Connection joint structure of multi-coupled steel component

A technology for connecting nodes and steel components, used in building structures, buildings, etc., can solve the problems of low strength at the connection between high-strength steel components and cast steel parts, low strength of cast steel parts, and long processing cycles, and achieve weight reduction. , shorten the processing cycle, improve the effect of local stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

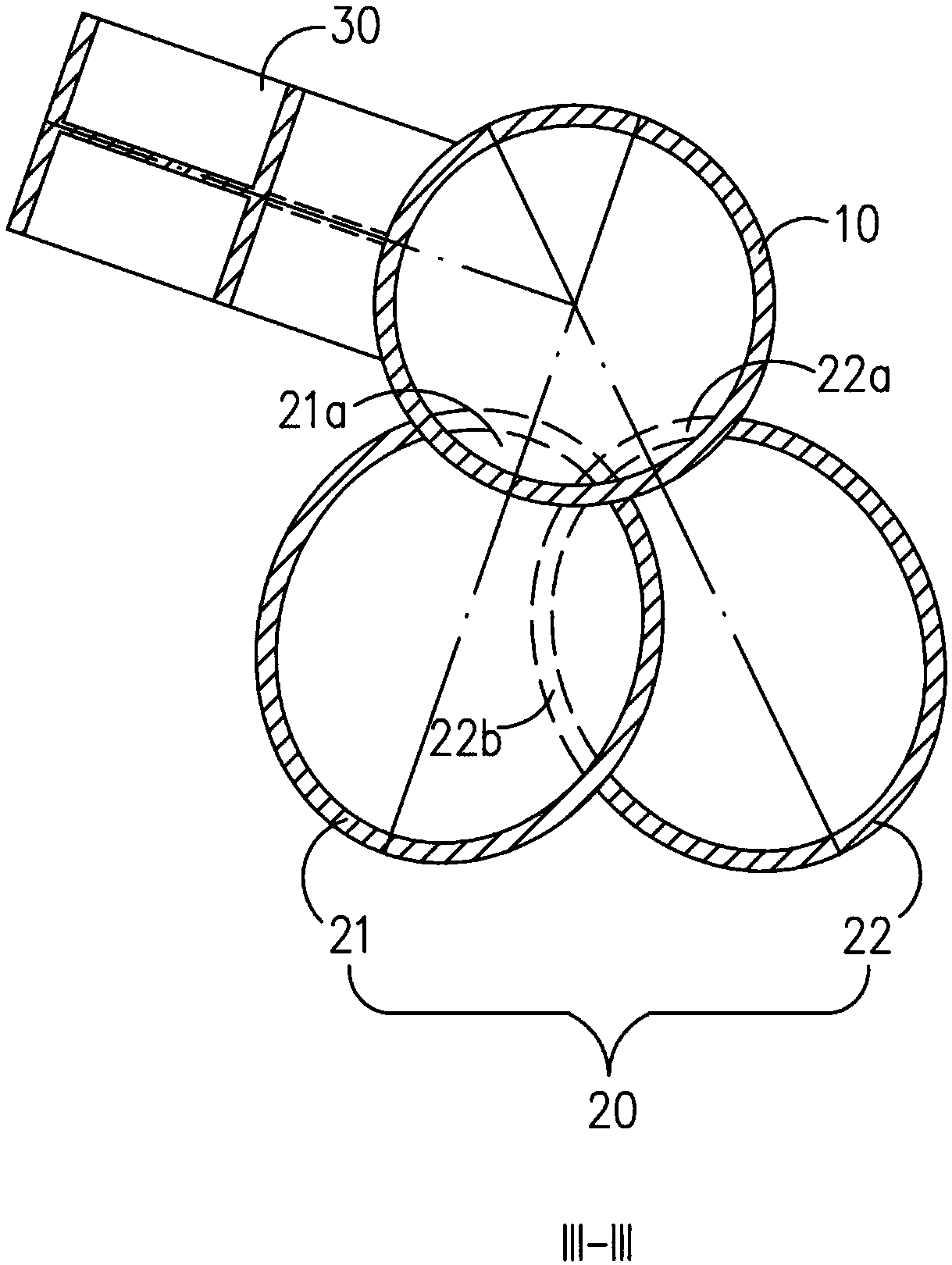

[0059] Please also see Figure 1 to Figure 3 , is a structural schematic diagram of the connection node structure of the multi-joint steel member provided by the embodiment of the present invention. The connection node structure 100 of the multi-joint steel member provided by the embodiment of the present invention includes a main member 10 and several connection members 20, the main member 10 is a hollow tubular structure, and the main member 10 is provided with a connection node area 11, and the connection node area 11 is provided with a steel pipe 111 in the node area, the steel pipe 111 in the node area is connected to the main component 10, and the wall thickness of the steel tube 111 in the node area is greater than the wall thickness of the main component 10. The main component 10 is provided with a plurality of first inner reinforcing ring plates 12 , and each first inner reinforcing ring plate 12 is arranged at intervals along the height direction of the main componen...

Embodiment 2

[0086] Please also refer to Figure 4 to Figure 7 , is a schematic diagram of the connection node structure of the multi-joint steel member provided by Embodiment 2 of the present invention. The difference between the connection node structure 200 of the multi-joint steel member provided by the second embodiment of the present invention and the connection node structure 100 of the multi-joint steel member provided by the first embodiment of the present invention is that:

[0087] The main component 10 is a vertically arranged straight pipe, including a first part 201 and a second part 202 arranged coaxially, and the second part 202 includes a first connecting part 202a and a second connecting part 202b arranged oppositely, the first The connecting portion 202a is located in the first portion 201 , and the second connecting portion 202b protrudes out of the first portion 201 . That is, the outer diameter of the first part 201 is larger than the outer diameter of the second par...

Embodiment 3

[0104] Please also refer to Figure 9 to Figure 11 , is a schematic diagram of the connection node structure of the multi-joint steel member provided by Embodiment 3 of the present invention. The difference between the connection node structure 300 of the multi-joint steel member provided in Embodiment 3 of the present invention and the connection node structure 200 of the multi-joint steel member in Embodiment 2 of the present invention is that:

[0105] In this embodiment, the main component 10 is a straight pipe arranged vertically, including a first part 301 and a second part 302 coaxially arranged, the second part 302 is connected with the first part 301, and the second part 302 is located at The first part is 301 outside. Specifically, the second part 302 includes a first connecting part 302a and a second connecting part 302b oppositely arranged, the first connecting part 302a is connected between the first part 301 and the second connecting part 302b, and the second co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com