Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Reduce pollution area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

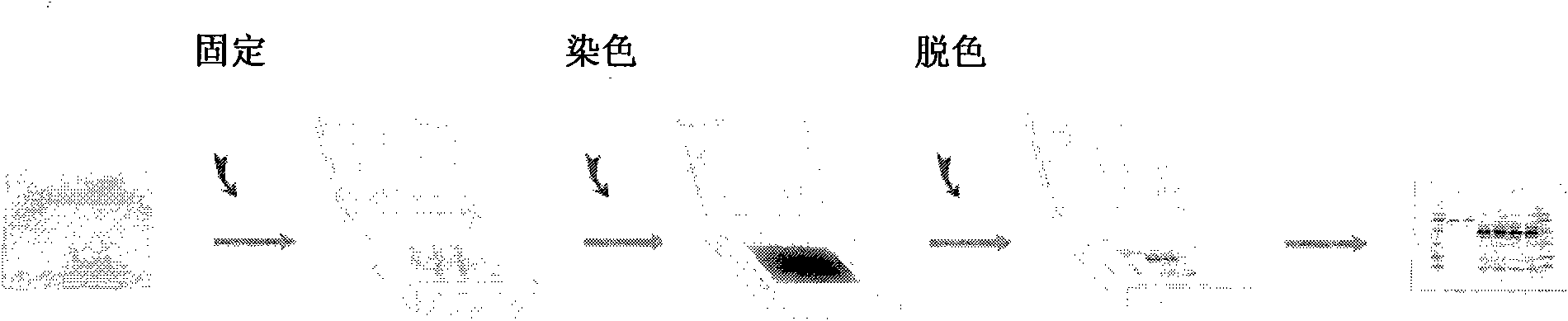

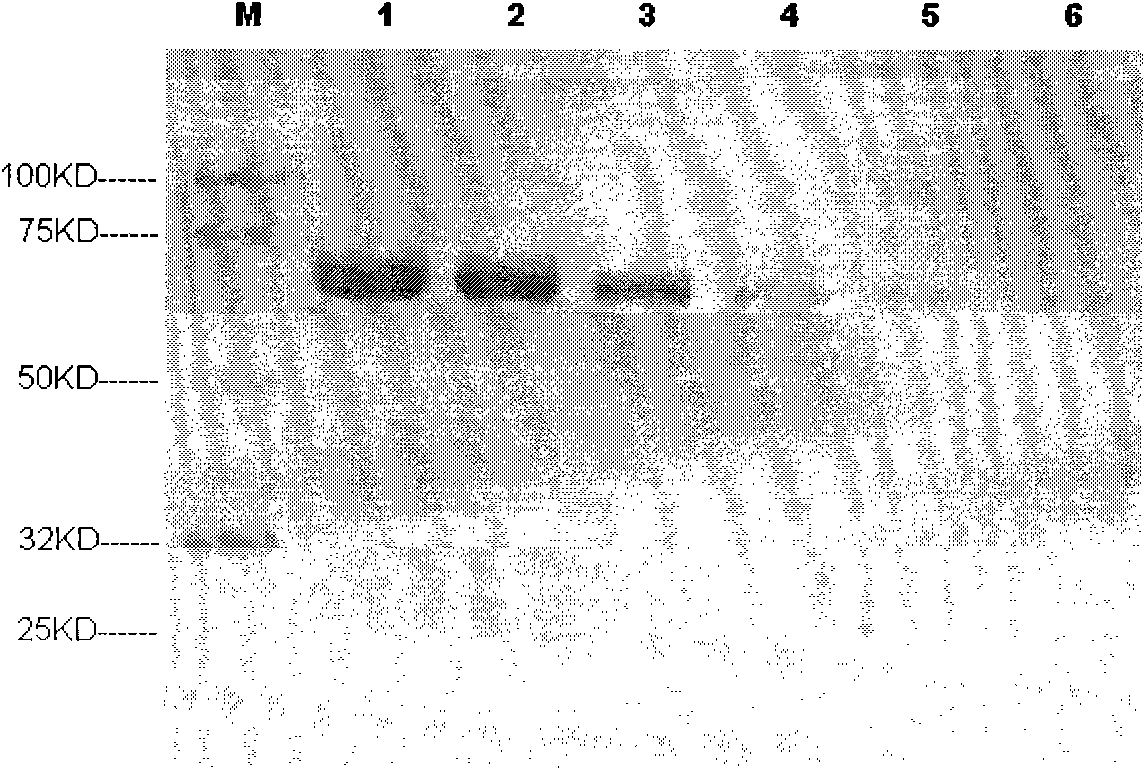

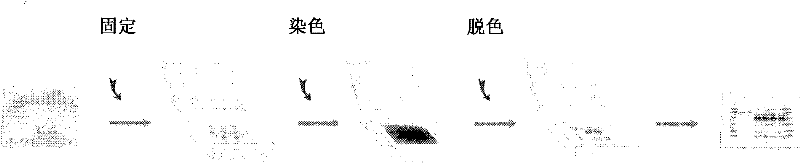

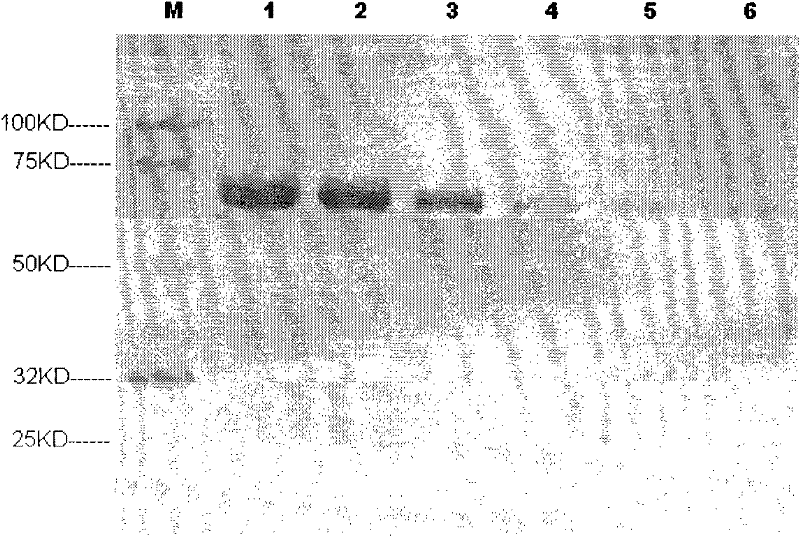

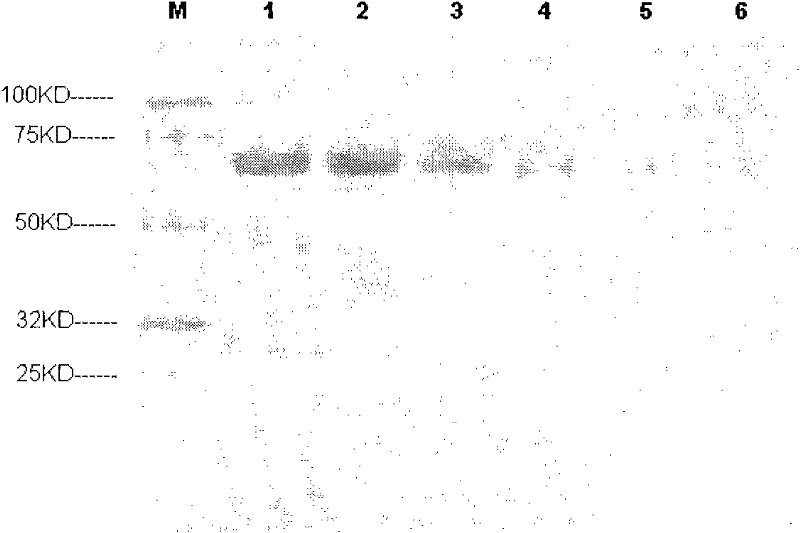

Rapid staining method for biopolymers

ActiveCN101936837AShorten the timeLow costPreparing sample for investigationMaterial analysis by electric/magnetic meansBiopolymerComputer science

The invention belongs to the field of biotechnology, and discloses a rapid staining method for biopolymers. The rapid staining method comprises the steps of: combination of stain and a to-be-stained biopolymer, separation of uncombined stain and a biopolymer combined with the stain, and imaging of the biopolymer combined with the stain. The rapid staining method enables the stain to rapidly combine with the biopolymer through utilizing different mobilities of the stain and the biopolymer in a medium applied with an electric field, and can rapidly separate the uncombined stain and the biopolymer combined with the stain, shorten the whole staining time, save the cost, is simple to operate as the staining, destaining and color development can be finished in one step, and can combine the separation step and the staining step of the biopolymer together.

Owner:NANJING GENSCRIPT BIOTECH CO LTD

Biological cement reinforced roadbed on under-consolidation silt blowing foundation and construction method of roadbed

PendingCN109736291AImprove carrying capacityReduce load capacitySoil preservationCrushed stoneEngineering

The invention belongs to the field of soft soil foundation treatment, and relates to a biological cement reinforced roadbed on an under-consolidation silt blowing foundation and a construction method.Grille gravel piles in the roadbed penetrate through the under-consolidation silt blowing foundation and are embedded into a lower horizontal bearing layer. A plastic drainage plate is driven into the under-consolidation silt blowing foundation. A biological cement-grille reinforced cushion layer is flatly paved on the upper surface of the grille gravel piles. Non-woven geotextiles are laid on the upper surface and the lower surface of the biological cement-grille reinforced cushion layer. The non-woven geotextiles and a sealing film are sealed at the bottom of a tamped clay sealing ditch. Roadbed filling soil is packed on the upper surface of the biological cement-grille reinforced cushion layer and on the non-woven geotextile. Biological waterproof layers are arranged on the upper surface and the side surface of the roadbed filling soil. A soil layer is arranged on the biological waterproof layer on the roadbed side face, and slope protection vegetation is planted to form a roadbedslope ecological waterproof protection layer. The roadbed has the advantages of being reasonable in structure, high in bearing capacity, short in construction period, environmentally friendly and thelike, and is a green ecological structure worthy of popularization.

Owner:HUAZHONG UNIV OF SCI & TECH

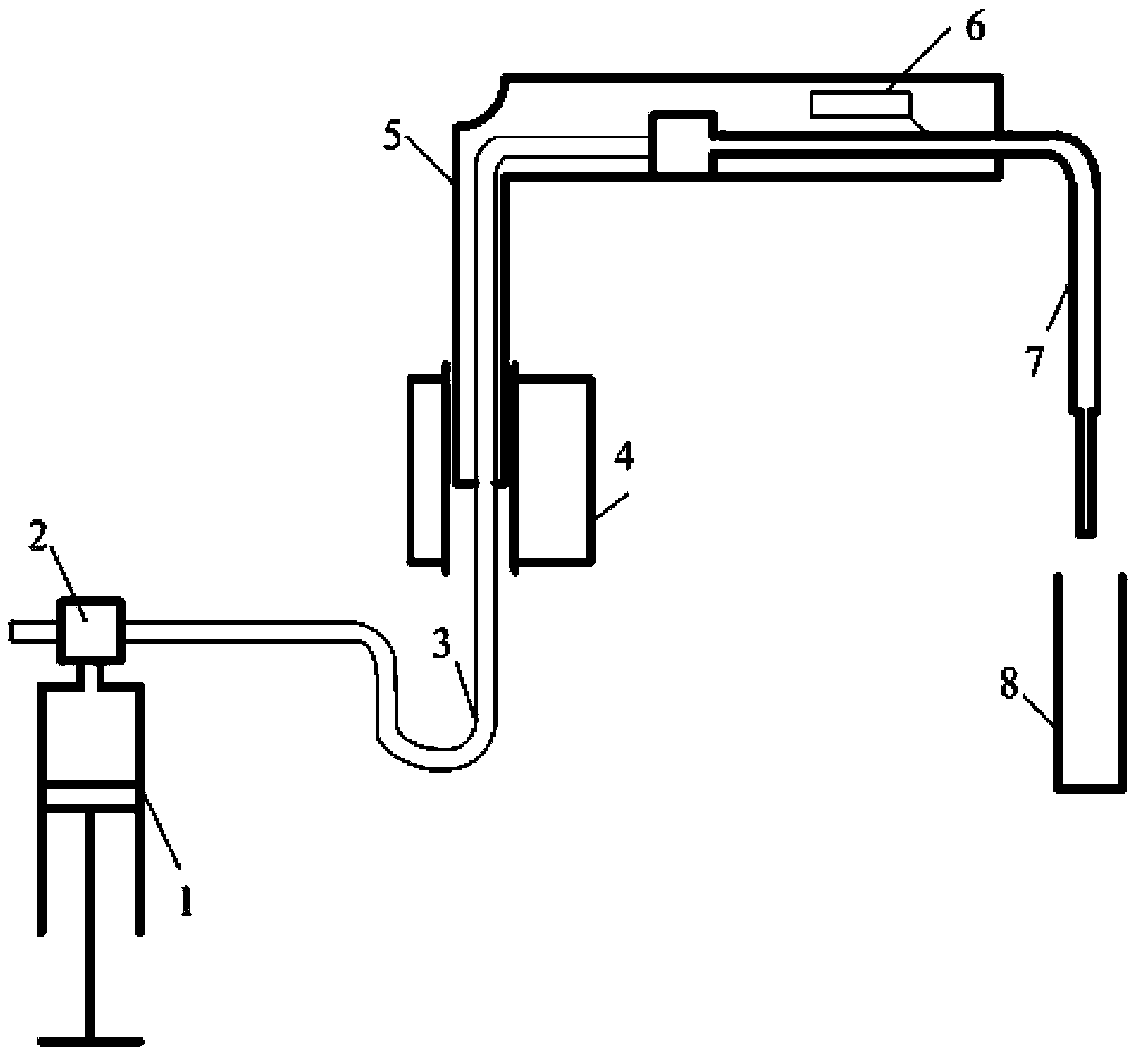

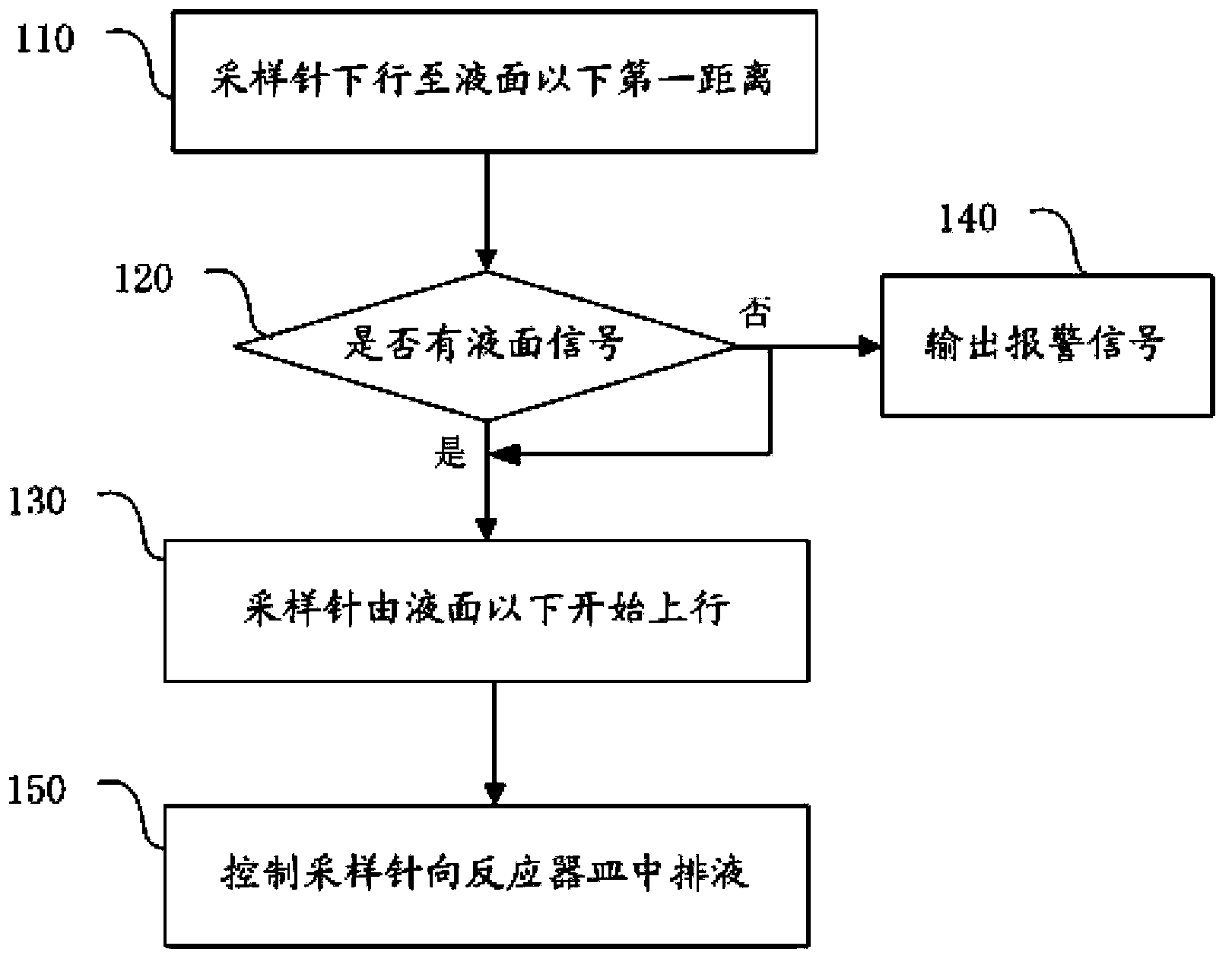

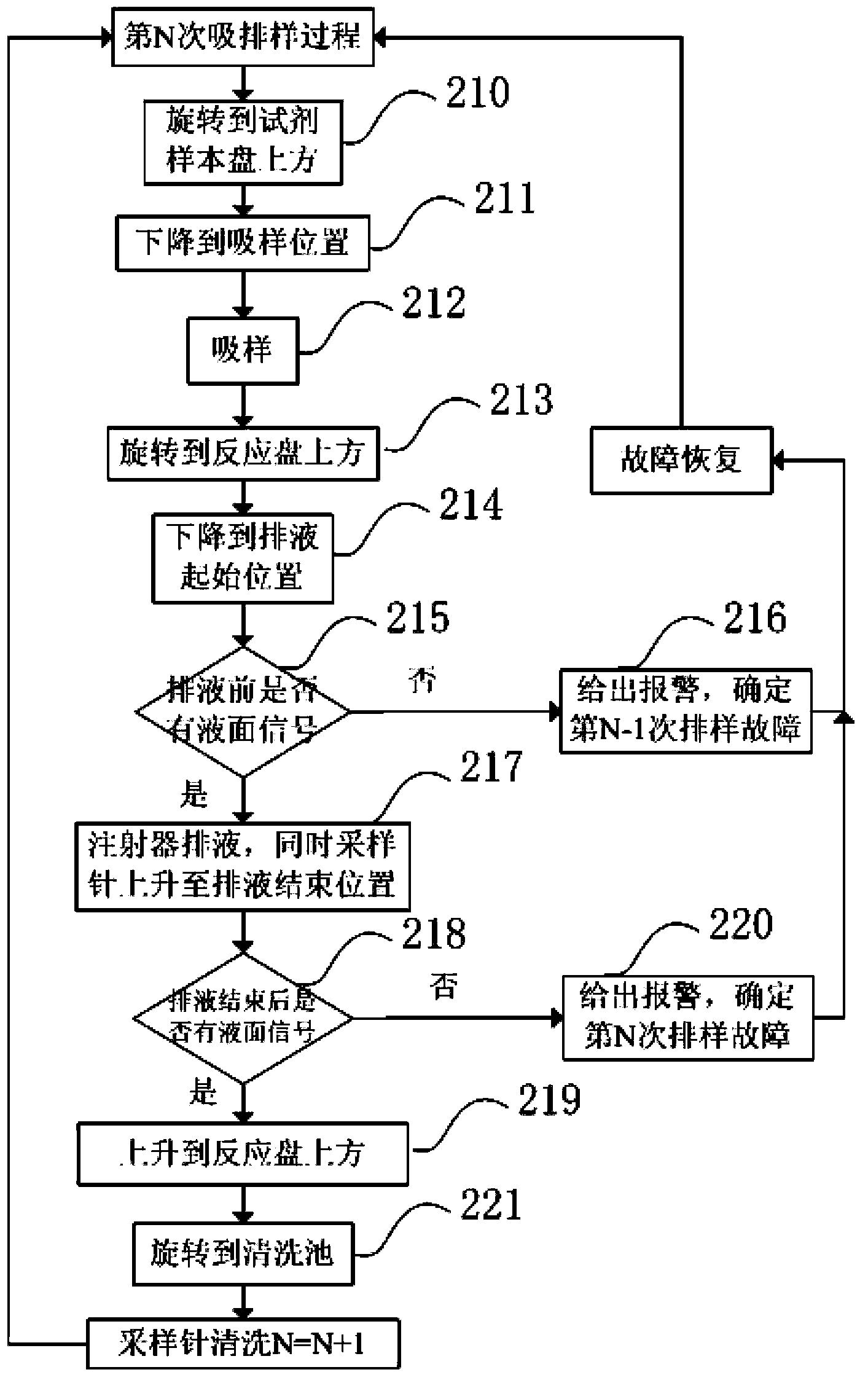

Sample analyser and method and device for detecting liquor drainage of sampling needle

ActiveCN103900997AReduce pollution areaDetection speedPreparing sample for investigationTransmissivity measurementsAnalyserEnvironmental geology

The invention discloses a sample analyser and a method and device for detecting liquor drainage of a sampling needle. The method comprises the following steps: firstly, controlling the sampling needle to move downwards to a first distance below the liquid level of reaction liquid in a reaction vessel when the sampling needle discharges liquid; confirming a liquid level signal, and then controlling the sampling needle to move upwards for a second distance from the first distance below the liquid level; controlling the sampling needle to discharge liquid to the reaction vessel in the process of controlling the sampling needle to move upwards for the second distance, or controlling the sampling needle to discharge liquid to the reaction vessel after controlling the sampling needle to move upwards for the second distance and stopping moving. The sampling needle is controlled to move upwards after the first liquor drainage is confirmed to be correct, and discharges liquor in the process of moving upwards or after moving upwards to a preset position and stopping moving. Thus, the sampling needle can be prevented from being excessively immersed into the reaction liquid after liquid is discharged, and the area of the polluted outer wall of the sampling needle is reduced.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

