Integrated shell sound absorption unit for rail transit sound barrier

An integrated technology for rail transit, applied in the field of integrated shell sound-absorbing units for rail transit sound barriers, can solve the problems of poor reliability of riveted connectors, affecting landscape effects, and easy falling off of connectors, and achieves wind load resistance. Strong, sound absorption and sound insulation performance, the effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the embodiments and the drawings. It should be pointed out that the described embodiments are only intended to facilitate the understanding of the present invention and do not have any limiting effect on it.

[0031] Existing metal sound barrier sound-absorbing panels are divided into panels, back panels, or end caps. The panels, back panels or end caps are assembled separately, and there are problems such as easy parts falling off, environmental protection and durability of painting, and difficulty in assembly; The sound absorption unit of concrete sound barrier has problems such as the inertia effect and heavy weight of concrete materials. Based on the defects of the prior art, a technical solution of the integrated shell sound absorption unit for rail traffic sound barriers of the present invention is developed.

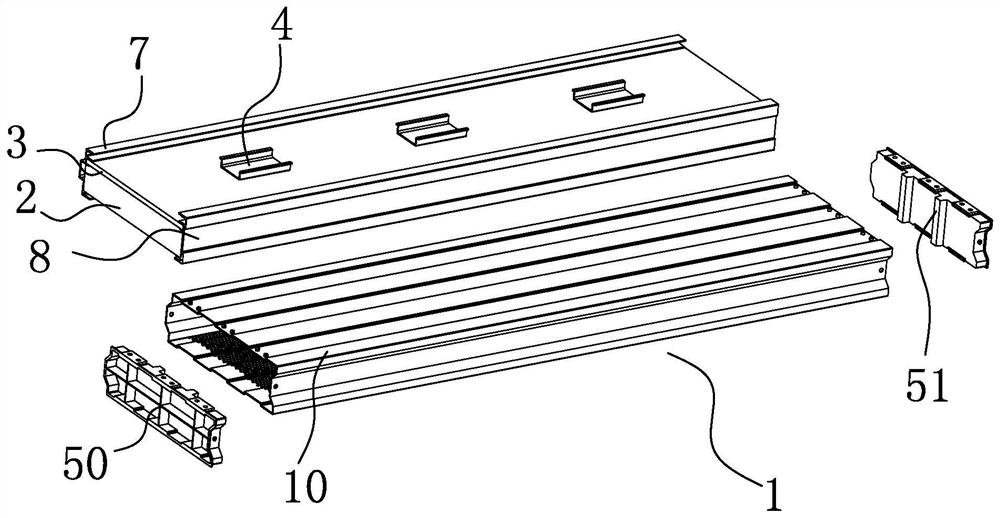

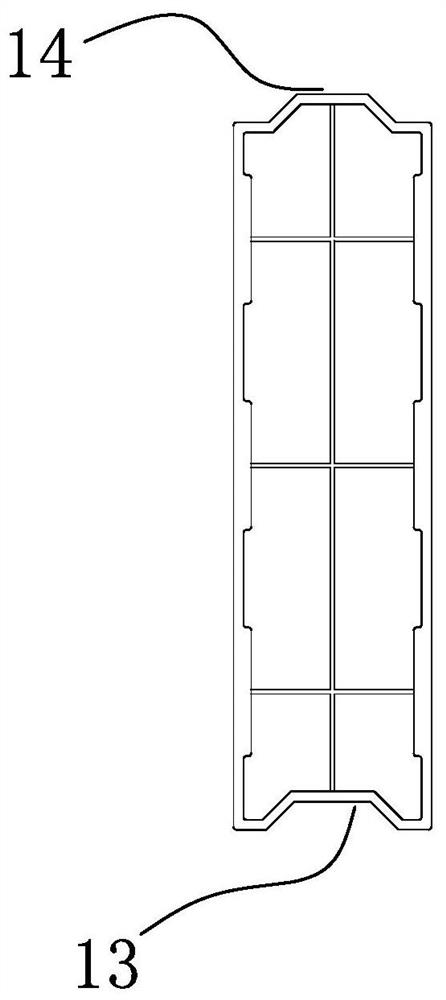

[0032] See figure 1 with figure 2 As shown, this embodiment provides an integrated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com