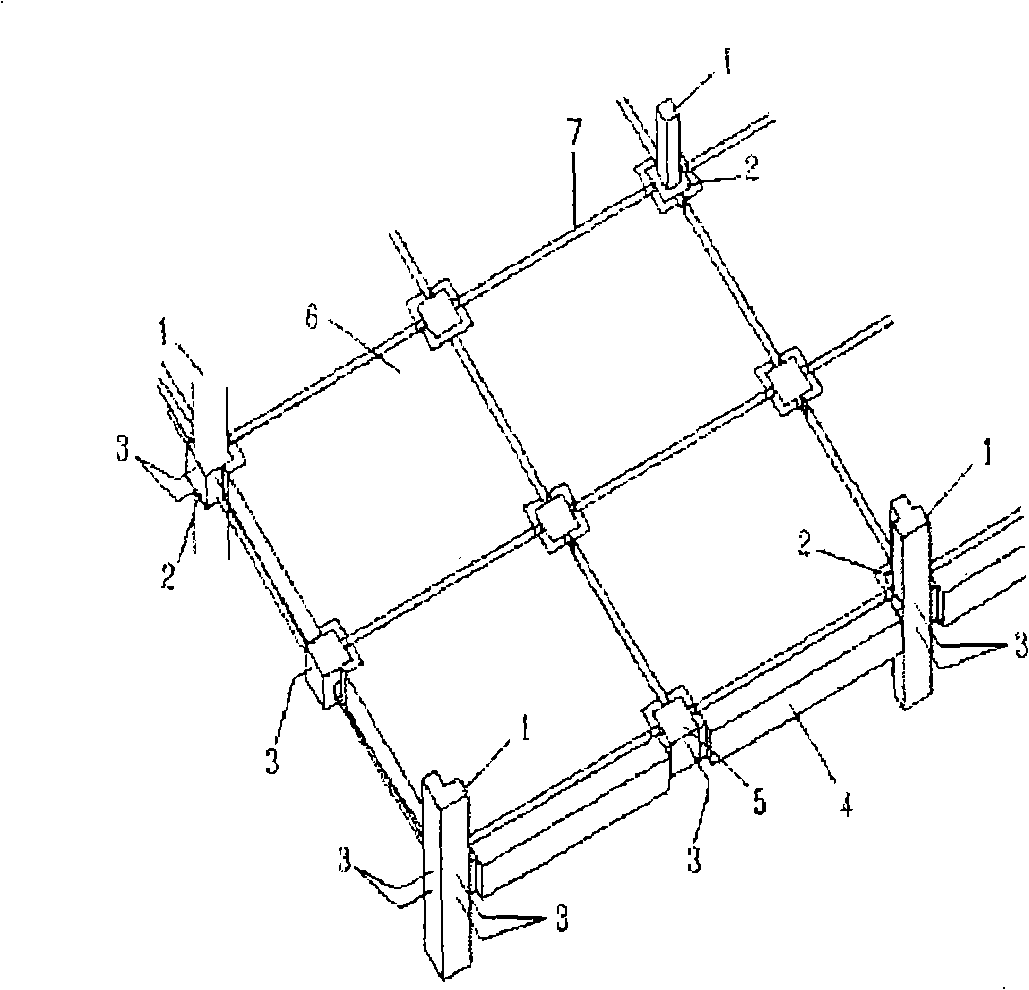

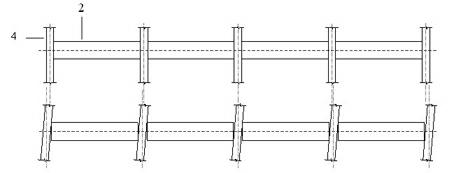

Self-centering pre-stressed concrete framework floor slab structure

ActiveCN102425257AAvoid damageReduce the cost of post-earthquake repairsFloorsShock proofingFloor slabPre stress

The invention discloses a self-centering pre-stressed concrete framework floor slab structure, which comprises spans with the quantity of N which are horizontally arranged, wherein each span comprises four main beams, secondary beams with the quantity of M, four framework columns and floor slabs, wherein the main beams are arranged between two adjacent framework columns through a pre-stressed steel stranded wire, each secondary beam is arranged between two opposite main beams, and the floor slab is arranged above the main beams and the secondary beams; every two adjacent spans share one main beam and two framework columns, in one of the spans, the secondary beams and the two main beams which are connected with the secondary beams are respectively and fixedly connected with the floor slab through a tightening device, and the rest two main beams are connected with the floor slab through a sliding device; and in each span of the rest spans, the main beams and the secondary beams are respectively connected with the floor slab through the sliding device. Under the action of single-direction earthquake, due to the adoption of the concrete framework floor slab structure, the damage to the self-centering pre-stressed concrete framework caused by the restriction effect of the floor slab can be reduced.

Owner:SOUTHEAST UNIV

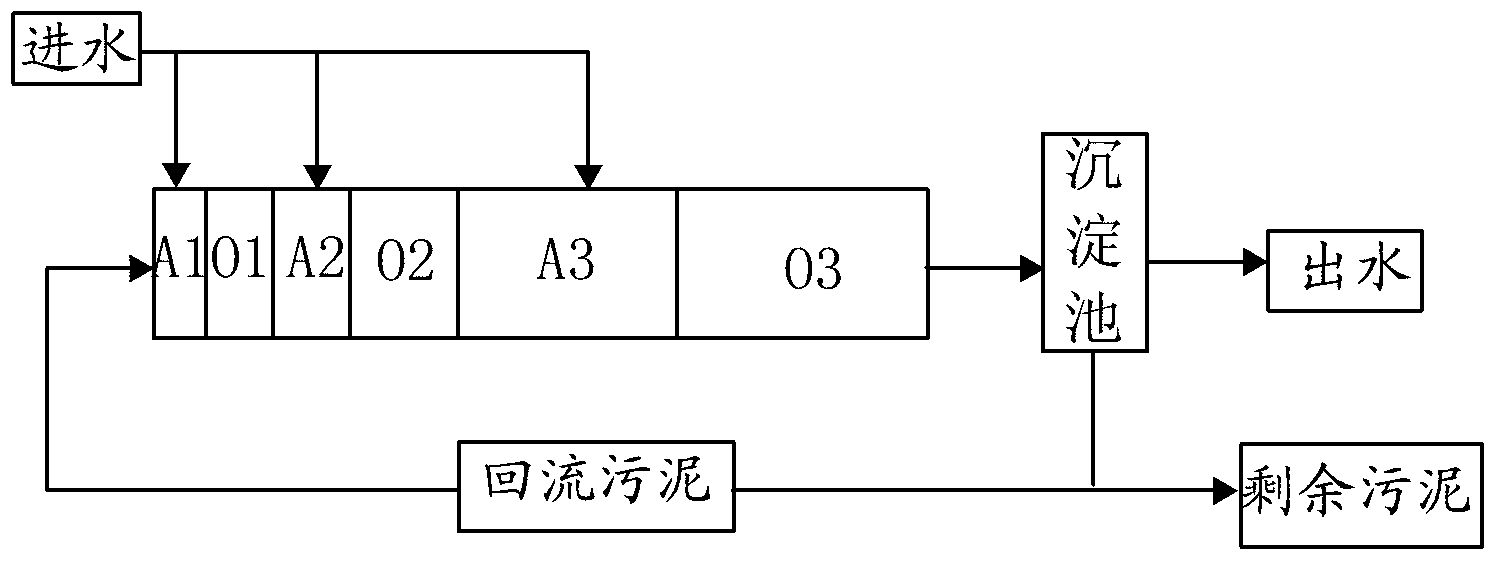

Movable floated bioreactor

ActiveCN102815787BPromote harmonious developmentAdaptableTreatment with aerobic and anaerobic processesEnergy based wastewater treatmentEngineeringSewage

Owner:项栋才 +2

Nondestructive demounting method for prefabricated part of IMS system Dai nationality folk house major structure

The invention discloses a method for demounting a prefabricated part without damage in an IMS system Dai nationality dwelling major structure, which selects and marks key points on the IMS system Dai nationality dwelling major structure, and carries out controllable slow release to the prestress of a steel stranded wire in each key point, without impact and damage on the prefabricated part in theprestress release process. After a prefabricated beam and a prefabricated slab of a floor are demounted and hanged back to the ground, open-channel post-cast concrete and the steel stranded wire contained in the concrete are separated out from the prefabricated beam and the prefabricated slab for leading the prefabricated beam and the prefabricated slab to be restored. The method can realize the undamaged recovery and reuse of the prefabricated beam, the prefabricated slab and a prefabricated column when demounting the IMS system Dai nationality dwelling, and is economical and environmentallyfriendly, thus being suitable to demounting not only the IMS system Dai nationality dwelling but also other IMS system buildings, and having reference function for demounting non-IMS system prestressstructures.

