Washing recycling treatment process of sludge from physical and chemical treatment and special apparatus for process

A treatment process and special equipment technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of low efficiency of physical and chemical sludge treatment, secondary pollution, etc., reduce environmental pollution and floor space, and realize resource utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

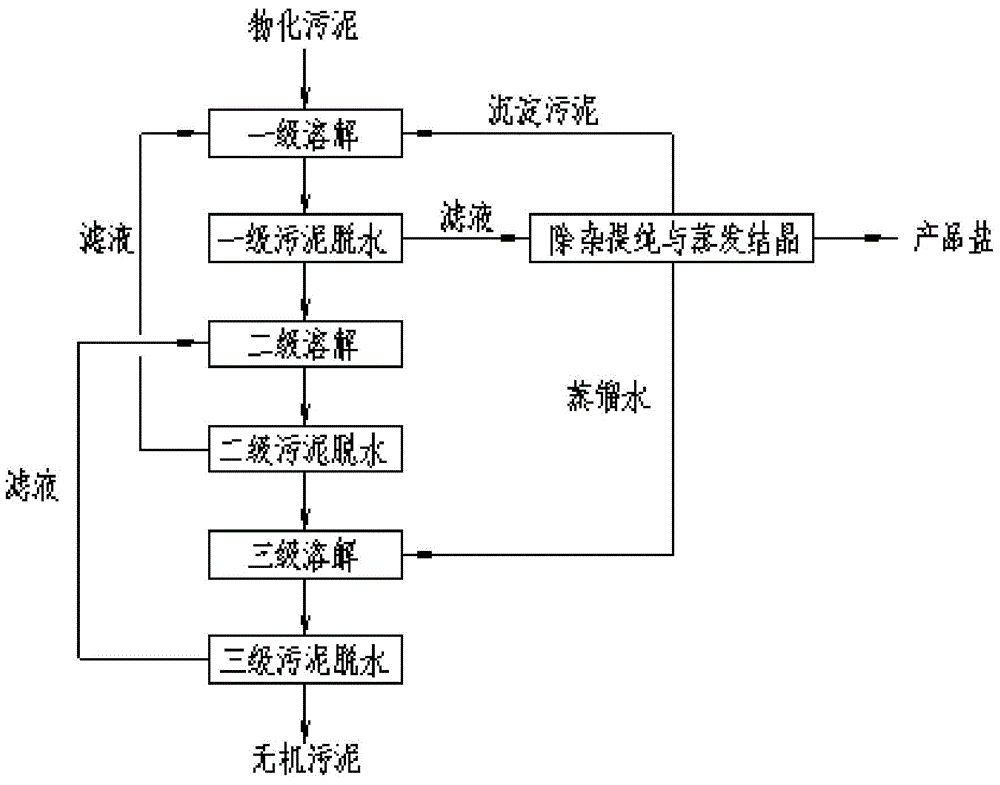

Method used

Image

Examples

Embodiment

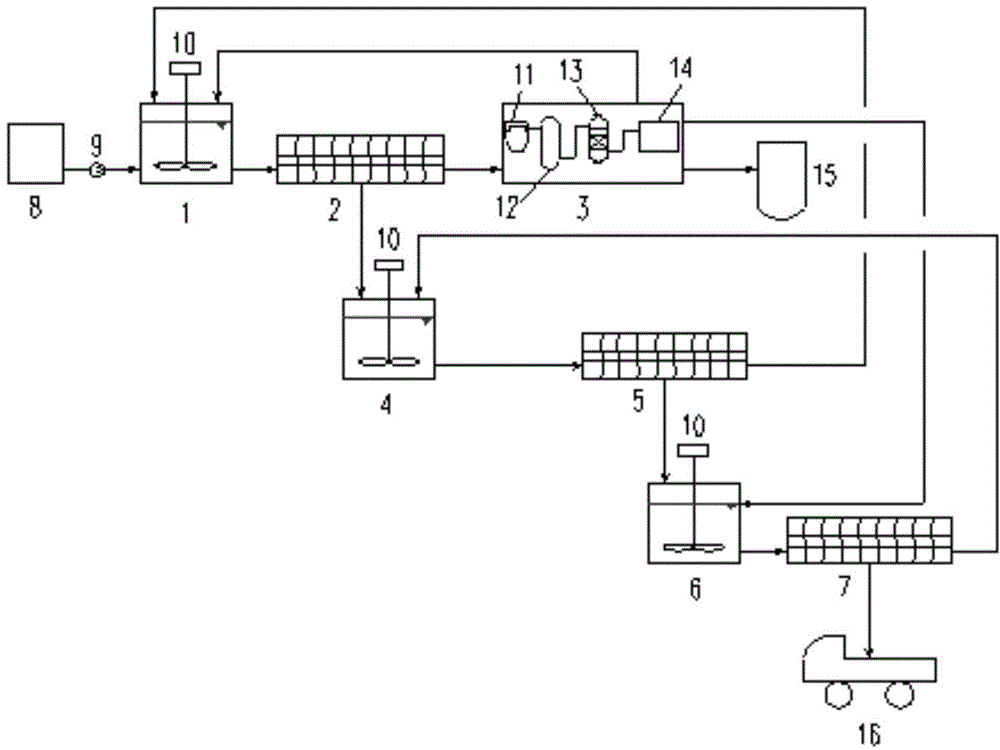

[0029] as attached figure 2 The special equipment for the physical and chemical sludge washing and recycling treatment process shown includes a primary dissolution tank 1, a primary sludge dehydration unit 2, impurity removal purification and evaporation crystallization equipment 3, a secondary dissolution tank 4, and secondary sludge dehydration Unit 5, tertiary dissolving tank 6, tertiary sludge dehydration unit 7.

[0030] The sludge silo 8 is connected to the first-stage dissolving tank 1, and the connecting pipeline is equipped with a feed pump 9, the output end of the first-stage dissolving tank 1 is connected to the first-stage sludge dewatering unit 2, and the filtrate output of the first-stage sludge dewatering unit 2 The end is connected to the impurity removal, purification and evaporation crystallization equipment 3, the dewatered sludge end is connected to the secondary dissolution tank 4, the sedimentation sludge end of the impurity removal, purification and eva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com