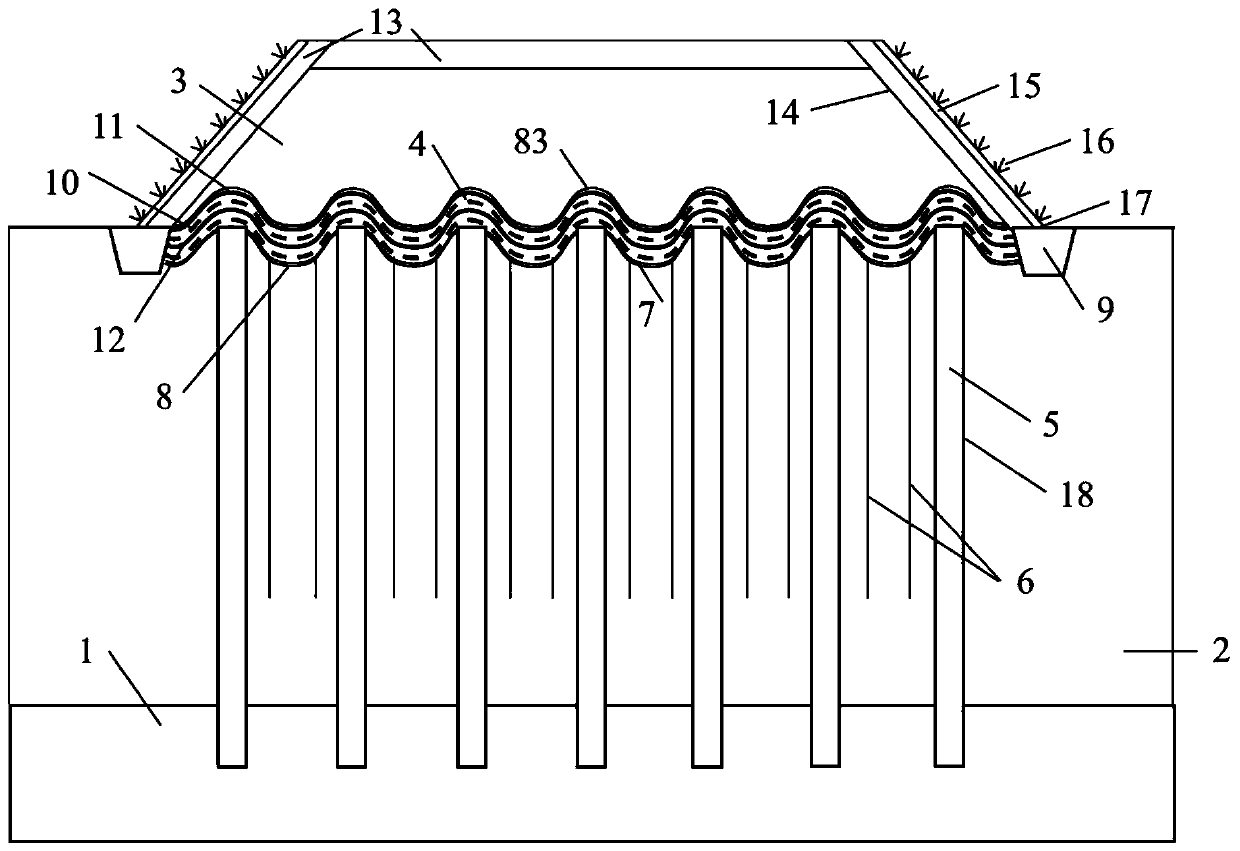

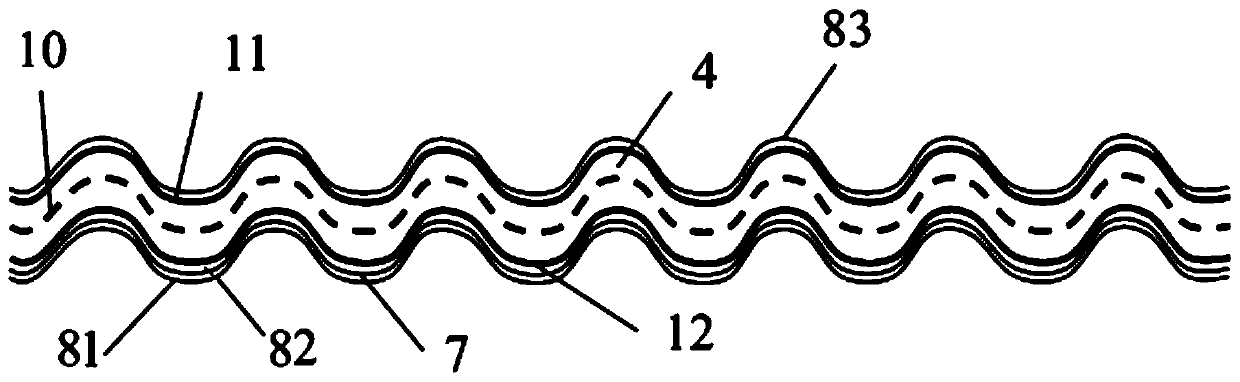

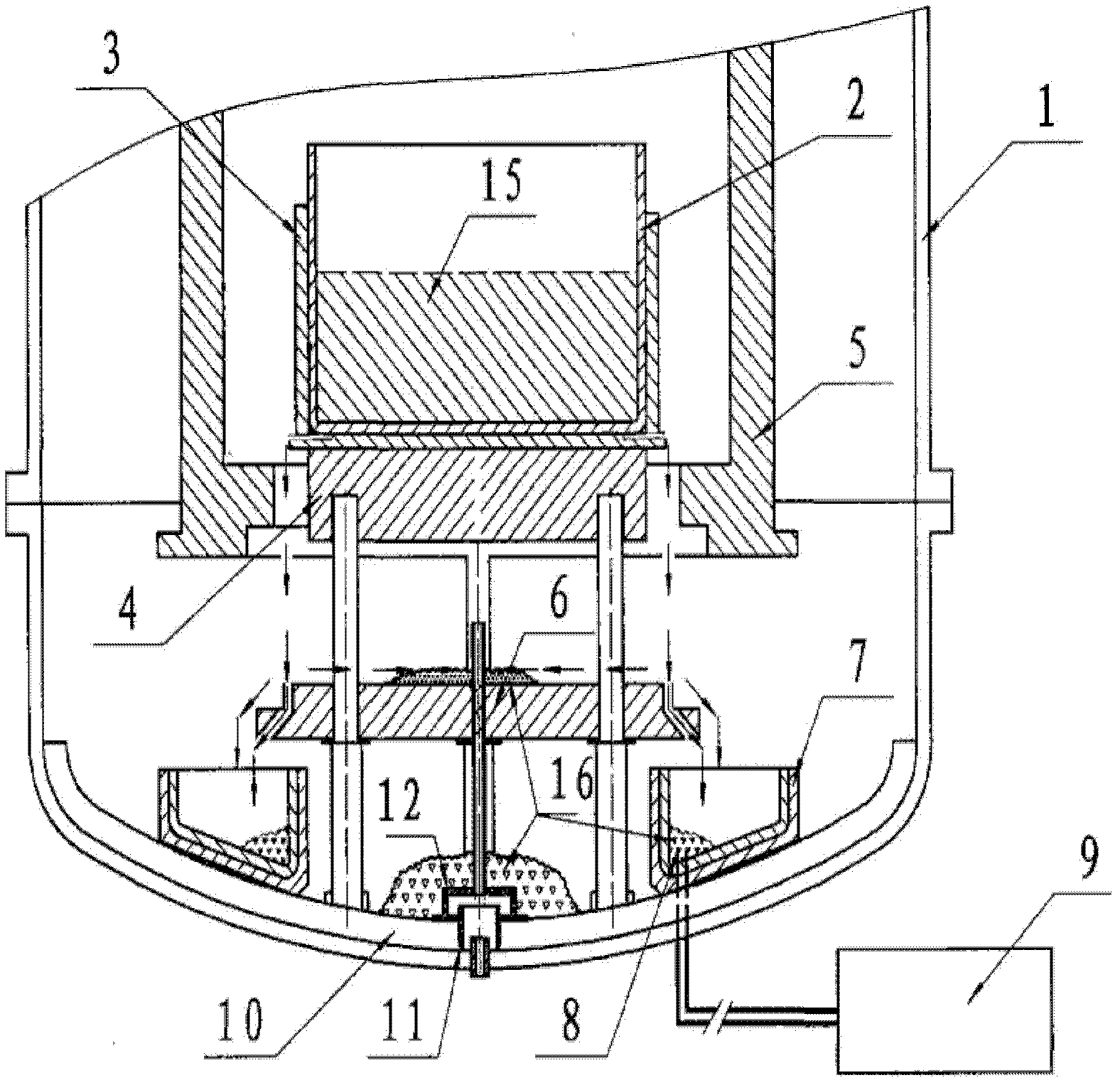

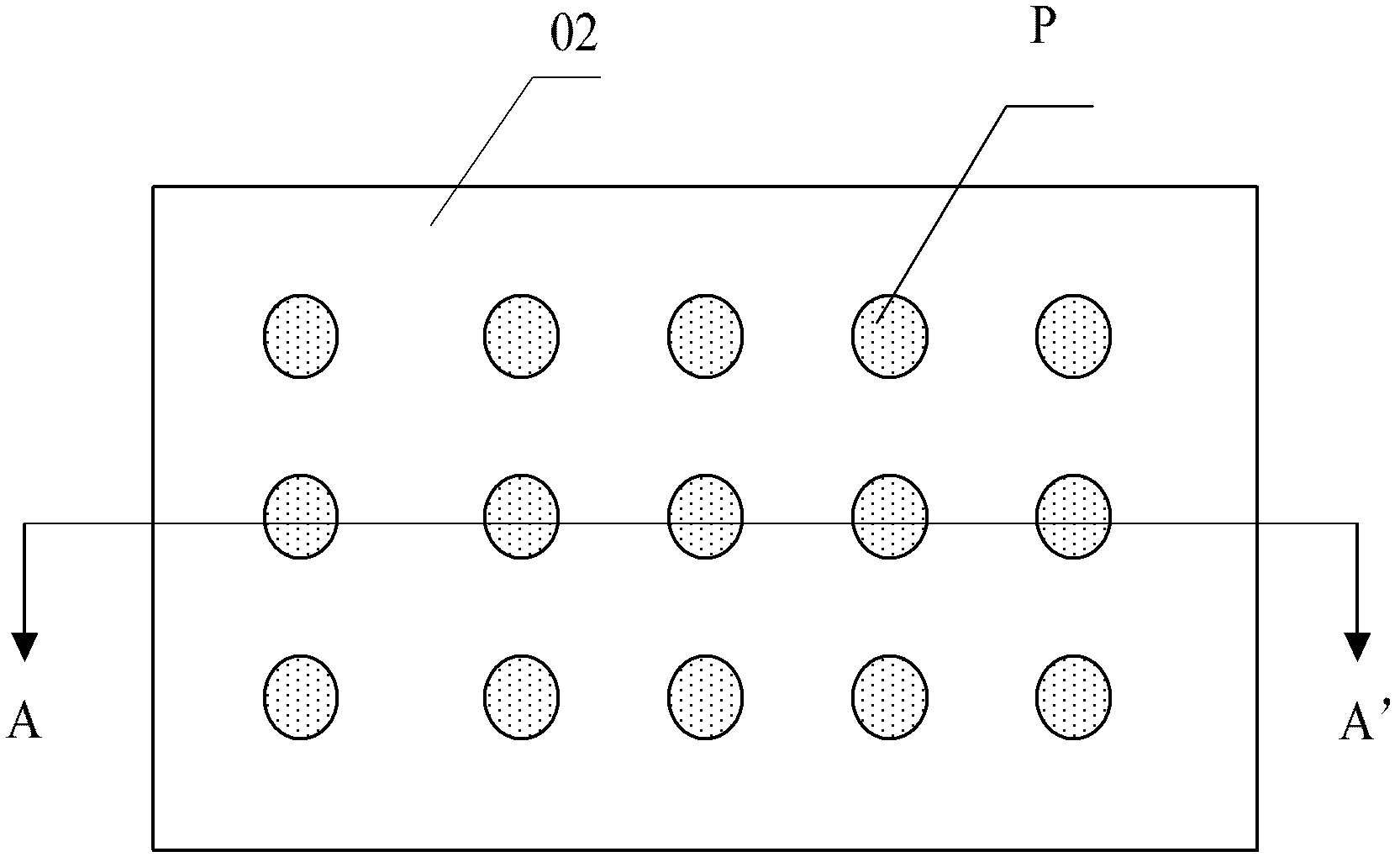

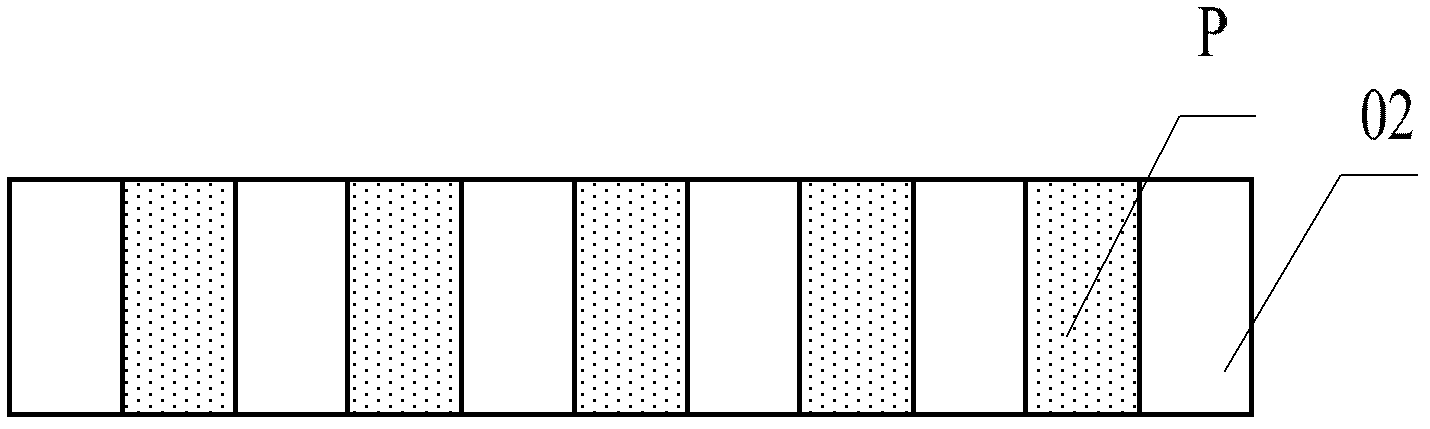

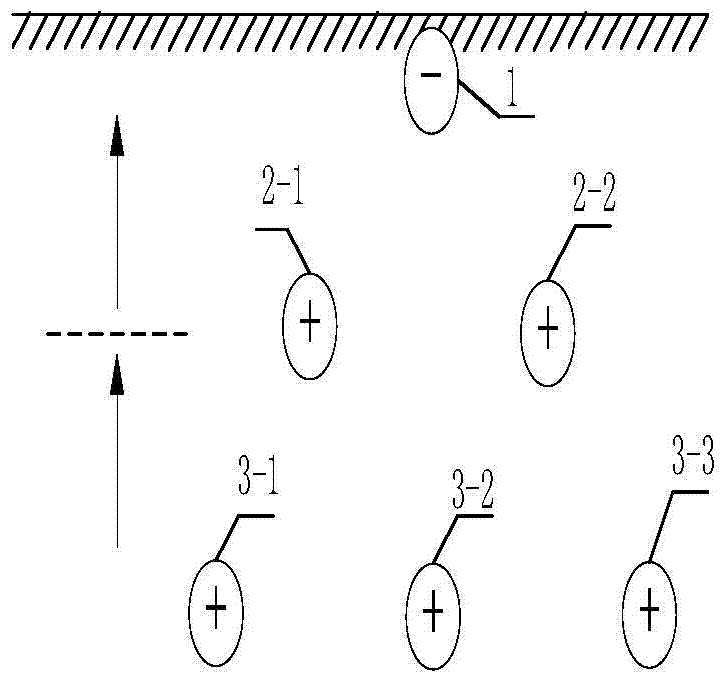

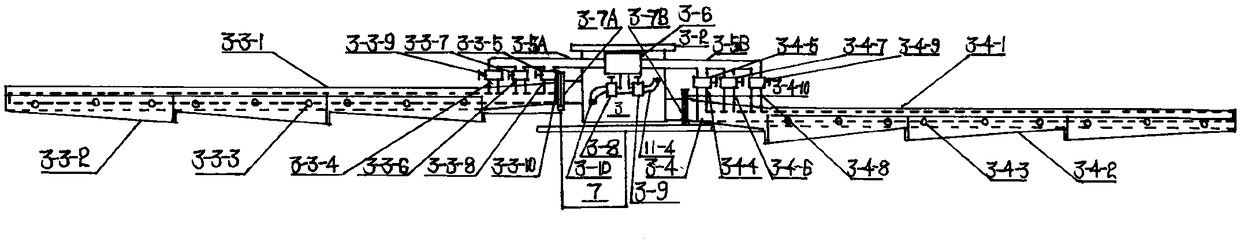

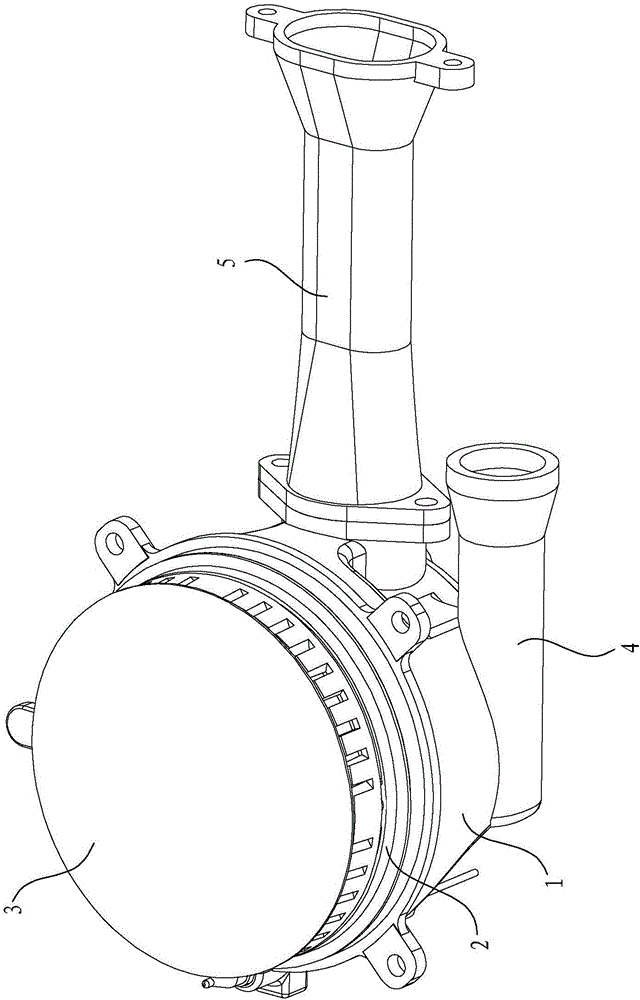

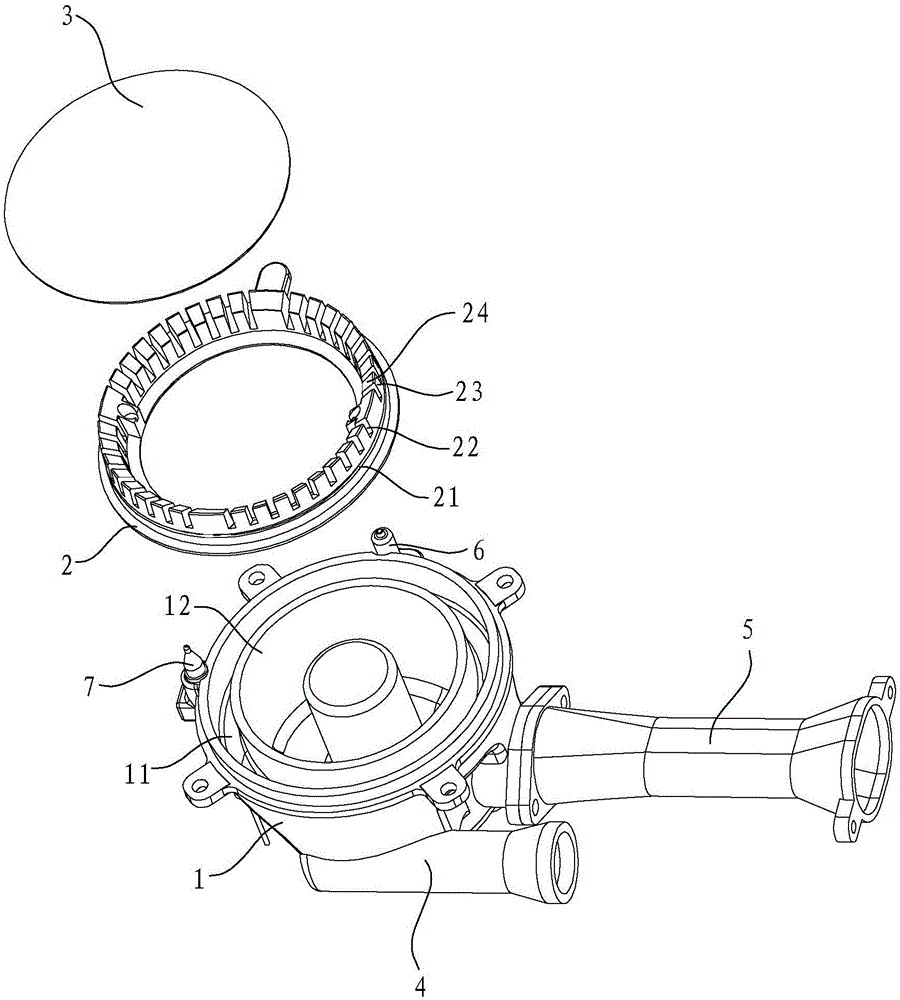

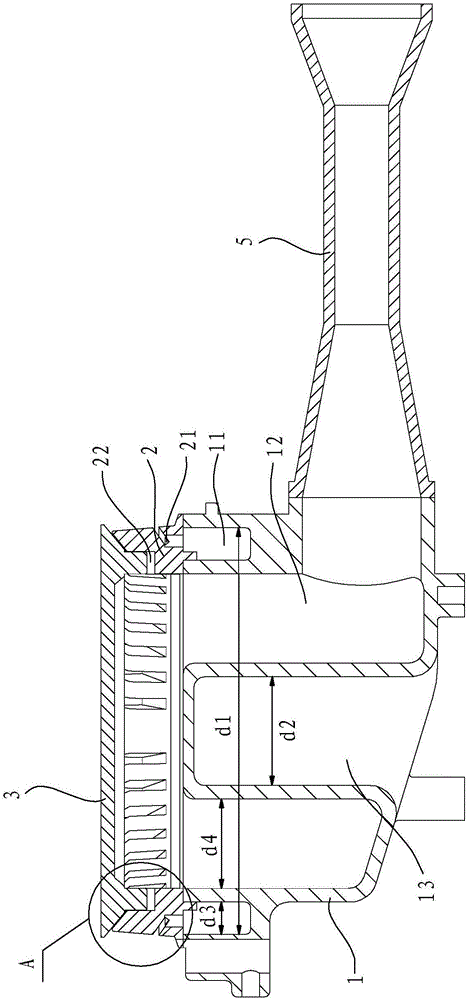

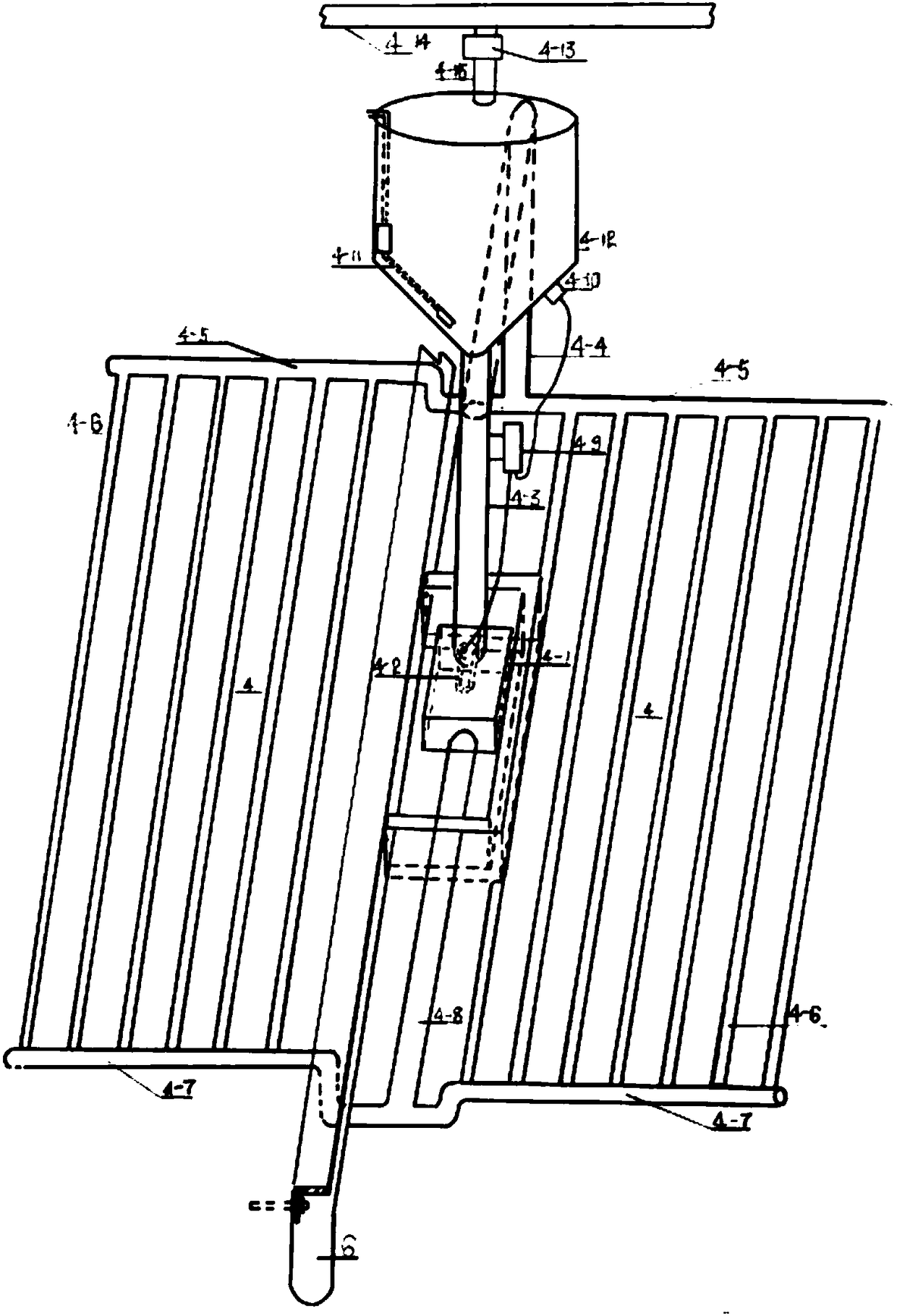

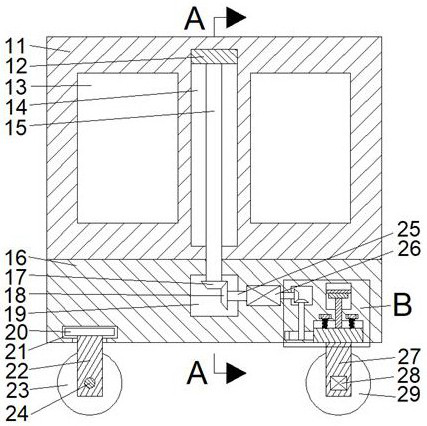

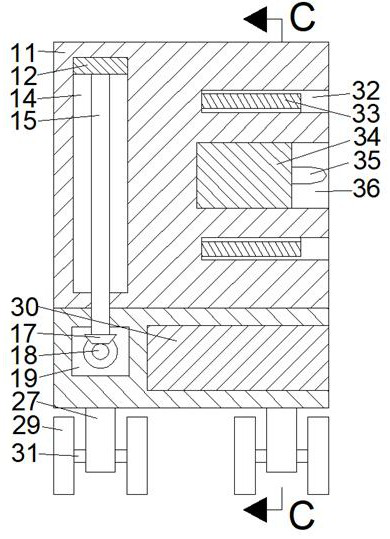

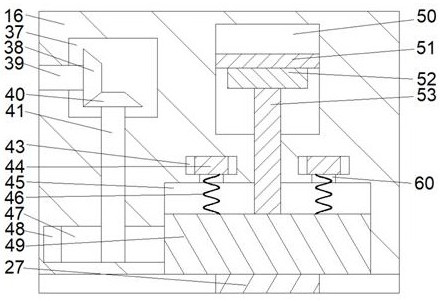

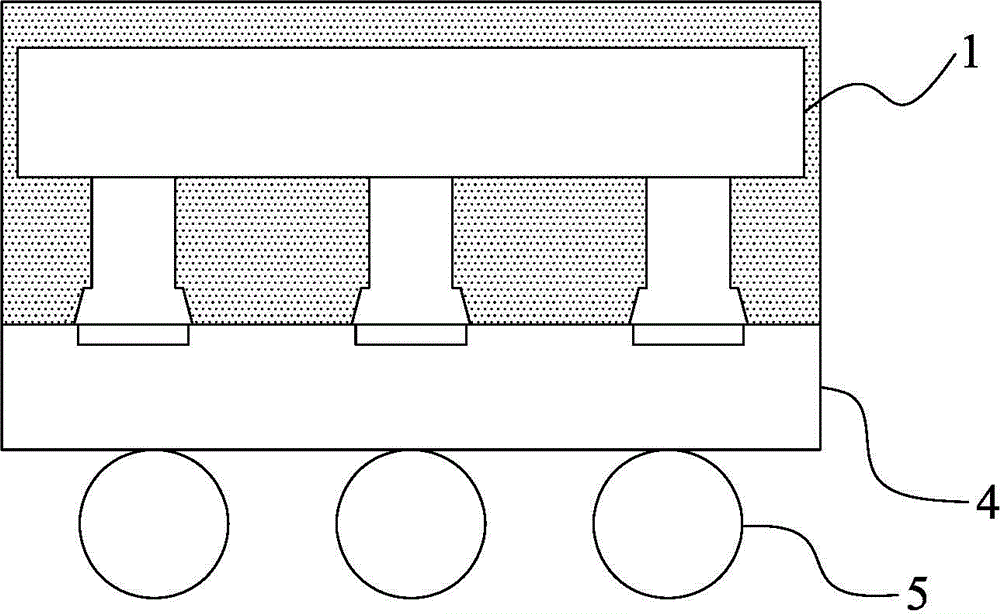

Crystalline silicon ingot casting furnace

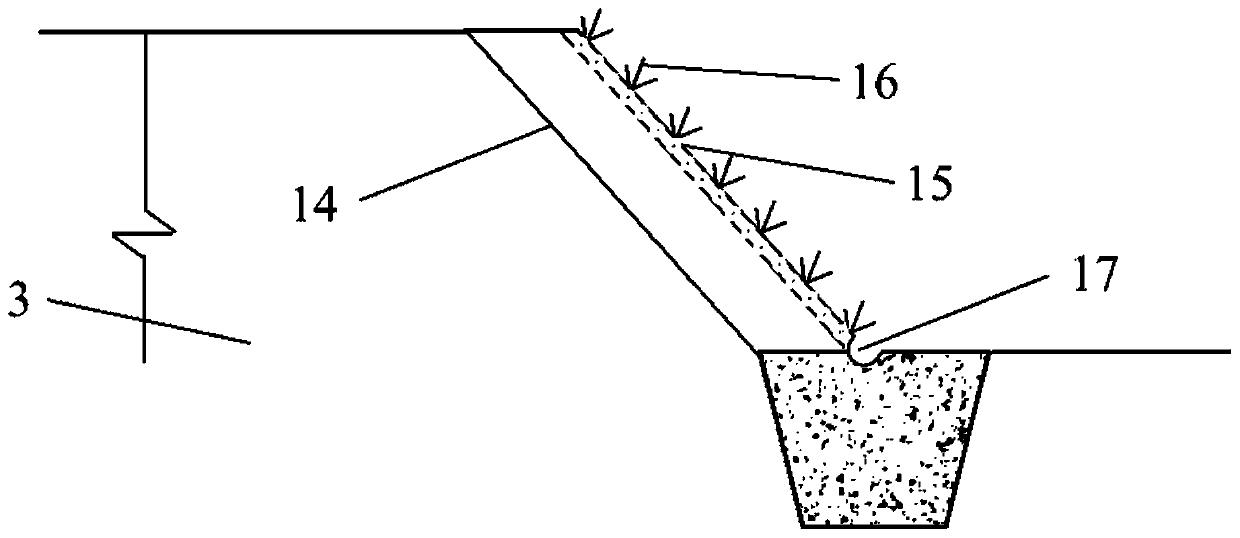

ActiveCN102383183ASingle pathReduce pollution areaPolycrystalline material growthFrom frozen solutionsCrystalline siliconCrucible

The embodiment of the invention discloses a crystalline silicon ingot casting furnace. The ingot casting furnace comprises a furnace body, a crucible, a crucible bottom plate, a cooling block, a flow guide pipe and a silicon liquid overflow detection wire, wherein the crucible is arranged in the furnace body; the crucible bottom plate is arranged below the bottom of the crucible; a plurality of flow guide holes are formed on the crucible bottom plate and pass through the crucible bottom plate; the cooling block is positioned below the crucible bottom plate; at least one flow guide groove is formed on the cooling block; the flow guide pipe is arranged below the cooling block; the flow guide groove is communicated with the flow guide holes and the flow guide pipe; the silicon liquid overflow detection wire is arranged at the upper end, near the cooling block, of a cavity channel of the flow guide pipe; and the silicon liquid overflow detection wire is connected with a silicon liquid overflow control device arranged outside the ingot casting furnace. According to the technical scheme, a silicon liquid overflow problem can be detected and solved timely; and the silicon liquid overflow route is single and controllable, the polluted area is small and the safety is high.