Owner:KUNMING UNIV OF SCI & TECH

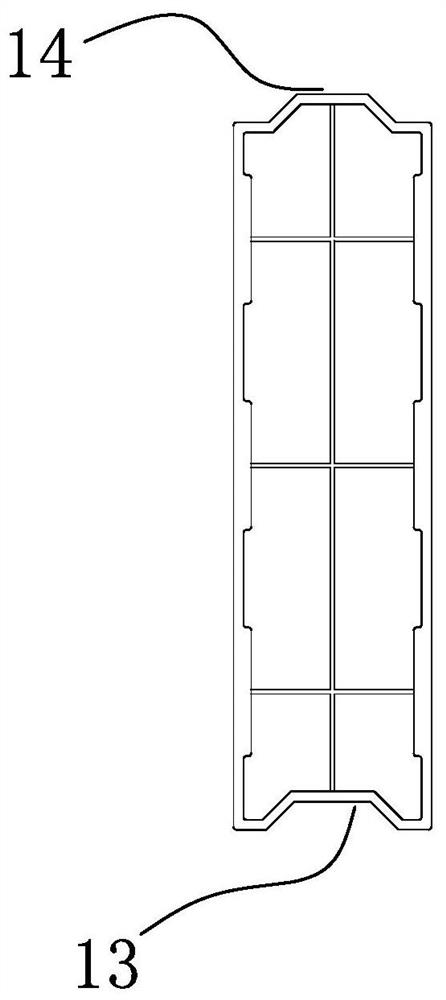

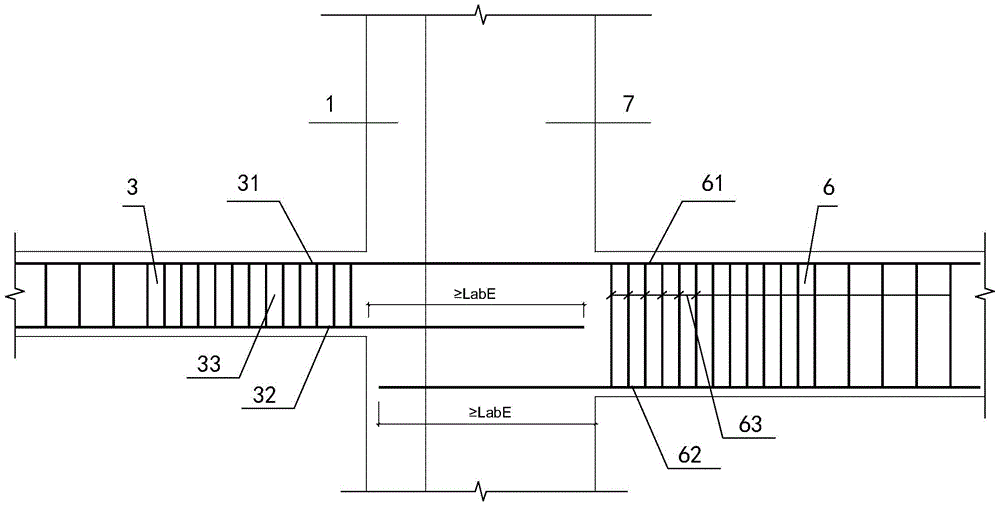

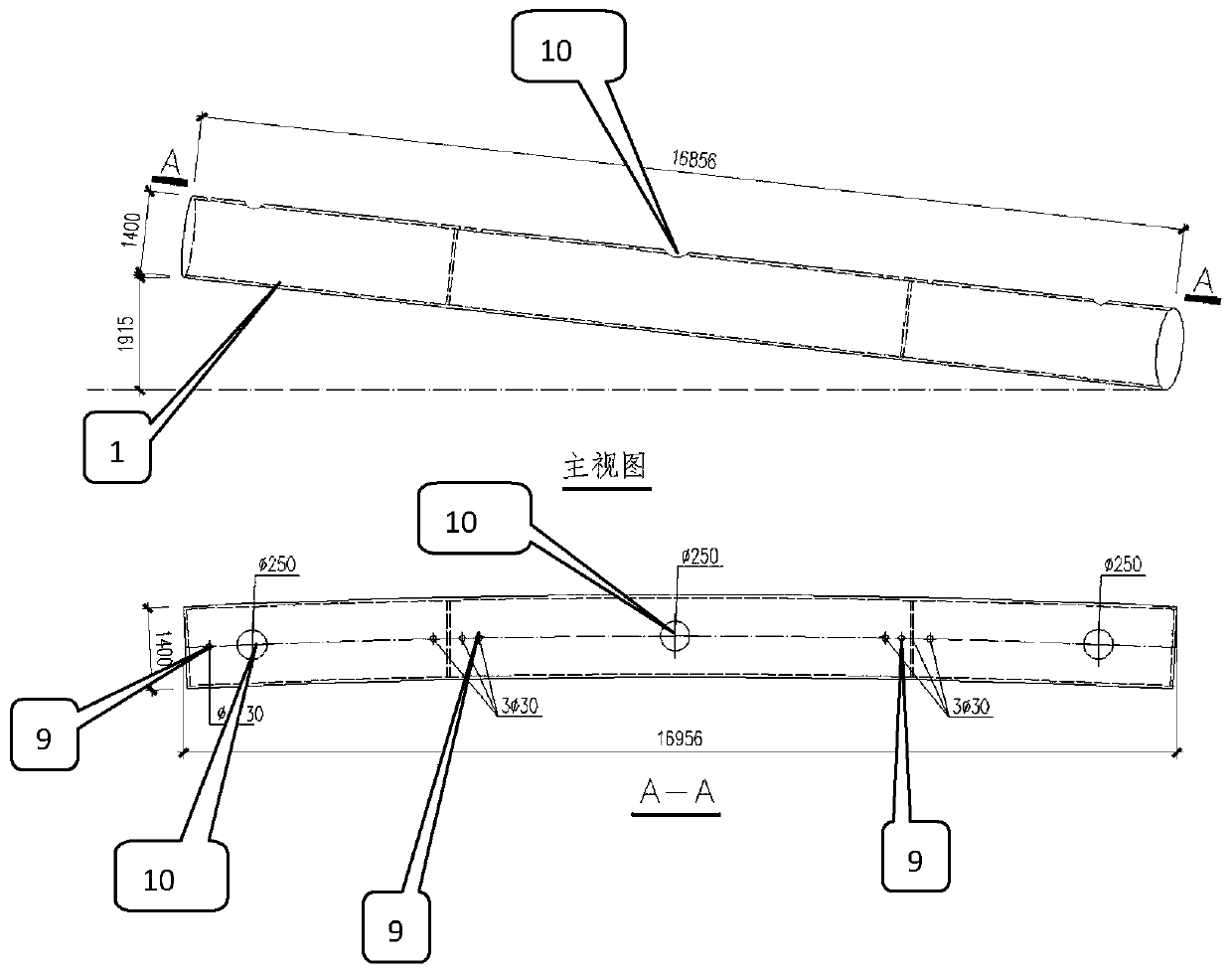

A Pre-tensioned Prestressed Reinforced Concrete Prefabricated Beam

ActiveCN103088962BImprove stress resistanceIncrease the tensile stressGirdersJoistsHoopingReinforced concrete

The invention discloses a prestressed reinforced concrete precast beam based on a pre-tensioning method. The prestressed reinforced concrete precast beam based on the pre-tensioning method is characterized in that a beam body is of an inverted T-shaped structure consisting of a horizontal rectangular compression resistant part and a vertical rectangular shearing resistant part; the vertical rectangular shearing resistant part is provided with hoopings, and the and hooping parts extend out of the upper surface of the shearing resistant part; at least one side wall of a web of the beam body is vertically provided with a plurality of mold supporting holes; and steel strands are vertically embedded in concrete of the compression resistant part. Because the width of a compressed area at the lower part of the beam is increased, compression resistant effective cross sections are enlarged; and the concrete of the compressed part is additionally matched with horizontal hoopings for restraining concrete from cracking vertically, so that the compression resistant capability at the lower part of the beam is improved, and the stretchability is improved.

