A Pre-tensioned Prestressed Reinforced Concrete Prefabricated Beam

A technology of prestressed steel bars and prestressed steel strands, which is applied in the field of pretensioned prestressed prefabricated concrete beams, can solve the problems that the effect is not fully exerted, the anti-arching of prestressed tendons is large, and the construction cost is increased, so as to reduce scaffolding Cost, increased beam width, and reduced structural cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

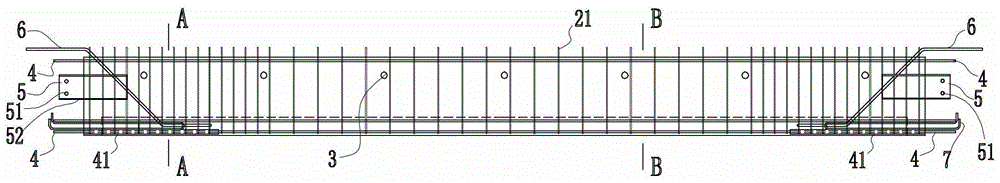

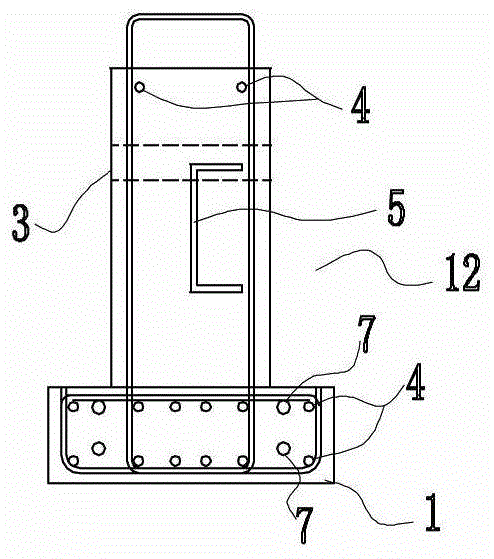

[0022] see Figure 1 to Figure 5 , in the embodiment of a pre-tensioned prestressed reinforced concrete prefabricated beam given in the present invention, the beam body is an inverted T-shaped structure composed of a horizontal rectangular compression part 1 and a vertical rectangular shear part 2, and the vertical The rectangular shear part 2 is provided with a stirrup 21, and the part of the stirrup 21 protrudes from the upper surface of the shear part 2, and the horizontal rectangular compression part is also provided with a stirrup 12, and the steel strand 4 is longitudinally Embedded in the concrete of the compression part 1 . The beam body in the present invention is designed as a structure composed of the compression part 1 and the shear part 2. This structure can well solve the problem that the concrete compression resistance and the shear resistance do not match in the existing beam body, so that the beam body The structure is more reasonable and the mechanical perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com