Owner:ADVANCED FOR MATERIALS & EQUIP

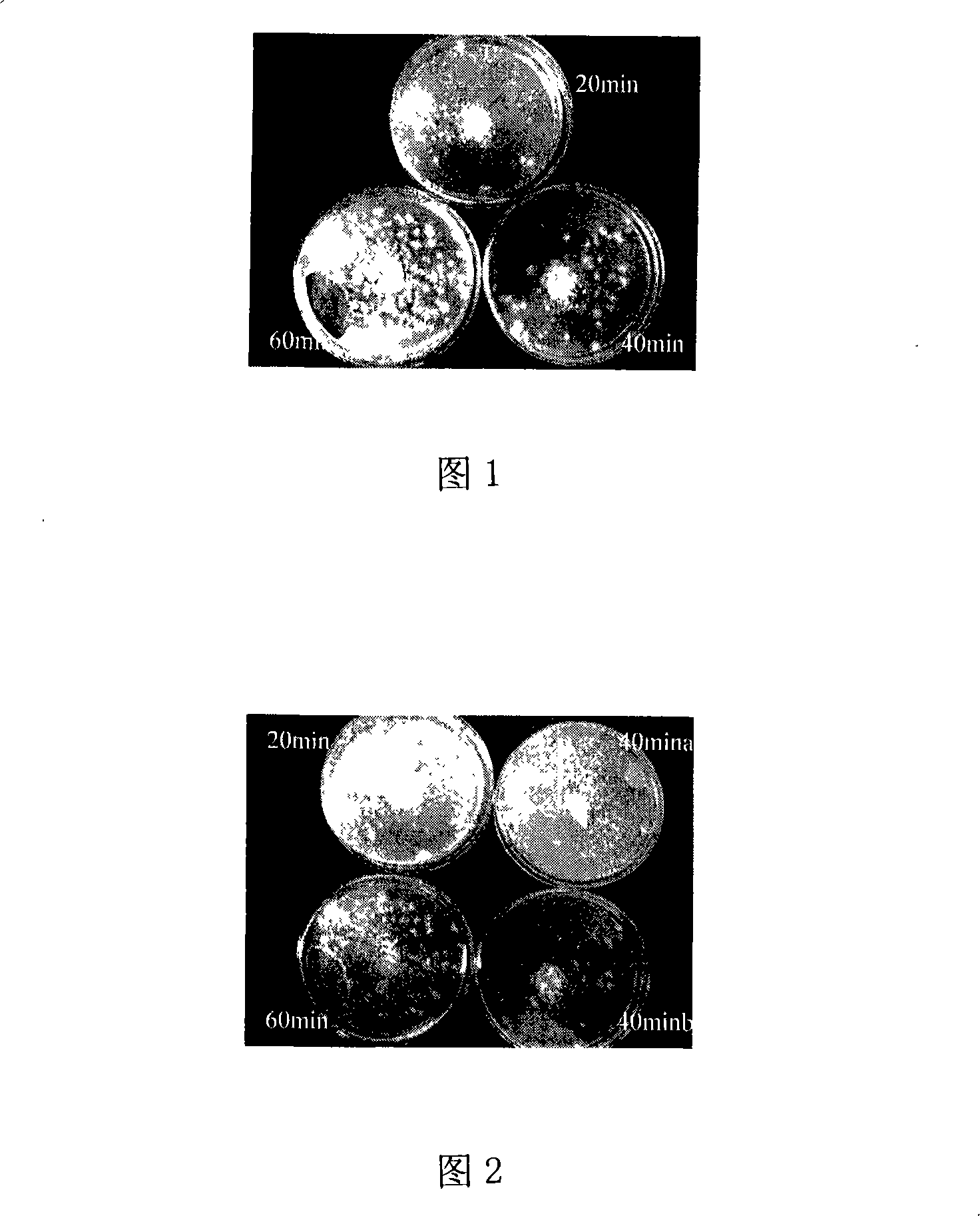

Filter paper sheet diaphragmatic foramen suspension spore ejection method

InactiveCN101220344AReduced Pollution ChancesReduce pollution areaSpore processesForamenSpore germination

The invention discloses a filter paper separated hole suspended spore ejection method, which firstly prepares a sterile potato culture medium slab with the thickness of 0.5cm and processes a sterile filter paper which is provided with a hole with the diameter of Phi 0.5 to 2 cm; then a culture dish cover is removed from a super clean workbench, and the sterile filter paper with the hole is arranged on a lower dish which is provided with the culture medium slab; a large-scale fungal sporophore block which is collected at the field is arranged on the filter paper hole of the sterile filter paper with the hole for still placement for 20 to 60min, then the filter paper and the sporophore are removed, the culture dish cover is covered, and a constant temperature culture is carried out after transferring the fungal sporophore block into a culture box at 22 - 26 DEG C; finally, the mycelia are selected after spore germination and transferred into the slope of a test tube for continual culture till the tube is full; the configuration identification is further carried out, so as to obtain a wild large-scale fungal pure culture. The invention has the advantages of reducing the opportunity of hybrid bacteria pollution, improving the success rate of the obtainment of large-scale fungal pure culture and having simplified operation.

Owner:JIANGXI AGRICULTURAL UNIVERSITY

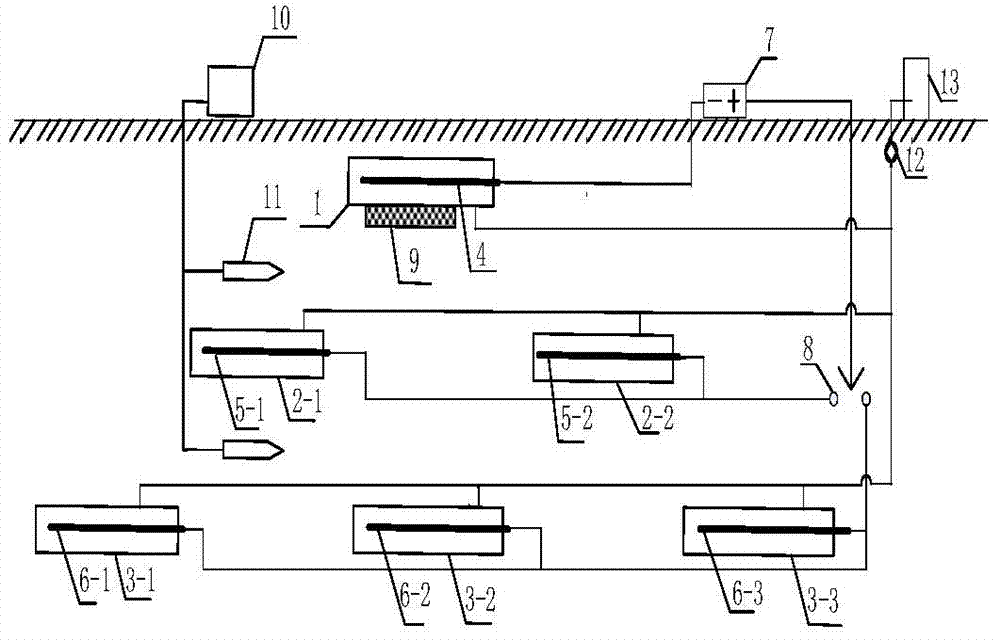

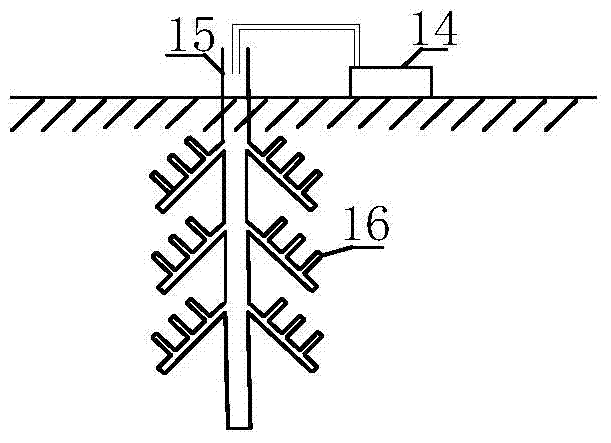

Device and method for repairing contaminated soil through combination of focusing type hierarchical electric method and injected solution

InactiveCN104259190AImprove migration speedReduce migration speedContaminated soil reclamationChemical agentTreatment system

The invention discloses a device and method for repairing contaminated soil through the combination of a focusing type hierarchical electric method and an injected solution. The repairing device comprises a focusing type hierarchical electric treatment system and an automatic injection control treatment system; a chemical agent is injected into the soil by using the automatic injection control treatment system so as to completely decompose various combination states of radioactive element-strontium; in the focusing type electrode repairing, contaminants in the deep soil is gradually focused to a central region of a surface layer at a certain angle, so that the containment area is reduced; the hierarchical electrode repairing not only can transport and enrich the containments to the surface layer, but also can lower the energy consumption, shorten the treatment time and improve the processing efficiency. The device and the method can increase the repairing speed, has the good repairing effect and is capable of effectively removing strontium containments.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

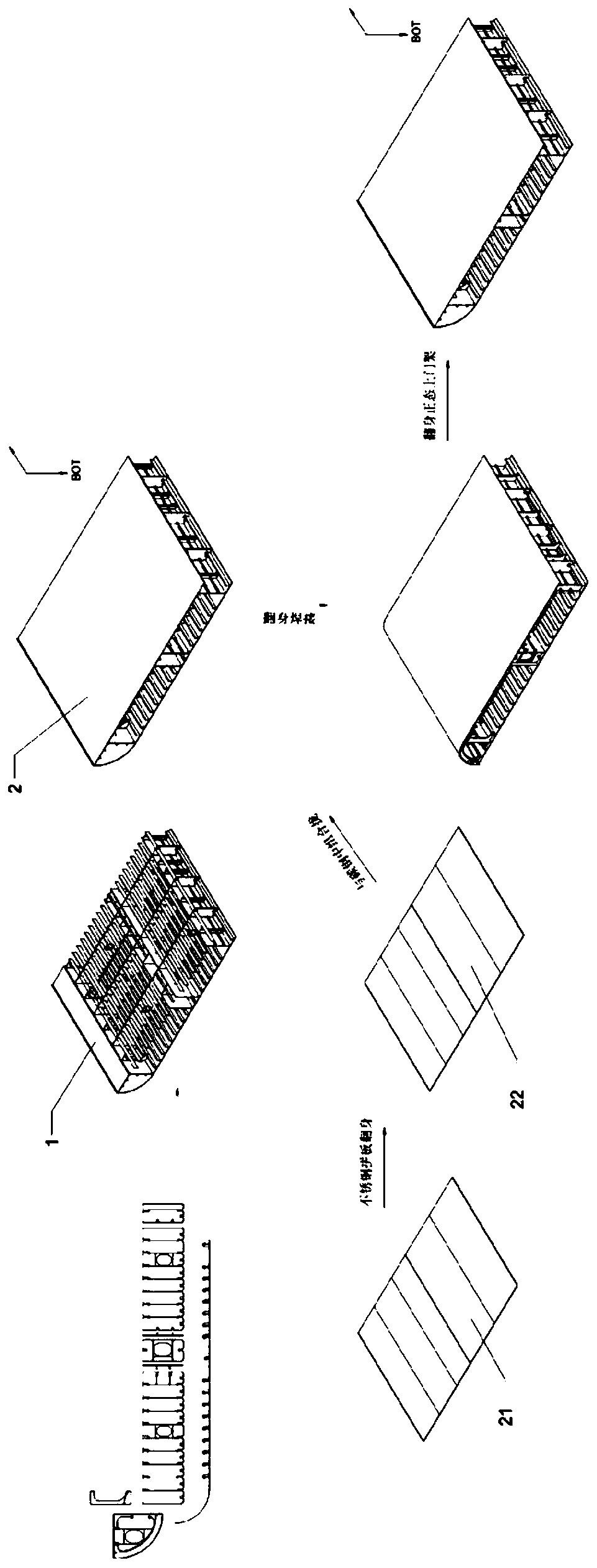

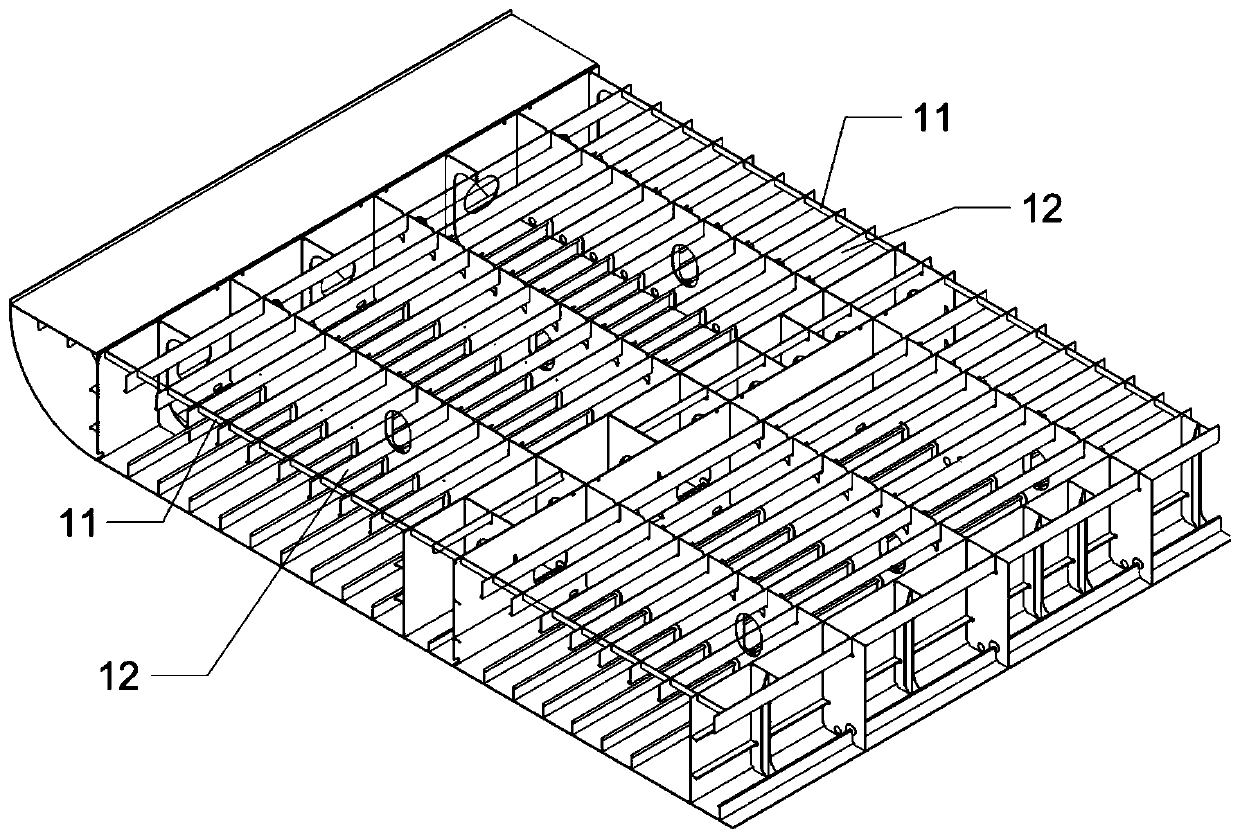

Dual-phase stainless steel segmented construction method for chemical ship

The invention discloses a dual-phase stainless steel segmented construction method for a chemical ship. The dual-phase stainless steel segmented construction method for the chemical ship comprises thefollowing steps that a carbon steel middle group and a stainless steel splicing plate are separately constructed, wherein the stainless steel splicing plate comprises a framework surface and a liquidcargo tank surface; the carbon steel middle group and the stainless steel splicing plate are combined; the stainless steel splicing plate is welded on the carbon steel middle group; an outfitting piece is arranged on the liquid cargo tank surface, and surface treatment is performed; and when the stainless steel splicing plate is welded on the carbon steel middle group, the framework surface is firstly welded, and then the liquid cargo tank surface is welded. The dual-phase stainless steel segmented construction method for the chemical ship has the beneficial effects that the number of stainless steel special jig frames and the arrangement of stainless steel segmentation special jig positions are reduced, the stainless steel segmented construction efficiency is improved, the welding efficiency and quality of stainless steel welding workers are further improved, the stainless steel welding deformation can be effectively controlled by fully utilizing the stainless steel deformation mechanism, so that the stainless steel segmented construction quality is improved.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

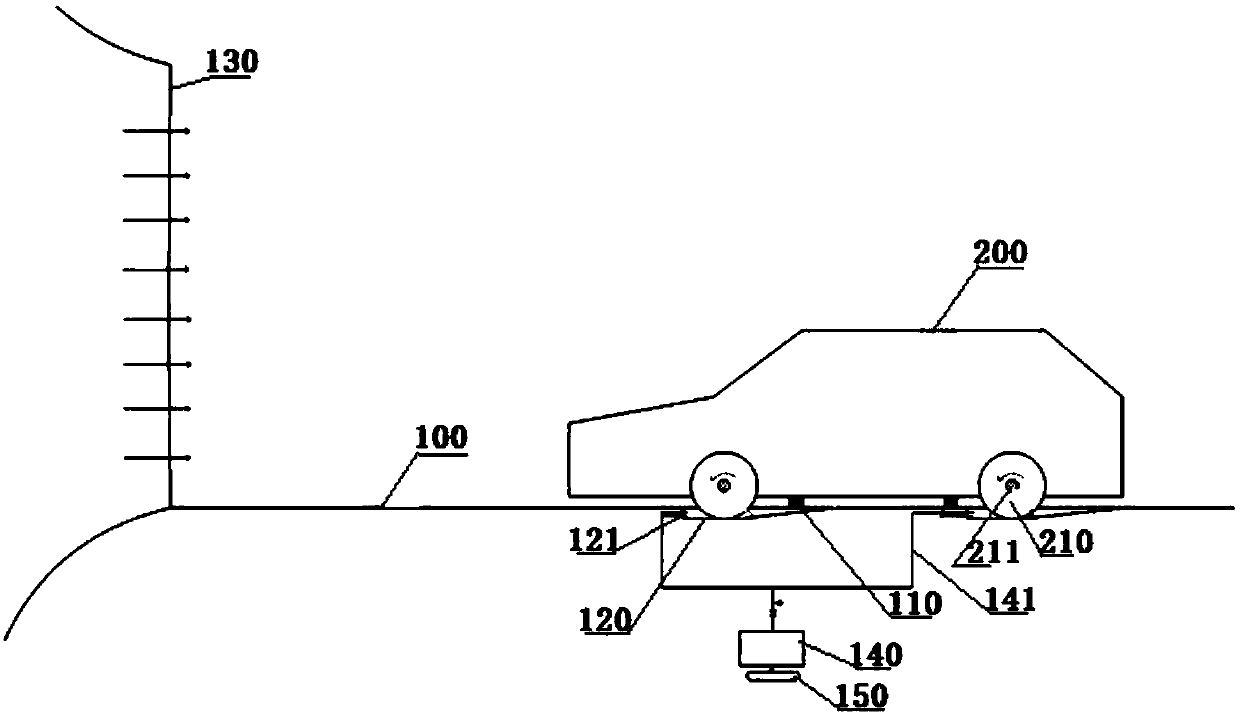

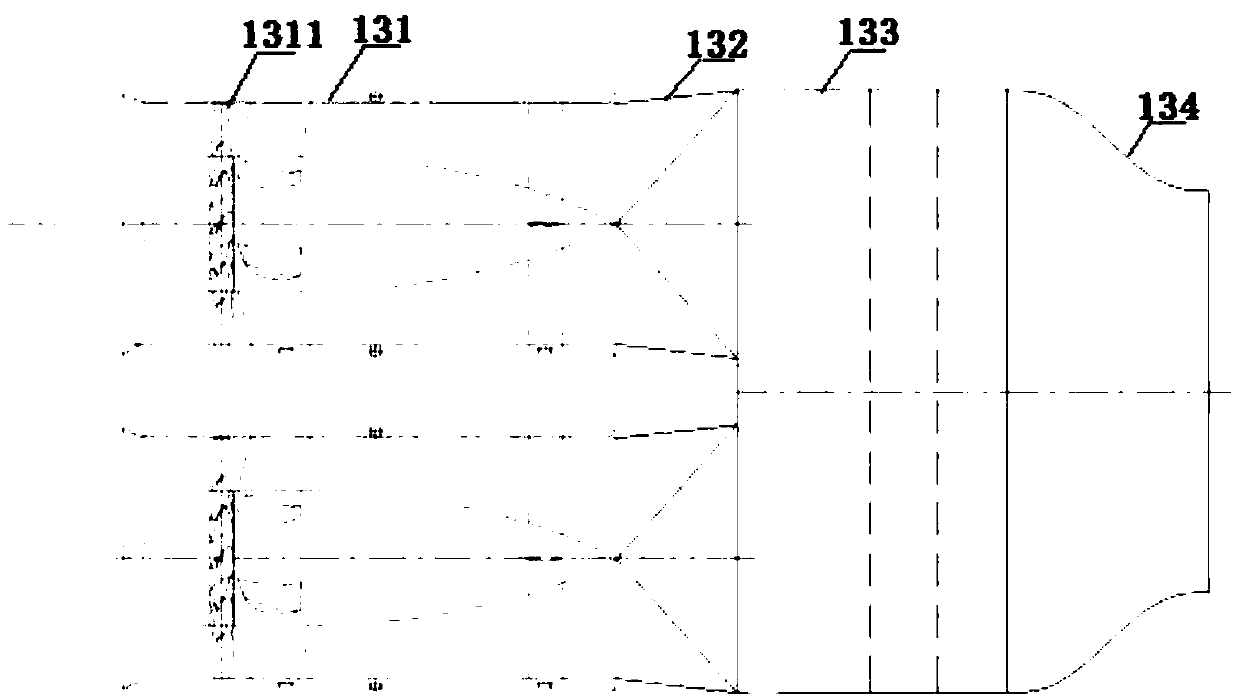

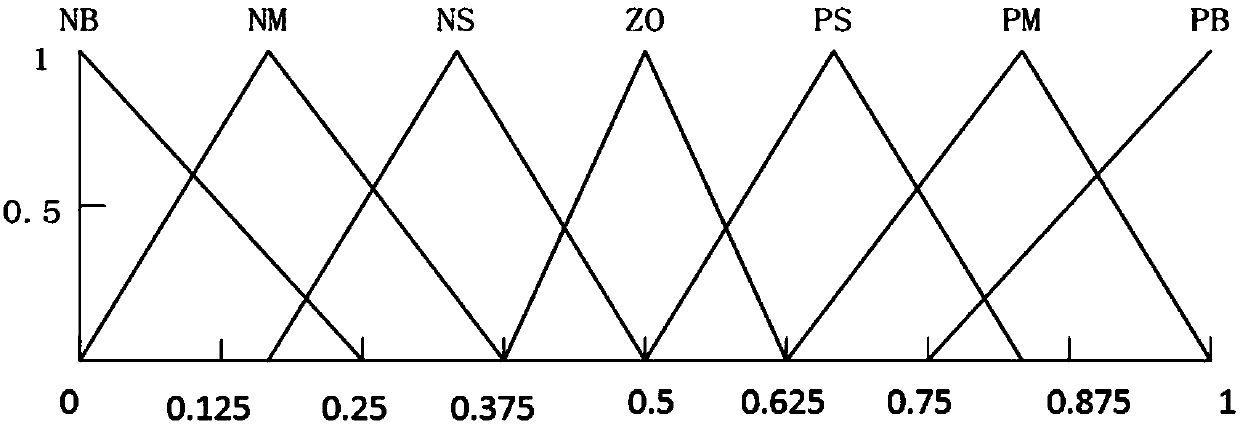

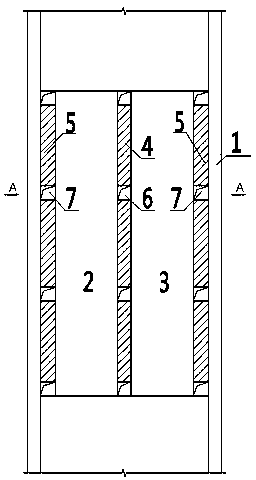

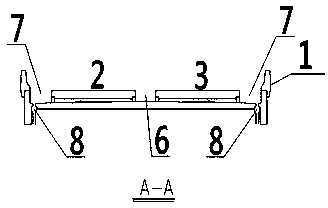

Vehicle wind tunnel mud throwing testing device and method

The invention discloses a vehicle wind tunnel mud throwing testing device which comprises a testbed, a plurality of supporting rods arranged at the four corners inside the region formed by the wheel,a mud water channel which is arranged below the testbed and corresponds to the wheels, and a wind tunnel system arranged right ahead of a to-be-tested vehicle model, wherein the height of the supporting rods is adjustable, the supporting rods are used for fixedly supporting the to-be-tested vehicle model, and mud water spraying openings are formed at the vertex angle, in front of the wheels, in the axial direction of the testbed. According to the vehicle wind tunnel mud throwing testing device, the various-condition wheel mud throwing testing condition can be covered, and the device is simplein structure and convenient to operate. The invention further provides a vehicle wind tunnel mud throwing testing method, the relative motion between air and the running vehicle can be simulated, thevarious-condition wheel mud throwing testing condition is covered, the size of a fender is adjusted, and the powerful basis is provided for vehicle shape fine adjustment.