Owner:杨众 +1

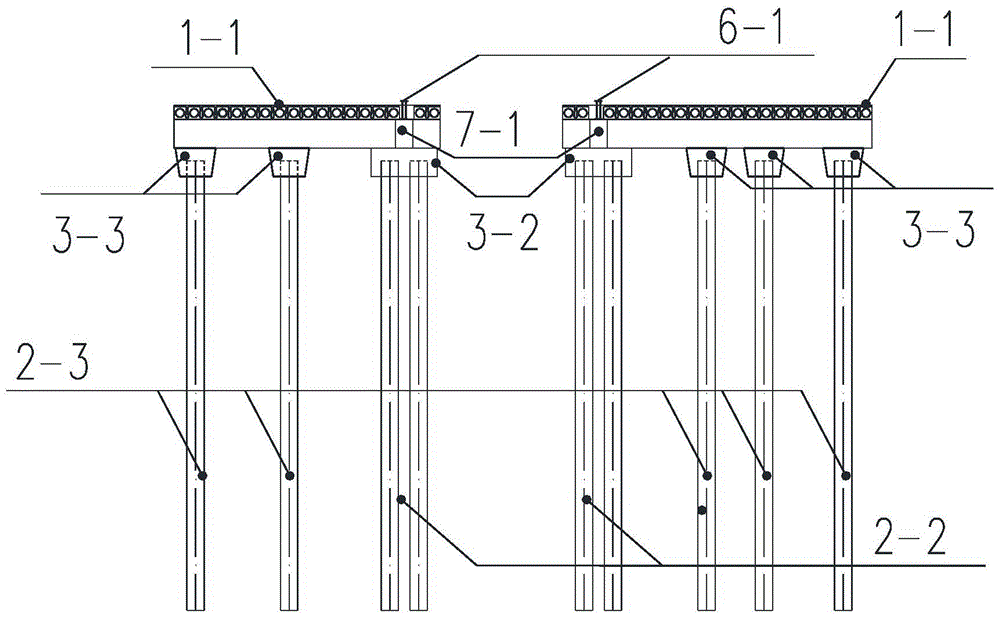

A Pile Foundation Reinforced Concrete Structure Offshore Oil Platform

ActiveCN105297698BStrong market supply capacityQuality assuranceArtificial islandsUnderwater structuresProcess equipmentReinforced concrete

The invention discloses a pile foundation type reinforced concrete structure offshore oil platform. The pile foundation type reinforced concrete structure offshore oil platform comprises a deck platform that is of a single-layer structure and provided with flush drilling area deck platform and a process equipment facility area deck platform; the drilling area deck platform comprises two subsections disposed on the two sides of a drill conductor wellhead area, respectively; a steel track is arranged on an inner side of each drilling area deck platform subsection and projects from an upper surface of the drilling area deck platform subsection, and the two parallel steel tracks form land drilling rig slipping tracks. The pile foundation type reinforced concrete structure offshore oil platform has the advantages of good mechanical properties, convenient construction and the like by fully utilizing excellent stress tolerance of the reinforced concrete structure and the tensile capacity of a reinforcement material. Compared with a traditional jacket type offshore platform, the pile foundation type reinforced concrete structure offshore oil platform is low in structure construction cost and long in service life, and the strength, stiffness, workability, shock and collision property and durability of the offshore platform can be improved. Besides, the pile foundation type reinforced concrete structure offshore oil platform is applicable to oilfield development projects of different scales within a range of charted depths being 3m to 30m.

Owner:CNOOC ENERGY TECH & SERVICES

External wall heat-insulation and fire-retardant material and preparation method thereof

The invention discloses an external wall heat-insulation and fire-retardant material and a preparation method thereof. The external wall heat-insulation and fire-retardant material is characterized by being prepared from 60-70 parts of foamable thermoset phenolic resin, 30-40 parts of thermoset linear urea resin, 3-8 parts of Tween 80, 10-30 parts of quartz powder, 10-15 parts of micro powder aluminium hydroxide, 10-20 parts of 4A zeolite, 5-12 parts of n-pentane and 2-6 parts of concentrated sulfuric acid. The external wall heat-insulation and fire-retardant material product disclosed by the invention is characterized in that the oxygen index is more than or equal to 55%, the water absorption is less than or equal to 2% (soaked for 24 hours), the heat conductivity coefficient is 0.02-0.029w / mk, the stability and weather resistance of the product are good, and the external wall heat-insulation and fire-retardant material product is non-toxic, odourless and environmentally-friendly. The external wall heat-insulation and fire-retardant material product is ideal fireproof, heat-insulation, energy-saving and beautiful environmentally-friendly decorative material. Detections carried out by national fireproof construction material quality supervision and inspection center show that the combustion performance of the external wall heat-insulation and fire-retardant material product disclosed by the invention is up to the grade A of the standard GB8624-2006 classification for burning behaviour of building materials and products.

