Crystalline silicon ingot casting furnace

A technology of ingot casting furnace and silicon liquid, which is applied in the field of solar cell manufacturing technology, can solve the problems of failure to issue emergency alarms in time, messy flow paths of silicon liquid, lagging treatment of silicon liquid overflow, etc., and achieve single overflow path of silicon liquid, The effect of high safety and short flow time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

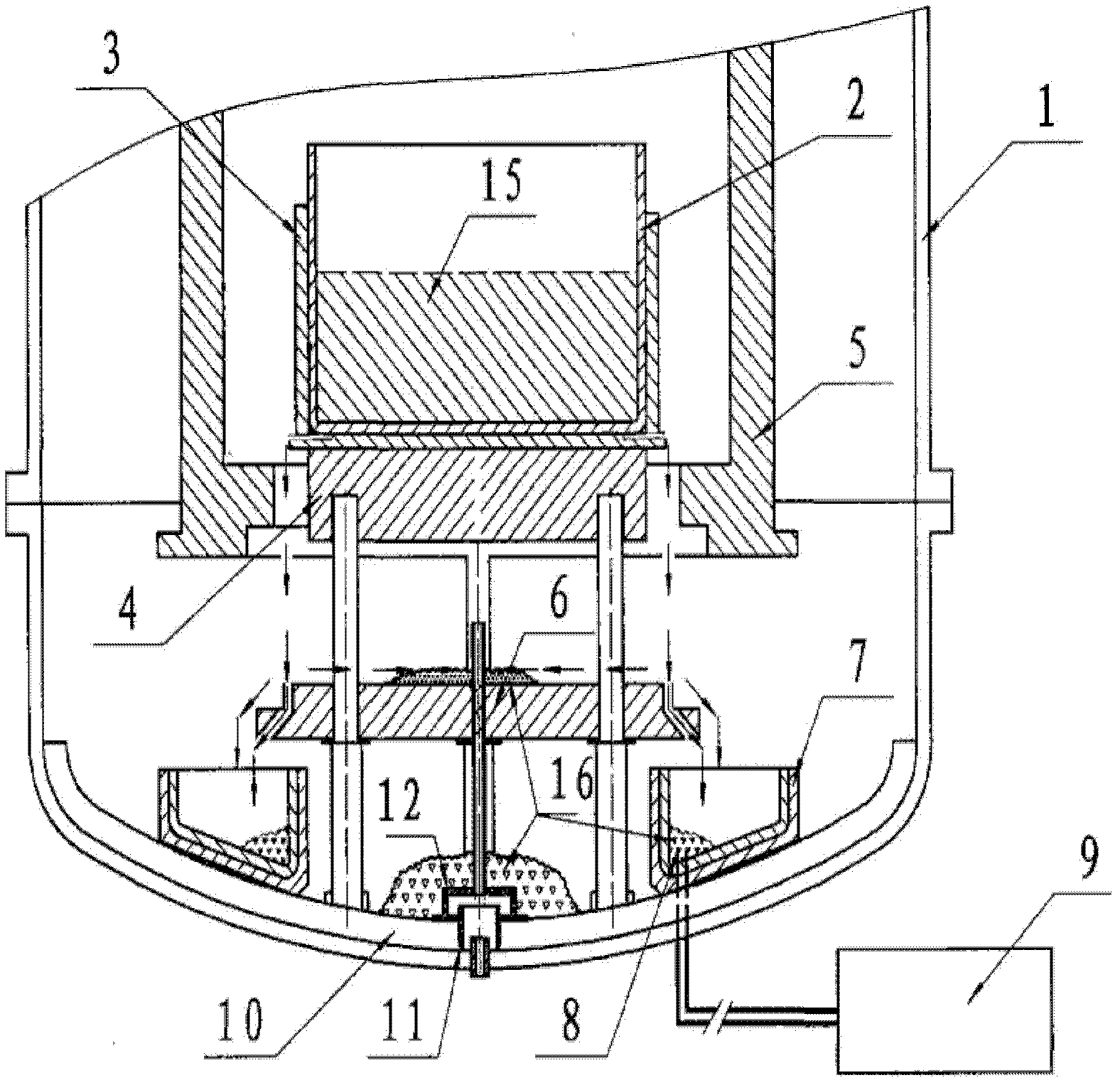

[0043] In view of the above problems, this embodiment provides a crystalline silicon ingot furnace provided with an overflow protection device for silicon liquid, including:

[0044] Furnace body

[0045] A crucible arranged in the furnace body, the crucible is preferably a quartz crucible, and is used for containing silicon material;

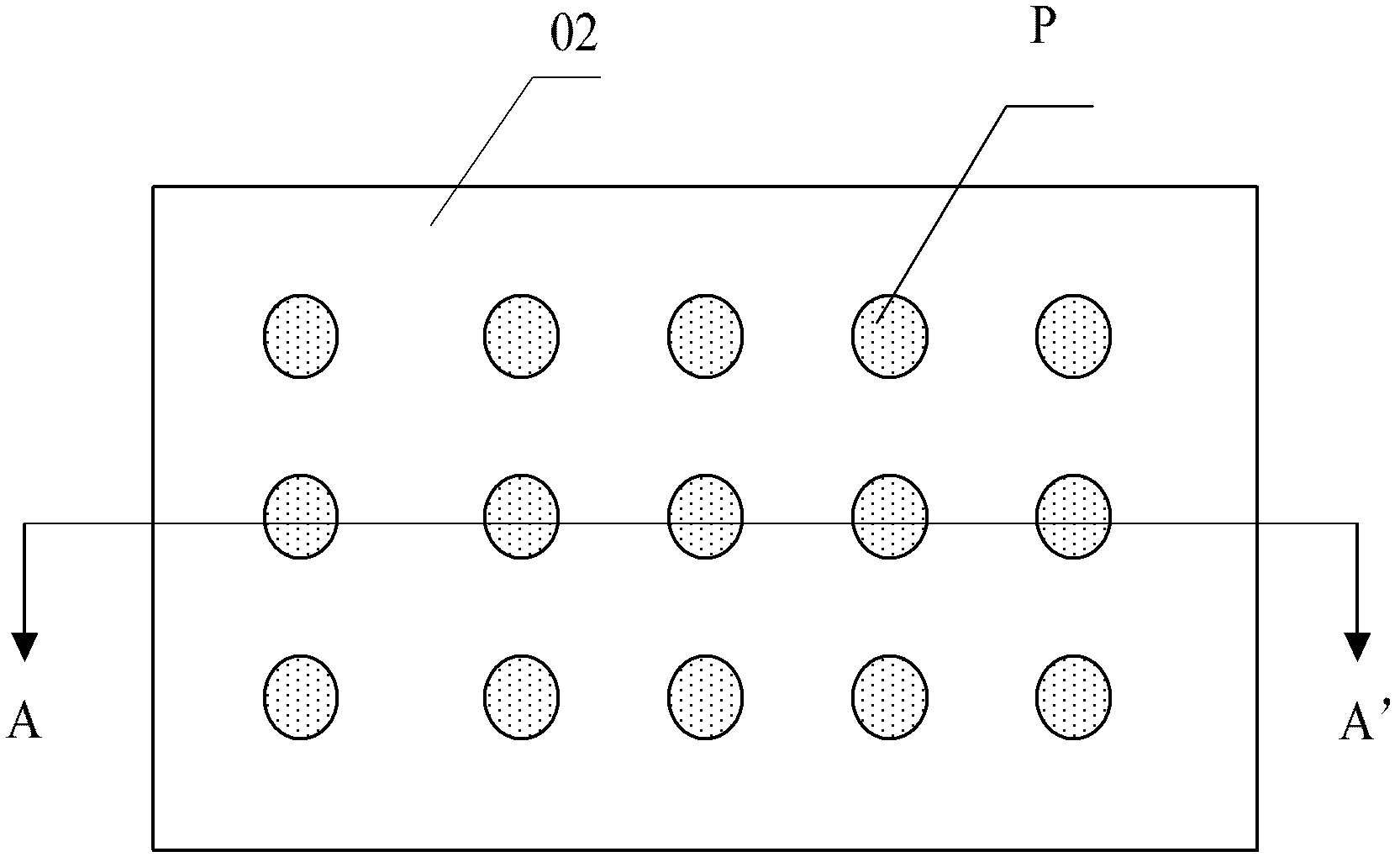

[0046] The crucible bottom plate is located below the bottom of the crucible. The crucible bottom plate is provided with a plurality of diversion holes penetrating the crucible bottom plate. When the crucible accidentally ruptures and causes the silicon liquid to overflow, the overflowing silicon liquid is removed from the crucible The bottom part passes through the bottom plate of the crucible through the orifice provided on the bottom plate of the crucible;

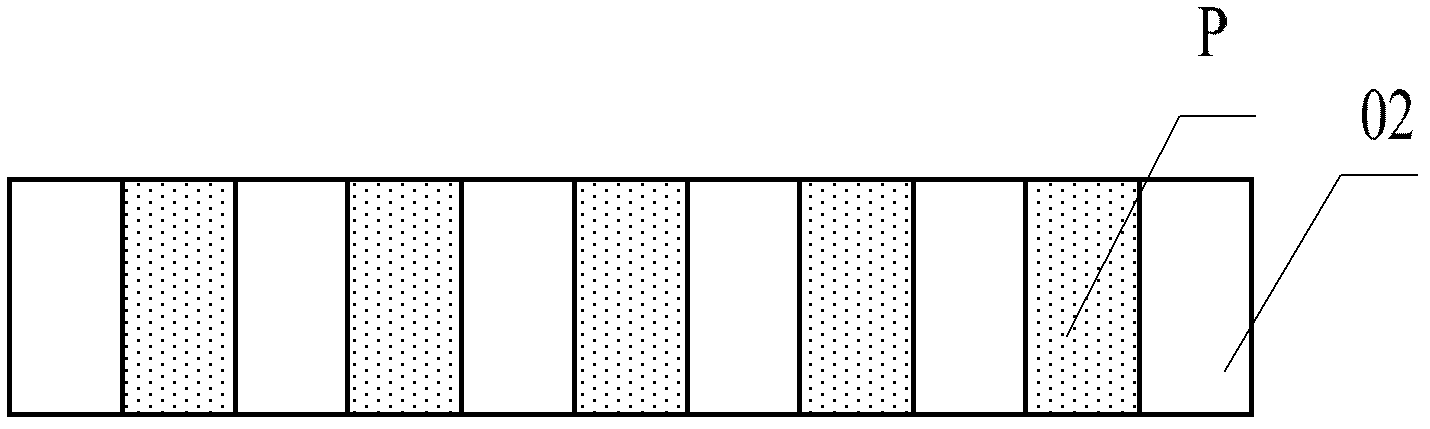

[0047] A cooling block located under the crucible bottom plate, the cooling block is provided with at least one flow guide groove;

[0048] A flow guide tube arranged under the cooling block, the...

Embodiment 2

[0053] Based on the above embodiments, the present invention also provides a crystalline silicon ingot furnace provided with a silicon liquid overflow protection device, including:

[0054] Furnace body

[0055] A crucible arranged in the furnace body, the crucible is preferably a quartz crucible, and is used for containing silicon material;

[0056] The crucible bottom plate is located below the bottom of the crucible. The crucible bottom plate is provided with a plurality of diversion holes penetrating the crucible bottom plate. When the crucible accidentally ruptures and causes the silicon liquid to overflow, the overflowing silicon liquid is removed from the crucible The bottom part passes through the bottom plate of the crucible through the orifice provided on the bottom plate of the crucible;

[0057] A cooling block located below the bottom of the crucible, the cooling block is provided with at least one diversion groove, and the silicon liquid passing through the diversion hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com