Owner:JILIN UNIV

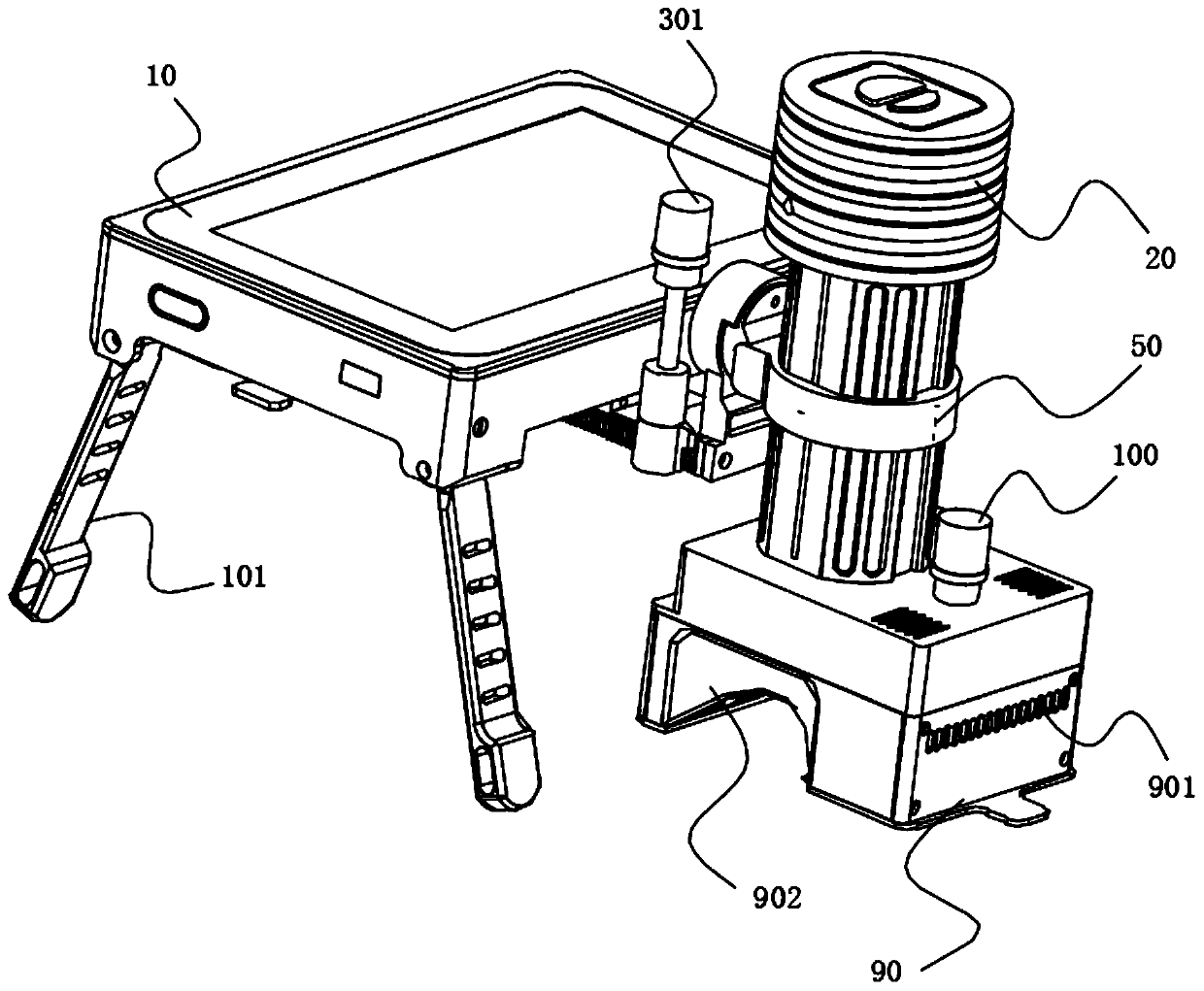

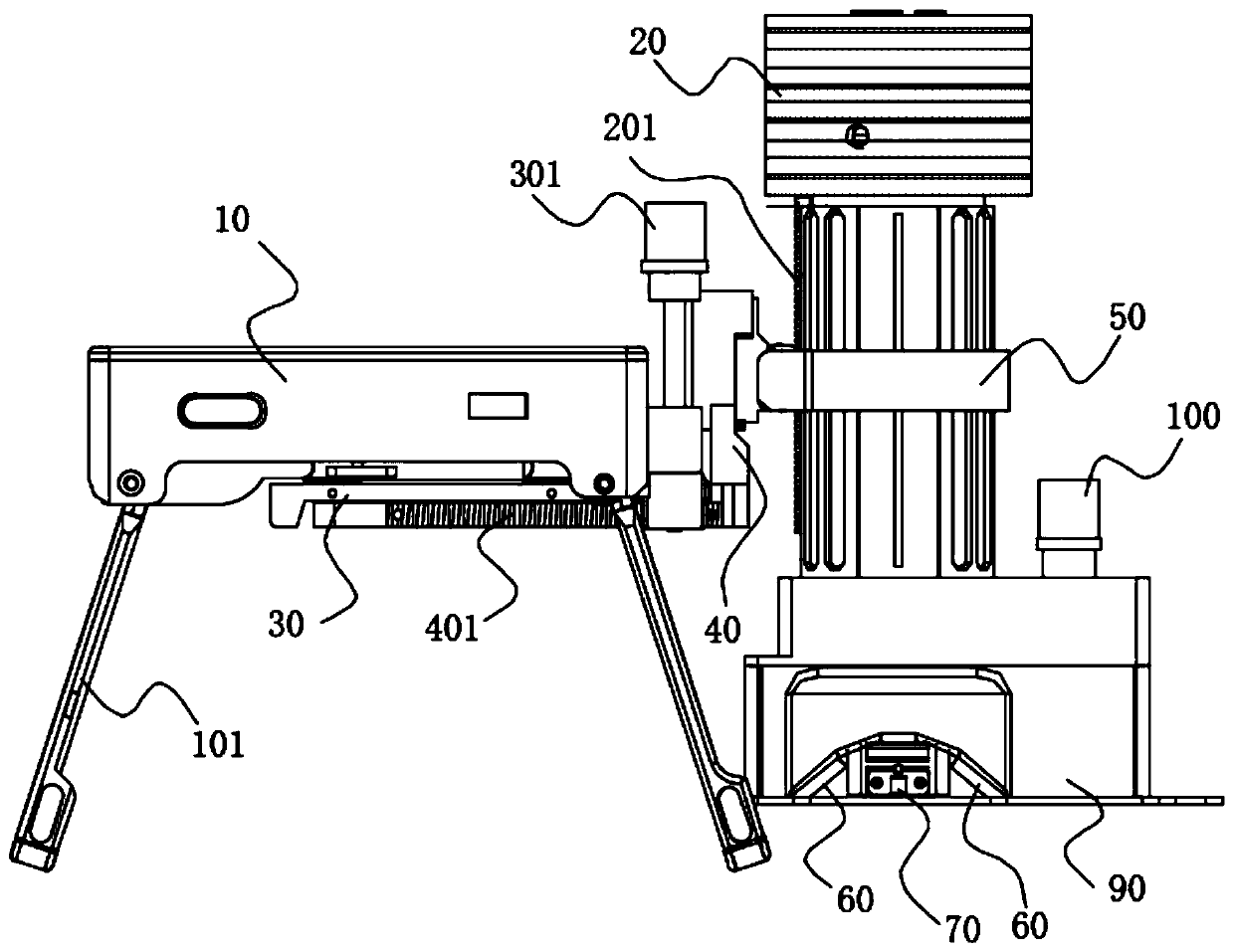

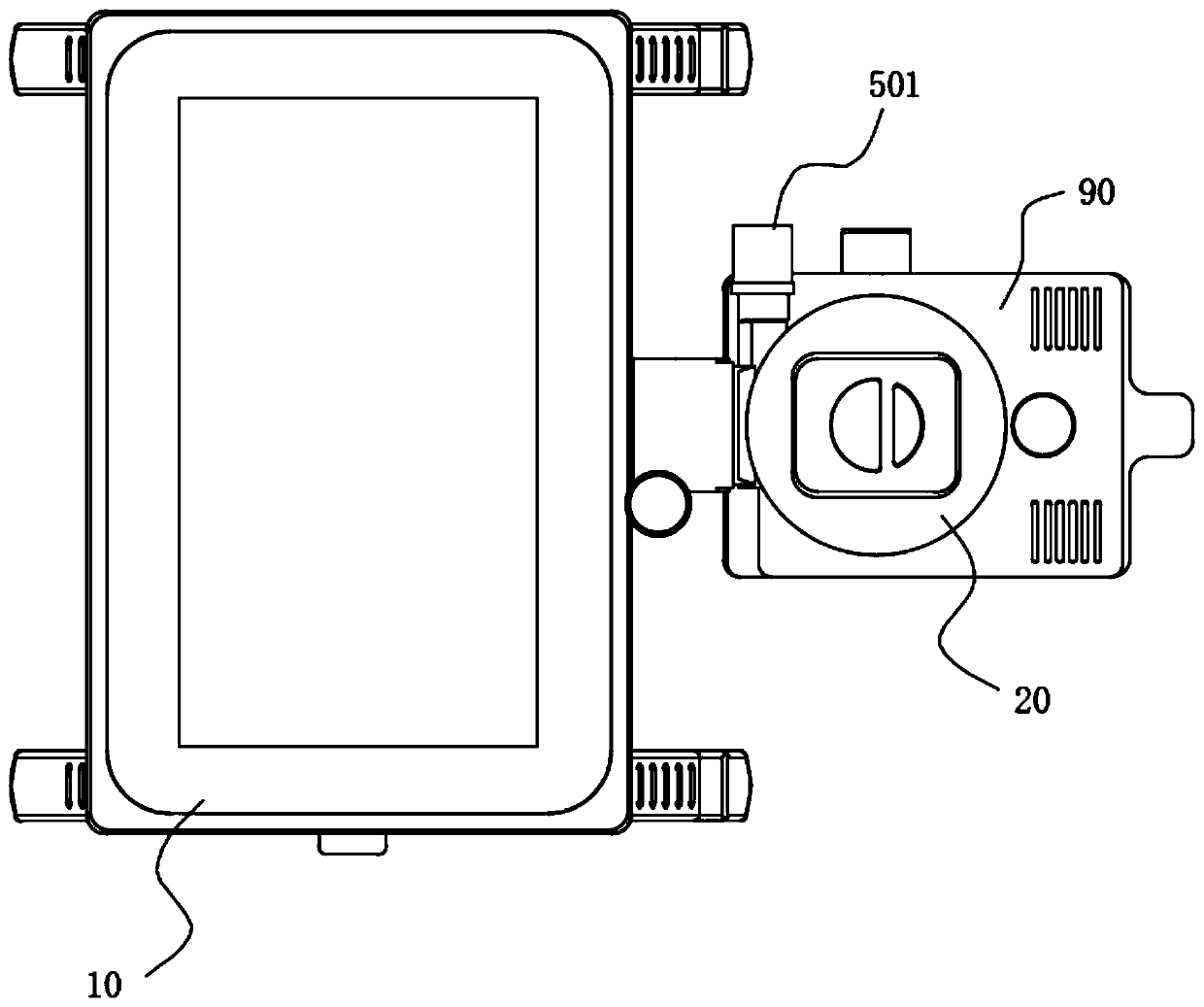

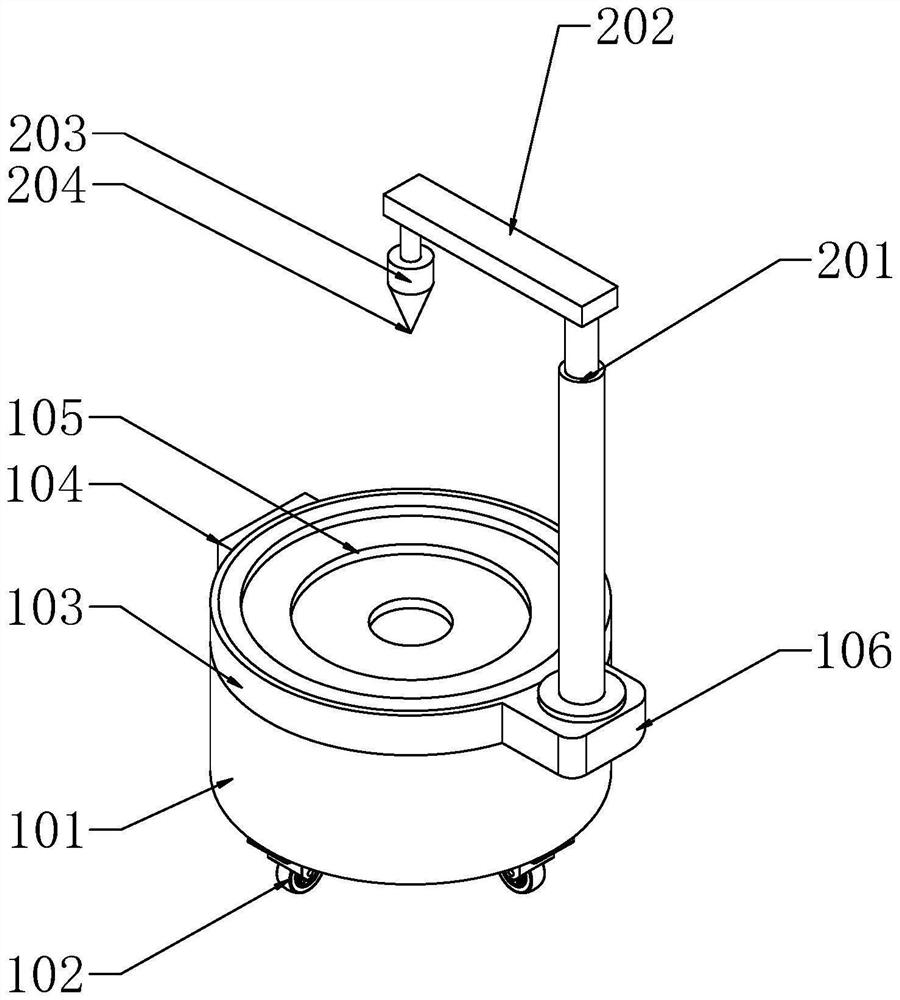

Physical evidence investigation equipment

The invention relates to the technical field of investigation equipment, in particular to physical evidence investigation equipment, which comprises a base, a microscope and a position adjusting mechanism. The base can be fixed on the surface of an object, the base and the microscope are both connected with the position adjusting mechanism, the position adjusting mechanism is used for adjusting the relative position of the microscope and the base, and the microscope can move relative to the base in the direction parallel to the fixed surface, making contact with the surface of the object, of the base. According to the physical evidence investigation equipment provided by the invention, the pollution area to the site can be reduced.

Owner:杭州衡利电子技术有限公司

Rapid staining method for biopolymers

ActiveCN101936837BShorten the timeLow costPreparing sample for investigationMaterial analysis by electric/magnetic meansBiopolymerComputer science

The invention belongs to the field of biotechnology, and discloses a rapid staining method for biopolymers. The rapid staining method comprises the steps of: combination of stain and a to-be-stained biopolymer, separation of uncombined stain and a biopolymer combined with the stain, and imaging of the biopolymer combined with the stain. The rapid staining method enables the stain to rapidly combine with the biopolymer through utilizing different mobilities of the stain and the biopolymer in a medium applied with an electric field, and can rapidly separate the uncombined stain and the biopolymer combined with the stain, shorten the whole staining time, save the cost, is simple to operate as the staining, destaining and color development can be finished in one step, and can combine the separation step and the staining step of the biopolymer together.

Owner:NANJING GENSCRIPT BIOTECH CO LTD

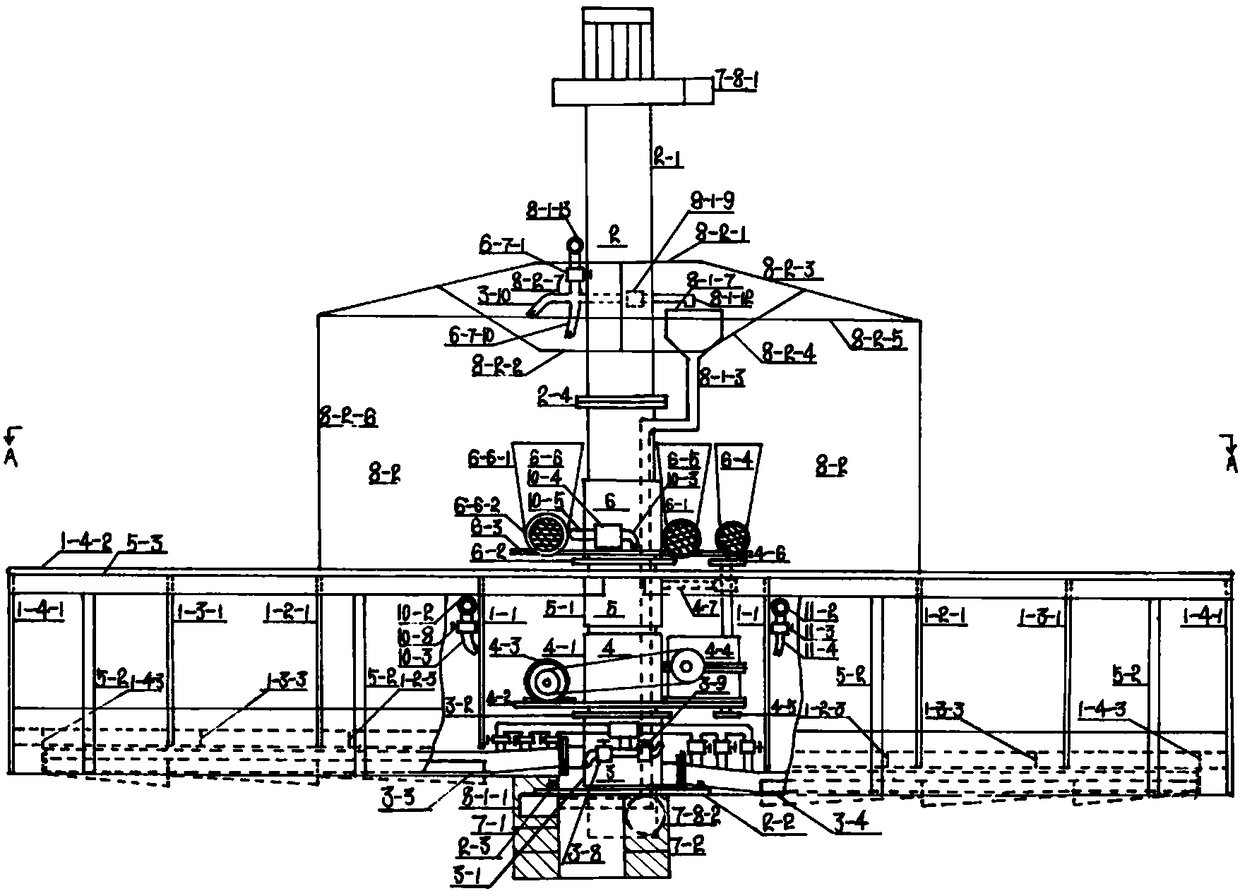

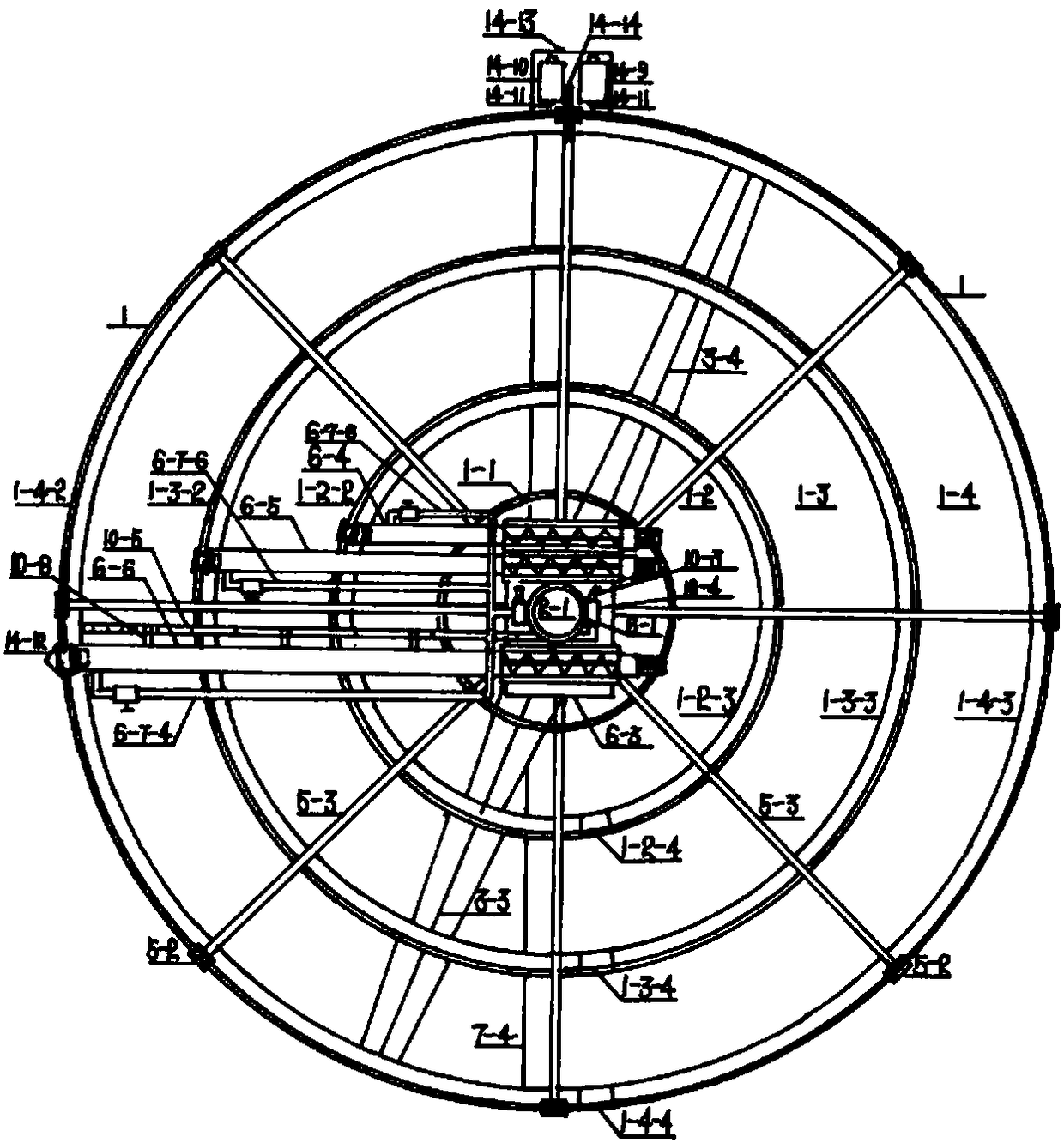

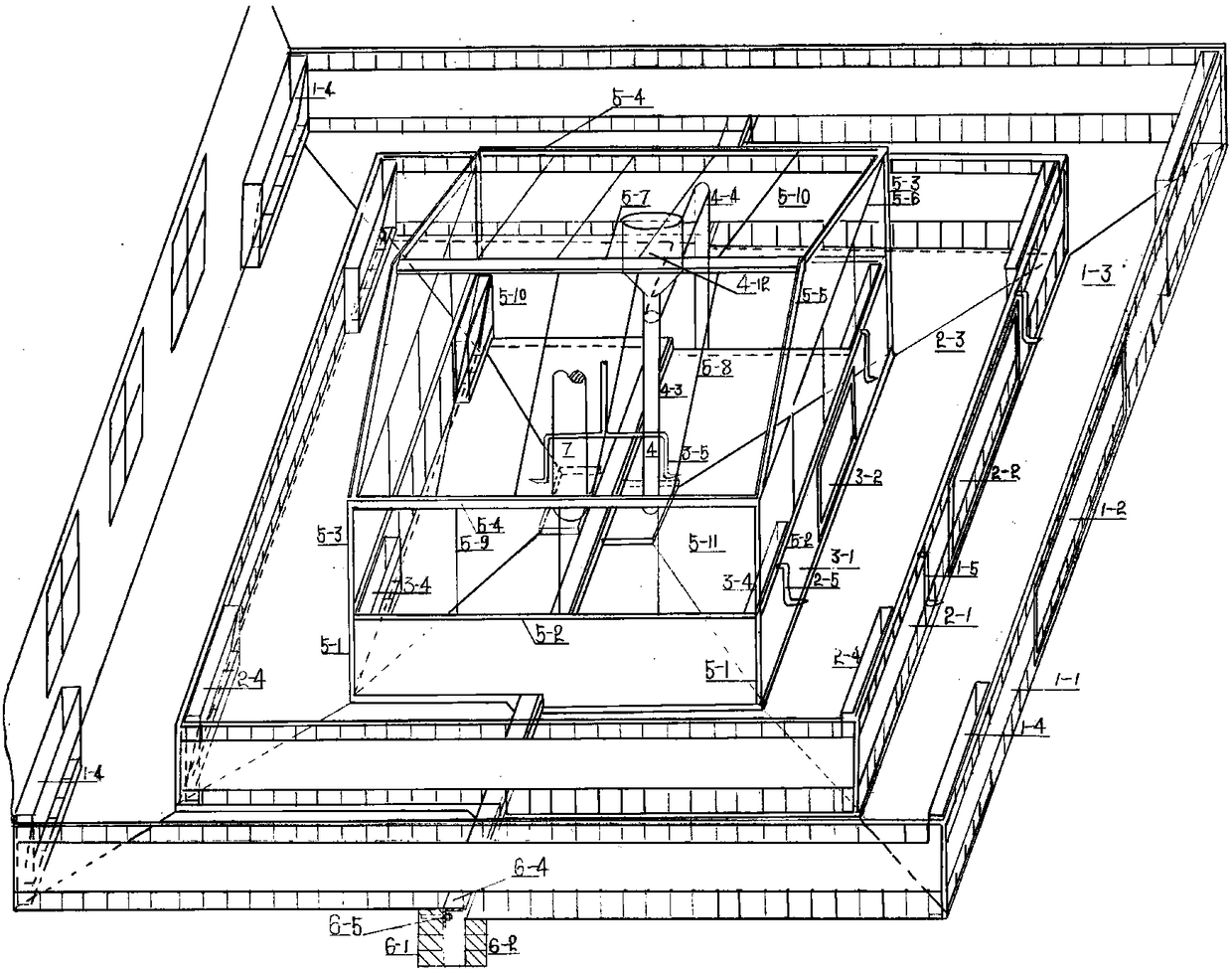

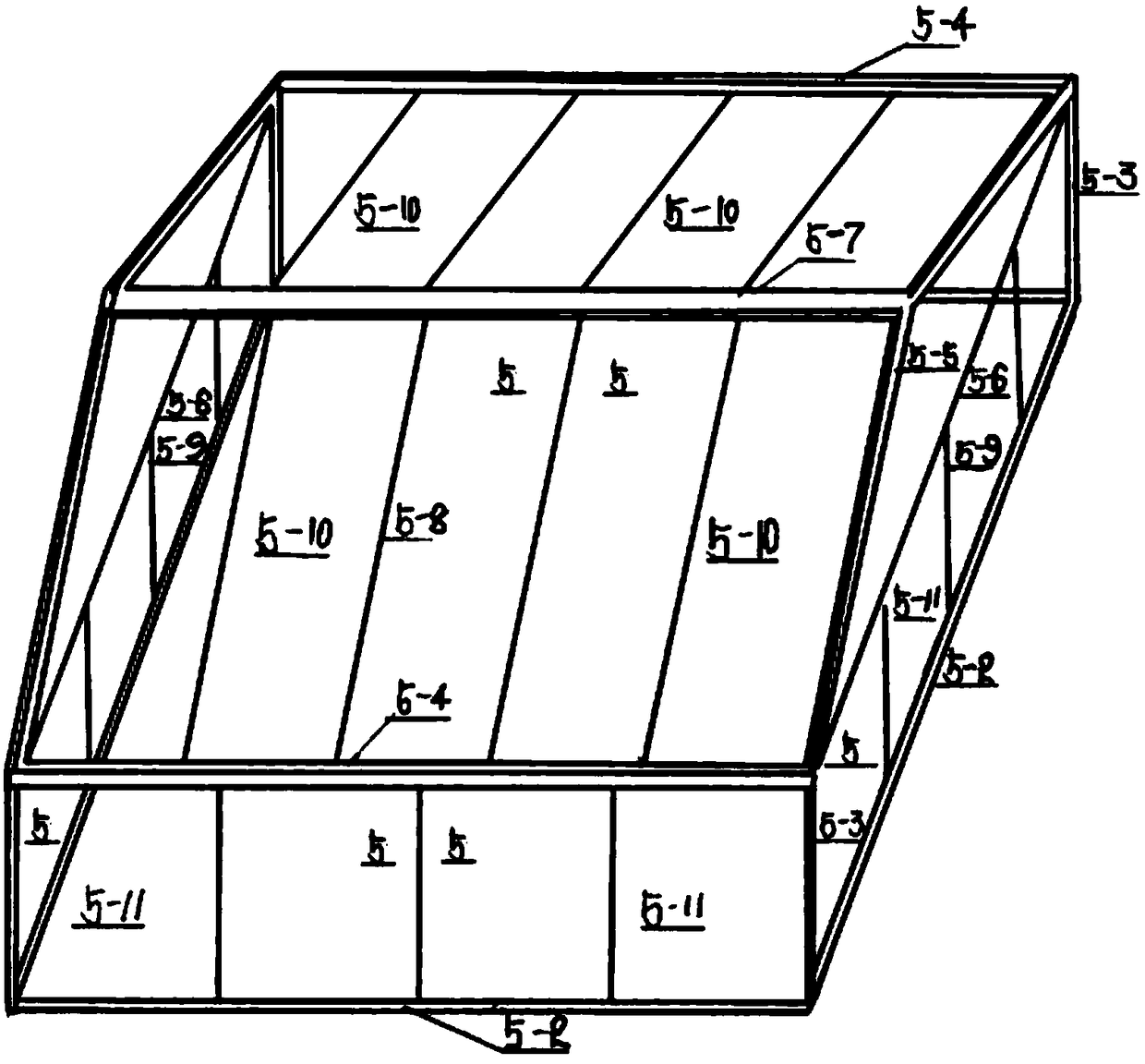

Ferrule live pig automatic breeding device and method based on round pens

InactiveCN108207639AAvoid harmAvoid cross infectionAnimal feeding devicesLavatory sanitoryPig breedingUnderfloor heating

The invention relates to a breeding device and method, in particular to a ferrule live pig automatic breeding device and method based on round pens, and aims to solve the problems of high pig breedingcost, high management difficulty, low production level and low enterprise benefit caused by low existing live pig breeding automation level. The ferrule live pig automatic breeding device is characterized in that a central vertical shaft air guide pipe device is arranged in the middle of the pen, and a dung-scraping and flushing device, a central driving device a pen fence suspending device, a wet-mixed feed meal-by-meal feeding device, an underfloor heating device of a nursery pen fence, a heat-insulating device, a high-low-edge dung collection ditch device, a polluted air discharging device, a disinfecting device, a monitoring device and an electric control device are mounted on the central vertical shaft air guide pipe sequentially from bottom to top in a sleeved manner. The method includes: setting area and ground of each pig pen; starting and stopping a rotating device; scraping, conveying and flushing dung; adjusting and determining feeding amount and water feeding amount; feeding a hopper of a feeder; performing wet mixing and feeding at the same time; transferring among the pens; disinfecting, and supervising. The ferrule live pig automatic breeding device and method is used for live pig breeding.