Owner:南充春飞纳米晶硅技术有限公司

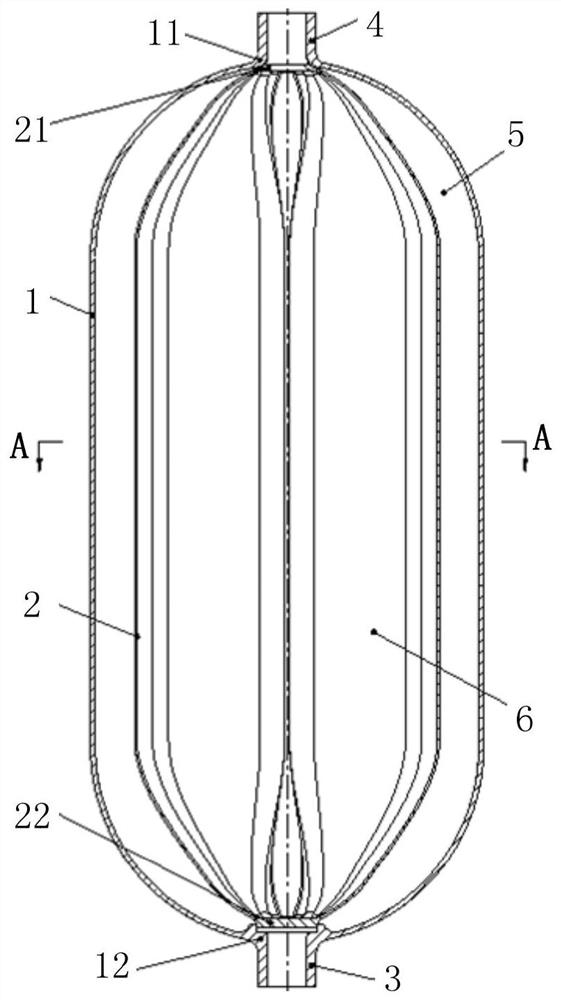

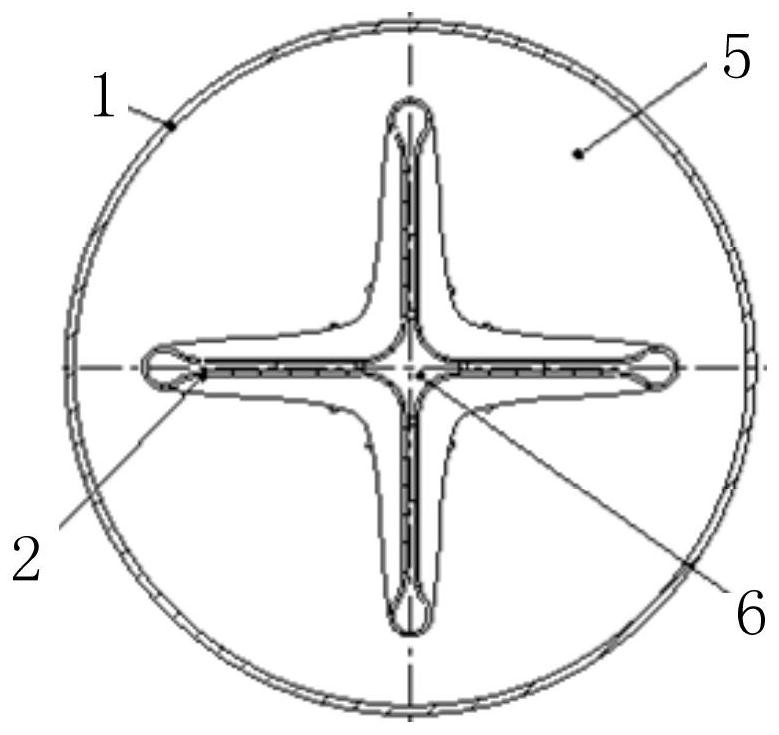

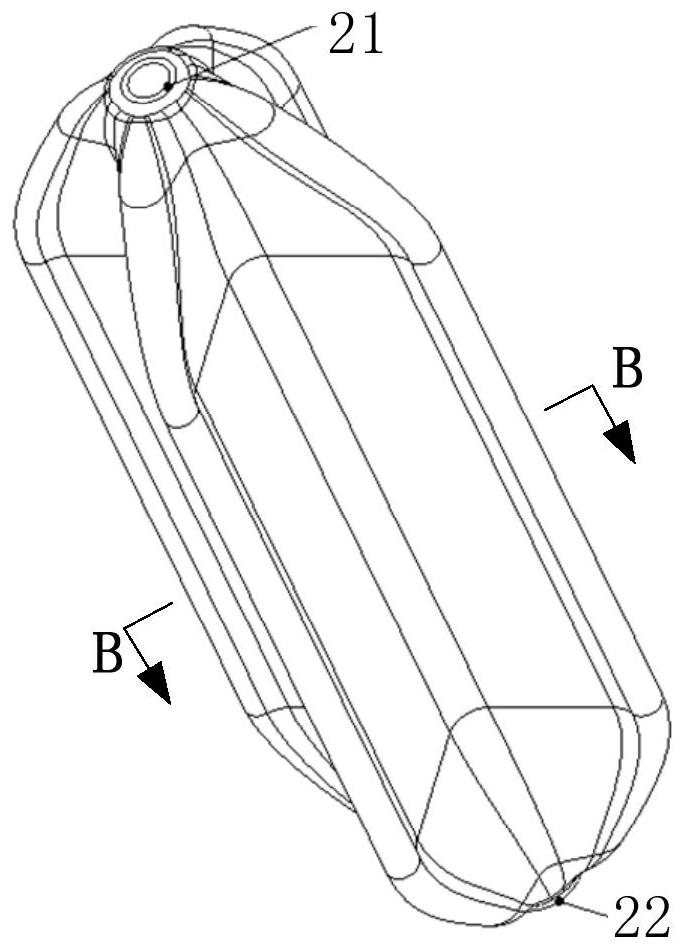

diaphragm tank

ActiveCN112389682BImprove expansion deformationImprove regularityCosmonautic vehiclesCosmonautic propulsion system apparatusLiquid mediumFlight vehicle

The invention provides a diaphragm storage tank, which includes a storage tank shell and a gas-liquid diaphragm. The two ends of the tank shell are respectively provided with an air charging and discharging port, and a liquid filling and discharging port. The two ends of the gas-liquid diaphragm are respectively It is an opening end and a blind hole end. The gas-liquid diaphragm is arranged inside the tank shell and a liquid storage chamber is formed between the tank shell and the gas-liquid diaphragm. Air discharge port, liquid addition and discharge port, gas storage chamber is formed inside the gas-liquid diaphragm and the gas storage chamber communicates with the gas filling and discharge port through the opening end, and the liquid storage chamber communicates with the liquid addition and discharge port; the gas-liquid diaphragm is in storage Driven by the internal pressure of the gas chamber, expansion can be generated to realize the discharge of liquid in the liquid storage chamber. The invention realizes a stable center of mass and no liquid sloshing during the liquid discharge process, which is beneficial to the attitude control of the aircraft, and has the advantages of small mass, safety, and It has the advantages of high reliability, good compatibility with liquid medium, long service life, strong adaptability to mechanical environment, low quality and low cost.

Owner:SHANGHAI INST OF SPACE PROPULSION

Detachable high-temperature oil pump bracket

ActiveCN111648955ASimplify the installation processSimplify disassembly stepsPositive displacement pump componentsLiquid fuel engine componentsDrive shaftEngineering

The invention discloses a detachable high-temperature oil pump bracket. The detachable high-temperature oil pump bracket comprises a fixing plate; a mounting body is mounted on the fixing plate, a placement frame is mounted on the mounting body, and the placement frame is used for mounting a high-temperature oil pump; the placement frame is mounted on the mounting body, and a driving shaft is horizontally mounted on the mounting body in an inserted mode; a driving piece is fixedly mounted on the driving shaft, and the driving piece is of a circular sheet structure; a circular hole is formed inthe center of the driving piece, and a plurality of spike-shaped teeth are arranged on the circumference of the driving piece; and the driving shaft runs through the circular hole in the center of the driving piece and is fixedly connected with the circular hole, and one end of the driving shaft is the connecting end which is used for being connected with a wrench. The detachable high-temperatureoil pump bracket has the beneficial effects that a bracket structure can be easily and rapidly dismounted and mounted.

