Connection structure of connection of floor beam and steel pipe concrece pole and construction method thereof

A technology for concrete-filled steel tubular columns and concrete beams, which is applied to structural elements, building components, building structures, etc., can solve the problems of difficult alignment of upper and lower columns, increased structural self-weight, limited stiffness of nodes, etc., and avoids the alignment problem of upper and lower steel pipes. , Reduce the cost of the structure, the effect of small welding workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

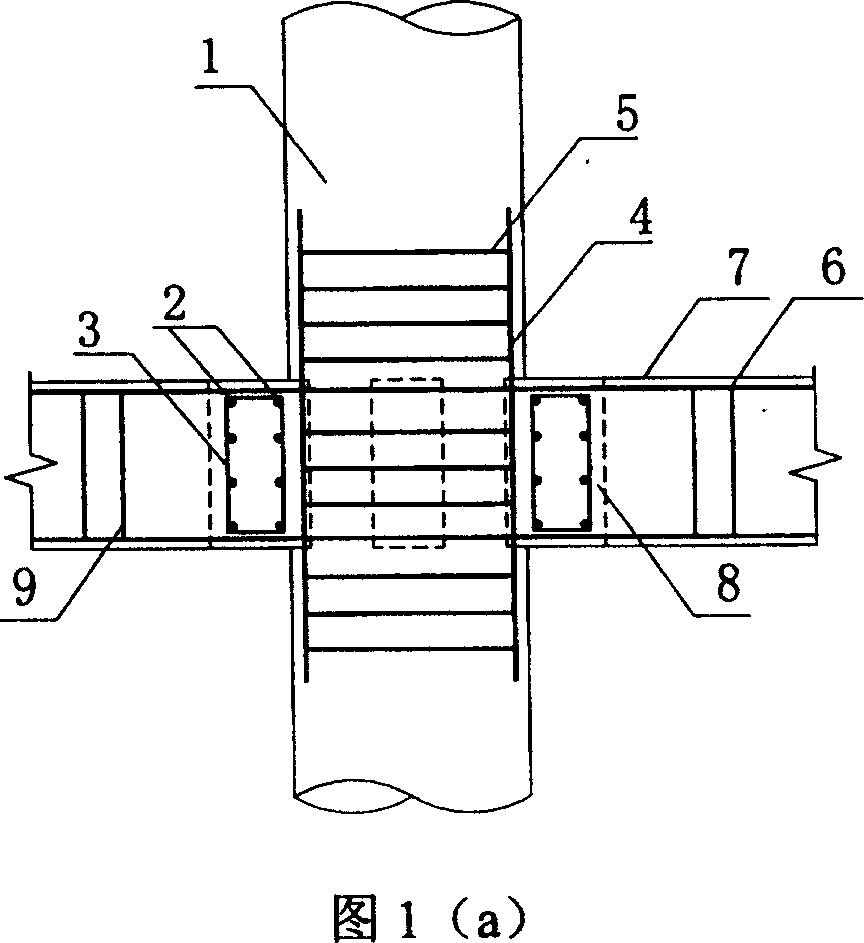

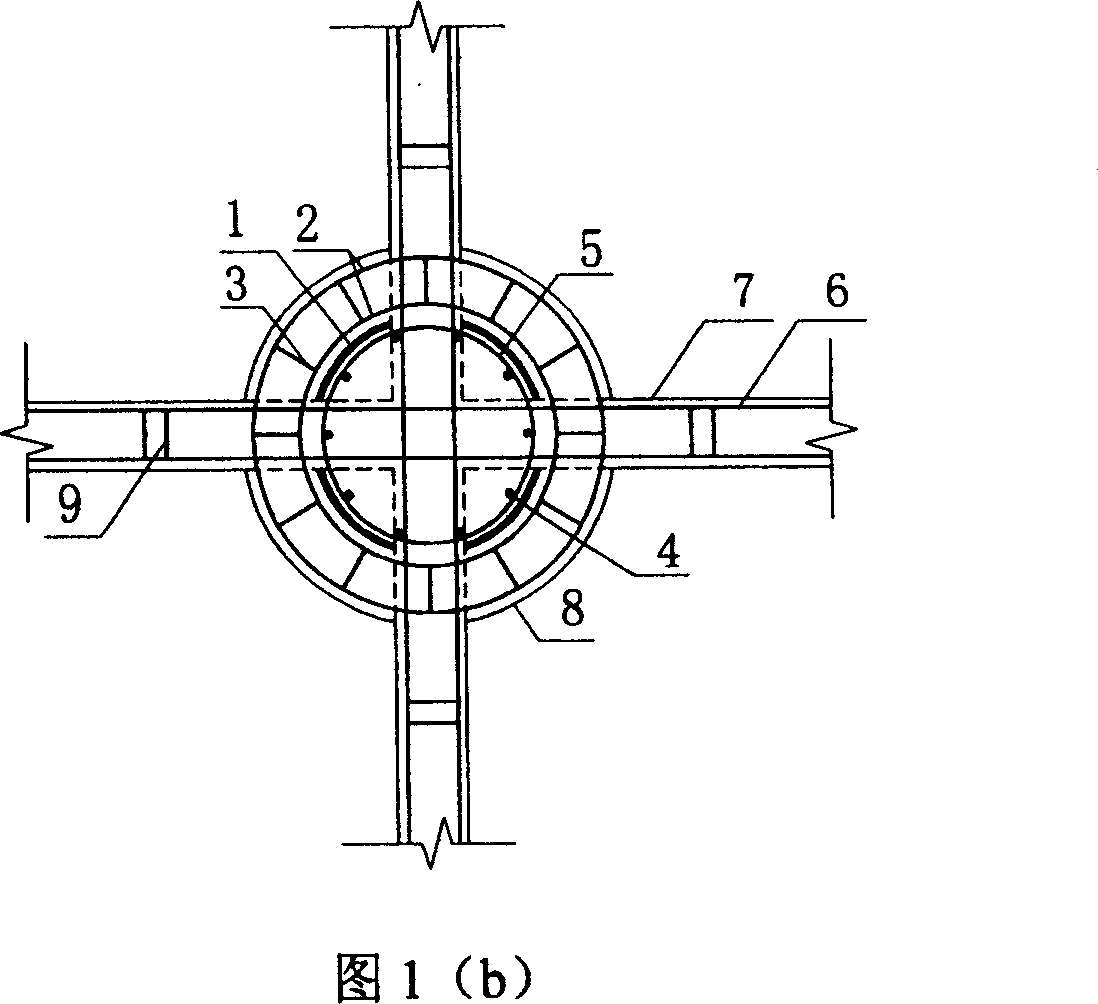

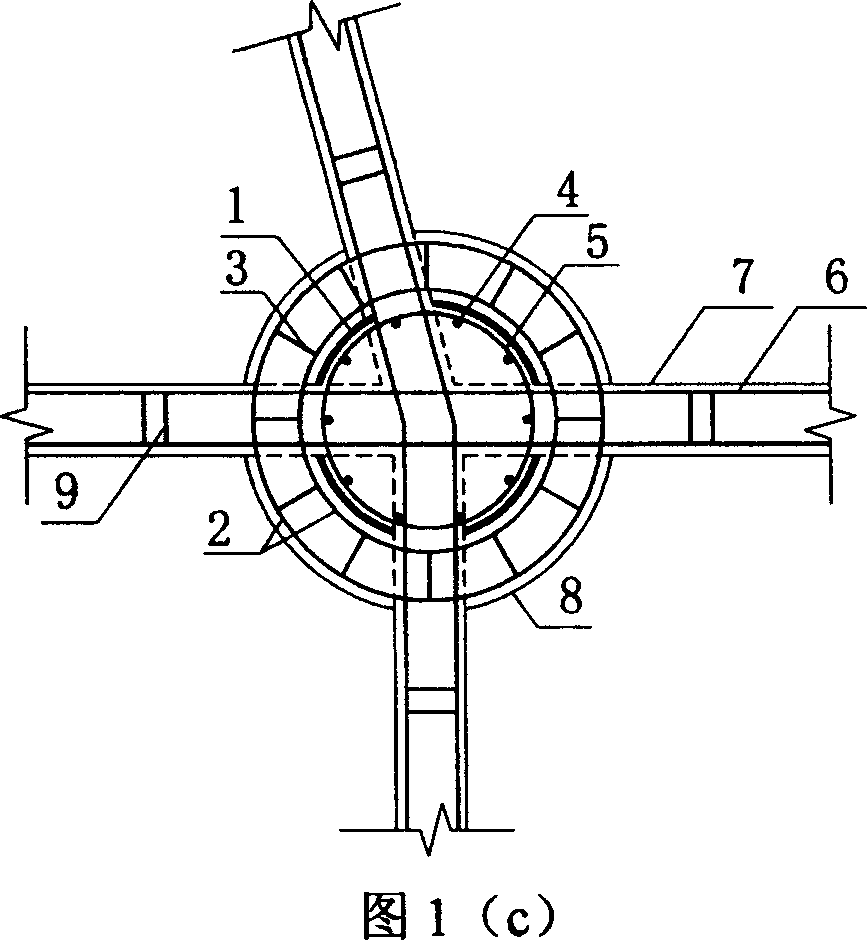

[0040] The present invention will be further described below in conjunction with accompanying drawing.

[0041] The flow chart of the construction method of the joint structure of the steel pipe concrete column and the floor beam connection of the present invention is as shown in Figure 2, and the construction steps are as follows:

[0042] ① Hoist the single-layer or multi-layer steel pipe column to the column positioning position of the construction plane;

[0043] ② Hoist the reinforcement cage to the inner node position of the steel pipe and fix it;

[0044] ③ placing the steel skeleton of the annular concrete beam 8 bound on the open space in the formwork of the annular concrete beam 8;

[0045] ④ Pass the beam longitudinal reinforcement 6 of the floor beam 7 through the node area, bind the beam stirrup 9, and set a steel wire mesh at the opening of the steel pipe to prevent the concrete from flowing out of the node area;

[0046] ⑤Pour concrete into the steel pipe colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com