Owner:李久峰

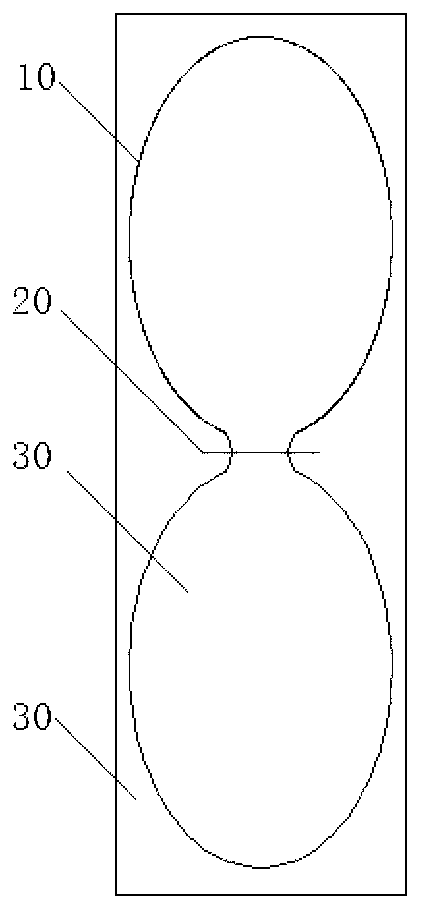

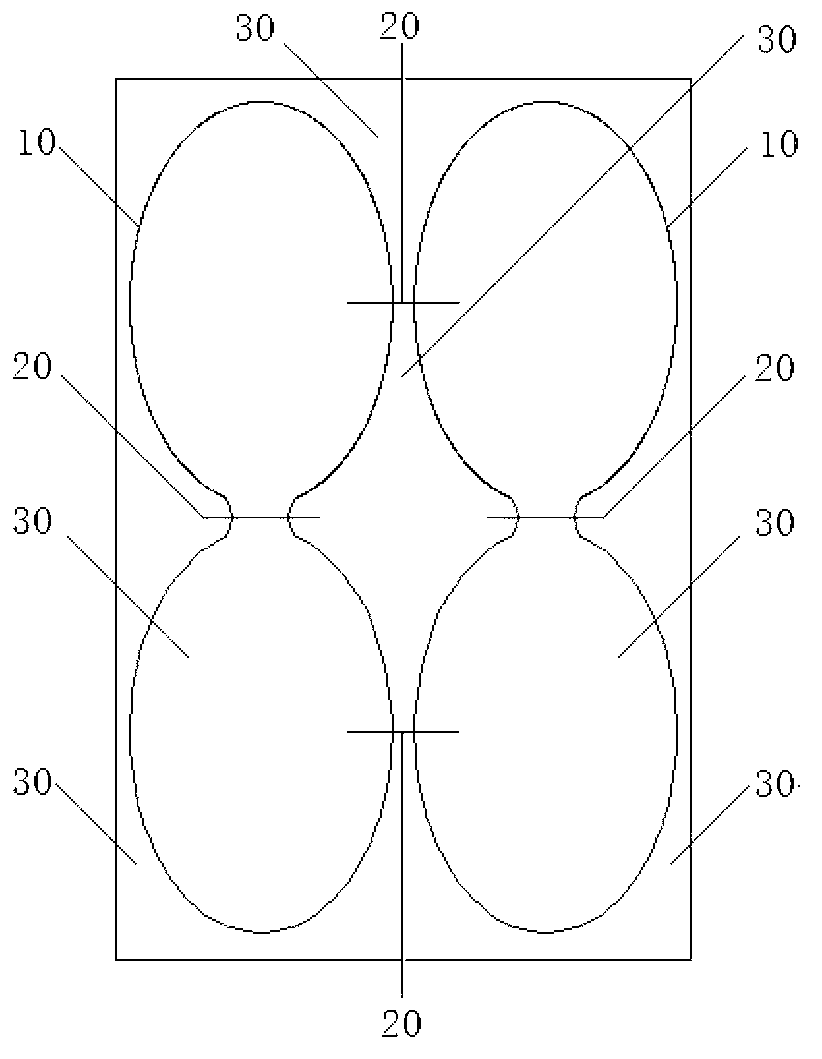

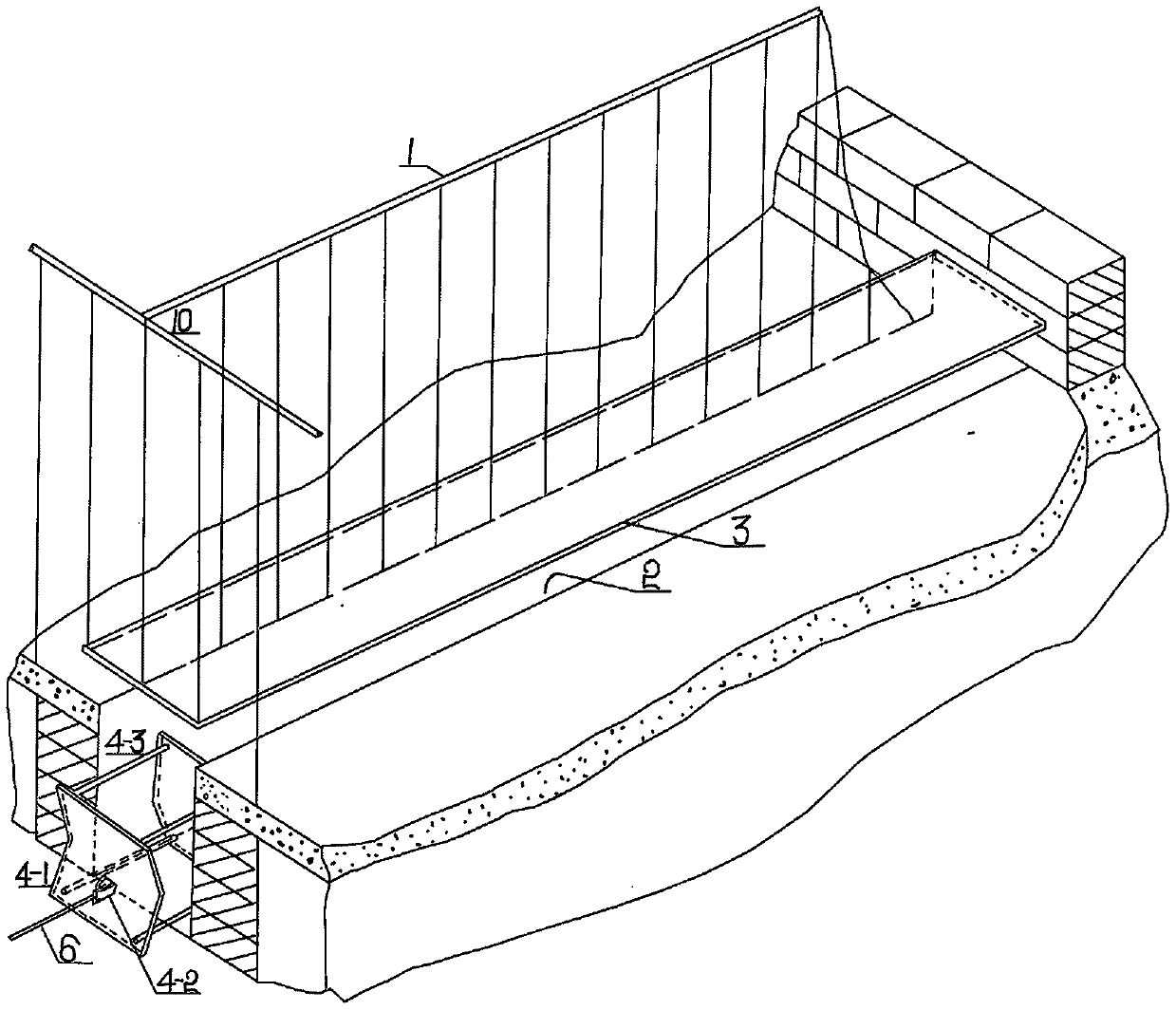

Flexible reinforced earth structure based on 8-shaped tyre

InactiveCN103276718AReduce horizontal thrustPassive drag reductionSoil preservationEarth materialsEngineering

The invention discloses a flexible reinforced earth structure based on an 8-shaped tyre and relates to a reinforced earth structure. A basic unit structurally comprises 8-shaped waste tyres (10), high-strength plastic bolt nuts (20) and building padding (30). The high-strength plastic bolt nuts (20) are connected among the 8-shaped waste tyres (10), and the building padding (30) is paved at holes inside and outside the 8-shaped waste tyres (10). The 8-shaped waste tyres (10) are arranged in a plane transversely and longitudinally to form a planar net structure. A three-dimensional net structure is composed of a plurality of layers of vertical planar net structures. The flexible reinforced earth structure is easy to compact and avoids damage caused by too much deformation. The reinforced earth structure is good in ductility and durability, low in modulus of deformation, high in damp and good in seismic resistance and has good deformation adaptation and long-term stability. The reinforced earth structure is simple, convenient to construct and low in cost, fully uses waste and earth materials on the field and reduces environment pollution and covering area.

Owner:HUBEI UNIV OF TECH

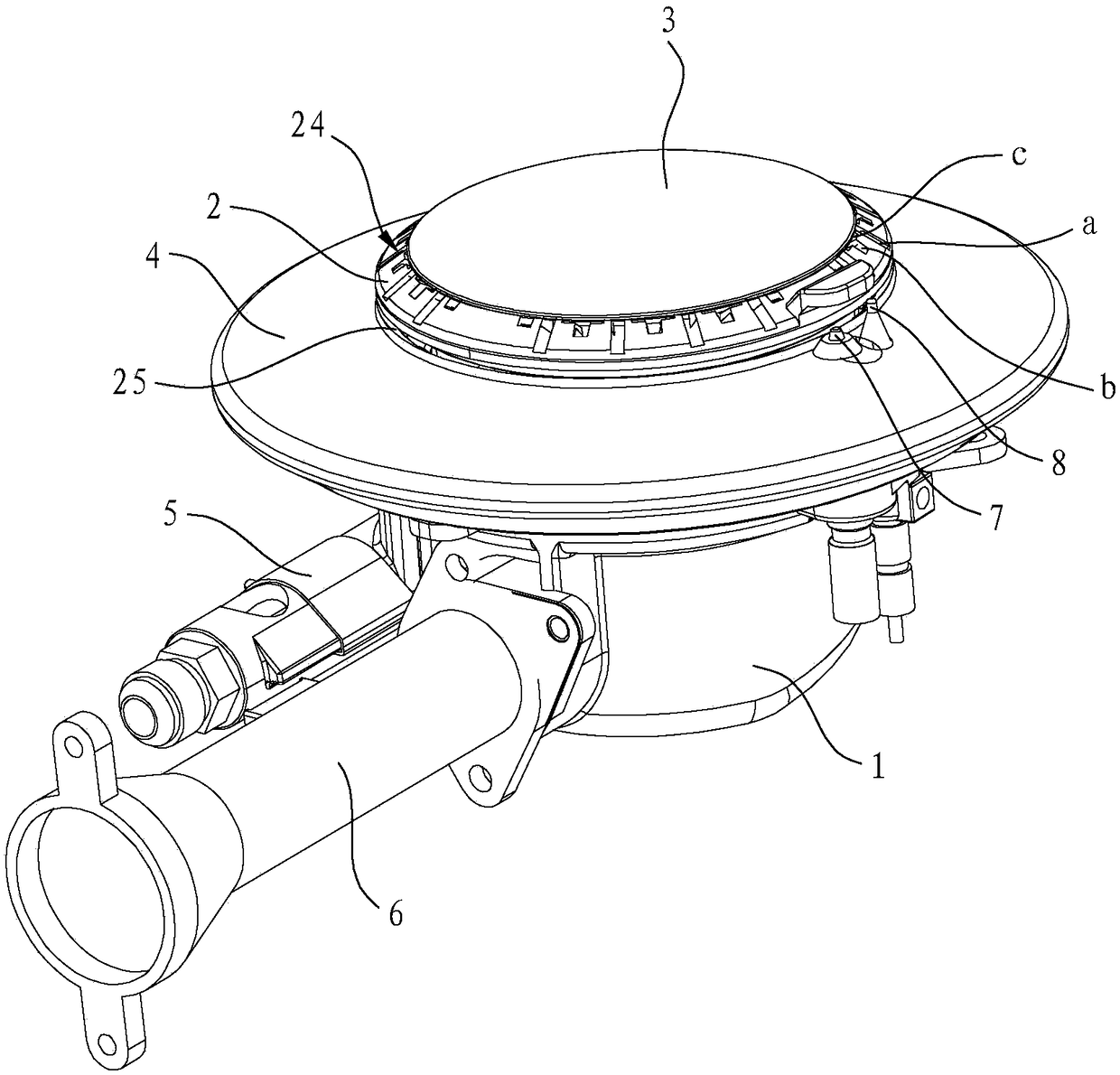

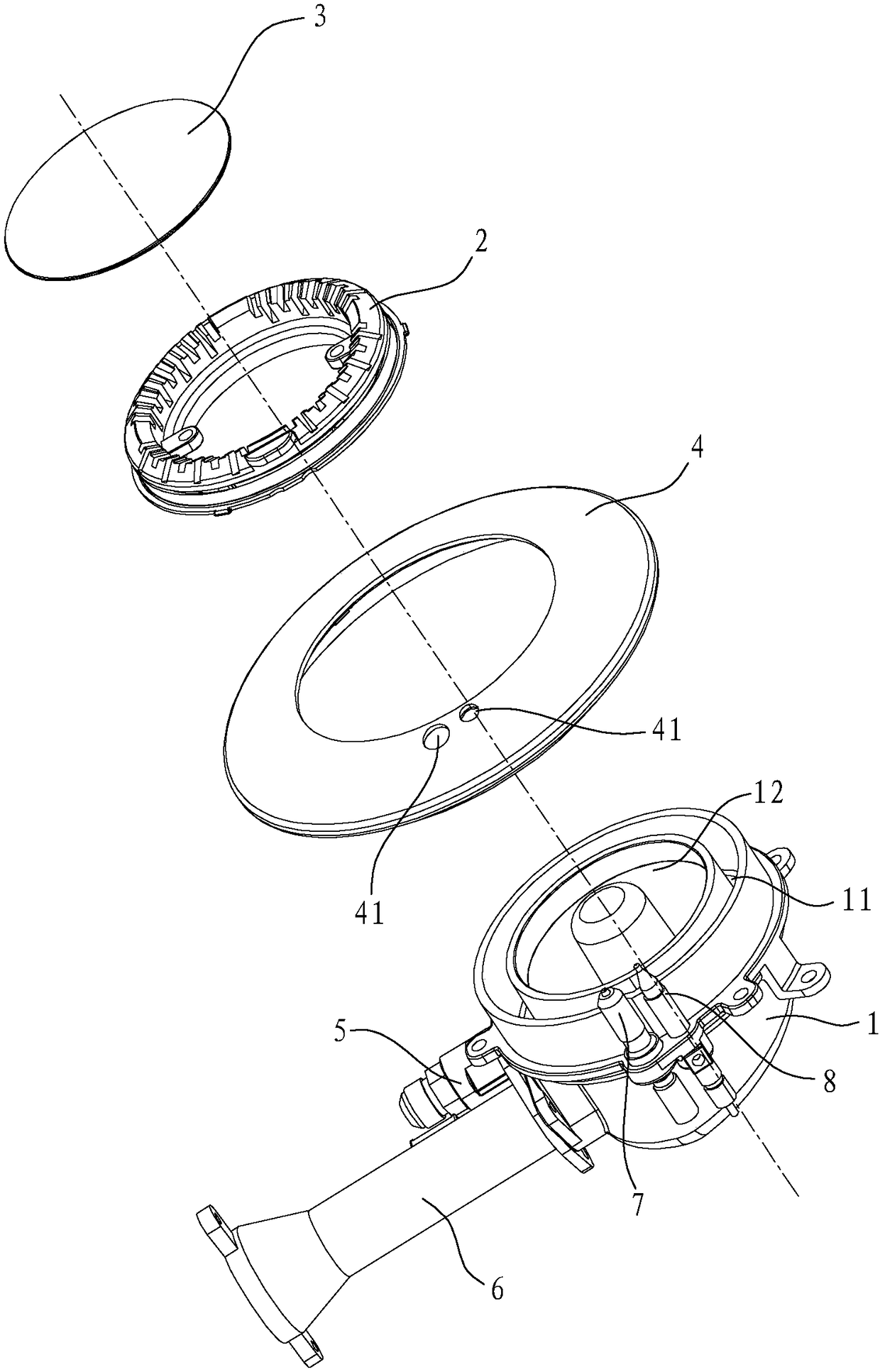

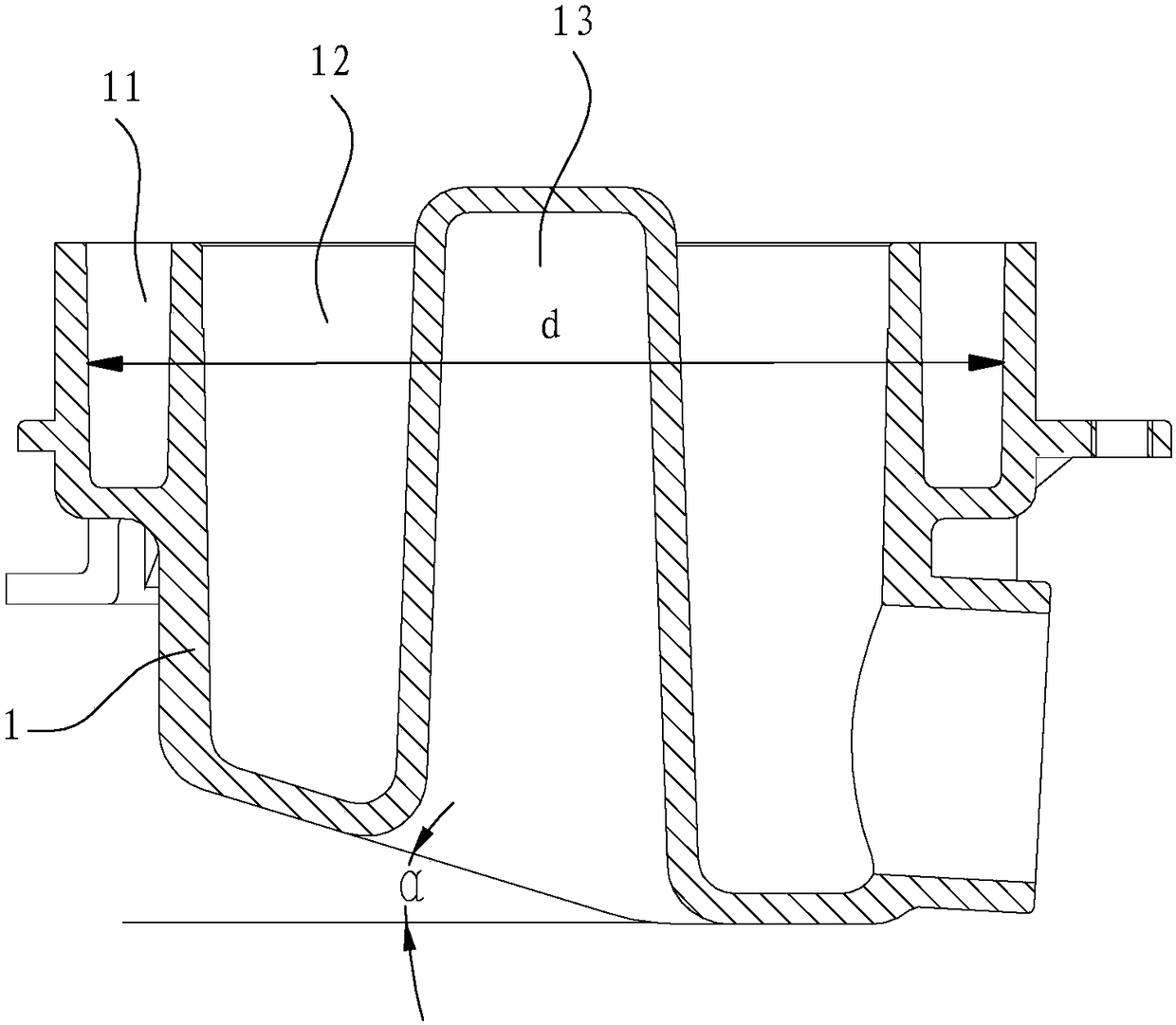

Stove burner

A stove burner comprises a furnace head, an outer-ring gas ejector pipe, an inner-ring gas ejector pipe and a burner cap, wherein the furnace head comprises an outer-ring cavity and an inner-ring cavity; the outer-ring gas ejector pipe communicates with the outer-ring cavity; the inner-ring gas ejector pipe communicates with the inner-ring cavity; and the burner cap is mounted on the furnace head. The stove burner is characterized in that the burner cap comprises a lower-ring flame channel communicating with the outer-ring cavity; a cover plate is arranged on the burner cap; an upper-ring flame channel communicating with the inner-ring cavity is formed between the cover plate and the burner cap; and in addition, the lower-ring flame channel is positioned below the upper-ring flame channel. After the stove burner provided by the invention adopts the upper-ring and lower-ring flame design, the flame stabilizing effect can be well achieved by adjusting the primary air coefficient of lower-ring flame, and secondary air can be directly supplemented; not only is the supplementing effect good, but also the problem that an overflowing liquid flows into a baseplate through a secondary air hole, and then the secondary air hole is difficult to clean can be solved; and in addition, the diameter of the stove burner is relatively small, so that is not only the heat efficiency improved, but also the stove burner is easier to clean.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

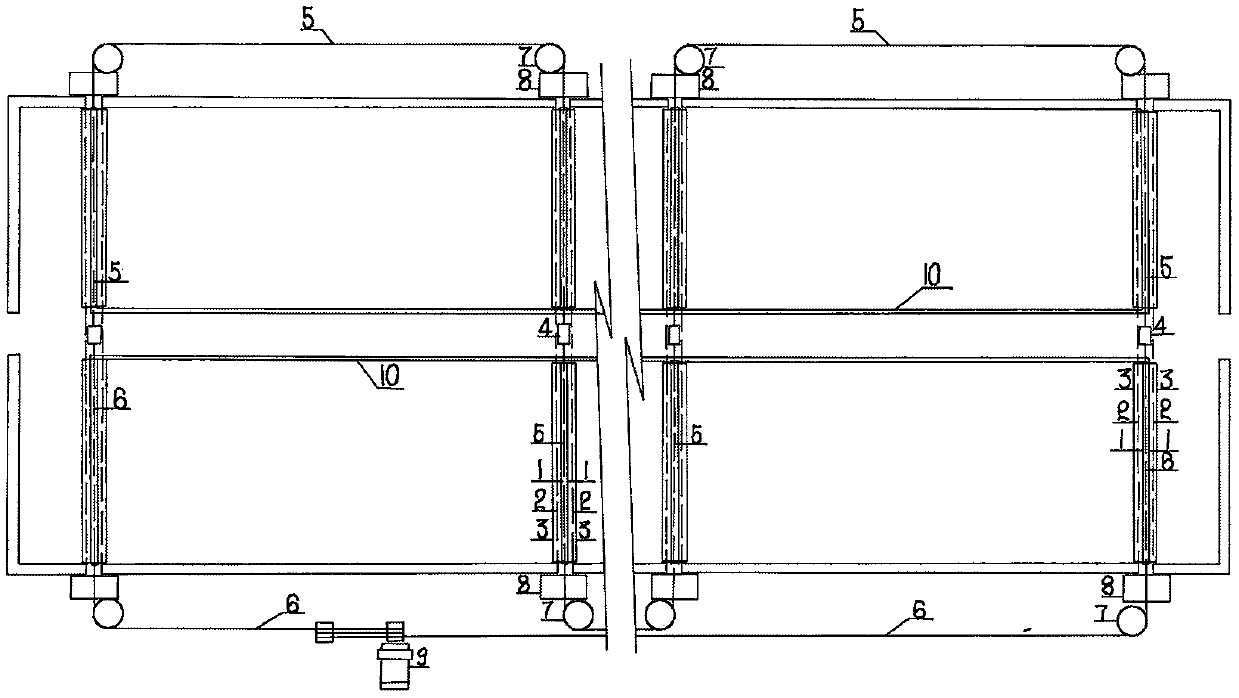

Transverse railing lower side based external excrement scraping device and operating method thereof

The invention relates to the technical field of excrement cleaning in livestock and poultry breeding, discloses a transverse railing lower side based external excrement scraping device and an operating method thereof and aims to solve problems of high labor intensity and low operating efficiency in manual outward transporting of excrement, severe water waste, high sewage treatment amount and environmental pollution in excrement flushing and poor pig raising environment in mechanical excrement scraping. The transverse railing lower side based external excrement scraping device comprises transverse railings, excrement scraping gutters, shielding plates, bidirectional excrement scraping components, connection ropes, pull ropes, corner wheels and an excrement collection tank. The transverse railings are arranged among pens in a whole row; the excrement scraping gutters are formed under the ground below the transverse railings; the connection ropes are connected with pull rings on the bidirectional excrement scraping components; the pull ropes are connected with the pull rings on the bidirectional excrement scraping components in the excrement scraping gutters at two ends of a housing through power transmission devices; the corner wheels are fixed to a base on the outer side of the excrement collection tank opposite to the excrement scraping gutters; the excrement collection tank isarranged under the ground between the excrement scraping gutters and the corner wheels. The transverse railing lower side based external excrement scraping device is used for excrement cleaning in livestock and poultry breeding.

Owner:李久峰

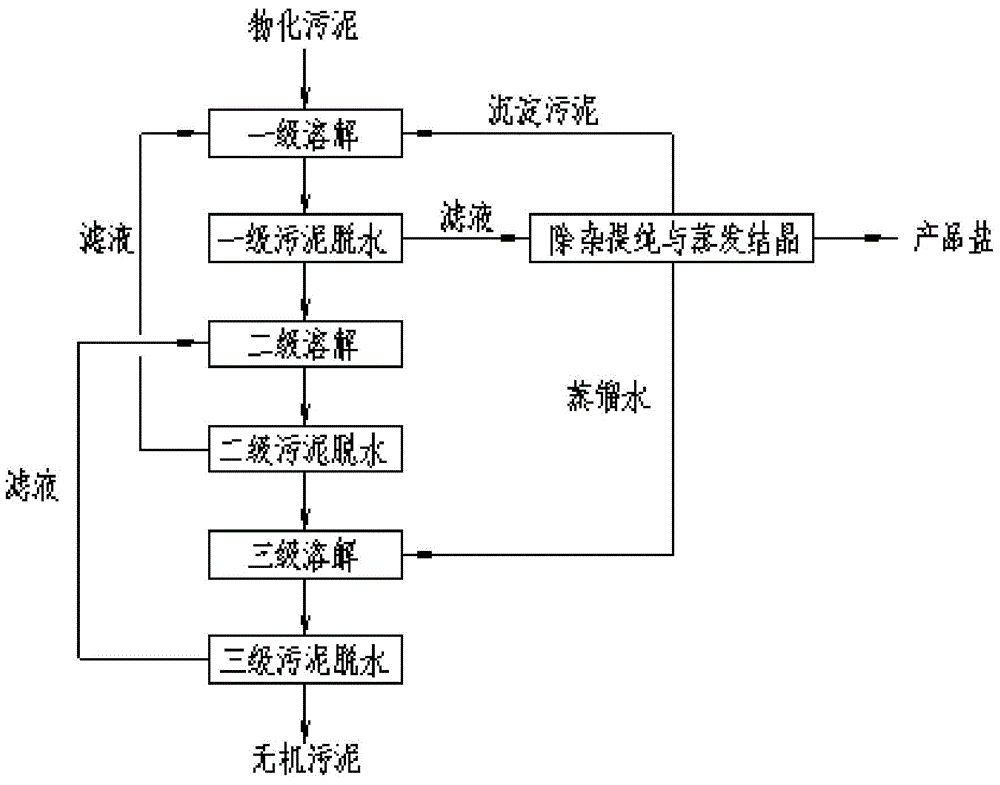

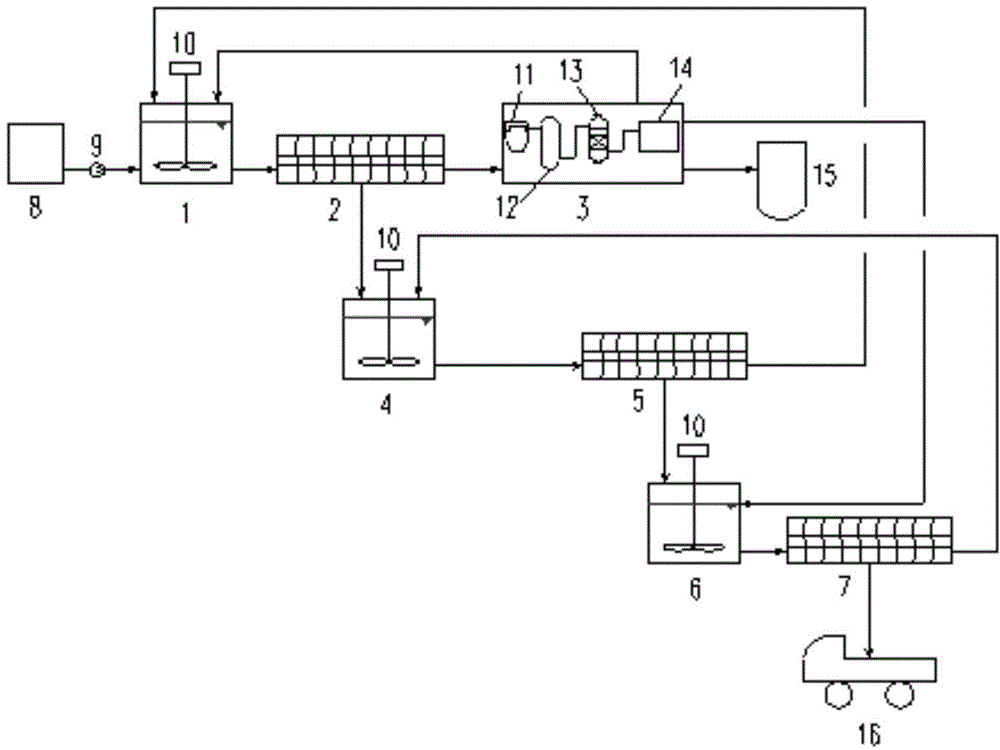

Washing recycling treatment process of sludge from physical and chemical treatment and special apparatus for process

ActiveCN104909536ARealize resourcesReduce pollution areaSludge treatment by de-watering/drying/thickeningChemical treatmentSludge

The invention provides a washing recycling treatment process of sludge from physical and chemical treatment and a special apparatus for the process. According to the process, the sludge from physical and chemical treatment is treated by use of a method of primary dissolution, primary dehydration, secondary dissolution, secondary dehydration, third dissolution and third dehydration, and finally, the obtained inorganic sludge has the moisture content below 60%, and the content of each of potassium, sodium and chlorine in the inorganic sludge is reduced to about 0.06%; as a result, the obtained inorganic sludge can be used as a cement kiln ingredient; the environmental pollution and the floor area due to sludge landfill are reduced; meanwhile, impurity removal purification and evaporative crystallization are performed on the filtrate, and the obtained salt products can be sold to the outside; and as a result, the sludge recycling is thoroughly realized.