Owner:武安市永盛机械泵业有限公司

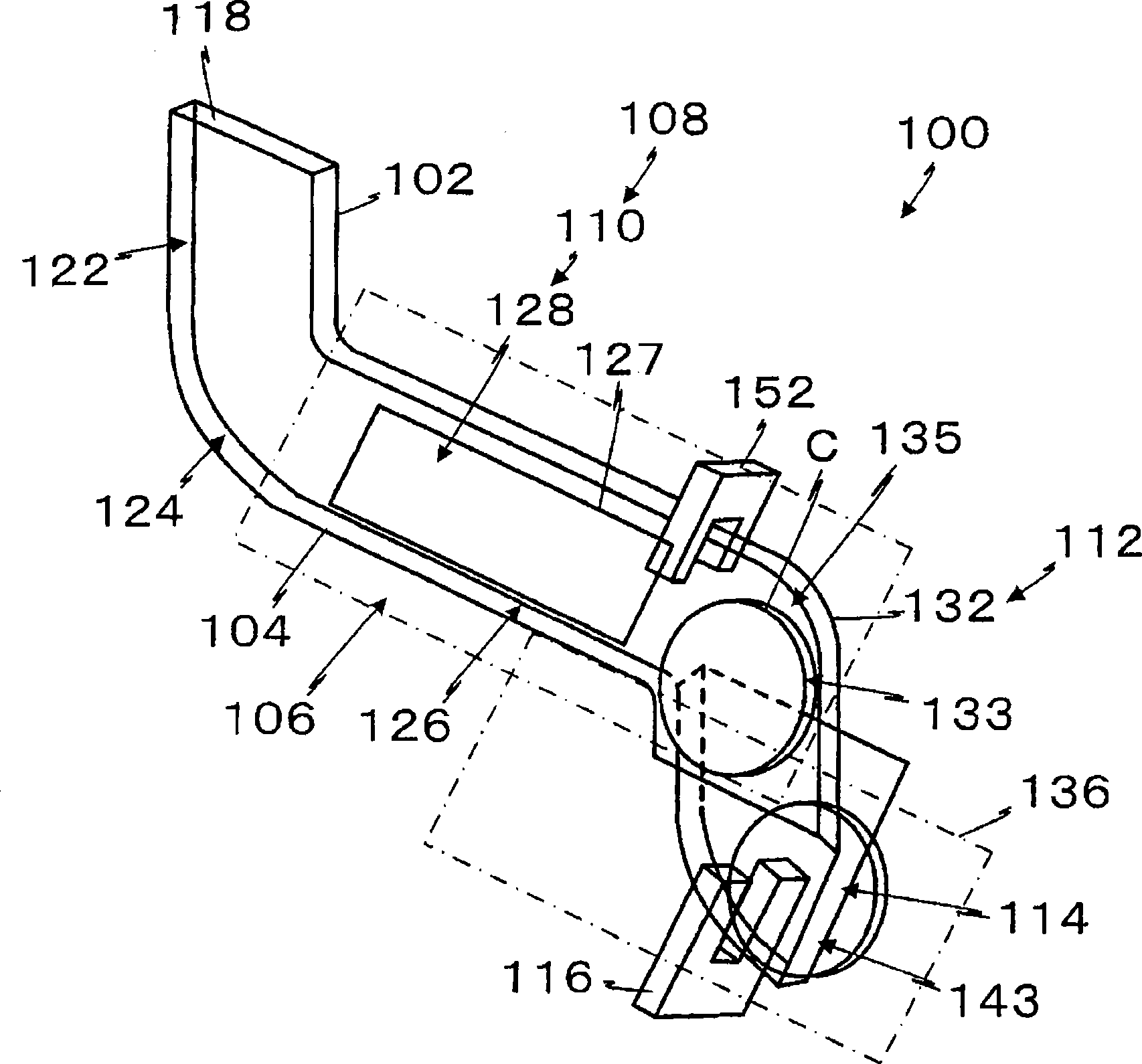

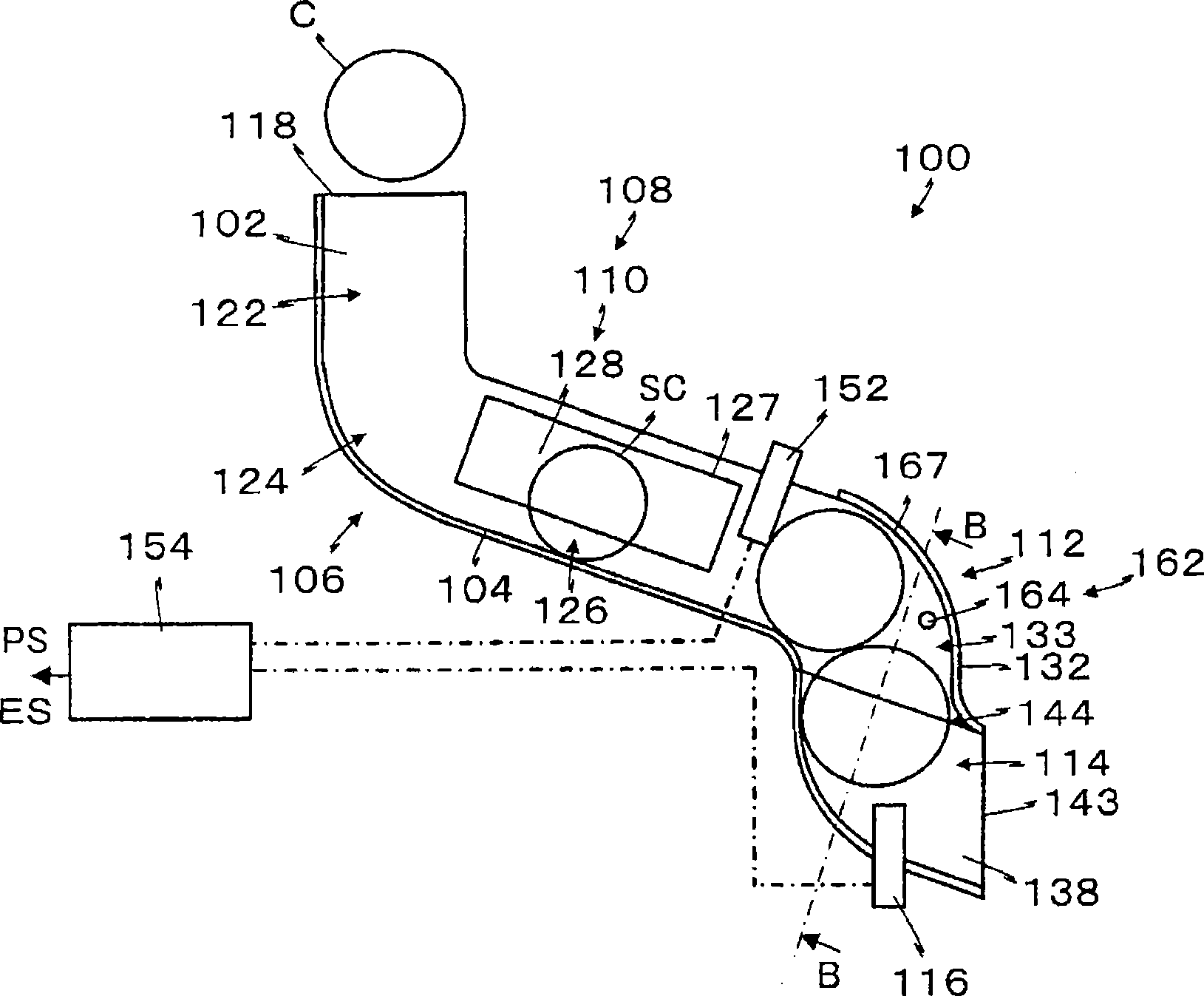

Coin selector

A coin selector prevents illegal actuation of a coin sensor for real coin detection and is reduced in size and has a high coin processing rate, and which can cancel a coin to be cancelled reliably. The coin selector detects the passage of a coin based upon a signal from a coin sensor disposed downstream of a real / fake discriminating unit formed along a coin passage through which the coin moves. Amoving direction changing unit for a coin is provided on the coin passage downstream of the real / fake discriminating unit and the coin passage downstream of the moving direction changing unit is disposed on a plane different from a plane on which the moving direction changing unit is present.

