A walking device for a bait throwing system

A technology of walking device and bait throwing machine, which is applied in application, climate change adaptation, fish farming, etc., and can solve problems such as high difficulty in control, power loss, and complicated towing control lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

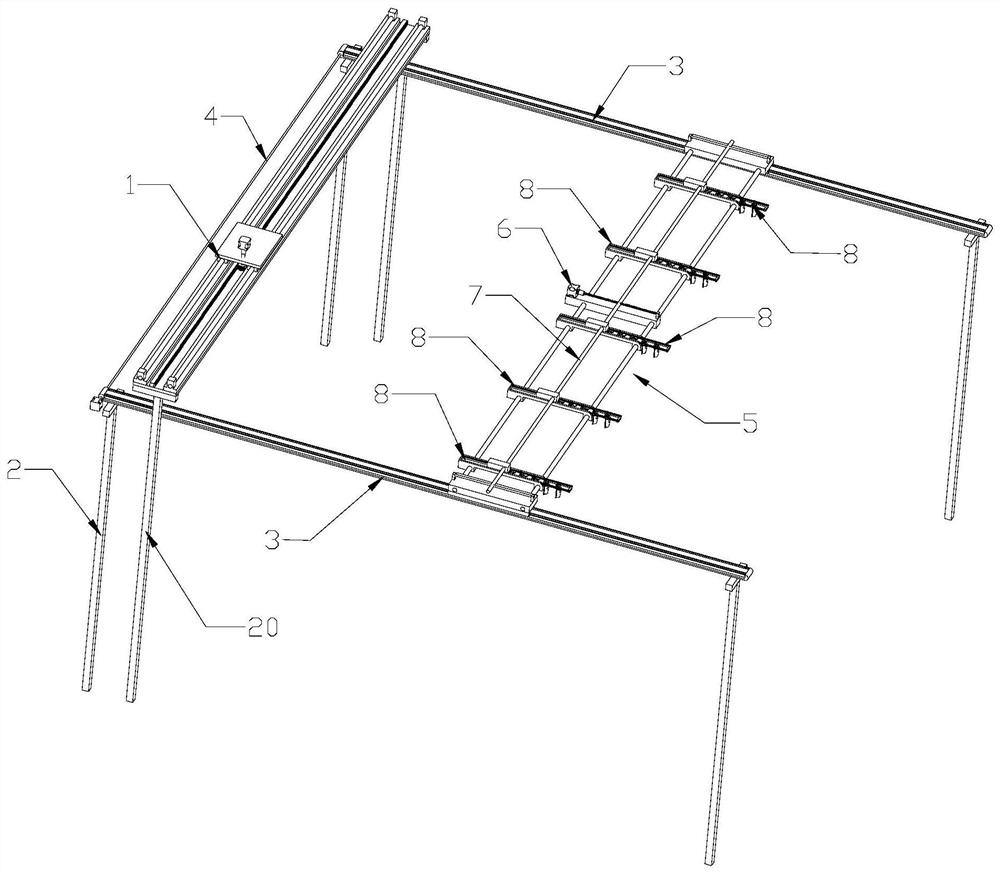

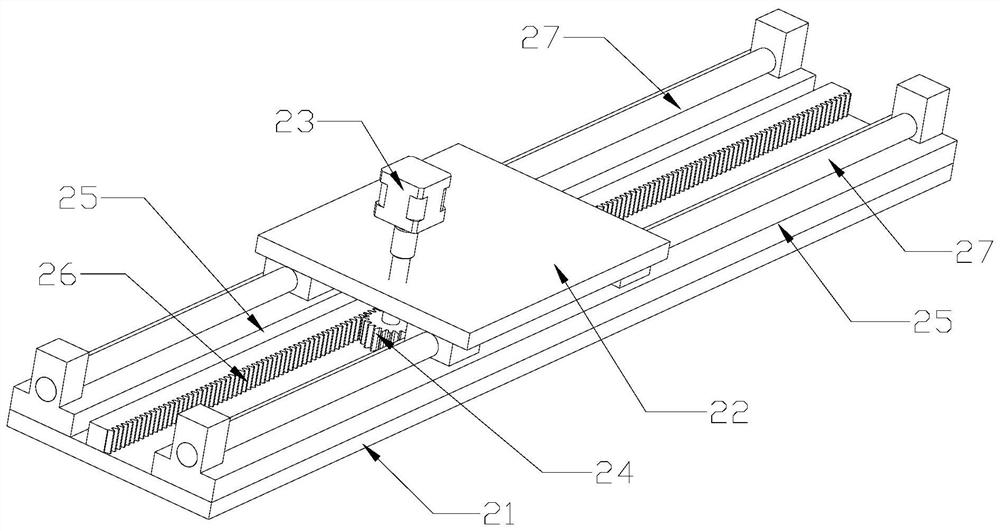

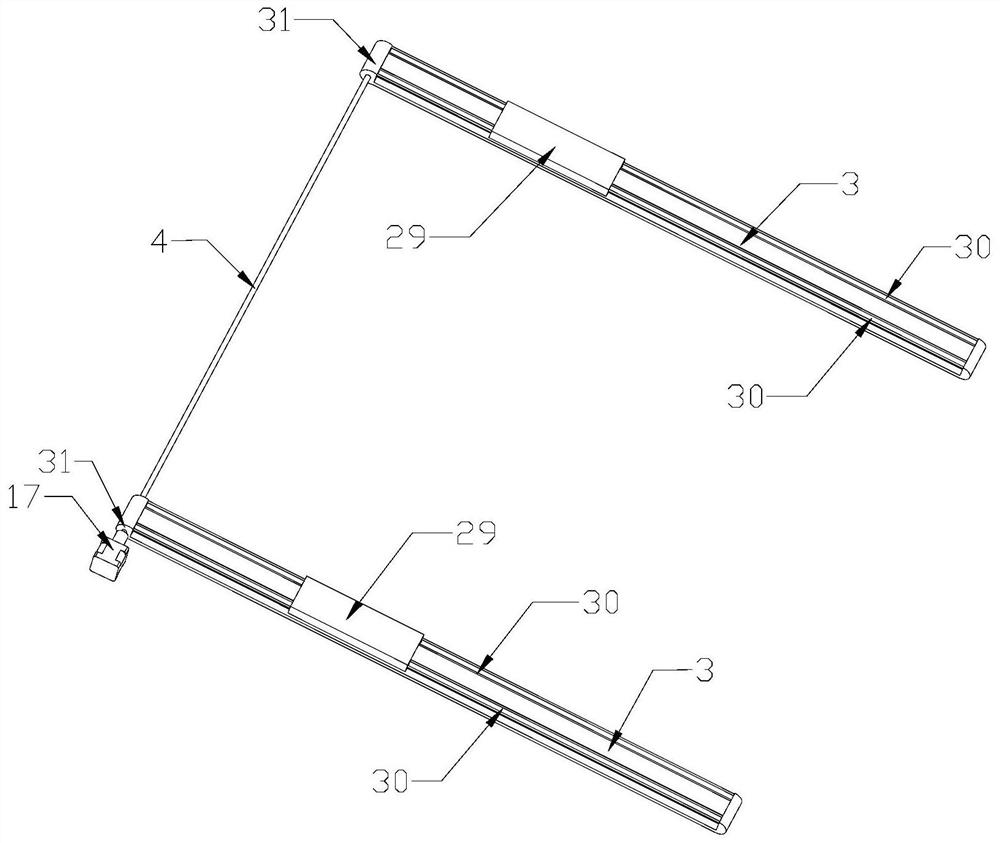

Embodiment 1

[0024]Embodiment 1: As shown in the figure, a running device of a bait casting system includes a longitudinal running mechanism 1 and a lateral running mechanism, the lateral running mechanism includes at least one lateral running assembly, and the lateral running assembly includes a first support 2, two conveyor belts. 3. The first motor 17, the first synchronous connection shaft 4 and the feeding unit 5, the two conveyor belts 3 are arranged on the first bracket 2 in parallel and at intervals, and the two conveyor belts 3 extend to the bottom of the longitudinal traveling mechanism 1. The conveying direction of the conveyor belt 3 Perpendicular to the conveying direction of the longitudinal traveling mechanism 1 , one end of each conveying belt 3 has a conveying shaft 31 , the conveying shafts 31 of the two conveying belts 3 are connected by the first synchronous connecting shaft 4 , the output shaft of the first motor 17 is The transmission shaft 31 is connected, and the fee...

Embodiment 2

[0031] Embodiment 2: As shown in the figure, a running device of a bait-casting system includes a longitudinal running mechanism 1 and a lateral running mechanism, the lateral running mechanism includes at least one lateral running assembly, and the lateral running assembly includes a first support 2, two conveyor belts. 3. The first motor 17, the first synchronous connection shaft 4 and the feeding unit 5, the two conveyor belts 3 are arranged on the first bracket 2 in parallel and at intervals, and the two conveyor belts 3 extend to the bottom of the longitudinal traveling mechanism 1. The conveying direction of the conveyor belt 3 Perpendicular to the conveying direction of the longitudinal traveling mechanism 1 , one end of each conveying belt 3 has a conveying shaft 31 , the conveying shafts 31 of the two conveying belts 3 are connected by the first synchronous connecting shaft 4 , the output shaft of the first motor 17 is The transmission shaft 31 is connected, and the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com