Owner:SHANGHAI JINGYU ENVIRONMENT ENG

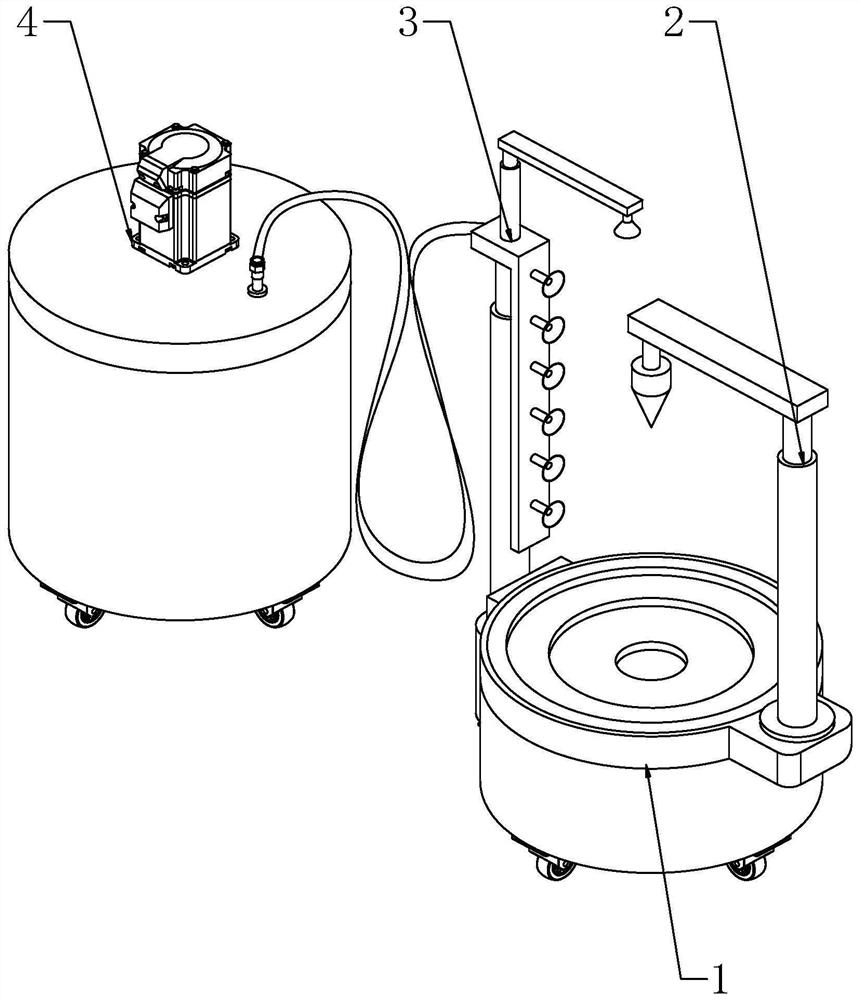

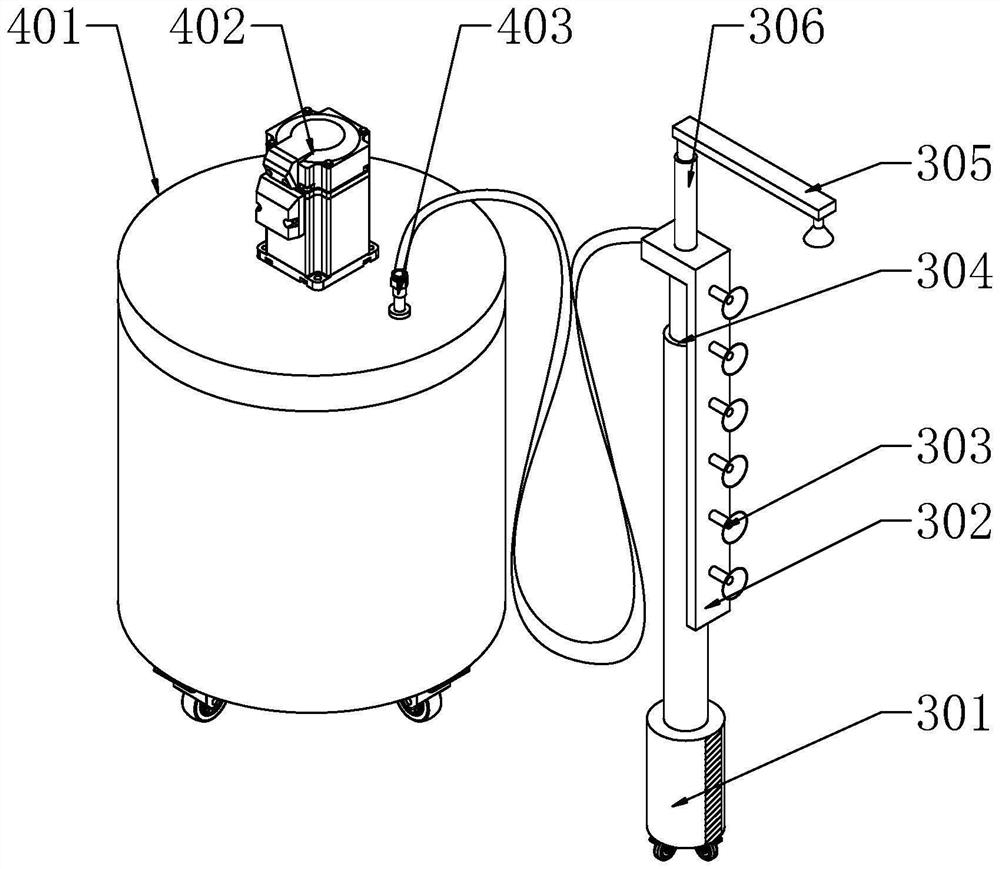

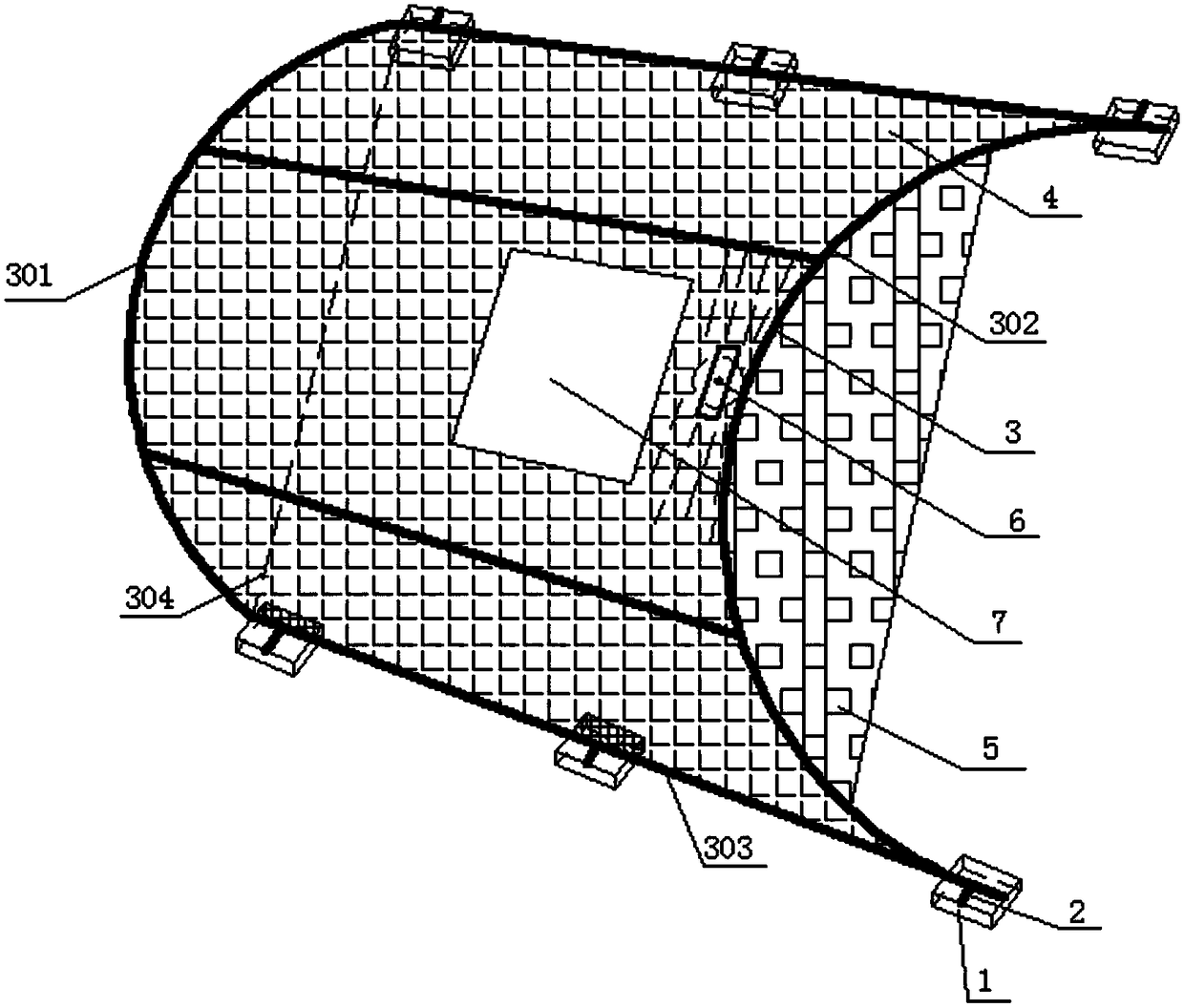

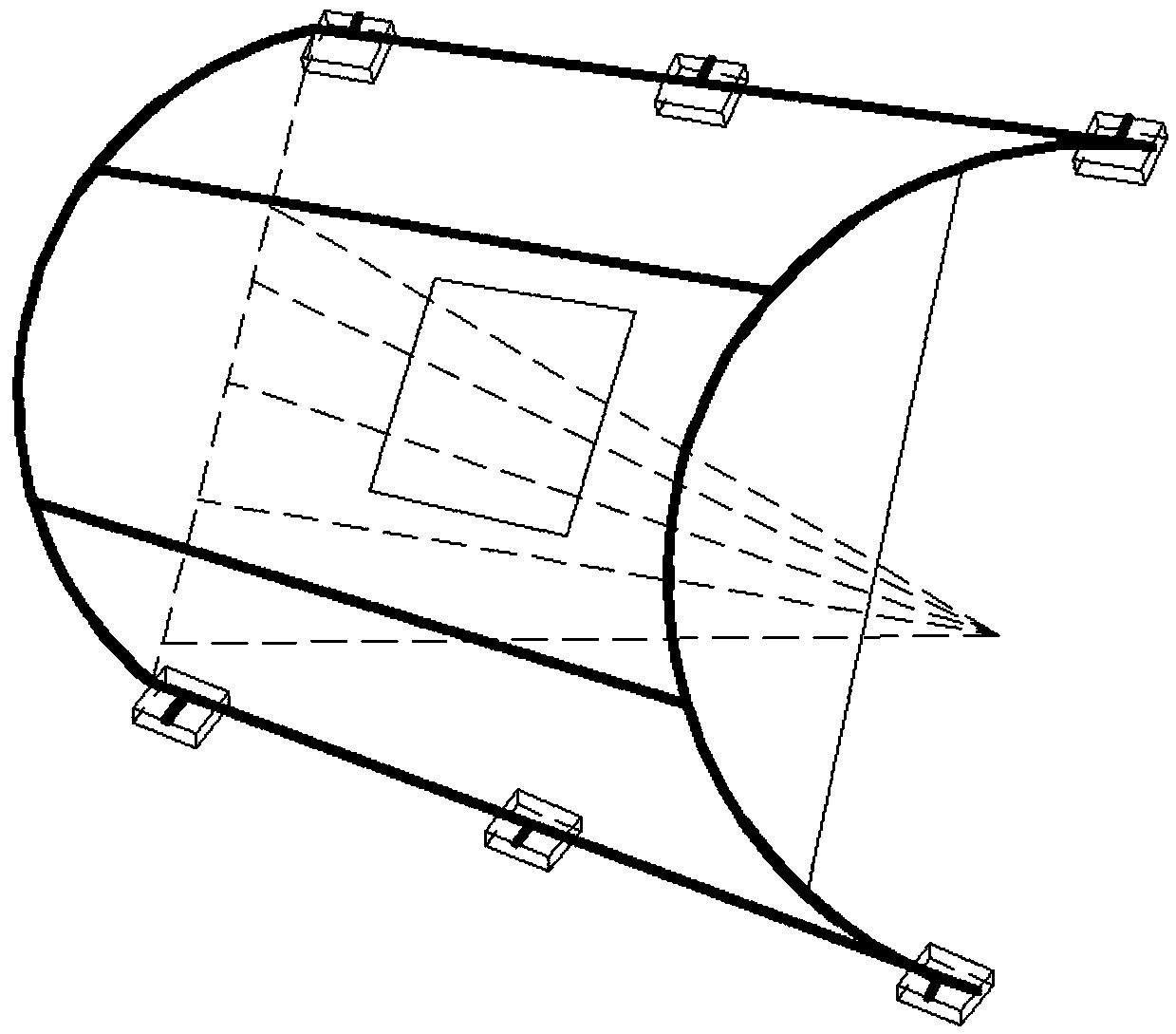

Paint spraying equipment for cylindrical metal product machining

InactiveCN113843065AEasy to operateReduce pollution areaLiquid spraying apparatusElectric machineryStructural engineering

The invention relates to the technical field of paint spraying equipment, in particular to paint spraying equipment for cylindrical metal product machining. The equipment comprises a loading assembly; the loading assembly is composed of a loading box, a loading table, a first limiting seat, a second limiting seat and a rotating motor; the upper end of the second limiting seat is connected with a positioning assembly; the positioning assembly is composed of a first lifting air cylinder, a connecting plate, a bearing seat and a positioning column; a paint spraying assembly is arranged on one side of the first limiting seat; the paint spraying assembly is composed of a moving seat, a first mounting plate, a paint spraying head, a second lifting air cylinder, a second mounting plate and a third lifting air cylinder; the second lifting air cylinder is connected to the upper end of the moving seat; a first mounting plate is connected to the upper end of the second lifting air cylinder; a paint storage assembly is arranged on one side of the paint spraying assembly; and the paint storage assembly is composed of a paint storage barrel, and a self-priming pump and a paint outlet which are arranged at the upper end of the paint storage barrel.

Owner:中矿(麻阳)矿业有限公司

Pen-in-pen based pig breeding device and method

InactiveCN108094219AAvoid damageSave manpower and material resourcesAnimal housingAnimal scienceEconomic benefits

The invention relates to a breeding device and method, in particular to a pen-in-pen based pig breeding device and method and aims to solve the problem of pig breeding economic benefit reduction caused by serious stress and harms to pigs due to group mixing in a house transferring and pen transferring process and house transferring and pen transferring in an existing pig breeding process. By sequential arrangement of a nursing pen, a growth pen and a fattening pen from inside to outside, the device is characterized in that a floor heating device is arranged under the ground of the nursing pen,a heat preservation device is arranged above the nursing pen, a high-low-side dung collection channel device is arranged under the ground at a pen-in-pen middle position, a bad air discharging deviceis arranged at the pen-in-pen middle position, and a ladder for nursed pigs to enter the pen is movably mounted in the pen. The method includes pen arrangement; allowing of nursed pigs to enter the pen; feeding and pen transferring; feeding; realization of bringing in fresh air under the action of negative pressure formed by bad air discharging; dung clearing; in-pen ground setting; pig pen areadetermination; pen internal setting. The pen-in-pen based pig breeding device and method are used for pig breeding.

Owner:李久峰

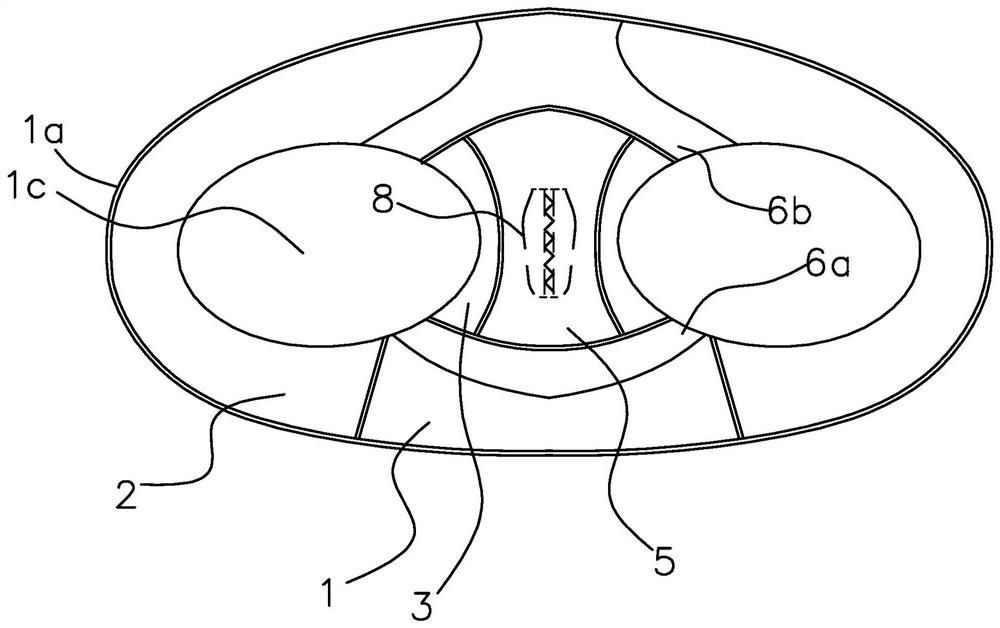

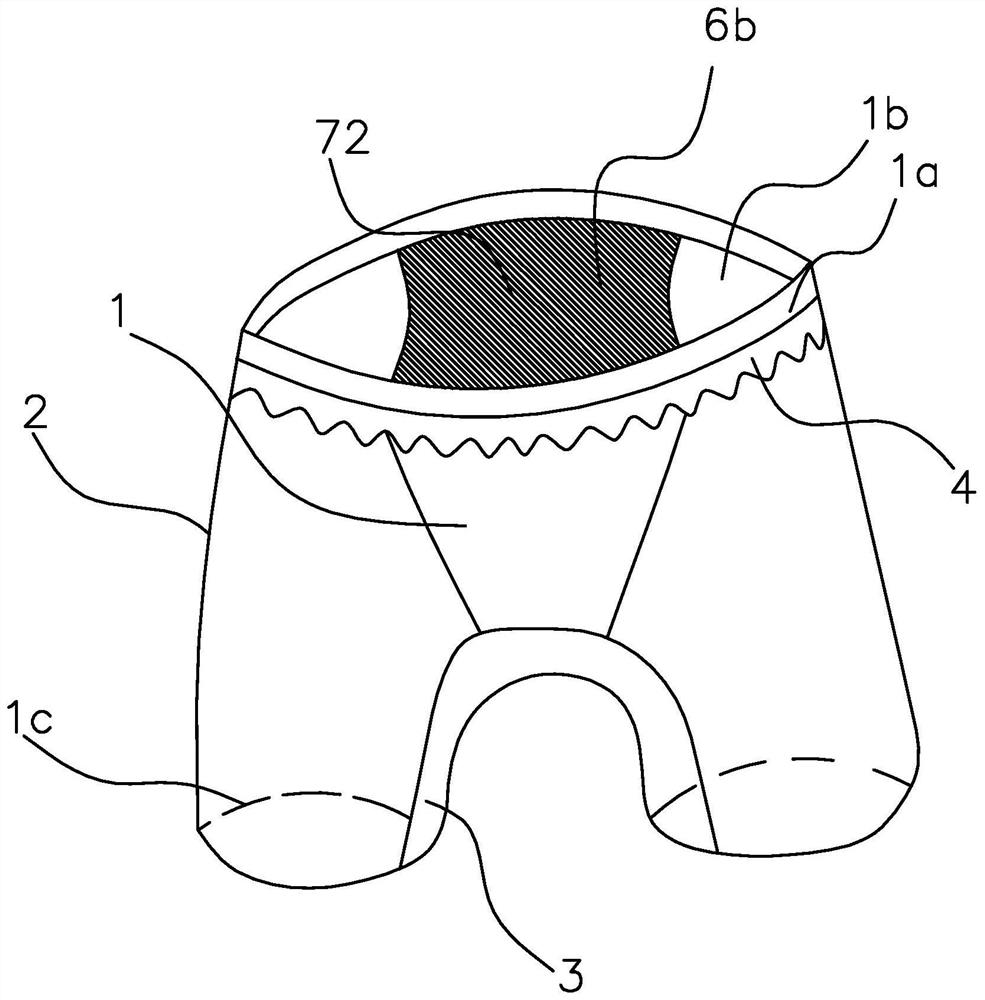

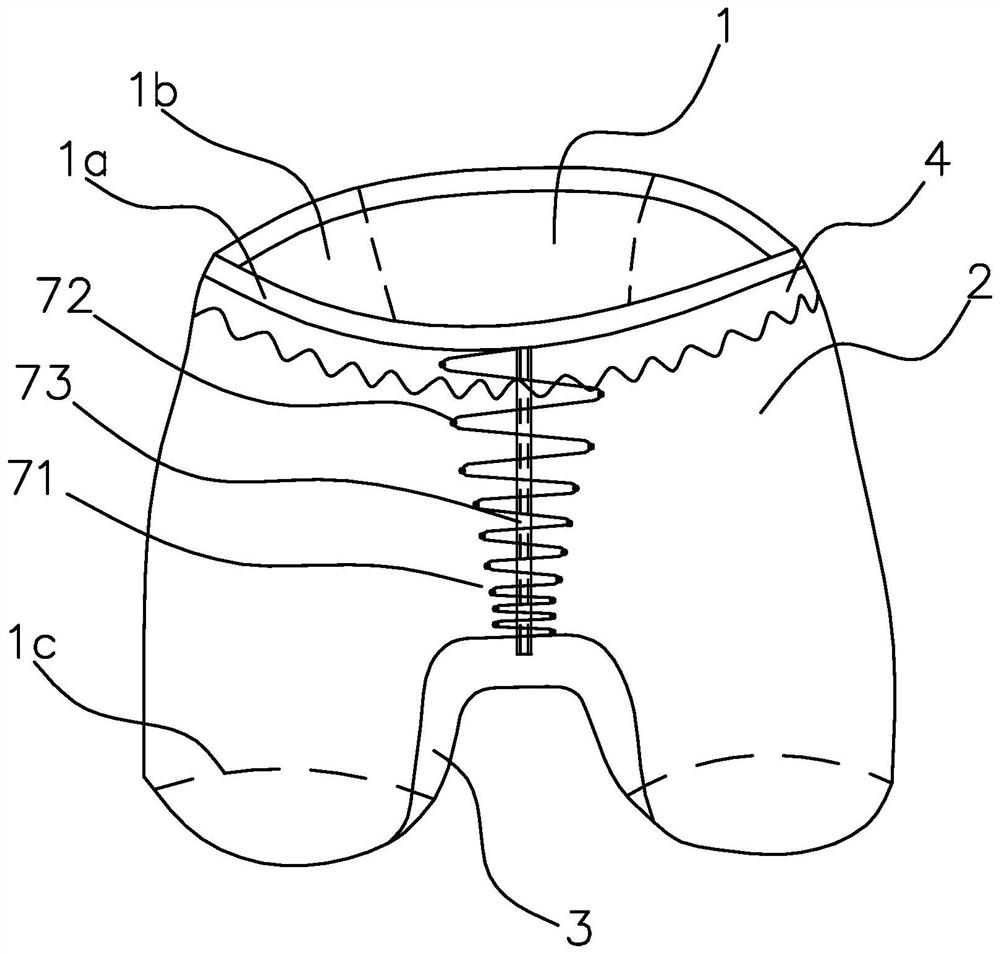

Traceless boxer super-fit leakage-proof menstrual period underpants

InactiveCN111802712AIncrease coverageNo strangulationHandkerchiefsBaby linensHuman bodyAnimal science

The invention relates to the field of underpants, particularly to a traceless boxer super-fit leakproof menstrual period underpants, which comprises a front sheet, a rear sheet and a bottom crotch which are used for being attached to the abdomen side of a human body, wherein the rear sheet and the bottom crotch are sewn and spliced front and back to form two trouser legs, an inner crotch for sticking a sanitary towel is arranged at the top end of the bottom crotch, and the inner crotch at the top end of the bottom crotch is bonded and fixed with an external sanitary towel. According to the invention, when menstrual blood tidal surge occurs to cause side leakage, the covering of the bottom crotch on the inner crotch is difficult to find, the inner crotch is used for locally absorbing the laterally leaked liquid, the absorbing liquid is blocked by the water-repellent layer of the inner crotch layer, part of leaked liquid can be blocked by the back surface of the water-repellent layer, sothat the side leakage liquid is prevented from diffusing through the hydrophilic layer to pollute the bottom crotch fabric during the use; and the covering length of the rear leakage-proof cloth exceeds the length of the worn sanitary towel, and when the side leakage liquid leaks towards the rear side through the inner crotch part, the leakage-proof cloth at the rear end can absorb leaked blood in time, so that the pollution area is reduced.

Owner:FUJIAN HENGAN HLDG CO LTD +2

Multifunctional material loading trestle bridge of waste-incineration power plant

ActiveCN103866685AImprove transportation efficiencyEasy to collectBridge applicationsStorage devicesPower stationSewage

The invention relates to a multifunctional material loading trestle bridge of a waste-incineration power plant. The multifunctional material loading trestle bridge comprises a material loading trestle bridge and truck scales, wherein the near-level grade section of the material loading trestle bridge is provided with a foundation pit; the foundation pit is internally provided with the first truck scale and the second truck scale which are mutually parallelly arranged along the longitudinal direction of the material loading trestle bridge; a concrete isolation strip is arranged between the first truck scale and the second truck scale along the longitudinal direction of the material loading trestle bridge on the outer side and is internally provided with more than two inner and outer access holes; the bottoms of the access holes are provided with sewage buckets; the sewage buckets are connected with an external leachate collecting system. According to the technical scheme adopted by the invention, the design is reasonable, so that the problems of non-corresponding relation between a material loading system and a weighing system and difficulty in leachate collection during the waste transportation peak period of an existing waste-incineration power plant can be solved, and the land of the waste-incineration power plant is saved; furthermore waste loading and weighing can be synchronously performed, so that the waste transportation efficiency is improved, environmental pollution is reduced, and the multifunctional material loading trestle bridge is applicable to all types of waste-incineration power plants.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

Forest-grass-poultry ecological cycle mode for improving economic benefits of carya illinoensis orchard

InactiveCN111955257ASlow runoff emergenceReduce churnHops/wine cultivationLiquid fertiliser distributionEcological environmentDrip irrigation

The invention relates to the technical field of carya illinoensis planting, and particularly provides a forest-grass-poultry ecological cycle mode for improving economic benefits of a carya illinoensis orchard. The ecological cycle mode comprises the steps of orchard site selection, variety selection, soil improvement, carya illinoensis planting, under-forest forage grass planting, poultry house construction and pasturing area division, irrigation and pest and disease damage management, poultry excrement treatment and use. Carya illinoensis planting, forage grass planting and poultry breedingare combined, the open space of an orchard forest is fully utilized, poultry are raised in the forest and fed by mowing forage grass, excrement generated by the poultry serves as organic fertilizer tobe applied to the orchard, and a water and fertilizer integrated drip irrigation system is adopted, so that water and soil protection is facilitated; moreover, the fertility of orchard soil is improved, the growth speed of trees is increased, the early economic benefits of the carya illinoensis orchard are improved, the growth of miscellaneous trees and weeds is reduced, the pesticide pollution area of forest land is reduced, the ecological environment of the orchard is obviously improved, and the ecological benefits are obviously improved.