Owner:ASAHI SEIKO CO LTD

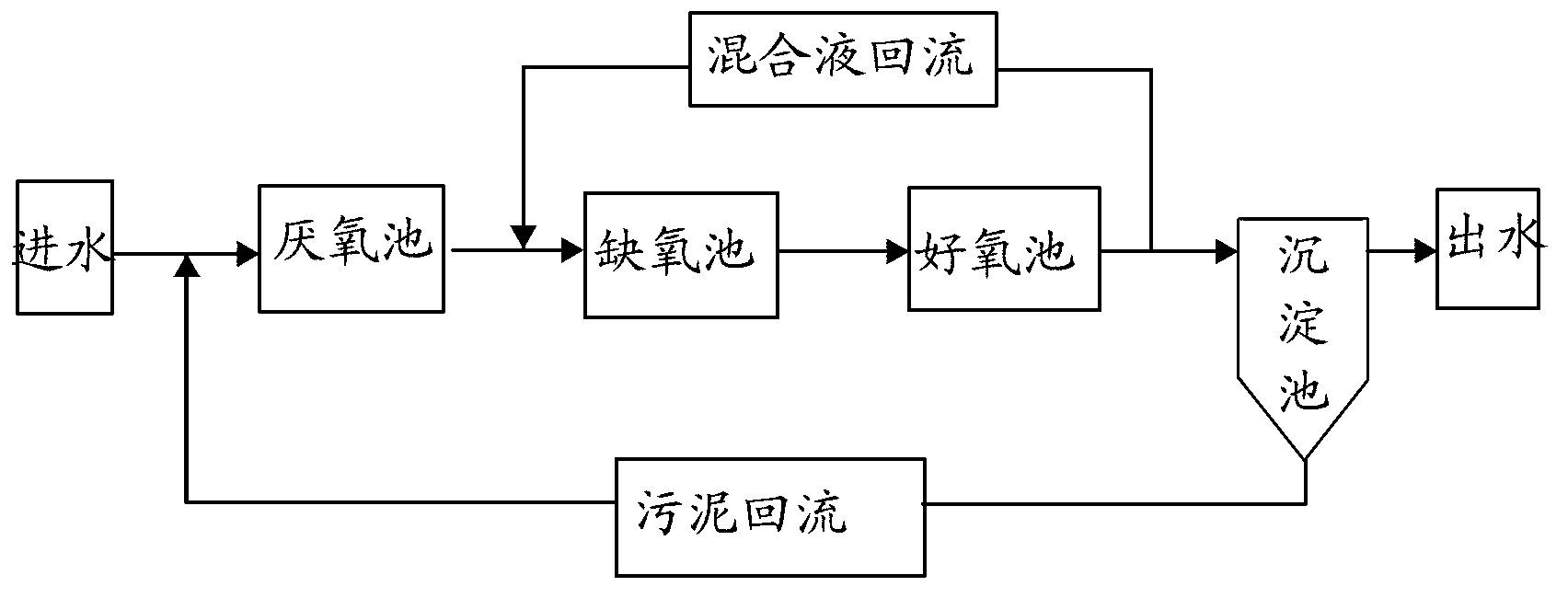

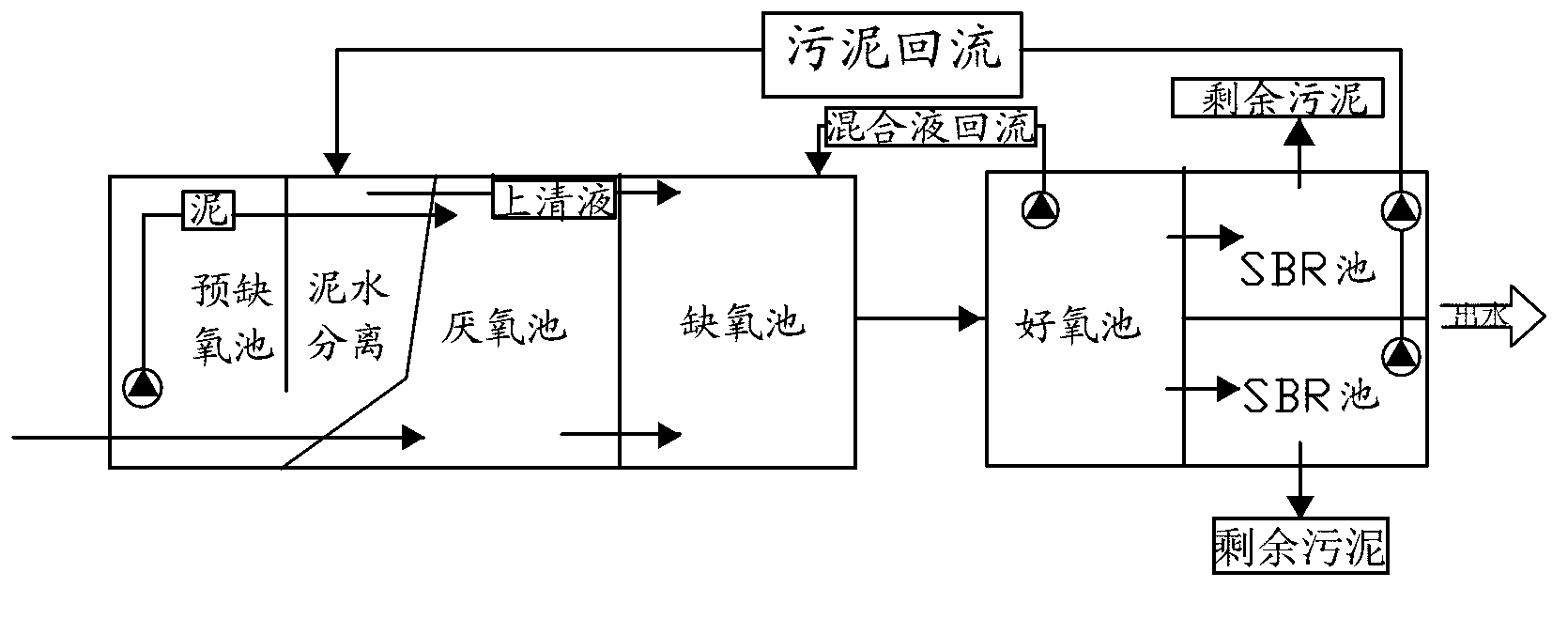

System and method for constant water level sequential batch type sewage treatment system with continuous variable volume

ActiveCN102765858BMeet the basic requirements for safe and stable operationEasy loadingMultistage water/sewage treatmentWater qualityProcess engineering

The invention discloses a system and a method for constant water level sequential batch type sewage treatment system with continuous variable volume. The method includes continuously injecting sewage into a constant water level variable volume adjusting area to enable an adjustable volume area to float on the liquid level in separation mode, injecting water to a constant water level variable volume reaction area through a distribution pump, injecting water to a constant water level variable volume water quality stabilizing area through a constant water level water decanting device and a waterdecanting pump, enabling supernate after reaction to be discharged into the supernate of the a constant water level variable volume water quality stabilizing area on the other side of the constant water level variable volume reaction area, pass through a smoothing clearing area and finally pass through an inclined plate clearing area and continuously discharging purification water equivalent withpreprocessing feeding water. The system and the method resolve the technical problem that denitrification and dephosphorization efficiency is low, single process structure water outlet index cannot meet requirements of indexes of the national standard first grade A, and process structure is complex. The system has the advantages of being simple in structure, low in integral process energy consumption, good in processing effect and the like.

Owner:鲍洪泉

A frame hollow core tube structural system of a high-rise building

The invention discloses a hollow core tube structure system of a high-rise building frame. The hollow core tube structure system comprises shear walls, connecting beams, peripheral columns, frame beams and a slab. The shear walls are arranged at the center of the high-rise building and are vertically arranged, the connecting beams are erected between the adjacent shear walls, the shear walls and the connecting beams enclose a hollow core tube, the peripheral columns are arranged on the periphery of the hollow core tube and are vertical steel pipe concrete columns, a part of the frame beams are erected between the peripheral columns and the shear walls, and the other frame beams are erected between the two adjacent peripheral columns. A plurality of inside-tube columns are arranged in the hollow core tube in a staggered manner, two ends of the inside-tube columns are overlapped on the shear walls respectively so as to reduce weight of the hollow core tube and reduce basic load and structural seismic force and manufacturing cost. The hollow core tube structure system can give the function of a second defense line of the peripheral columns into play.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

Connection joint structure of multi-coupled steel component

PendingCN107806177AHigh strengthImprove local stiffnessBuilding constructionsStructural engineeringMachining

The invention discloses a connection joint structure of a multi-coupled steel component. The connection joint structure of the multi-limb steel component comprises a main component and a plurality ofconnecting components, the main component is of a hollow tubular structure, the main component is provided with a connection joint area, and the wall thickness of the connecting joint area is greaterthan the wall thickness of the main component; the main component is internally provided with a plurality of first inner strengthening ring plates, and all the first inner strengthening ring plates are arranged in the height direction of the main component at intervals in an arrayed mode; and the multiple connecting components are fixedly connected with the main component, and the ends, fixedly connected with the main component, of the multiple connecting components are located in the connecting joint area. The connection joint structure of the multi-coupled steel component can effectively optimize local force of the main component, an existing method by adopting cast steel joints or increasing the wall thickness of the main component is replaced, the wall thickness of the main component is effectively controlled, the machining period is shortened, and the weight of the multi-coupled steel component is reduced. Therefore, the whole structure cost of the connection joint structure of the multiple-limb steel component is lower than that of the method by adopting cast steel joint design and increasing the wall thickness of the main component.