Owner:INST OF BOTANY JIANGSU PROVINCE & CHINESE ACADEMY OF SCI

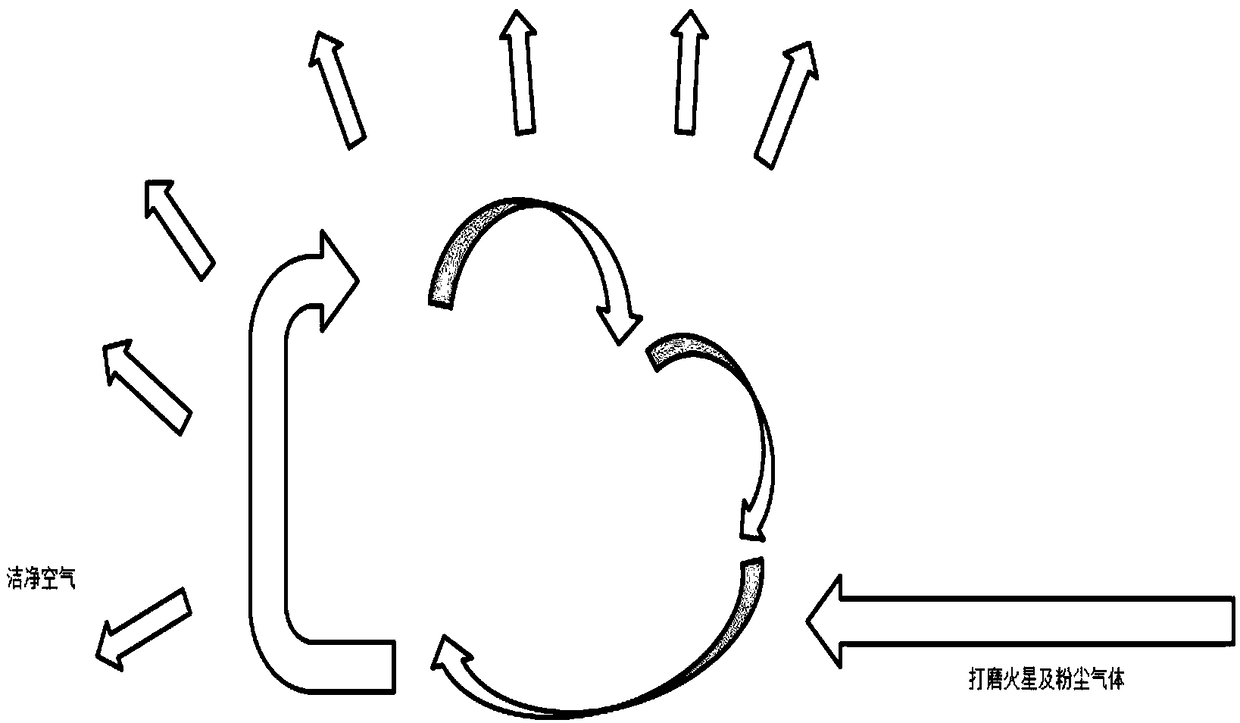

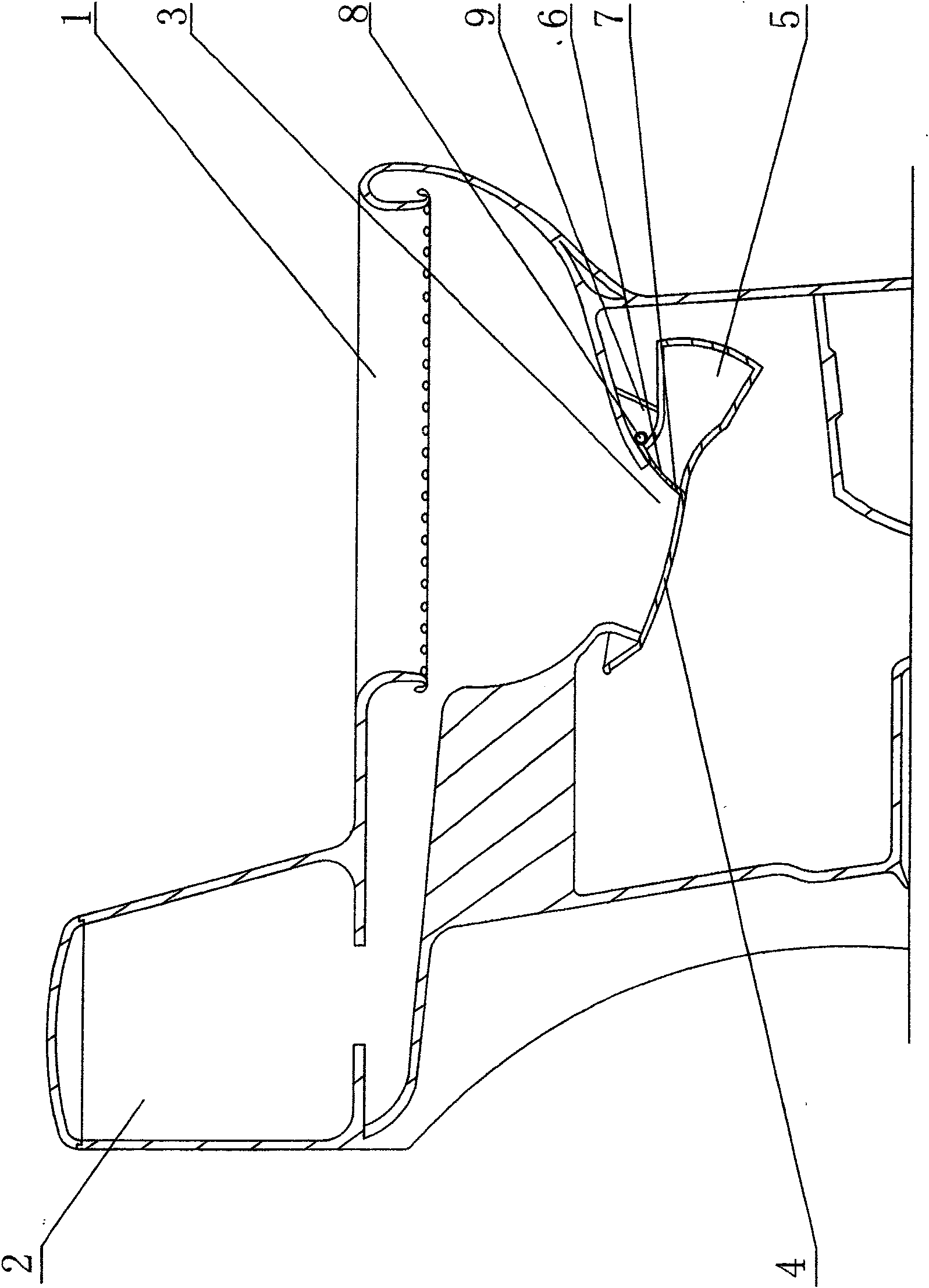

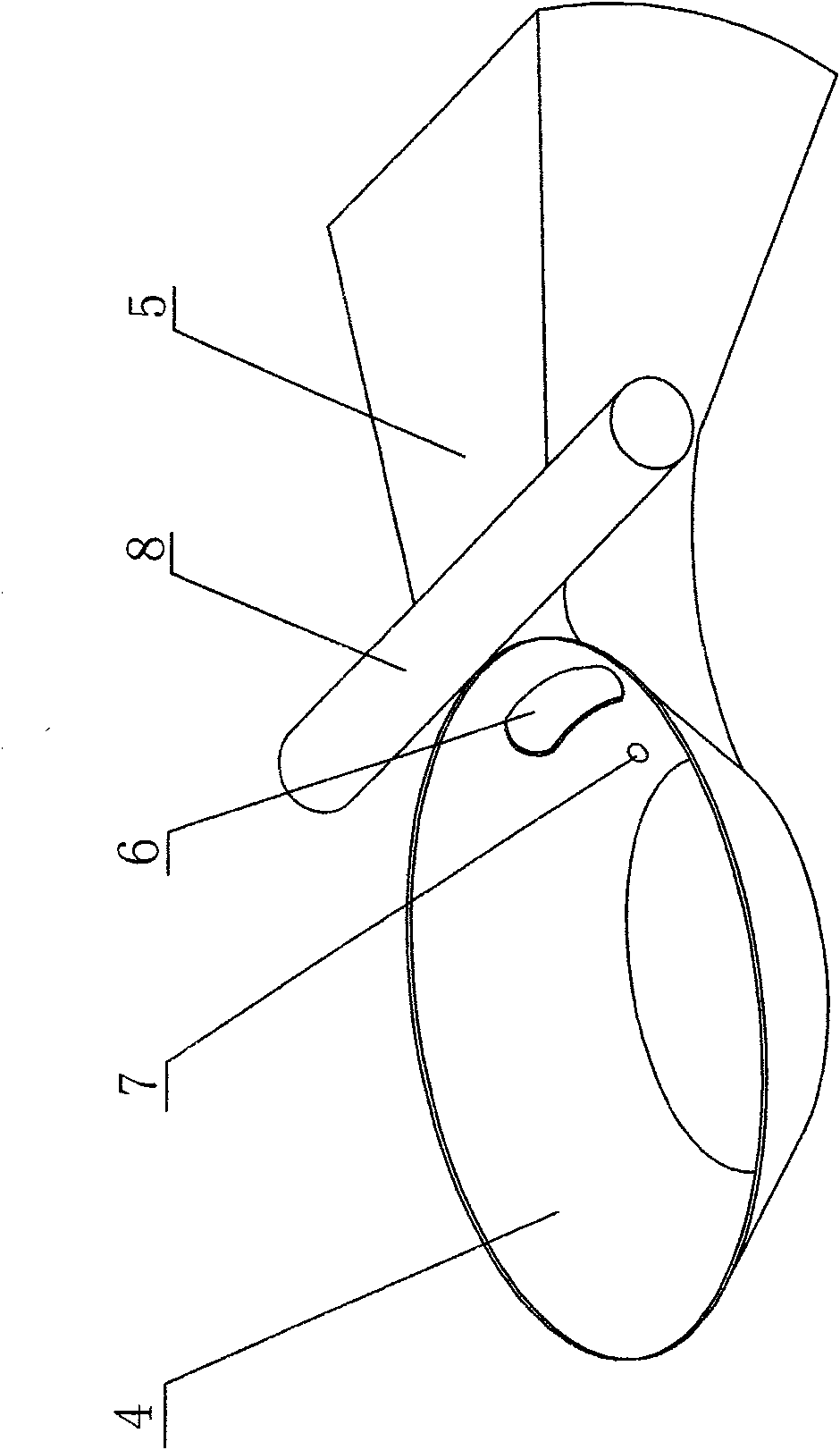

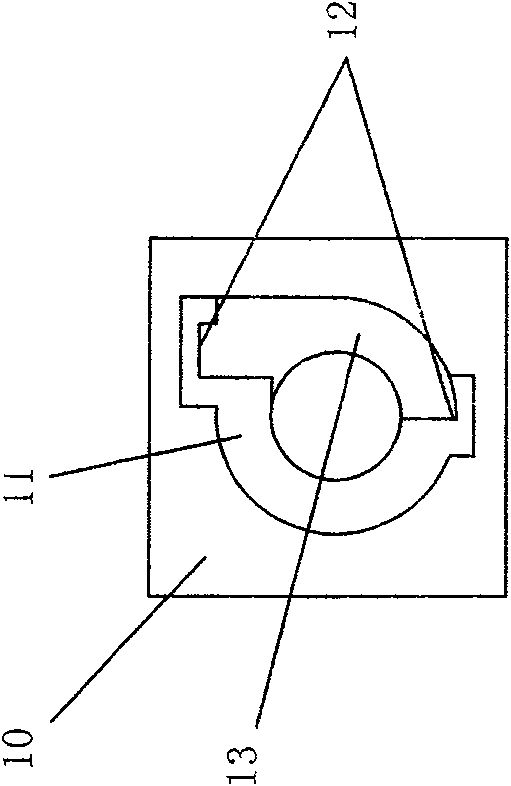

Grinding protecting and dust gathering device

PendingCN108687667AImprove work efficiencyAvoid affecting grinding efficiencyGrinding/polishing safety devicesSurface cleaningEngineering

The invention relates to the technical field of grinding protecting and dust treating, and particularly provides a grinding protecting and dust gathering device. The grinding protecting and dust gathering device comprises magnets, magnet framework linkage buckles and a supporting framework. The supporting framework and the multiple magnets are connected together through the magnet framework linkage buckles, and it can be achieved that during grinding work, the magnets can be attracted to the surface of a casting at any angle according to the actual production requirements through the magnetismof the magnets. The device is used for filtering and gathering dust generated in the surface cleaning processes such as grinding and relief grinding on the surface of the steel part by operators andprotecting other people against spark harm, the grinding efficiency is prevented from being affected, the surroundings during cleaning of the surface of the steel casting are improved, and the workingefficiency of grinding of the surface of the casting by the operators is improved.

Owner:KOCEL STEEL

Fluid power flushing toilet

InactiveCN100585102CAvoid easy cloggingReduce pollution areaWater closetsFlushing devicesSewageFlush toilet

Owner:李发中

Auxiliary support of building wall drilling machine

InactiveCN112140359AReduce vibrationReduce pollution areaWorking accessoriesStone-like material working toolsArchitectural engineeringDust control

The invention discloses an auxiliary support of a building wall drilling machine. The auxiliary support comprises a box body, wherein a dust removal device is arranged on the front side in the box body, the dust removal device comprises a dust removal cavity which is formed in the box body and provided with a forward opening, a dust removal baffle is arranged in the dust removal cavity in a sliding mode, dust removal sliding cavities which are symmetrical left and right are formed in the rear end wall of the dust removal cavity in a communicating mode, electromagnetic plates are fixedly arranged on the end walls of the ends, far away from the drilling machine, of the dust removal sliding cavities, and electric sliding blocks are arranged on the end faces of the ends, close to the drillingmachine, of the electromagnetic plates in a sliding mode. According to the auxiliary support, the drilling machine can be directly fixed to carry out wall drilling work, meanwhile, the totally-closedbaffle is arranged around a drilled hole, so that waste chips and dust generated during wall drilling can be collected for treatment, the pollution area is greatly reduced, and the situation that thework of workers is influenced due to flying of the waste chips and the dust is avoided; and the wall drilling position can be adjusted, the support does not need to be repeatedly erected for drilling,and the operation is convenient and rapid.

Owner:FUZHOU GULOU TONGZHENG TECH CO LTD

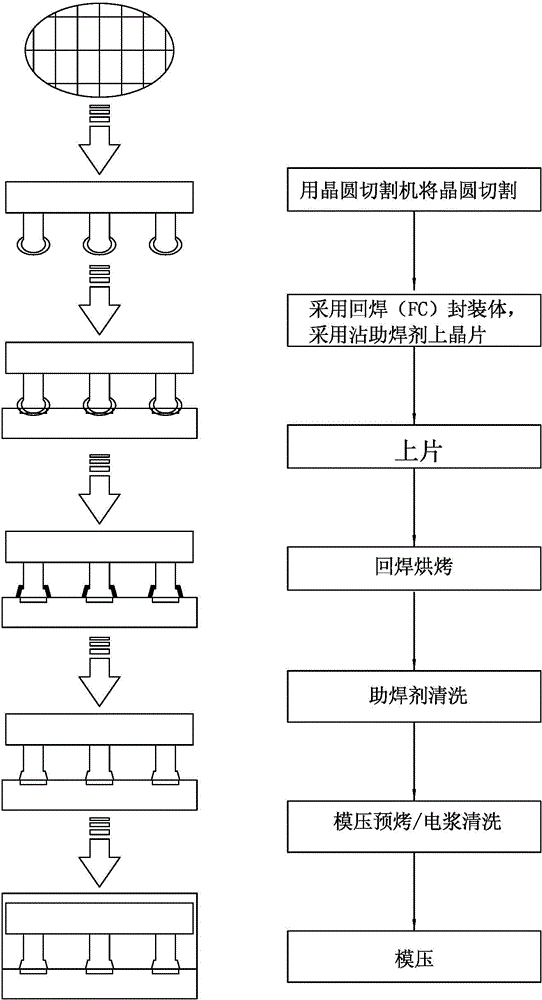

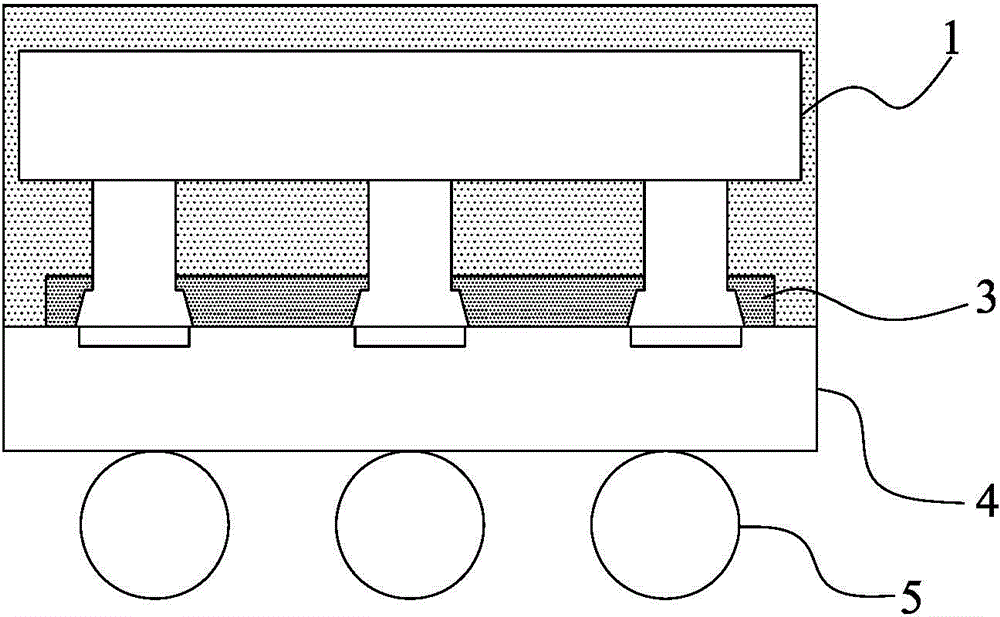

Wafer encapsulation method

InactiveCN106158671AImprove tin cold soldering conditionHinder heat diffusionSolid-state devicesSemiconductor/solid-state device manufacturingSteel platesSoldering

The invention discloses a wafer encapsulation method. The method comprises the following steps that: a wafer cutter is utilized to cut a wafer, a wafer is sucked by a wafer mounting device, and the tin bumps of the wafer are coated with soldering flux; a paste coating and printing device is utilized to apply non-conductive paste onto the front surface of a substrate by means of steel plate printing, rubber head transfer or air valve jet printing; the tin bumps are directly welded on the copper pads of the substrate through using a post-tin melting welding technology under 290 DEG C to 300 DEG C; a post-wafer mounting material is baked, and plasma cleaning and resin mould pressing encapsulation are carried out; and a post-tin melting welding encapsulation body can be obtained. According to the wafer encapsulation method of the invention, the post-tin melting welding encapsulation body is obtained through a post-tin melting welding procedure; the post-tin melting welding encapsulation body requires the application of one non-conductive paste layer onto the surface of the substrate, and a paste coating and printing machine has a built-in non-conductive paste coating function, and therefore, work hours are not affected. Compared with a conventional wafer encapsulation process, the wafer encapsulation method does not contain reflow baking and soldering flux washing, and therefore, equipment can be reduced, and manpower and soldering flux cleaning costs can be also decreased.

Owner:双峰发展顾问有限公司

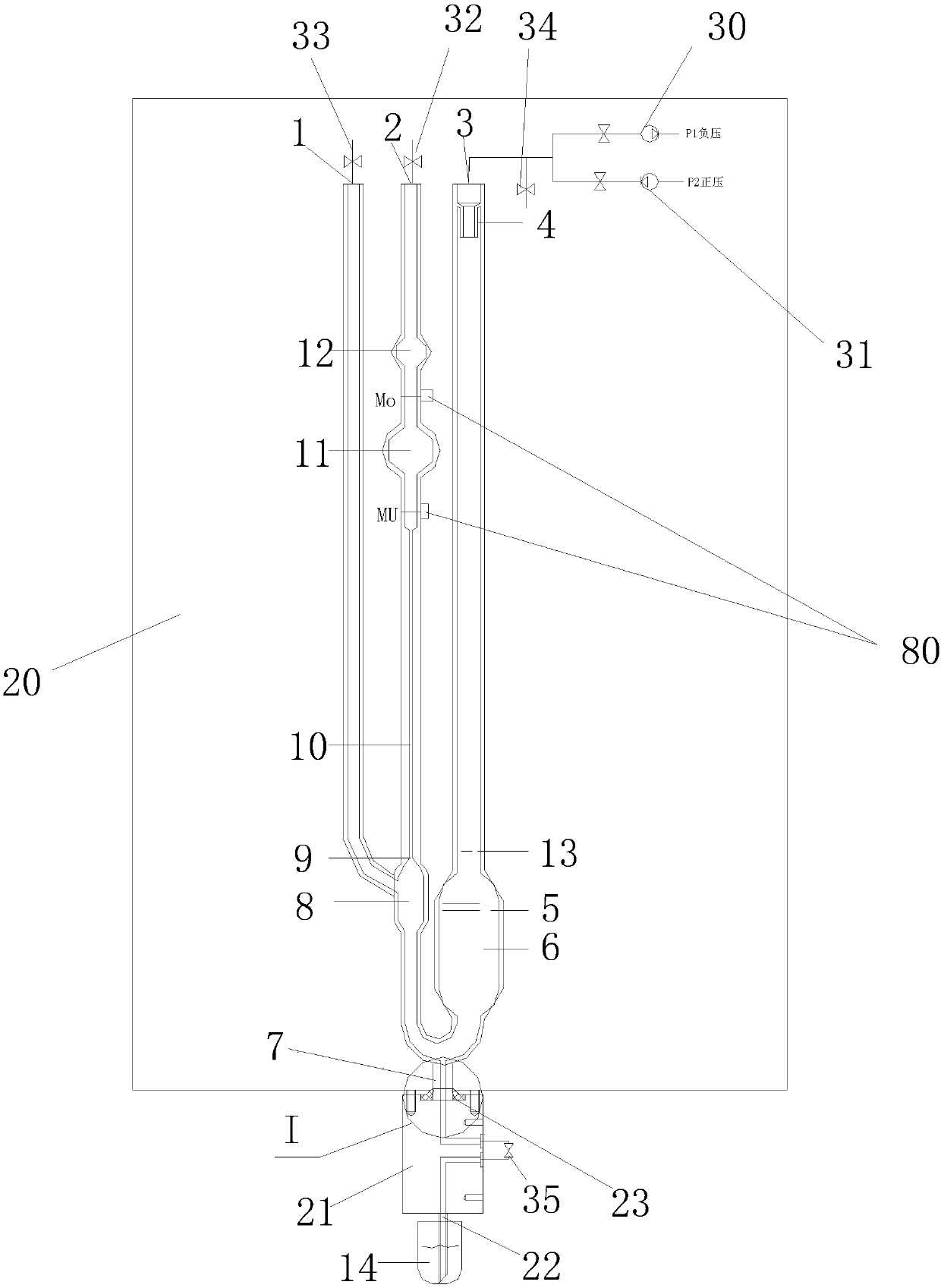

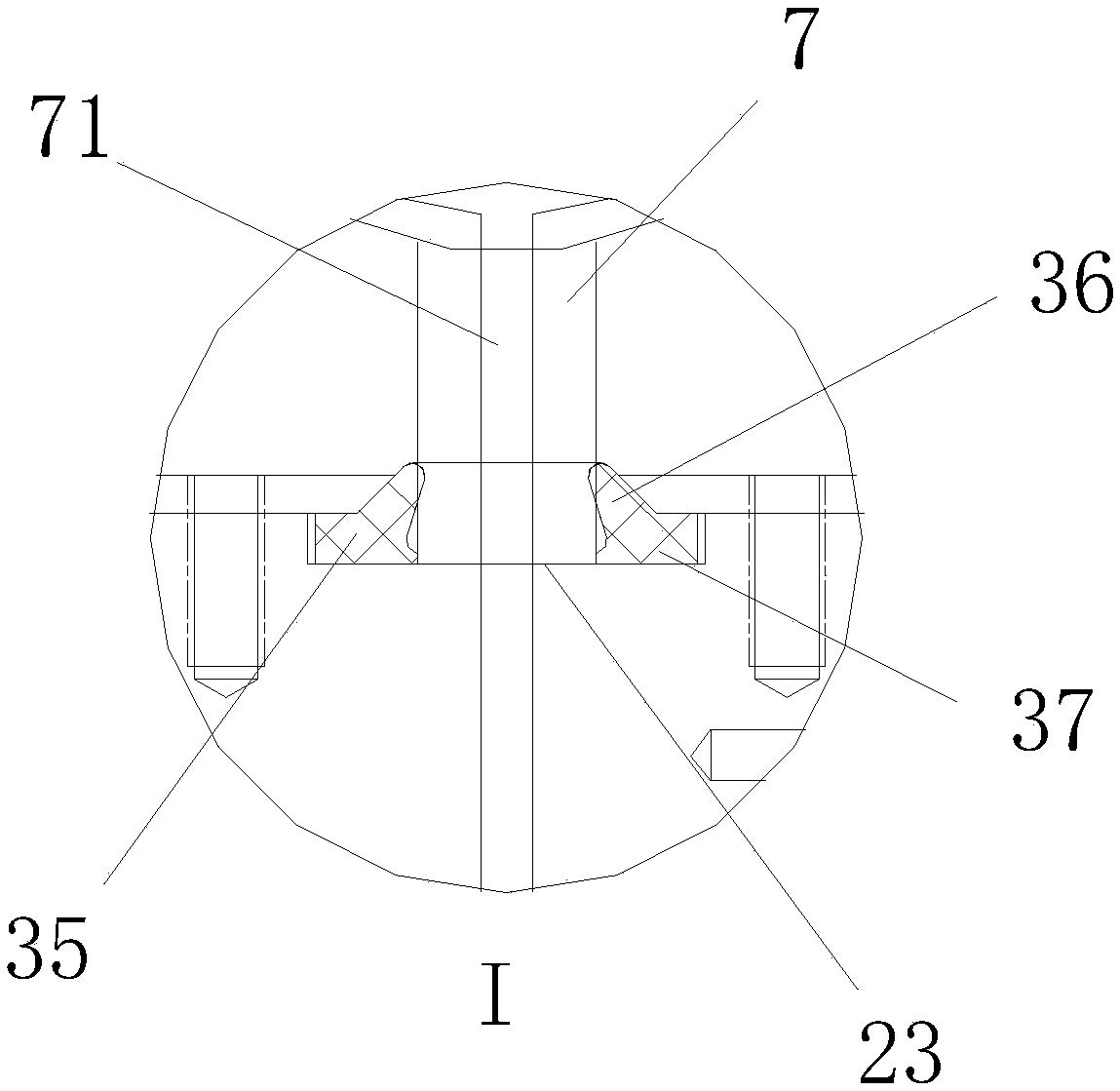

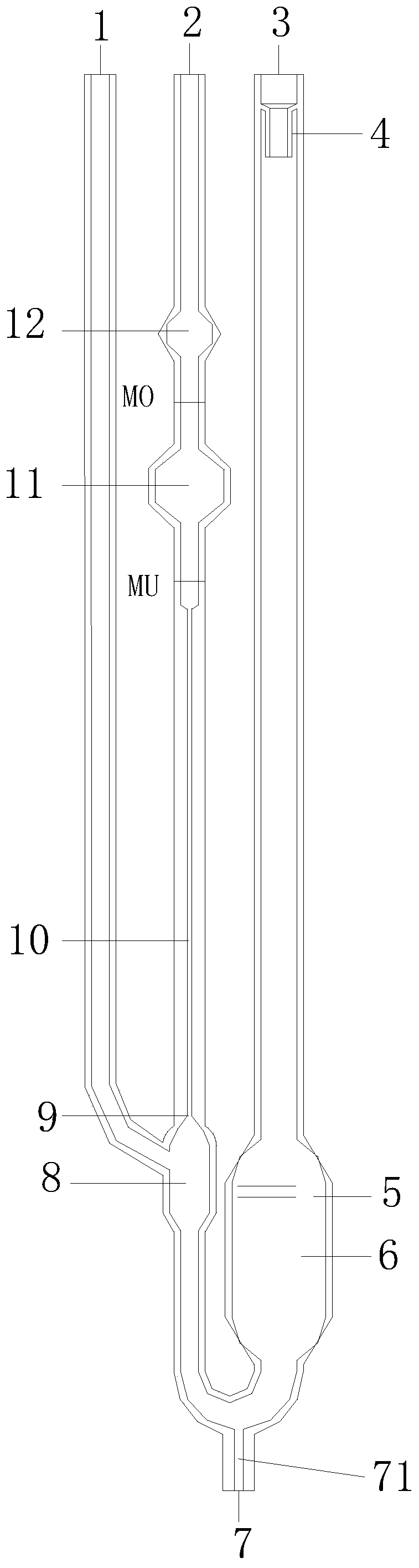

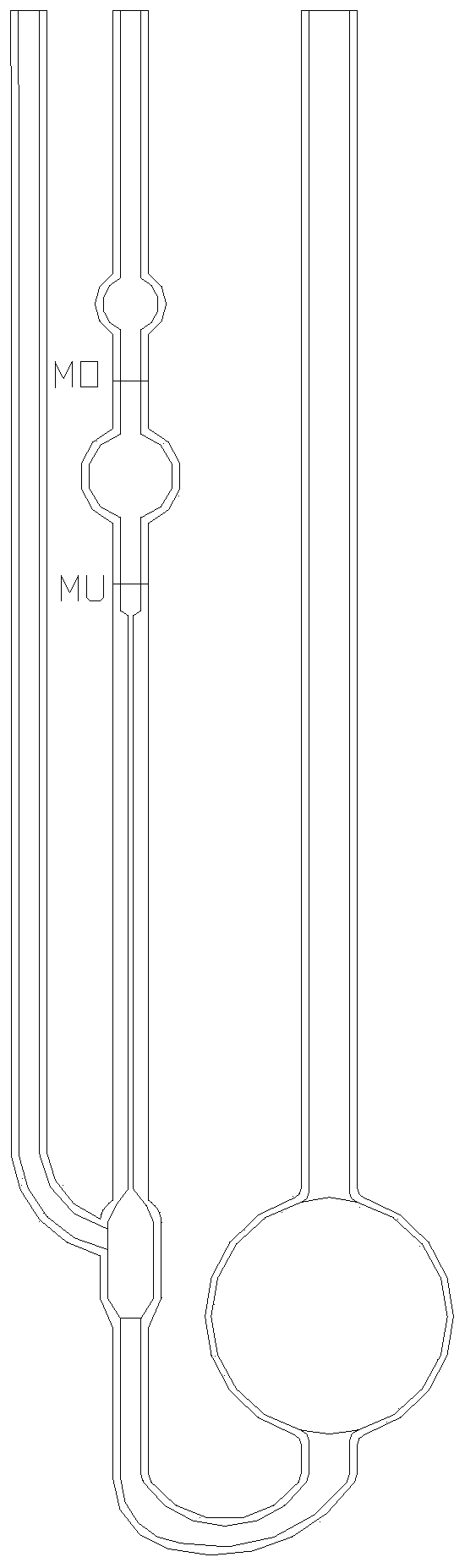

Fully-automatic Ubbelohde viscometer and measurement method

ActiveCN107907446AHigh measurement accuracyImprove fluid utilizationDirect flow property measurementEngineeringFully automatic

The invention relates to the field of viscometers, and discloses a fully-automatic Ubbelohde viscometer and a measurement method. The fully-automatic Ubbelohde viscometer comprises an installation box(20) and an Ubbelohde viscometer installed in the installation box (20), wherein the Ubbelohde viscometer comprises a liquid sucking and discharging pipe (3) and a measurement pipe (2), a lower liquid storage ball (6) is connected below the liquid sucking and discharging pipe (3), a liquid inlet and discharge pipe (7) directly inserted into a sample bottle is communicated below the lower liquid storage ball (6), the bottom portion of the measurement pipe (2) is communicated to the bottom portion of the lower liquid storage ball (6), one side of the measurement pipe (2) is connected to an emptying pipe (1), the opening of the liquid sucking and discharging pipe (3) is connected to a liquid sucking device (30) and a liquid pushing device (31), the measurement pipe (2) is connected to a first opening / closing device (32) for controlling the sealing of the opening of the measurement pipe (2), and the emptying pipe (1) is connected to a second first opening / closing device (33) for controlling the sealing of the opening of the emptying pipe (1). According to the present invention, the fully-automatic Ubbelohde viscometer has advantages of high automation degree, high liquid recovery rate, resource saving, convenient cleaning and the like.

Owner:杭州震越科技有限公司

stove burner

A stove burner comprises a furnace head, an outer-ring gas ejector pipe, an inner-ring gas ejector pipe and a burner cap, wherein first main flame slots and second main flame slots which are radially distributed are formed in the upper surface of the burner cap along the circumferential direction, and arranged in a spacing manner; meanwhile, the slotting depth of each first main flame slot is greater than that of each second main flame slot; the length of each first main flame slot is greater than that of each second main flame slot; an upper-ring flame channel is formed between the peripheral part of a cover plate as well as the first main flame slots and the second main flame slots, and communicates with an inner-ring cavity; and a lower-ring flame channel positioned below the upper-ring flame channel is also formed in the burner cap, and communicates with the outer-ring cavity. After the stove burner provided by the invention adopts the upper-ring and lower-ring flame design, both the slight flaming effect and the flame stabilizing effect of lower-ring flame can be achieved; as the first main flame slots and the second main flame slots are arranged in a spacing manner, the secondary air supplementing effect is better; and in addition, the diameter of the stove burner is relatively small, so that is not only the heat efficiency improved, but also the stove burner is easier to clean.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

A kind of Ubbelohde viscometer

ActiveCN107884314BEmission reductionSimple purification and reuseViscometer maintainanceDirect flow property measurementAutomatic controlCapillary Tubing

The invention relates to the field of viscometers, and discloses a ubbelohde viscometer. The ubbelohde viscometer comprises a liquid draining pipe (3) and a measurement pipe (2), wherein a lower liquid storage ball (6) is connected with the lower part of the liquid draining pipe (3); the lower part of the lower liquid storage ball (6) is communicated with a liquid inlet and outlet pipe (7) which is directly inserted into a sample bottle; the bottom of the measurement pipe (2) is communicated with the bottom of the lower liquid storage ball (6); one side of the measurement pipe (2) is connectedwith a blow-down pipe (1); the measurement pipe (2) is sequentially connected with an upper liquid storage ball (12), a timing ball (11), a capillary pipe (10) and a suspending liquid column ball (8)from top to bottom; and the suspending liquid column ball (8) is communicated with the liquid inlet and outlet pipe (7) and the lower liquid storage ball (6). The viscometer has the advantages of accurate measurement and simple liquid reclaiming and the like, is easy for automatic control, and is convenient to wash.

Owner:杭州震越科技有限公司

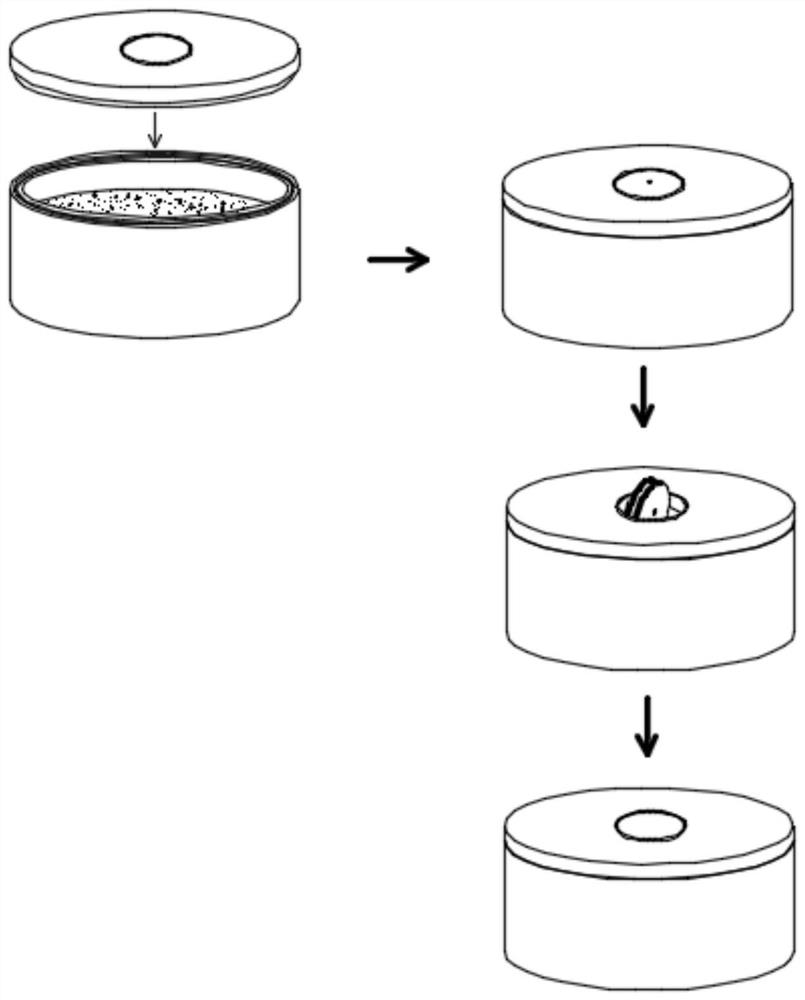

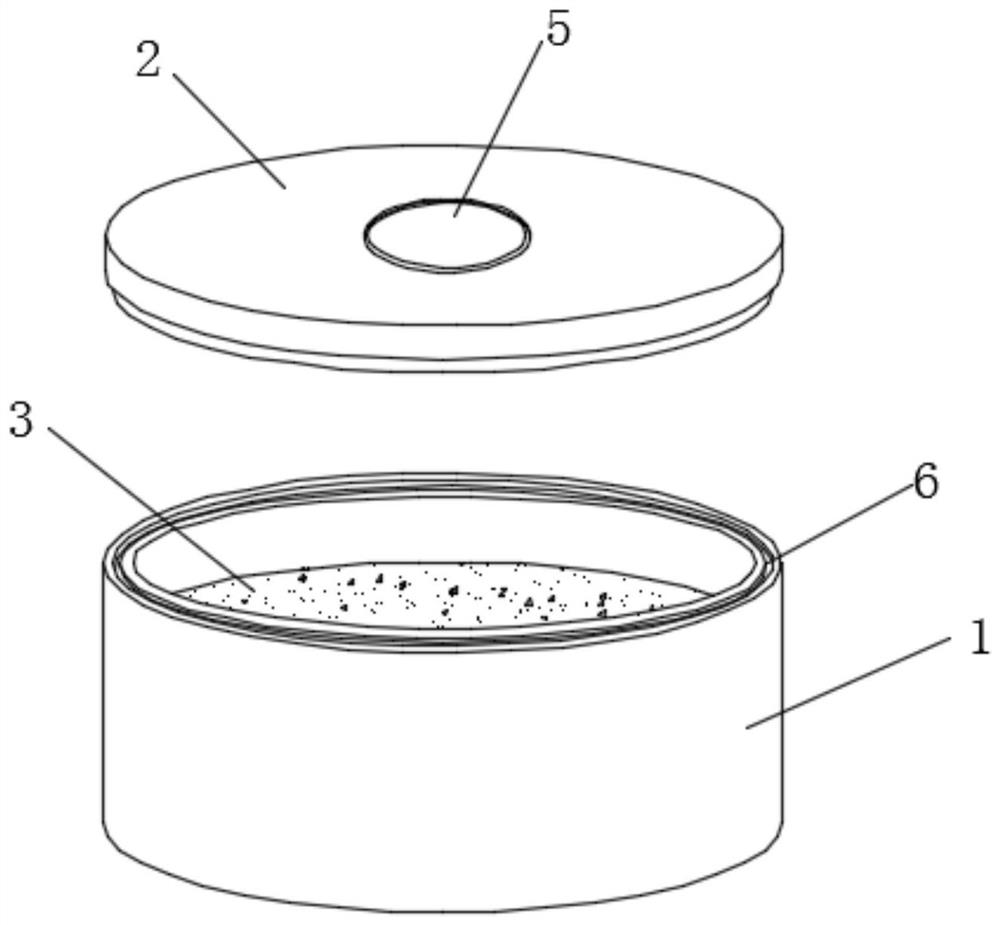

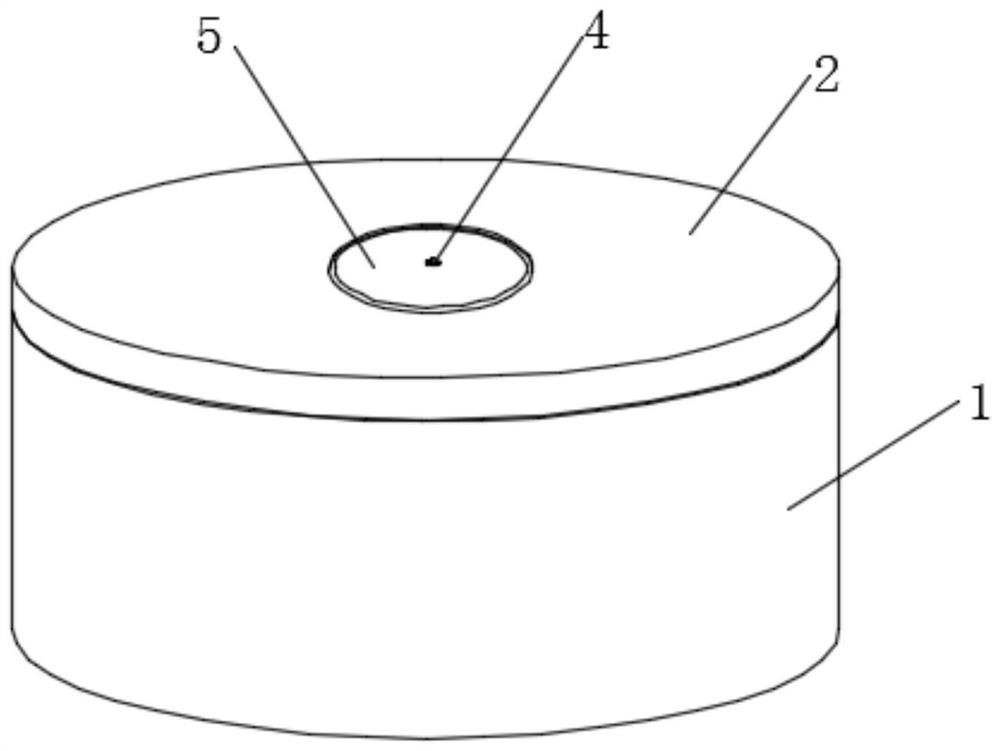

Stem cell directed differentiation device and method of use thereof

ActiveCN110283722BAvoid flippingSmooth preparation processBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyPetri dish

The invention discloses a device for directional differentiation of stem cells and a method for using the same, belonging to the field of cell differentiation devices. A device for directional differentiation of stem cells comprises a bacterial culture dish body and a culture cover. A first annular sealing groove is dug at the upper end of the bacterial culture dish body. The lower end of the culture cover is fixedly connected with an integral sealing ring matching the first annular sealing groove. A round hole is dug in the center of the culture cover, and an auxiliary culture cover is arranged at the round hole. rod, and a pair of cylindrical rotating rods are symmetrically distributed on the auxiliary culture cover with the center of the auxiliary culture cover as the center. Partial flipping, compared with the original flipping method, can reduce the area of contamination during the partial flipping process by at least 95%, ensuring the smooth preparation of embryoid bodies and promoting the directional differentiation process of stem cells.

Owner:华夏源细胞工程集团股份有限公司

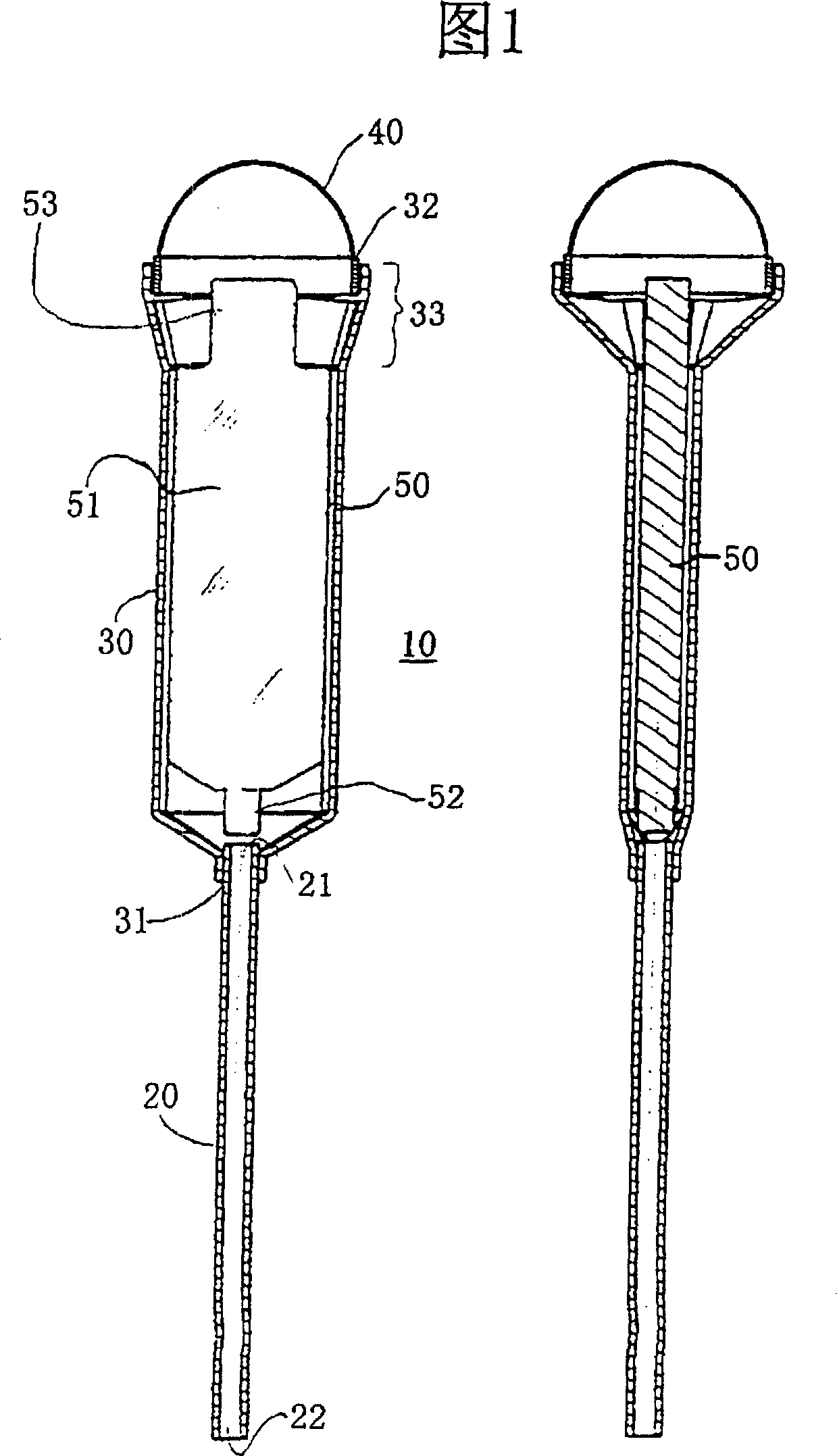

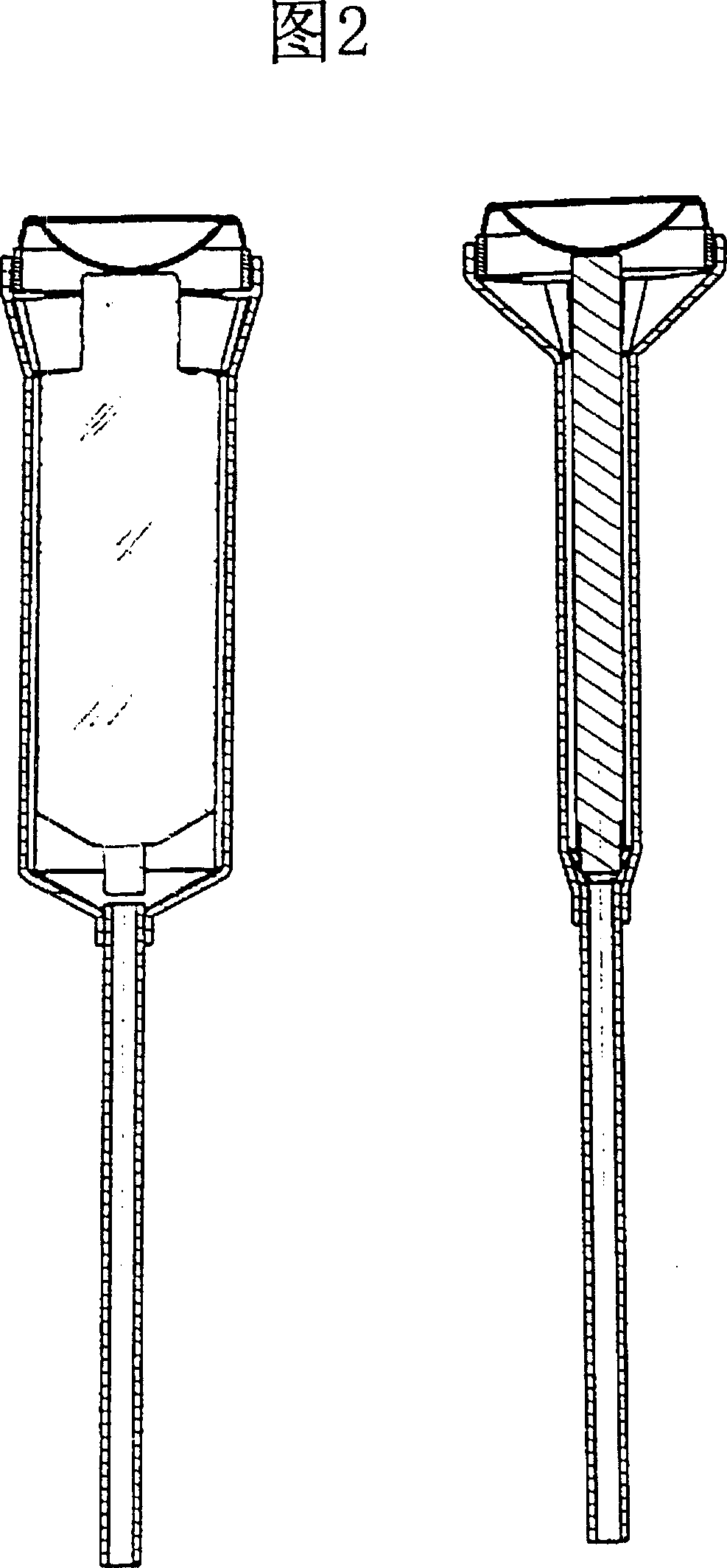

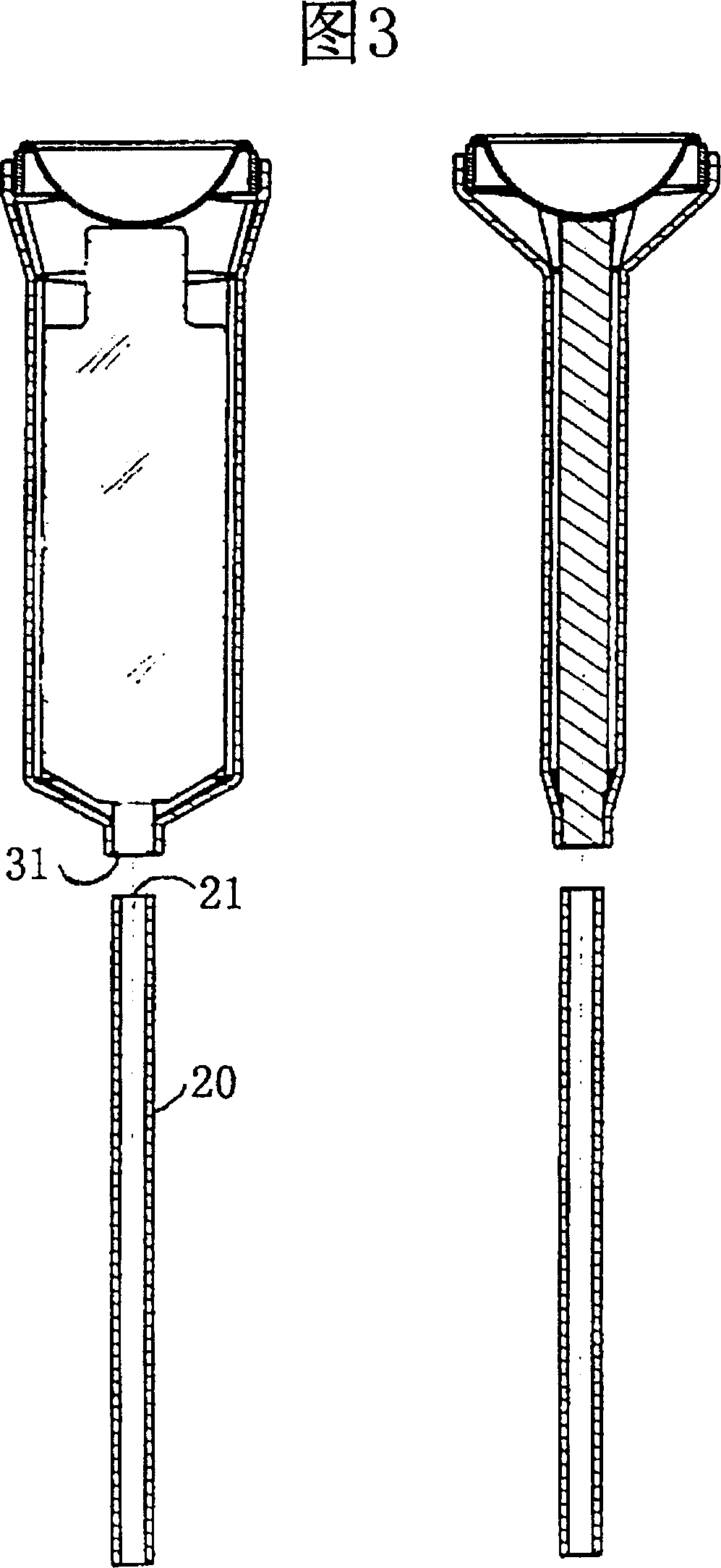

Equipment and method for detecting liquid fluid

InactiveCN1313592CReduce manufacturing costReduced number of different partsMicrobiological testing/measurementBiological testingLiquid stateEngineering

The equipment for simplifying sampling process and detecting liquid fluid, minimizing pollution and inhibiting bacterial growth includes a pointed end, a container, a regulating device which is connected with said container and is flexible, said regulating device and the container are formed into an opened continuous compartment, and a mobile member which is placed in the container and mechanically acted by regulating device. Said invention also relates to a method for simplifying sampling and detecting fluid.

Owner:CELL WORKS

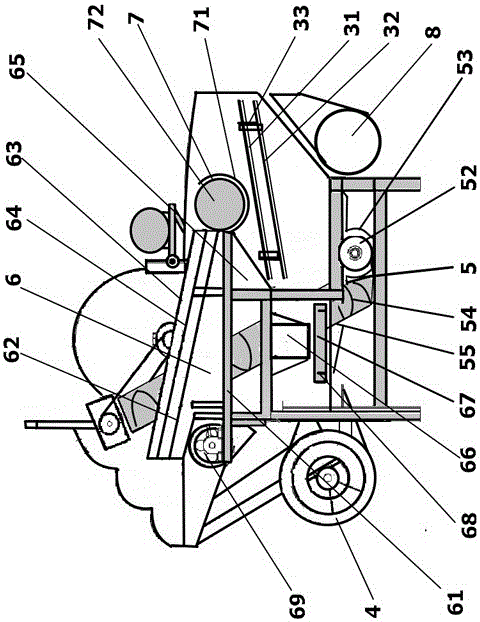

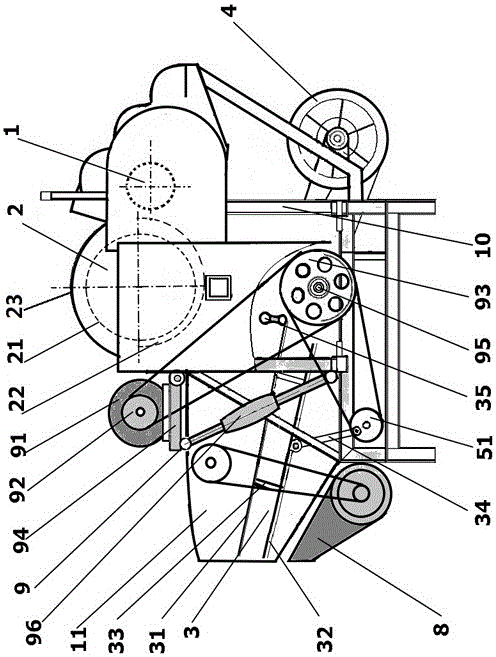

Selected grain thresher

InactiveCN107517666AReduce windOvercoming the disadvantage of being difficult to be blown out of the machineThreshersLoss rateElectricity

The invention relates to a selected grain thresher. The main assessment indicators of the existing threshers are the total loss rate, crushing rate, impurity content rate, and cleaning rate, etc., which cannot meet the standards, resulting in poor grain quality and poor applicability. The invention includes a frame and a feeding mechanism arranged on the frame, a crushing and threshing mechanism, a winnowing device, a secondary cleaning device, a power source mechanism, and a transmission mechanism. The feeding mechanism is arranged at the front part of the crushing and threshing mechanism. The lower part of the crushing and threshing mechanism is equipped with a wind separation device, and one side of the frame is equipped with a secondary cleaning device, and the wind separation device communicates with the secondary cleaning device through a transport mechanism. The invention avoids the grain being blown out of the machine, overcomes the shortage that orange stalk powder is difficult to be blown out of the machine, improves the screening efficiency, realizes that the crushed orange stalk is blown out by one outlet, reduces the area polluted by sand and dust, and adapts to various Energy, use electricity with electricity, use tractor energy without electricity, so that customers have one more choice.

Owner:MOYU COUNTY YIJIADI AGRI MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com