Owner:深圳华森建筑与工程设计顾问有限公司

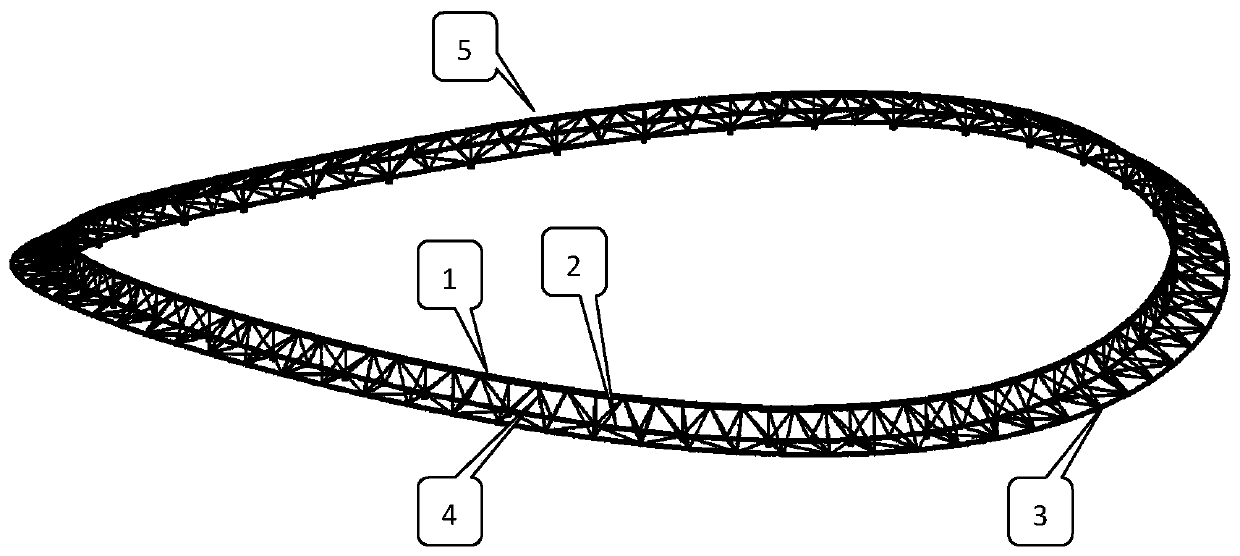

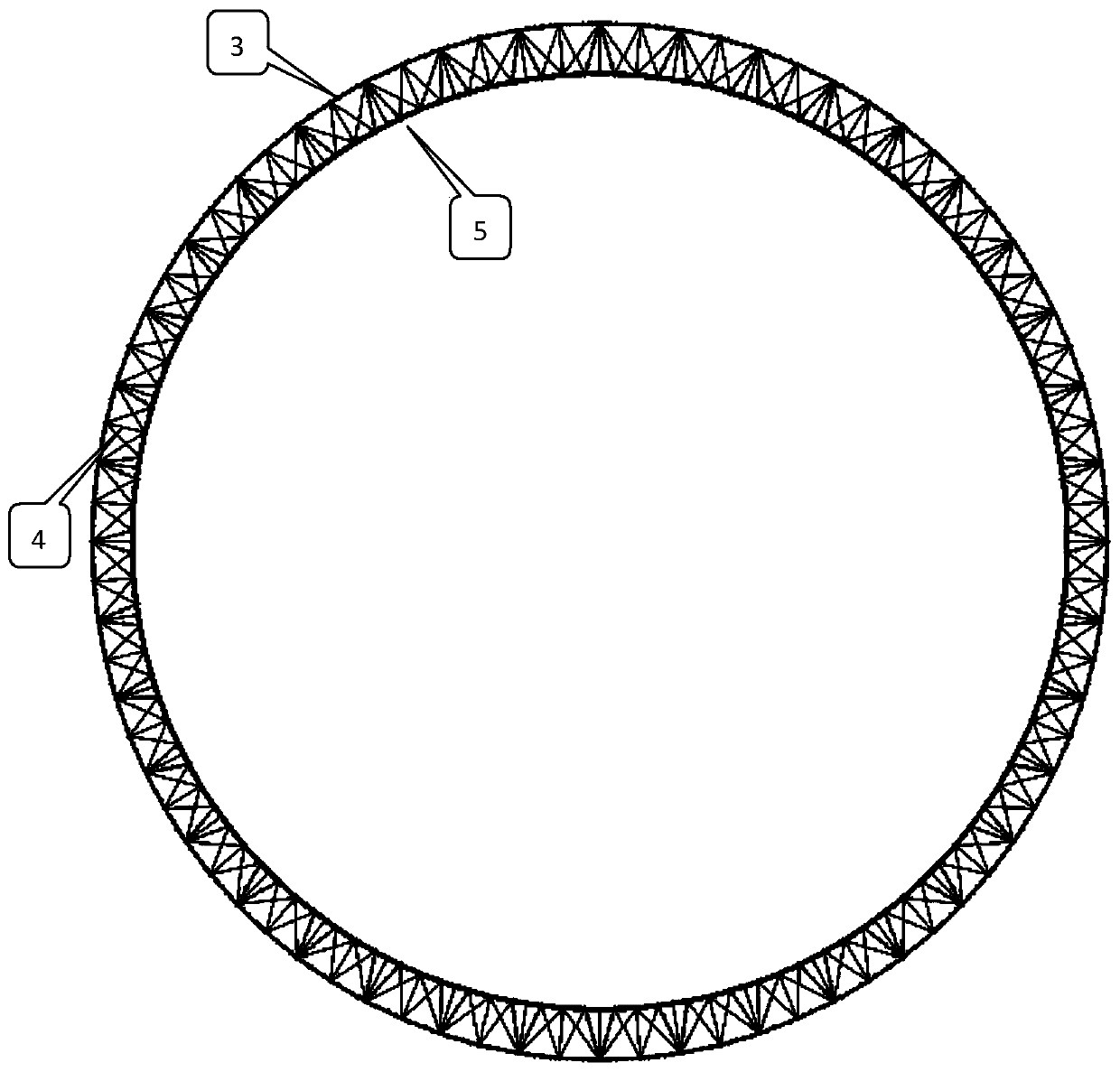

A steel and concrete composite space triangular ring truss structure and its construction method

ActiveCN106988416BOptimizing Structural SectionsReduce structure costBuilding constructionsAxial pressureSpatial structure

The invention provides a steel and concrete combined space triangle ring truss structure. According to the structure, steel and concrete are ingeniously combined together, the material characteristics of the steel and the concrete are brought into full play, and part of enormous torque, axial tensile force and axial pressure which are erected on a ring truss in a self-balanced closed saddle-shaped space structure system are borne through a small steel using quantity and concrete using quantity; and cost is reduced, the construction progress is accelerated, economic benefits are obtained, structural durability is improved, and structure stress is more reasonable.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV

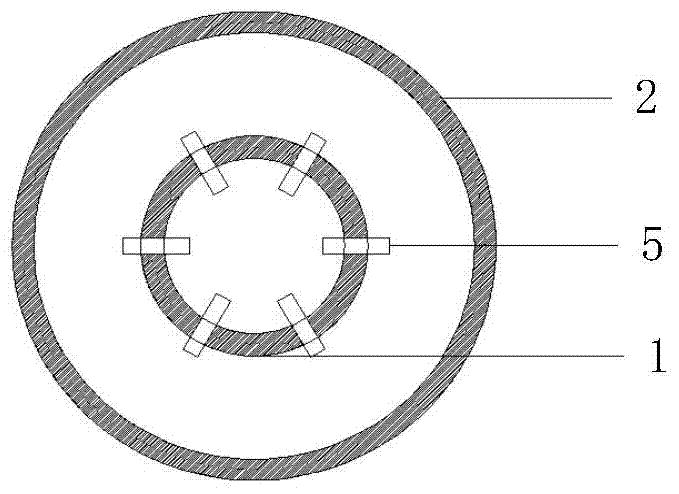

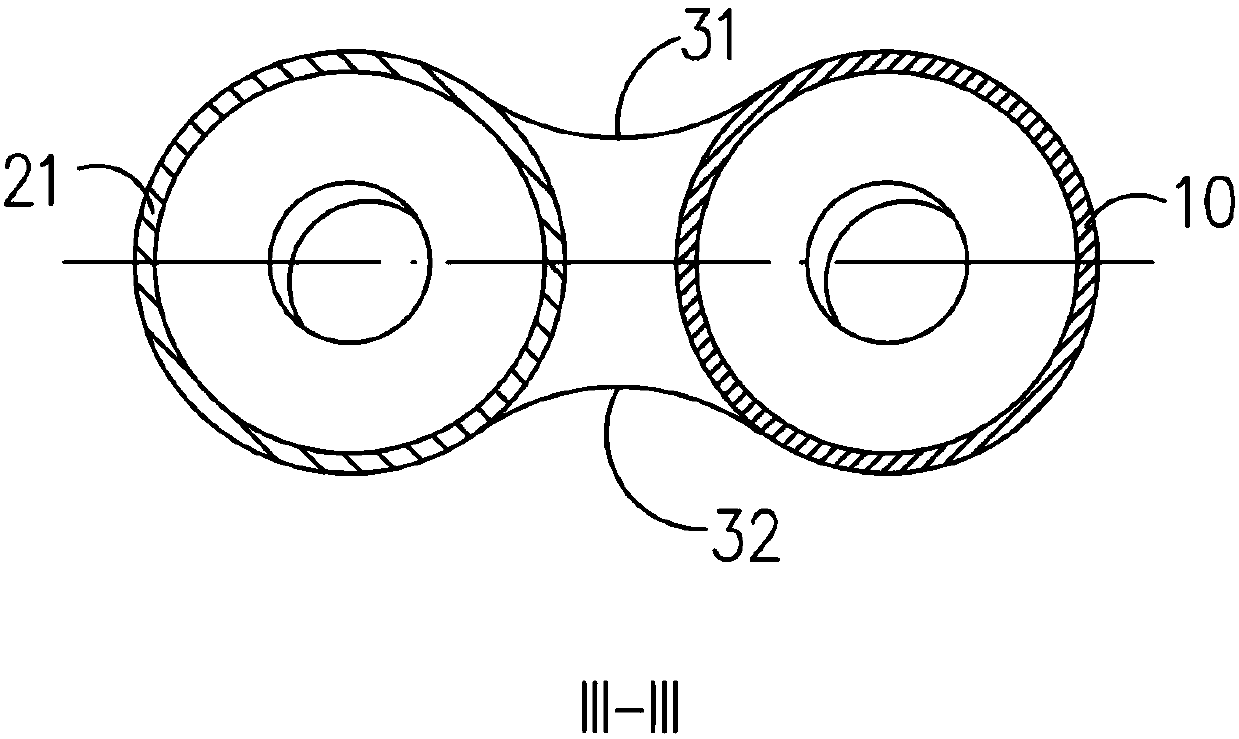

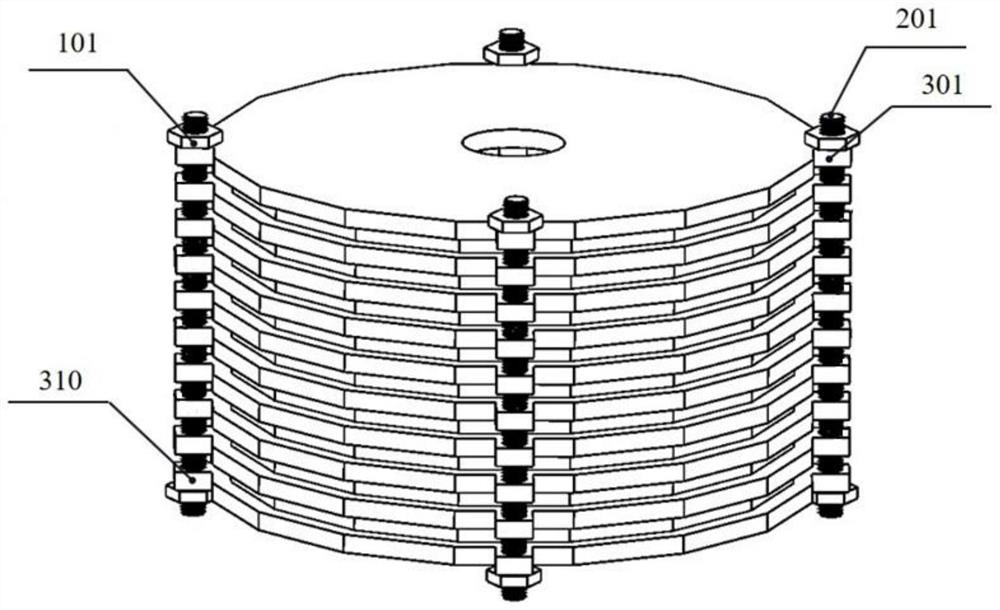

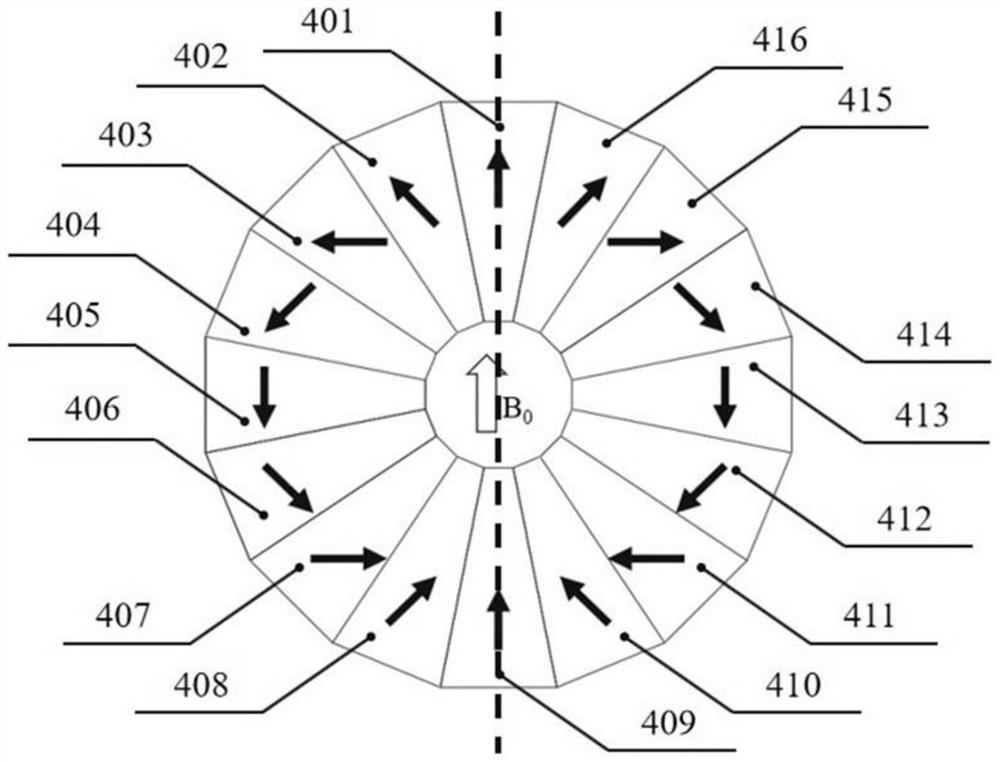

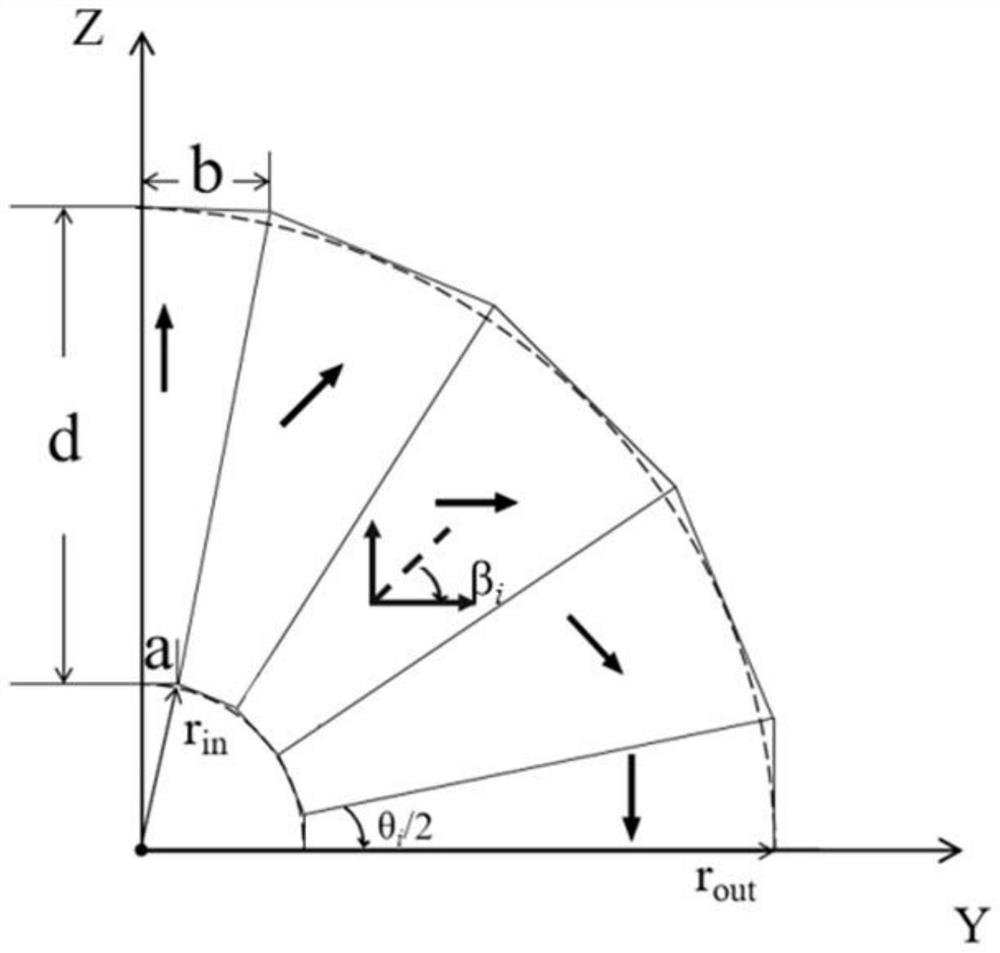

Permanent magnet capable of axially adjusting uniform field

PendingCN113035490AMake up for end effectsReduce weight and costMagnetic measurementsPermanent magnetsMagnetic field magnitudeUniform field

The invention relates to a permanent magnet capable of axially adjusting a uniform field, which is characterized in that the permanent magnet comprises base plates and magnetic rings, the base plate is annular, N + 1 layers of base plates and N layers of magnetic rings are alternately overlapped from bottom to top, the first layer of base plate is used as a bottom plate and is positioned at the lowest part of the magnetic ring, and the N + 1 layer of base plate is used as a cover plate and is positioned at the uppermost part of the magnetic ring; the N + 1 layers of base plates are fixedly connected in sequence from bottom to top, so that the N layers of magnetic rings are stacked to form a column type permanent magnet with an internal cavity, the internal cavity of the column type permanent magnet is a uniform magnetic field, and N>2 . According to the structure, only the heights of part of the magnetic blocks need to be finely adjusted, less magnetic materials are used, the weight and manufacturing cost of the permanent magnet structure are reduced, and the phenomenon of excessive compensation is prevented. Therefore, the permanent magnet provided by the invention can generate a magnetic field with high magnetic field intensity and high uniformity in a miniaturized instrument.

Owner:NORTHEAST DIANLI UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com